brake sensor SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2133 of 2453

5AT(diag)-16

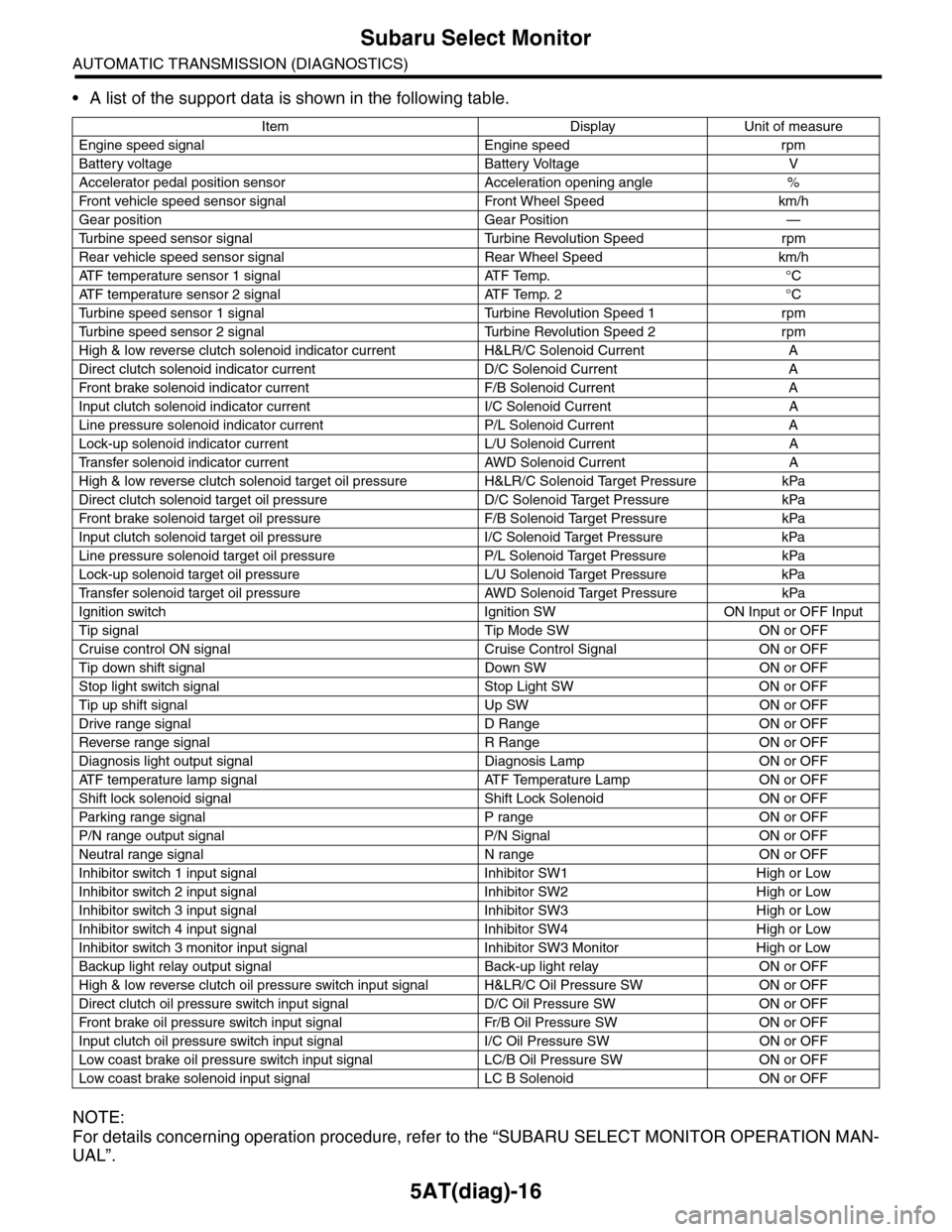

Subaru Select Monitor

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

•A list of the support data is shown in the following table.

NOTE:

For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MAN-

UAL”.

Item Display Unit of measure

Engine speed signal Engine speed rpm

Battery voltage Battery Voltage V

Accelerator pedal position sensor Acceleration opening angle %

Fr o nt veh ic l e sp e ed se n so r s ig n al Fr o n t W h ee l S p e ed km/ h

Gear position Gear Position —

Tu r b i n e s p e e d s e n s o r s i g n a l Tu r b i n e R e v o l u t i o n S p e e d r p m

Rear vehicle speed sensor signal Rear Wheel Speed km/h

ATF temperature sensor 1 signal ATF Temp. °C

ATF temperature sensor 2 signal ATF Temp. 2 °C

Tu r b i n e s p e e d s e n s o r 1 s i g n a l Tu r b i n e R e v o l u t i o n S p e e d 1 r p m

Tu r b i n e s p e e d s e n s o r 2 s i g n a l Tu r b i n e R e v o l u t i o n S p e e d 2 r p m

High & low reverse clutch solenoid indicator current H&LR/C Solenoid Current A

Direct clutch solenoid indicator current D/C Solenoid Current A

Fr o nt b rake so l en oi d in di c at o r c u rr e n t F / B S o l en o id Cur r e nt A

Input clutch solenoid indicator current I/C Solenoid Current A

Line pressure solenoid indicator current P/L Solenoid Current A

Lock-up solenoid indicator current L/U Solenoid Current A

Tr a n s f e r s o l e n o i d i n d i c a t o r c u r r e n t A W D S o l e n o i d C u r r e n t A

High & low reverse clutch solenoid target oil pressure H&LR/C Solenoid Target Pressure kPa

Direct clutch solenoid target oil pressure D/C Solenoid Target Pressure kPa

Fr o nt b rake so l en oi d ta r g et o il pr e ss ur e F / B S o l en o id Ta r g et P r es su r e kPa

Input clutch solenoid target oil pressure I/C Solenoid Target Pressure kPa

Line pressure solenoid target oil pressure P/L Solenoid Target Pressure kPa

Lock-up solenoid target oil pressure L/U Solenoid Target Pressure kPa

Tr a n s f e r s o l e n o i d t a r g e t o i l p r e s s u r e A W D S o l e n o i d Ta r g e t P r e s s u r e k P a

Ignition switch Ignition SW ON Input or OFF Input

Tip signal Tip Mode SW ON or OFF

Cruise control ON signal Cruise Control Signal ON or OFF

Tip down shift signal Down SW ON or OFF

Stop light switch signal Stop Light SW ON or OFF

Tip up shift signal Up SW ON or OFF

Drive range signal D Range ON or OFF

Reverse range signal R Range ON or OFF

Diagnosis light output signal Diagnosis Lamp ON or OFF

AT F t e m p e r a t u r e l a m p s i g n a l AT F Te m p e r a t u r e L a m p O N o r O F F

Shift lock solenoid signal Shift Lock Solenoid ON or OFF

Par king range signal P range ON or OFF

P/N range output signal P/N Signal ON or OFF

Neutral range signal N range ON or OFF

Inhibitor switch 1 input signal Inhibitor SW1 High or Low

Inhibitor switch 2 input signal Inhibitor SW2 High or Low

Inhibitor switch 3 input signal Inhibitor SW3 High or Low

Inhibitor switch 4 input signal Inhibitor SW4 High or Low

Inhibitor switch 3 monitor input signal Inhibitor SW3 Monitor High or Low

Backup light relay output signal Back-up light relay ON or OFF

High & low reverse clutch oil pressure switch input signal H&LR/C Oil Pressure SW ON or OFF

Direct clutch oil pressure switch input signal D/C Oil Pressure SW ON or OFF

Fr o nt b rake oi l pr e ss ur e swi tc h i n pu t si gn a l Fr / B Oi l P r e ss ur e S W ON or OF F

Input clutch oil pressure switch input signal I/C Oil Pressure SW ON or OFF

Low coast brake oil pressure switch input signal LC/B Oil Pressure SW ON or OFF

Low coast brake solenoid input signal LC B Solenoid ON or OFF

Page 2145 of 2453

5AT(diag)-28

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

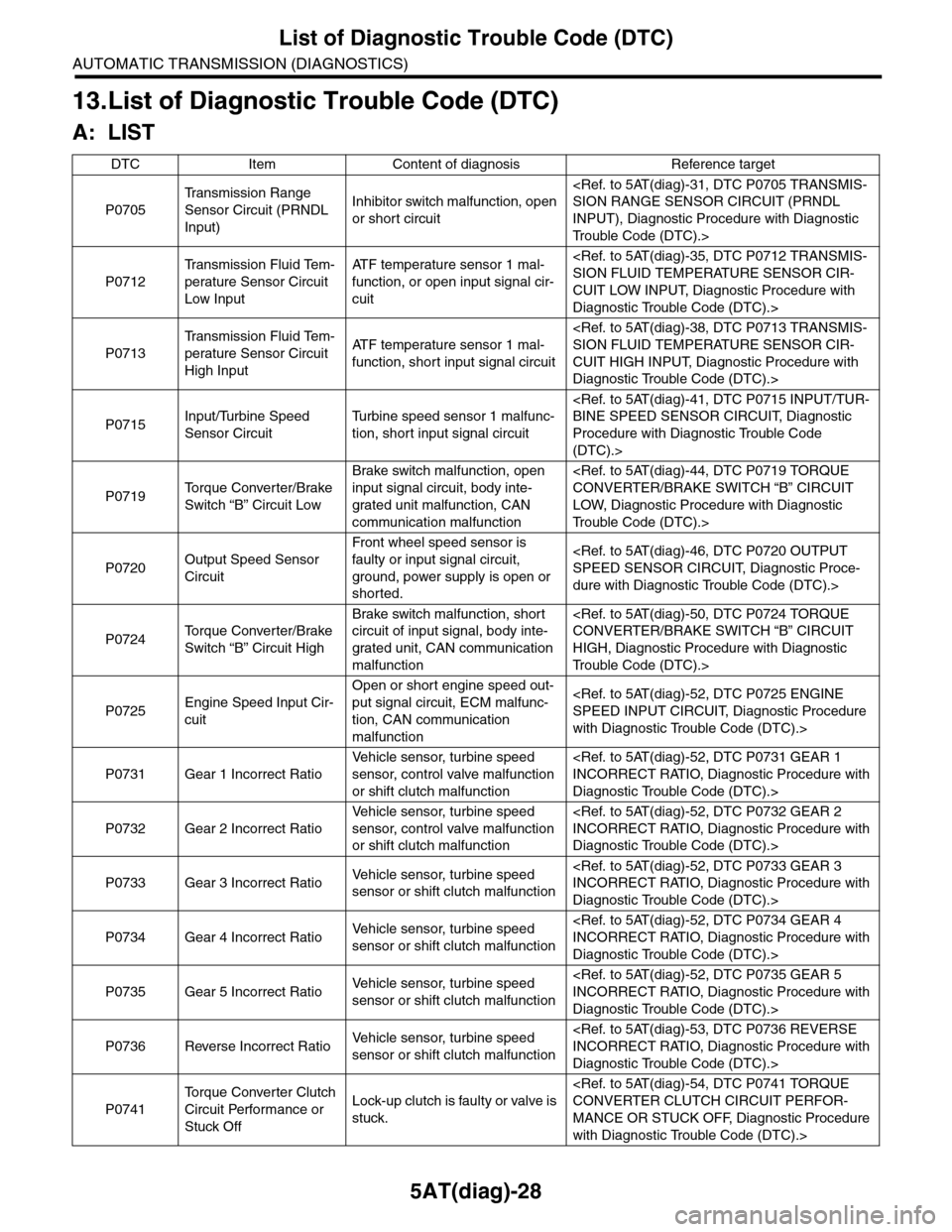

13.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Content of diagnosis Reference target

P0705

Tr a n s m i s s i o n R a n g e

Sensor Circuit (PRNDL

Input)

Inhibitor switch malfunction, open

or short circuit

INPUT), Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0712

Tr a n s m i s s i o n F l u i d Te m -

perature Sensor Circuit

Low Input

AT F t e m p e r a t u r e s e n s o r 1 m a l -

function, or open input signal cir-

cuit

CUIT LOW INPUT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0713

Tr a n s m i s s i o n F l u i d Te m -

perature Sensor Circuit

High Input

AT F t e m p e r a t u r e s e n s o r 1 m a l -

function, short input signal circuit

CUIT HIGH INPUT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0715Input/Turbine Speed

Sensor Circuit

Tu r b i n e s p e e d s e n s o r 1 m a l f u n c -

tion, short input signal circuit

Procedure with Diagnostic Trouble Code

(DTC).>

P0719To r q u e C o n v e r t e r / B r a k e

Switch “B” Circuit Low

Brake switch malfunction, open

input signal circuit, body inte-

grated unit malfunction, CAN

communication malfunction

LOW, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0720Output Speed Sensor

Circuit

Front wheel speed sensor is

faulty or input signal circuit,

ground, power supply is open or

shorted.

dure with Diagnostic Trouble Code (DTC).>

P0724To r q u e C o n v e r t e r / B r a k e

Switch “B” Circuit High

Brake switch malfunction, short

circuit of input signal, body inte-

grated unit, CAN communication

malfunction

HIGH, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0725Engine Speed Input Cir-

cuit

Open or short engine speed out-

put signal circuit, ECM malfunc-

tion, CAN communication

malfunction

with Diagnostic Trouble Code (DTC).>

P0731 Gear 1 Incorrect Ratio

Ve h i c l e s e n s o r, t u r b i n e s p e e d

sensor, control valve malfunction

or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0732 Gear 2 Incorrect Ratio

Ve h i c l e s e n s o r, t u r b i n e s p e e d

sensor, control valve malfunction

or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0733 Gear 3 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0734 Gear 4 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0735 Gear 5 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0736 Reverse Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0741

To r q u e C o n v e r t e r C l u t c h

Circuit Performance or

Stuck Off

Lock-up clutch is faulty or valve is

stuck.

MANCE OR STUCK OFF, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

Page 2147 of 2453

5AT(diag)-30

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

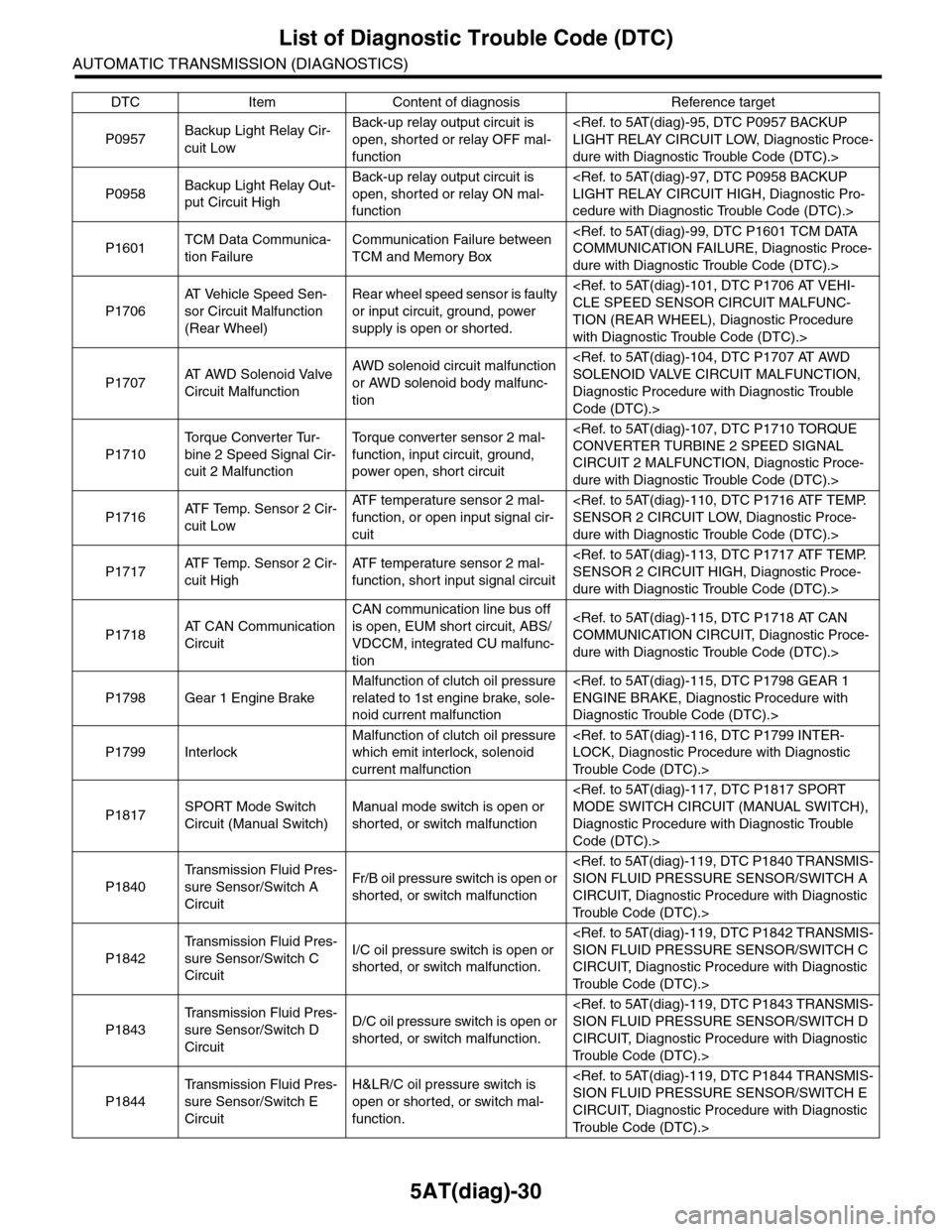

P0957Backup Light Relay Cir-

cuit Low

Back-up relay output circuit is

open, shorted or relay OFF mal-

function

dure with Diagnostic Trouble Code (DTC).>

P0958Backup Light Relay Out-

put Circuit High

Back-up relay output circuit is

open, shorted or relay ON mal-

function

cedure with Diagnostic Trouble Code (DTC).>

P1601TCM Data Communica-

tion Failure

Communication Failure between

TCM and Memory Box

dure with Diagnostic Trouble Code (DTC).>

P1706

AT Ve h i c l e S p e e d S e n -

sor Circuit Malfunction

(Rear Wheel)

Rear wheel speed sensor is faulty

or input circuit, ground, power

supply is open or shorted.

TION (REAR WHEEL), Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1707AT A W D S o l e n o i d V a l v e

Circuit Malfunction

AWD solenoid circuit malfunction

or AWD solenoid body malfunc-

tion

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1710

To r q u e C o n v e r t e r Tu r -

bine 2 Speed Signal Cir-

cuit 2 Malfunction

To r q u e c o n v e r t e r s e n s o r 2 m a l -

function, input circuit, ground,

power open, short circuit

CIRCUIT 2 MALFUNCTION, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P1716AT F Te m p . S e n s o r 2 C i r -

cuit Low

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, or open input signal cir-

cuit

dure with Diagnostic Trouble Code (DTC).>

P1717AT F Te m p . S e n s o r 2 C i r -

cuit High

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, short input signal circuit

dure with Diagnostic Trouble Code (DTC).>

P1718AT C A N C o m m u n i c a t i o n

Circuit

CAN communication line bus off

is open, EUM short circuit, ABS/

VDCCM, integrated CU malfunc-

tion

dure with Diagnostic Trouble Code (DTC).>

P1798 Gear 1 Engine Brake

Malfunction of clutch oil pressure

related to 1st engine brake, sole-

noid current malfunction

Diagnostic Trouble Code (DTC).>

P1799 Interlock

Malfunction of clutch oil pressure

which emit interlock, solenoid

current malfunction

Tr o u b l e C o d e ( D T C ) . >

P1817SPORT Mode Switch

Circuit (Manual Switch)

Manual mode switch is open or

shorted, or switch malfunction

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1840

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch A

Circuit

Fr/B oil pressure switch is open or

shorted, or switch malfunction

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1842

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch C

Circuit

I/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1843

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch D

Circuit

D/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1844

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch E

Circuit

H&LR/C oil pressure switch is

open or shorted, or switch mal-

function.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

DTC Item Content of diagnosis Reference target

Page 2162 of 2453

5AT(diag)-45

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

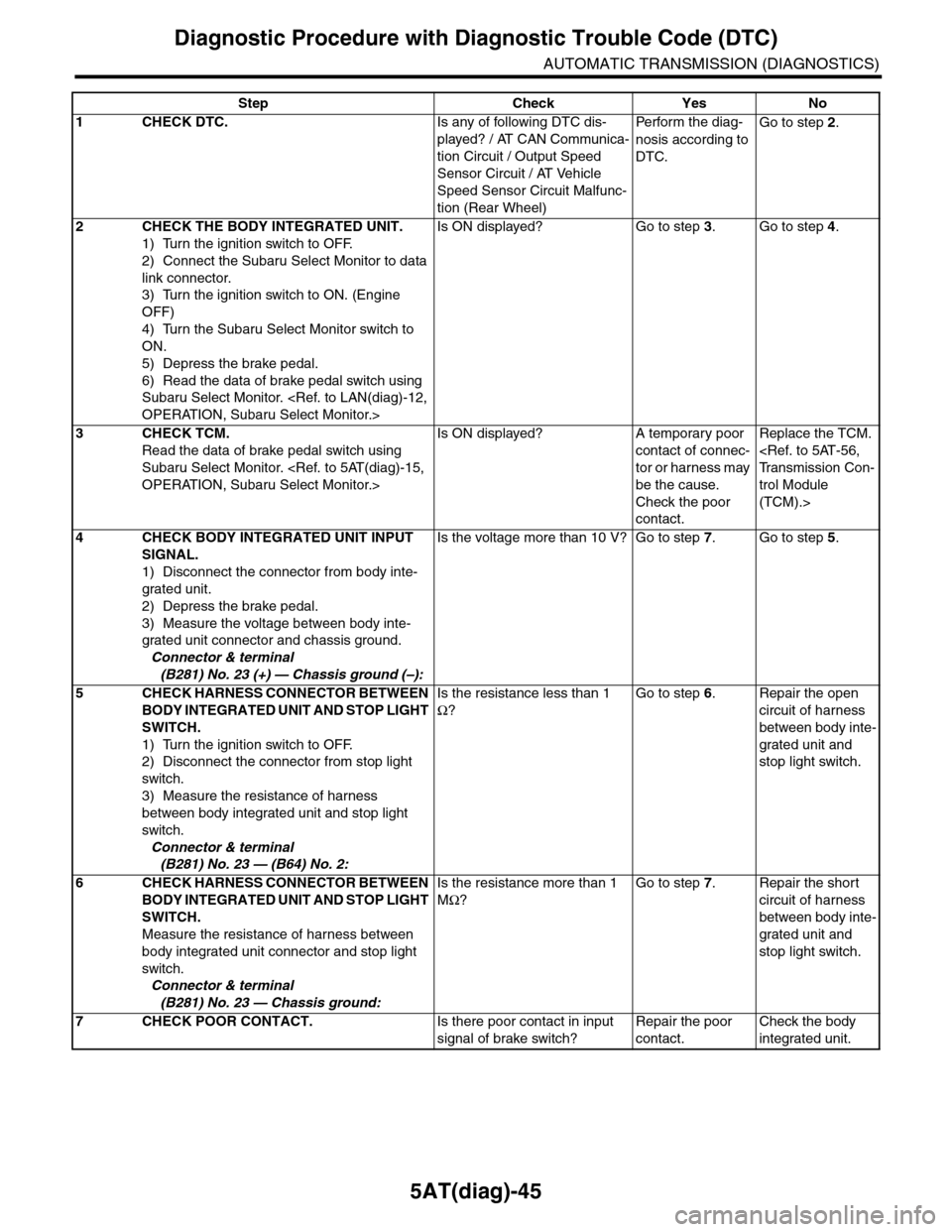

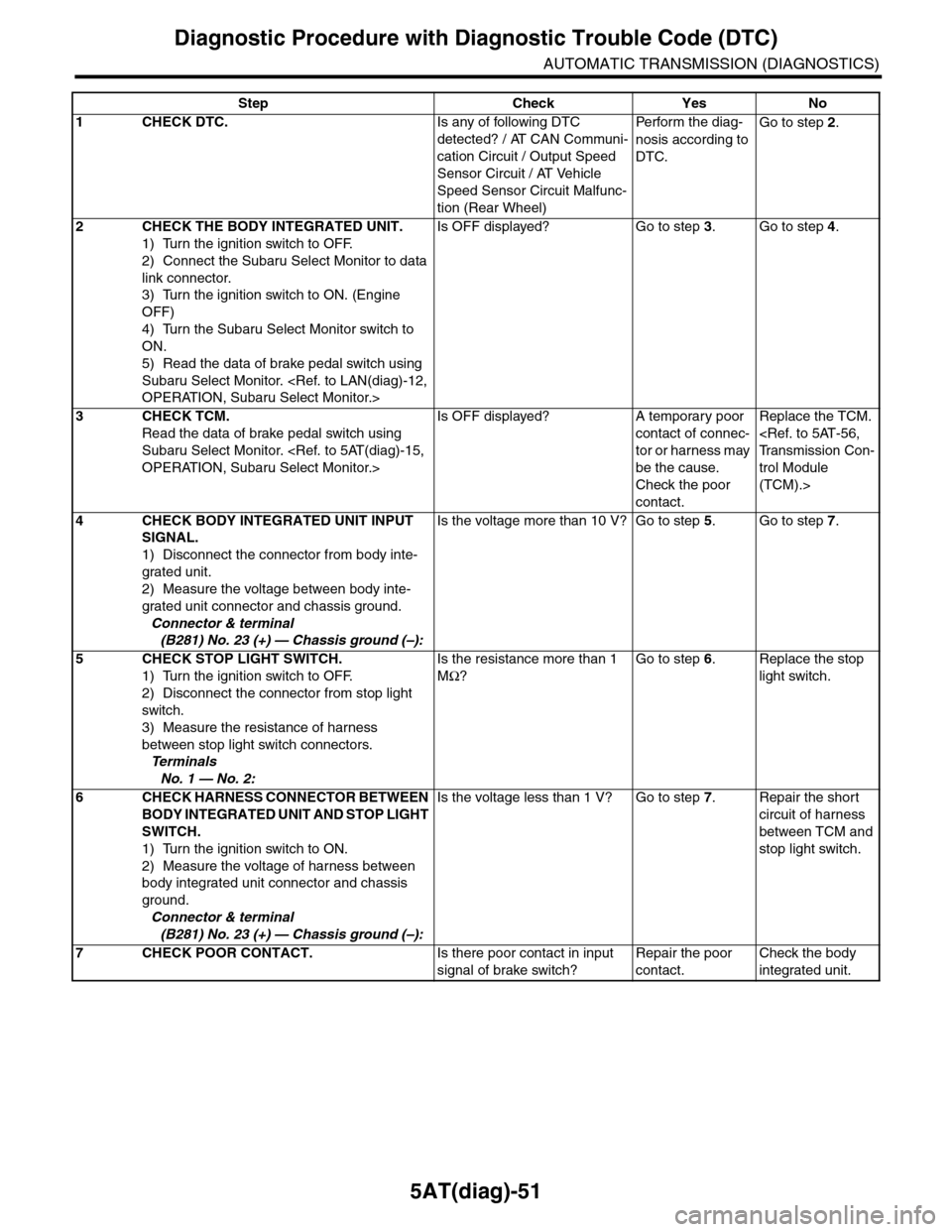

Step Check Yes No

1CHECK DTC.Is any of following DTC dis-

played? / AT CAN Communica-

tion Circuit / Output Speed

Sensor Circuit / AT Vehicle

Speed Sensor Circuit Malfunc-

tion (Rear Wheel)

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK THE BODY INTEGRATED UNIT.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON. (Engine

OFF)

4) Turn the Subaru Select Monitor switch to

ON.

5) Depress the brake pedal.

6) Read the data of brake pedal switch using

Subaru Select Monitor.

Is ON displayed? Go to step 3.Go to step 4.

3CHECK TCM.

Read the data of brake pedal switch using

Subaru Select Monitor.

Is ON displayed? A temporary poor

contact of connec-

tor or harness may

be the cause.

Check the poor

contact.

Replace the TCM.

trol Module

(TCM).>

4CHECK BODY INTEGRATED UNIT INPUT

SIGNAL.

1) Disconnect the connector from body inte-

grated unit.

2) Depress the brake pedal.

3) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(B281) No. 23 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 7.Go to step 5.

5CHECK HARNESS CONNECTOR BETWEEN

BODY INTEGRATED UNIT AND STOP LIGHT

SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from stop light

switch.

3) Measure the resistance of harness

between body integrated unit and stop light

switch.

Connector & terminal

(B281) No. 23 — (B64) No. 2:

Is the resistance less than 1

Ω?

Go to step 6.Repair the open

circuit of harness

between body inte-

grated unit and

stop light switch.

6CHECK HARNESS CONNECTOR BETWEEN

BODY INTEGRATED UNIT AND STOP LIGHT

SWITCH.

Measure the resistance of harness between

body integrated unit connector and stop light

switch.

Connector & terminal

(B281) No. 23 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the short

circuit of harness

between body inte-

grated unit and

stop light switch.

7CHECK POOR CONTACT.Is there poor contact in input

signal of brake switch?

Repair the poor

contact.

Check the body

integrated unit.

Page 2168 of 2453

5AT(diag)-51

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

1CHECK DTC.Is any of following DTC

detected? / AT CAN Communi-

cation Circuit / Output Speed

Sensor Circuit / AT Vehicle

Speed Sensor Circuit Malfunc-

tion (Rear Wheel)

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK THE BODY INTEGRATED UNIT.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON. (Engine

OFF)

4) Turn the Subaru Select Monitor switch to

ON.

5) Read the data of brake pedal switch using

Subaru Select Monitor.

Is OFF displayed? Go to step 3.Go to step 4.

3CHECK TCM.

Read the data of brake pedal switch using

Subaru Select Monitor.

Is OFF displayed? A temporary poor

contact of connec-

tor or harness may

be the cause.

Check the poor

contact.

Replace the TCM.

trol Module

(TCM).>

4CHECK BODY INTEGRATED UNIT INPUT

SIGNAL.

1) Disconnect the connector from body inte-

grated unit.

2) Measure the voltage between body inte-

grated unit connector and chassis ground.

Connector & terminal

(B281) No. 23 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 5.Go to step 7.

5CHECK STOP LIGHT SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from stop light

switch.

3) Measure the resistance of harness

between stop light switch connectors.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance more than 1

MΩ?

Go to step 6.Replace the stop

light switch.

6CHECK HARNESS CONNECTOR BETWEEN

BODY INTEGRATED UNIT AND STOP LIGHT

SWITCH.

1) Turn the ignition switch to ON.

2) Measure the voltage of harness between

body integrated unit connector and chassis

ground.

Connector & terminal

(B281) No. 23 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 7.Repair the short

circuit of harness

between TCM and

stop light switch.

7CHECK POOR CONTACT.Is there poor contact in input

signal of brake switch?

Repair the poor

contact.

Check the body

integrated unit.

Page 2232 of 2453

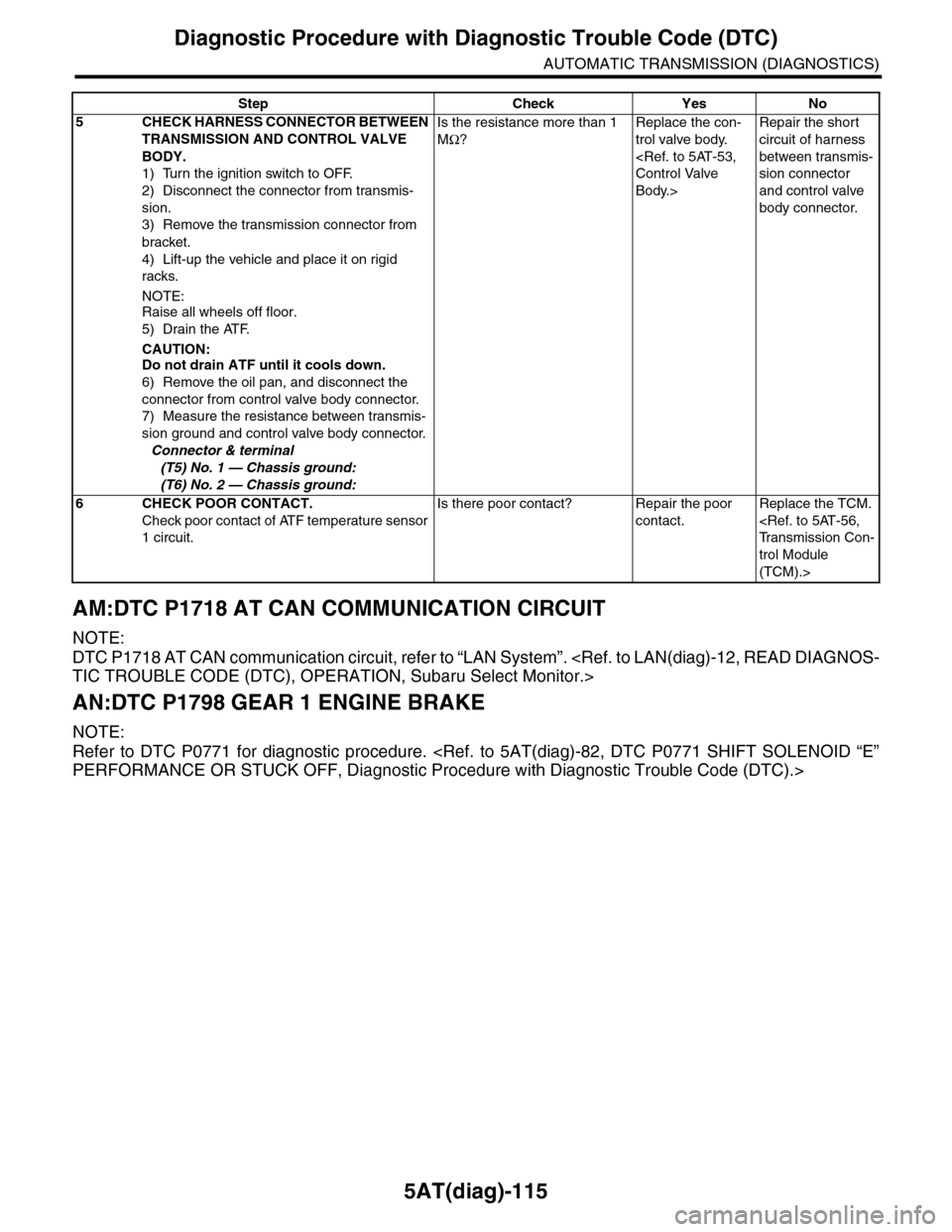

5AT(diag)-115

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

AM:DTC P1718 AT CAN COMMUNICATION CIRCUIT

NOTE:

DTC P1718 AT CAN communication circuit, refer to “LAN System”.

AN:DTC P1798 GEAR 1 ENGINE BRAKE

NOTE:

Refer to DTC P0771 for diagnostic procedure.

5CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:Raise all wheels off floor.

5) Drain the ATF.

CAUTION:Do not drain ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmis-

sion ground and control valve body connector.

Connector & terminal

(T5) No. 1 — Chassis ground:

(T6) No. 2 — Chassis ground:

Is the resistance more than 1

MΩ?

Replace the con-

trol valve body.

Body.>

Repair the short

circuit of harness

between transmis-

sion connector

and control valve

body connector.

6CHECK POOR CONTACT.

Check poor contact of ATF temperature sensor

1 circuit.

Is there poor contact? Repair the poor

contact.

Replace the TCM.

trol Module

(TCM).>

Step Check Yes No

Page 2236 of 2453

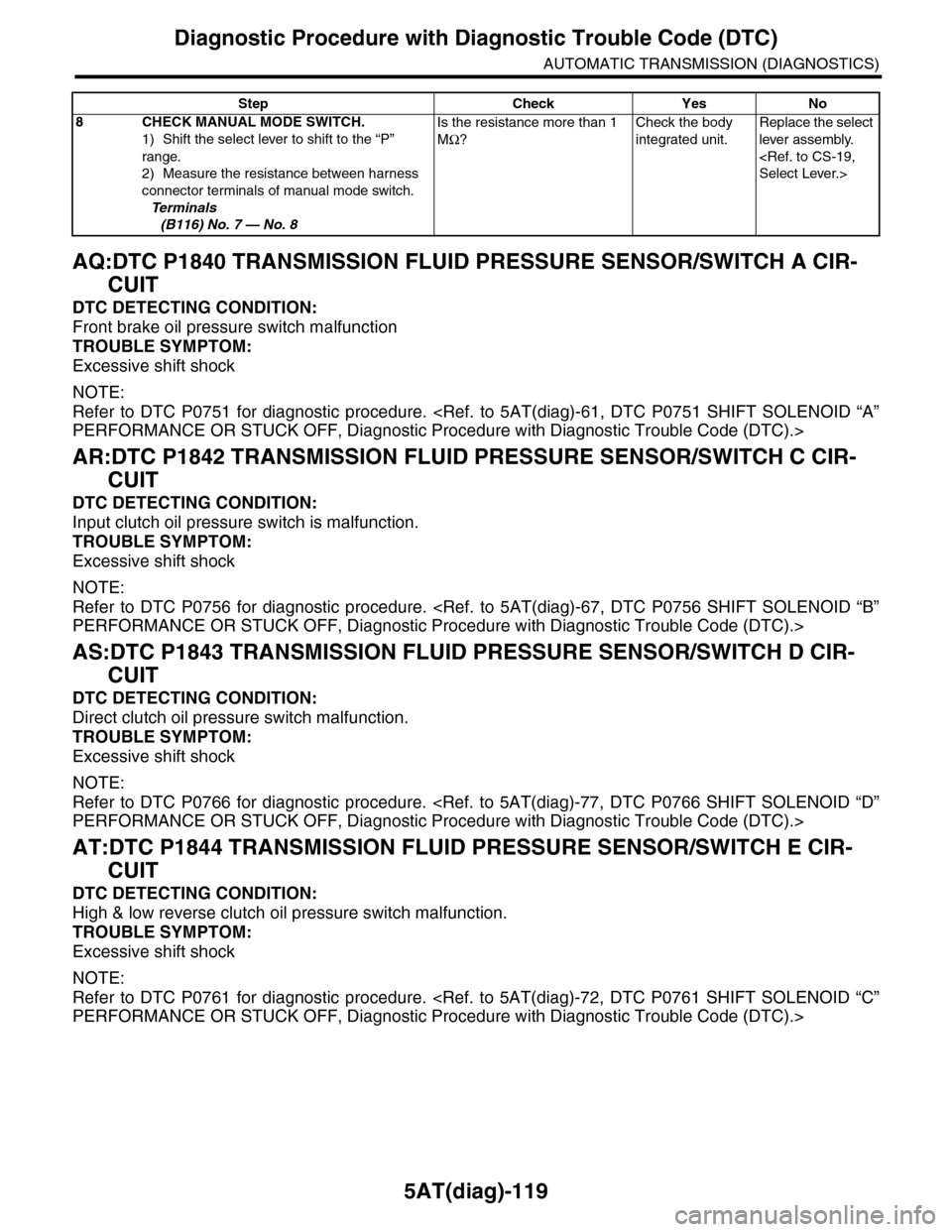

5AT(diag)-119

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

AQ:DTC P1840 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH A CIR-

CUIT

DTC DETECTING CONDITION:

Front brake oil pressure switch malfunction

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0751 for diagnostic procedure.

AR:DTC P1842 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH C CIR-

CUIT

DTC DETECTING CONDITION:

Input clutch oil pressure switch is malfunction.

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0756 for diagnostic procedure.

AS:DTC P1843 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH D CIR-

CUIT

DTC DETECTING CONDITION:

Direct clutch oil pressure switch malfunction.

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0766 for diagnostic procedure.

AT:DTC P1844 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH E CIR-

CUIT

DTC DETECTING CONDITION:

High & low reverse clutch oil pressure switch malfunction.

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0761 for diagnostic procedure.

8CHECK MANUAL MODE SWITCH.

1) Shift the select lever to shift to the “P”

range.

2) Measure the resistance between harness

connector terminals of manual mode switch.

Te r m i n a l s

(B116) No. 7 — No. 8

Is the resistance more than 1

MΩ?

Check the body

integrated unit.

Replace the select

lever assembly.

Step Check Yes No

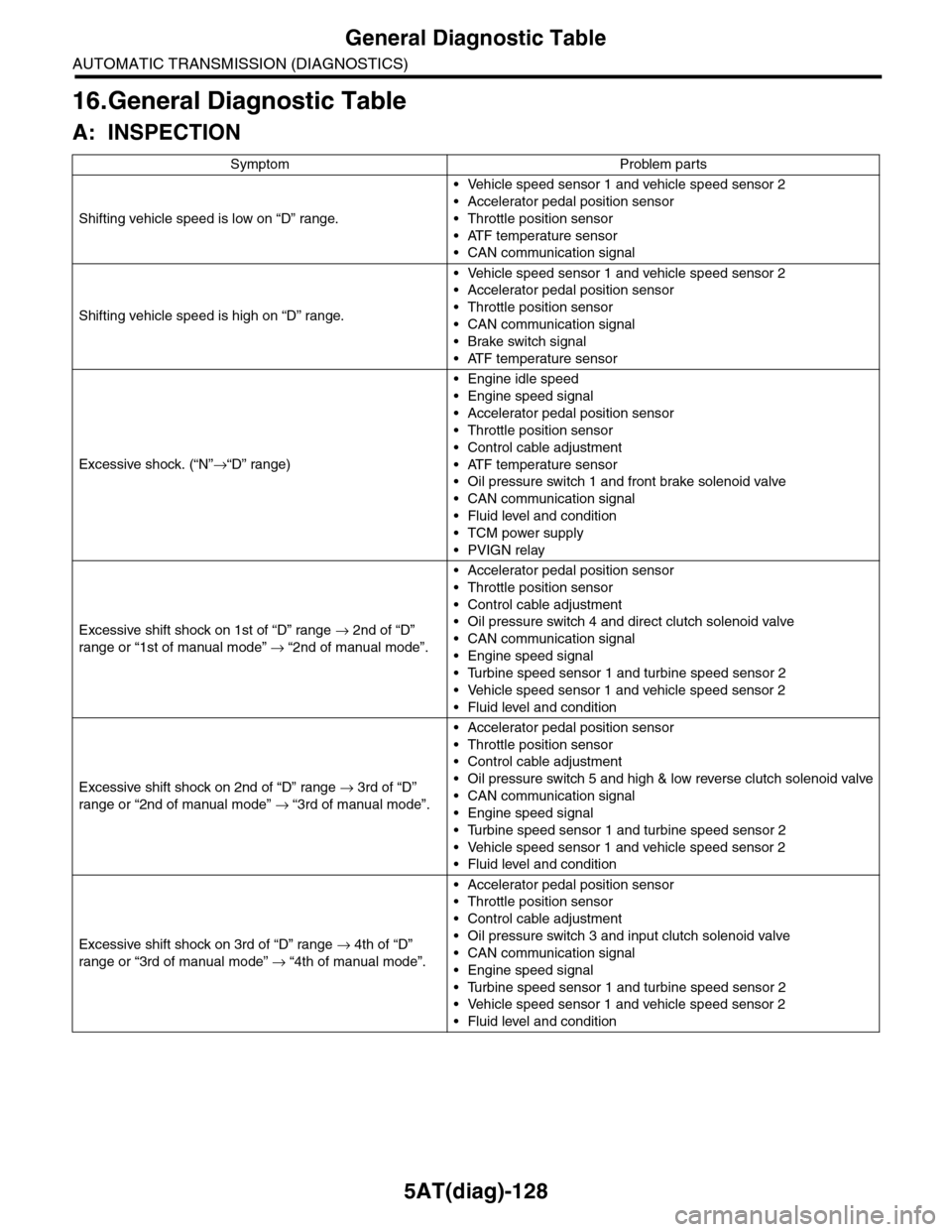

Page 2245 of 2453

5AT(diag)-128

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

16.General Diagnostic Table

A: INSPECTION

Symptom Problem parts

Shifting vehicle speed is low on “D” range.

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Accelerator pedal position sensor

•Throttle position sensor

•ATF temperature sensor

•CAN communication signal

Shifting vehicle speed is high on “D” range.

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Brake switch signal

•ATF temperature sensor

Excessive shock. (“N”→“D” range)

•Engine idle speed

•Engine speed signal

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•ATF temperature sensor

•Oil pressure switch 1 and front brake solenoid valve

•CAN communication signal

•Fluid level and condition

•TCM power supply

•PVIGN relay

Excessive shift shock on 1st of “D” range → 2nd of “D”

range or “1st of manual mode” → “2nd of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 4 and direct clutch solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shift shock on 2nd of “D” range → 3rd of “D”

range or “2nd of manual mode” → “3rd of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shift shock on 3rd of “D” range → 4th of “D”

range or “3rd of manual mode” → “4th of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 3 and input clutch solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Page 2246 of 2453

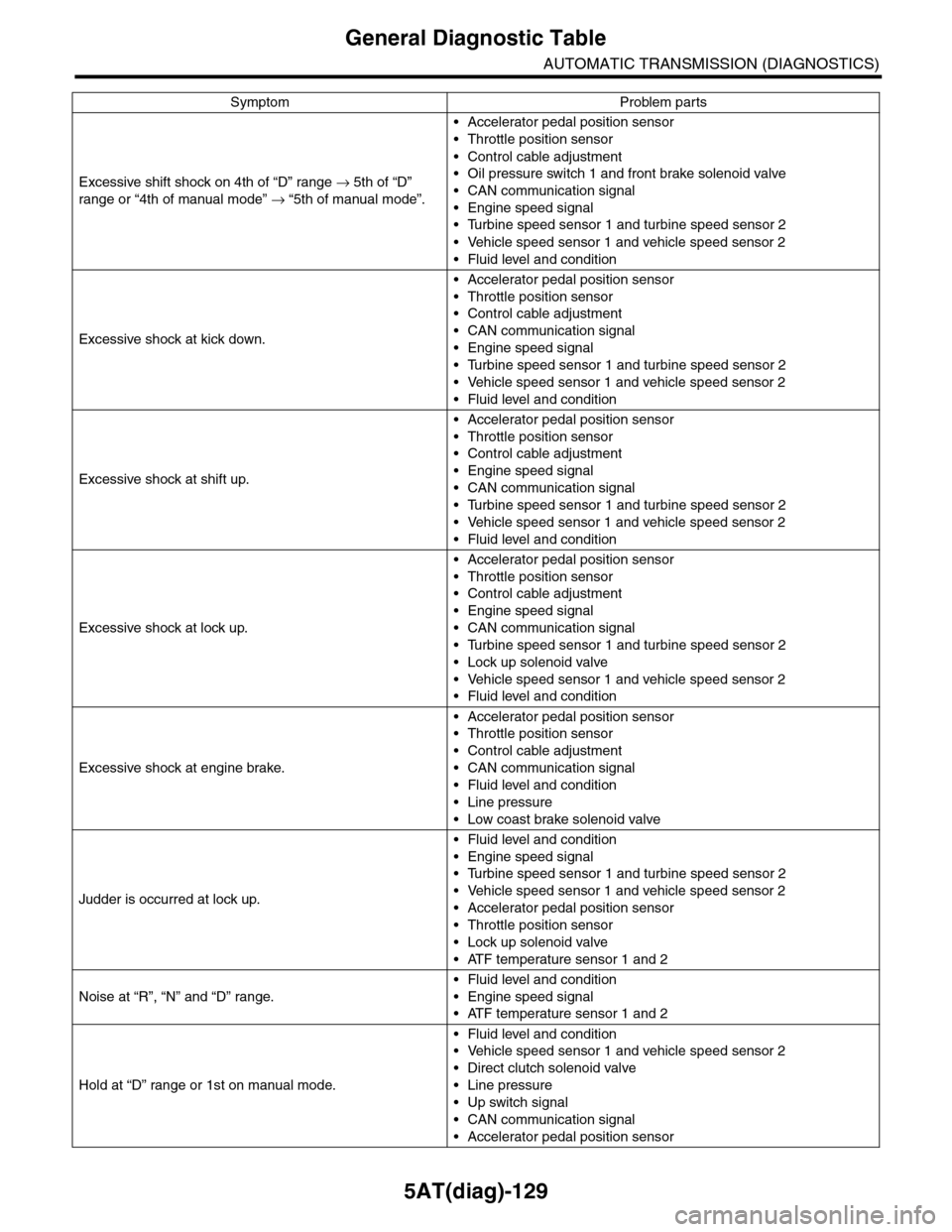

5AT(diag)-129

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Excessive shift shock on 4th of “D” range → 5th of “D”

range or “4th of manual mode” → “5th of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 1 and front brake solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shock at kick down.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shock at shift up.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Engine speed signal

•CAN communication signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shock at lock up.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Engine speed signal

•CAN communication signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Lock up solenoid valve

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shock at engine brake.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•CAN communication signal

•Fluid level and condition

•Line pressure

•Low coast brake solenoid valve

Judder is occurred at lock up.

•Fluid level and condition

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Accelerator pedal position sensor

•Throttle position sensor

•Lock up solenoid valve

•ATF temperature sensor 1 and 2

Noise at “R”, “N” and “D” range.

•Fluid level and condition

•Engine speed signal

•ATF temperature sensor 1 and 2

Hold at “D” range or 1st on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Direct clutch solenoid valve

•Line pressure

•Up switch signal

•CAN communication signal

•Accelerator pedal position sensor

Symptom Problem parts

Page 2247 of 2453

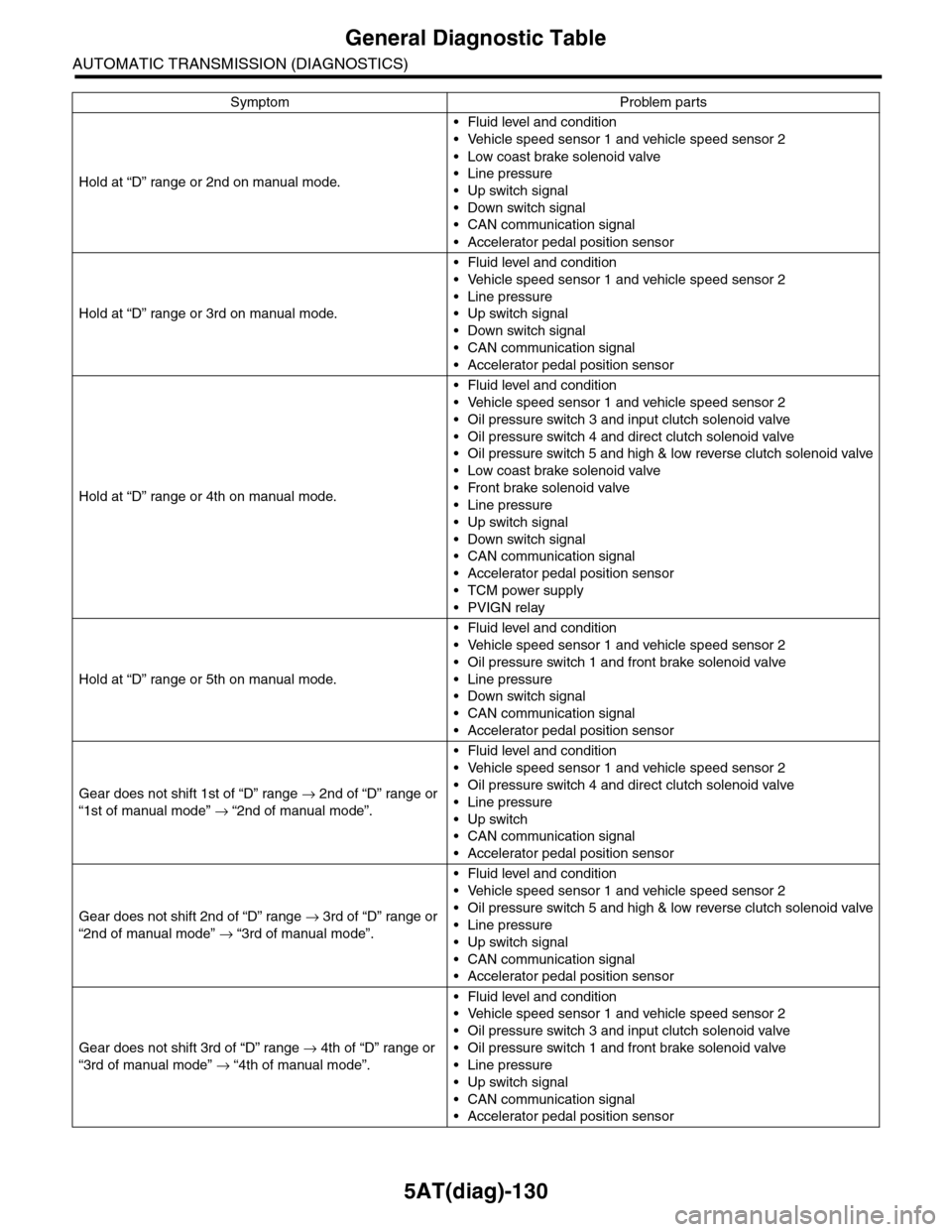

5AT(diag)-130

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Hold at “D” range or 2nd on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Low coast brake solenoid valve

•Line pressure

•Up switch signal

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Hold at “D” range or 3rd on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Line pressure

•Up switch signal

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Hold at “D” range or 4th on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•Low coast brake solenoid valve

•Front brake solenoid valve

•Line pressure

•Up switch signal

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

•TCM power supply

•PVIGN relay

Hold at “D” range or 5th on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift 1st of “D” range → 2nd of “D” range or

“1st of manual mode” → “2nd of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Up switch

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift 2nd of “D” range → 3rd of “D” range or

“2nd of manual mode” → “3rd of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•Line pressure

•Up switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift 3rd of “D” range → 4th of “D” range or

“3rd of manual mode” → “4th of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•Up switch signal

•CAN communication signal

•Accelerator pedal position sensor

Symptom Problem parts