weight SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1722 of 2453

GD(H6DO)-110

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BT:DTC P0327 KNOCK SENSOR 1 CIRCUIT LOW INPUT (BANK 1 OR SINGLE

SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of knock sensor.

Judge as NG if it is out of specification.

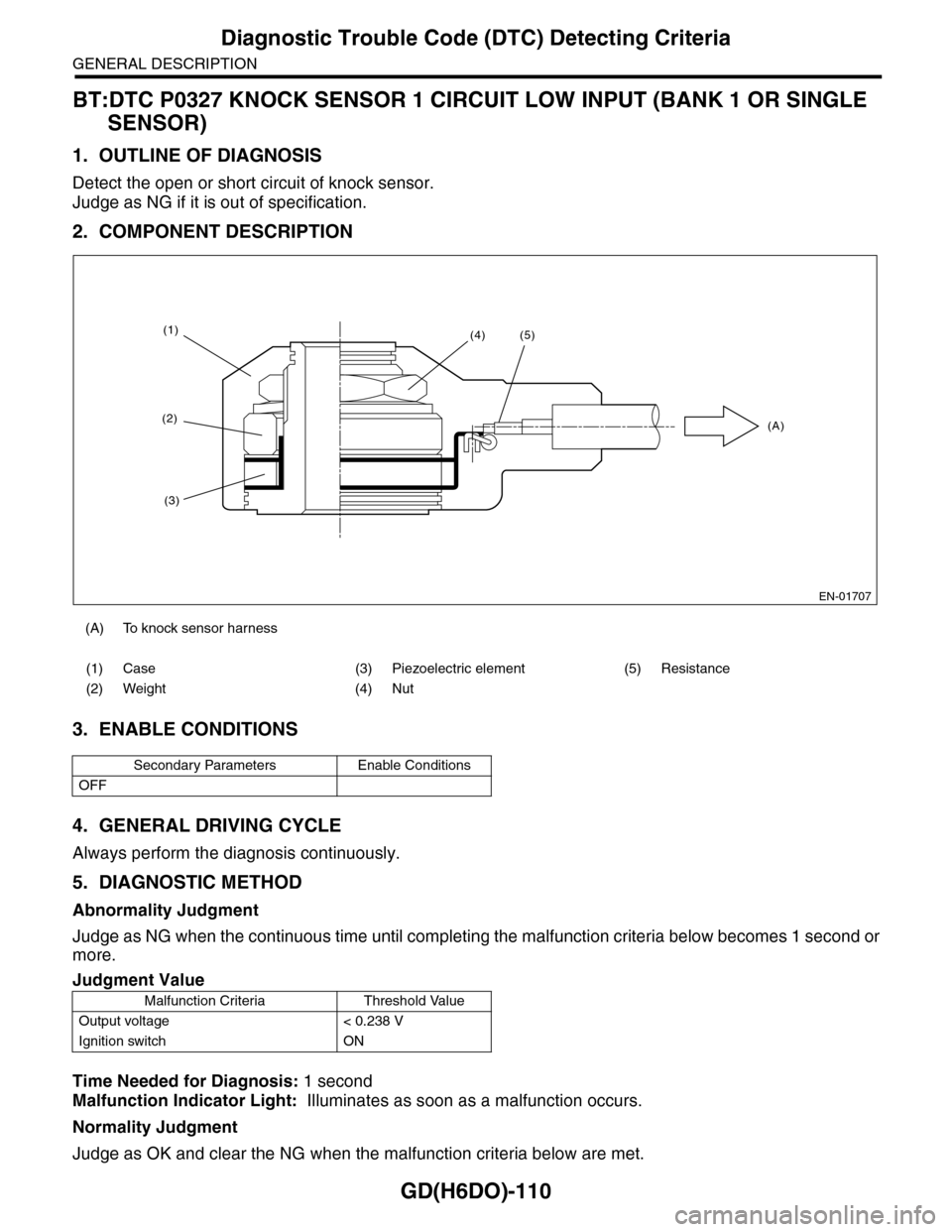

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

(A) To knock sensor harness

(1) Case (3) Piezoelectric element (5) Resistance

(2) Weight (4) Nut

Secondary Parameters Enable Conditions

OFF

Judgment Value

Malfunction Criteria Threshold Value

Output voltage < 0.238 V

Ignition switch ON

EN-01707

(1)

(2)

(3)

(4)(5)

(A)

Page 1724 of 2453

GD(H6DO)-112

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BU:DTC P0328 KNOCK SENSOR 1 CIRCUIT HIGH INPUT (BANK 1 OR SINGLE

SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of knock sensor.

Judge as NG if it is out of specification.

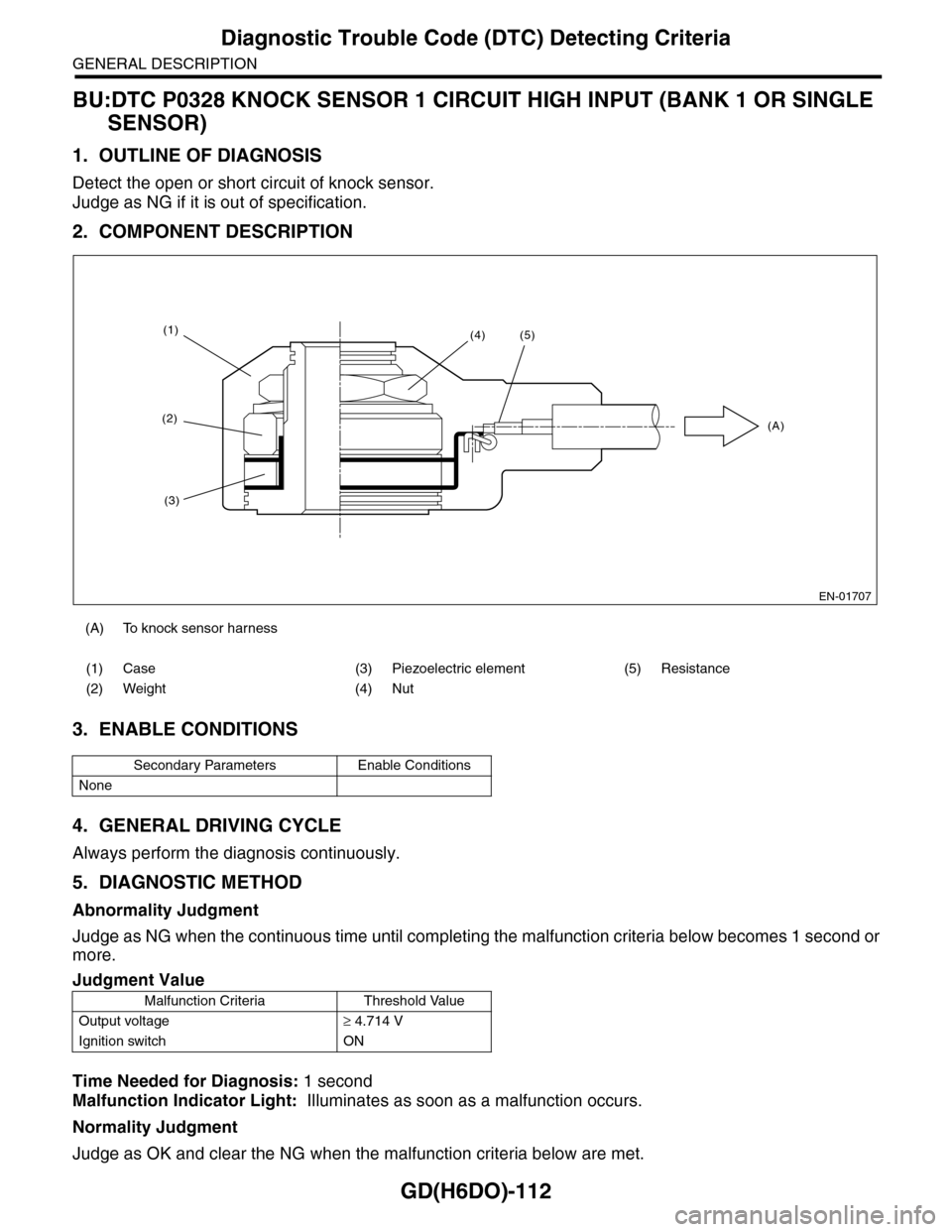

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

(A) To knock sensor harness

(1) Case (3) Piezoelectric element (5) Resistance

(2) Weight (4) Nut

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage≥ 4.714 V

Ignition switch ON

EN-01707

(1)

(2)

(3)

(4)(5)

(A)

Page 1901 of 2453

ME(H6DO)-35

Engine Assembly

MECHANICAL

29) Disconnect the fuel delivery hose and evapora-

tion hose.

(1) Disconnect the connector of fuel pipe by

pushing the ST in the direction of arrow.

ST 42099AE000 CONNECTOR REMOVER

(2) Remove the clamp, and disconnect the

evaporation hose from the pipe.

CAUTION:

•Collect fuel from the hose into container.

•Disconnect the hose with its end wrapped

with cloth to prevent fuel from splashing.

30) Support the engine with a lifting device and

wire ropes.

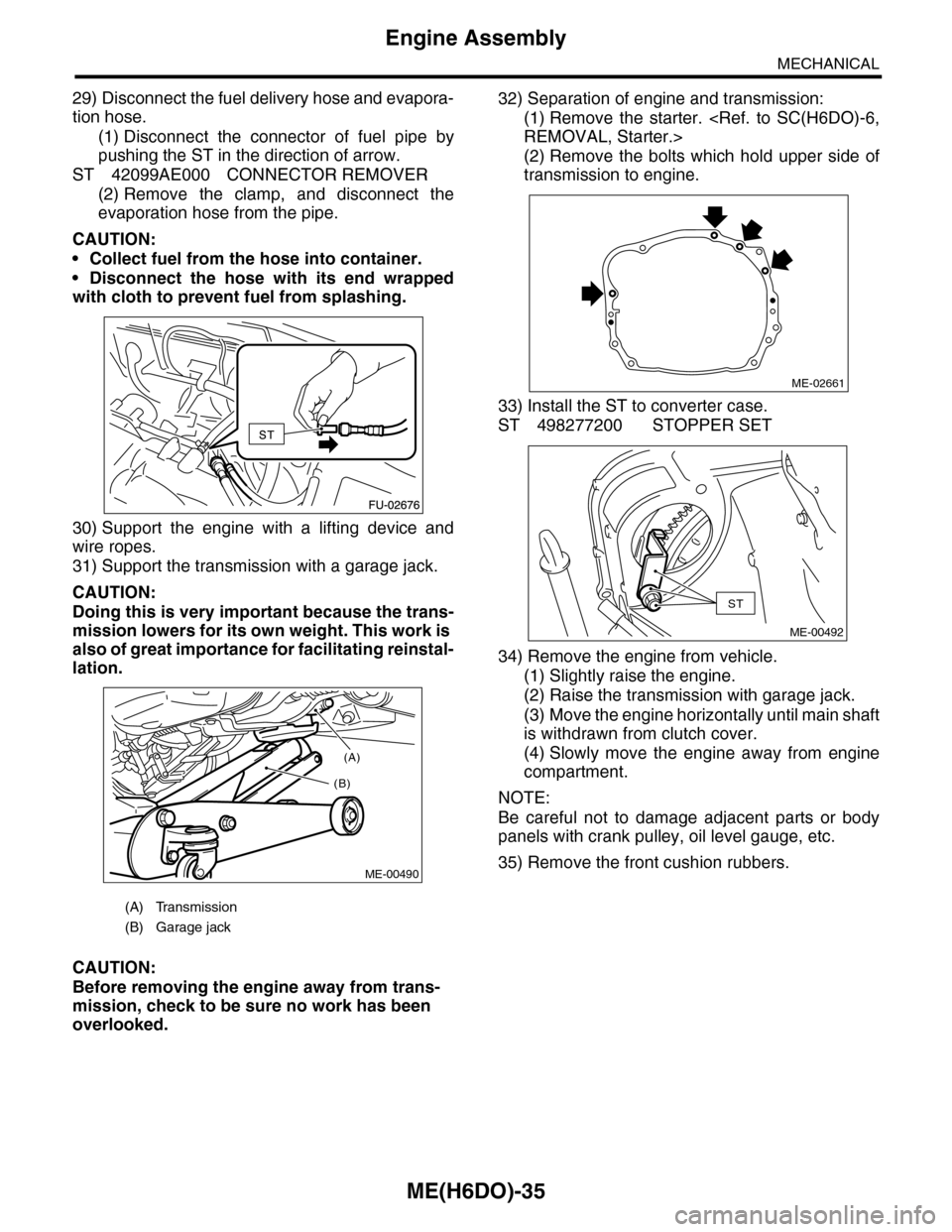

31) Support the transmission with a garage jack.

CAUTION:

Doing this is very important because the trans-

mission lowers for its own weight. This work is

also of great importance for facilitating reinstal-

lation.

CAUTION:

Before removing the engine away from trans-

mission, check to be sure no work has been

overlooked.

32) Separation of engine and transmission:

(1) Remove the starter.

(2) Remove the bolts which hold upper side of

transmission to engine.

33) Install the ST to converter case.

ST 498277200 STOPPER SET

34) Remove the engine from vehicle.

(1) Slightly raise the engine.

(2) Raise the transmission with garage jack.

(3) Move the engine horizontally until main shaft

is withdrawn from clutch cover.

(4) Slowly move the engine away from engine

compartment.

NOTE:

Be careful not to damage adjacent parts or body

panels with crank pulley, oil level gauge, etc.

35) Remove the front cushion rubbers.

(A) Transmission

(B) Garage jack

(A)

(B)

ME-00490

ME-02661

ST

ME-00492

Page 2007 of 2453

PM-24

Suspension

PERIODIC MAINTENANCE SERVICES

17.Suspension

A: INSPECTION

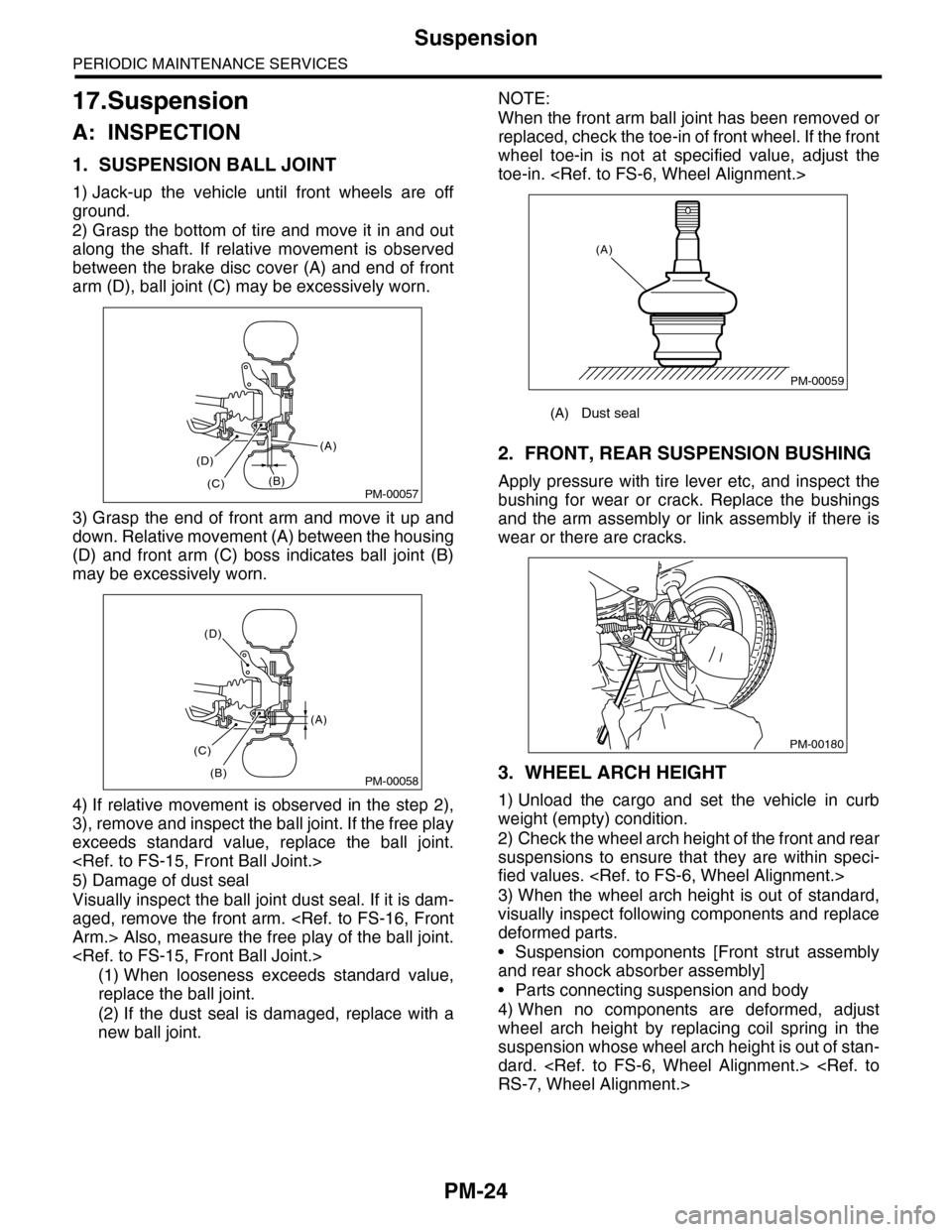

1. SUSPENSION BALL JOINT

1) Jack-up the vehicle until front wheels are off

ground.

2) Grasp the bottom of tire and move it in and out

along the shaft. If relative movement is observed

between the brake disc cover (A) and end of front

arm (D), ball joint (C) may be excessively worn.

3) Grasp the end of front arm and move it up and

down. Relative movement (A) between the housing

(D) and front arm (C) boss indicates ball joint (B)

may be excessively worn.

4) If relative movement is observed in the step 2),

3), remove and inspect the ball joint. If the free play

exceeds standard value, replace the ball joint.

5) Damage of dust seal

Visually inspect the ball joint dust seal. If it is dam-

aged, remove the front arm.

(1) When looseness exceeds standard value,

replace the ball joint.

(2) If the dust seal is damaged, replace with a

new ball joint.

NOTE:

When the front arm ball joint has been removed or

replaced, check the toe-in of front wheel. If the front

wheel toe-in is not at specified value, adjust the

toe-in.

2. FRONT, REAR SUSPENSION BUSHING

Apply pressure with tire lever etc, and inspect the

bushing for wear or crack. Replace the bushings

and the arm assembly or link assembly if there is

wear or there are cracks.

3. WHEEL ARCH HEIGHT

1) Unload the cargo and set the vehicle in curb

weight (empty) condition.

2) Check the wheel arch height of the front and rear

suspensions to ensure that they are within speci-

fied values.

3) When the wheel arch height is out of standard,

visually inspect following components and replace

deformed parts.

•Suspension components [Front strut assembly

and rear shock absorber assembly]

•Parts connecting suspension and body

4) When no components are deformed, adjust

wheel arch height by replacing coil spring in the

suspension whose wheel arch height is out of stan-

dard.

PM-00057

(A)

(B)(C)

(D)

PM-00058

(A)

(B)

(C)

(D)

(A) Dust seal

PM-00059

(A)

PM-00180