Steering Terminal SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1066 of 2453

VDC(diag)-74

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

Step Check Yes No

1CHECK THE POWER SUPPLY OF THE

STEERING ANGLE SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from steering

angle sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between steering

angle sensor and chassis ground.

Connector & terminal

(B231) No. 4 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 2.Repair power sup-

ply circuit in the

steering angle

sensor.

2CHECK GROUND CIRCUIT OF STEERING

ANGLE SENSOR.

Measure the voltage between steering angle

sensor and chassis ground.

Connector & terminal

(B231) No. 3 (+) — Chassis ground (–):

Is the resistance less than 0.5

Ω?

Go to step 3.Repair ground cir-

cuit in the steering

angle sensor.

3CHECK POOR CONTACT OF CONNEC-

TORS.

Is there poor contact in con-

nector?

Correct or replace

the connector.

Go to step 4.

4CHECK STEERING ANGLE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect all the connectors.

3) Erase the memory.

4) Perform the inspection mode.

5) Read the DTC.

Is the same DTC displayed? Replace the steer-

ing angle sensor.

Go to step 5.

5CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

Te m p o r a r y p o o r

contact occurs.

Page 1068 of 2453

VDC(diag)-76

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

Step Check Yes No

1CHECK LAN SYSTEM.

Perfor m the diagnosis for LAN system.

Tr o u b l e C o d e ( D T C ) . >

Is there any fault in LAN sys-

tem?

Pe r for m t h e d ia g -

nosis according to

DTC for LAN sys-

tem.

Go to step 2.

2CHECK POWER SUPPLY FOR STEERING

ANGLE SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from steering

angle sensor.

3) Turn the ignition switch to ON.

4) Measure the voltage between steering

angle sensor and chassis ground.

Connector & terminal

(B231) No. 4 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 3.Repair the power

supply circuit.

3CHECK GROUND CIRCUIT OF STEERING

ANGLE SENSOR.

Measure the resistance between steering

angle sensor and chassis ground.

Connector & terminal

(B231) No. 3 — Chassis ground:

Is the resistance less than 0.5

Ω?

Go to step 4.Repair ground cir-

cuit in the steering

angle sensor.

4CHECK STEERING ANGLE SENSOR HAR-

NESS.

1) Disconnect the connector from the

VDCCM&H/U.

2) Measure the resistance between

VDCCM&H/U and steering angel sensor.

Connector & terminal

(B231) No. 1 — (B310) No. 20:

(B231) No. 2 — (B310) No. 34:

Is the resistance less than 0.5

Ω?

Go to step 5.Repair the har-

ness between the

steering angle

sensor and

VDCCM&H/U.

5CHECK GROUND SHORT CIRCUIT OF

STEERING ANGLE SENSOR HARNESS.

Measure the resistance between steering

angle sensor and chassis ground.

Connector & terminal

(B231) No. 1 — Chassis ground:

(B231) No. 2 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 6.Repair the har-

ness between the

steering angle

sensor and

VDCCM&H/U.

6CHECK STEERING ANGLE SENSOR.

1) Turn the ignition switch to OFF.

2) Connect all the connectors.

3) Erase the memory.

4) Perform the inspection mode.

5) Read the DTC.

Is the same DTC displayed? Go to step 7.Go to step 8.

7CHECK THE VDCCM&H/U.

1) Turn the ignition switch to OFF.

2) Replace the steering angle sensor.

3) Erase the memory.

4) Perform the inspection mode.

5) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 9.

8CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

Te m p o r a r y p o o r

contact occurs.

9CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

Original steering

angle sensor mal-

function

Page 1166 of 2453

EN(H6DO)(diag)-5

General Description

ENGINE (DIAGNOSTICS)

3. General Description

A: CAUTION

1) Airbag system wiring harness is routed near the

ECM, main relay and fuel pump relay.

CAUTION:

•All airbag system wiring harnesses and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the ECM, TCM,

main relay and fuel pump relay.

2) Never connect the battery in reverse polarity.

•The ECM will be destroyed instantly.

•The fuel injector and other parts will be dam-

aged.

3) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as ECM etc.

4) Before disconnecting the connectors of each

sensor and ECM, be sure to turn the ignition switch

to OFF. Perform the clear memory mode after con-

necting the connectors.

5) Poor contact has been identified as a primary

cause of this problem. Measure the voltage or re-

sistance of individual sensor or all electrical control

modules using a tapered pin with a diameter of less

than 0.64 mm (0.025 in). Do not insert the pin more

than 5 mm (0.20 in) into the part.

6) Remove the ECM from the located position after

disconnecting two cables on battery.

Otherwise, the ECM may be damaged.

CAUTION:

When replacing the ECM, be careful not to use

the wrong spec. ECM to avoid any damage on

the fuel injection system.

7) Connectors of each sensor in the engine com-

partment and the harness connectors on the en-

gine side and body side are all designed to be

waterproof. Even if the connectors are waterproof,

take care not to allow water to get into them when

washing the vehicle, or when servicing the vehicle

in rainy weather.

8) Use ECM mounting stud bolts as the grounding

point to chassis when measuring voltage and resis-

tance in the passenger compartment.

9) Use the engine ground terminal or engine as-

sembly as the grounding point to chassis when

measuring the voltage and resistance in engine

compartment.

10) Every MFI-related part is a precision part. Do

not drop them.

11) Observe the following cautions when installing

a radio in MFI equipped models.

CAUTION:

•The antenna must be kept as far apart as pos-

sible from control unit. (The ECM is located un-

der the steering column, inside of the

instrument panel lower trim panel.)

•The antenna feeder must be placed as far apart

as possible from the ECM and MFI harness.

•Carefully adjust the antenna for correct

matching.

•When mounting a large power type radio, pay

special attention to the three items mentioned

above.

•Incorrect installation of the radio may affect

the operation of ECM.

12) Release the pressure in the fuel system before

disconnecting the fuel hose. If engine starts during

this operation, run it until it stops.

13) For the model with ABS, the ABS warning light

may illuminate when performing driving test with

jacked-up or lifted-up condition, but this is not a

system malfunction. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clear procedure of self-

diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect engine problems.

1. BATTERY

1) Measure the battery voltage and specific gravity

of electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

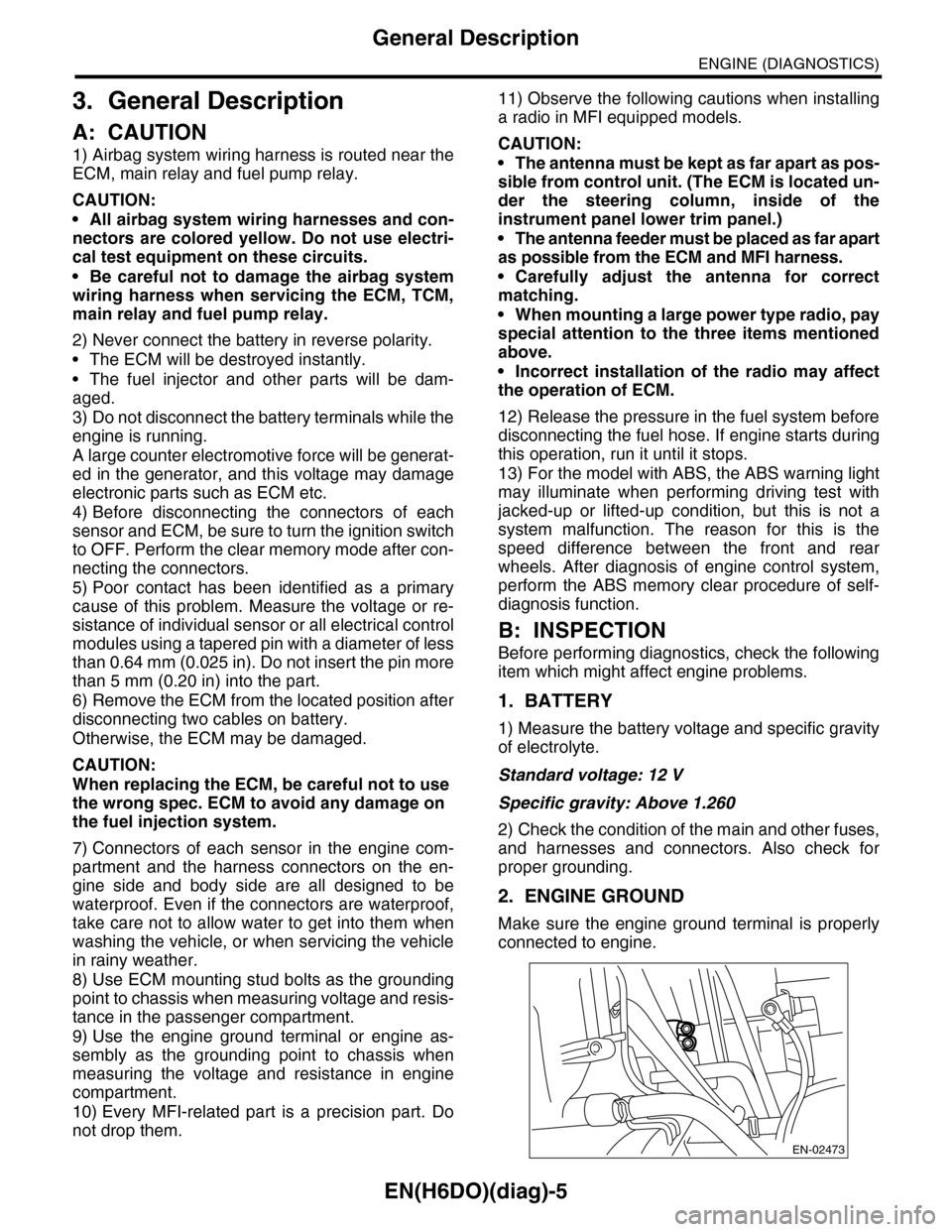

2. ENGINE GROUND

Make sure the engine ground terminal is properly

connected to engine.

EN-02473

Page 1898 of 2453

ME(H6DO)-32

Engine Assembly

MECHANICAL

10.Engine Assembly

A: REMOVAL

1) Set the vehicle on a lift.

2) Change the bolt mounting position from (A) to

(B), then completely open the front hood.

3) Remove the collector cover.

4) Collect the refrigerant from A/C system.

cedure.>

5) Release the fuel pressure.

6) Remove the battery from vehicle.

7) Remove the air intake duct, air cleaner case and

air intake chamber.

8) Remove the engine front cover.

9) Remove the radiator from the vehicle.

NOTE:

Protect the condenser so that it will not be dam-

aged.

10) Remove the fuel hose bracket.

11) Remove the V-belts.

12) Disconnect the A/C pressure hoses from A/C

compressor.

13) Remove the engine ground terminal.

14) Disconnect the following connector.

(1) Engine harness connectors

(2) Generator connector, terminal and A/C

compressor connector

(3) Power steering switch connector

ME-02652

(A)

(B)

CO-02176

ME-02653

ME-00476

ME-02654

Page 1904 of 2453

ME(H6DO)-38

Engine Assembly

MECHANICAL

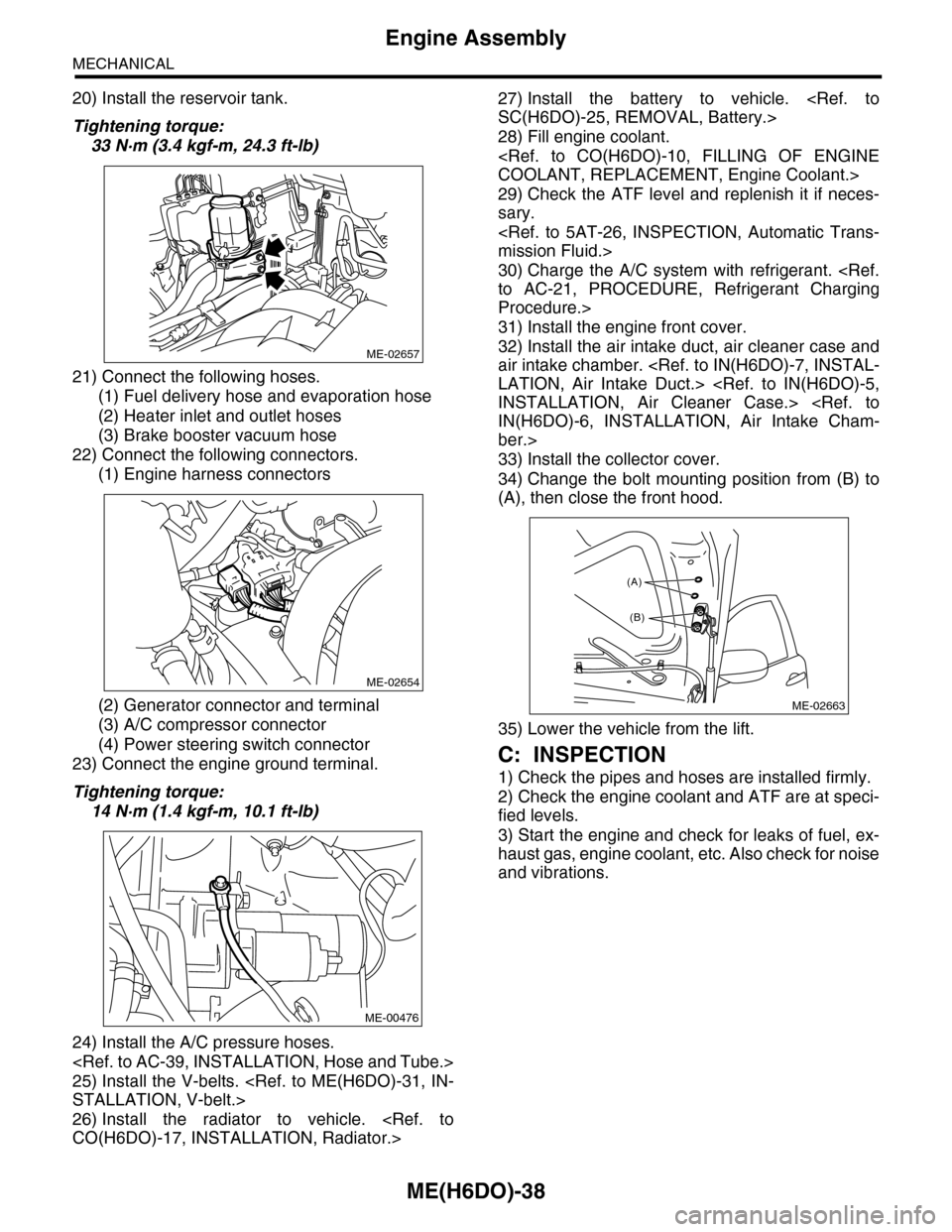

20) Install the reservoir tank.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

21) Connect the following hoses.

(1) Fuel delivery hose and evaporation hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

22) Connect the following connectors.

(1) Engine harness connectors

(2) Generator connector and terminal

(3) A/C compressor connector

(4) Power steering switch connector

23) Connect the engine ground terminal.

Tightening torque:

14 N·m (1.4 kgf-m, 10.1 ft-lb)

24) Install the A/C pressure hoses.

25) Install the V-belts.

26) Install the radiator to vehicle.

27) Install the battery to vehicle.

28) Fill engine coolant.

29) Check the ATF level and replenish it if neces-

sary.

30) Charge the A/C system with refrigerant.

Procedure.>

31) Install the engine front cover.

32) Install the air intake duct, air cleaner case and

air intake chamber.

ber.>

33) Install the collector cover.

34) Change the bolt mounting position from (B) to

(A), then close the front hood.

35) Lower the vehicle from the lift.

C: INSPECTION

1) Check the pipes and hoses are installed firmly.

2) Check the engine coolant and ATF are at speci-

fied levels.

3) Start the engine and check for leaks of fuel, ex-

haust gas, engine coolant, etc. Also check for noise

and vibrations.

ME-02657

ME-02654

ME-00476

ME-02663

(A)

(B)

Page 2327 of 2453

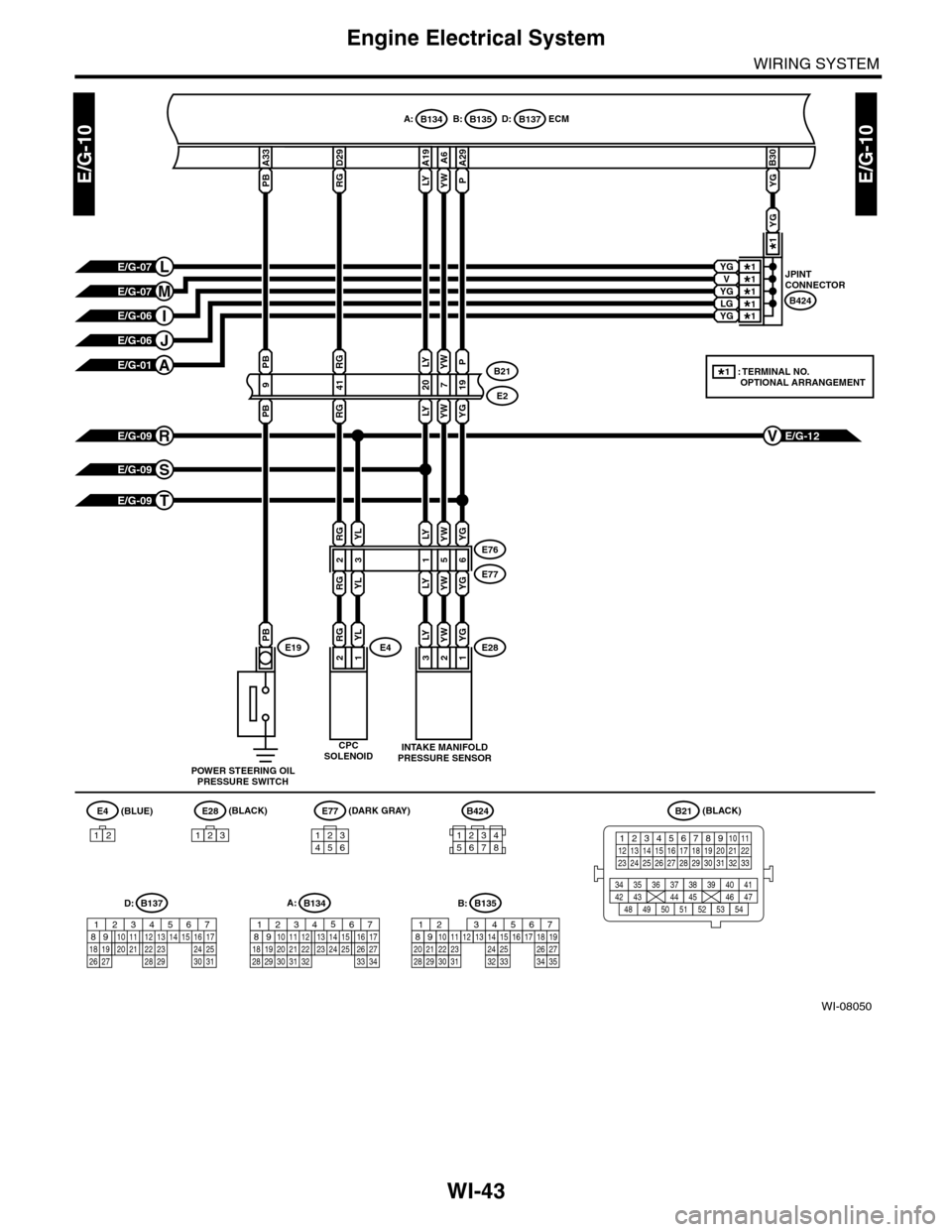

WI-43

Engine Electrical System

WIRING SYSTEM

WI-08050

E/G-10E/G-10

D:B137

D29

RG

A6

YW

31E28

E76

E77

A19

LY

YWYGE4

B:B135A:B134ECM

CPCSOLENOID

E2

B21

A33

PB

LYYW

LYYW

21

15

RGYL

(BLUE)E4

12

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47

YG

YG

B30

YG

LGYG

YGV

B424

JPINTCONNECTORE/G-07M

B424

34561278

D: B137

85610 11 12 13 14 157213416

3019 20 2228 29

91718 2521 23 243126 27

E/G-12V

YG

YG

6

E/G-09R

LY

2

RG

RG

2

YL

YL

3

E/G-07L

E/G-06I

E/G-06J

E/G-01A

POWER STEERING OILPRESSURE SWITCH

E19PB

9

PB

PB

E/G-09S

E/G-09T

41

RG

RG

197

PYW

YGYW

20

LY

LY

A29

P

INTAKE MANIFOLDPRESSURE SENSOR

E28

123

(BLACK)(BLACK)E77

134562

(DARK GRAY)

A:B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

*1

*1

*1

*1

*1*1

*1 : TERMINAL NO. OPTIONAL ARRANGEMENT

B:B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

Page 2338 of 2453

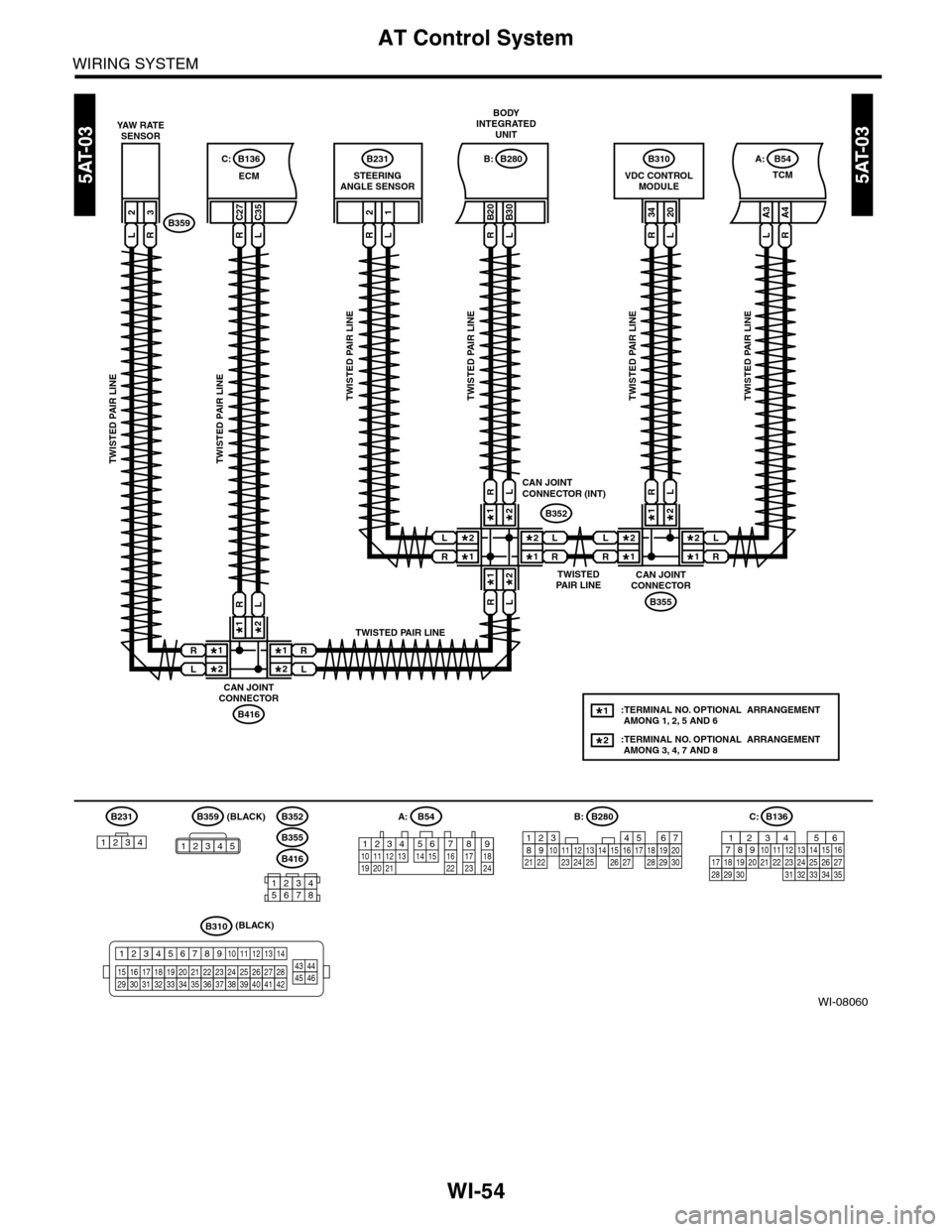

WI-54

AT Control System

WIRING SYSTEM

WI-08060

5AT-035AT-03

B231

TCM

B54A:

TWISTED PAIR LINETWISTED PAIR LINETWISTED PAIR LINETWISTED PAIR LINE

TWISTED PAIR LINE

TWISTED PAIR LINE

TWISTEDPAIR LINE

TWISTED PAIR LINE

B355

CAN JOINTCONNECTOR

1*

2*1*

2*L

R

L

R

2*1*

RL

B352

CAN JOINTCONNECTOR (INT)

1*

2*1*

2*L

R

L

R

2*1*

RL

2*1*

RL

LR

A3A4

RL

B20B30

RL

21

VDC CONTROLMODULESTEERINGANGLE SENSOR

B310

RL

3420

B416

CAN JOINTCONNECTOR

2*

1*2*

1*R

L

R

L

2*1*

RL

ECM

B136C:

RL

C27C35

YAW RATESENSOR

B359LR

23

:TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 1, 2, 5 AND 6

:TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 3, 4, 7 AND 8

1*

2*

B231

12345467821931022 23111213141524 25 26 2716171828 29192021 30

B280B:

B310

1234

1516171819202122232425262728293031323334353637383940414245464344568910 11 12 13 147

B416

B355

B352

34561278

B359

12345

A:B54

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

C: B136

16101112131415252430

9871718192028212223293231

123456

2726333435

B280B:

BODYINTEGRATEDUNIT

(BLACK)

(BLACK)

Page 2346 of 2453

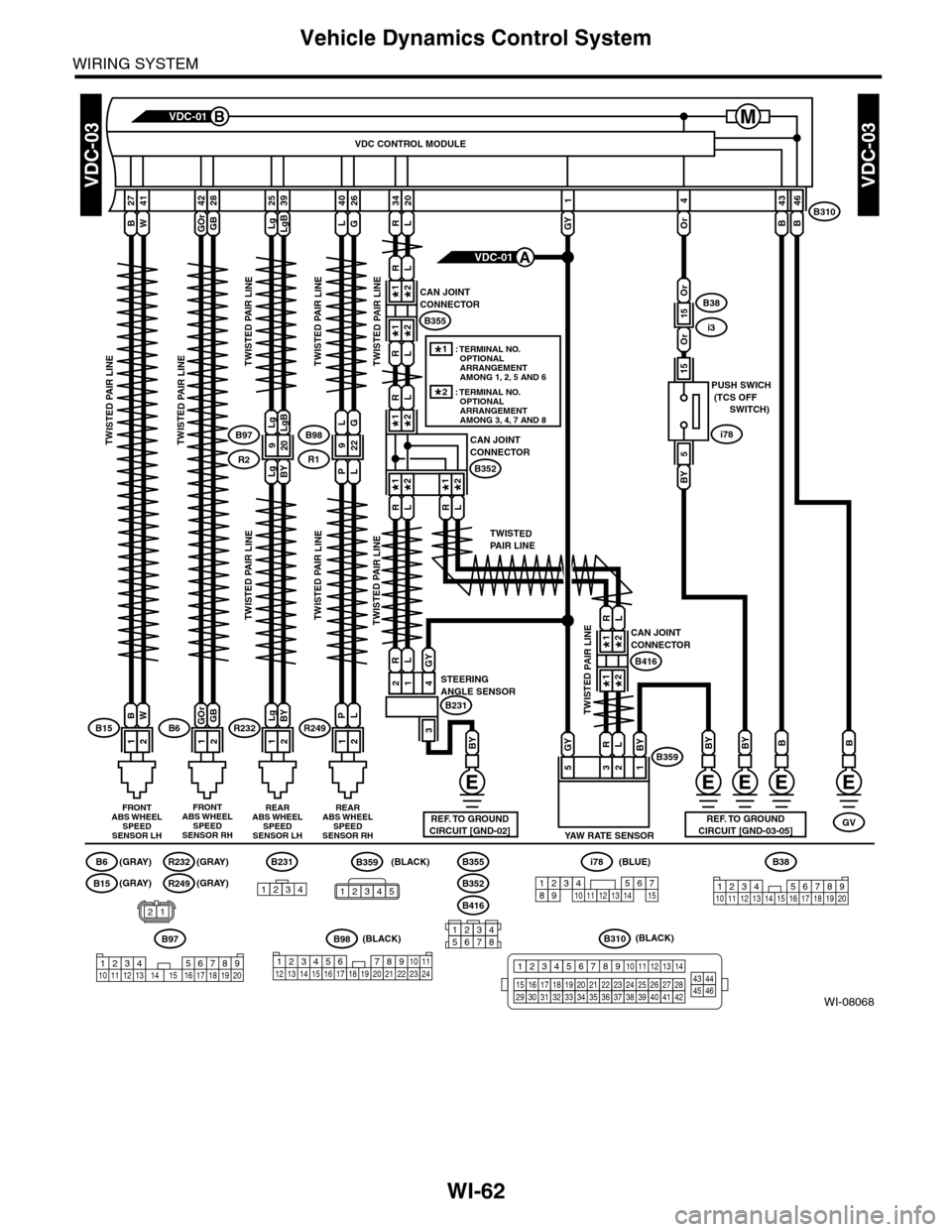

WI-62

Vehicle Dynamics Control System

WIRING SYSTEM

WI-08068

VDC-03VDC-03

FRONTABS WHEELSPEEDSENSOR LH

B310

209

2741

12

2539

1212

4026

BW

1

GY

46

B

43

BLgLgBLG

BWLgBYPL

RLGY

B15R232R249

B359

GVREARABS WHEELSPEEDSENSOR LH

REARABS WHEELSPEEDSENSOR RHYAW RATE SENSOR

B

9

LgLgBLG

22

LgBYPL

B97

R2

B98

R1

BY

TWISTED PAIR LINETWISTED PAIR LINE

TWISTED PAIR LINE

TWISTED PAIR LINE

TWISTED PAIR LINETWISTED PAIR LINE

TWISTED PAIR LINE

TWISTED PAIR LINE

TWISTED PAIR LINE

TWISTEDPAIR LINE

FRONTABS WHEELSPEEDSENSOR RH

4228

12

GOrGB

GOrGBB6

3420

BYBYBY

STEERINGANGLE SENSOR2

RL

1

GY

4

3

B231

CAN JOINTCONNECTOR

RL

LR

B352

3251

VDC CONTROL MODULE

VDC-01B

VDC-01A

LR

REF. TO GROUNDCIRCUIT [GND-02]REF. TO GROUNDCIRCUIT [GND-03-05]

B38

1234 5678910 11 12 13 14 15 16 17 18 19 20B352

B355

B416

34561278

CAN JOINTCONNECTOR

LR

B355

B

15

4

B38

i3Or

Or

Or

i78

PUSH SWICH (TCS OFF SWITCH)

BY

5

15

131415123456789101112

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 1, 2, 5 AND 6: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 3, 4, 7 AND 8

1*

2*

1*2*

1*2*

1*2*

1*2*1*2*

RL

LR

B359

12345

R232(GRAY) (BLACK)

(BLACK)

B15(GRAY)

B6(GRAY)

R249(GRAY)

12

B310

1234

1516171819202122232425262728293031323334353637383940414245464344568910 11 12 13 147

B97

12345678910 11 12 13 16 17 18 19 201415

i78(BLUE)

B98(BLACK)

123456 78910 1112 13 16 1714 15 18 19 2021222324

B231

1234

CAN JOINTCONNECTOR

B416

1*2*

1*2*

RL

Page 2363 of 2453

![SUBARU TRIBECA 2009 1.G Service Owners Manual WI-79

CAN Communication System

WIRING SYSTEM

WI-08085

CAN-02CAN-02

BODY INTEGRATED UNIT

B280B:

B231

TCM

B54A:

TWISTED PAIR LINE

BY

REF. TO GROUNDCIRCUIT [GND-02]

B355

CAN JOINTCONNECTOR(TCM)

1*

2*1*

2 SUBARU TRIBECA 2009 1.G Service Owners Manual WI-79

CAN Communication System

WIRING SYSTEM

WI-08085

CAN-02CAN-02

BODY INTEGRATED UNIT

B280B:

B231

TCM

B54A:

TWISTED PAIR LINE

BY

REF. TO GROUNDCIRCUIT [GND-02]

B355

CAN JOINTCONNECTOR(TCM)

1*

2*1*

2](/img/17/7322/w960_7322-2362.png)

WI-79

CAN Communication System

WIRING SYSTEM

WI-08085

CAN-02CAN-02

BODY INTEGRATED UNIT

B280B:

B231

TCM

B54A:

TWISTED PAIR LINE

BY

REF. TO GROUNDCIRCUIT [GND-02]

B355

CAN JOINTCONNECTOR(TCM)

1*

2*1*

2*L

R

L

R

2*1*

RL

B352

CAN JOINTCONNECTOR(INT)

1*

2*1*

2*L

R

L

R

2*1*

RL

2*1*

RL

LR

A3A4

RL

B20B30

RBYGrL

2431

VDC CONTROLMODULE

STEERINGANGLE SENSOR

B310RGrL

34201

B416

CAN JOINTCONNECTOR(YAW)

2*

1*2*

1*R

L

R

L

1*2*

RL

ECM

B136C:RL

C27C35

YAW RATESENSOR

B359LR

23

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 1, 2, 3, 4, 5 AND 6

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 3, 4, 7 AND 8

1*

2*

B231

12345467821931022 23111213141524 25 26 2716171828 29192021 30

B280B:

B310

1234

1516171819202122232425262728293031323334353637383940414245464344568910 11 12 13 147

B416

B355

B352

34561278

B359

12345

A:B54

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

C: B136

16101112131415252430

9871718192028212223293231

123456

2726333435