brake sensor SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 831 of 2453

DS-14

Front Axle

DRIVE SHAFT SYSTEM

11) Remove the front arm ball joint from the front

housing.

12) Remove the PTJ from transmission.

13) Remove the front drive shaft assembly from the

hub. If it is hard to remove, use the ST.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

14) After scribing an alignment mark on the camber

adjusting bolt head, remove the bolts which con-

nect the front housing and strut, and disconnect the

front housing from the strut.

15) Remove the front axle.

B: INSTALLATION

1) Align the alignment mark on the camber adjust-

ing bolt head, and affix the front housing and strut

together using a new selflocking nut.

Tightening torque:

175 N·m (17.9 kgf-m, 129 ft-lb)

2) Install the front drive shaft.

3) Install the front arm ball joint to the front housing.

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

4) Install the ABS wheel speed sensor on the front

housing.

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

5) Install the disc rotor to hub.

6) Install the disc brake caliper to the front housing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

7) Install the stabilizer link.

8) Connect the tie-rod end ball joint to the knuckle

arm with a castle nut.

Tightening torque:

27.0 N·m (2.75 kgf-m, 19.9 ft-lb)

CAUTION:

When connecting the tie–rod, do not hit the cap

at bottom of tie–rod end with a hammer.

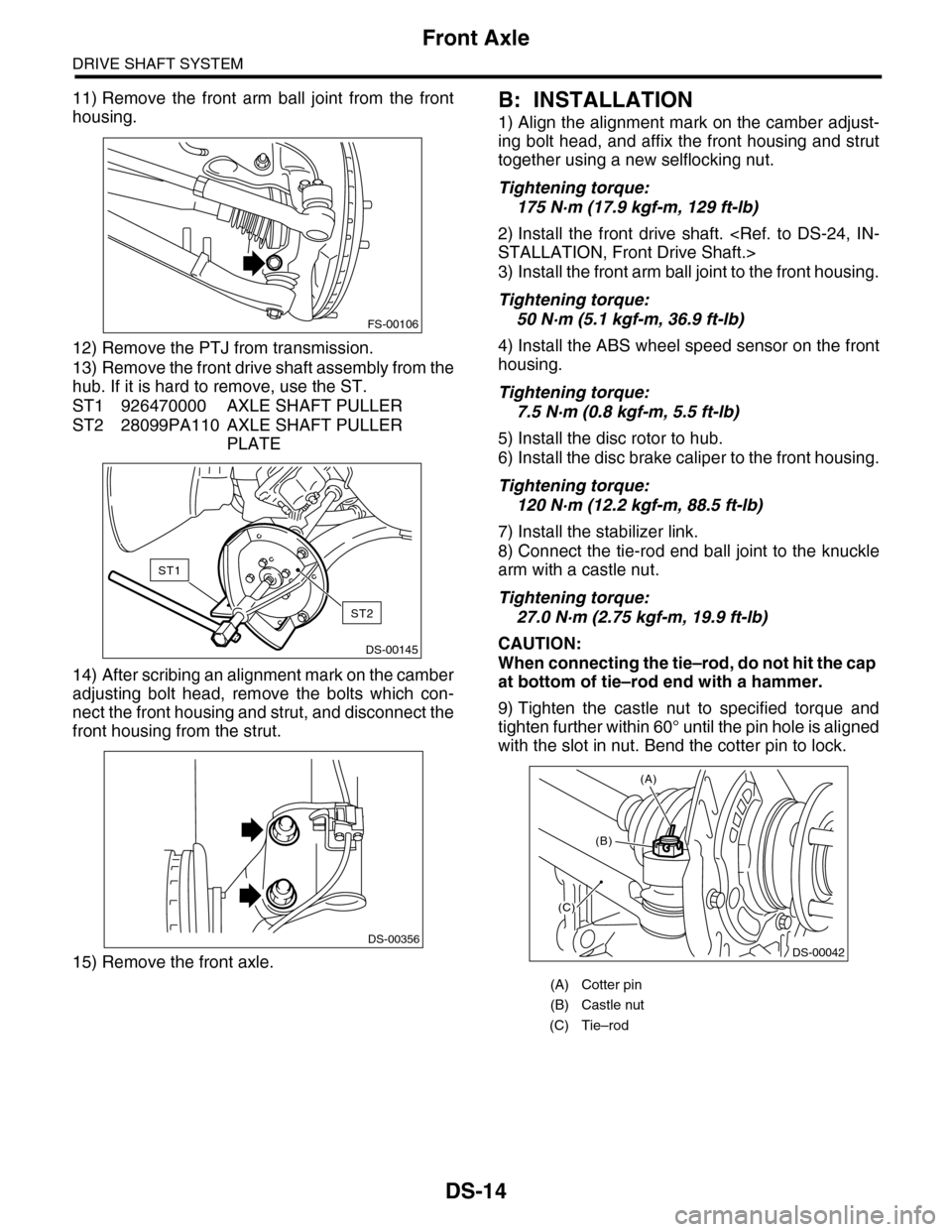

9) Tighten the castle nut to specified torque and

tighten further within 60° until the pin hole is aligned

with the slot in nut. Bend the cotter pin to lock.

FS-00106

DS-00145

ST2

ST1

DS-00356

(A) Cotter pin

(B) Castle nut

(C) Tie–rod

DS-00042

(C)

(B)

(A)

Page 834 of 2453

DS-17

Rear Axle

DRIVE SHAFT SYSTEM

4. Rear Axle

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and then remove the rear

wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the parking brake cable from parking

brake assembly.

6) Remove the rear ABS wheel speed sensor.

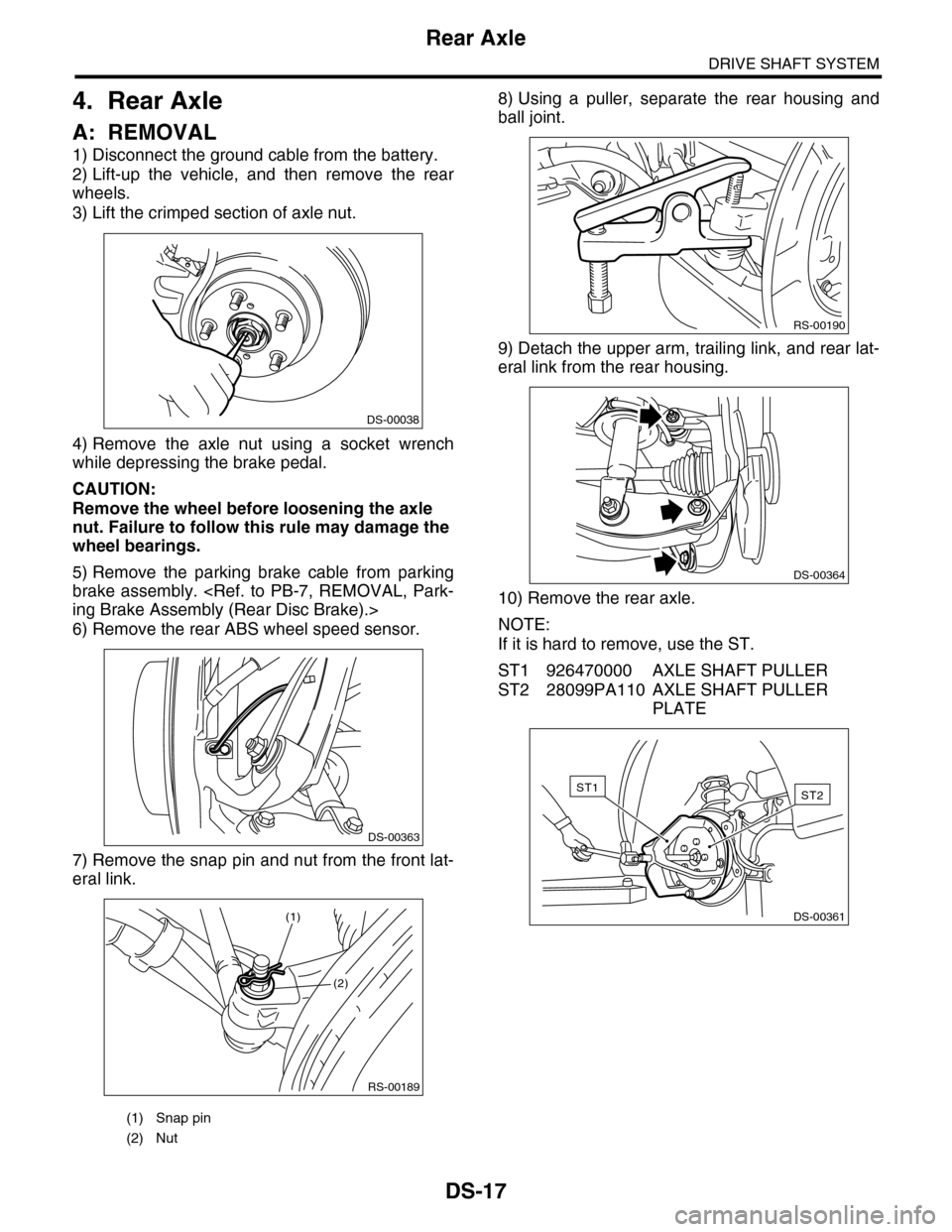

7) Remove the snap pin and nut from the front lat-

eral link.

8) Using a puller, separate the rear housing and

ball joint.

9) Detach the upper arm, trailing link, and rear lat-

eral link from the rear housing.

10) Remove the rear axle.

NOTE:

If it is hard to remove, use the ST.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

(1) Snap pin

(2) Nut

DS-00038

DS-00363

RS-00189

(2)

(1)

RS-00190

DS-00364

ST2ST1

DS-00361

Page 867 of 2453

FS-19

Front Strut

FRONT SUSPENSION

7. Front Strut

A: REMOVAL

1) Lift-up the vehicle, and then remove the front

wheels.

2) Place an alignment mark on the camber adjust-

ing bolt and strut.

3) Remove the bolt securing the brake hose from

the strut.

4) Remove the clip securing the ABS wheel speed

sensor harness.

5) Remove the two bolts securing the housing to

the strut.

NOTE:

While holding the head of the adjusting bolt, loosen

the self–locking nut.

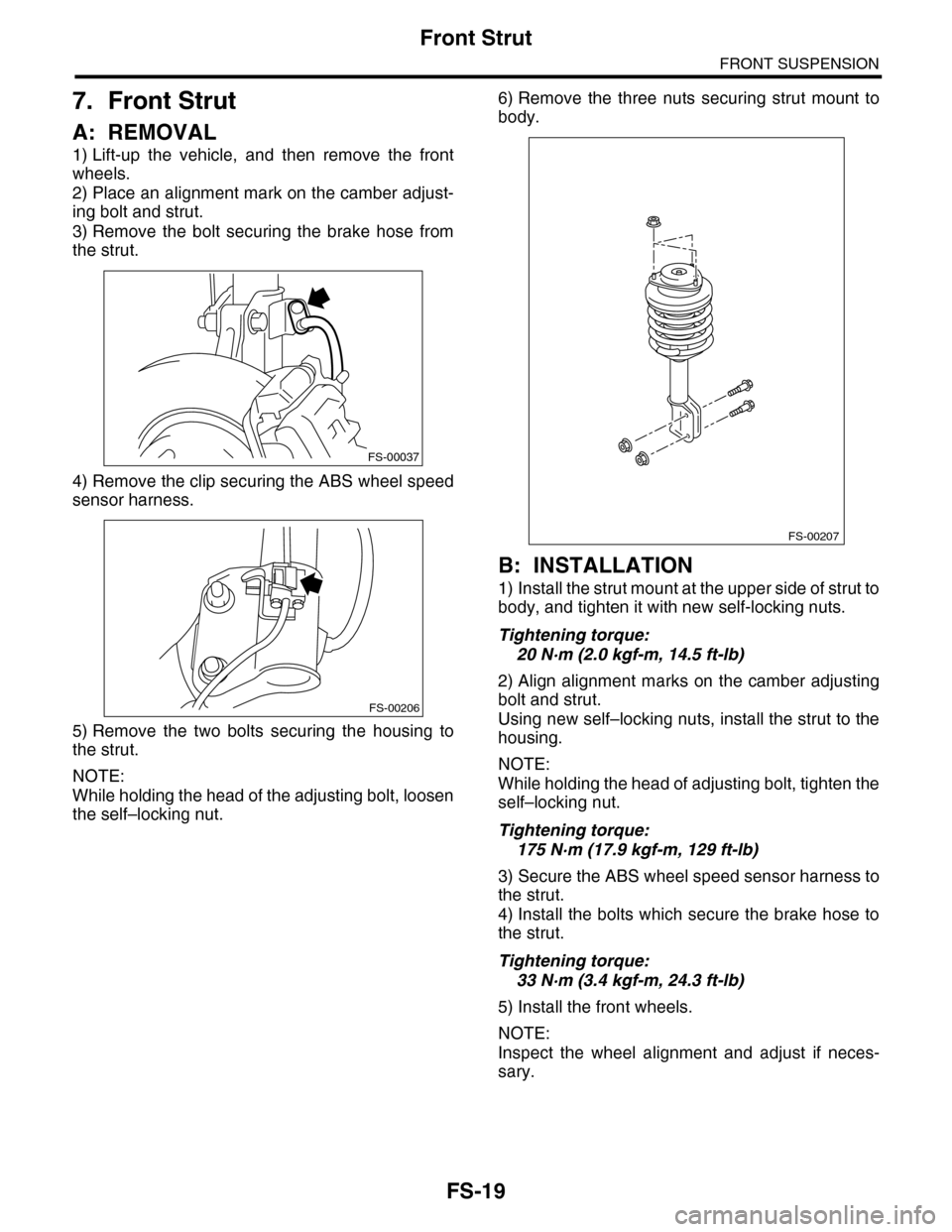

6) Remove the three nuts securing strut mount to

body.

B: INSTALLATION

1) Install the strut mount at the upper side of strut to

body, and tighten it with new self-locking nuts.

Tightening torque:

20 N·m (2.0 kgf-m, 14.5 ft-lb)

2) Align alignment marks on the camber adjusting

bolt and strut.

Using new self–locking nuts, install the strut to the

housing.

NOTE:

While holding the head of adjusting bolt, tighten the

self–locking nut.

Tightening torque:

175 N·m (17.9 kgf-m, 129 ft-lb)

3) Secure the ABS wheel speed sensor harness to

the strut.

4) Install the bolts which secure the brake hose to

the strut.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

5) Install the front wheels.

NOTE:

Inspect the wheel alignment and adjust if neces-

sary.

FS-00037

FS-00206

FS-00207

Page 933 of 2453

PS-53

General Diagnostic Table

POWER ASSISTED SYSTEM (POWER STEERING)

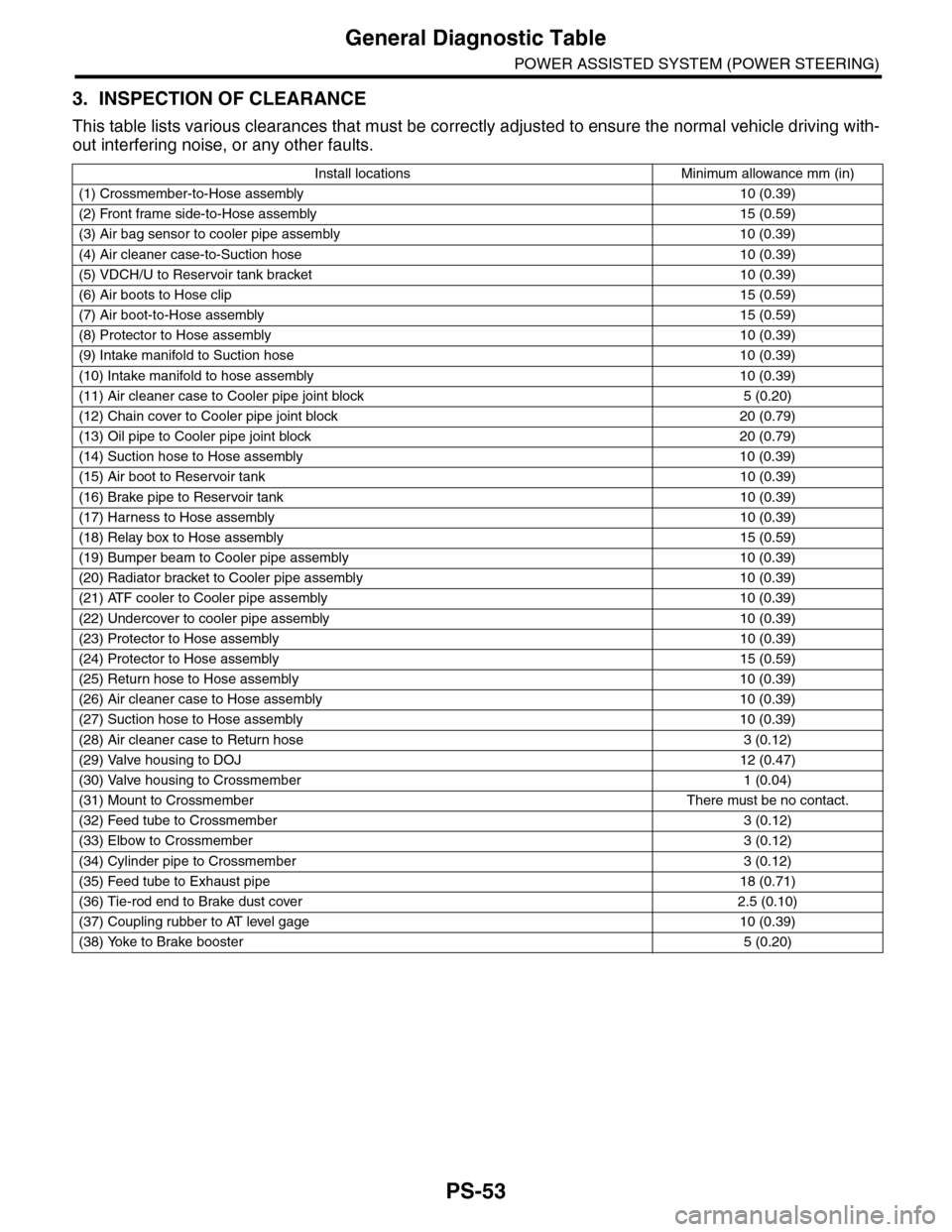

3. INSPECTION OF CLEARANCE

This table lists various clearances that must be correctly adjusted to ensure the normal vehicle driving with-

out interfering noise, or any other faults.

Install locations Minimum allowance mm (in)

(1) Crossmember-to-Hose assembly 10 (0.39)

(2) Front frame side-to-Hose assembly 15 (0.59)

(3) Air bag sensor to cooler pipe assembly 10 (0.39)

(4) Air cleaner case-to-Suction hose 10 (0.39)

(5) VDCH/U to Reservoir tank bracket 10 (0.39)

(6) Air boots to Hose clip15 (0.59)

(7) Air boot-to-Hose assembly15 (0.59)

(8) Protector to Hose assembly10 (0.39)

(9) Intake manifold to Suction hose 10 (0.39)

(10) Intake manifold to hose assembly 10 (0.39)

(11) Air cleaner case to Cooler pipe joint block 5 (0.20)

(12) Chain cover to Cooler pipe joint block 20 (0.79)

(13) Oil pipe to Cooler pipe joint block 20 (0.79)

(14) Suction hose to Hose assembly 10 (0.39)

(15) Air boot to Reservoir tank10 (0.39)

(16) Brake pipe to Reservoir tank10 (0.39)

(17) Harness to Hose assembly10 (0.39)

(18) Relay box to Hose assembly15 (0.59)

(19) Bumper beam to Cooler pipe assembly 10 (0.39)

(20) Radiator bracket to Cooler pipe assembly 10 (0.39)

(21) ATF cooler to Cooler pipe assembly 10 (0.39)

(22) Undercover to cooler pipe assembly 10 (0.39)

(23) Protector to Hose assembly10 (0.39)

(24) Protector to Hose assembly15 (0.59)

(25) Return hose to Hose assembly 10 (0.39)

(26) Air cleaner case to Hose assembly 10 (0.39)

(27) Suction hose to Hose assembly 10 (0.39)

(28) Air cleaner case to Return hose 3 (0.12)

(29) Valve housing to DOJ12 (0.47)

(30) Valve housing to Crossmember 1 (0.04)

(31) Mount to Crossmember There must be no contact.

(32) Feed tube to Crossmember3 (0.12)

(33) Elbow to Crossmember3 (0.12)

(34) Cylinder pipe to Crossmember 3 (0.12)

(35) Feed tube to Exhaust pipe18 (0.71)

(36) Tie-rod end to Brake dust cover 2.5 (0.10)

(37) Coupling rubber to AT level gage 10 (0.39)

(38) Yoke to Brake booster5 (0.20)

Page 942 of 2453

RS-9

Rear Trailing Link

REAR SUSPENSION

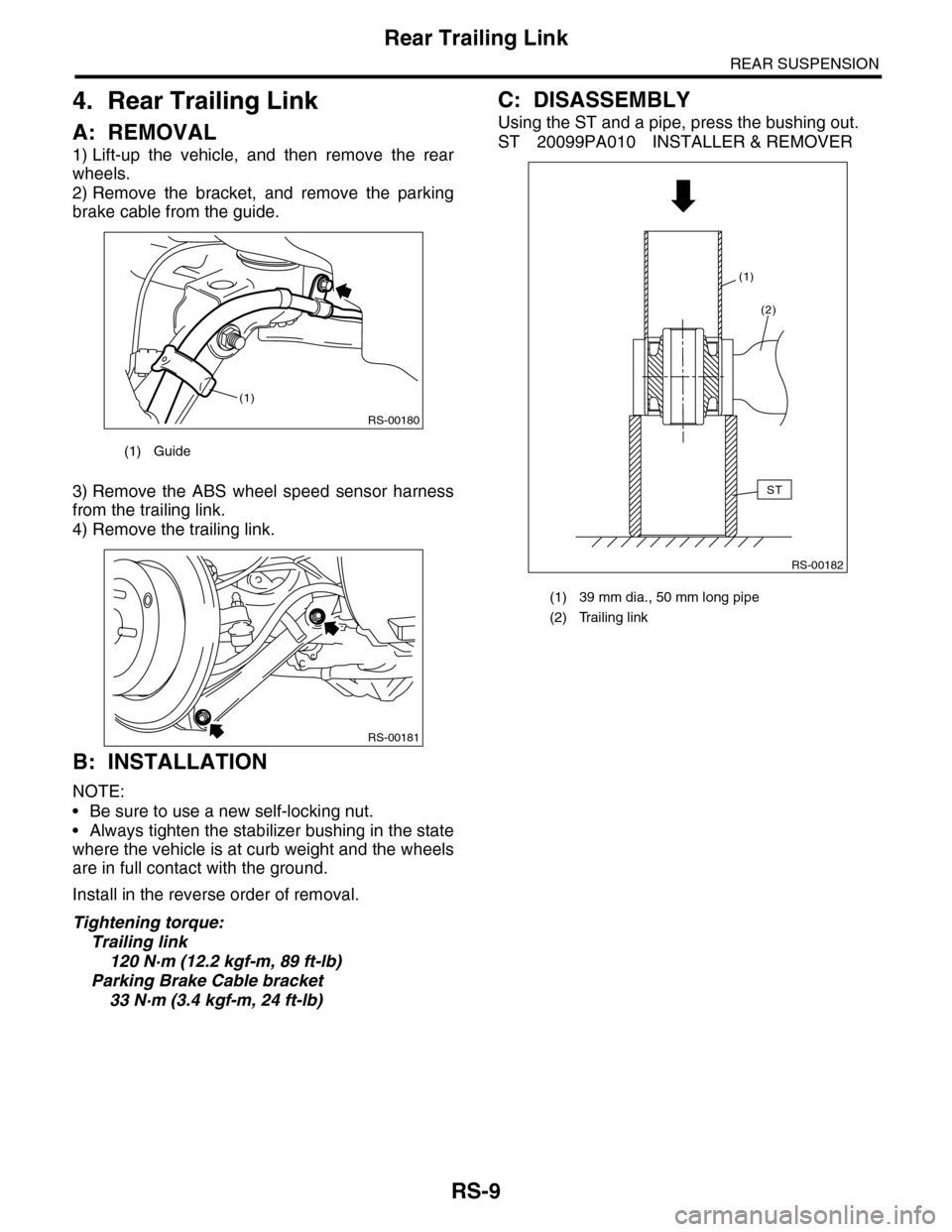

4. Rear Trailing Link

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Remove the bracket, and remove the parking

brake cable from the guide.

3) Remove the ABS wheel speed sensor harness

from the trailing link.

4) Remove the trailing link.

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

Install in the reverse order of removal.

Tightening torque:

Trailing link

120 N·m (12.2 kgf-m, 89 ft-lb)

Parking Brake Cable bracket

33 N·m (3.4 kgf-m, 24 ft-lb)

C: DISASSEMBLY

Using the ST and a pipe, press the bushing out.

ST 20099PA010 INSTALLER & REMOVER

(1) Guide

RS-00180

(1)

RS-00181

(1) 39 mm dia., 50 mm long pipe

(2) Trailing link

RS-00182

ST

(2)

(1)

Page 949 of 2453

RS-16

Rear Sub Frame

REAR SUSPENSION

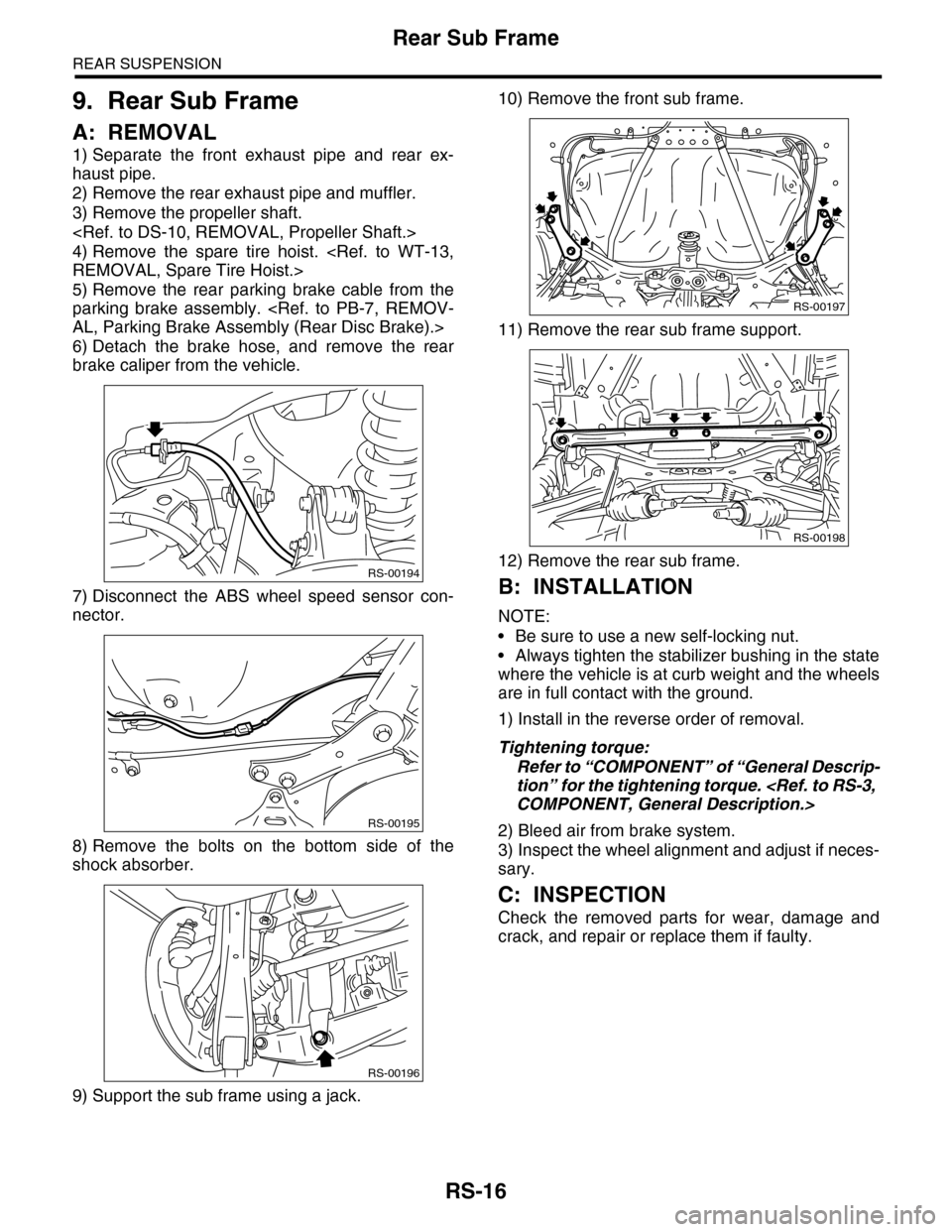

9. Rear Sub Frame

A: REMOVAL

1) Separate the front exhaust pipe and rear ex-

haust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the propeller shaft.

4) Remove the spare tire hoist.

5) Remove the rear parking brake cable from the

parking brake assembly.

6) Detach the brake hose, and remove the rear

brake caliper from the vehicle.

7) Disconnect the ABS wheel speed sensor con-

nector.

8) Remove the bolts on the bottom side of the

shock absorber.

9) Support the sub frame using a jack.

10) Remove the front sub frame.

11) Remove the rear sub frame support.

12) Remove the rear sub frame.

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

1) Install in the reverse order of removal.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion” for the tightening torque.

2) Bleed air from brake system.

3) Inspect the wheel alignment and adjust if neces-

sary.

C: INSPECTION

Check the removed parts for wear, damage and

crack, and repair or replace them if faulty.

RS-00194

RS-00195

RS-00196

RS-00197

RS-00198

Page 1001 of 2453

VDC(diag)-9

General Description

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

3. General Description

A: CAUTION

1. SRS AIRBAG SYSTEM

Airbag system wiring harness is routed near the

ABS wheel speed sensor and VDCCM&H/U.

CAUTION:

•All airbag system wiring harness and con-

nectors are colored yellow. Do not use the elec-

trical test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the ABS wheel

speed sensor and VDCCM&H/U.

B: INSPECTION

Before performing diagnosis, check the following

items which might affect VDC problems.

1. BATTERY

Measure the battery voltage and check electrolyte.

Standard voltage: 12 V or more

Specific gravity: 1.260 or more

2. GROUND

Check the tightening torque of ground (GB-7) bolt

of VDC.

Tightening torque:

13 N·m (1.3 kgf-m, 9.6 ft-lb)

3. BRAKE FLUID

1) Check the brake fluid level.

2) Check the brake fluid for leaks.

4. HYDRAULIC UNIT

Check the hydraulic unit.

•With brake tester

TESTER, INSPECTION, VDC Control Module &

Hydraulic Control Unit (VDCCM&H/U).>

•Without brake tester

USING A PRESSURE GAUGE, INSPECTION,

VDC Control Module & Hydraulic Control Unit (VD-

CCM&H/U).>

5. BRAKE DRAG

Check for brake drag.

6. BRAKE PAD AND ROTOR

Check the brake pad and rotor.

•Front

•Rear

7. TIRE

Check the tire specifications, tire wear and air pres-

sure.

Page 1003 of 2453

VDC(diag)-11

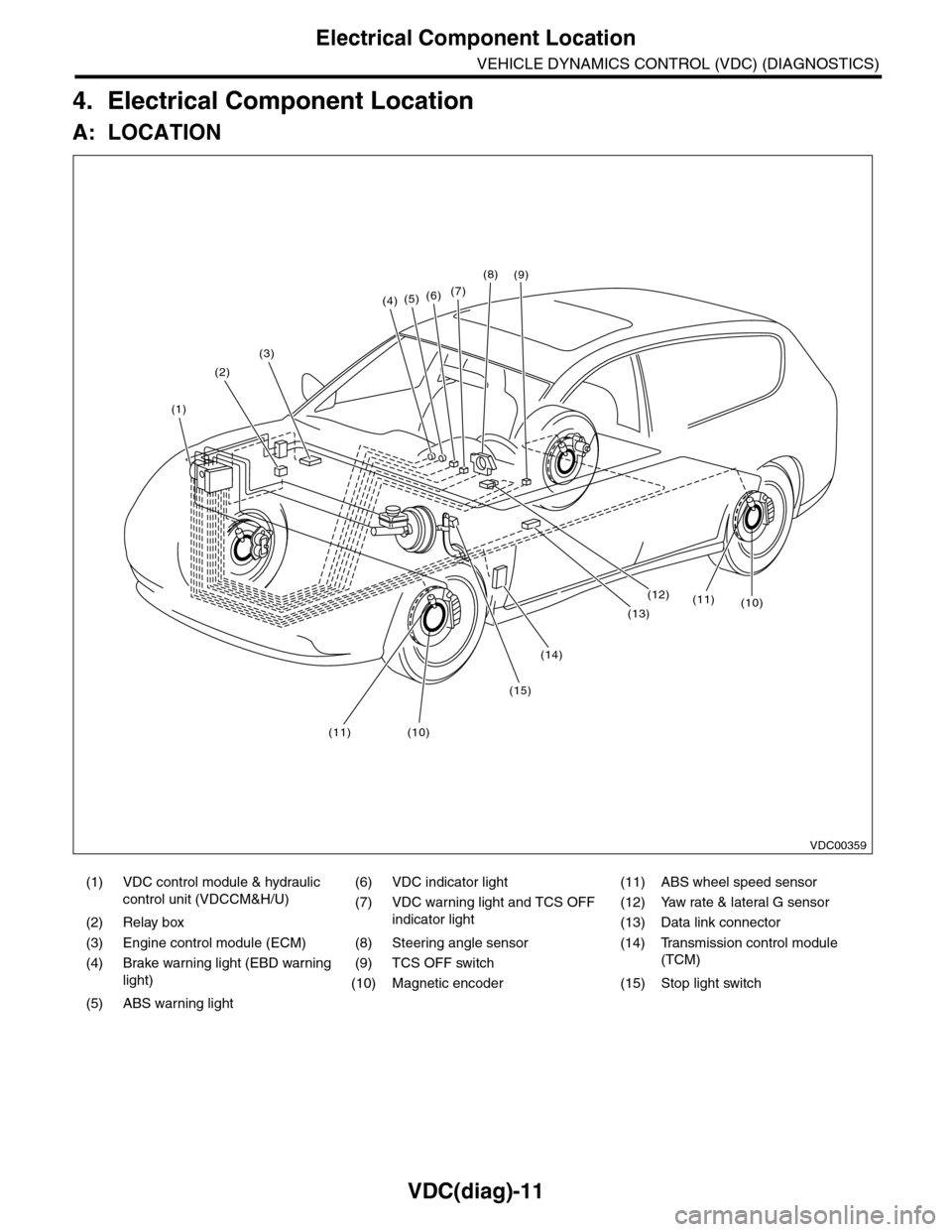

Electrical Component Location

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

4. Electrical Component Location

A: LOCATION

(1) VDC control module & hydraulic

control unit (VDCCM&H/U)

(6) VDC indicator light (11) ABS wheel speed sensor

(7) VDC warning light and TCS OFF

indicator light

(12) Yaw rate & lateral G sensor

(2) Relay box (13) Data link connector

(3) Engine control module (ECM) (8) Steering angle sensor (14) Transmission control module

(TCM)(4) Brake warning light (EBD warning

light)

(9) TCS OFF switch

(10) Magnetic encoder (15) Stop light switch

(5) ABS warning light

(4)(5)(6)(7)

(8)

(1)

(2)

(3)

(15)

(14)

(12)

(13)

(11)(10)

(11)(10)

(9)

VDC00359

Page 1006 of 2453

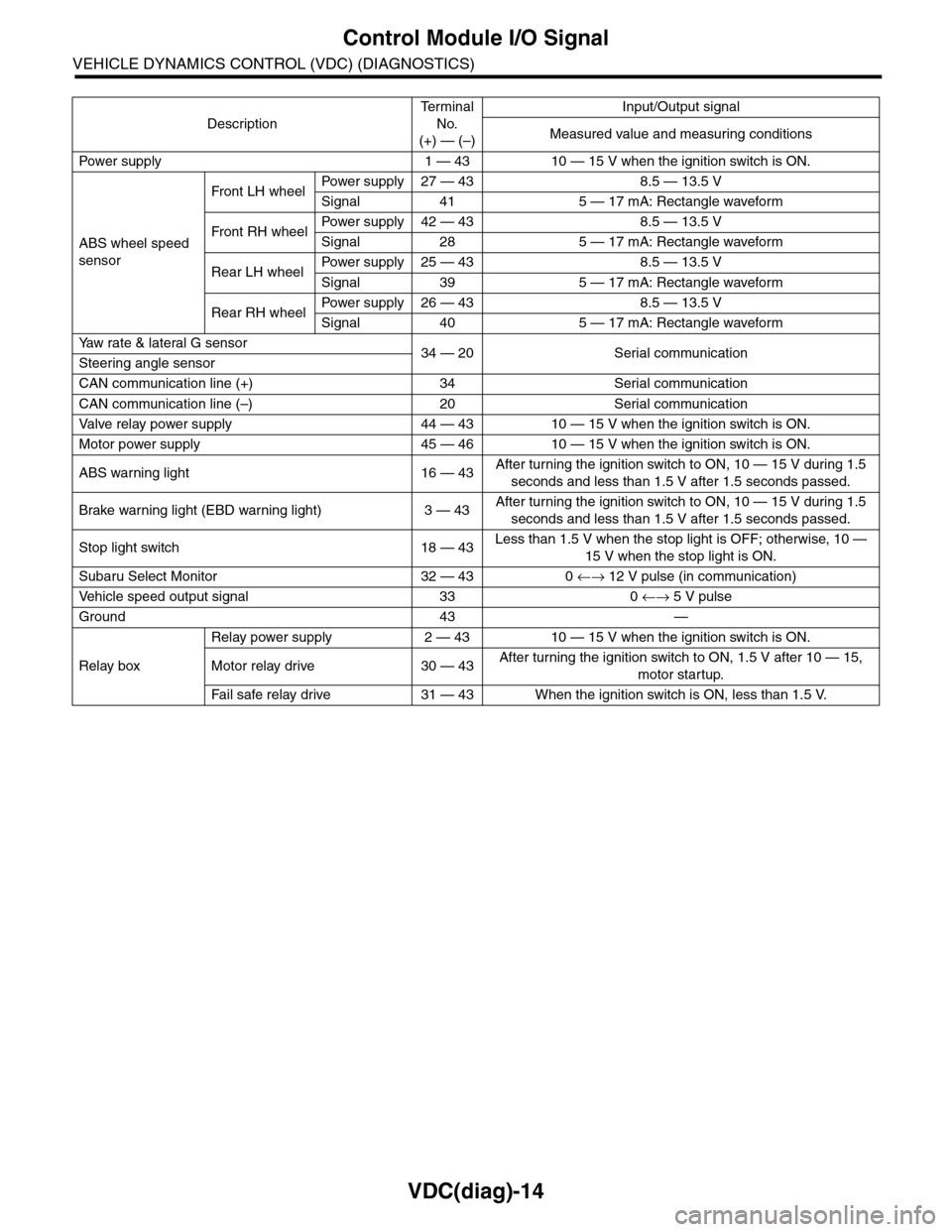

VDC(diag)-14

Control Module I/O Signal

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

Description

Te r m i n a l

No.

(+) — (–)

Input/Output signal

Measured value and measuring conditions

Pow er s up p ly 1 — 43 10 — 15 V w h e n t h e i gn i t io n sw it ch i s ON .

ABS wheel speed

sensor

Front LH wheelPowe r s u pp ly 27 — 4 3 8 . 5 — 1 3. 5 V

Signal 41 5 — 17 mA: Rectangle waveform

Front RH wheelPower supply 42 — 43 8.5 — 13.5 V

Signal 28 5 — 17 mA: Rectangle waveform

Rear LH wheelPower supply 25 — 43 8.5 — 13.5 V

Signal 39 5 — 17 mA: Rectangle waveform

Rear RH wheelPower supply 26 — 43 8.5 — 13.5 V

Signal 40 5 — 17 mA: Rectangle waveform

Ya w r a t e & l a t e r a l G s e n s o r34 — 20 Serial communicationSteering angle sensor

CAN communication line (+) 34 Serial communication

CAN communication line (–) 20 Serial communication

Valve relay power supply 44 — 43 10 — 15 V when the ignition switch is ON.

Motor power supply 45 — 46 10 — 15 V when the ignition switch is ON.

ABS warning light 16 — 43After turning the ignition switch to ON, 10 — 15 V during 1.5

seconds and less than 1.5 V after 1.5 seconds passed.

Brake warning light (EBD warning light) 3 — 43After turning the ignition switch to ON, 10 — 15 V during 1.5

seconds and less than 1.5 V after 1.5 seconds passed.

Stop light switch 18 — 43Less than 1.5 V when the stop light is OFF; otherwise, 10 —

15 V when the stop light is ON.

Subaru Select Monitor 32 — 43 0 ←→ 12 V pulse (in communication)

Ve h i c l e s p e e d o u t p u t s i g n a l 3 3 0 ←→ 5 V pulse

Ground 43 —

Relay box

Relay power supply 2 — 43 10 — 15 V when the ignition switch is ON.

Motor relay drive 30 — 43After turning the ignition switch to ON, 1.5 V after 10 — 15,

motor startup.

Fa i l s afe r e lay d r ive 31 — 4 3 W he n t h e i g ni t io n swit c h i s ON, l es s t ha n 1 . 5 V.

Page 1007 of 2453

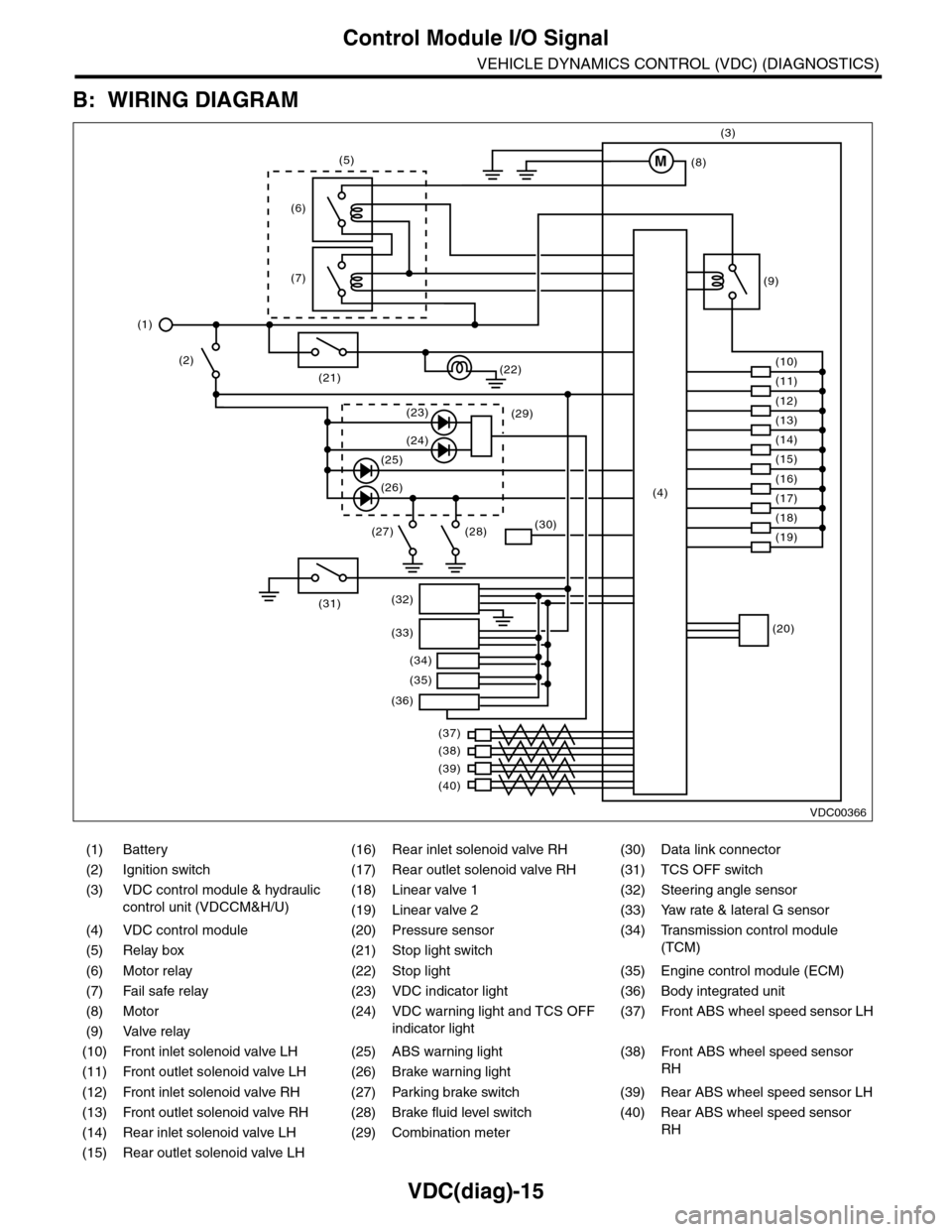

VDC(diag)-15

Control Module I/O Signal

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

B: WIRING DIAGRAM

(1) Battery (16) Rear inlet solenoid valve RH (30) Data link connector

(2) Ignition switch (17) Rear outlet solenoid valve RH (31) TCS OFF switch

(3) VDC control module & hydraulic

control unit (VDCCM&H/U)

(18) Linear valve 1 (32) Steering angle sensor

(19) Linear valve 2 (33) Yaw rate & lateral G sensor

(4) VDC control module (20) Pressure sensor (34)

Tr a n s m i s s i o n c o n t r o l m o d u l e

(TCM)(5) Relay box (21) Stop light switch

(6) Motor relay (22) Stop light (35) Engine control module (ECM)

(7) Fail safe relay (23) VDC indicator light (36) Body integrated unit

(8) Motor (24) VDC warning light and TCS OFF

indicator light

(37)

Fr o nt A B S w he e l sp ee d se n so r L H

(9) Valve relay

(10) Front inlet solenoid valve LH (25) ABS warning light (38)

Fr o nt A B S w he e l sp e ed se n so r

RH(11) Front outlet solenoid valve LH (26) Brake warning light

(12) Front inlet solenoid valve RH (27) Parking brake switch (39) Rear ABS wheel speed sensor LH

(13) Front outlet solenoid valve RH (28) Brake fluid level switch (40) Rear ABS wheel speed sensor

RH(14) Rear inlet solenoid valve LH (29) Combination meter

(15) Rear outlet solenoid valve LH

VDC00366

M

(17)(4)(16)

(19)

(20)

(18)

(38)

(37)

(32)

(33)

(36)

(34)

(35)

(40)

(39)

(15)

(14)

(13)

(12)

(7)

(22)(21)

(31)

(23)(29)

(24)

(25)

(26)

(27) (28)(30)

(1)

(2)

(6)

(11)

(10)

(9)

(8)

(3)

(5)