Ecm SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 517 of 2453

LAN(diag)-61

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

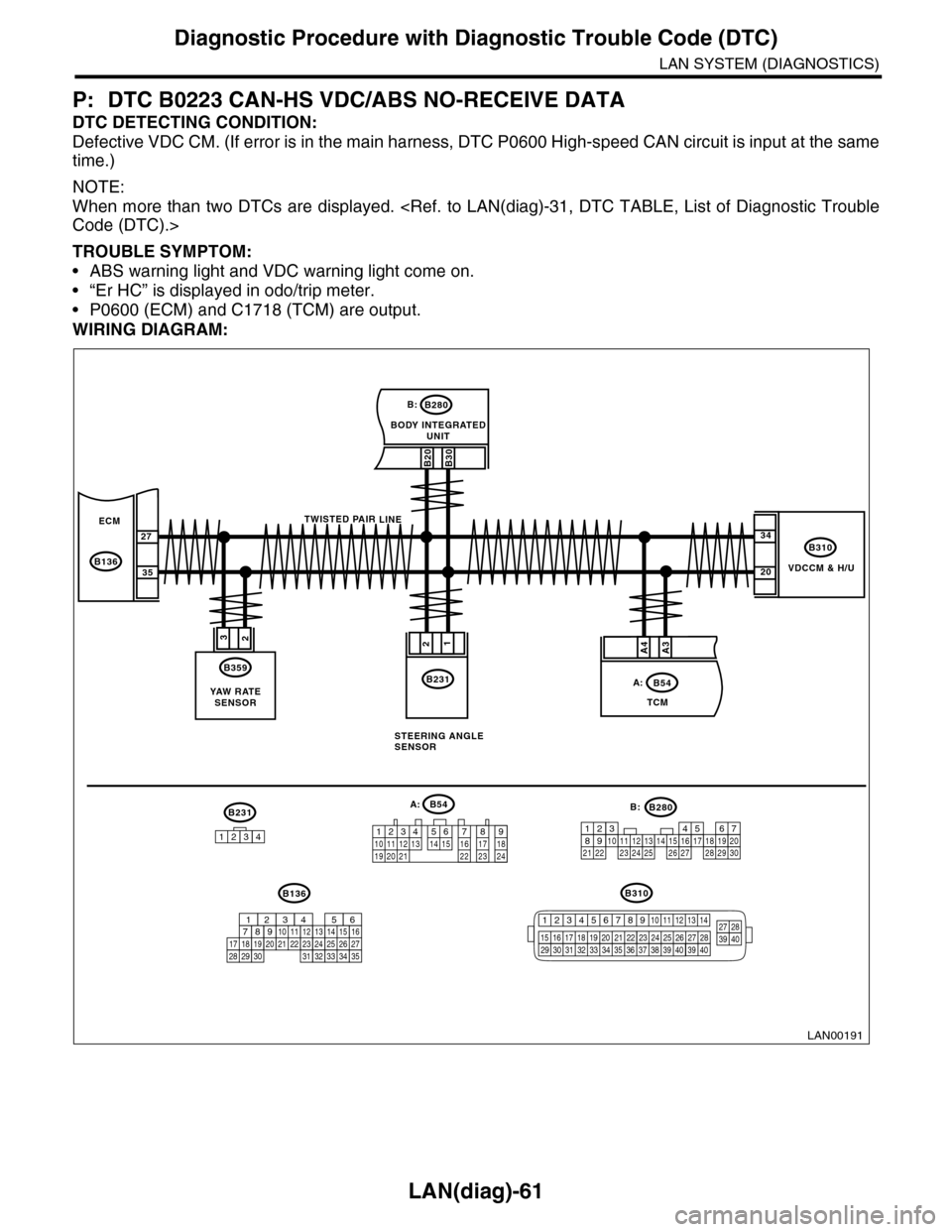

P: DTC B0223 CAN-HS VDC/ABS NO-RECEIVE DATA

DTC DETECTING CONDITION:

Defective VDC CM. (If error is in the main harness, DTC P0600 High-speed CAN circuit is input at the same

time.)

NOTE:

When more than two DTCs are displayed.

TROUBLE SYMPTOM:

•ABS warning light and VDC warning light come on.

•“Er HC” is displayed in odo/trip meter.

•P0600 (ECM) and C1718 (TCM) are output.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Page 522 of 2453

LAN(diag)-66

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

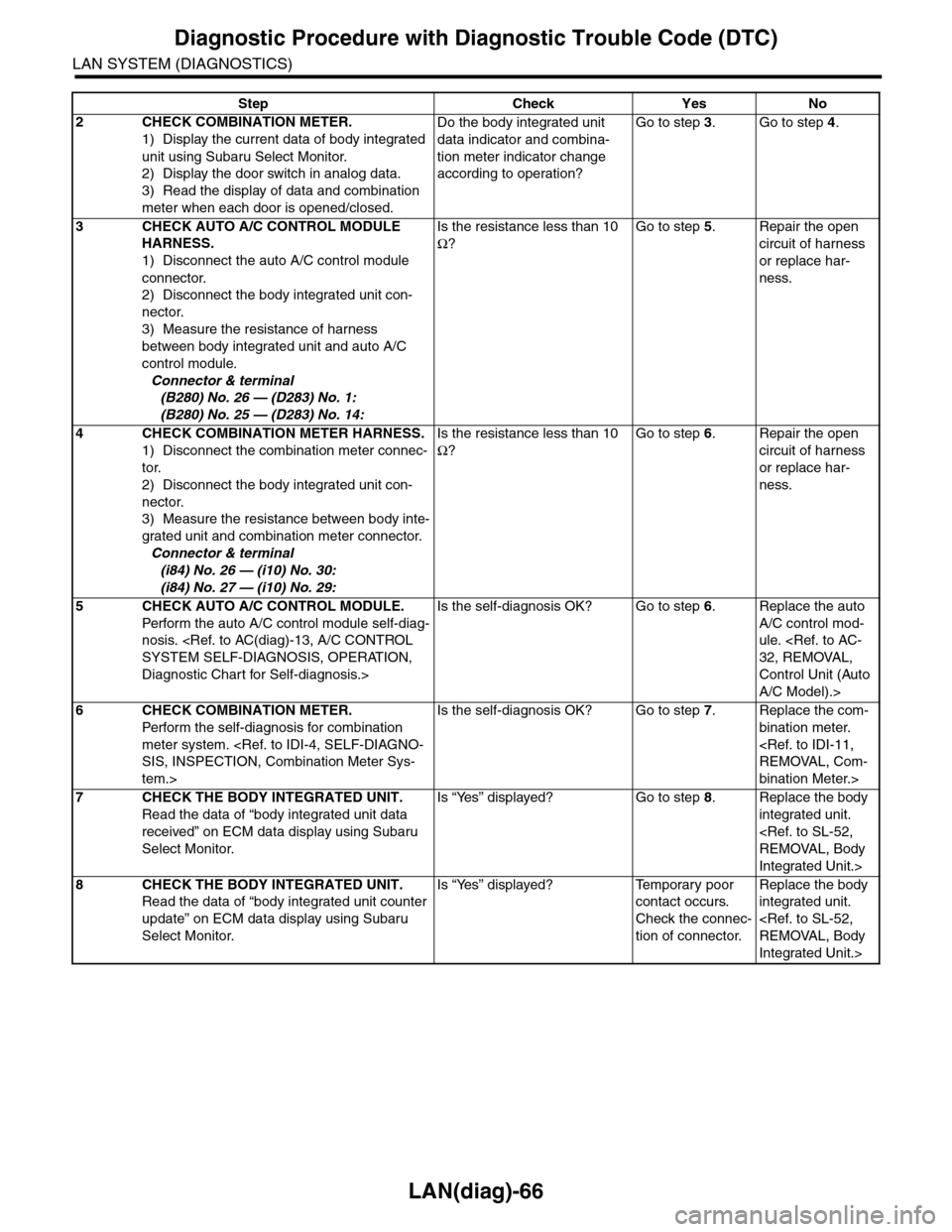

2CHECK COMBINATION METER.

1) Display the current data of body integrated

unit using Subaru Select Monitor.

2) Display the door switch in analog data.

3) Read the display of data and combination

meter when each door is opened/closed.

Do the body integrated unit

data indicator and combina-

tion meter indicator change

according to operation?

Go to step 3.Go to step 4.

3CHECK AUTO A/C CONTROL MODULE

HARNESS.

1) Disconnect the auto A/C control module

connector.

2) Disconnect the body integrated unit con-

nector.

3) Measure the resistance of harness

between body integrated unit and auto A/C

control module.

Connector & terminal

(B280) No. 26 — (D283) No. 1:

(B280) No. 25 — (D283) No. 14:

Is the resistance less than 10

Ω?

Go to step 5.Repair the open

circuit of harness

or replace har-

ness.

4CHECK COMBINATION METER HARNESS.

1) Disconnect the combination meter connec-

tor.

2) Disconnect the body integrated unit con-

nector.

3) Measure the resistance between body inte-

grated unit and combination meter connector.

Connector & terminal

(i84) No. 26 — (i10) No. 30:

(i84) No. 27 — (i10) No. 29:

Is the resistance less than 10

Ω?

Go to step 6.Repair the open

circuit of harness

or replace har-

ness.

5CHECK AUTO A/C CONTROL MODULE.

Perfor m the auto A/C control module self-diag-

nosis.

Diagnostic Chart for Self-diagnosis.>

Is the self-diagnosis OK? Go to step 6.Replace the auto

A/C control mod-

ule.

Control Unit (Auto

A/C Model).>

6CHECK COMBINATION METER.

Perfor m the self-diagnosis for combination

meter system.

tem.>

Is the self-diagnosis OK? Go to step 7.Replace the com-

bination meter.

bination Meter.>

7CHECK THE BODY INTEGRATED UNIT.

Read the data of “body integrated unit data

received” on ECM data display using Subaru

Select Monitor.

Is “Yes” displayed? Go to step 8.Replace the body

integrated unit.

Integrated Unit.>

8CHECK THE BODY INTEGRATED UNIT.

Read the data of “body integrated unit counter

update” on ECM data display using Subaru

Select Monitor.

Is “Yes” displayed? Temporary poor

contact occurs.

Check the connec-

tion of connector.

Replace the body

integrated unit.

Integrated Unit.>

Step Check Yes No

Page 524 of 2453

LAN(diag)-68

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

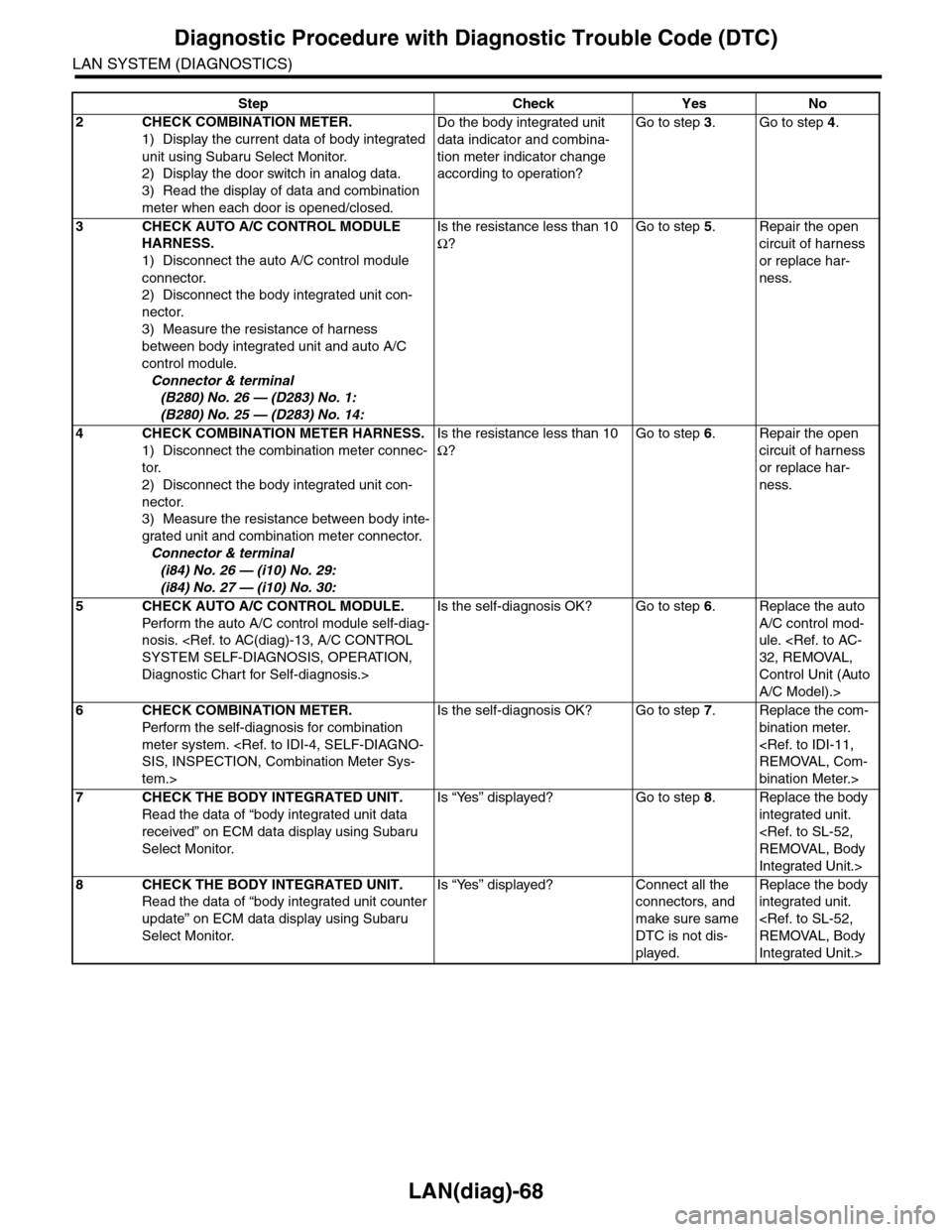

2CHECK COMBINATION METER.

1) Display the current data of body integrated

unit using Subaru Select Monitor.

2) Display the door switch in analog data.

3) Read the display of data and combination

meter when each door is opened/closed.

Do the body integrated unit

data indicator and combina-

tion meter indicator change

according to operation?

Go to step 3.Go to step 4.

3CHECK AUTO A/C CONTROL MODULE

HARNESS.

1) Disconnect the auto A/C control module

connector.

2) Disconnect the body integrated unit con-

nector.

3) Measure the resistance of harness

between body integrated unit and auto A/C

control module.

Connector & terminal

(B280) No. 26 — (D283) No. 1:

(B280) No. 25 — (D283) No. 14:

Is the resistance less than 10

Ω?

Go to step 5.Repair the open

circuit of harness

or replace har-

ness.

4CHECK COMBINATION METER HARNESS.

1) Disconnect the combination meter connec-

tor.

2) Disconnect the body integrated unit con-

nector.

3) Measure the resistance between body inte-

grated unit and combination meter connector.

Connector & terminal

(i84) No. 26 — (i10) No. 29:

(i84) No. 27 — (i10) No. 30:

Is the resistance less than 10

Ω?

Go to step 6.Repair the open

circuit of harness

or replace har-

ness.

5CHECK AUTO A/C CONTROL MODULE.

Perfor m the auto A/C control module self-diag-

nosis.

Diagnostic Chart for Self-diagnosis.>

Is the self-diagnosis OK? Go to step 6.Replace the auto

A/C control mod-

ule.

Control Unit (Auto

A/C Model).>

6CHECK COMBINATION METER.

Perfor m the self-diagnosis for combination

meter system.

tem.>

Is the self-diagnosis OK? Go to step 7.Replace the com-

bination meter.

bination Meter.>

7CHECK THE BODY INTEGRATED UNIT.

Read the data of “body integrated unit data

received” on ECM data display using Subaru

Select Monitor.

Is “Yes” displayed? Go to step 8.Replace the body

integrated unit.

Integrated Unit.>

8CHECK THE BODY INTEGRATED UNIT.

Read the data of “body integrated unit counter

update” on ECM data display using Subaru

Select Monitor.

Is “Yes” displayed? Connect all the

connectors, and

make sure same

DTC is not dis-

played.

Replace the body

integrated unit.

Integrated Unit.>

Step Check Yes No

Page 532 of 2453

LAN(diag)-76

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

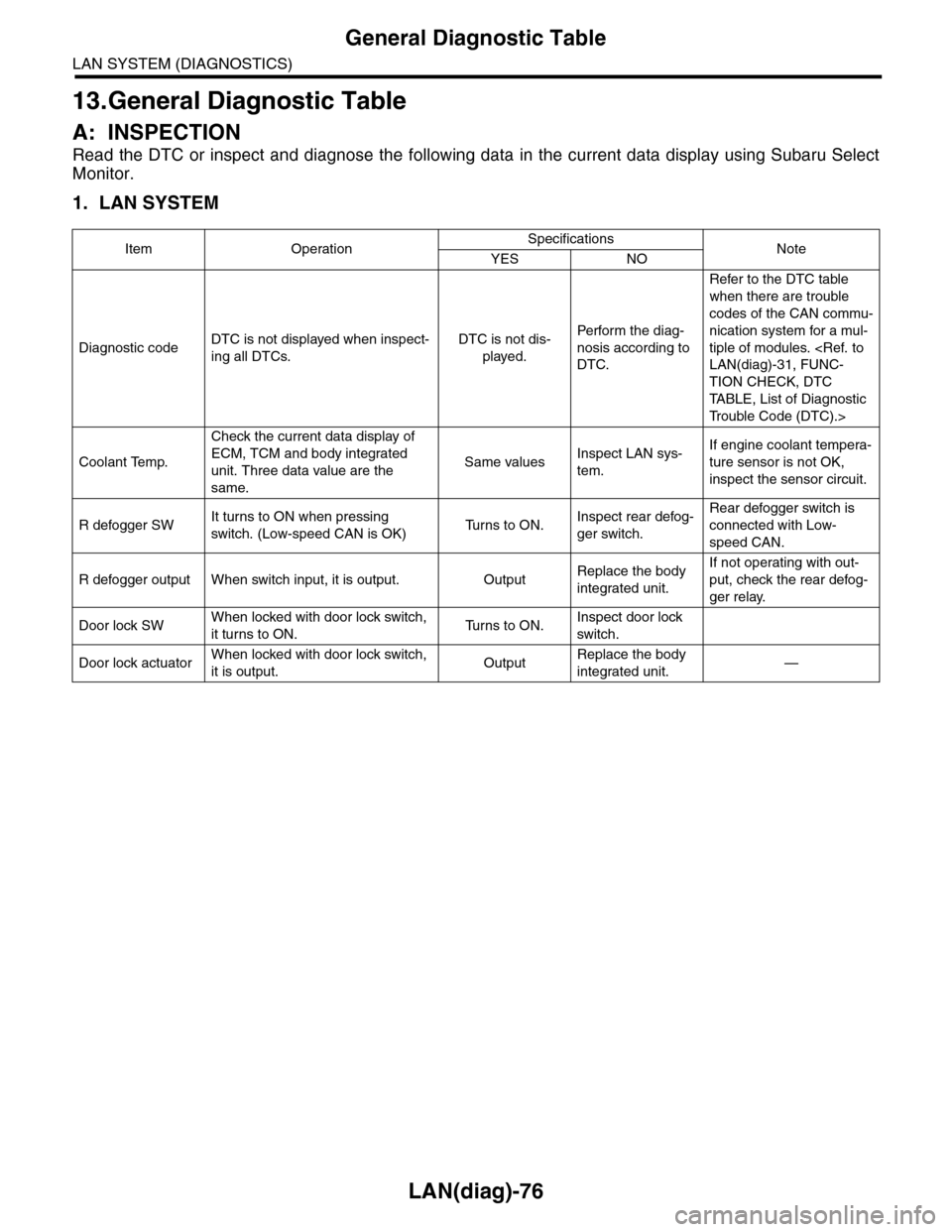

13.General Diagnostic Table

A: INSPECTION

Read the DTC or inspect and diagnose the following data in the current data display using Subaru Select

Monitor.

1. LAN SYSTEM

Item OperationSpecificationsNoteYES NO

Diagnostic codeDTC is not displayed when inspect-

ing all DTCs.

DTC is not dis-

played.

Perfor m the diag-

nosis according to

DTC.

Refer to the DTC table

when there are trouble

codes of the CAN commu-

nication system for a mul-

tiple of modules.

TION CHECK, DTC

TA B L E , L i s t o f D i a g n o s t i c

Tr o u b l e C o d e ( D T C ) . >

Coolant Temp.

Check the current data display of

ECM, TCM and body integrated

unit. Three data value are the

same.

Same valuesInspect LAN sys-

tem.

If engine coolant tempera-

ture sensor is not OK,

inspect the sensor circuit.

R defogger SWIt turns to ON when pressing

switch. (Low-speed CAN is OK)Tu r n s t o O N .Inspect rear defog-

ger switch.

Rear defogger switch is

connected with Low-

speed CAN.

R defogger output When switch input, it is output. OutputReplace the body

integrated unit.

If not operating with out-

put, check the rear defog-

ger relay.

Door lock SWWhen locked with door lock switch,

it turns to ON.Tu r n s t o O N .Inspect door lock

switch.

Door lock actuatorWhen locked with door lock switch,

it is output.OutputReplace the body

integrated unit.—

Page 662 of 2453

SL-33

Security System

SECURITY AND LOCKS

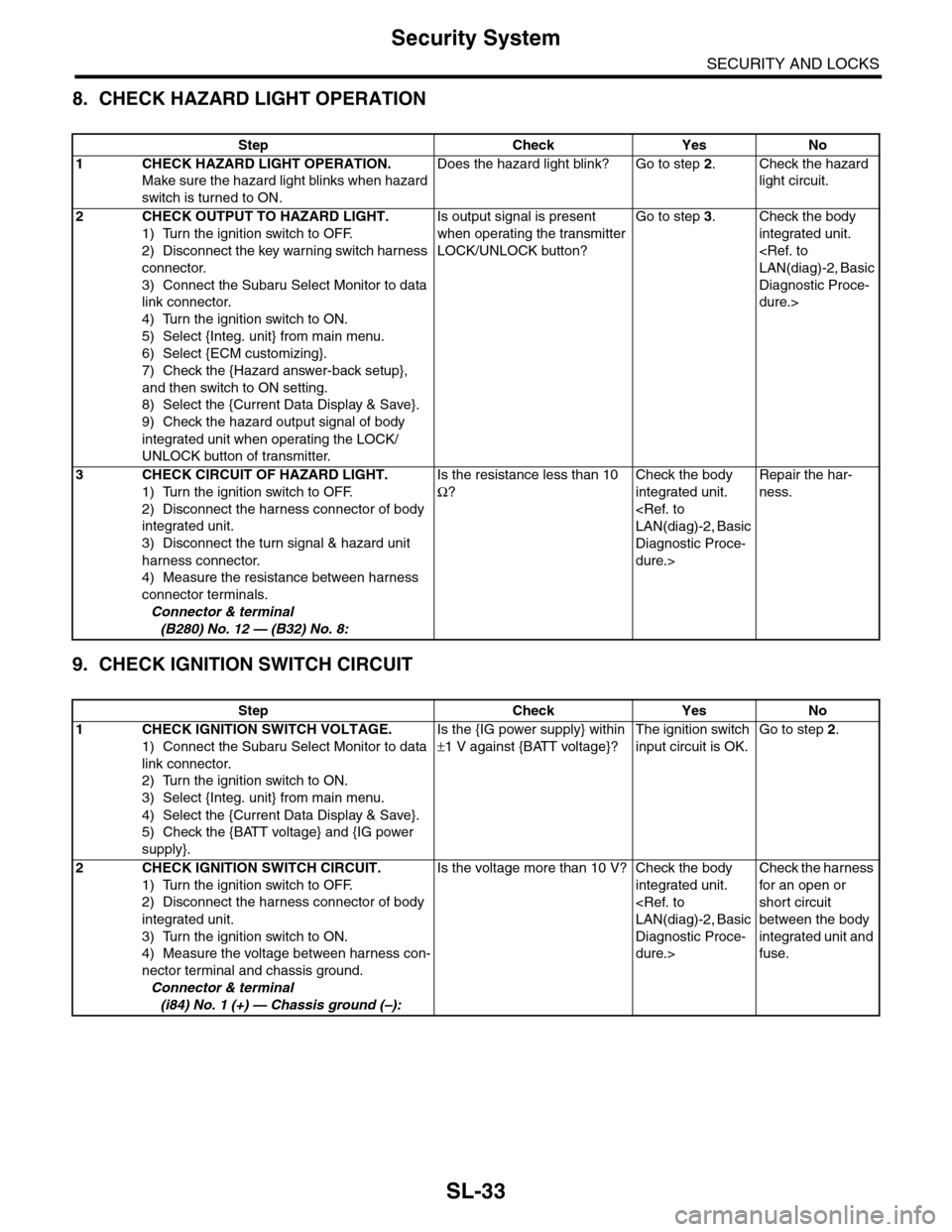

8. CHECK HAZARD LIGHT OPERATION

9. CHECK IGNITION SWITCH CIRCUIT

Step Check Yes No

1CHECK HAZARD LIGHT OPERATION.

Make sure the hazard light blinks when hazard

switch is turned to ON.

Does the hazard light blink? Go to step 2.Check the hazard

light circuit.

2CHECK OUTPUT TO HAZARD LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the key warning switch harness

connector.

3) Connect the Subaru Select Monitor to data

link connector.

4) Turn the ignition switch to ON.

5) Select {Integ. unit} from main menu.

6) Select {ECM customizing}.

7) Check the {Hazard answer-back setup},

and then switch to ON setting.

8) Select the {Current Data Display & Save}.

9) Check the hazard output signal of body

integrated unit when operating the LOCK/

UNLOCK button of transmitter.

Is output signal is present

when operating the transmitter

LOCK/UNLOCK button?

Go to step 3.Check the body

integrated unit.

Diagnostic Proce-

dure.>

3CHECK CIRCUIT OF HAZARD LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector of body

integrated unit.

3) Disconnect the turn signal & hazard unit

harness connector.

4) Measure the resistance between harness

connector terminals.

Connector & terminal

(B280) No. 12 — (B32) No. 8:

Is the resistance less than 10

Ω?

Check the body

integrated unit.

Diagnostic Proce-

dure.>

Repair the har-

ness.

Step Check Yes No

1CHECK IGNITION SWITCH VOLTAGE.

1) Connect the Subaru Select Monitor to data

link connector.

2) Turn the ignition switch to ON.

3) Select {Integ. unit} from main menu.

4) Select the {Current Data Display & Save}.

5) Check the {BATT voltage} and {IG power

supply}.

Is the {IG power supply} within

±1 V against {BATT voltage}?

The ignition switch

input circuit is OK.

Go to step 2.

2 CHECK IGNITION SWITCH CIRCUIT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector of body

integrated unit.

3) Turn the ignition switch to ON.

4) Measure the voltage between harness con-

nector terminal and chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Check the body

integrated unit.

Diagnostic Proce-

dure.>

Check the harness

for an open or

short circuit

between the body

integrated unit and

fuse.

Page 757 of 2453

BVC(diag)-2

Basic Diagnostic Procedure

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

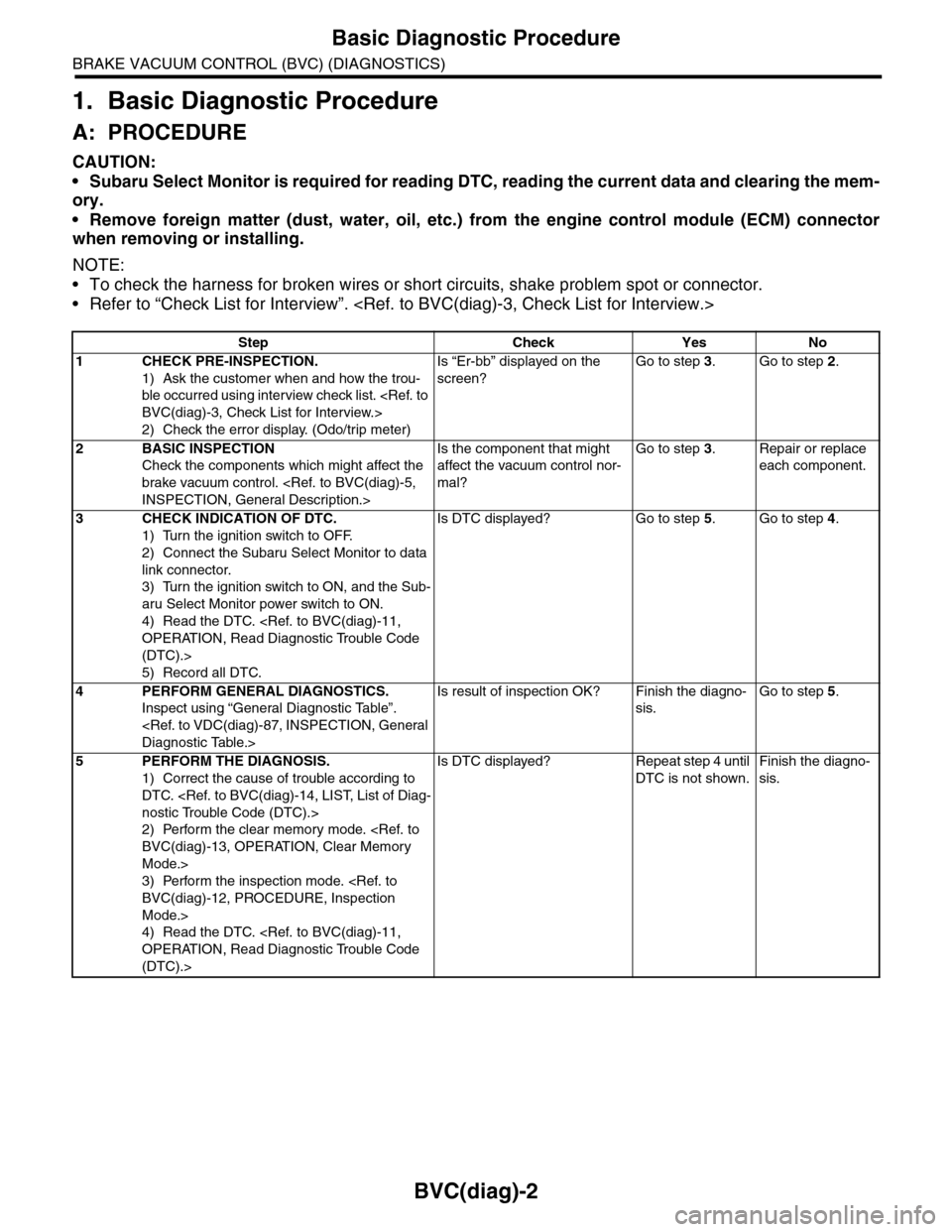

1. Basic Diagnostic Procedure

A: PROCEDURE

CAUTION:

•Subaru Select Monitor is required for reading DTC, reading the current data and clearing the mem-

ory.

•Remove foreign matter (dust, water, oil, etc.) from the engine control module (ECM) connector

when removing or installing.

NOTE:

•To check the harness for broken wires or short circuits, shake problem spot or connector.

•Refer to “Check List for Interview”.

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using interview check list.

2) Check the error display. (Odo/trip meter)

Is “Er-bb” displayed on the

screen?

Go to step 3.Go to step 2.

2BASIC INSPECTION

Check the components which might affect the

brake vacuum control.

Is the component that might

affect the vacuum control nor-

mal?

Go to step 3.Repair or replace

each component.

3CHECK INDICATION OF DTC.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Read the DTC.

(DTC).>

5) Record all DTC.

Is DTC displayed? Go to step 5.Go to step 4.

4PERFORM GENERAL DIAGNOSTICS.

Inspect using “General Diagnostic Table”.

Is result of inspection OK? Finish the diagno-

sis.

Go to step 5.

5PERFORM THE DIAGNOSIS.

1) Correct the cause of trouble according to

DTC.

2) Perform the clear memory mode.

Mode.>

3) Perform the inspection mode.

Mode.>

4) Read the DTC.

(DTC).>

Is DTC displayed? Repeat step 4 until

DTC is not shown.

Finish the diagno-

sis.

Page 761 of 2453

BVC(diag)-6

Electrical Component Location

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

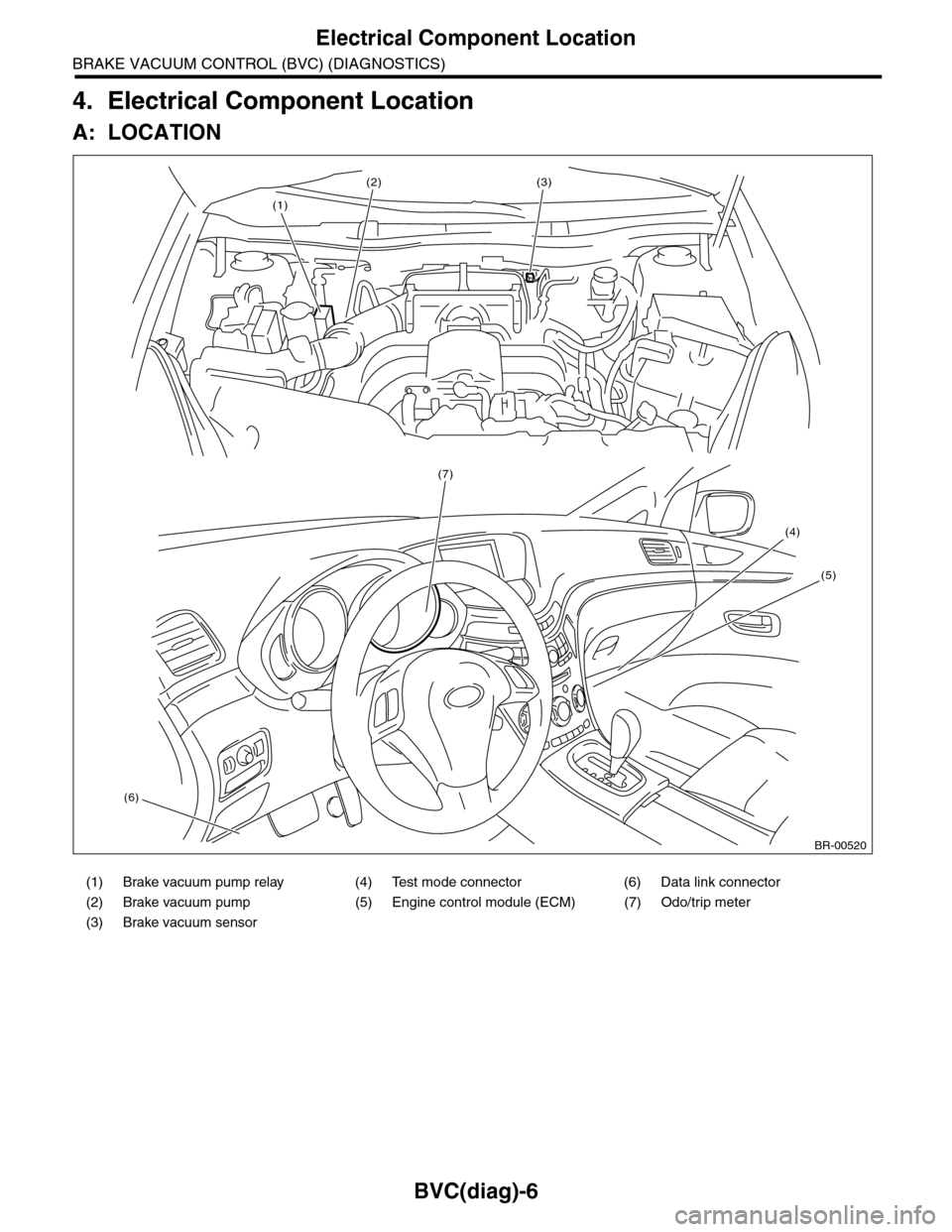

4. Electrical Component Location

A: LOCATION

(1) Brake vacuum pump relay (4) Test mode connector (6) Data link connector

(2) Brake vacuum pump (5) Engine control module (ECM) (7) Odo/trip meter

(3) Brake vacuum sensor

BR-00520

(1)

(2)(3)

(7)

(4)

(5)

(6)

Page 763 of 2453

BVC(diag)-8

Engine Control Module (ECM) I/O Signal

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

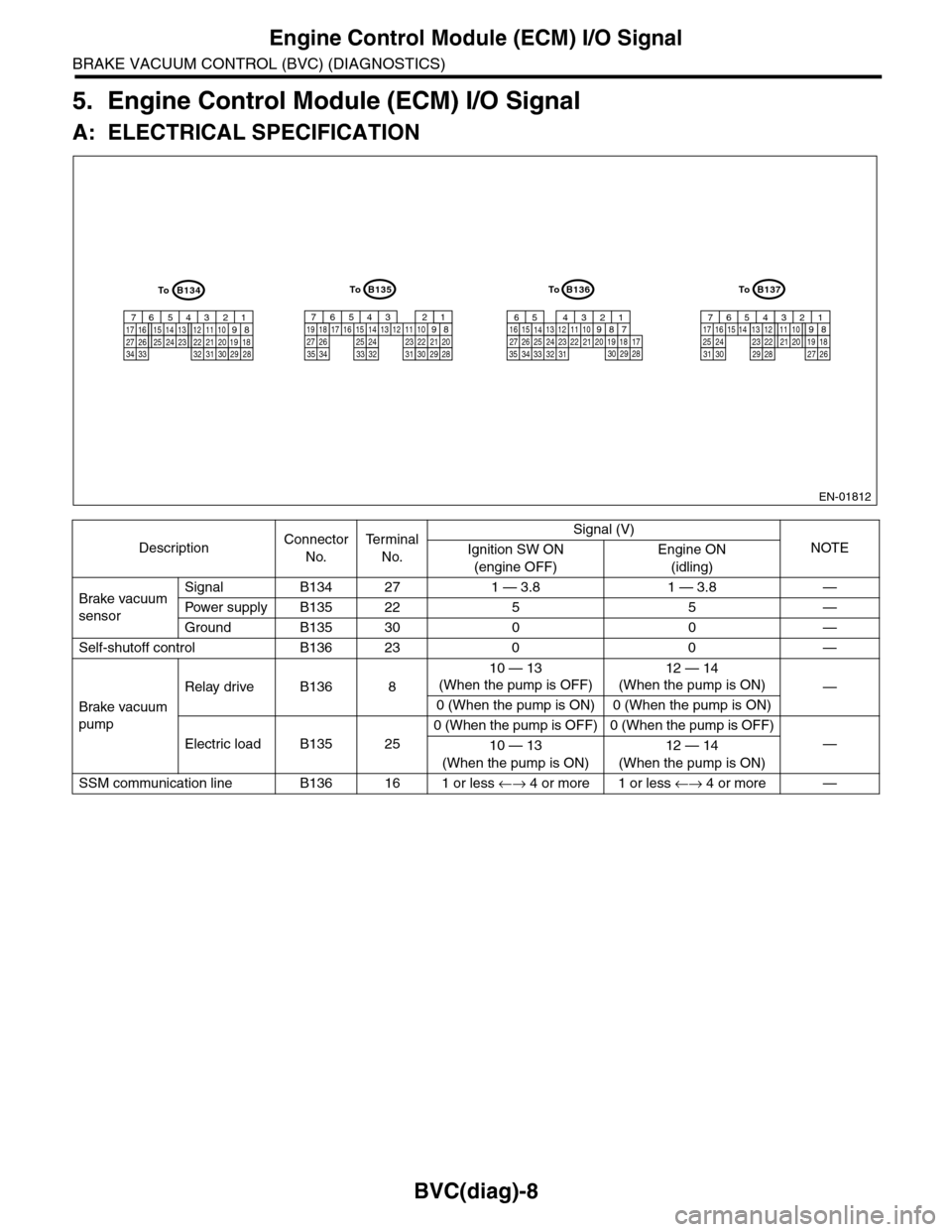

5. Engine Control Module (ECM) I/O Signal

A: ELECTRICAL SPECIFICATION

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

NOTEIgnition SW ON

(engine OFF)

Engine ON

(idling)

Brake vacuum

sensor

Signal B134 27 1 — 3.8 1 — 3.8 —

Pow er s up pl y B 1 35 2 2 5 5 —

Ground B135 30 0 0 —

Self-shutoff control B136 23 0 0 —

Brake vacuum

pump

Relay drive B136 8

10 — 13

(When the pump is OFF)

12 — 14

(When the pump is ON)—

0 (When the pump is ON) 0 (When the pump is ON)

Electric load B135 25

0 (When the pump is OFF) 0 (When the pump is OFF)

—10 — 13

(When the pump is ON)

12 — 14

(When the pump is ON)

SSM communication line B136 16 1 or less ←→ 4 or more 1 or less ←→ 4 or more —

EN-01812

B134

5678219431024 2223251112131415262728

1617181920213334 2932 3031

B136

5678219431024 2223251112131415262728

16171819202133342932303135

B135

5678219431024 2223251112131415262728

16171819202129303132333435

B137

5678219431022231112131415242526

1617181920212728293031

ToToToTo

Page 770 of 2453

BVC(diag)-15

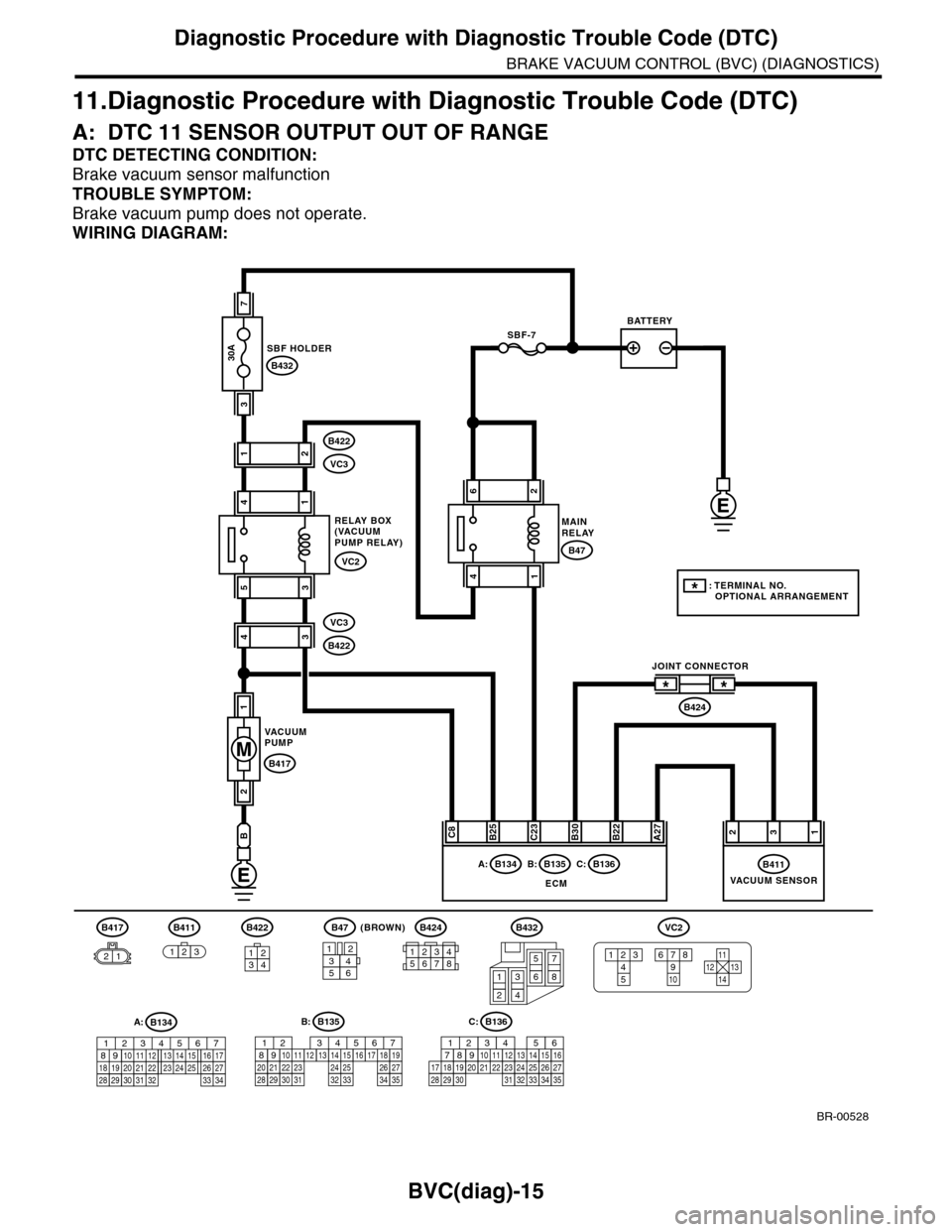

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

11.Diagnostic Procedure with Diagnostic Trouble Code (DTC)

A: DTC 11 SENSOR OUTPUT OUT OF RANGE

DTC DETECTING CONDITION:

Brake vacuum sensor malfunction

TROUBLE SYMPTOM:

Brake vacuum pump does not operate.

WIRING DIAGRAM:

BR-00528

2

1

B25B

B422

1234

B432

2

1

4

36

5

8

7

B432

SBF HOLDER

3

7

14

21

53

43

VC2

VC3

B422

B422

VC3

RELAY BOX(VACUUMPUMP RELAY)

B417

VAC U U MPUMP

26

41

B47

MAINRELAY

B411

VAC U U M S E N S O RECM

A: B134B: B135C: B136

C23B30B22A27C8312

JOINT CONNECTOR

B424

**

B417B411

213

B: C:B135

5672134

29

101112131415252416

30

98171819202821222332312627333435

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

VC2

A:B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

B424

34561278

(BROWN)

21

5436

B47

* : TERMINAL NO. OPTIONAL ARRANGEMENT

21

SBF-7BATTERY

30A

3412

5

8967

10131211

14

Page 771 of 2453

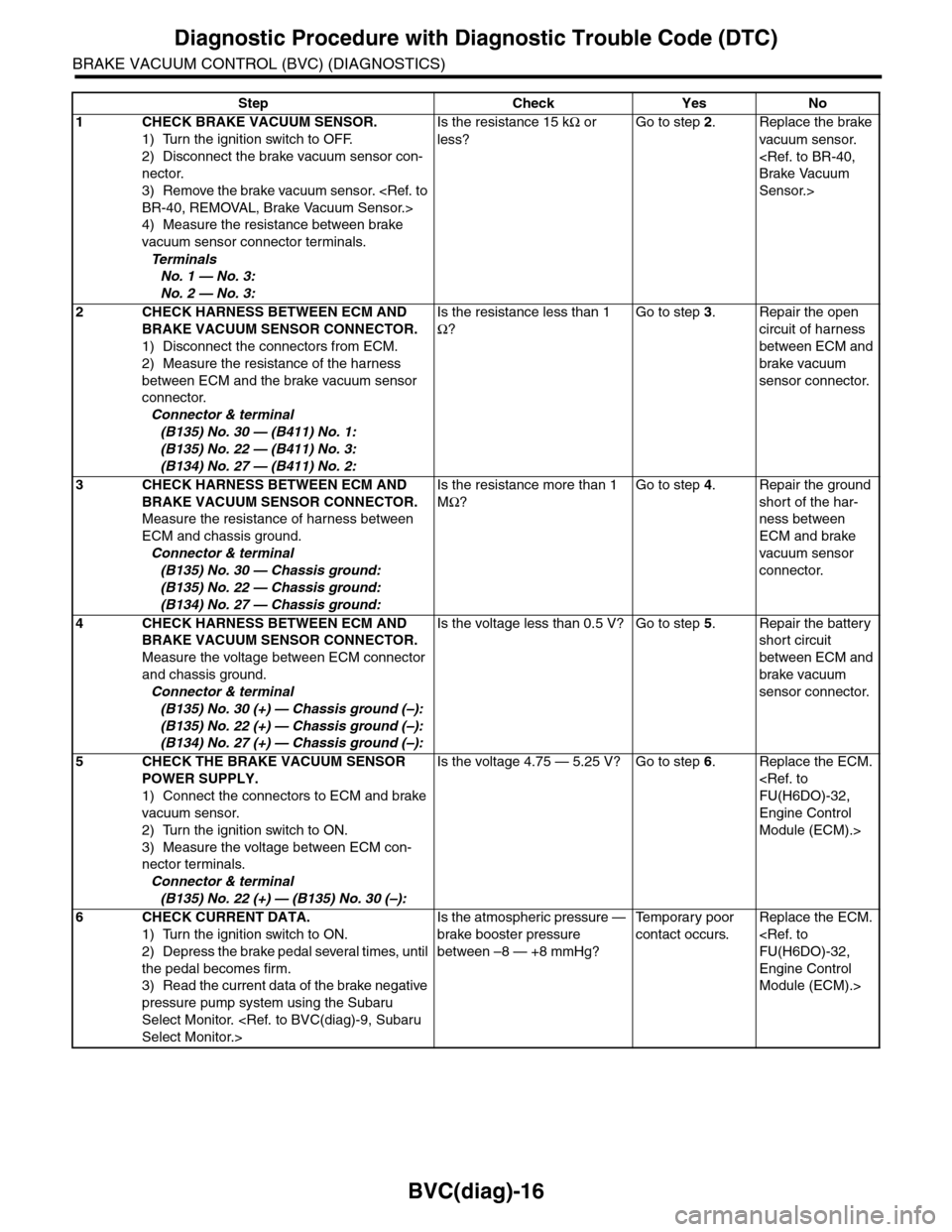

BVC(diag)-16

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

Step Check Yes No

1CHECK BRAKE VACUUM SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the brake vacuum sensor con-

nector.

3) Remove the brake vacuum sensor.

4) Measure the resistance between brake

vacuum sensor connector terminals.

Te r m i n a l s

No. 1 — No. 3:

No. 2 — No. 3:

Is the resistance 15 kΩ or

less?

Go to step 2.Replace the brake

vacuum sensor.

Sensor.>

2CHECK HARNESS BETWEEN ECM AND

BRAKE VACUUM SENSOR CONNECTOR.

1) Disconnect the connectors from ECM.

2) Measure the resistance of the harness

between ECM and the brake vacuum sensor

connector.

Connector & terminal

(B135) No. 30 — (B411) No. 1:

(B135) No. 22 — (B411) No. 3:

(B134) No. 27 — (B411) No. 2:

Is the resistance less than 1

Ω?

Go to step 3.Repair the open

circuit of harness

between ECM and

brake vacuum

sensor connector.

3CHECK HARNESS BETWEEN ECM AND

BRAKE VACUUM SENSOR CONNECTOR.

Measure the resistance of harness between

ECM and chassis ground.

Connector & terminal

(B135) No. 30 — Chassis ground:

(B135) No. 22 — Chassis ground:

(B134) No. 27 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 4.Repair the ground

short of the har-

ness between

ECM and brake

vacuum sensor

connector.

4CHECK HARNESS BETWEEN ECM AND

BRAKE VACUUM SENSOR CONNECTOR.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 30 (+) — Chassis ground (–):

(B135) No. 22 (+) — Chassis ground (–):

(B134) No. 27 (+) — Chassis ground (–):

Is the voltage less than 0.5 V? Go to step 5.Repair the battery

short circuit

between ECM and

brake vacuum

sensor connector.

5CHECK THE BRAKE VACUUM SENSOR

POWER SUPPLY.

1) Connect the connectors to ECM and brake

vacuum sensor.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM con-

nector terminals.

Connector & terminal

(B135) No. 22 (+) — (B135) No. 30 (–):

Is the voltage 4.75 — 5.25 V? Go to step 6.Replace the ECM.

Engine Control

Module (ECM).>

6CHECK CURRENT DATA.

1) Turn the ignition switch to ON.

2) Depress the brake pedal several times, until

the pedal becomes firm.

3) Read the current data of the brake negative

pressure pump system using the Subaru

Select Monitor.

Is the atmospheric pressure —

brake booster pressure

between –8 — +8 mmHg?

Te m p o r a r y p o o r

contact occurs.

Replace the ECM.

Engine Control

Module (ECM).>