Manifold SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1297 of 2453

EN(H6DO)(diag)-136

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Y: DTC P0107 MANIFOLD ABSOLUTE PRESSURE/BAROMETRIC PRESSURE

CIRCUIT LOW INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

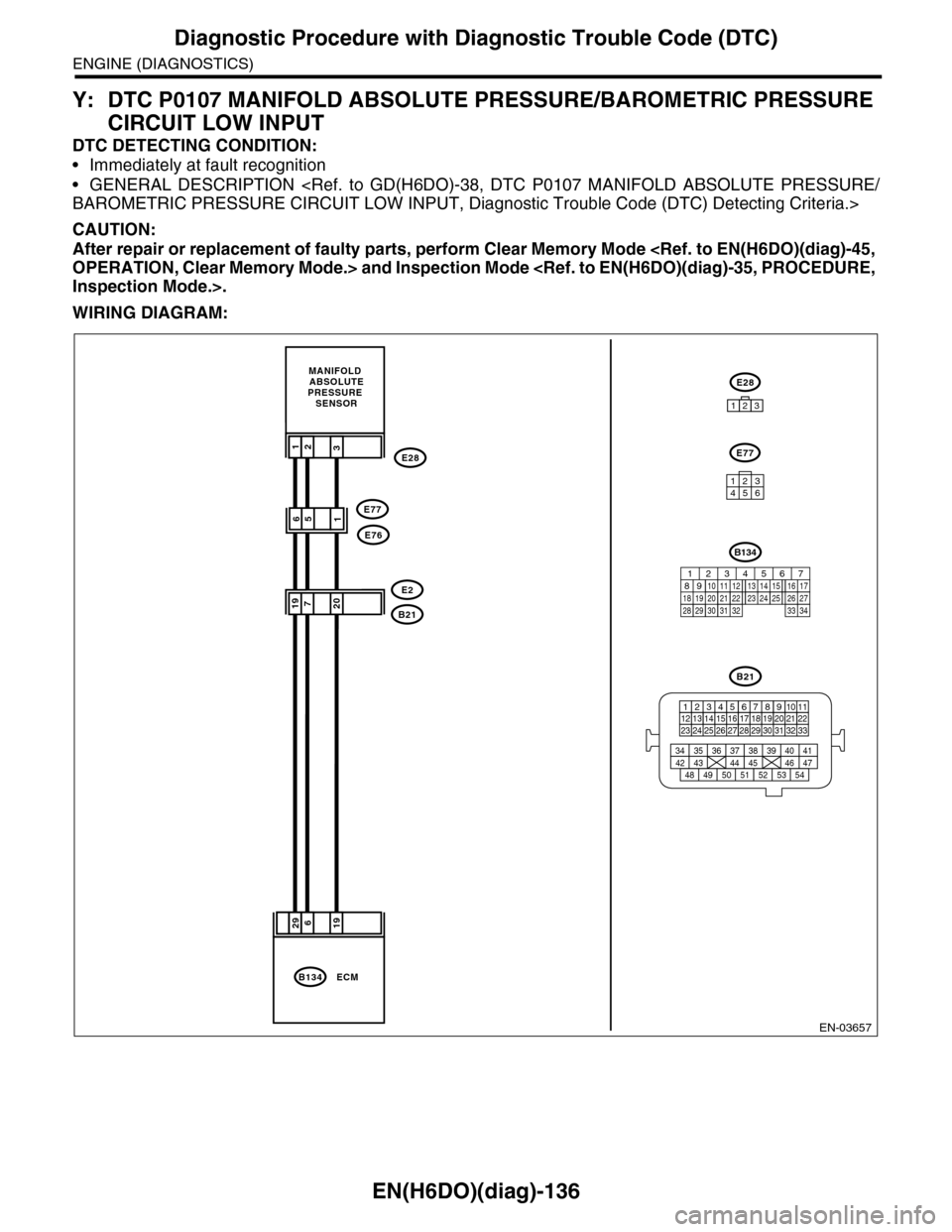

WIRING DIAGRAM:

EN-03657

29619

MANIFOLD ABSOLUTEPRESSURE SENSOR

19207B21

E2

132E28

ECMB134

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

651E77

E76

E28

123

E77

134562

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1298 of 2453

EN(H6DO)(diag)-137

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

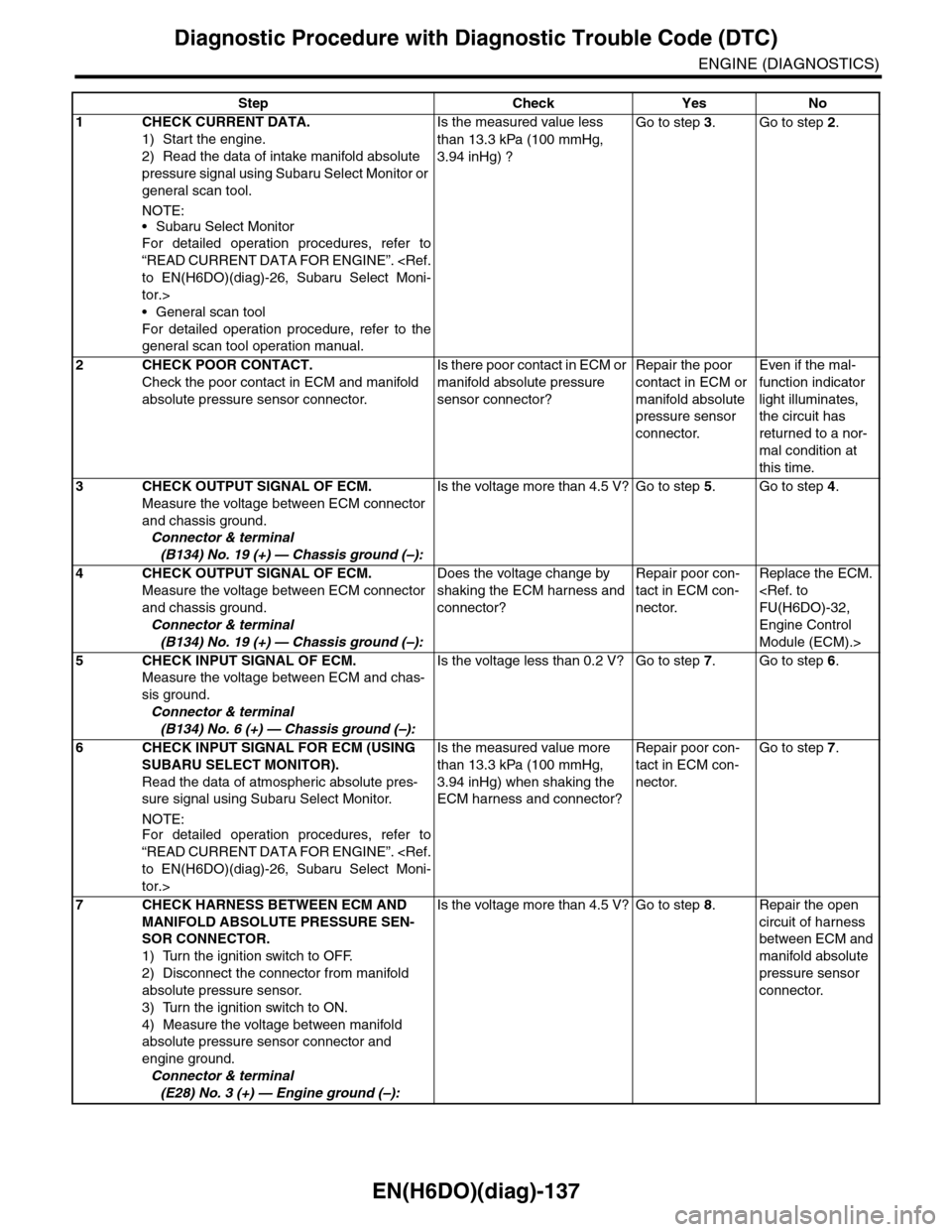

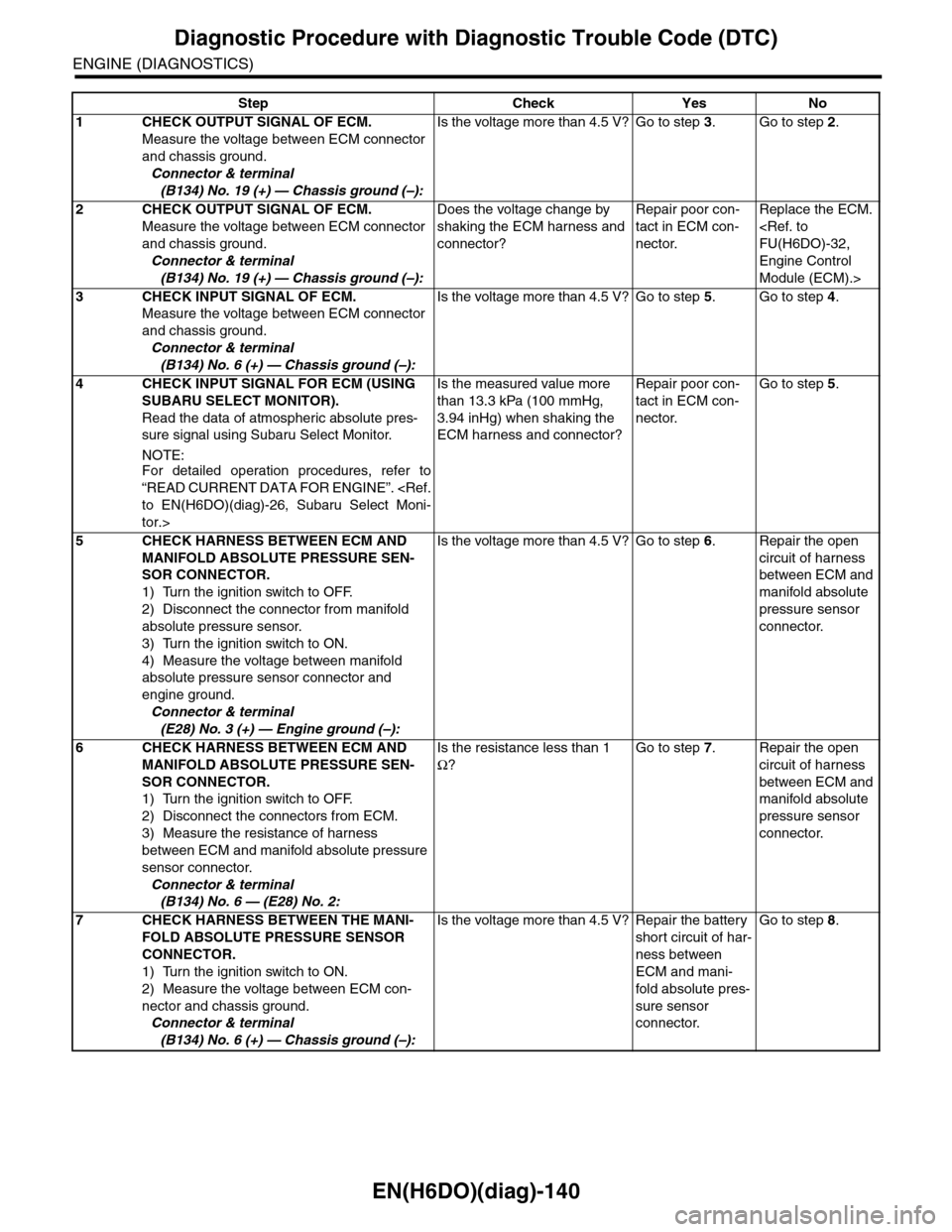

Step Check Yes No

1CHECK CURRENT DATA.

1) Start the engine.

2) Read the data of intake manifold absolute

pressure signal using Subaru Select Monitor or

general scan tool.

NOTE:

•Subaru Select Monitor

For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

•General scan tool

For detailed operation procedure, refer to the

general scan tool operation manual.

Is the measured value less

than 13.3 kPa (100 mmHg,

3.94 inHg) ?

Go to step 3.Go to step 2.

2CHECK POOR CONTACT.

Check the poor contact in ECM and manifold

absolute pressure sensor connector.

Is there poor contact in ECM or

manifold absolute pressure

sensor connector?

Repair the poor

contact in ECM or

manifold absolute

pressure sensor

connector.

Even if the mal-

function indicator

light illuminates,

the circuit has

returned to a nor-

mal condition at

this time.

3CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 19 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Go to step 5.Go to step 4.

4CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 19 (+) — Chassis ground (–):

Does the voltage change by

shaking the ECM harness and

connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

5CHECK INPUT SIGNAL OF ECM.

Measure the voltage between ECM and chas-

sis ground.

Connector & terminal

(B134) No. 6 (+) — Chassis ground (–):

Is the voltage less than 0.2 V? Go to step 7.Go to step 6.

6CHECK INPUT SIGNAL FOR ECM (USING

SUBARU SELECT MONITOR).

Read the data of atmospheric absolute pres-

sure signal using Subaru Select Monitor.

NOTE:For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the measured value more

than 13.3 kPa (100 mmHg,

3.94 inHg) when shaking the

ECM harness and connector?

Repair poor con-

tact in ECM con-

nector.

Go to step 7.

7CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from manifold

absolute pressure sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between manifold

absolute pressure sensor connector and

engine ground.

Connector & terminal

(E28) No. 3 (+) — Engine ground (–):

Is the voltage more than 4.5 V? Go to step 8.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

Page 1299 of 2453

EN(H6DO)(diag)-138

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

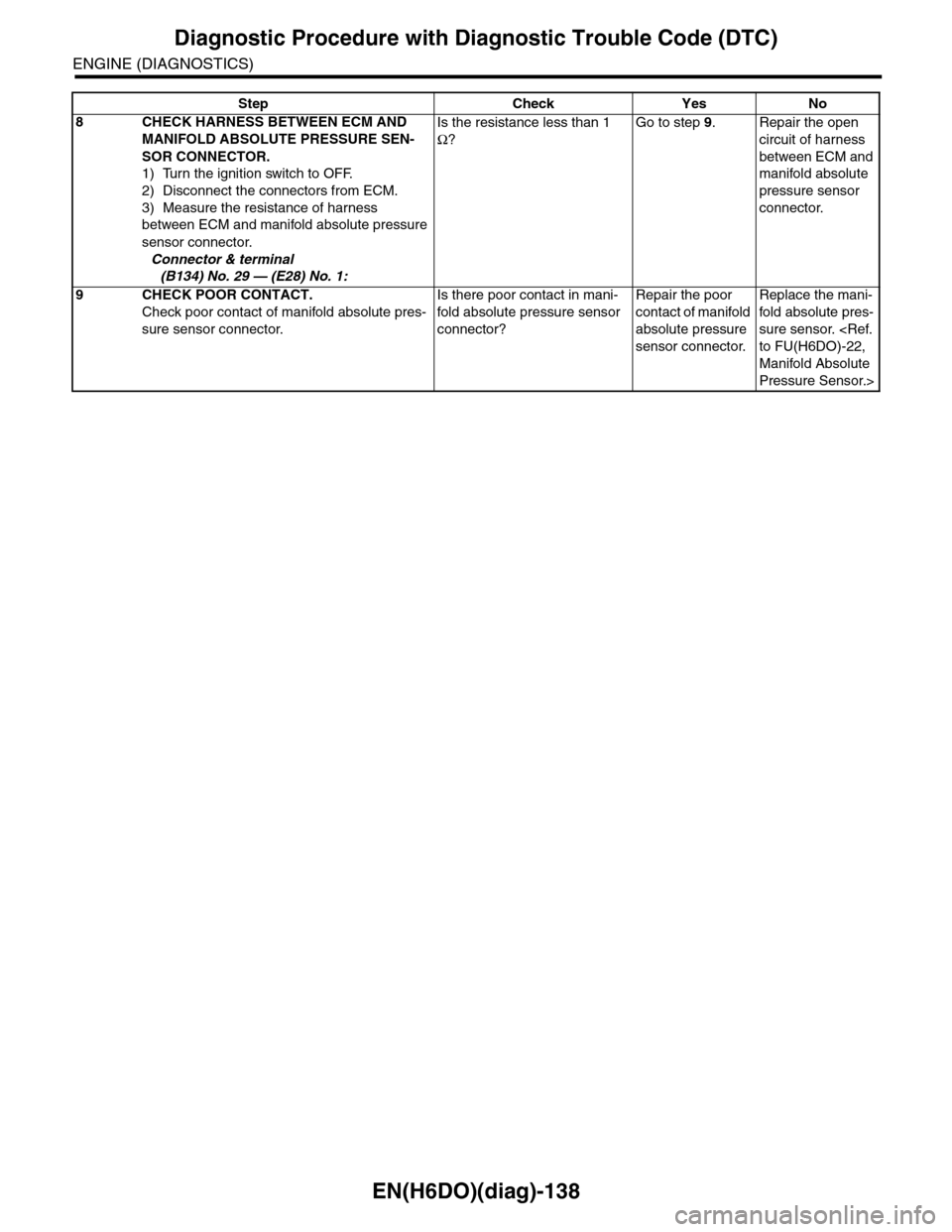

8CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM and manifold absolute pressure

sensor connector.

Connector & terminal

(B134) No. 29 — (E28) No. 1:

Is the resistance less than 1

Ω?

Go to step 9.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

9CHECK POOR CONTACT.

Check poor contact of manifold absolute pres-

sure sensor connector.

Is there poor contact in mani-

fold absolute pressure sensor

connector?

Repair the poor

contact of manifold

absolute pressure

sensor connector.

Replace the mani-

fold absolute pres-

sure sensor.

Manifold Absolute

Pressure Sensor.>

Step Check Yes No

Page 1300 of 2453

EN(H6DO)(diag)-139

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Z: DTC P0108 MANIFOLD ABSOLUTE PRESSURE/BAROMETRIC PRESSURE

CIRCUIT HIGH INPUT

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

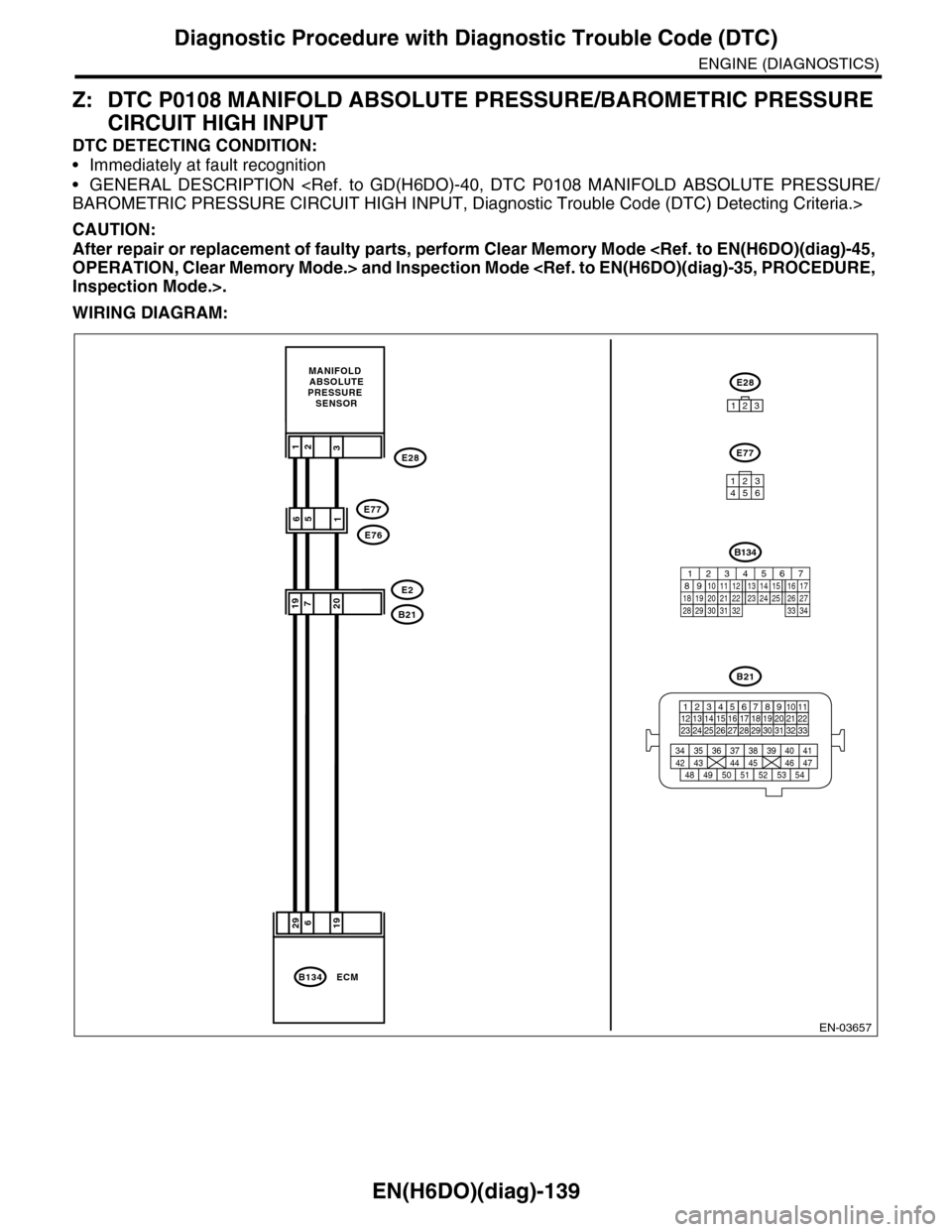

WIRING DIAGRAM:

EN-03657

29619

MANIFOLD ABSOLUTEPRESSURE SENSOR

19207B21

E2

132E28

ECMB134

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

651E77

E76

E28

123

E77

134562

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

Page 1301 of 2453

EN(H6DO)(diag)-140

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 19 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Go to step 3.Go to step 2.

2CHECK OUTPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 19 (+) — Chassis ground (–):

Does the voltage change by

shaking the ECM harness and

connector?

Repair poor con-

tact in ECM con-

nector.

Replace the ECM.

Engine Control

Module (ECM).>

3CHECK INPUT SIGNAL OF ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B134) No. 6 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Go to step 5.Go to step 4.

4CHECK INPUT SIGNAL FOR ECM (USING

SUBARU SELECT MONITOR).

Read the data of atmospheric absolute pres-

sure signal using Subaru Select Monitor.

NOTE:For detailed operation procedures, refer to

“READ CURRENT DATA FOR ENGINE”.

tor.>

Is the measured value more

than 13.3 kPa (100 mmHg,

3.94 inHg) when shaking the

ECM harness and connector?

Repair poor con-

tact in ECM con-

nector.

Go to step 5.

5CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from manifold

absolute pressure sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between manifold

absolute pressure sensor connector and

engine ground.

Connector & terminal

(E28) No. 3 (+) — Engine ground (–):

Is the voltage more than 4.5 V? Go to step 6.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

6CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance of harness

between ECM and manifold absolute pressure

sensor connector.

Connector & terminal

(B134) No. 6 — (E28) No. 2:

Is the resistance less than 1

Ω?

Go to step 7.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

7CHECK HARNESS BETWEEN THE MANI-

FOLD ABSOLUTE PRESSURE SENSOR

CONNECTOR.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B134) No. 6 (+) — Chassis ground (–):

Is the voltage more than 4.5 V? Repair the battery

short circuit of har-

ness between

ECM and mani-

fold absolute pres-

sure sensor

connector.

Go to step 8.

Page 1302 of 2453

EN(H6DO)(diag)-141

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

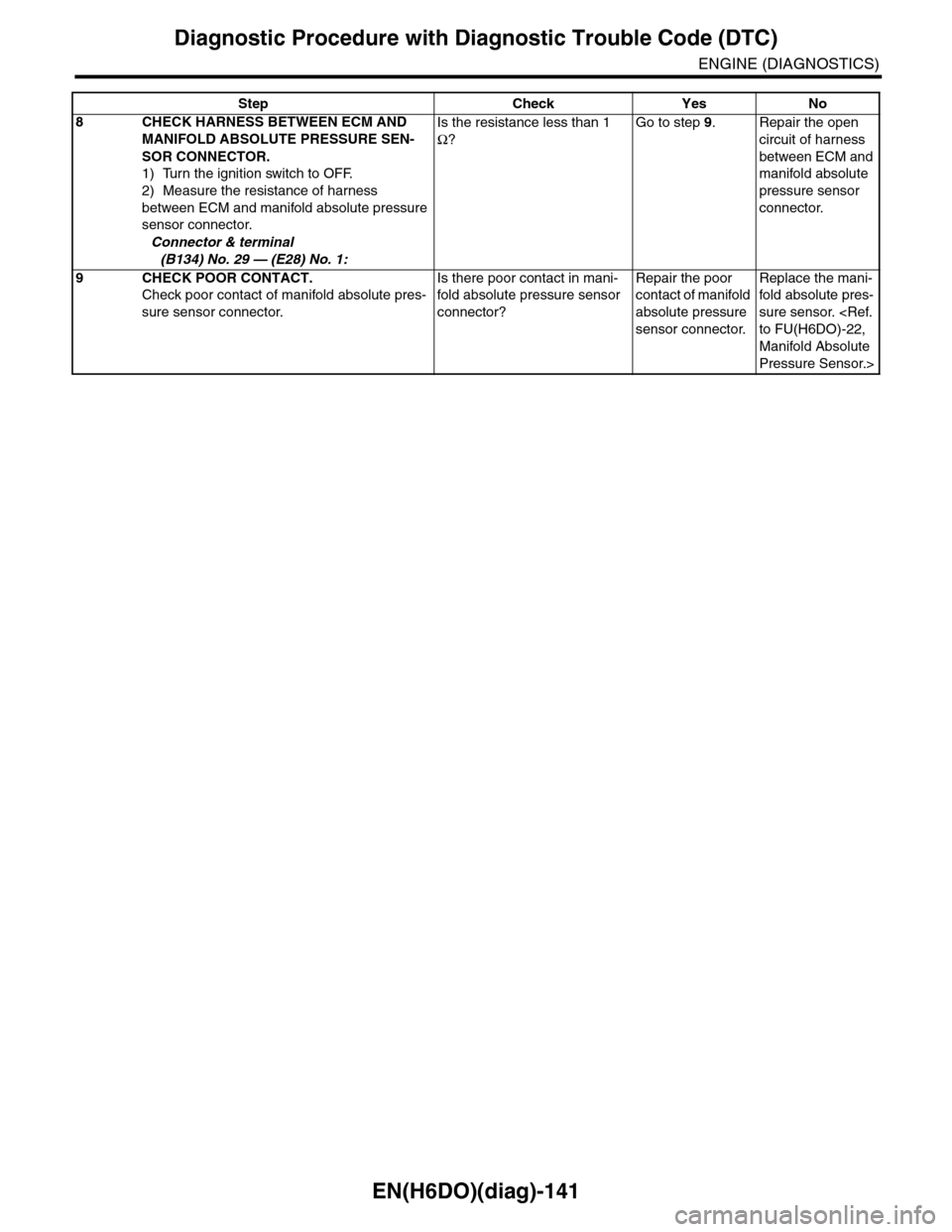

8CHECK HARNESS BETWEEN ECM AND

MANIFOLD ABSOLUTE PRESSURE SEN-

SOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness

between ECM and manifold absolute pressure

sensor connector.

Connector & terminal

(B134) No. 29 — (E28) No. 1:

Is the resistance less than 1

Ω?

Go to step 9.Repair the open

circuit of harness

between ECM and

manifold absolute

pressure sensor

connector.

9CHECK POOR CONTACT.

Check poor contact of manifold absolute pres-

sure sensor connector.

Is there poor contact in mani-

fold absolute pressure sensor

connector?

Repair the poor

contact of manifold

absolute pressure

sensor connector.

Replace the mani-

fold absolute pres-

sure sensor.

Manifold Absolute

Pressure Sensor.>

Step Check Yes No

Page 1458 of 2453

EN(H6DO)(diag)-297

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

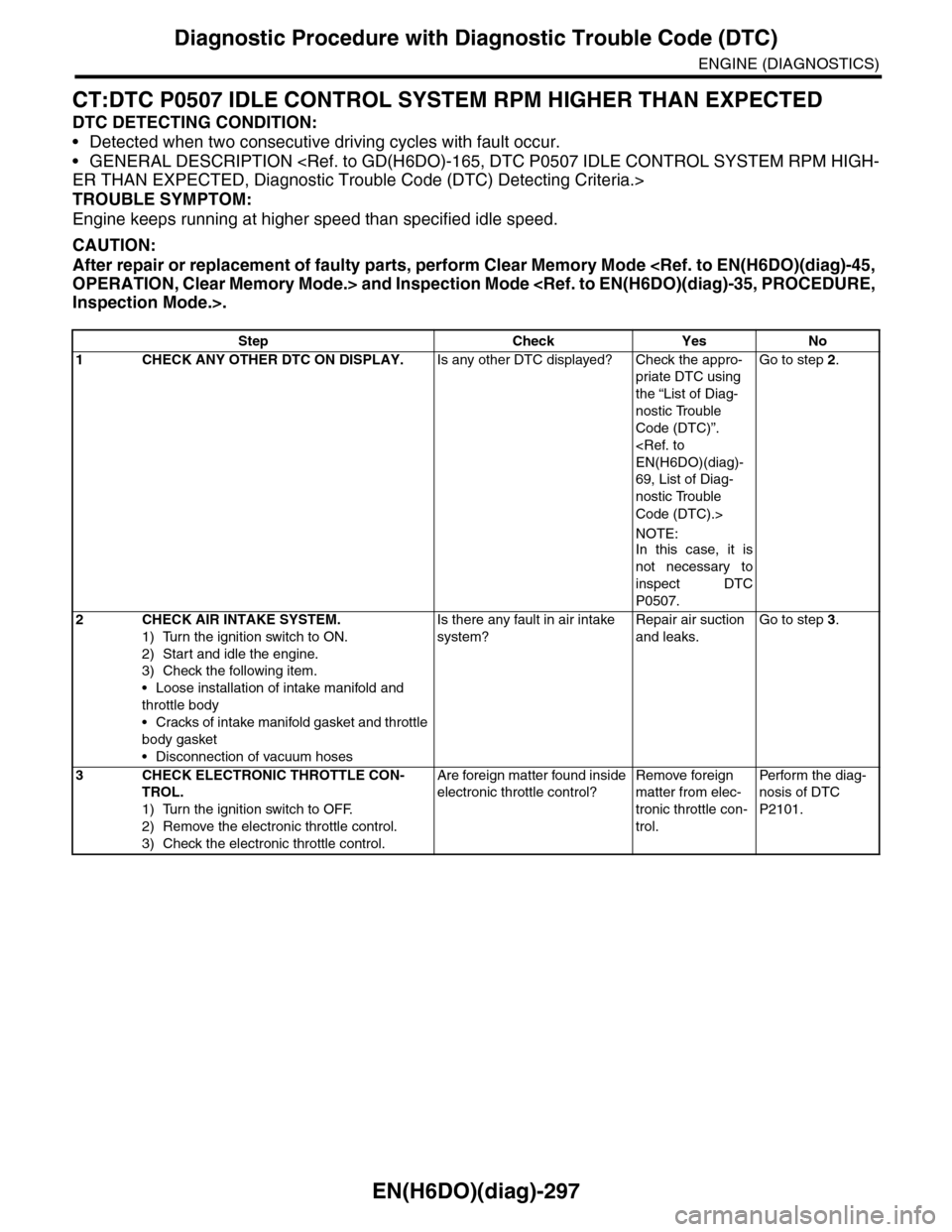

CT:DTC P0507 IDLE CONTROL SYSTEM RPM HIGHER THAN EXPECTED

DTC DETECTING CONDITION:

•Detected when two consecutive driving cycles with fault occur.

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

Engine keeps running at higher speed than specified idle speed.

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:In this case, it is

not necessary to

inspect DTC

P0507.

Go to step 2.

2CHECK AIR INTAKE SYSTEM.

1) Turn the ignition switch to ON.

2) Start and idle the engine.

3) Check the following item.

•Loose installation of intake manifold and

throttle body

•Cracks of intake manifold gasket and throttle

body gasket

•Disconnection of vacuum hoses

Is there any fault in air intake

system?

Repair air suction

and leaks.

Go to step 3.

3CHECK ELECTRONIC THROTTLE CON-

TROL.

1) Turn the ignition switch to OFF.

2) Remove the electronic throttle control.

3) Check the electronic throttle control.

Are foreign matter found inside

electronic throttle control?

Remove foreign

matter from elec-

tronic throttle con-

trol.

Per fo r m th e di ag -

nosis of DTC

P2101.

Page 1461 of 2453

EN(H6DO)(diag)-300

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

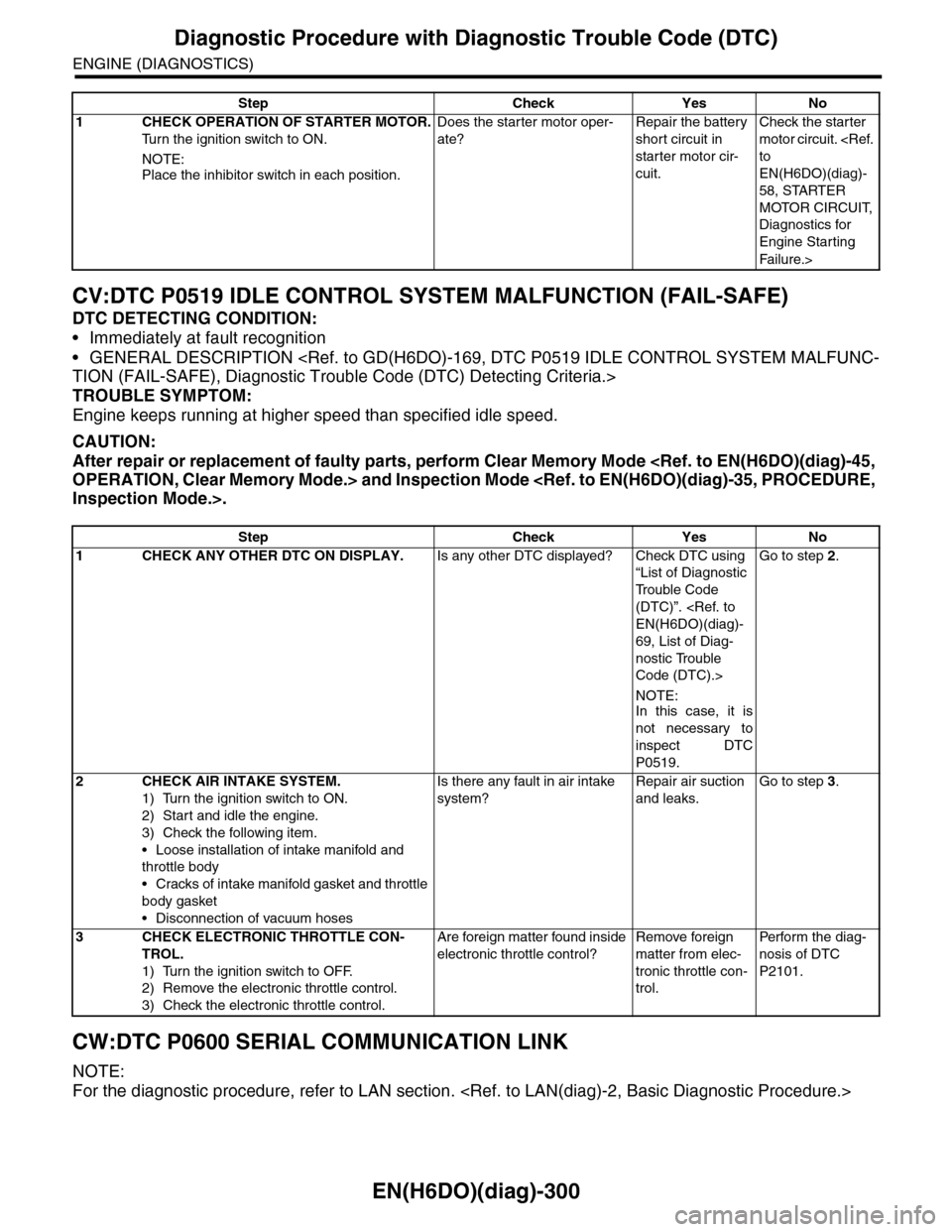

CV:DTC P0519 IDLE CONTROL SYSTEM MALFUNCTION (FAIL-SAFE)

DTC DETECTING CONDITION:

•Immediately at fault recognition

•GENERAL DESCRIPTION

TROUBLE SYMPTOM:

Engine keeps running at higher speed than specified idle speed.

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

CW:DTC P0600 SERIAL COMMUNICATION LINK

NOTE:

For the diagnostic procedure, refer to LAN section.

Step Check Yes No

1CHECK OPERATION OF STARTER MOTOR.

Tu r n t h e i g n i t i o n s w i t c h t o O N .

NOTE:

Place the inhibitor switch in each position.

Does the starter motor oper-

ate?

Repair the battery

short circuit in

starter motor cir-

cuit.

Check the starter

motor circuit.

EN(H6DO)(diag)-

58, STARTER

MOTOR CIRCUIT,

Diagnostics for

Engine Starting

Fai lu r e.>

Step Check Yes No

1CHECK ANY OTHER DTC ON DISPLAY.Is any other DTC displayed? Check DTC using

“List of Diagnostic

Tr o u b l e C o d e

(DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

NOTE:In this case, it is

not necessary to

inspect DTC

P0519.

Go to step 2.

2CHECK AIR INTAKE SYSTEM.

1) Turn the ignition switch to ON.

2) Start and idle the engine.

3) Check the following item.

•Loose installation of intake manifold and

throttle body

•Cracks of intake manifold gasket and throttle

body gasket

•Disconnection of vacuum hoses

Is there any fault in air intake

system?

Repair air suction

and leaks.

Go to step 3.

3CHECK ELECTRONIC THROTTLE CON-

TROL.

1) Turn the ignition switch to OFF.

2) Remove the electronic throttle control.

3) Check the electronic throttle control.

Are foreign matter found inside

electronic throttle control?

Remove foreign

matter from elec-

tronic throttle con-

trol.

Per fo r m th e di ag -

nosis of DTC

P2101.

Page 1553 of 2453

EN(H6DO)(diag)-392

General Diagnostic Table

ENGINE (DIAGNOSTICS)

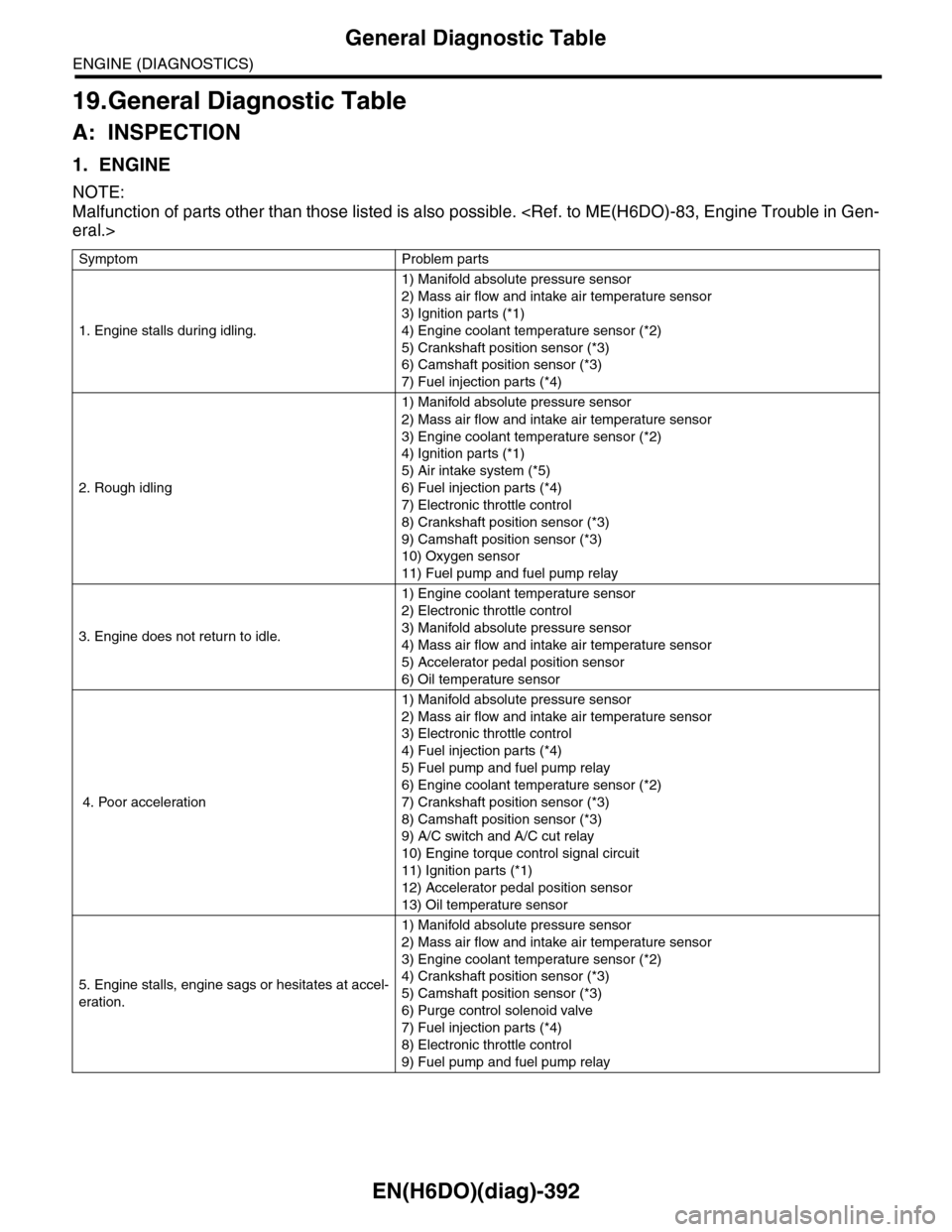

19.General Diagnostic Table

A: INSPECTION

1. ENGINE

NOTE:

Malfunction of parts other than those listed is also possible.

Symptom Problem parts

1. Engine stalls during idling.

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Ignition parts (*1)

4) Engine coolant temperature sensor (*2)

5) Crankshaft position sensor (*3)

6) Camshaft position sensor (*3)

7) Fuel injection parts (*4)

2. Rough idling

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Ignition parts (*1)

5) Air intake system (*5)

6) Fuel injection parts (*4)

7) Electronic throttle control

8) Crankshaft position sensor (*3)

9) Camshaft position sensor (*3)

10) Oxygen sensor

11) Fuel pump and fuel pump relay

3. Engine does not return to idle.

1) Engine coolant temperature sensor

2) Electronic throttle control

3) Manifold absolute pressure sensor

4) Mass air flow and intake air temperature sensor

5) Accelerator pedal position sensor

6) Oil temperature sensor

4. Poor acceleration

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Electronic throttle control

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

6) Engine coolant temperature sensor (*2)

7) Crankshaft position sensor (*3)

8) Camshaft position sensor (*3)

9) A/C switch and A/C cut relay

10) Engine torque control signal circuit

11) Ignition parts (*1)

12) Accelerator pedal position sensor

13) Oil temperature sensor

5. Engine stalls, engine sags or hesitates at accel-

eration.

1) Manifold absolute pressure sensor

2) Mass air flow and intake air temperature sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Purge control solenoid valve

7) Fuel injection parts (*4)

8) Electronic throttle control

9) Fuel pump and fuel pump relay

Page 1554 of 2453

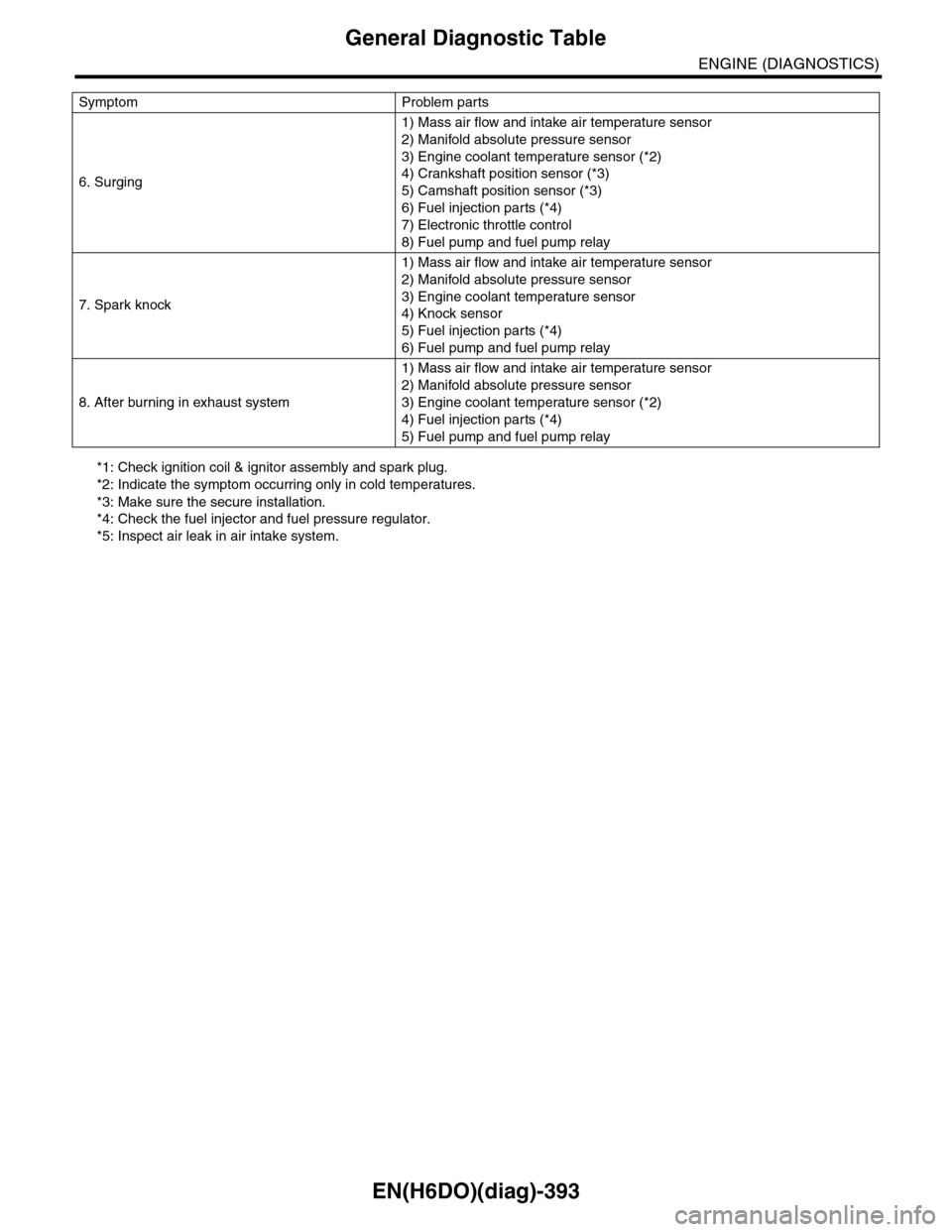

EN(H6DO)(diag)-393

General Diagnostic Table

ENGINE (DIAGNOSTICS)

*1: Check ignition coil & ignitor assembly and spark plug.

*2: Indicate the symptom occurring only in cold temperatures.

*3: Make sure the secure installation.

*4: Check the fuel injector and fuel pressure regulator.

*5: Inspect air leak in air intake system.

6. Surging

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Electronic throttle control

8) Fuel pump and fuel pump relay

7. Spark knock

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor

4) Knock sensor

5) Fuel injection parts (*4)

6) Fuel pump and fuel pump relay

8. After burning in exhaust system

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

Symptom Problem parts