check engine SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 673 of 2453

SL-44

Front Hood Lock Assembly

SECURITY AND LOCKS

15.Front Hood Lock Assembly

A: REMOVAL

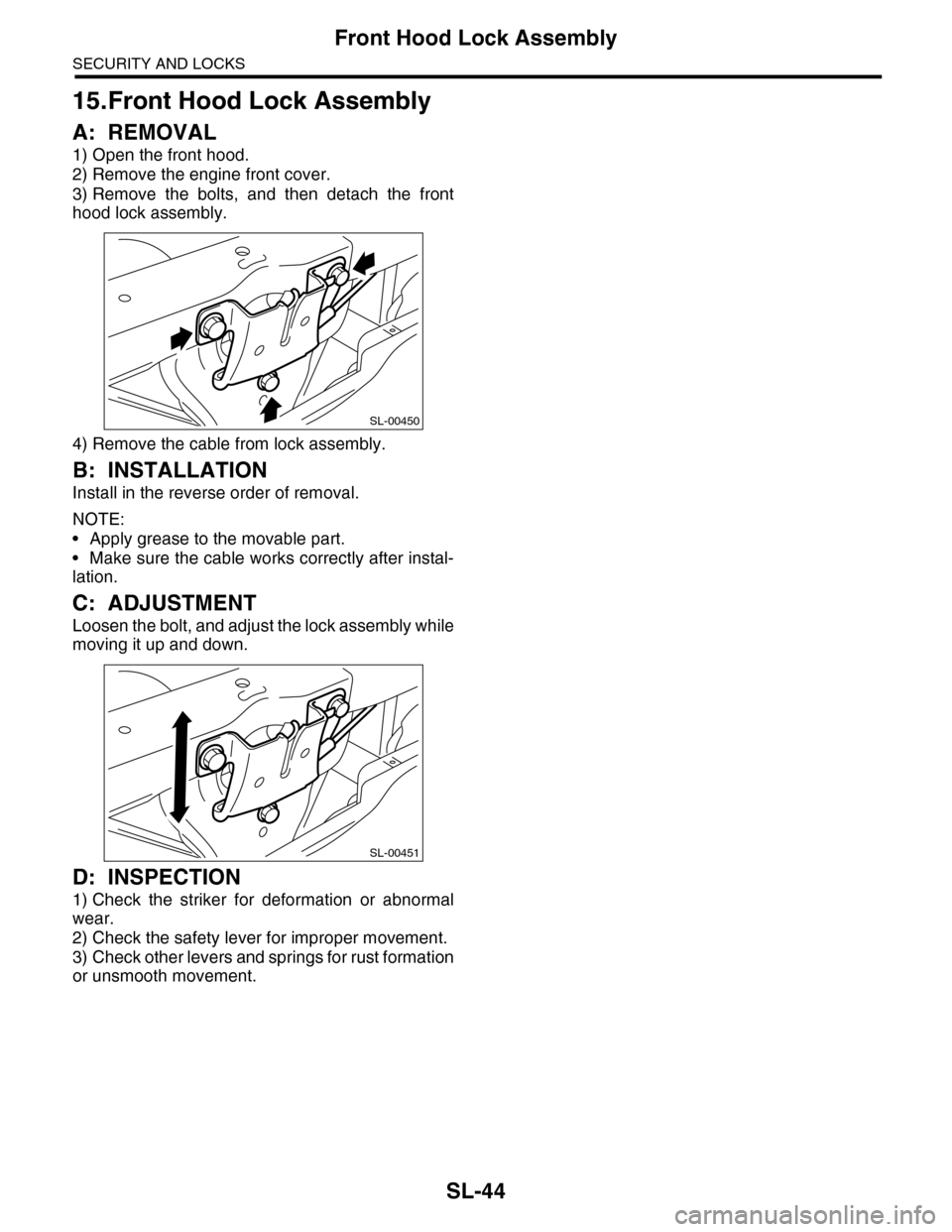

1) Open the front hood.

2) Remove the engine front cover.

3) Remove the bolts, and then detach the front

hood lock assembly.

4) Remove the cable from lock assembly.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

•Apply grease to the movable part.

•Make sure the cable works correctly after instal-

lation.

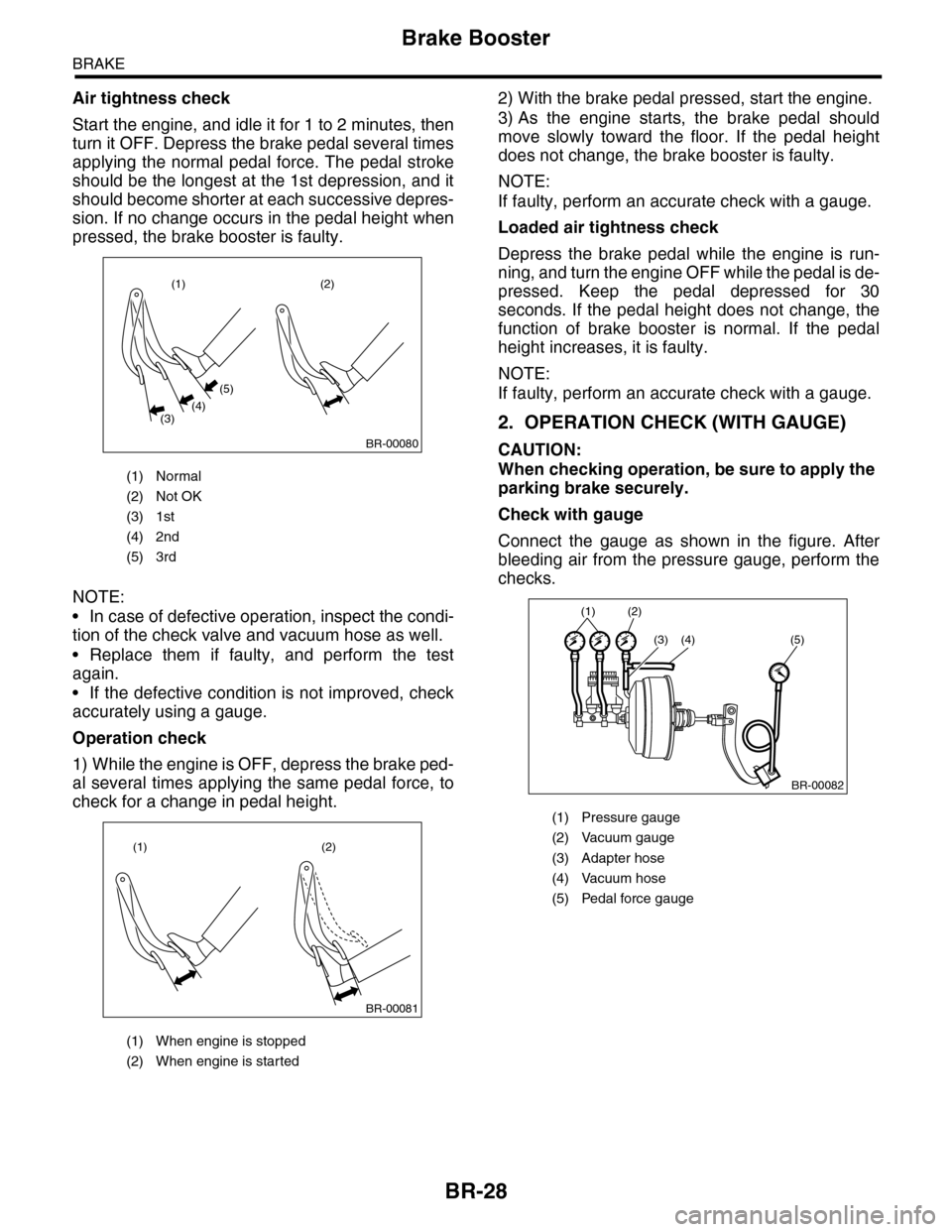

C: ADJUSTMENT

Loosen the bolt, and adjust the lock assembly while

moving it up and down.

D: INSPECTION

1) Check the striker for deformation or abnormal

wear.

2) Check the safety lever for improper movement.

3) Check other levers and springs for rust formation

or unsmooth movement.

SL-00450

SL-00451

Page 742 of 2453

BR-28

Brake Booster

BRAKE

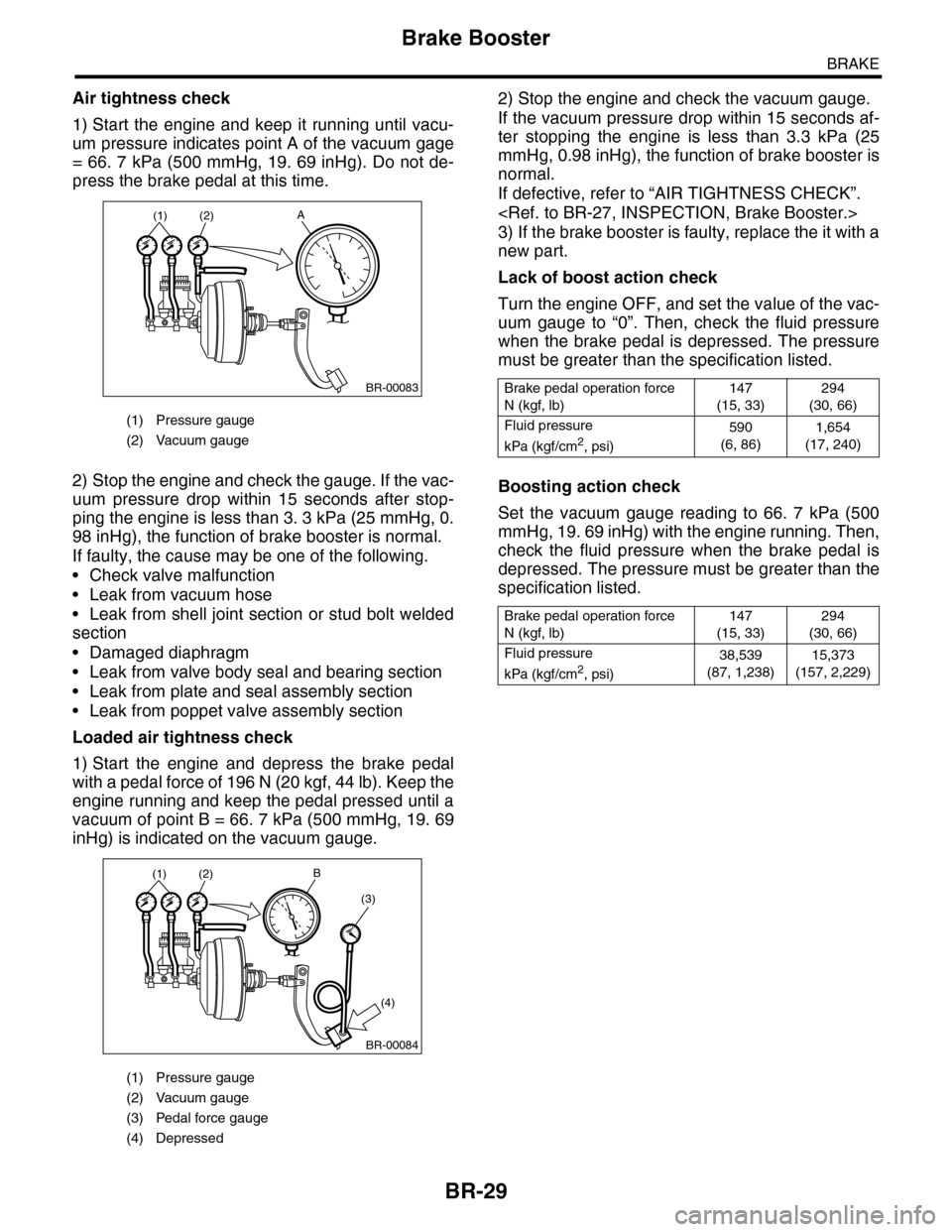

Air tightness check

Start the engine, and idle it for 1 to 2 minutes, then

turn it OFF. Depress the brake pedal several times

applying the normal pedal force. The pedal stroke

should be the longest at the 1st depression, and it

should become shorter at each successive depres-

sion. If no change occurs in the pedal height when

pressed, the brake booster is faulty.

NOTE:

•In case of defective operation, inspect the condi-

tion of the check valve and vacuum hose as well.

•Replace them if faulty, and perform the test

again.

•If the defective condition is not improved, check

accurately using a gauge.

Operation check

1) While the engine is OFF, depress the brake ped-

al several times applying the same pedal force, to

check for a change in pedal height.

2) With the brake pedal pressed, start the engine.

3) As the engine starts, the brake pedal should

move slowly toward the floor. If the pedal height

does not change, the brake booster is faulty.

NOTE:

If faulty, perform an accurate check with a gauge.

Loaded air tightness check

Depress the brake pedal while the engine is run-

ning, and turn the engine OFF while the pedal is de-

pressed. Keep the pedal depressed for 30

seconds. If the pedal height does not change, the

function of brake booster is normal. If the pedal

height increases, it is faulty.

NOTE:

If faulty, perform an accurate check with a gauge.

2. OPERATION CHECK (WITH GAUGE)

CAUTION:

When checking operation, be sure to apply the

parking brake securely.

Check with gauge

Connect the gauge as shown in the figure. After

bleeding air from the pressure gauge, perform the

checks.

(1) Normal

(2) Not OK

(3) 1st

(4) 2nd

(5) 3rd

(1) When engine is stopped

(2) When engine is started

(1)

(3)(4)

(5)

(2)

BR-00080

(1) (2)

BR-00081

(1) Pressure gauge

(2) Vacuum gauge

(3) Adapter hose

(4) Vacuum hose

(5) Pedal force gauge

(1) (2)

(3) (4) (5)

BR-00082

Page 743 of 2453

BR-29

Brake Booster

BRAKE

Air tightness check

1) Start the engine and keep it running until vacu-

um pressure indicates point A of the vacuum gage

= 66. 7 kPa (500 mmHg, 19. 69 inHg). Do not de-

press the brake pedal at this time.

2) Stop the engine and check the gauge. If the vac-

uum pressure drop within 15 seconds after stop-

ping the engine is less than 3. 3 kPa (25 mmHg, 0.

98 inHg), the function of brake booster is normal.

If faulty, the cause may be one of the following.

•Check valve malfunction

•Leak from vacuum hose

•Leak from shell joint section or stud bolt welded

section

•Damaged diaphragm

•Leak from valve body seal and bearing section

•Leak from plate and seal assembly section

•Leak from poppet valve assembly section

Loaded air tightness check

1) Start the engine and depress the brake pedal

with a pedal force of 196 N (20 kgf, 44 lb). Keep the

engine running and keep the pedal pressed until a

vacuum of point B = 66. 7 kPa (500 mmHg, 19. 69

inHg) is indicated on the vacuum gauge.

2) Stop the engine and check the vacuum gauge.

If the vacuum pressure drop within 15 seconds af-

ter stopping the engine is less than 3.3 kPa (25

mmHg, 0.98 inHg), the function of brake booster is

normal.

If defective, refer to “AIR TIGHTNESS CHECK”.

3) If the brake booster is faulty, replace the it with a

new part.

Lack of boost action check

Turn the engine OFF, and set the value of the vac-

uum gauge to “0”. Then, check the fluid pressure

when the brake pedal is depressed. The pressure

must be greater than the specification listed.

Boosting action check

Set the vacuum gauge reading to 66. 7 kPa (500

mmHg, 19. 69 inHg) with the engine running. Then,

check the fluid pressure when the brake pedal is

depressed. The pressure must be greater than the

specification listed.

(1) Pressure gauge

(2) Vacuum gauge

(1) Pressure gauge

(2) Vacuum gauge

(3) Pedal force gauge

(4) Depressed

(1) (2)A

BR-00083

B(1) (2)

(3)

(4)

BR-00084

Brake pedal operation force

N (kgf, lb)

147

(15, 33)

294

(30, 66)

Fluid pressure

kPa (kgf/cm2, psi)

590

(6, 86)

1,654

(17, 240)

Brake pedal operation force

N (kgf, lb)

147

(15, 33)

294

(30, 66)

Fluid pressure

kPa (kgf/cm2, psi)

38,539

(87, 1,238)

15,373

(157, 2,229)

Page 746 of 2453

BR-32

Air Bleeding

BRAKE

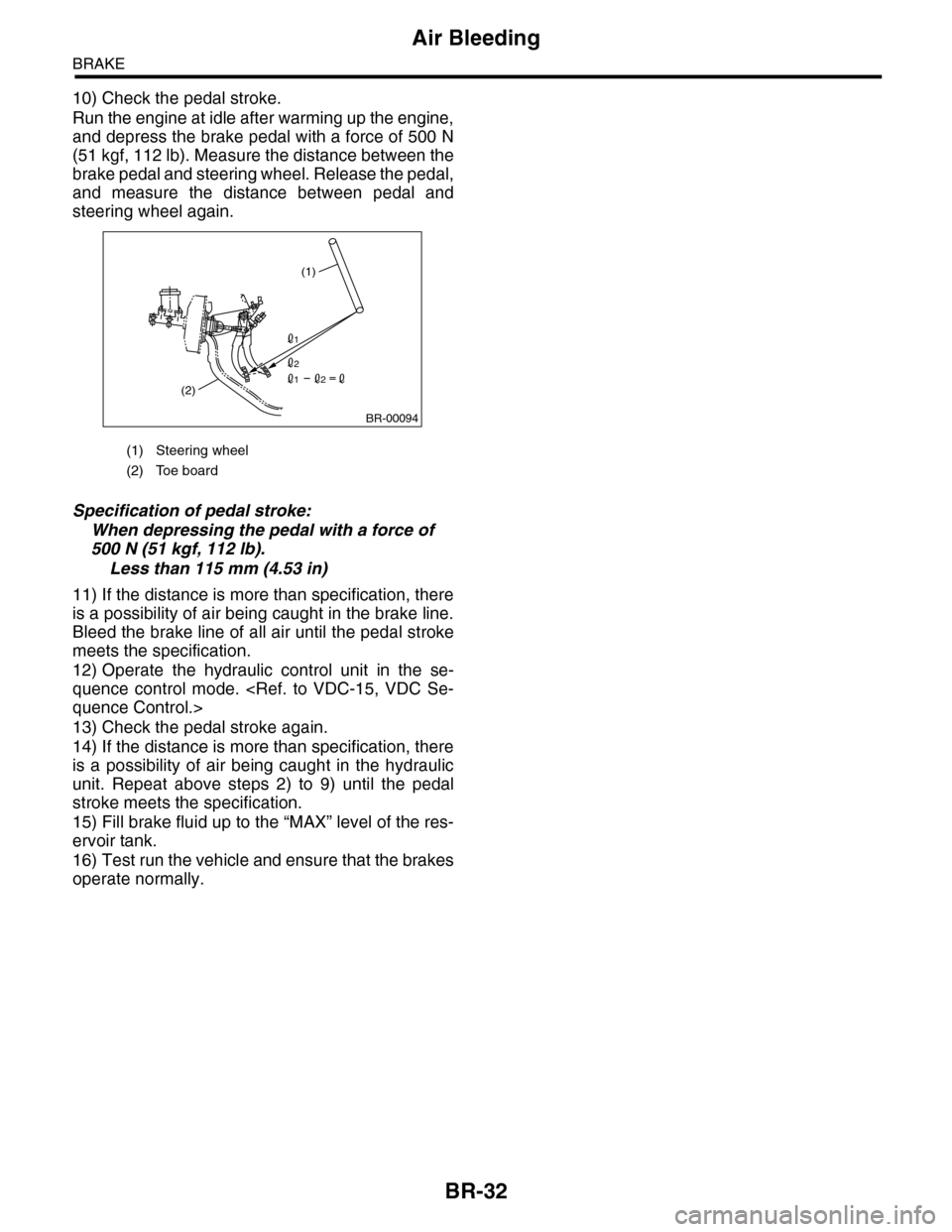

10) Check the pedal stroke.

Run the engine at idle after warming up the engine,

and depress the brake pedal with a force of 500 N

(51 kgf, 112 lb). Measure the distance between the

brake pedal and steering wheel. Release the pedal,

and measure the distance between pedal and

steering wheel again.

Specification of pedal stroke:

When depressing the pedal with a force of

500 N (51 kgf, 112 lb).

Less than 115 mm (4.53 in)

11) If the distance is more than specification, there

is a possibility of air being caught in the brake line.

Bleed the brake line of all air until the pedal stroke

meets the specification.

12) Operate the hydraulic control unit in the se-

quence control mode.

13) Check the pedal stroke again.

14) If the distance is more than specification, there

is a possibility of air being caught in the hydraulic

unit. Repeat above steps 2) to 9) until the pedal

stroke meets the specification.

15) Fill brake fluid up to the “MAX” level of the res-

ervoir tank.

16) Test run the vehicle and ensure that the brakes

operate normally.

(1) Steering wheel

(2) Toe board

(1)

(2)

BR-00094

1

2

21

Page 753 of 2453

BR-39

Brake Vacuum Pump

BRAKE

16.Brake Vacuum Pump

A: REMOVAL

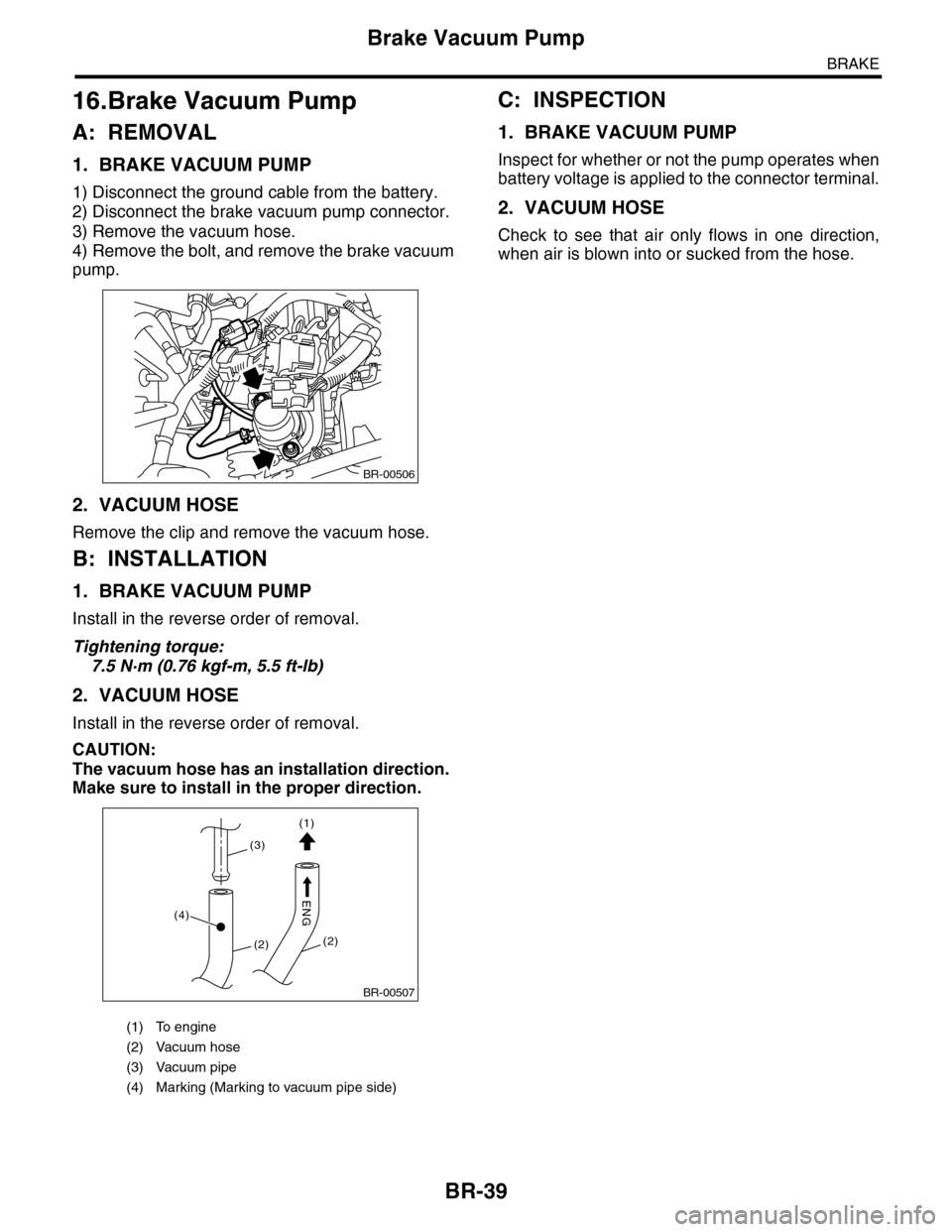

1. BRAKE VACUUM PUMP

1) Disconnect the ground cable from the battery.

2) Disconnect the brake vacuum pump connector.

3) Remove the vacuum hose.

4) Remove the bolt, and remove the brake vacuum

pump.

2. VACUUM HOSE

Remove the clip and remove the vacuum hose.

B: INSTALLATION

1. BRAKE VACUUM PUMP

Install in the reverse order of removal.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

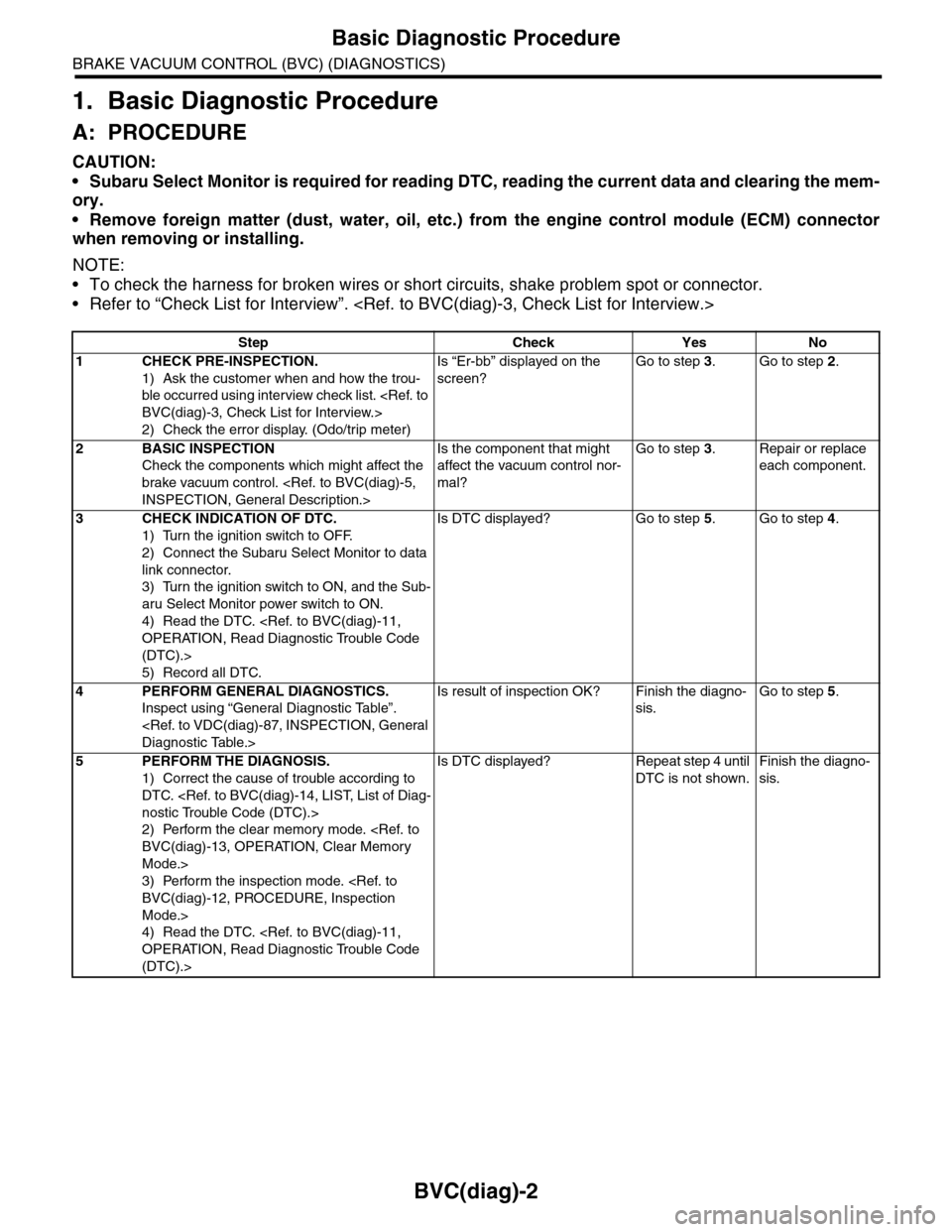

2. VACUUM HOSE

Install in the reverse order of removal.

CAUTION:

The vacuum hose has an installation direction.

Make sure to install in the proper direction.

C: INSPECTION

1. BRAKE VACUUM PUMP

Inspect for whether or not the pump operates when

battery voltage is applied to the connector terminal.

2. VACUUM HOSE

Check to see that air only flows in one direction,

when air is blown into or sucked from the hose.

(1) To engine

(2) Vacuum hose

(3) Vacuum pipe

(4) Marking (Marking to vacuum pipe side)

BR-00506

BR-00507

(1)

(2)(2)

(4)

(3)

ENG

Page 757 of 2453

BVC(diag)-2

Basic Diagnostic Procedure

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

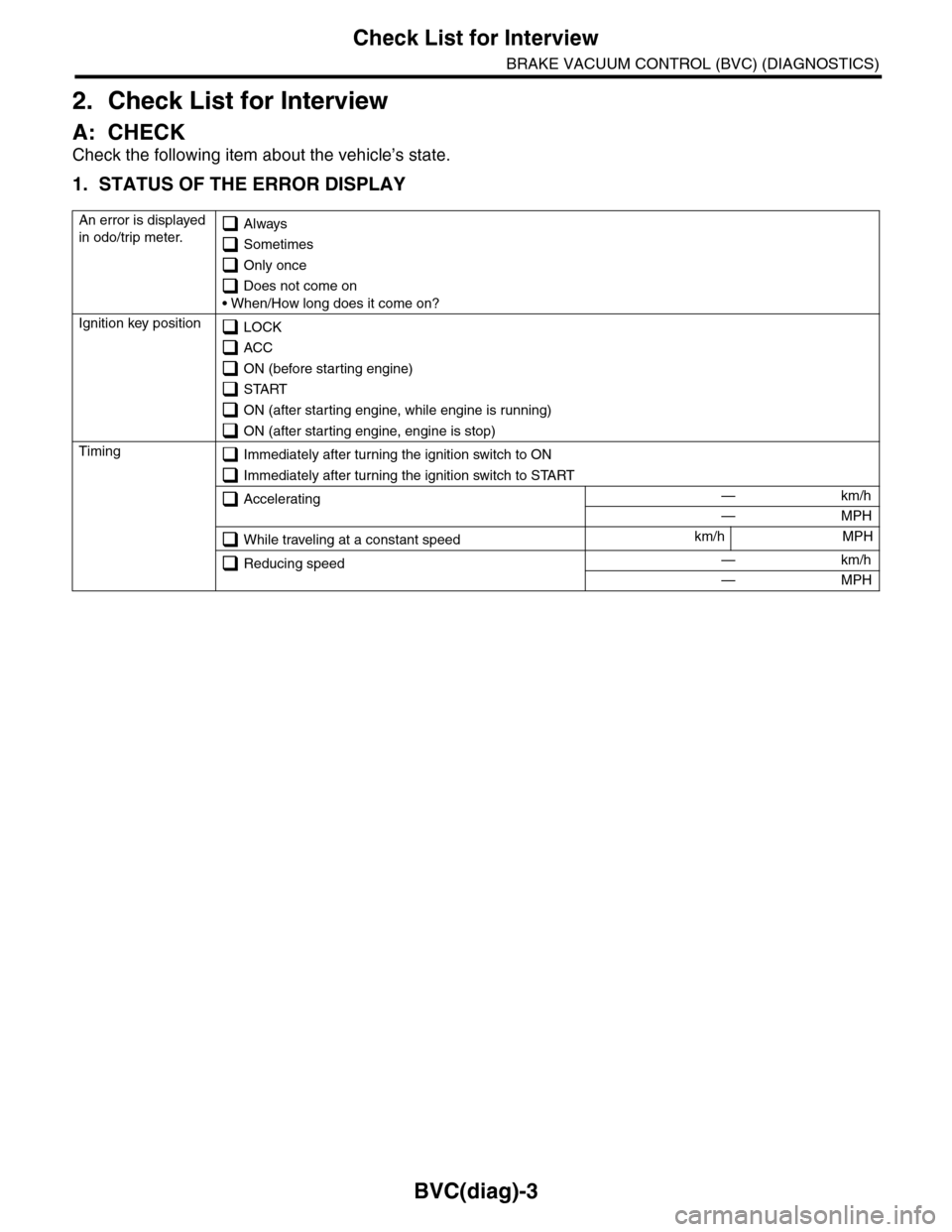

1. Basic Diagnostic Procedure

A: PROCEDURE

CAUTION:

•Subaru Select Monitor is required for reading DTC, reading the current data and clearing the mem-

ory.

•Remove foreign matter (dust, water, oil, etc.) from the engine control module (ECM) connector

when removing or installing.

NOTE:

•To check the harness for broken wires or short circuits, shake problem spot or connector.

•Refer to “Check List for Interview”.

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using interview check list.

2) Check the error display. (Odo/trip meter)

Is “Er-bb” displayed on the

screen?

Go to step 3.Go to step 2.

2BASIC INSPECTION

Check the components which might affect the

brake vacuum control.

Is the component that might

affect the vacuum control nor-

mal?

Go to step 3.Repair or replace

each component.

3CHECK INDICATION OF DTC.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Read the DTC.

(DTC).>

5) Record all DTC.

Is DTC displayed? Go to step 5.Go to step 4.

4PERFORM GENERAL DIAGNOSTICS.

Inspect using “General Diagnostic Table”.

Is result of inspection OK? Finish the diagno-

sis.

Go to step 5.

5PERFORM THE DIAGNOSIS.

1) Correct the cause of trouble according to

DTC.

2) Perform the clear memory mode.

Mode.>

3) Perform the inspection mode.

Mode.>

4) Read the DTC.

(DTC).>

Is DTC displayed? Repeat step 4 until

DTC is not shown.

Finish the diagno-

sis.

Page 758 of 2453

BVC(diag)-3

Check List for Interview

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

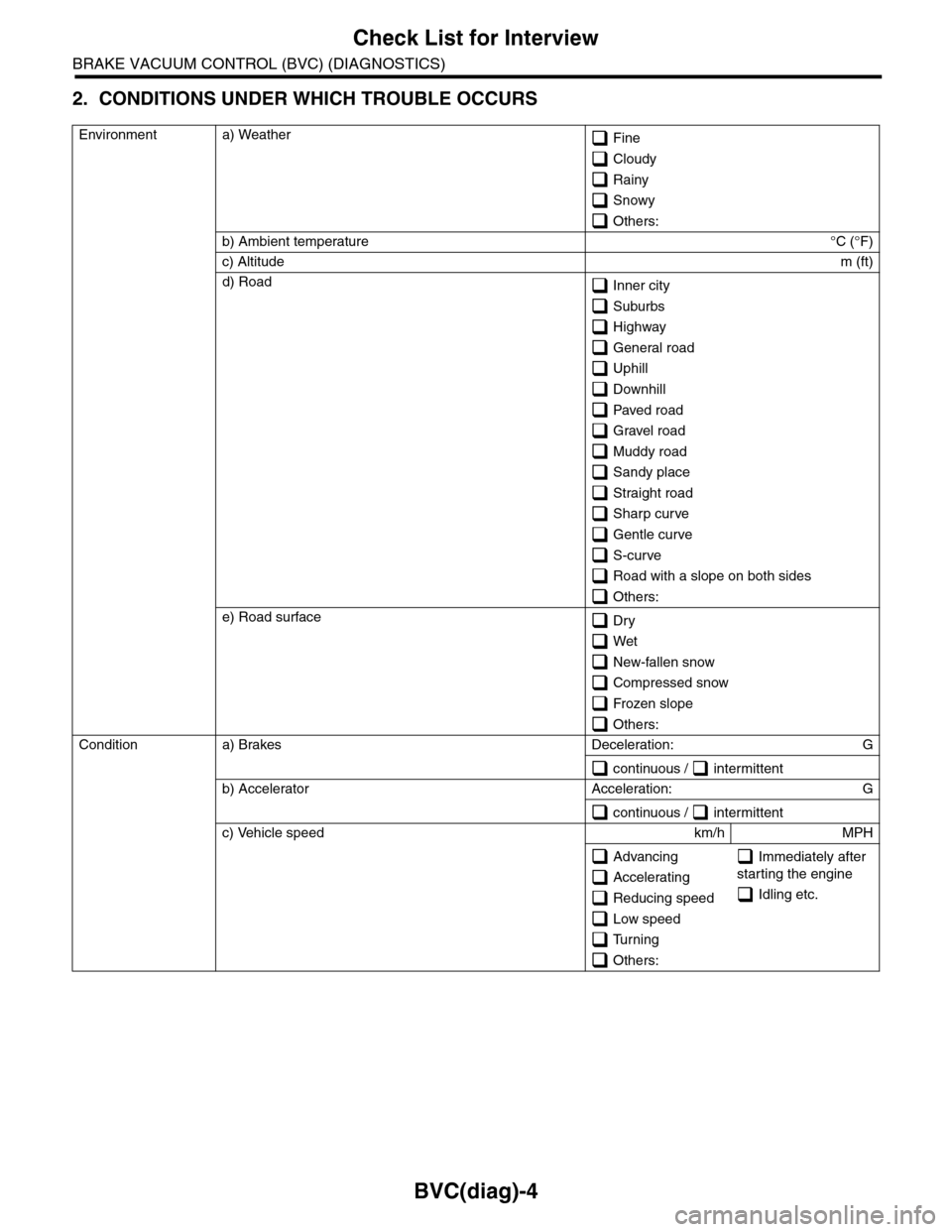

2. Check List for Interview

A: CHECK

Check the following item about the vehicle’s state.

1. STATUS OF THE ERROR DISPLAY

An error is displayed

in odo/trip meter. Always

Sometimes

Only once

Does not come on

• When/How long does it come on?

Ignition key position LOCK

ACC

ON (before starting engine)

START

ON (after starting engine, while engine is running)

ON (after starting engine, engine is stop)

Timing Immediately after turning the ignition switch to ON

Immediately after turning the ignition switch to START

Accelerating — km/h

— MPH

While traveling at a constant speedkm/h MPH

Reducing speed — km/h

— MPH

Page 759 of 2453

BVC(diag)-4

Check List for Interview

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

2. CONDITIONS UNDER WHICH TROUBLE OCCURS

Environment a) Weather Fine

Cloudy

Rainy

Snowy

Others:

b) Ambient temperature°C (°F)

c) Altitudem (ft)

d) Road Inner city

Suburbs

Highway

General road

Uphill

Downhill

Paved road

Gravel road

Muddy road

Sandy place

Straight road

Sharp cur ve

Gentle curve

S-curve

Road with a slope on both sides

Others:

e) Road surface Dr y

Wet

New-fallen snow

Compressed snow

Frozen slope

Others:

Condition a) Brakes Deceleration: G

continuous / intermittent

b) Accelerator Acceleration: G

continuous / intermittent

c) Vehicle speed km/h MPH

Advancing

Accelerating

Reducing speed

Low speed

Turning

Others:

Immediately after

starting the engine

Idling etc.

Page 764 of 2453

BVC(diag)-9

Subaru Select Monitor

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

6. Subaru Select Monitor

A: OPERATION

1. READ DIAGNOSTIC TROUBLE CODE

(DTC)

1) Prepare the Subaru Select Monitor kit.

TOOL, General Description.>

2) Connect the diagnosis cable to Subaru Select

Monitor.

3) Insert the cartridge to the Subaru Select Monitor.

4) Connect the Subaru Select Monitor to data link

connector.

(1) Data link connector is located in the lower

portion of instrument panel (on the driver’s

side).

(2) Connect the diagnosis cable to data link

connector.

CAUTION:

Do not connect the scan tools except for Suba-

ru Select Monitor.

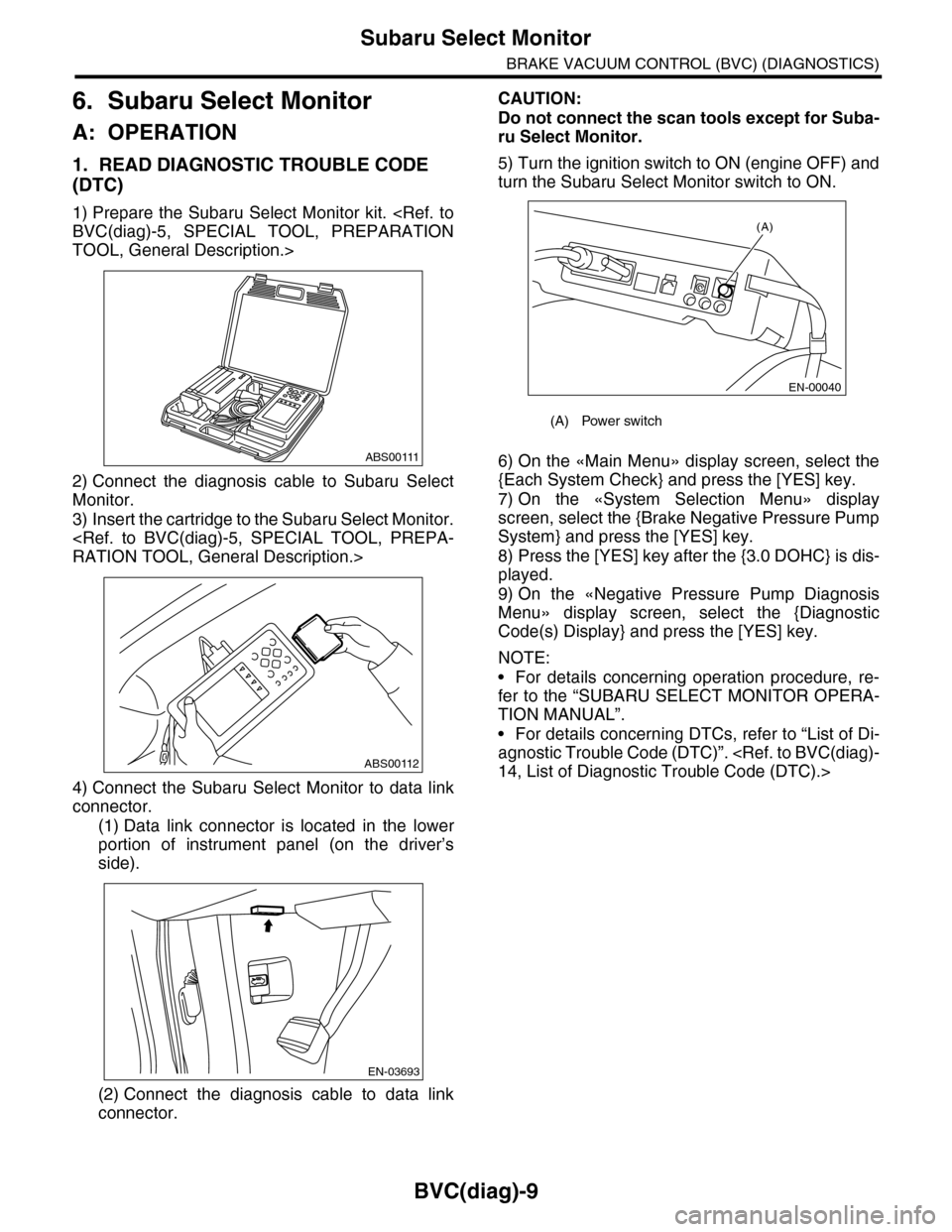

5) Turn the ignition switch to ON (engine OFF) and

turn the Subaru Select Monitor switch to ON.

6) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

7) On the «System Selection Menu» display

screen, select the {Brake Negative Pressure Pump

System} and press the [YES] key.

8) Press the [YES] key after the {3.0 DOHC} is dis-

played.

9) On the «Negative Pressure Pump Diagnosis

Menu» display screen, select the {Diagnostic

Code(s) Display} and press the [YES] key.

NOTE:

•For details concerning operation procedure, re-

fer to the “SUBARU SELECT MONITOR OPERA-

TION MANUAL”.

•For details concerning DTCs, refer to “List of Di-

agnostic Trouble Code (DTC)”.

ABS00111

ABS00112

EN-03693

(A) Power switch

(A)

EN-00040

Page 765 of 2453

![SUBARU TRIBECA 2009 1.G Service Repair Manual BVC(diag)-10

Subaru Select Monitor

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On t SUBARU TRIBECA 2009 1.G Service Repair Manual BVC(diag)-10

Subaru Select Monitor

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On t](/img/17/7322/w960_7322-764.png)

BVC(diag)-10

Subaru Select Monitor

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

2. READ CURRENT DATA

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Brake Negative Pressure Pump System} and

press the [YES] key.

3) Press the [YES] key after the {3.0 DOHC} is displayed.

4) On the «Negative Pressure Diagnosis Menu» display screen, select the {Current Data Display/Save}, and

then press the [YES] key.

5) On the «Data Display Menu» screen, select the {Data Display} and press the [YES] key.

6) Using a scroll key, scroll the display screen up or down until necessary data is shown.

•A list of the support data is shown in the following table.

NOTE:

For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MAN-

UAL”.

3. CLEAR MEMORY MODE

1) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display

screen, select the {Brake Negative Pressure Pump

System} and press the [YES] key.

3) Press the [YES] key after the {3.0 DOHC} is dis-

played.

4) On the «Negative Pressure Pump Diagnosis

Menu» display screen, select the {Clear Memory}

and press the [YES] key.

5) When “Done” and “Turn ignition switch OFF” are

shown on the display screen, turn the Subaru Se-

lect Monitor and ignition switch to OFF.

NOTE:

For details concerning operation procedure, refer

to the “SUBARU SELECT MONITOR OPERATION

MANUAL”.

4. FUNCTION CHECK MODE

1) Connect the test mode connector located under

the glove box.

2) Turn the ignition switch to ON (engine OFF) and

turn the Subaru Select Monitor switch to ON.

3) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

4) On the «System Selection Menu» display

screen, select the {Brake Negative Pressure Pump

System} and press the [YES] key.

5) Press the [YES] key after the {3.0 DOHC} is dis-

played.

6) On the «Negative Pressure Pump Diagnosis

Menu» display screen, select the {Function Check

Mode} and press the [YES] key.

7) When the “Start Function Check Mode” is shown

on the screen, press the [YES] key.

8) When the “Depress the Brake Pedal 5 Times” is

shown on the screen, depress the brake pedal 5

times, and press the [YES] key while brake pedal is

not depressed.

9) Press the [YES] key after the {OK} is displayed.

Display Contents to be monitored Unit of measure

Atmospheric pressure Atmospheric pressure is displayed. mmHg, kPa or psig

Brake booster pressure Brake booster pressure is displayed. mmHg, kPa or psig

Te s t m o d e t e r m i n a l Te s t m o d e t e r m i n a l c o n n e c t i o n s t a t u s i s d i s p l a y e d . D C h e c k o r U C h e c k

Negative pressure pump motor Negative pressure motor operating status is displayed. ON or OFF

Negative pressure pump motor relay Negative pressure pump motor relay operating status is displayed. ON or OFF

Display Contents to be monitored

Clear Memory? DTC deleting function

(A) Test mode connector

EN-03694

(4)