g sensor SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1710 of 2453

GD(H6DO)-98

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BK:DTC P0222 THROTTLE/PEDAL POSITION SENSOR/SWITCH “B” CIRCUIT

LOW INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of throttle position sensor 2.

Judge as NG if it is out of specification.

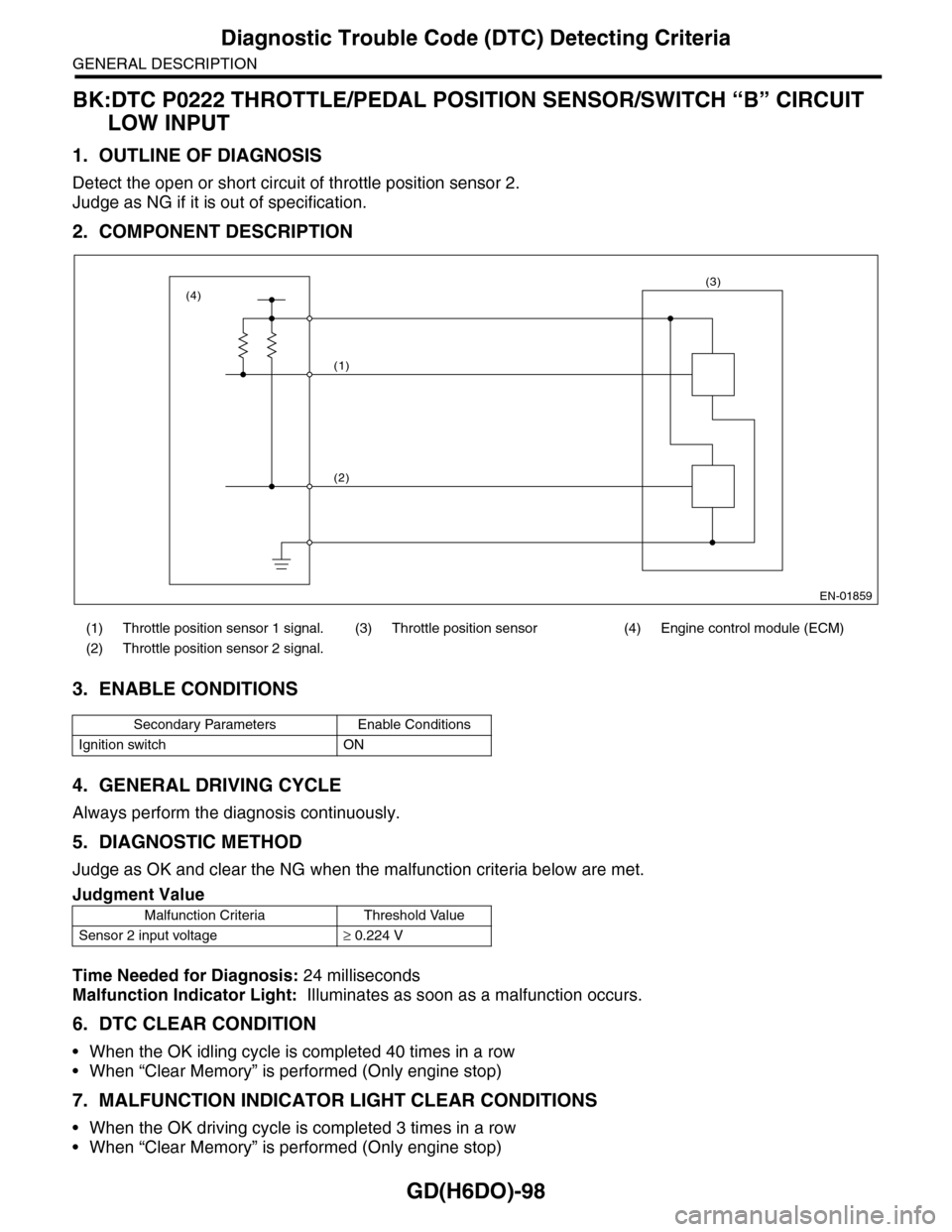

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as OK and clear the NG when the malfunction criteria below are met.

Time Needed for Diagnosis: 24 milliseconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed (Only engine stop)

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed (Only engine stop)

(1) Throttle position sensor 1 signal. (3) Throttle position sensor (4) Engine control module (ECM)

(2) Throttle position sensor 2 signal.

Secondary Parameters Enable Conditions

Ignition switch ON

Judgment Value

Malfunction Criteria Threshold Value

Sensor 2 input voltage≥ 0.224 V

EN-01859

(1)

(2)

(3)(4)

Page 1712 of 2453

GD(H6DO)-100

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BL:DTC P0223 THROTTLE/PEDAL POSITION SENSOR/SWITCH “B” CIRCUIT

HIGH INPUT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of throttle position sensor 2.

Judge as NG if it is out of specification.

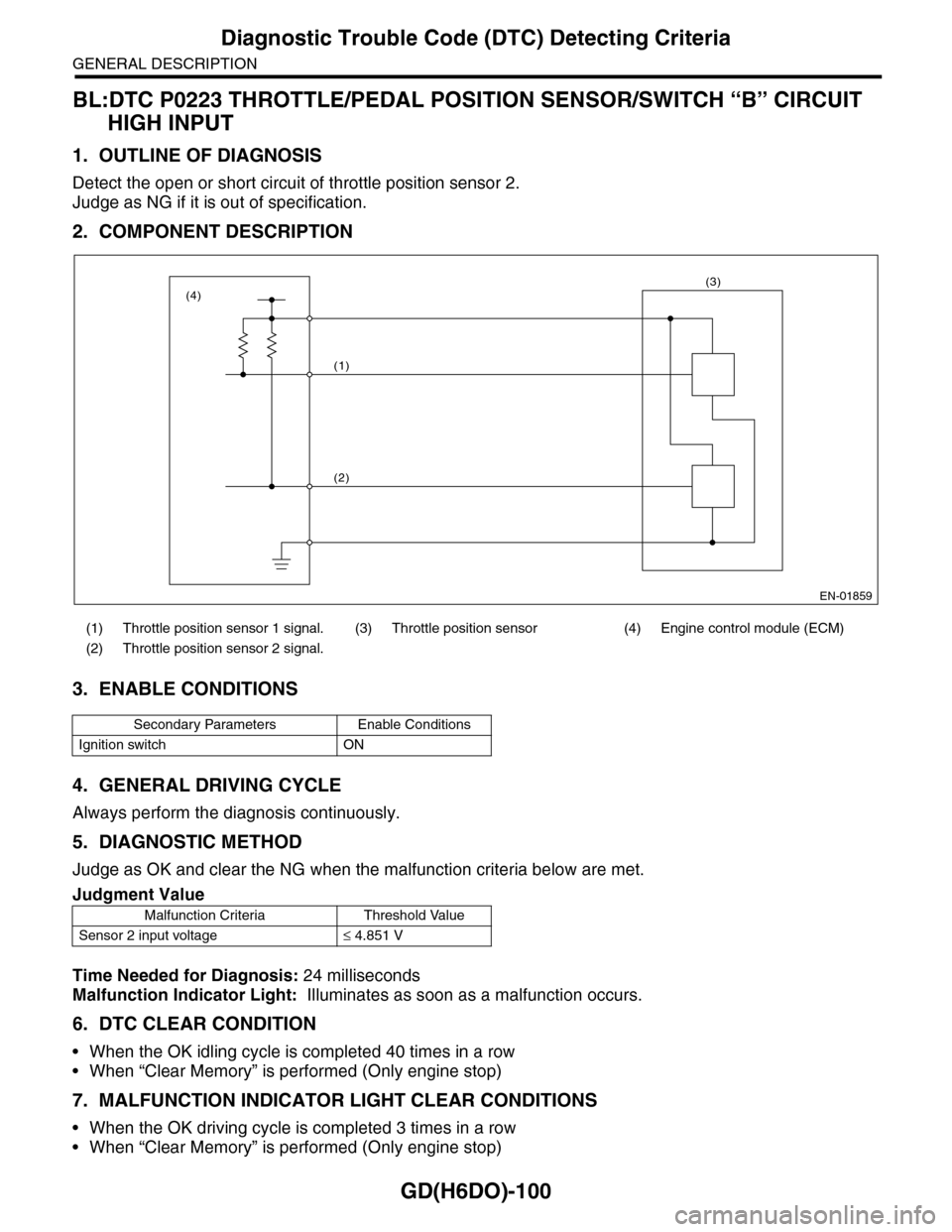

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as OK and clear the NG when the malfunction criteria below are met.

Time Needed for Diagnosis: 24 milliseconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed (Only engine stop)

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed (Only engine stop)

(1) Throttle position sensor 1 signal. (3) Throttle position sensor (4) Engine control module (ECM)

(2) Throttle position sensor 2 signal.

Secondary Parameters Enable Conditions

Ignition switch ON

Judgment Value

Malfunction Criteria Threshold Value

Sensor 2 input voltage≤ 4.851 V

EN-01859

(1)

(2)

(3)(4)

Page 1722 of 2453

GD(H6DO)-110

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BT:DTC P0327 KNOCK SENSOR 1 CIRCUIT LOW INPUT (BANK 1 OR SINGLE

SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of knock sensor.

Judge as NG if it is out of specification.

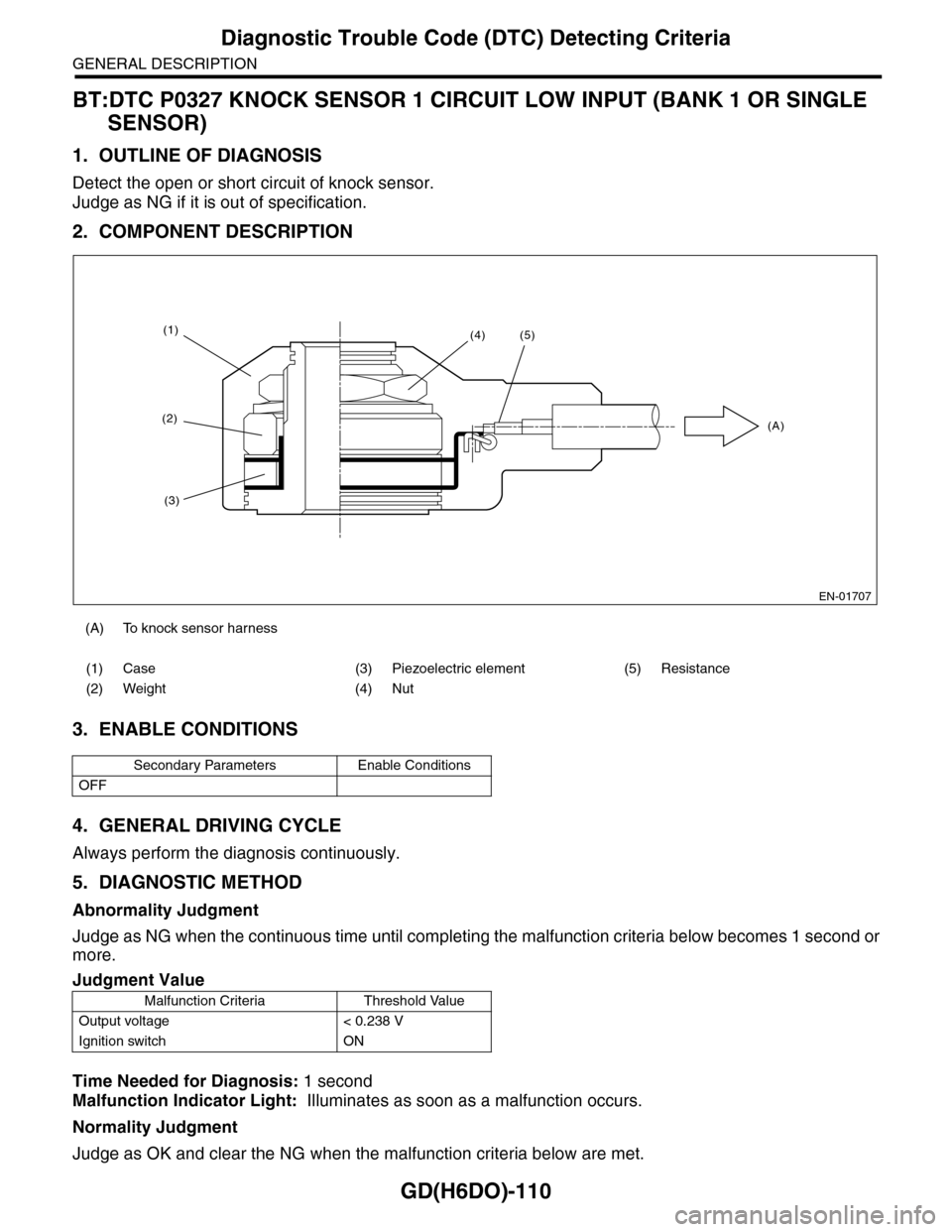

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

(A) To knock sensor harness

(1) Case (3) Piezoelectric element (5) Resistance

(2) Weight (4) Nut

Secondary Parameters Enable Conditions

OFF

Judgment Value

Malfunction Criteria Threshold Value

Output voltage < 0.238 V

Ignition switch ON

EN-01707

(1)

(2)

(3)

(4)(5)

(A)

Page 1724 of 2453

GD(H6DO)-112

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

BU:DTC P0328 KNOCK SENSOR 1 CIRCUIT HIGH INPUT (BANK 1 OR SINGLE

SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of knock sensor.

Judge as NG if it is out of specification.

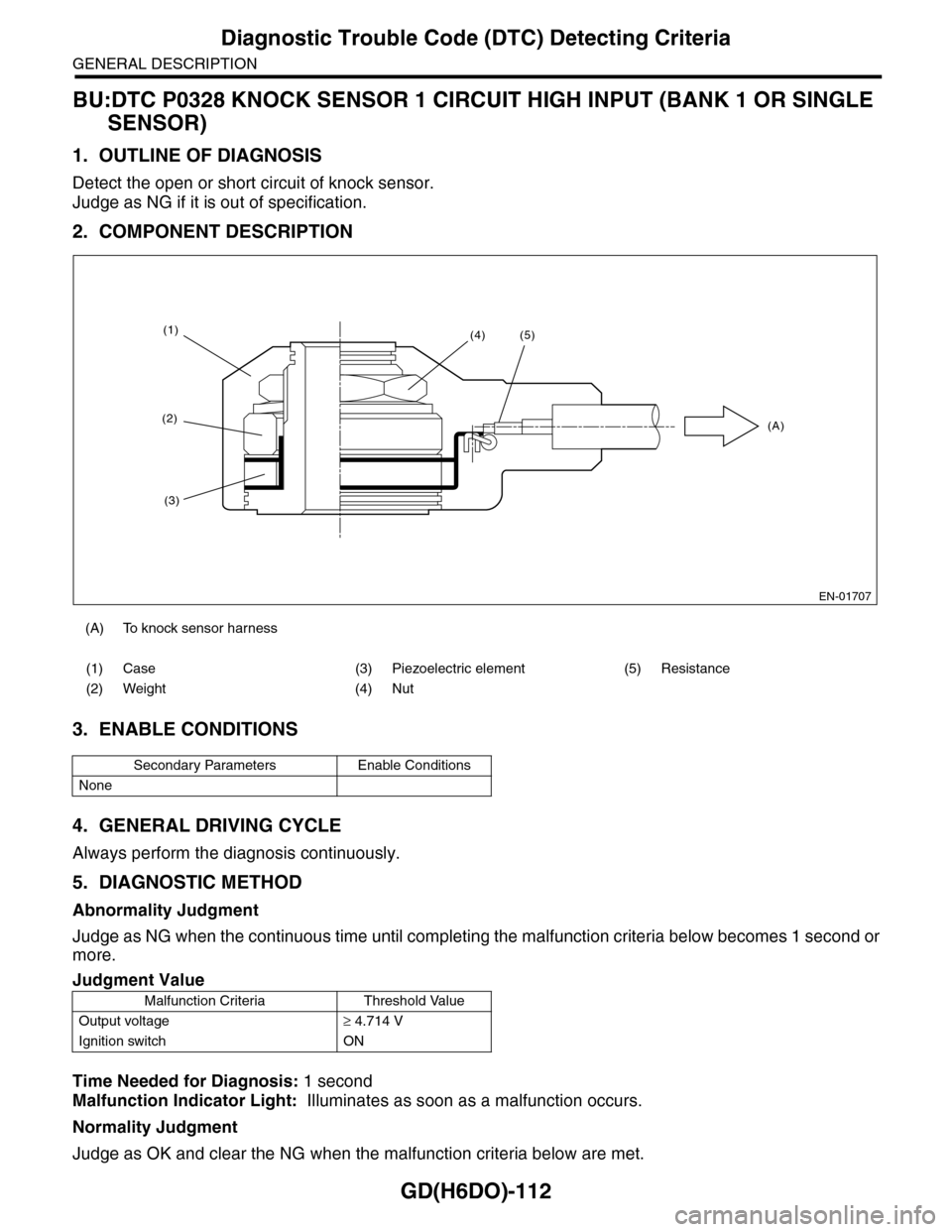

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

(A) To knock sensor harness

(1) Case (3) Piezoelectric element (5) Resistance

(2) Weight (4) Nut

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage≥ 4.714 V

Ignition switch ON

EN-01707

(1)

(2)

(3)

(4)(5)

(A)

Page 1725 of 2453

GD(H6DO)-113

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

Knocking compensation

When normal: Learning ignition advance angle value = knock F/B advance angle + entire learning advance

angle value + portional learning advance angle value

Failure: Learning ignition advance angle value = –5.0°CA

Knock F/B advancing angle = 0°CA

Whole learning prohibited

Portional learning prohibited

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

BV:DTC P0332 KNOCK SENSOR 2 CIRCUIT LOW INPUT (BANK 2)

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0327.

ria.>

BW:DTC P0333 KNOCK SENSOR 2 CIRCUIT HIGH INPUT (BANK 2)

1. OUTLINE OF DIAGNOSIS

NOTE:

For the diagnostic procedure, refer to DTC P0328.

ria.>

Judgment Value

Malfunction Criteria Threshold Value

Output voltage < 4.714 V

Ignition switch ON

Page 1726 of 2453

GD(H6DO)-114

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

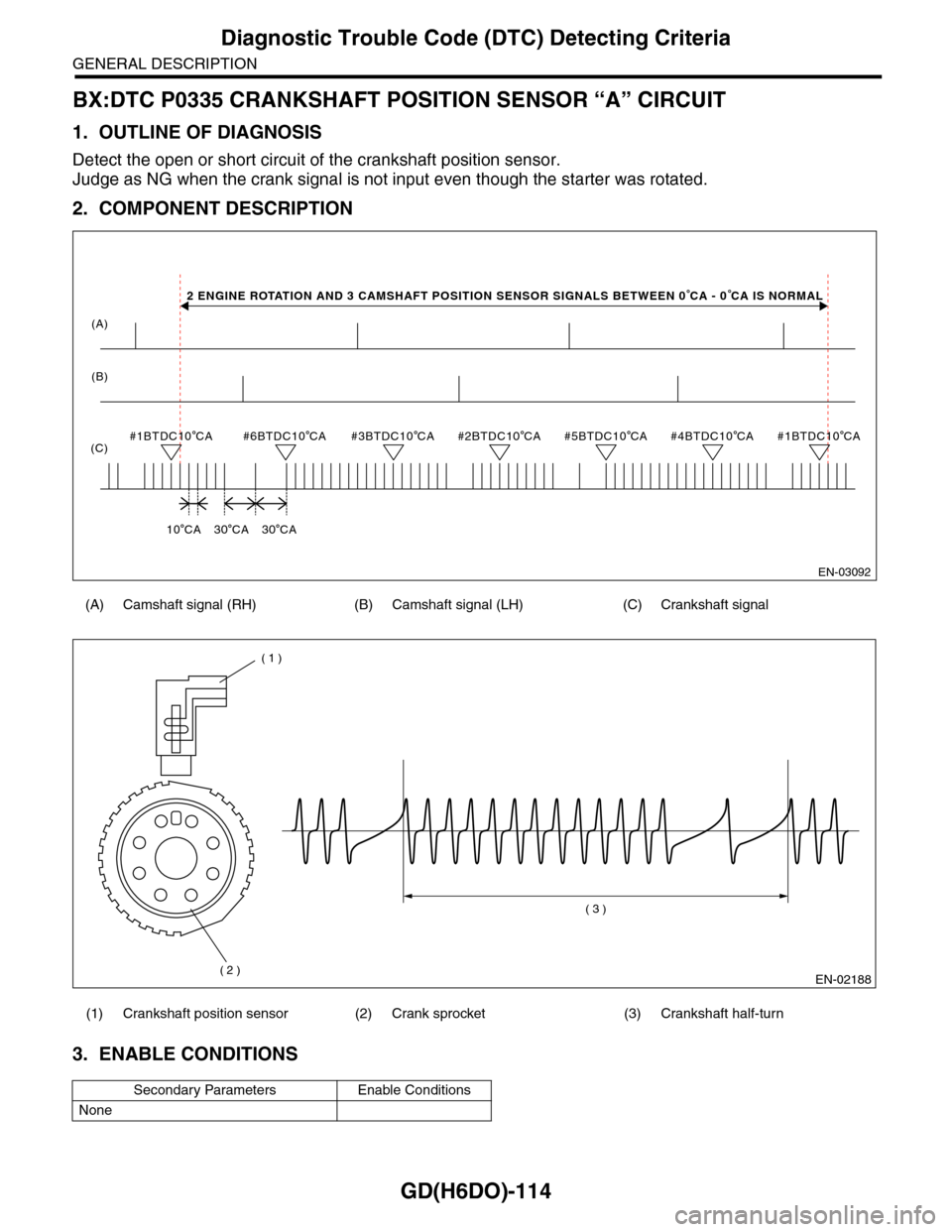

BX:DTC P0335 CRANKSHAFT POSITION SENSOR “A” CIRCUIT

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the crankshaft position sensor.

Judge as NG when the crank signal is not input even though the starter was rotated.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

(A) Camshaft signal (RH) (B) Camshaft signal (LH) (C) Crankshaft signal

(1) Crankshaft position sensor (2) Crank sprocket (3) Crankshaft half-turn

Secondary Parameters Enable Conditions

None

(A)

(C)#6BTDC10 CA#3BTDC10 CA#2BTDC10 CA#5BTDC10 CA#4BTDC10 CA

10 CA30 CA30 CA

#1BTDC10 CA#1BTDC10 CA

EN-03092

(B)

2 ENGINE ROTATION AND 3 CAMSHAFT POSITION SENSOR SIGNALS BETWEEN 0 CA - 0 CA IS NORMAL

EN-02188

( 1 )

( 2 )

( 3 )

Page 1727 of 2453

GD(H6DO)-115

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time of completing the malfunction criteria below becomes more than 3

seconds.

Time Needed for Diagnosis: 3 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK when the continuous time while meeting the malfunction criteria below is 3 seconds or more.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

None

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Judgment Value

Malfunction Criteria Threshold Value

Starter switch ON

Crankshaft position sensor signal Not detected

Battery voltage≥ 8 V

Judgment Value

Malfunction Criteria Threshold Value

Crankshaft position sensor signal Input exists

Battery voltage≥ 8 V

Page 1728 of 2453

GD(H6DO)-116

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

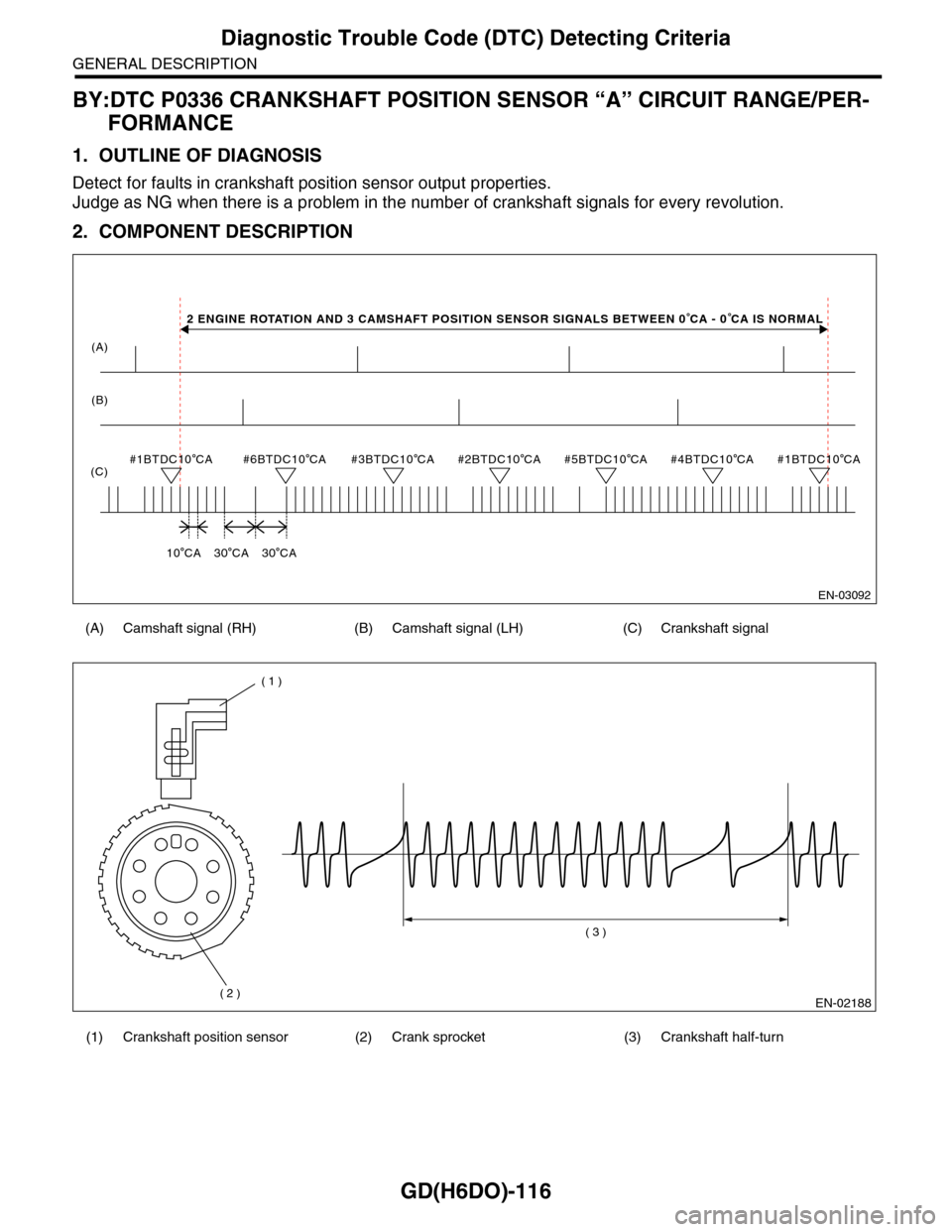

BY:DTC P0336 CRANKSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PER-

FORMANCE

1. OUTLINE OF DIAGNOSIS

Detect for faults in crankshaft position sensor output properties.

Judge as NG when there is a problem in the number of crankshaft signals for every revolution.

2. COMPONENT DESCRIPTION

(A) Camshaft signal (RH) (B) Camshaft signal (LH) (C) Crankshaft signal

(1) Crankshaft position sensor (2) Crank sprocket (3) Crankshaft half-turn

(A)

(C)#6BTDC10 CA#3BTDC10 CA#2BTDC10 CA#5BTDC10 CA#4BTDC10 CA

10 CA30 CA30 CA

#1BTDC10 CA#1BTDC10 CA

EN-03092

(B)

2 ENGINE ROTATION AND 3 CAMSHAFT POSITION SENSOR SIGNALS BETWEEN 0 CA - 0 CA IS NORMAL

EN-02188

( 1 )

( 2 )

( 3 )

Page 1729 of 2453

GD(H6DO)-117

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously under 3000 rpm engine RPM.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when all the malfunction criteria below are completed more than 10 times in a row.

Time Needed for Diagnosis: 10 engine rotations

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

None

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

Battery voltage≥ 8 V

Engine speed < 3000 rpm

Judgment Value

Malfunction Criteria Threshold Value

Cylinder number identification Completed

Amount of crank sensor signal during 1

rev.

Not = 30

Judgment Value

Malfunction Criteria Threshold Value

Cylinder number distinction Completed

Amount of crank sensor signal during 1

rev.

= 30

Page 1730 of 2453

GD(H6DO)-118

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

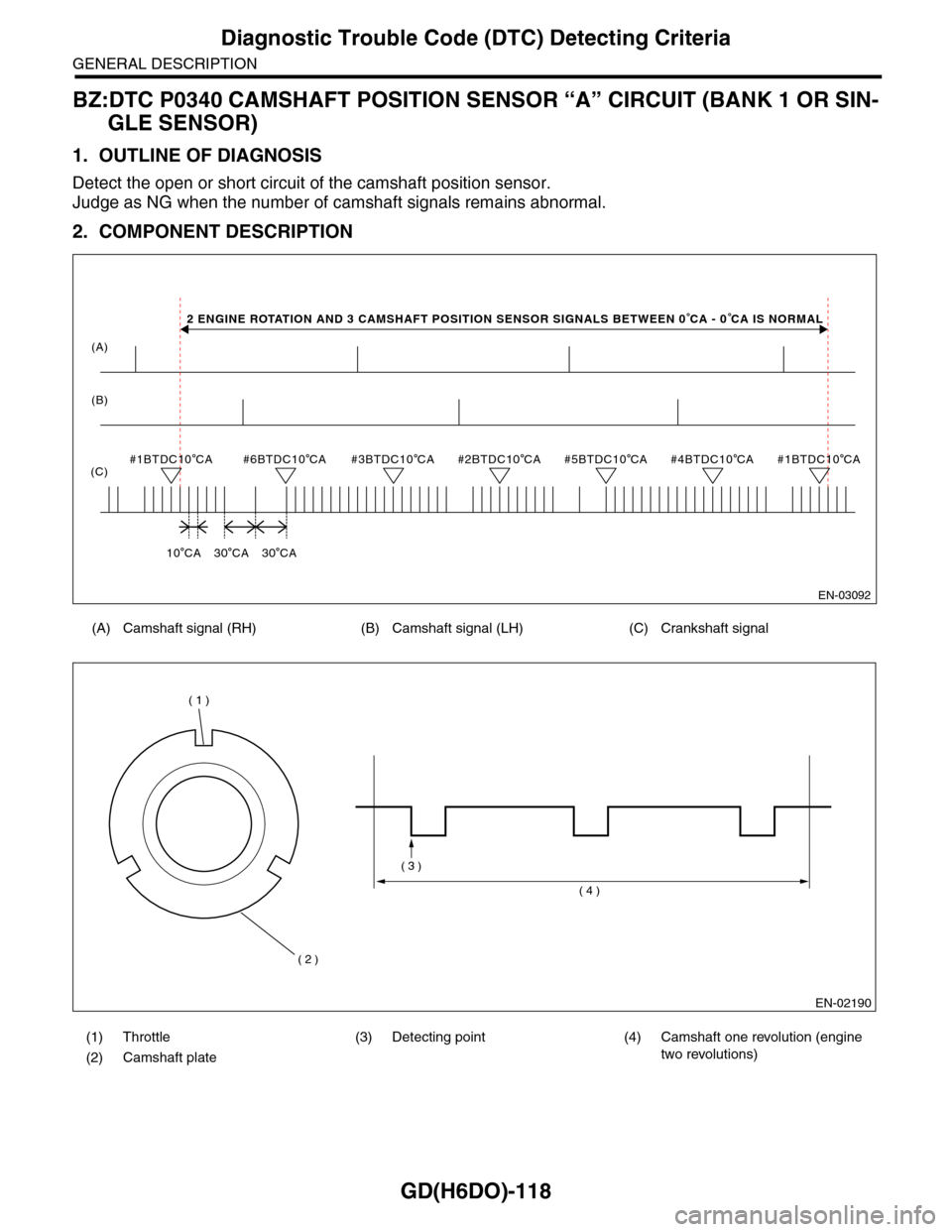

BZ:DTC P0340 CAMSHAFT POSITION SENSOR “A” CIRCUIT (BANK 1 OR SIN-

GLE SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the camshaft position sensor.

Judge as NG when the number of camshaft signals remains abnormal.

2. COMPONENT DESCRIPTION

(A) Camshaft signal (RH) (B) Camshaft signal (LH) (C) Crankshaft signal

(1) Throttle (3) Detecting point (4) Camshaft one revolution (engine

two revolutions)(2) Camshaft plate

(A)

(C)#6BTDC10 CA#3BTDC10 CA#2BTDC10 CA#5BTDC10 CA#4BTDC10 CA

10 CA30 CA30 CA

#1BTDC10 CA#1BTDC10 CA

EN-03092

(B)

2 ENGINE ROTATION AND 3 CAMSHAFT POSITION SENSOR SIGNALS BETWEEN 0 CA - 0 CA IS NORMAL

EN-02190

( 1 )

( 2 )

( 3 )

( 4 )