Manifold SUBARU TRIBECA 2009 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1585 of 2453

FU(H6DO)-24

Fuel Injector

FUEL INJECTION (FUEL SYSTEMS)

11.Fuel Injector

A: REMOVAL

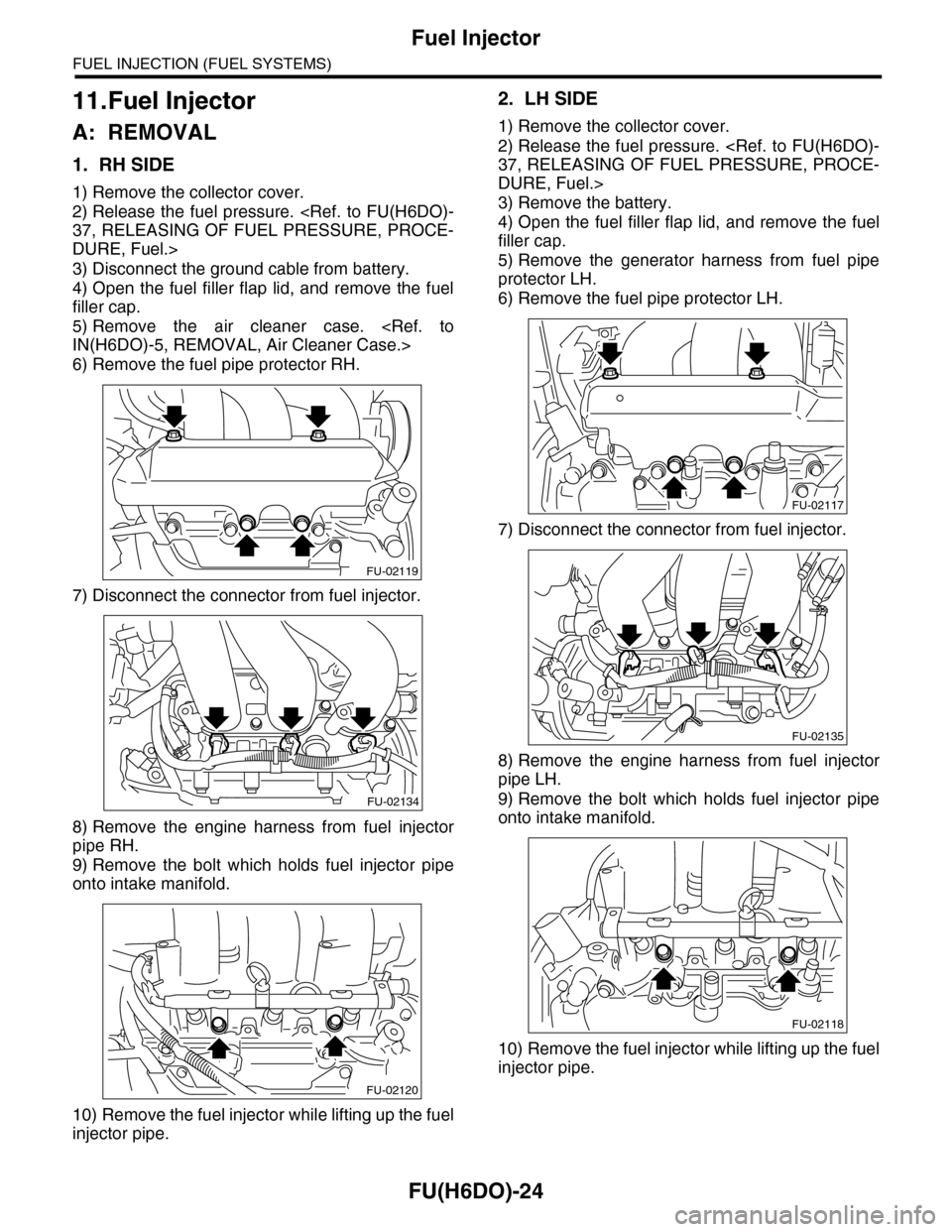

1. RH SIDE

1) Remove the collector cover.

2) Release the fuel pressure.

DURE, Fuel.>

3) Disconnect the ground cable from battery.

4) Open the fuel filler flap lid, and remove the fuel

filler cap.

5) Remove the air cleaner case.

6) Remove the fuel pipe protector RH.

7) Disconnect the connector from fuel injector.

8) Remove the engine harness from fuel injector

pipe RH.

9) Remove the bolt which holds fuel injector pipe

onto intake manifold.

10) Remove the fuel injector while lifting up the fuel

injector pipe.

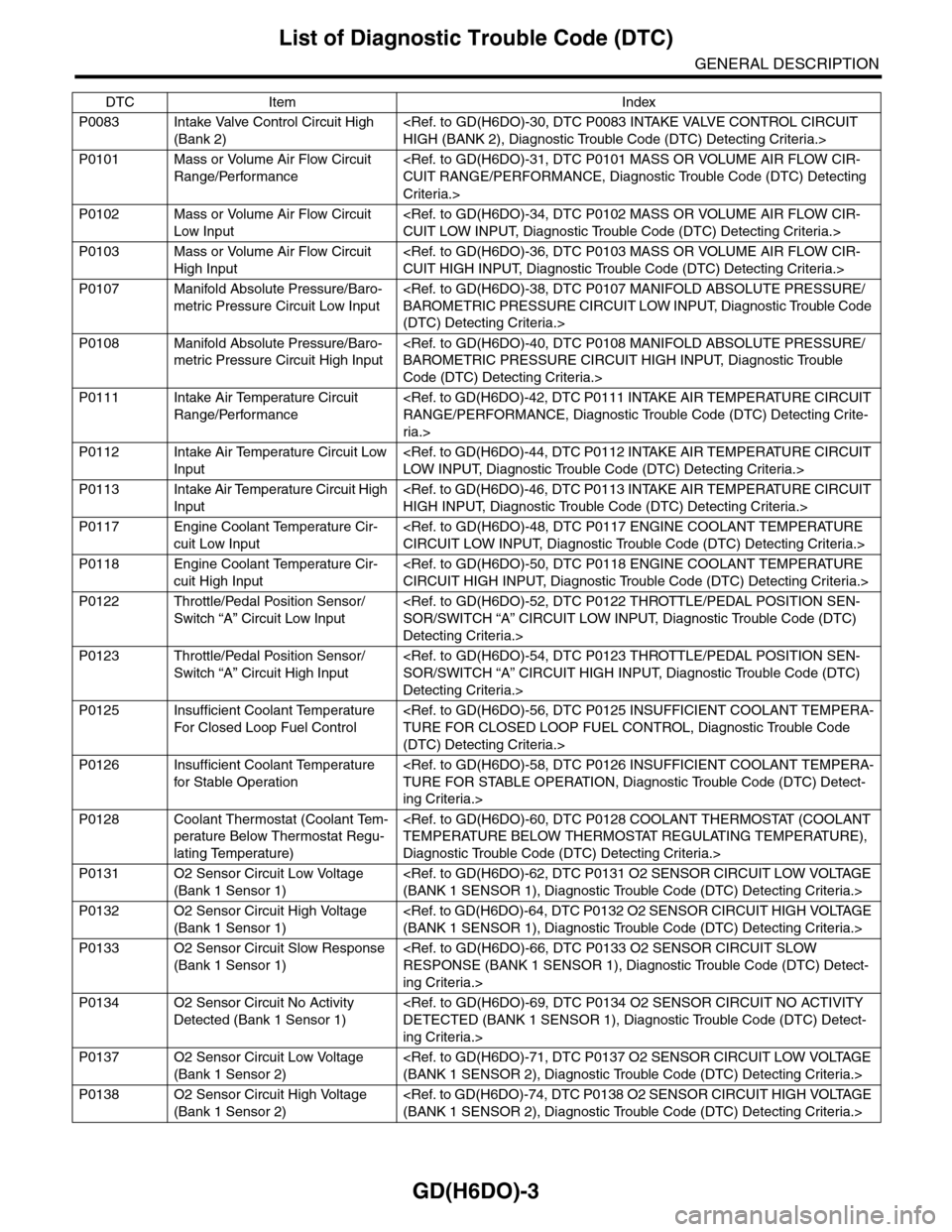

2. LH SIDE

1) Remove the collector cover.

2) Release the fuel pressure.

DURE, Fuel.>

3) Remove the battery.

4) Open the fuel filler flap lid, and remove the fuel

filler cap.

5) Remove the generator harness from fuel pipe

protector LH.

6) Remove the fuel pipe protector LH.

7) Disconnect the connector from fuel injector.

8) Remove the engine harness from fuel injector

pipe LH.

9) Remove the bolt which holds fuel injector pipe

onto intake manifold.

10) Remove the fuel injector while lifting up the fuel

injector pipe.

FU-02119

FU-02134

FU-02120

FU-02117

FU-02135

FU-02118

Page 1615 of 2453

GD(H6DO)-3

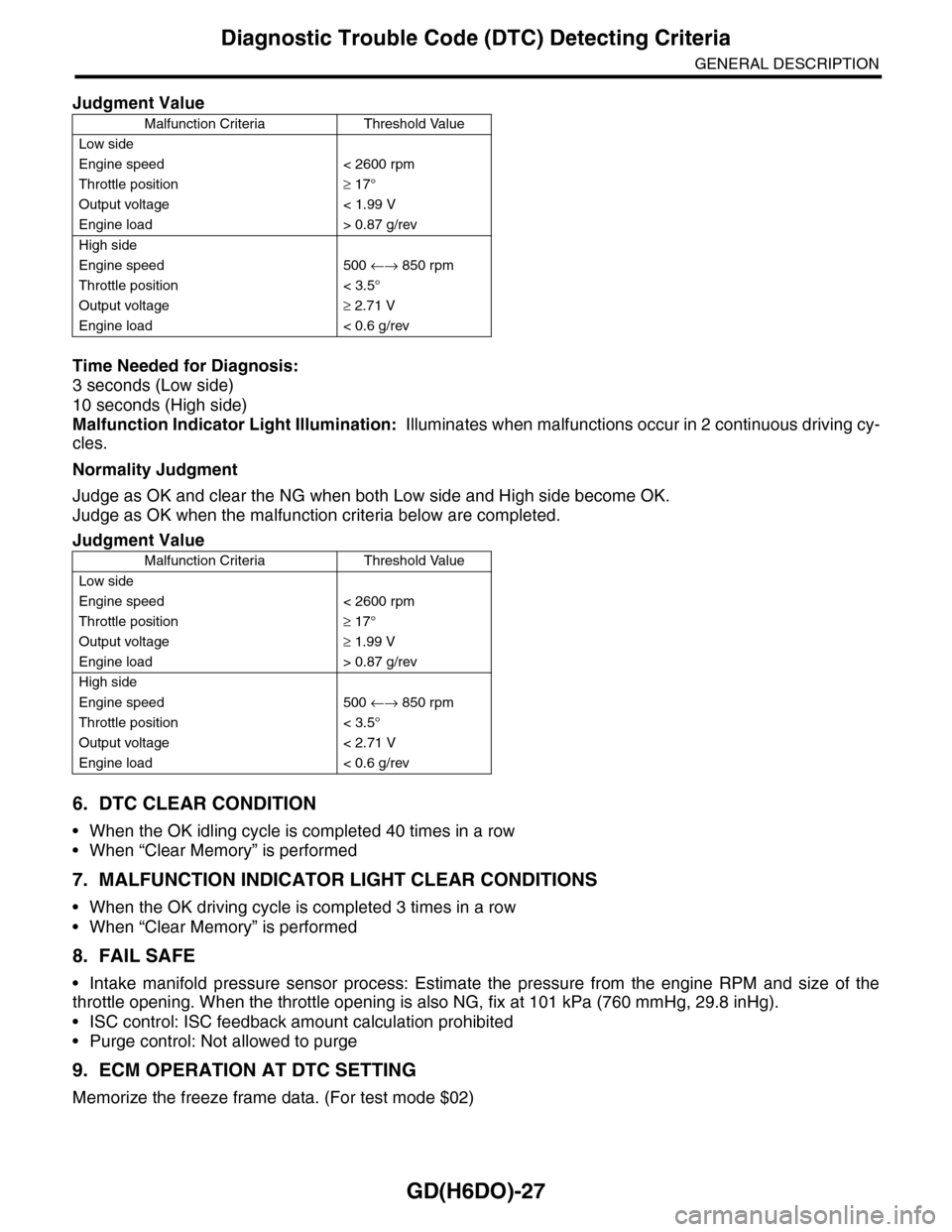

List of Diagnostic Trouble Code (DTC)

GENERAL DESCRIPTION

P0083 Intake Valve Control Circuit High

(Bank 2)

P0101 Mass or Volume Air Flow Circuit

Range/Performance

Criteria.>

P0102 Mass or Volume Air Flow Circuit

Low Input

P0103 Mass or Volume Air Flow Circuit

High Input

P0107 Manifold Absolute Pressure/Baro-

metric Pressure Circuit Low Input

(DTC) Detecting Criteria.>

P0108 Manifold Absolute Pressure/Baro-

metric Pressure Circuit High Input

Code (DTC) Detecting Criteria.>

P0111 Intake Air Temperature Circuit

Range/Performance

ria.>

P0112 Intake Air Temperature Circuit Low

Input

P0113 Intake Air Temperature Circuit High

Input

P0117 Engine Coolant Temperature Cir-

cuit Low Input

P0118 Engine Coolant Temperature Cir-

cuit High Input

P0122 Throttle/Pedal Position Sensor/

Switch “A” Circuit Low Input

Detecting Criteria.>

P0123 Throttle/Pedal Position Sensor/

Switch “A” Circuit High Input

Detecting Criteria.>

P0125 Insufficient Coolant Temperature

For Closed Loop Fuel Control

(DTC) Detecting Criteria.>

P0126 Insufficient Coolant Temperature

for Stable Operation

ing Criteria.>

P0128 Coolant Thermostat (Coolant Tem-

perature Below Thermostat Regu-

lating Temperature)

Diagnostic Trouble Code (DTC) Detecting Criteria.>

P0131 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 1)

P0132 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 1)

P0133 O2 Sensor Circuit Slow Response

(Bank 1 Sensor 1)

ing Criteria.>

P0134 O2 Sensor Circuit No Activity

Detected (Bank 1 Sensor 1)

ing Criteria.>

P0137 O2 Sensor Circuit Low Voltage

(Bank 1 Sensor 2)

P0138 O2 Sensor Circuit High Voltage

(Bank 1 Sensor 2)

DTC Item Index

Page 1638 of 2453

GD(H6DO)-26

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

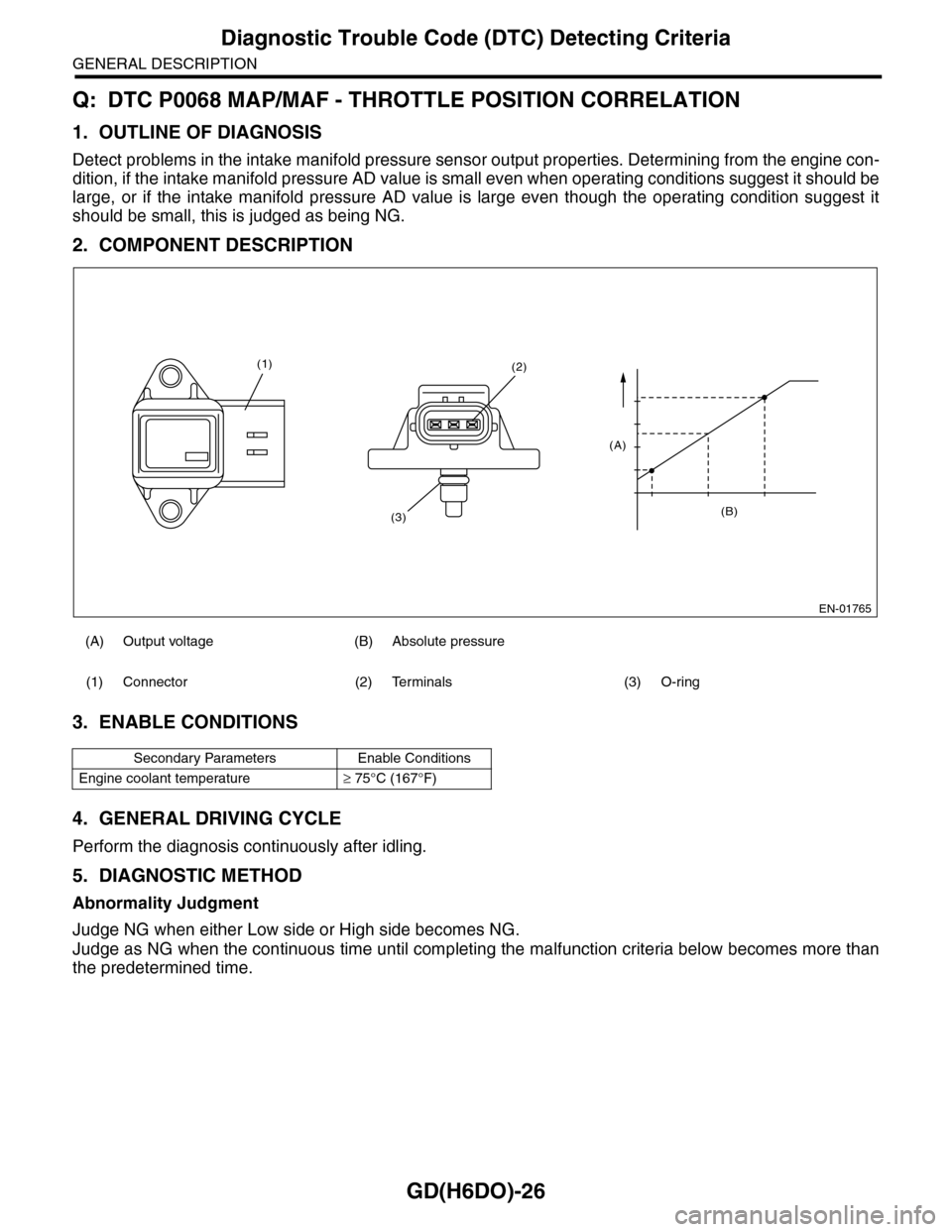

Q: DTC P0068 MAP/MAF - THROTTLE POSITION CORRELATION

1. OUTLINE OF DIAGNOSIS

Detect problems in the intake manifold pressure sensor output properties. Determining from the engine con-

dition, if the intake manifold pressure AD value is small even when operating conditions suggest it should be

large, or if the intake manifold pressure AD value is large even though the operating condition suggest it

should be small, this is judged as being NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously after idling.

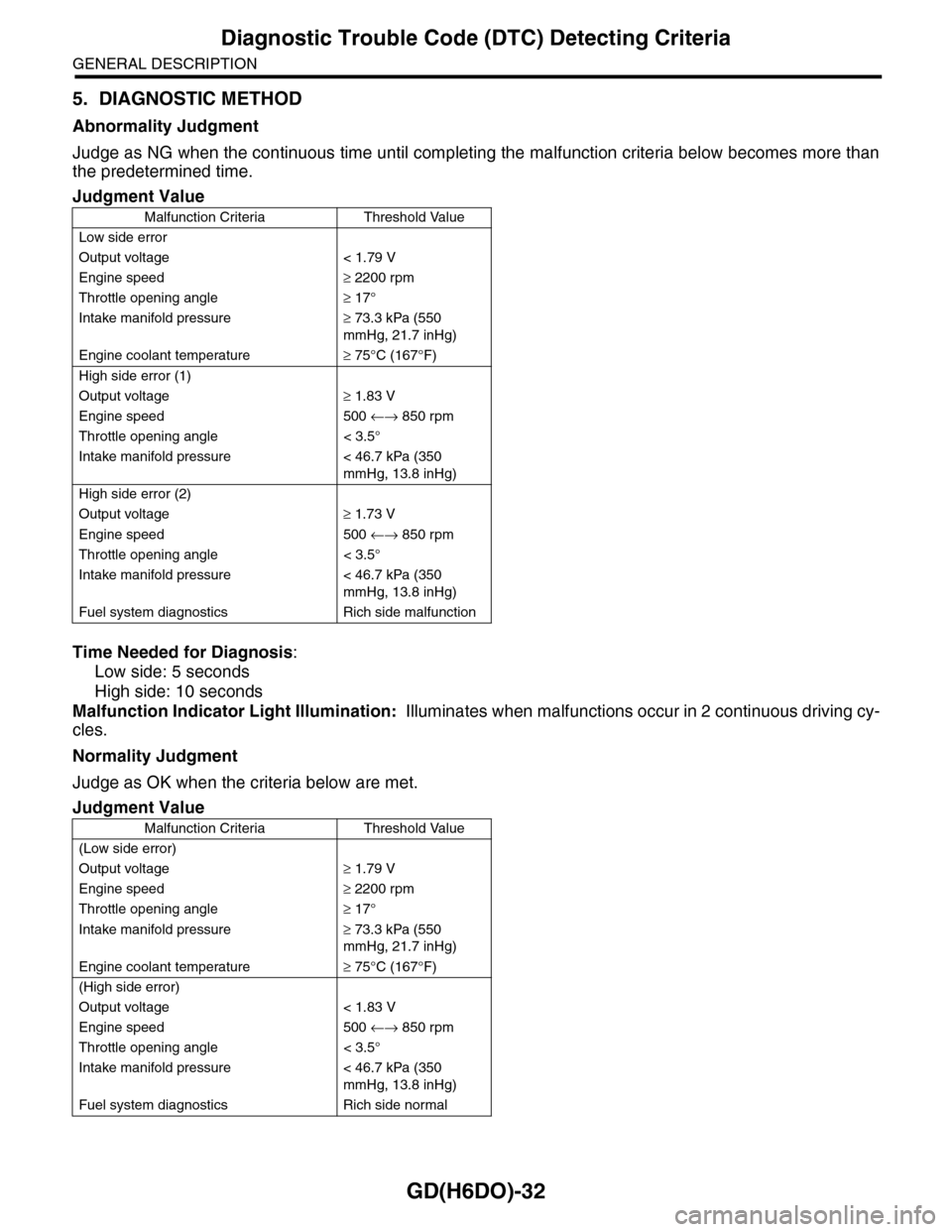

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge NG when either Low side or High side becomes NG.

Judge as NG when the continuous time until completing the malfunction criteria below becomes more than

the predetermined time.

(A) Output voltage (B) Absolute pressure

(1) Connector (2) Terminals (3) O-ring

Secondary Parameters Enable Conditions

Engine coolant temperature≥ 75°C (167°F)

EN-01765

(B)

(A)

(2)

(3)

(1)

Page 1639 of 2453

GD(H6DO)-27

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

Time Needed for Diagnosis:

3 seconds (Low side)

10 seconds (High side)

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear the NG when both Low side and High side become OK.

Judge as OK when the malfunction criteria below are completed.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Intake manifold pressure sensor process: Estimate the pressure from the engine RPM and size of the

throttle opening. When the throttle opening is also NG, fix at 101 kPa (760 mmHg, 29.8 inHg).

•ISC control: ISC feedback amount calculation prohibited

•Purge control: Not allowed to purge

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Judgment Value

Malfunction Criteria Threshold Value

Low side

Engine speed < 2600 rpm

Throttle position≥ 17°

Output voltage < 1.99 V

Engine load > 0.87 g/rev

High side

Engine speed 500 ←→ 850 rpm

Throttle position < 3.5°

Output voltage≥ 2.71 V

Engine load < 0.6 g/rev

Judgment Value

Malfunction Criteria Threshold Value

Low side

Engine speed < 2600 rpm

Throttle position≥ 17°

Output voltage≥ 1.99 V

Engine load > 0.87 g/rev

High side

Engine speed 500 ←→ 850 rpm

Throttle position < 3.5°

Output voltage < 2.71 V

Engine load < 0.6 g/rev

Page 1644 of 2453

GD(H6DO)-32

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes more than

the predetermined time.

Time Needed for Diagnosis:

Low side: 5 seconds

High side: 10 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK when the criteria below are met.

Judgment Value

Malfunction Criteria Threshold Value

Low side error

Output voltage < 1.79 V

Engine speed≥ 2200 rpm

Throttle opening angle≥ 17°

Intake manifold pressure≥ 73.3 kPa (550

mmHg, 21.7 inHg)

Engine coolant temperature≥ 75°C (167°F)

High side error (1)

Output voltage≥ 1.83 V

Engine speed 500 ←→ 850 rpm

Throttle opening angle < 3.5°

Intake manifold pressure < 46.7 kPa (350

mmHg, 13.8 inHg)

High side error (2)

Output voltage≥ 1.73 V

Engine speed 500 ←→ 850 rpm

Throttle opening angle < 3.5°

Intake manifold pressure < 46.7 kPa (350

mmHg, 13.8 inHg)

Fuel system diagnostics Rich side malfunction

Judgment Value

Malfunction Criteria Threshold Value

(Low side error)

Output voltage≥ 1.79 V

Engine speed≥ 2200 rpm

Throttle opening angle≥ 17°

Intake manifold pressure≥ 73.3 kPa (550

mmHg, 21.7 inHg)

Engine coolant temperature≥ 75°C (167°F)

(High side error)

Output voltage < 1.83 V

Engine speed 500 ←→ 850 rpm

Throttle opening angle < 3.5°

Intake manifold pressure < 46.7 kPa (350

mmHg, 13.8 inHg)

Fuel system diagnostics Rich side normal

Page 1650 of 2453

GD(H6DO)-38

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

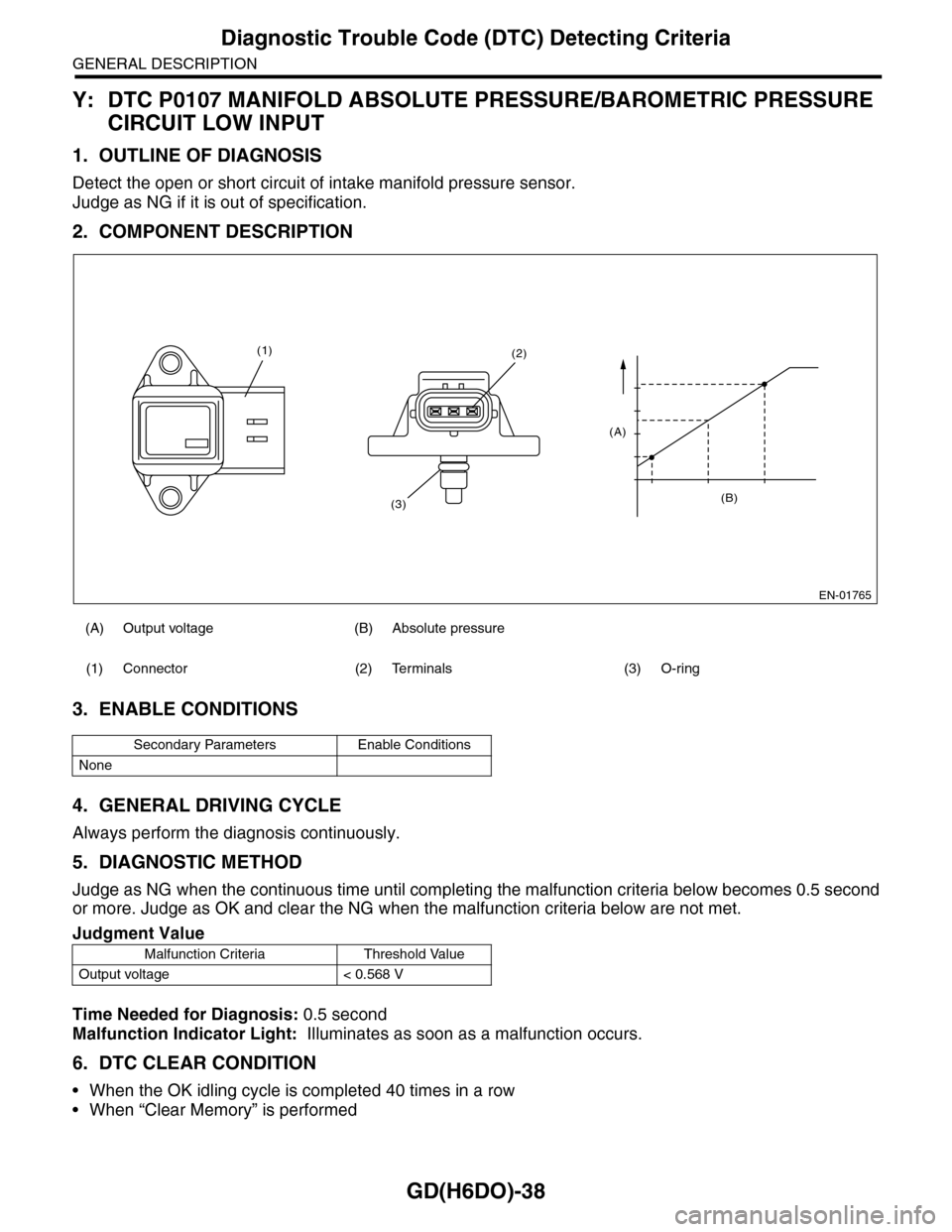

Y: DTC P0107 MANIFOLD ABSOLUTE PRESSURE/BAROMETRIC PRESSURE

CIRCUIT LOW INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of intake manifold pressure sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time until completing the malfunction criteria below becomes 0.5 second

or more. Judge as OK and clear the NG when the malfunction criteria below are not met.

Time Needed for Diagnosis: 0.5 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

(A) Output voltage (B) Absolute pressure

(1) Connector (2) Terminals (3) O-ring

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage < 0.568 V

EN-01765

(B)

(A)

(2)

(3)

(1)

Page 1652 of 2453

GD(H6DO)-40

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

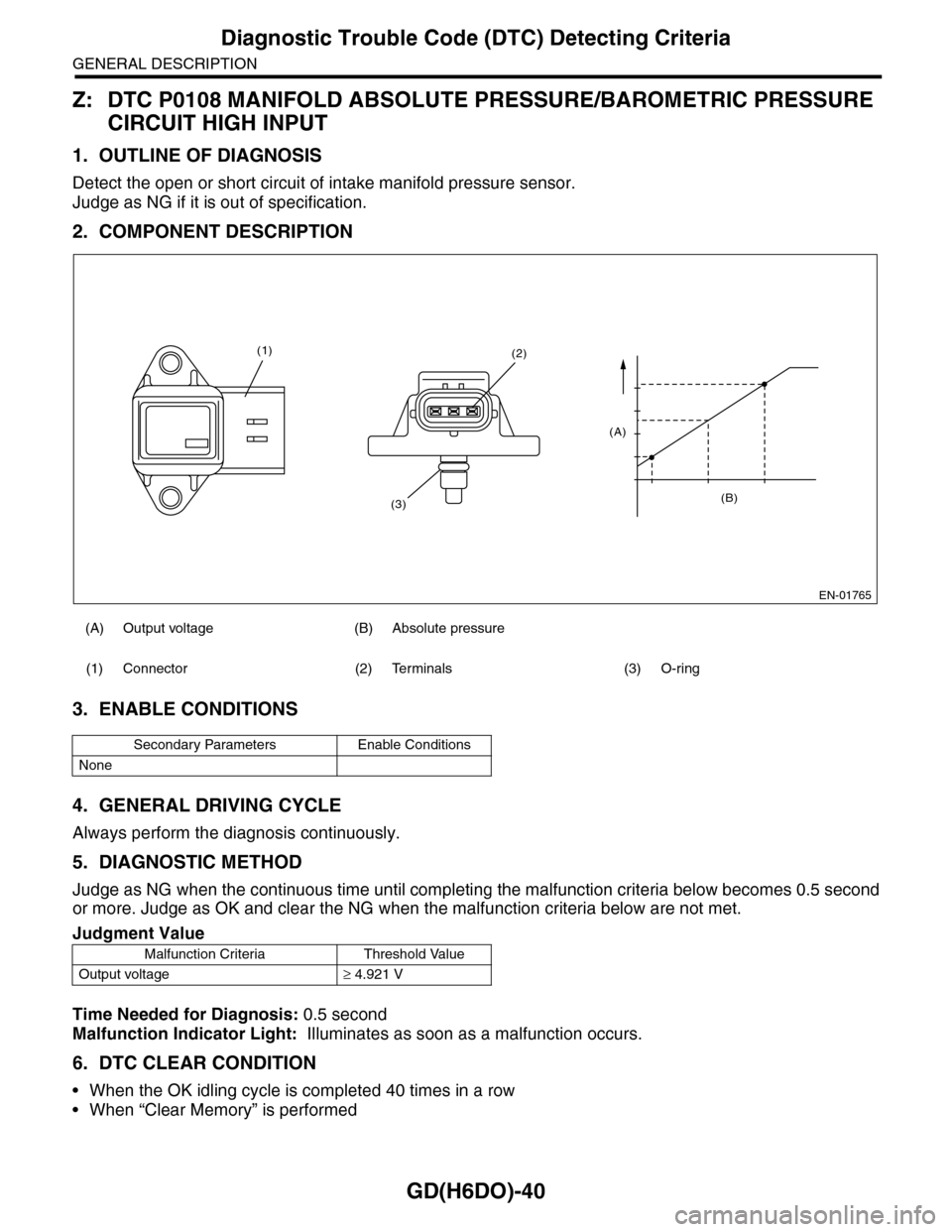

Z: DTC P0108 MANIFOLD ABSOLUTE PRESSURE/BAROMETRIC PRESSURE

CIRCUIT HIGH INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of intake manifold pressure sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time until completing the malfunction criteria below becomes 0.5 second

or more. Judge as OK and clear the NG when the malfunction criteria below are not met.

Time Needed for Diagnosis: 0.5 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

(A) Output voltage (B) Absolute pressure

(1) Connector (2) Terminals (3) O-ring

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage≥ 4.921 V

EN-01765

(B)

(A)

(2)

(3)

(1)

Page 1697 of 2453

GD(H6DO)-85

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BB:DTC P0172 SYSTEM TOO RICH (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect fuel system malfunction by the amount of main feedback control.

Diagnostic method

Fuel system is diagnosed by comparing the target air fuel ratio calculated by ECM with the actual air fuel ra-

tio measured by sensor.

2. ENABLE CONDITIONS

3. GENERAL DRIVING CYCLE

Perform the diagnosis continuously at idling or at a constant speed after warming up the engine.

4. DIAGNOSTIC METHOD

Abnormality Judgment

Compare the diagnosed value (fsobd) with the threshold value, and if a condition where the malfunction cri-

teria are met continues for more than 50 seconds, judge that there is a fault in the fuel system.

Time Needed for Diagnosis: 10 seconds × 5 times

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK when the malfunction criteria below continues for 10 seconds.

5. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

Secondary Parameters Enable Conditions

A/F main learning system In operation

Engine coolant temperature≥ 75°C (167°F)

Cumulative time of canister purge after

engine start

20 seconds or more

Continuous period after canister purge

starting

30 seconds or more

Intake manifold absolute pressure≥ Map 1

Judgment Value

Malfunction Criteria Threshold Value

fsobd = (sglmd – tglmda) + faf + flaf≤ fsobdR1

In this case: sglmd = measured lambda,

tglmda = target lambda, faf = main feed-

back compensation coefficient (every 64

milliseconds), flaf = main feedback learn-

ing compensation coefficient

Refer to Map 4.

fsobdR1 = rich side

threshold value of

fsobd

Map 4

Amount of air (g(oz)/s) 0 (0)3.2

(0.113)

6.4

(0.226)

9.6

(0.339)

12.8

(0.451)

16

(0.564)

19.2

(0.677)

fsobdR1 (%) –40 –40 –31.2 –26.5 –26.5 –26.5 26.5

Judgment Value

Malfunction Criteria Threshold Value

fsobd = (sglmd – tglmda) + faf + flaf≥ –20%

Page 1716 of 2453

GD(H6DO)-104

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

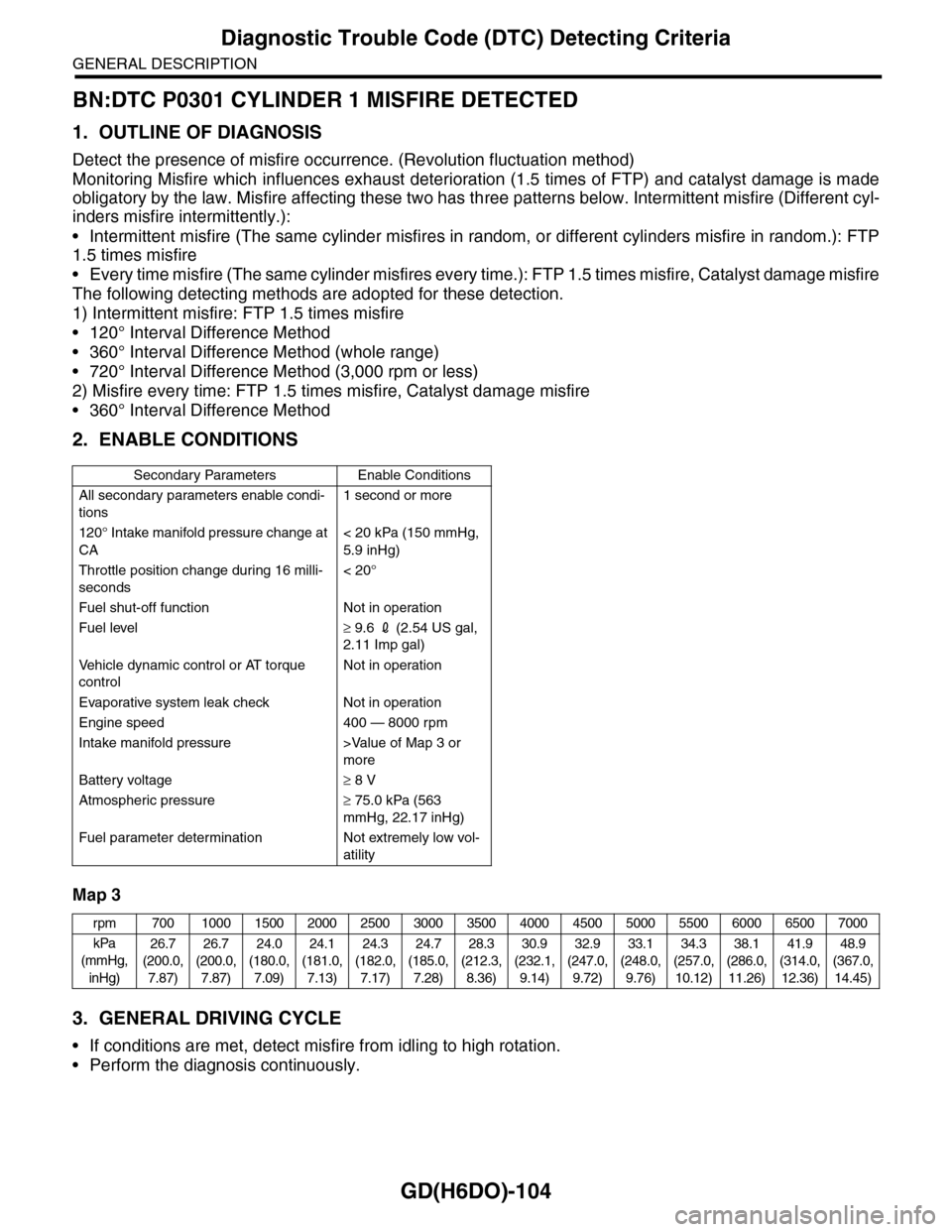

BN:DTC P0301 CYLINDER 1 MISFIRE DETECTED

1. OUTLINE OF DIAGNOSIS

Detect the presence of misfire occurrence. (Revolution fluctuation method)

Monitoring Misfire which influences exhaust deterioration (1.5 times of FTP) and catalyst damage is made

obligatory by the law. Misfire affecting these two has three patterns below. Intermittent misfire (Different cyl-

inders misfire intermittently.):

•Intermittent misfire (The same cylinder misfires in random, or different cylinders misfire in random.): FTP

1.5 times misfire

•Every time misfire (The same cylinder misfires every time.): FTP 1.5 times misfire, Catalyst damage misfire

The following detecting methods are adopted for these detection.

1) Intermittent misfire: FTP 1.5 times misfire

•120° Interval Difference Method

•360° Interval Difference Method (whole range)

•720° Interval Difference Method (3,000 rpm or less)

2) Misfire every time: FTP 1.5 times misfire, Catalyst damage misfire

•360° Interval Difference Method

2. ENABLE CONDITIONS

Map 3

3. GENERAL DRIVING CYCLE

•If conditions are met, detect misfire from idling to high rotation.

•Perform the diagnosis continuously.

Secondary Parameters Enable Conditions

All secondary parameters enable condi-

tions

1 second or more

120° Intake manifold pressure change at

CA

< 20 kPa (150 mmHg,

5.9 inHg)

Throttle position change during 16 milli-

seconds

< 20°

Fuel shut-off function Not in operation

Fuel level≥ 9.6 2 (2.54 US gal,

2.11 Imp gal)

Ve h i c l e d y n a m i c c o n t r o l o r AT t o r q u e

control

Not in operation

Evaporative system leak check Not in operation

Engine speed 400 — 8000 rpm

Intake manifold pressure >Value of Map 3 or

more

Battery voltage≥ 8 V

Atmospheric pressure≥ 75.0 kPa (563

mmHg, 22.17 inHg)

Fuel parameter determination Not extremely low vol-

atility

rpm 700 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000

kPa

(mmHg,

inHg)

26.7

(200.0,

7.87)

26.7

(200.0,

7.87)

24.0

(180.0,

7.09)

24.1

(181.0,

7.13)

24.3

(182.0,

7.17)

24.7

(185.0,

7.28)

28.3

(212.3,

8.36)

30.9

(232.1,

9.14)

32.9

(247.0,

9.72)

33.1

(248.0,

9.76)

34.3

(257.0,

10.12)

38.1

(286.0,

11.26)

41.9

(314.0,

12.36)

48.9

(367.0,

14.45)

Page 1736 of 2453

GD(H6DO)-124

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

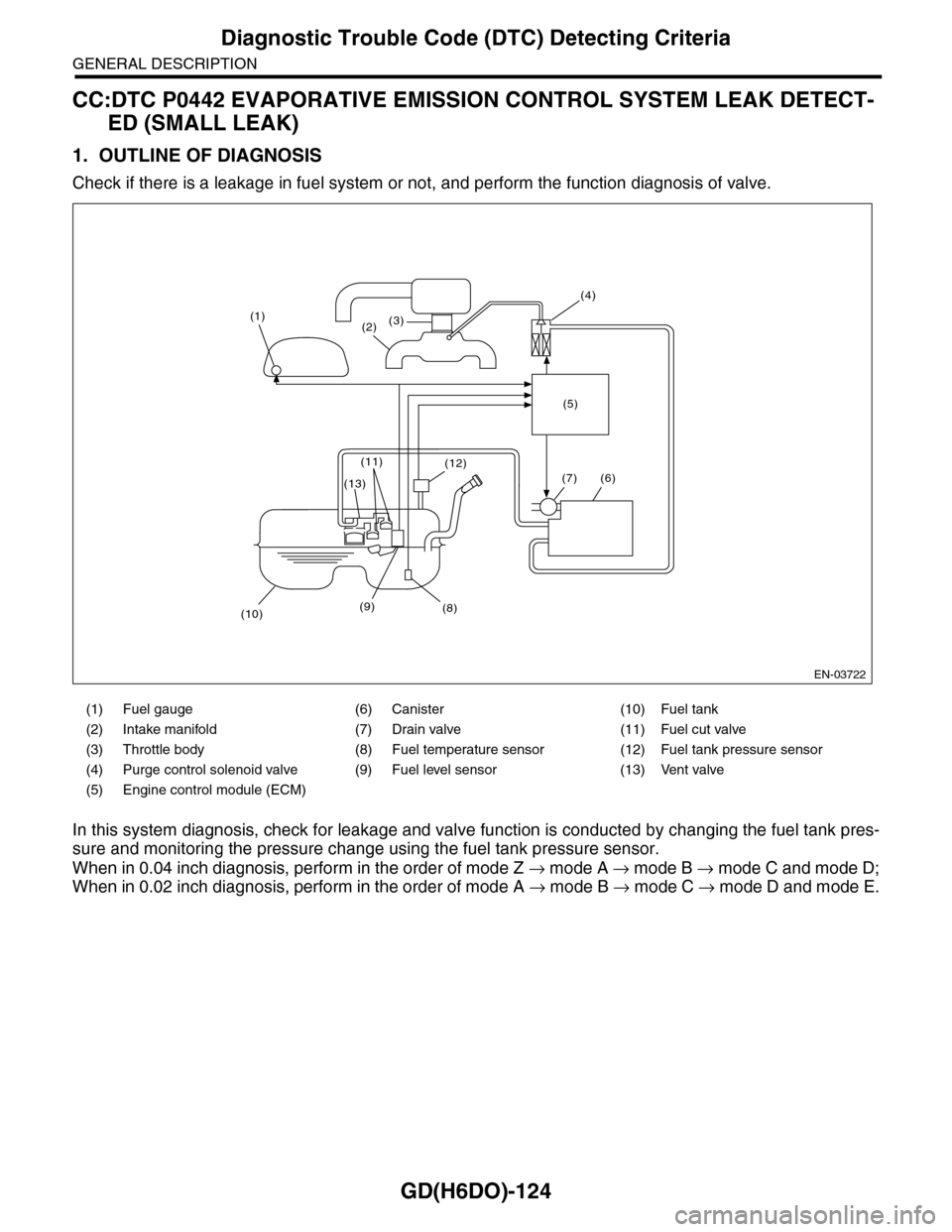

CC:DTC P0442 EVAPORATIVE EMISSION CONTROL SYSTEM LEAK DETECT-

ED (SMALL LEAK)

1. OUTLINE OF DIAGNOSIS

Check if there is a leakage in fuel system or not, and perform the function diagnosis of valve.

In this system diagnosis, check for leakage and valve function is conducted by changing the fuel tank pres-

sure and monitoring the pressure change using the fuel tank pressure sensor.

When in 0.04 inch diagnosis, perform in the order of mode Z → mode A → mode B → mode C and mode D;

When in 0.02 inch diagnosis, perform in the order of mode A → mode B → mode C → mode D and mode E.

(1) Fuel gauge (6) Canister (10) Fuel tank

(2) Intake manifold (7) Drain valve (11) Fuel cut valve

(3) Throttle body (8) Fuel temperature sensor (12) Fuel tank pressure sensor

(4) Purge control solenoid valve (9) Fuel level sensor (13) Vent valve

(5) Engine control module (ECM)

EN-03722

(1)(2)(3)

(4)

(5)

(6)

(8)

(12)

(9)(10)

(13)

(11)

(7)