Steering Terminal SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 504 of 2453

LAN(diag)-48

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

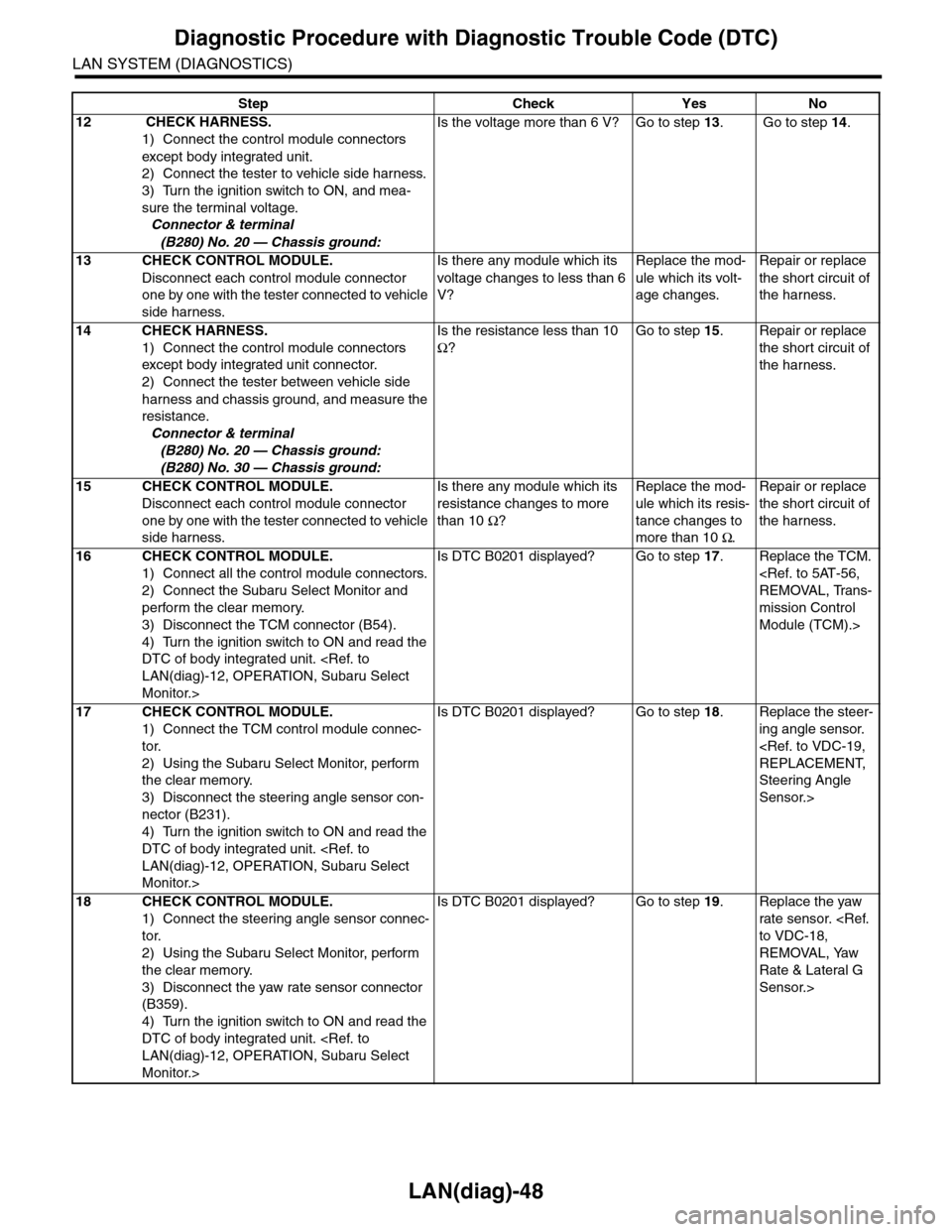

12 CHECK HARNESS.

1) Connect the control module connectors

except body integrated unit.

2) Connect the tester to vehicle side harness.

3) Turn the ignition switch to ON, and mea-

sure the terminal voltage.

Connector & terminal

(B280) No. 20 — Chassis ground:

Is the voltage more than 6 V? Go to step 13. Go to step 14.

13 CHECK CONTROL MODULE.

Disconnect each control module connector

one by one with the tester connected to vehicle

side harness.

Is there any module which its

voltage changes to less than 6

V?

Replace the mod-

ule which its volt-

age changes.

Repair or replace

the shor t circuit of

the harness.

14 CHECK HARNESS.

1) Connect the control module connectors

except body integrated unit connector.

2) Connect the tester between vehicle side

harness and chassis ground, and measure the

resistance.

Connector & terminal

(B280) No. 20 — Chassis ground:

(B280) No. 30 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 15.Repair or replace

the shor t circuit of

the harness.

15 CHECK CONTROL MODULE.

Disconnect each control module connector

one by one with the tester connected to vehicle

side harness.

Is there any module which its

resistance changes to more

than 10 Ω?

Replace the mod-

ule which its resis-

tance changes to

more than 10 Ω.

Repair or replace

the shor t circuit of

the harness.

16 CHECK CONTROL MODULE.

1) Connect all the control module connectors.

2) Connect the Subaru Select Monitor and

perform the clear memory.

3) Disconnect the TCM connector (B54).

4) Turn the ignition switch to ON and read the

DTC of body integrated unit.

Monitor.>

Is DTC B0201 displayed? Go to step 17.Replace the TCM.

mission Control

Module (TCM).>

17 CHECK CONTROL MODULE.

1) Connect the TCM control module connec-

tor.

2) Using the Subaru Select Monitor, perform

the clear memory.

3) Disconnect the steering angle sensor con-

nector (B231).

4) Turn the ignition switch to ON and read the

DTC of body integrated unit.

Monitor.>

Is DTC B0201 displayed? Go to step 18.Replace the steer-

ing angle sensor.

Steering Angle

Sensor.>

18 CHECK CONTROL MODULE.

1) Connect the steering angle sensor connec-

tor.

2) Using the Subaru Select Monitor, perform

the clear memory.

3) Disconnect the yaw rate sensor connector

(B359).

4) Turn the ignition switch to ON and read the

DTC of body integrated unit.

Monitor.>

Is DTC B0201 displayed? Go to step 19.Replace the yaw

rate sensor.

REMOVAL, Yaw

Rate & Lateral G

Sensor.>

Step Check Yes No

Page 507 of 2453

LAN(diag)-51

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

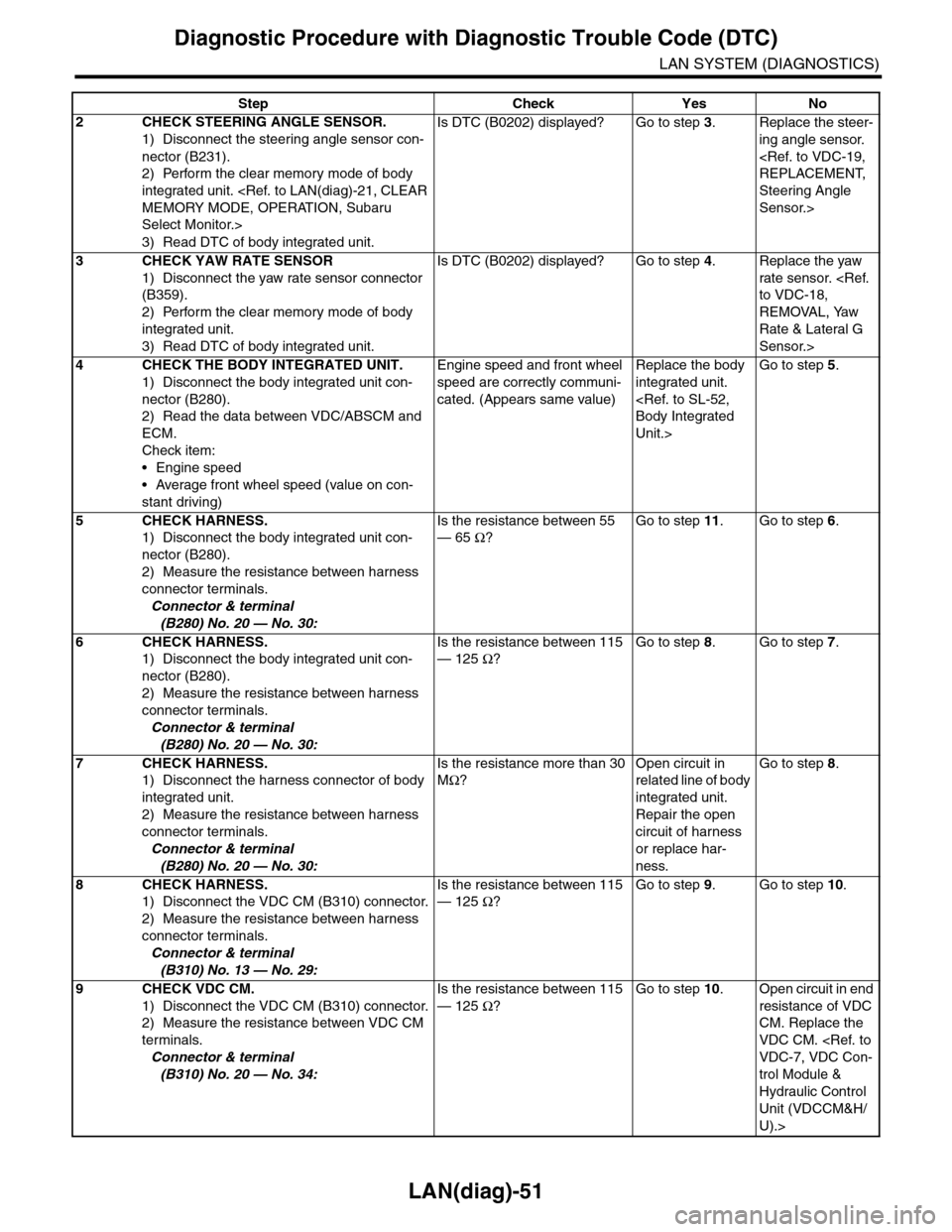

2CHECK STEERING ANGLE SENSOR.

1) Disconnect the steering angle sensor con-

nector (B231).

2) Perform the clear memory mode of body

integrated unit.

Select Monitor.>

3) Read DTC of body integrated unit.

Is DTC (B0202) displayed? Go to step 3.Replace the steer-

ing angle sensor.

Steering Angle

Sensor.>

3CHECK YAW RATE SENSOR

1) Disconnect the yaw rate sensor connector

(B359).

2) Perform the clear memory mode of body

integrated unit.

3) Read DTC of body integrated unit.

Is DTC (B0202) displayed? Go to step 4.Replace the yaw

rate sensor.

REMOVAL, Yaw

Rate & Lateral G

Sensor.>

4CHECK THE BODY INTEGRATED UNIT.

1) Disconnect the body integrated unit con-

nector (B280).

2) Read the data between VDC/ABSCM and

ECM.

Check item:

•Engine speed

•Average front wheel speed (value on con-

stant driving)

Engine speed and front wheel

speed are correctly communi-

cated. (Appears same value)

Replace the body

integrated unit.

Unit.>

Go to step 5.

5CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance between 55

— 65 Ω?

Go to step 11.Go to step 6.

6CHECK HARNESS.

1) Disconnect the body integrated unit con-

nector (B280).

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance between 115

— 125 Ω?

Go to step 8.Go to step 7.

7CHECK HARNESS.

1) Disconnect the harness connector of body

integrated unit.

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 20 — No. 30:

Is the resistance more than 30

MΩ?

Open circuit in

related line of body

integrated unit.

Repair the open

circuit of harness

or replace har-

ness.

Go to step 8.

8CHECK HARNESS.

1) Disconnect the VDC CM (B310) connector.

2) Measure the resistance between harness

connector terminals.

Connector & terminal

(B310) No. 13 — No. 29:

Is the resistance between 115

— 125 Ω?

Go to step 9.Go to step 10.

9CHECK VDC CM.

1) Disconnect the VDC CM (B310) connector.

2) Measure the resistance between VDC CM

terminals.

Connector & terminal

(B310) No. 20 — No. 34:

Is the resistance between 115

— 125 Ω?

Go to step 10.Open circuit in end

resistance of VDC

CM. Replace the

VDC CM.

trol Module &

Hydraulic Control

Unit (VDCCM&H/

U).>

Step Check Yes No

Page 510 of 2453

LAN(diag)-54

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

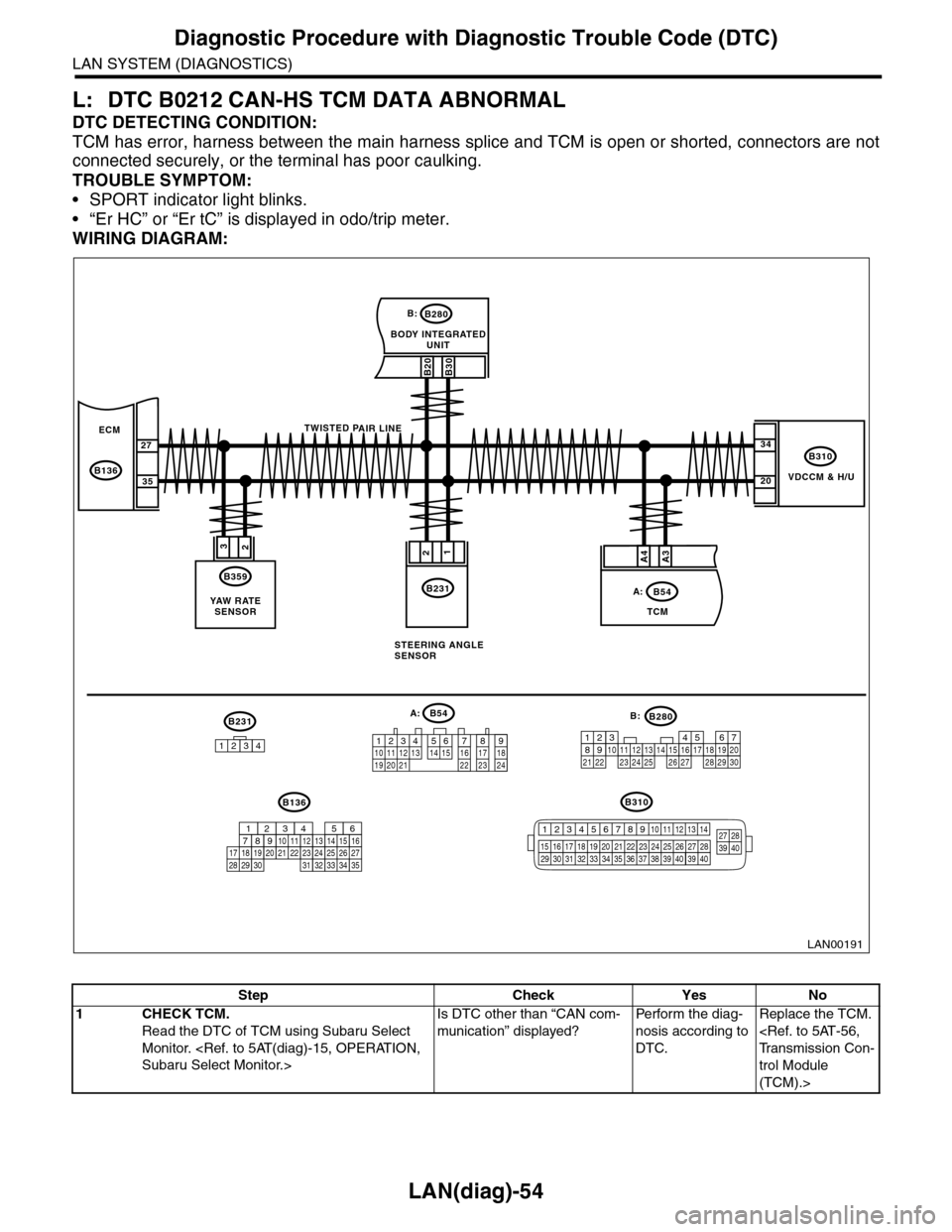

L: DTC B0212 CAN-HS TCM DATA ABNORMAL

DTC DETECTING CONDITION:

TCM has error, harness between the main harness splice and TCM is open or shorted, connectors are not

connected securely, or the terminal has poor caulking.

TROUBLE SYMPTOM:

•SPORT indicator light blinks.

•“Er HC” or “Er tC” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK TCM.

Read the DTC of TCM using Subaru Select

Monitor.

Is DTC other than “CAN com-

munication” displayed?

Pe r for m t h e d ia g -

nosis according to

DTC.

Replace the TCM.

trol Module

(TCM).>

Page 511 of 2453

LAN(diag)-55

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

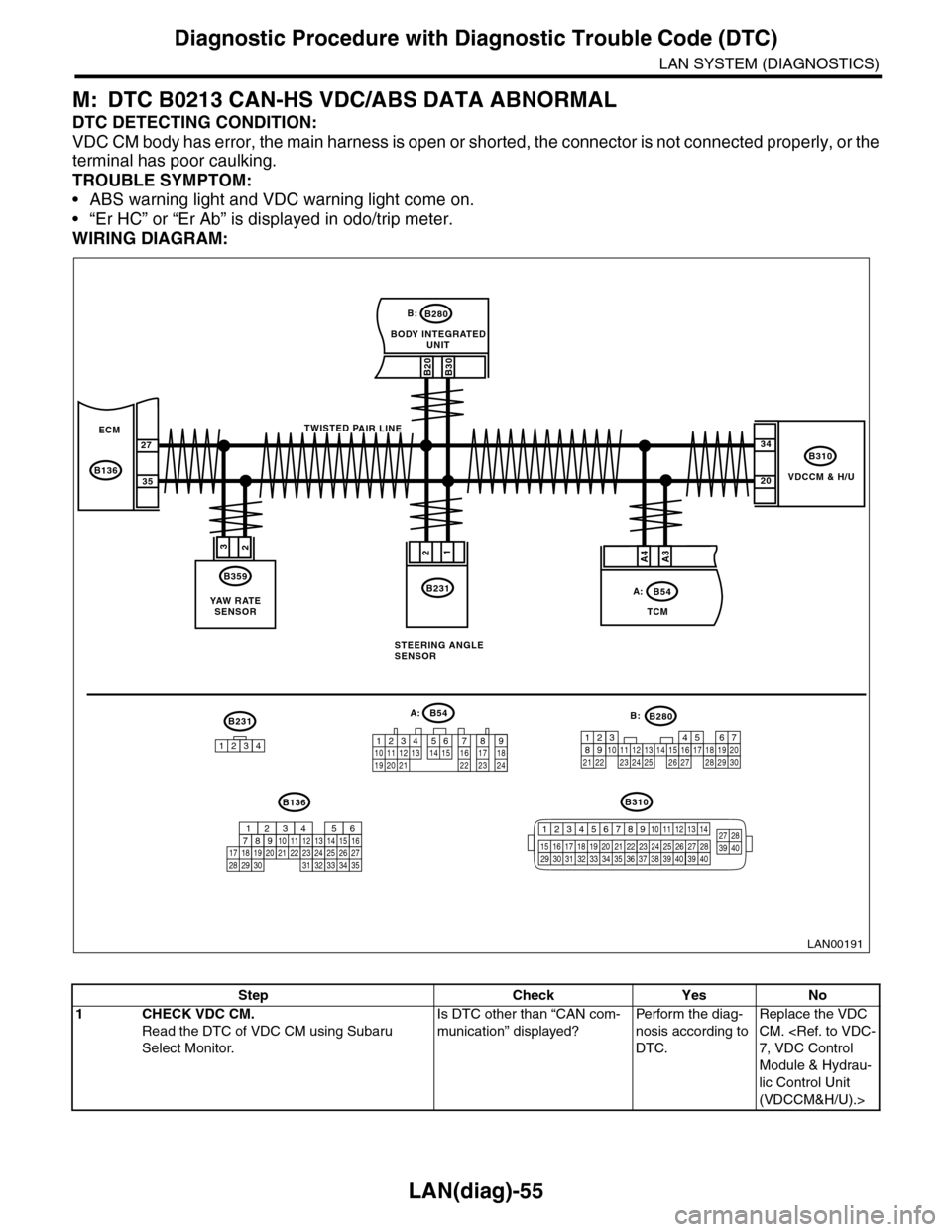

M: DTC B0213 CAN-HS VDC/ABS DATA ABNORMAL

DTC DETECTING CONDITION:

VDC CM body has error, the main harness is open or shorted, the connector is not connected properly, or the

terminal has poor caulking.

TROUBLE SYMPTOM:

•ABS warning light and VDC warning light come on.

•“Er HC” or “Er Ab” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK VDC CM.

Read the DTC of VDC CM using Subaru

Select Monitor.

Is DTC other than “CAN com-

munication” displayed?

Pe r for m t h e d ia g -

nosis according to

DTC.

Replace the VDC

CM.

Module & Hydrau-

lic Control Unit

(VDCCM&H/U).>

Page 515 of 2453

LAN(diag)-59

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

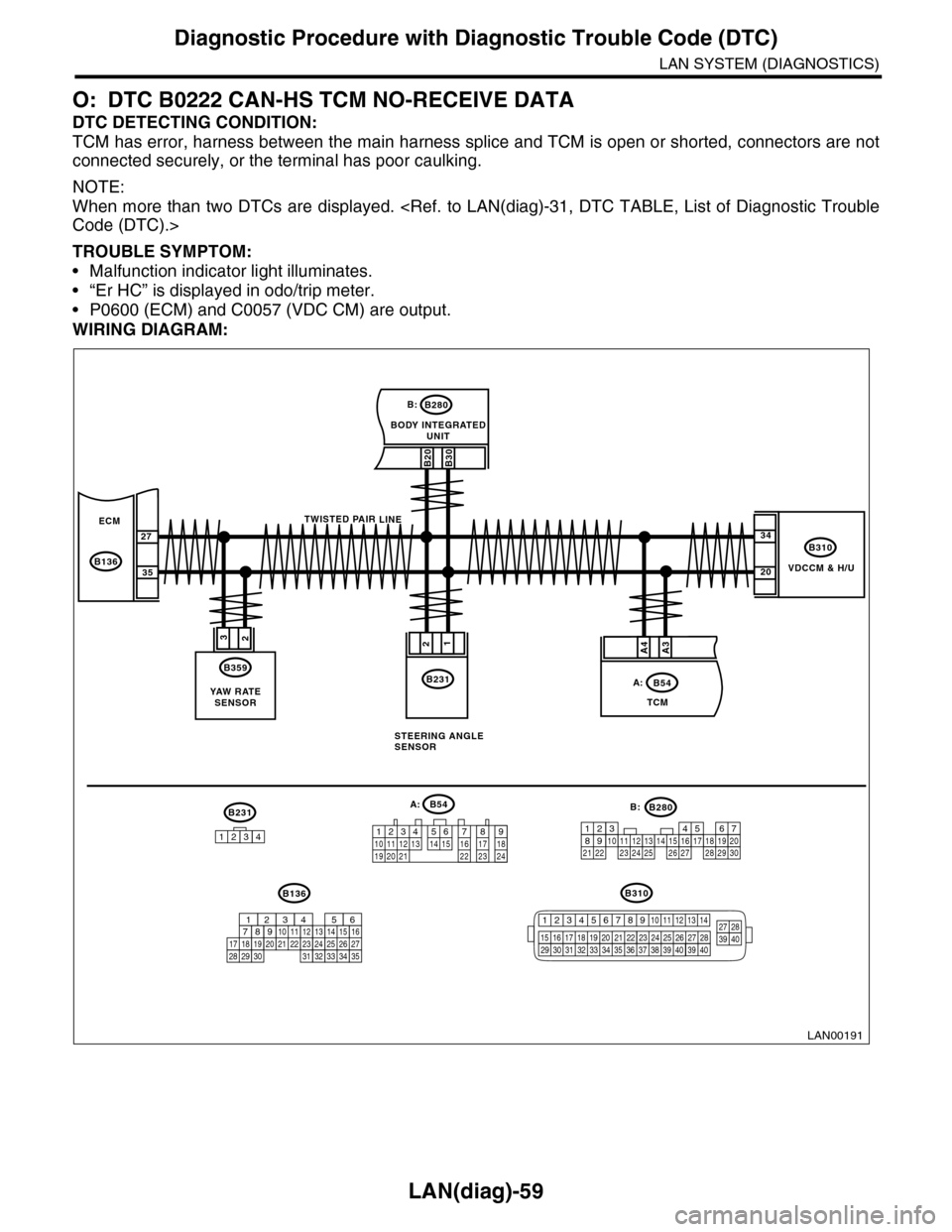

O: DTC B0222 CAN-HS TCM NO-RECEIVE DATA

DTC DETECTING CONDITION:

TCM has error, harness between the main harness splice and TCM is open or shorted, connectors are not

connected securely, or the terminal has poor caulking.

NOTE:

When more than two DTCs are displayed.

TROUBLE SYMPTOM:

•Malfunction indicator light illuminates.

•“Er HC” is displayed in odo/trip meter.

•P0600 (ECM) and C0057 (VDC CM) are output.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Page 542 of 2453

LI-9

Combination Switch (Light)

LIGHTING SYSTEM

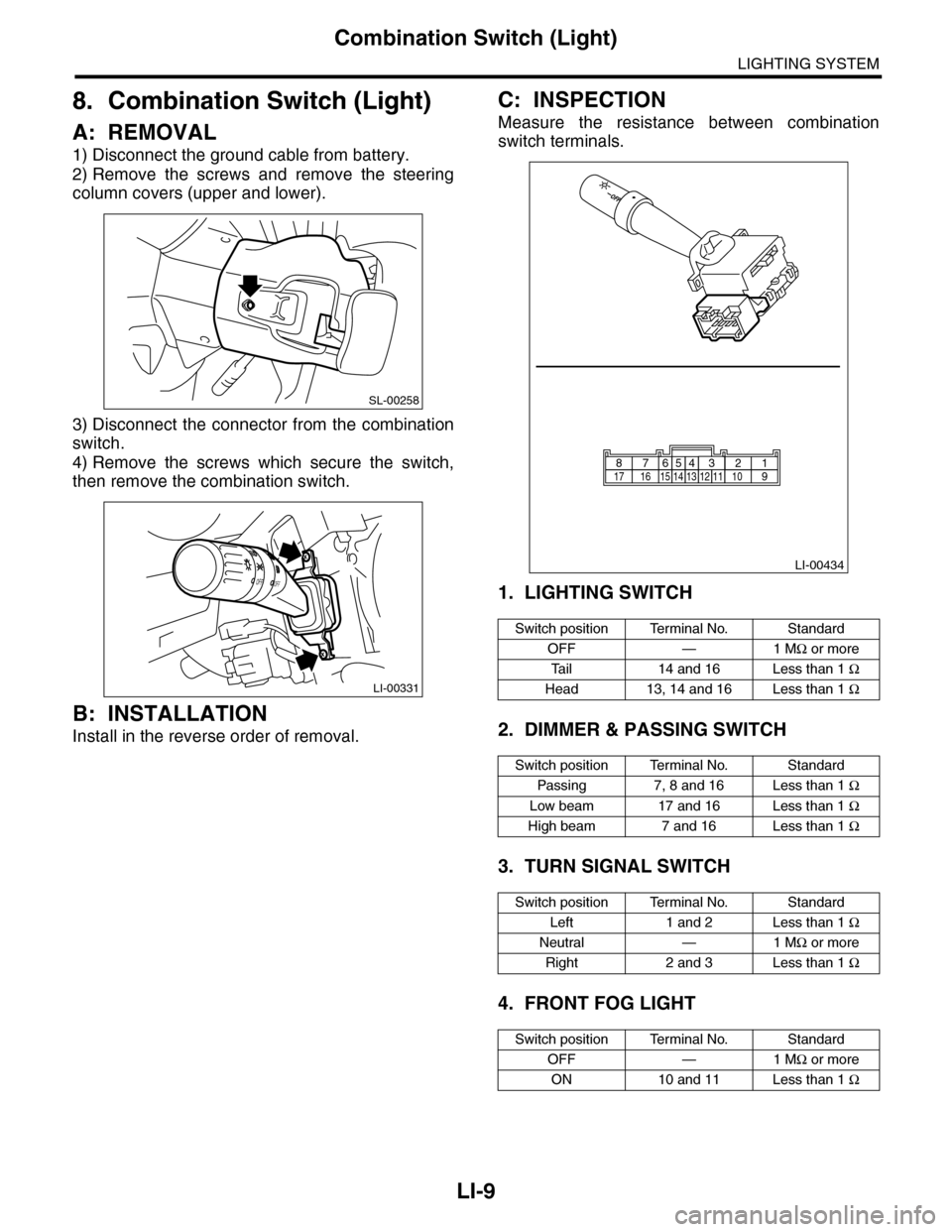

8. Combination Switch (Light)

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the screws and remove the steering

column covers (upper and lower).

3) Disconnect the connector from the combination

switch.

4) Remove the screws which secure the switch,

then remove the combination switch.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the resistance between combination

switch terminals.

1. LIGHTING SWITCH

2. DIMMER & PASSING SWITCH

3. TURN SIGNAL SWITCH

4. FRONT FOG LIGHT

SL-00258

LI-00331

OFFOFF

Switch position Terminal No. Standard

OFF — 1 MΩ or more

Ta i l 1 4 a n d 1 6 L e s s t h a n 1 Ω

Head 13, 14 and 16 Less than 1 Ω

Switch position Terminal No. Standard

Passing 7, 8 and 16 Less than 1 Ω

Low beam 17 and 16 Less than 1 Ω

High beam 7 and 16 Less than 1 Ω

Switch position Terminal No. Standard

Left 1 and 2 Less than 1 Ω

Neutral — 1 MΩ or more

Right 2 and 3 Less than 1 Ω

Switch position Terminal No. Standard

OFF — 1 MΩ or more

ON 10 and 11 Less than 1 Ω

LI-00434

1514131211109171665432187

Page 543 of 2453

LI-10

Combination Base Switch Assembly

LIGHTING SYSTEM

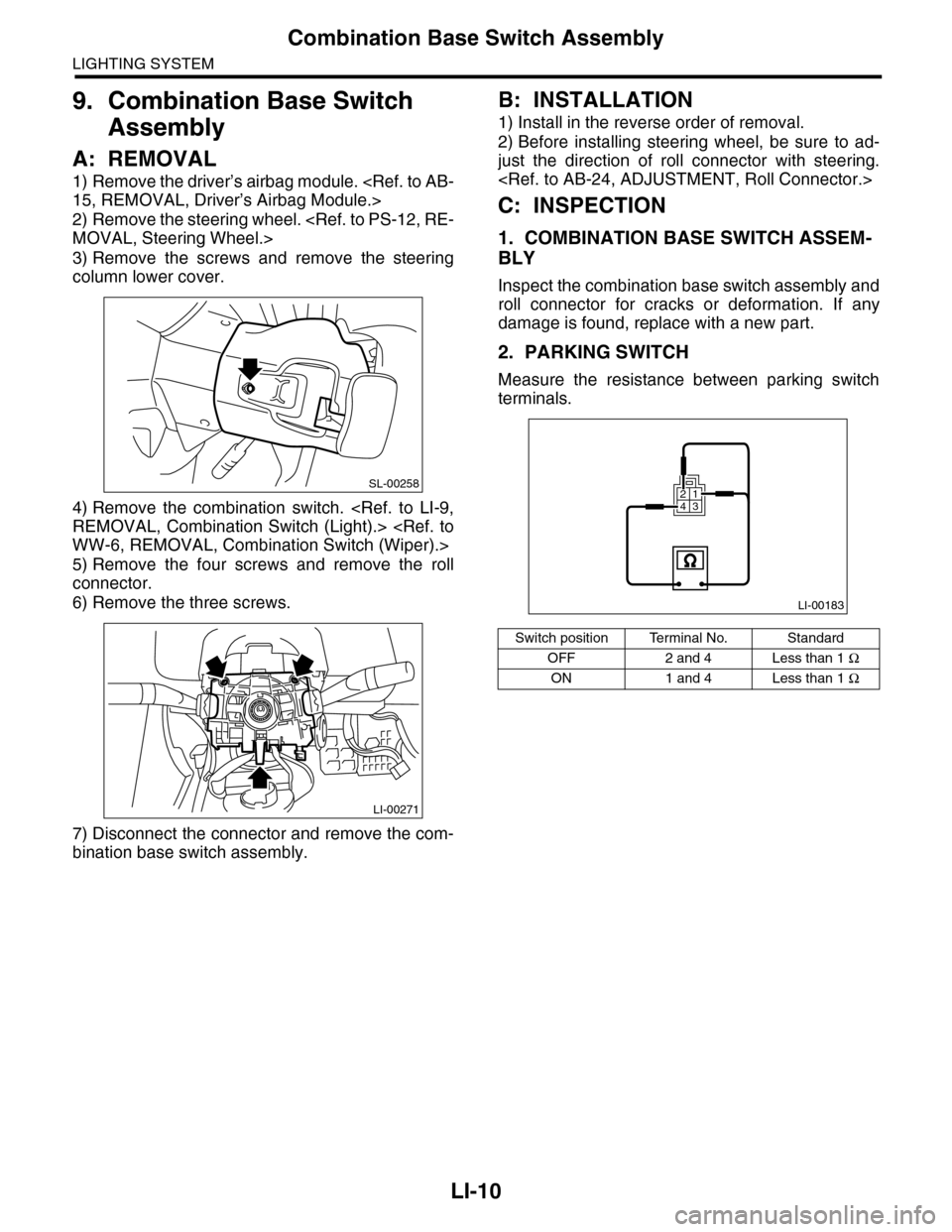

9. Combination Base Switch

Assembly

A: REMOVAL

1) Remove the driver’s airbag module.

2) Remove the steering wheel.

3) Remove the screws and remove the steering

column lower cover.

4) Remove the combination switch.

5) Remove the four screws and remove the roll

connector.

6) Remove the three screws.

7) Disconnect the connector and remove the com-

bination base switch assembly.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Before installing steering wheel, be sure to ad-

just the direction of roll connector with steering.

C: INSPECTION

1. COMBINATION BASE SWITCH ASSEM-

BLY

Inspect the combination base switch assembly and

roll connector for cracks or deformation. If any

damage is found, replace with a new part.

2. PARKING SWITCH

Measure the resistance between parking switch

terminals.

SL-00258

LI-00271

Switch position Terminal No. Standard

OFF 2 and 4 Less than 1 Ω

ON 1 and 4 Less than 1 Ω

LI-00183

1234

Page 675 of 2453

SL-46

Ignition Key Lock

SECURITY AND LOCKS

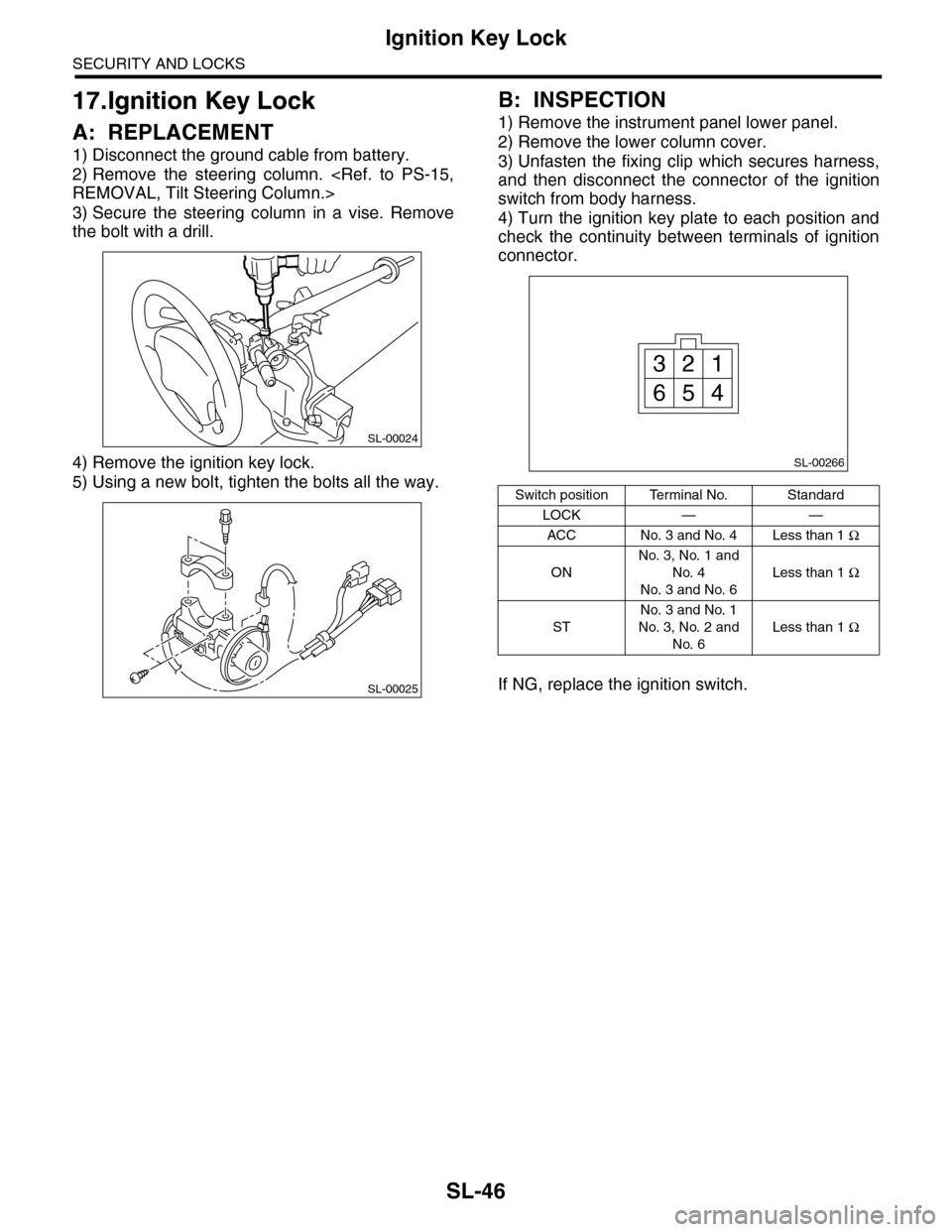

17.Ignition Key Lock

A: REPLACEMENT

1) Disconnect the ground cable from battery.

2) Remove the steering column.

3) Secure the steering column in a vise. Remove

the bolt with a drill.

4) Remove the ignition key lock.

5) Using a new bolt, tighten the bolts all the way.

B: INSPECTION

1) Remove the instrument panel lower panel.

2) Remove the lower column cover.

3) Unfasten the fixing clip which secures harness,

and then disconnect the connector of the ignition

switch from body harness.

4) Turn the ignition key plate to each position and

check the continuity between terminals of ignition

connector.

If NG, replace the ignition switch.

SL-00024

SL-00025

Switch position Terminal No. Standard

LOCK — —

ACC No. 3 and No. 4 Less than 1 Ω

ON

No. 3, No. 1 and

No. 4

No. 3 and No. 6

Less than 1 Ω

ST

No. 3 and No. 1

No. 3, No. 2 and

No. 6

Less than 1 Ω

SL-00266

13

456

2

Page 701 of 2453

WW-6

Combination Switch (Wiper)

WIPER AND WASHER SYSTEMS

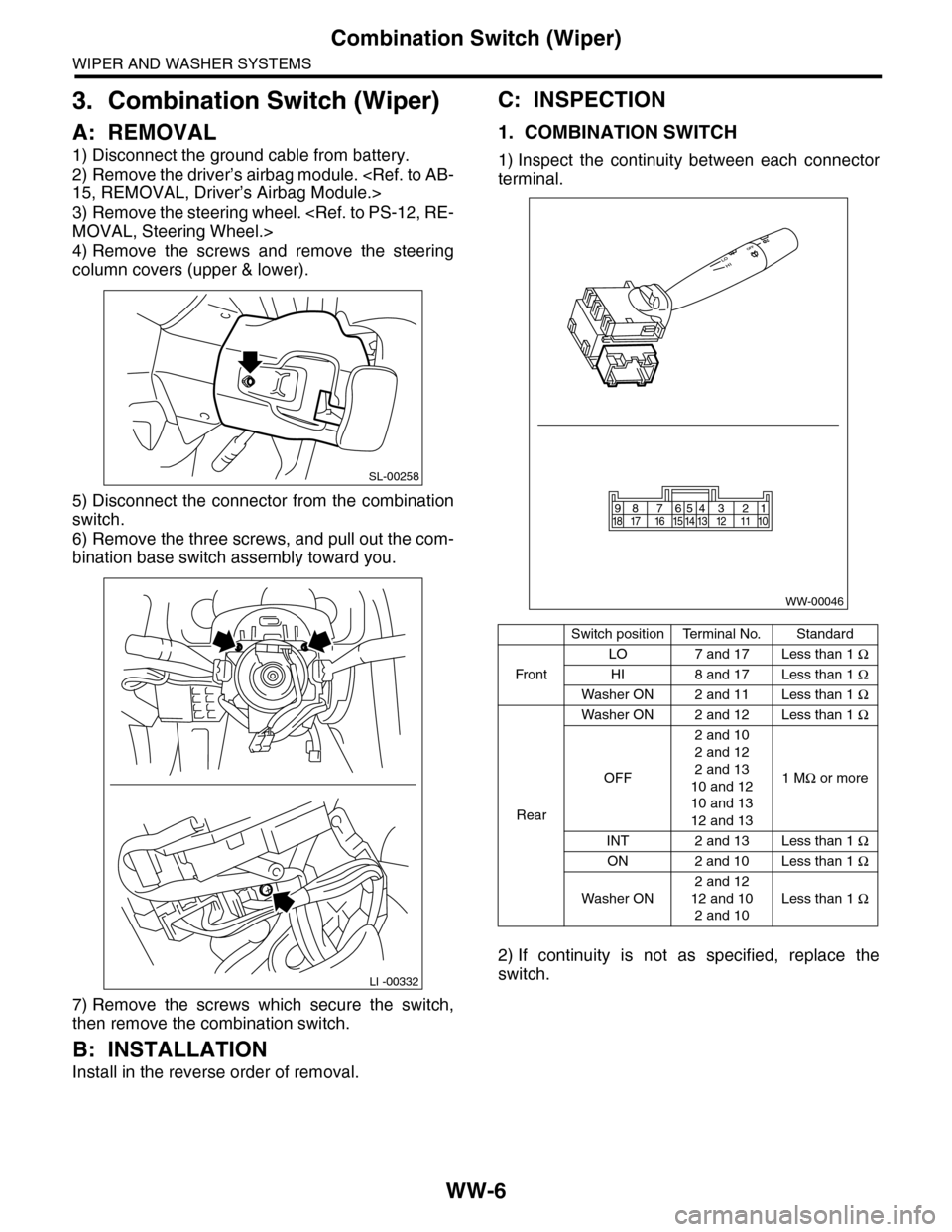

3. Combination Switch (Wiper)

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the driver’s airbag module.

3) Remove the steering wheel.

4) Remove the screws and remove the steering

column covers (upper & lower).

5) Disconnect the connector from the combination

switch.

6) Remove the three screws, and pull out the com-

bination base switch assembly toward you.

7) Remove the screws which secure the switch,

then remove the combination switch.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1. COMBINATION SWITCH

1) Inspect the continuity between each connector

terminal.

2) If continuity is not as specified, replace the

switch.

SL-00258

LI -00332

Switch positionTerminal No.Standard

Fr o n t

LO 7 and 17 Less than 1 Ω

HI 8 and 17 Less than 1 Ω

Washer ON 2 and 11 Less than 1 Ω

Rear

Washer ON 2 and 12 Less than 1 Ω

OFF

2 and 10

2 and 12

2 and 13

10 and 12

10 and 13

12 and 13

1 MΩ or more

INT 2 and 13 Less than 1 Ω

ON 2 and 10 Less than 1 Ω

Washer ON

2 and 12

12 and 10

2 and 10

Less than 1 Ω

WW-00046

87654321917 16 15 14 13 12 11 1018

Page 1036 of 2453

VDC(diag)-44

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

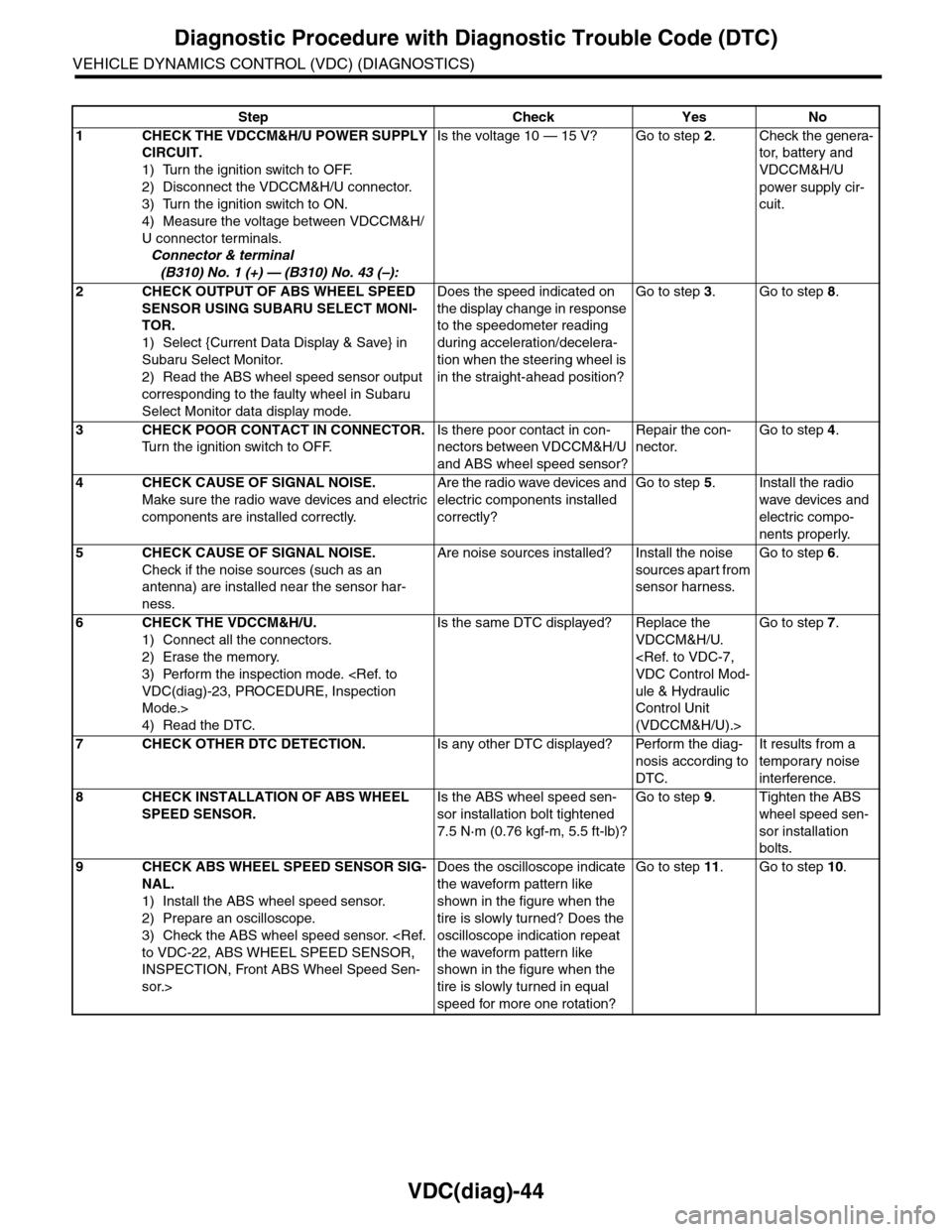

Step Check Yes No

1CHECK THE VDCCM&H/U POWER SUPPLY

CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the VDCCM&H/U connector.

3) Turn the ignition switch to ON.

4) Measure the voltage between VDCCM&H/

U connector terminals.

Connector & terminal

(B310) No. 1 (+) — (B310) No. 43 (–):

Is the voltage 10 — 15 V? Go to step 2.Check the genera-

tor, batter y and

VDCCM&H/U

power supply cir-

cuit.

2CHECK OUTPUT OF ABS WHEEL SPEED

SENSOR USING SUBARU SELECT MONI-

TOR.

1) Select {Current Data Display & Save} in

Subaru Select Monitor.

2) Read the ABS wheel speed sensor output

corresponding to the faulty wheel in Subaru

Select Monitor data display mode.

Does the speed indicated on

the display change in response

to the speedometer reading

during acceleration/decelera-

tion when the steering wheel is

in the straight-ahead position?

Go to step 3.Go to step 8.

3CHECK POOR CONTACT IN CONNECTOR.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Is there poor contact in con-

nectors between VDCCM&H/U

and ABS wheel speed sensor?

Repair the con-

nector.

Go to step 4.

4CHECK CAUSE OF SIGNAL NOISE.

Make sure the radio wave devices and electric

components are installed correctly.

Are the radio wave devices and

electric components installed

correctly?

Go to step 5.Install the radio

wave devices and

electric compo-

nents properly.

5CHECK CAUSE OF SIGNAL NOISE.

Check if the noise sources (such as an

antenna) are installed near the sensor har-

ness.

Are noise sources installed? Install the noise

sources apart from

sensor harness.

Go to step 6.

6CHECK THE VDCCM&H/U.

1) Connect all the connectors.

2) Erase the memory.

3) Perform the inspection mode.

Mode.>

4) Read the DTC.

Is the same DTC displayed? Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 7.

7CHECK OTHER DTC DETECTION.Is any other DTC displayed? Perform the diag-

nosis according to

DTC.

It results from a

temporary noise

interference.

8CHECK INSTALLATION OF ABS WHEEL

SPEED SENSOR.

Is the ABS wheel speed sen-

sor installation bolt tightened

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)?

Go to step 9.Tighten the ABS

wheel speed sen-

sor installation

bolts.

9CHECK ABS WHEEL SPEED SENSOR SIG-

NAL.

1) Install the ABS wheel speed sensor.

2) Prepare an oscilloscope.

3) Check the ABS wheel speed sensor.

INSPECTION, Front ABS Wheel Speed Sen-

sor.>

Does the oscilloscope indicate

the waveform pattern like

shown in the figure when the

tire is slowly turned? Does the

oscilloscope indication repeat

the waveform pattern like

shown in the figure when the

tire is slowly turned in equal

speed for more one rotation?

Go to step 11.Go to step 10.