transmission oil SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2095 of 2453

5AT-79

Oil Pump Cover

AUTOMATIC TRANSMISSION

6) Install the snap ring.

7) Measure the clearance between retainer plate

and snap ring, and then select the suitable retainer

plate from table.

Front brake clearance specification:

0.7 — 1.1 mm (0.028 — 0.043 in)

8) Remove the snap ring, replace the driven plate

used in measurement of clearance with the retainer

plate, and then reassemble.

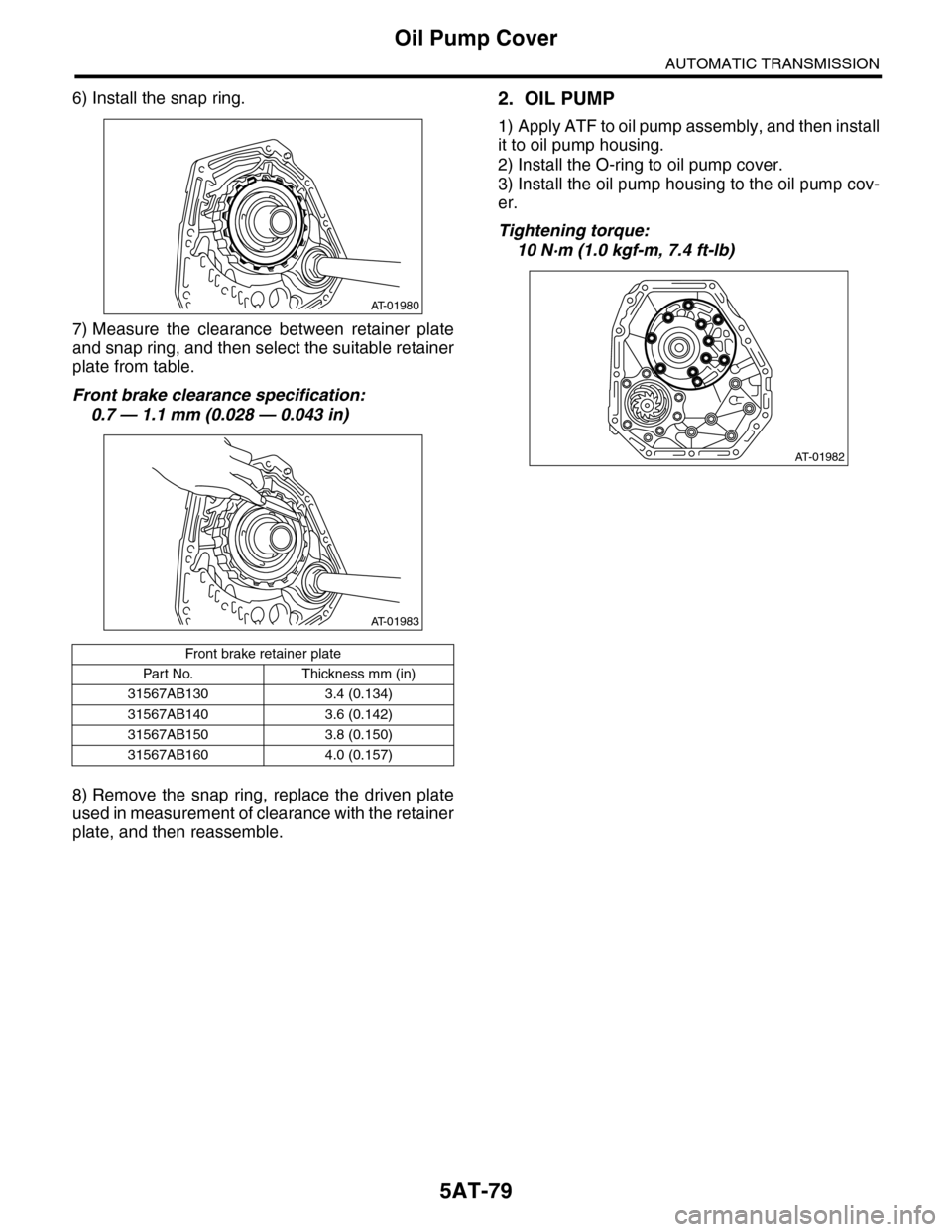

2. OIL PUMP

1) Apply ATF to oil pump assembly, and then install

it to oil pump housing.

2) Install the O-ring to oil pump cover.

3) Install the oil pump housing to the oil pump cov-

er.

Tightening torque:

10 N·m (1.0 kgf-m, 7.4 ft-lb)

Front brake retainer plate

Par t No. Thickness mm (in)

31567AB130 3.4 (0.134)

31567AB140 3.6 (0.142)

31567AB150 3.8 (0.150)

31567AB160 4.0 (0.157)

AT-01980

AT-01983

AT-01982

Page 2096 of 2453

5AT-80

Oil Pump Cover

AUTOMATIC TRANSMISSION

E: INSPECTION

1. FRONT BRAKE

Check the following items.

•Drive plate facing for wear and damage

•Snap ring for wear, return spring for damage,

and retainer for damage

•Piston for damage

•D-ring for damage

2. OIL PUMP

Check the following items.

•Oil pump cover and oil seal for breakage or dam-

age

•Oil pump body for scratch or damage

1) Check the seal ring and oil seal for breaks and

damage.

2) Check other parts for dents or faults.

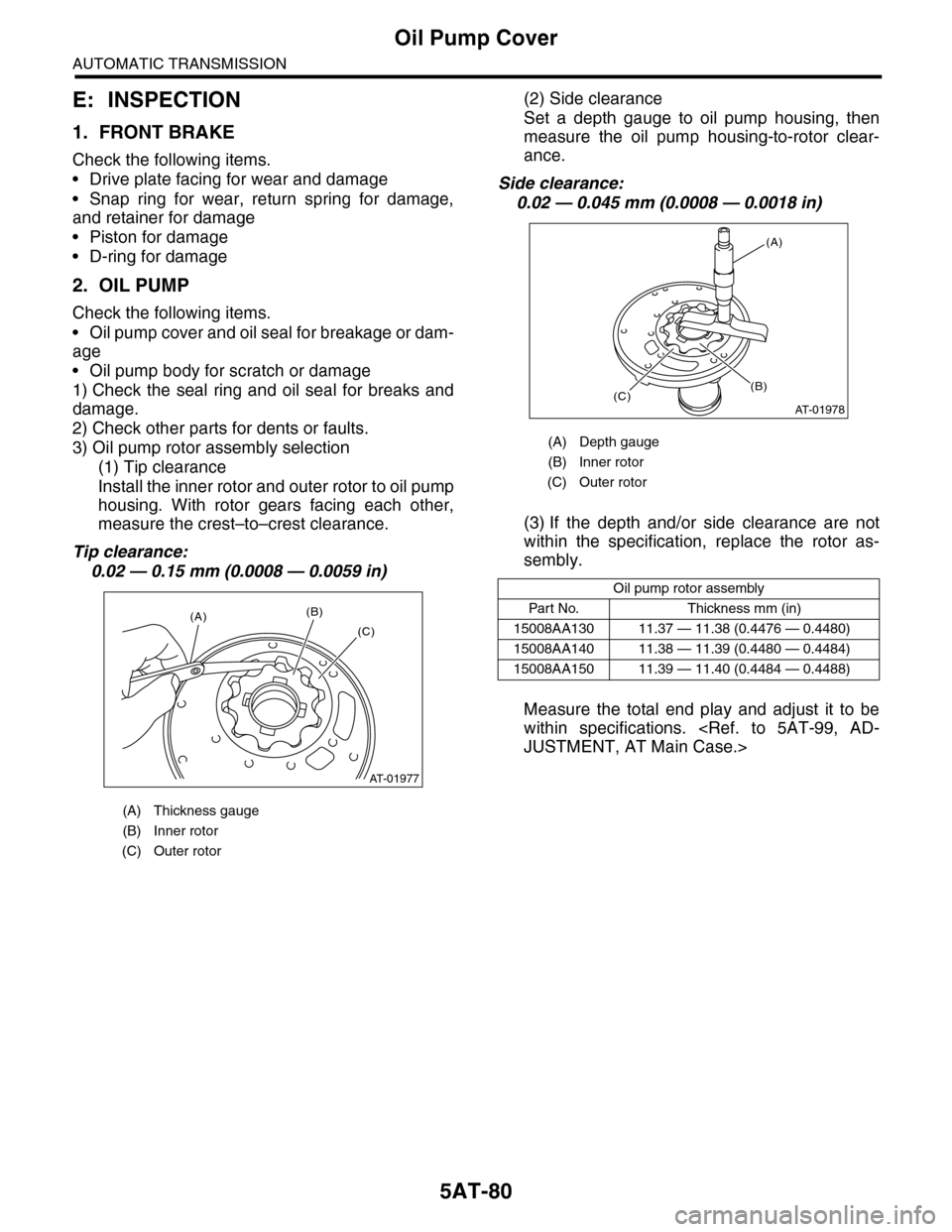

3) Oil pump rotor assembly selection

(1) Tip clearance

Install the inner rotor and outer rotor to oil pump

housing. With rotor gears facing each other,

measure the crest–to–crest clearance.

Tip clearance:

0.02 — 0.15 mm (0.0008 — 0.0059 in)

(2) Side clearance

Set a depth gauge to oil pump housing, then

measure the oil pump housing-to-rotor clear-

ance.

Side clearance:

0.02 — 0.045 mm (0.0008 — 0.0018 in)

(3) If the depth and/or side clearance are not

within the specification, replace the rotor as-

sembly.

Measure the total end play and adjust it to be

within specifications.

(A) Thickness gauge

(B) Inner rotor

(C) Outer rotor

AT-01977

(A)(B)

(C)

(A) Depth gauge

(B) Inner rotor

(C) Outer rotor

Oil pump rotor assembly

Par t No. Thickness mm (in)

15008AA130 11.37 — 11.38 (0.4476 — 0.4480)

15008AA140 11.38 — 11.39 (0.4480 — 0.4484)

15008AA150 11.39 — 11.40 (0.4484 — 0.4488)

AT-01978

(A)

(C)(B)

Page 2097 of 2453

5AT-81

Drive Pinion Shaft Assembly

AUTOMATIC TRANSMISSION

32.Drive Pinion Shaft Assembly

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Disconnect the air breather hose.

5) Remove the oil charge pipe.

6) Remove the ATF filter inlet and outlet pipes.

7) Separate the converter case and transmission

case.

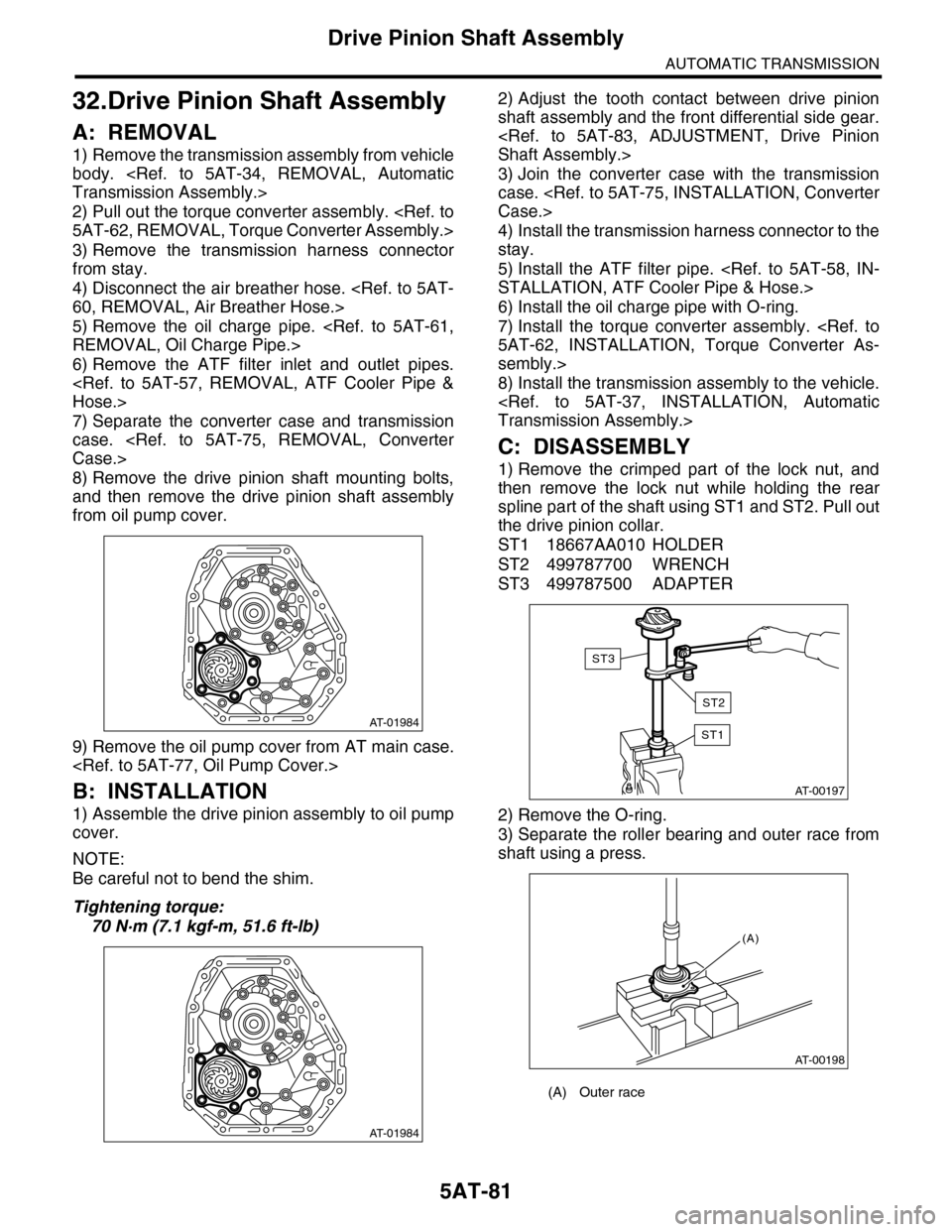

8) Remove the drive pinion shaft mounting bolts,

and then remove the drive pinion shaft assembly

from oil pump cover.

9) Remove the oil pump cover from AT main case.

B: INSTALLATION

1) Assemble the drive pinion assembly to oil pump

cover.

NOTE:

Be careful not to bend the shim.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

2) Adjust the tooth contact between drive pinion

shaft assembly and the front differential side gear.

3) Join the converter case with the transmission

case.

4) Install the transmission harness connector to the

stay.

5) Install the ATF filter pipe.

6) Install the oil charge pipe with O-ring.

7) Install the torque converter assembly.

sembly.>

8) Install the transmission assembly to the vehicle.

C: DISASSEMBLY

1) Remove the crimped part of the lock nut, and

then remove the lock nut while holding the rear

spline part of the shaft using ST1 and ST2. Pull out

the drive pinion collar.

ST1 18667AA010 HOLDER

ST2 499787700 WRENCH

ST3 499787500 ADAPTER

2) Remove the O-ring.

3) Separate the roller bearing and outer race from

shaft using a press.

AT-01984

AT-01984

(A) Outer race

AT-00197

ST1

ST3

ST2

AT-00198

(A)

Page 2099 of 2453

5AT-83

Drive Pinion Shaft Assembly

AUTOMATIC TRANSMISSION

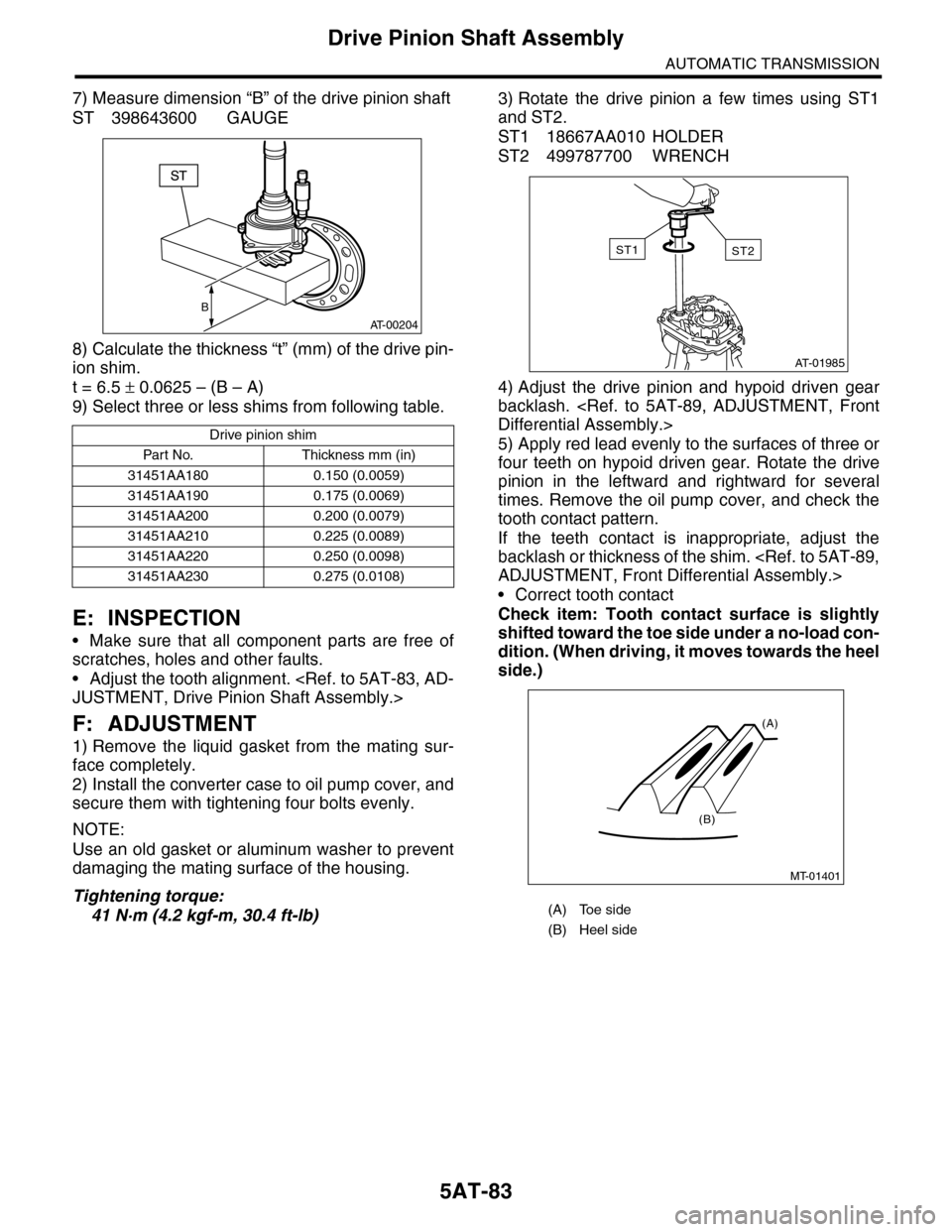

7) Measure dimension “B” of the drive pinion shaft

ST 398643600 GAUGE

8) Calculate the thickness “t” (mm) of the drive pin-

ion shim.

t = 6.5 ± 0.0625 – (B – A)

9) Select three or less shims from following table.

E: INSPECTION

•Make sure that all component parts are free of

scratches, holes and other faults.

•Adjust the tooth alignment.

F: ADJUSTMENT

1) Remove the liquid gasket from the mating sur-

face completely.

2) Install the converter case to oil pump cover, and

secure them with tightening four bolts evenly.

NOTE:

Use an old gasket or aluminum washer to prevent

damaging the mating surface of the housing.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

3) Rotate the drive pinion a few times using ST1

and ST2.

ST1 18667AA010 HOLDER

ST2 499787700 WRENCH

4) Adjust the drive pinion and hypoid driven gear

backlash.

5) Apply red lead evenly to the surfaces of three or

four teeth on hypoid driven gear. Rotate the drive

pinion in the leftward and rightward for several

times. Remove the oil pump cover, and check the

tooth contact pattern.

If the teeth contact is inappropriate, adjust the

backlash or thickness of the shim.

•Correct tooth contact

Check item: Tooth contact surface is slightly

shifted toward the toe side under a no-load con-

dition. (When driving, it moves towards the heel

side.)

Drive pinion shim

Par t No. Thickness mm (in)

31451AA180 0.150 (0.0059)

31451AA190 0.175 (0.0069)

31451AA200 0.200 (0.0079)

31451AA210 0.225 (0.0089)

31451AA220 0.250 (0.0098)

31451AA230 0.275 (0.0108)

B

AT-00204

(A) Toe side

(B) Heel side

AT-01985

ST2ST1

MT-01401

(A)

(B)

Page 2101 of 2453

5AT-85

Drive Pinion Shaft Assembly

AUTOMATIC TRANSMISSION

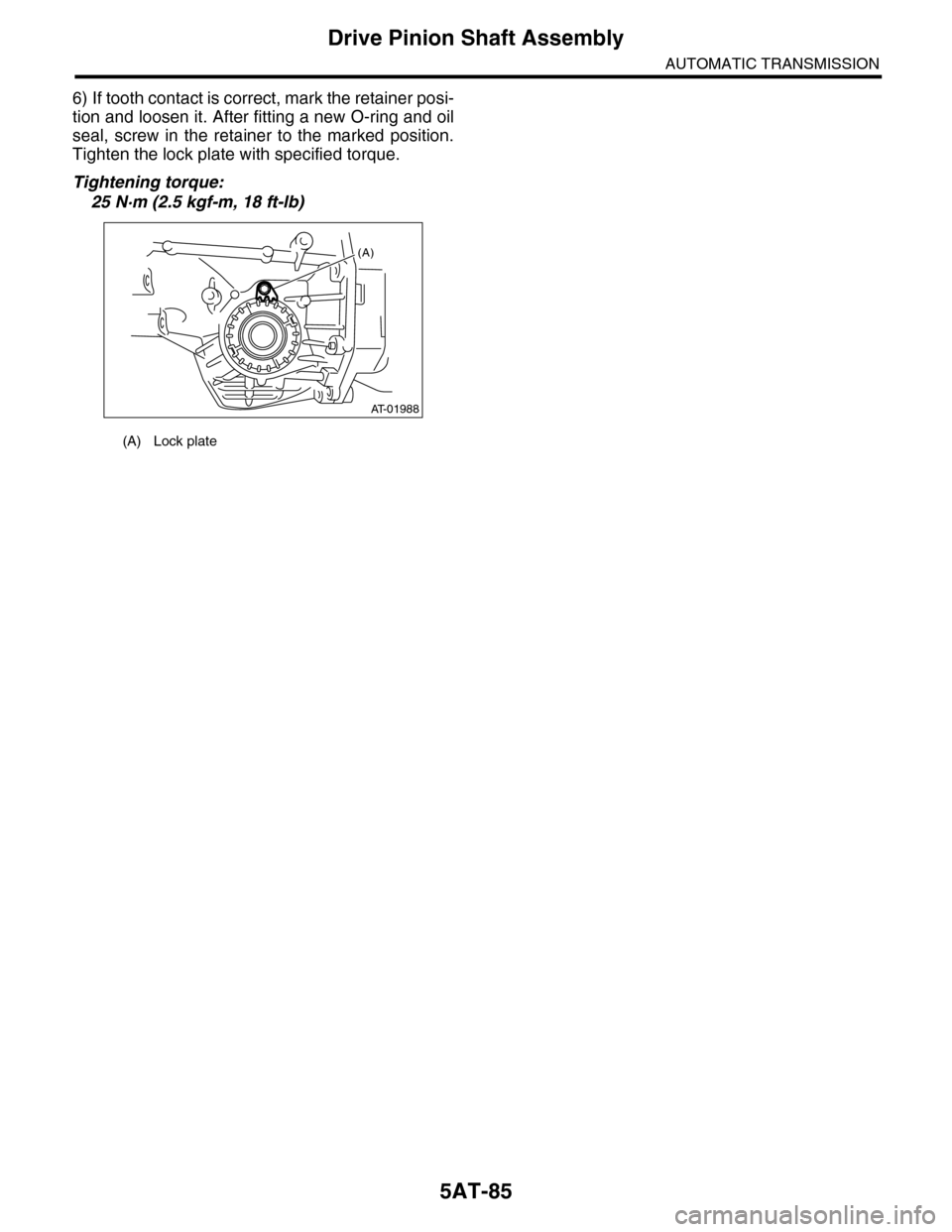

6) If tooth contact is correct, mark the retainer posi-

tion and loosen it. After fitting a new O-ring and oil

seal, screw in the retainer to the marked position.

Tighten the lock plate with specified torque.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

(A) Lock plate

AT-01988

(A)

Page 2102 of 2453

5AT-86

Front Differential Assembly

AUTOMATIC TRANSMISSION

33.Front Differential Assembly

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Remove the oil charge pipe.

5) Remove the ATF filter inlet and outlet pipes.

6) Separate the converter case from the transmis-

sion case.

7) Remove the differential side retainers using ST.

NOTE:

Hold the differential case assembly by hand to

avoid damaging the retainer mounting hole of the

converter case.

ST 18630AA010 WRENCH COMPL RETAIN-

ER

8) Remove the differential assembly while being

careful not to damage the attachment part of retain-

er.

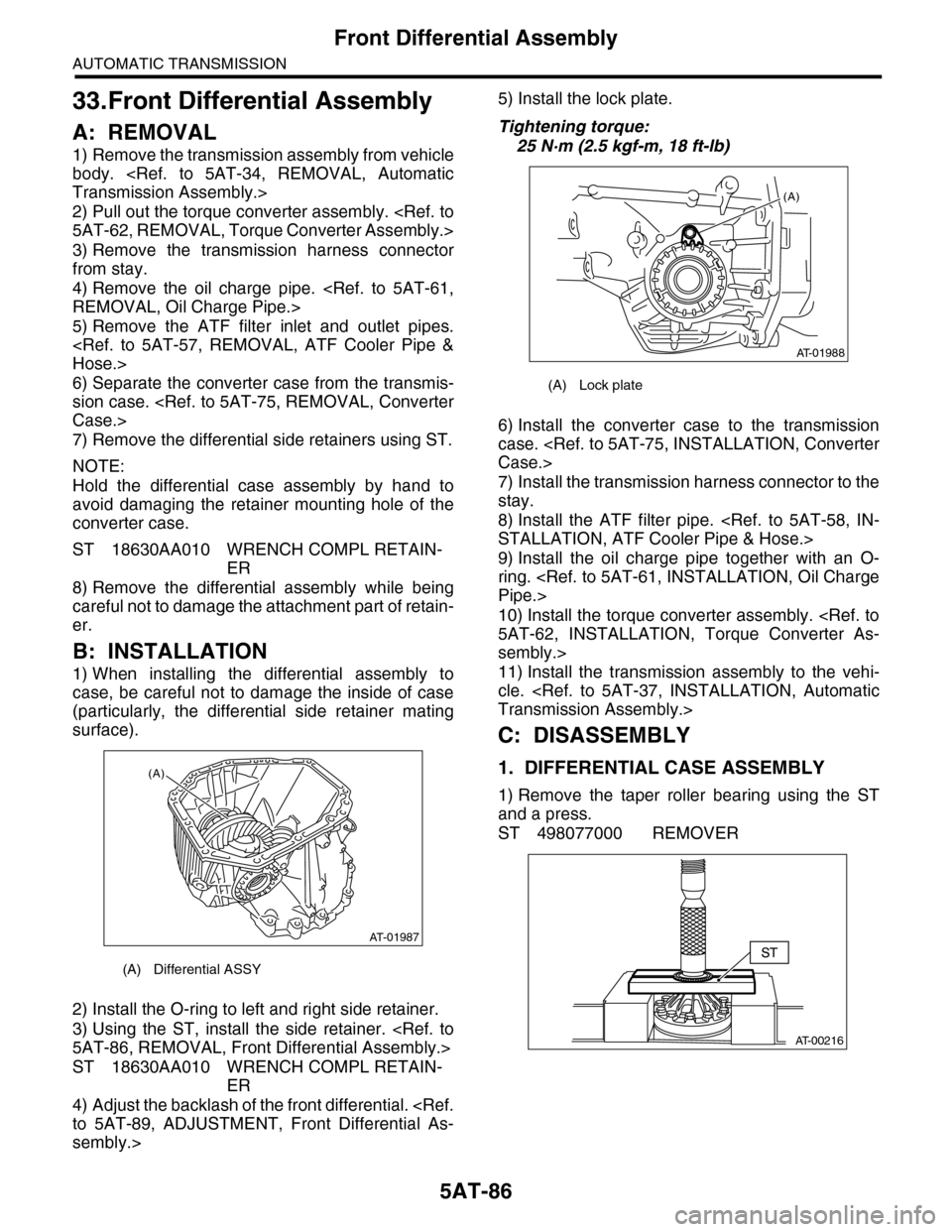

B: INSTALLATION

1) When installing the differential assembly to

case, be careful not to damage the inside of case

(particularly, the differential side retainer mating

surface).

2) Install the O-ring to left and right side retainer.

3) Using the ST, install the side retainer.

ST 18630AA010 WRENCH COMPL RETAIN-

ER

4) Adjust the backlash of the front differential.

sembly.>

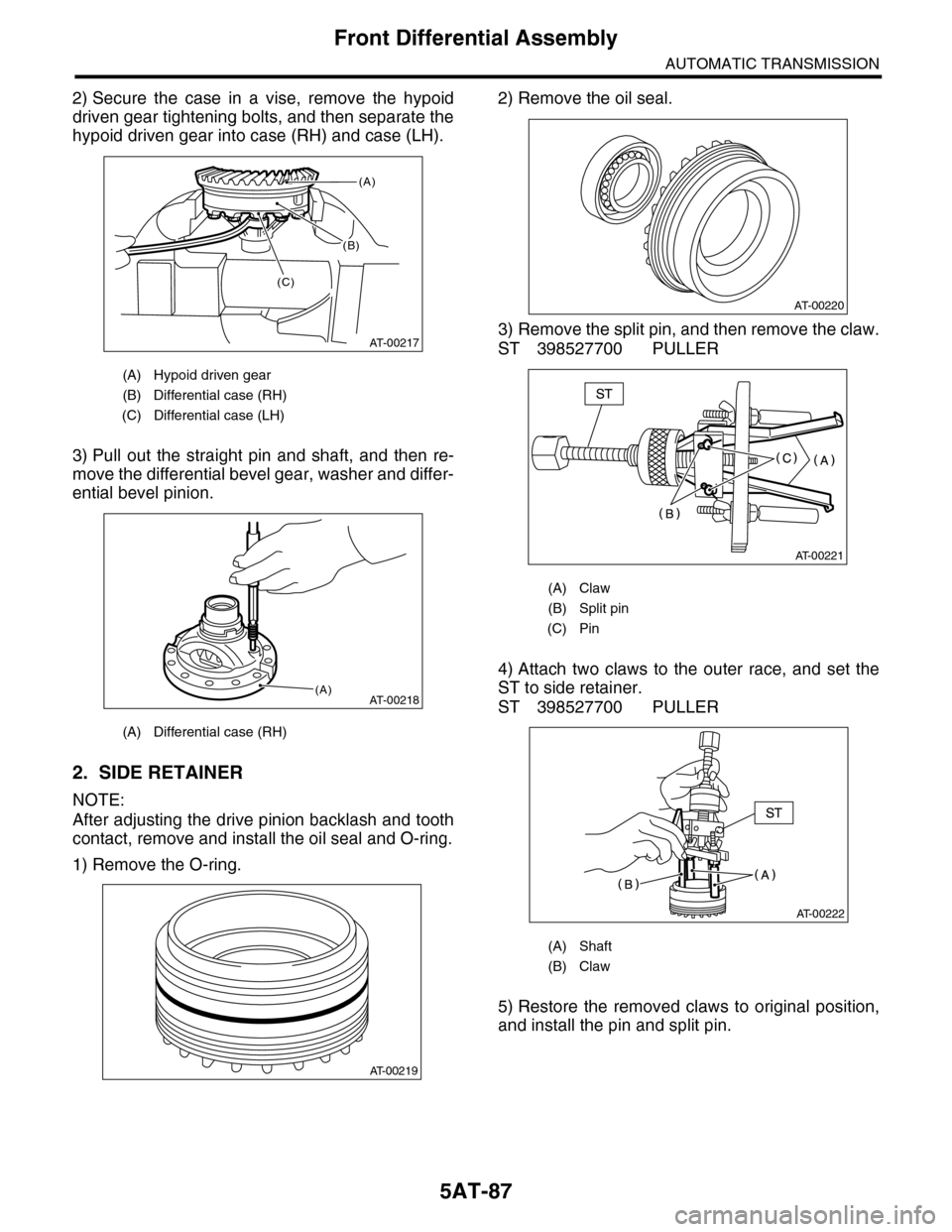

5) Install the lock plate.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

6) Install the converter case to the transmission

case.

7) Install the transmission harness connector to the

stay.

8) Install the ATF filter pipe.

9) Install the oil charge pipe together with an O-

ring.

10) Install the torque converter assembly.

sembly.>

11) Install the transmission assembly to the vehi-

cle.

C: DISASSEMBLY

1. DIFFERENTIAL CASE ASSEMBLY

1) Remove the taper roller bearing using the ST

and a press.

ST 498077000 REMOVER

(A) Differential ASSY

AT-01987

(A)

(A) Lock plate

AT-01988

(A)

AT-00216

Page 2103 of 2453

5AT-87

Front Differential Assembly

AUTOMATIC TRANSMISSION

2) Secure the case in a vise, remove the hypoid

driven gear tightening bolts, and then separate the

hypoid driven gear into case (RH) and case (LH).

3) Pull out the straight pin and shaft, and then re-

move the differential bevel gear, washer and differ-

ential bevel pinion.

2. SIDE RETAINER

NOTE:

After adjusting the drive pinion backlash and tooth

contact, remove and install the oil seal and O-ring.

1) Remove the O-ring.

2) Remove the oil seal.

3) Remove the split pin, and then remove the claw.

ST 398527700 PULLER

4) Attach two claws to the outer race, and set the

ST to side retainer.

ST 398527700 PULLER

5) Restore the removed claws to original position,

and install the pin and split pin.

(A) Hypoid driven gear

(B) Differential case (RH)

(C) Differential case (LH)

(A) Differential case (RH)

(B)

AT-00217

(A)

(C)

AT-00218(A)

AT-00219

(A) Claw

(B) Split pin

(C) Pin

(A) Shaft

(B) Claw

AT-00220

AT-00221

AT-00222

Page 2105 of 2453

5AT-89

Front Differential Assembly

AUTOMATIC TRANSMISSION

2. SIDE RETAINER

NOTE:

Install the oil seal and O-ring of side retainer after

the adjustment of backlash and tooth contact.

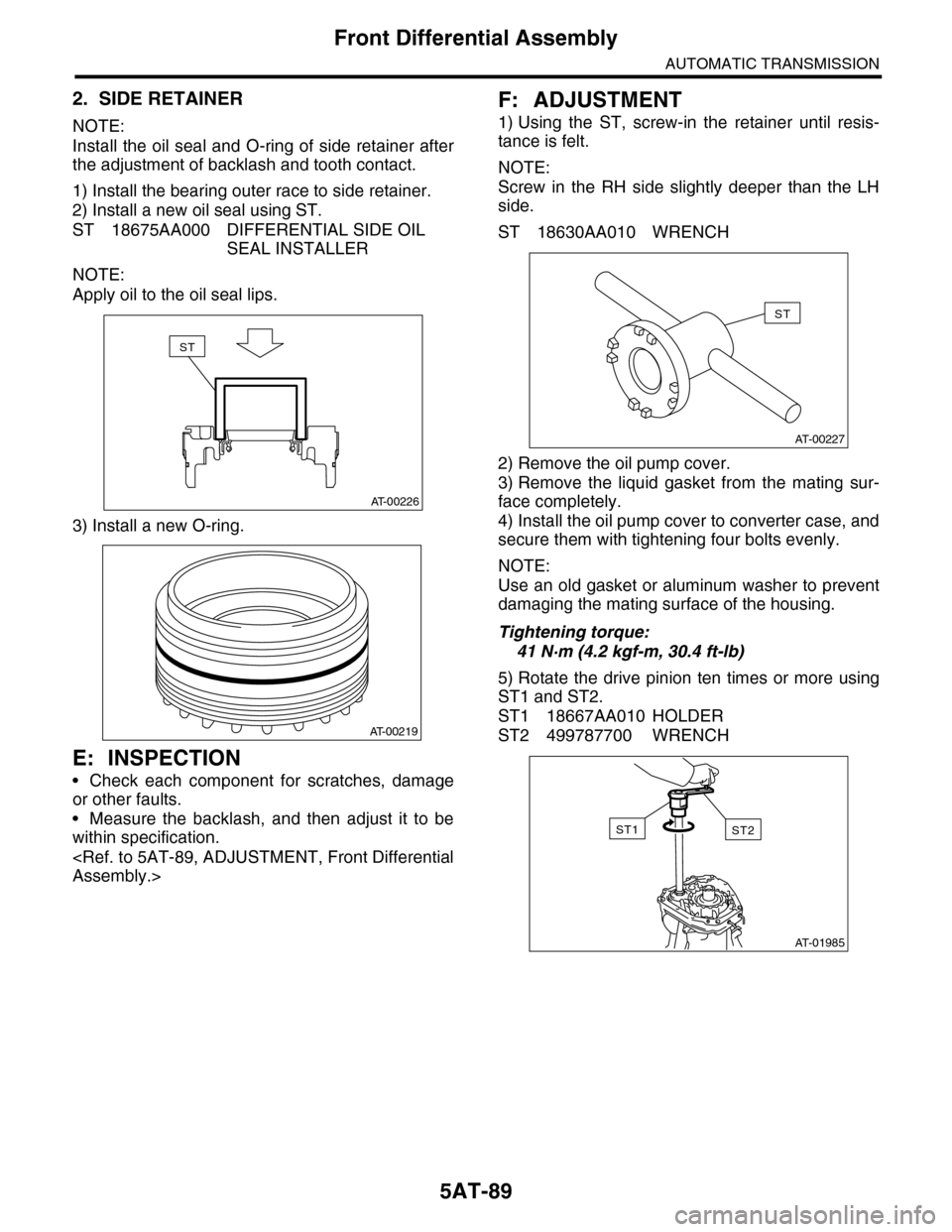

1) Install the bearing outer race to side retainer.

2) Install a new oil seal using ST.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

NOTE:

Apply oil to the oil seal lips.

3) Install a new O-ring.

E: INSPECTION

•Check each component for scratches, damage

or other faults.

•Measure the backlash, and then adjust it to be

within specification.

F: ADJUSTMENT

1) Using the ST, screw-in the retainer until resis-

tance is felt.

NOTE:

Screw in the RH side slightly deeper than the LH

side.

ST 18630AA010 WRENCH

2) Remove the oil pump cover.

3) Remove the liquid gasket from the mating sur-

face completely.

4) Install the oil pump cover to converter case, and

secure them with tightening four bolts evenly.

NOTE:

Use an old gasket or aluminum washer to prevent

damaging the mating surface of the housing.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

5) Rotate the drive pinion ten times or more using

ST1 and ST2.

ST1 18667AA010 HOLDER

ST2 499787700 WRENCH

AT-00226

ST

AT-00219

AT-00227

ST

AT-01985

ST2ST1

Page 2107 of 2453

5AT-91

AT Main Case

AUTOMATIC TRANSMISSION

34.AT Main Case

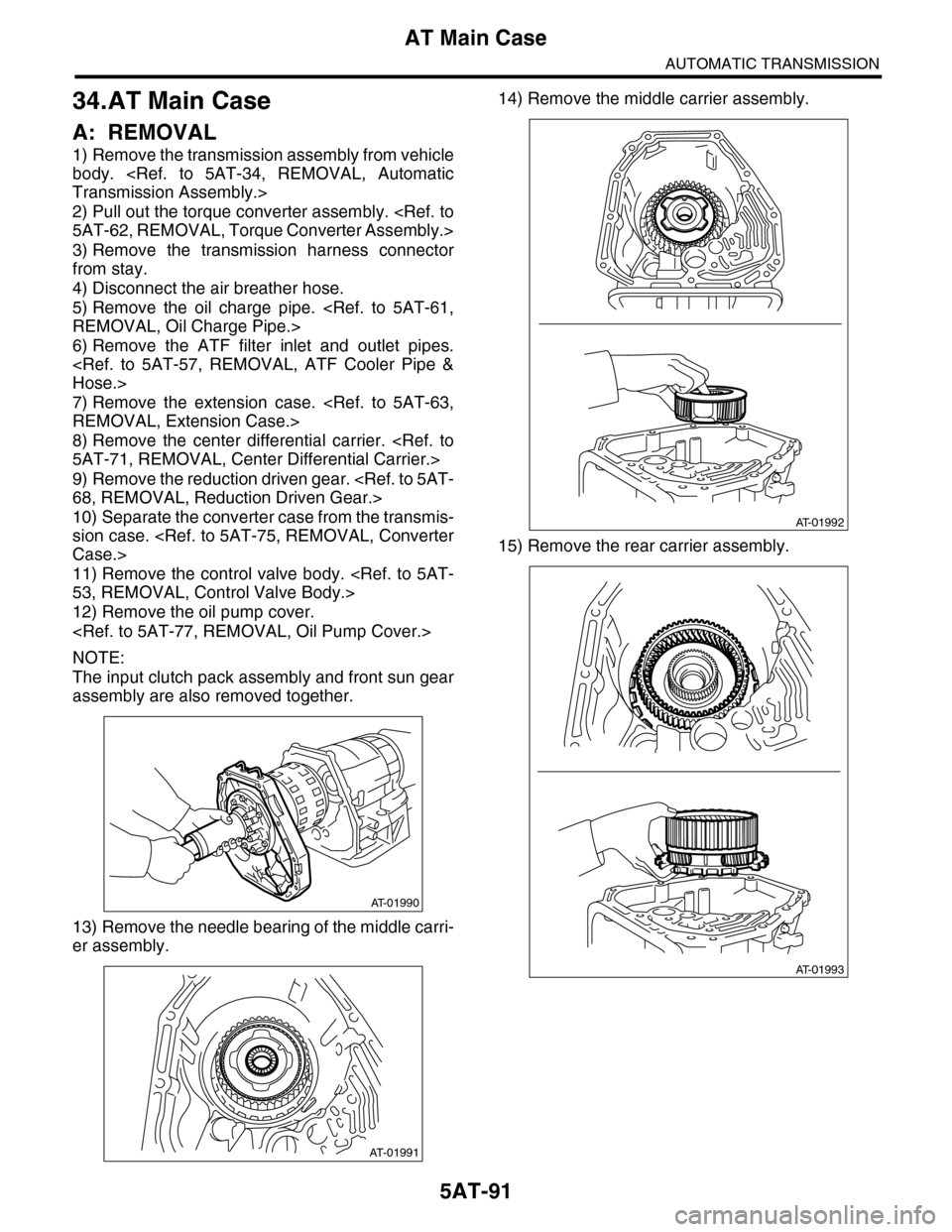

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Disconnect the air breather hose.

5) Remove the oil charge pipe.

6) Remove the ATF filter inlet and outlet pipes.

7) Remove the extension case.

8) Remove the center differential carrier.

9) Remove the reduction driven gear.

10) Separate the converter case from the transmis-

sion case.

11) Remove the control valve body.

12) Remove the oil pump cover.

NOTE:

The input clutch pack assembly and front sun gear

assembly are also removed together.

13) Remove the needle bearing of the middle carri-

er assembly.

14) Remove the middle carrier assembly.

15) Remove the rear carrier assembly.

AT-01990

AT-01991

AT-01992

AT-01993

Page 2112 of 2453

5AT-96

AT Main Case

AUTOMATIC TRANSMISSION

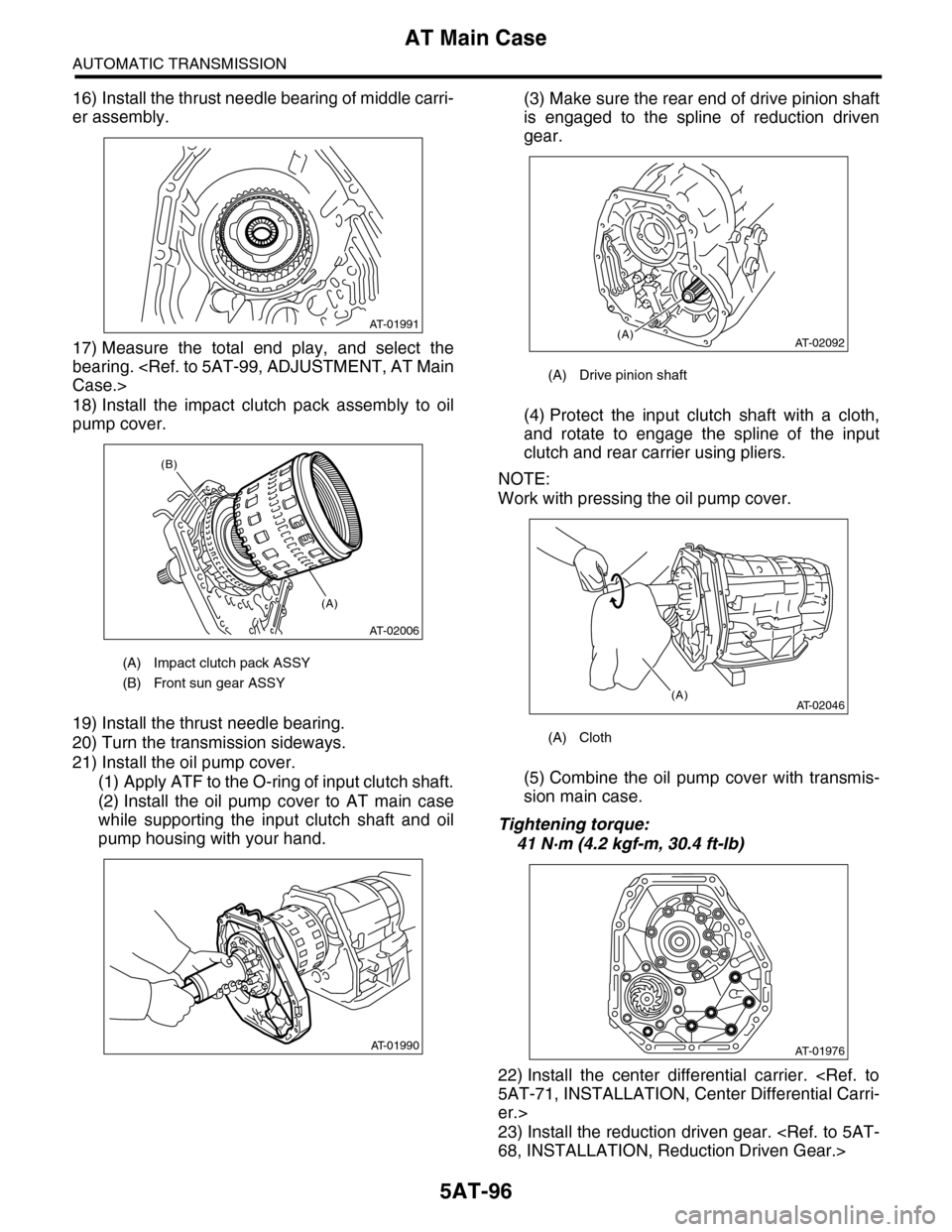

16) Install the thrust needle bearing of middle carri-

er assembly.

17) Measure the total end play, and select the

bearing.

18) Install the impact clutch pack assembly to oil

pump cover.

19) Install the thrust needle bearing.

20) Turn the transmission sideways.

21) Install the oil pump cover.

(1) Apply ATF to the O-ring of input clutch shaft.

(2) Install the oil pump cover to AT main case

while supporting the input clutch shaft and oil

pump housing with your hand.

(3) Make sure the rear end of drive pinion shaft

is engaged to the spline of reduction driven

gear.

(4) Protect the input clutch shaft with a cloth,

and rotate to engage the spline of the input

clutch and rear carrier using pliers.

NOTE:

Work with pressing the oil pump cover.

(5) Combine the oil pump cover with transmis-

sion main case.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

22) Install the center differential carrier.

er.>

23) Install the reduction driven gear.

(A) Impact clutch pack ASSY

(B) Front sun gear ASSY

AT-01991

AT-02006

(A)

(B)

AT-01990

(A) Drive pinion shaft

(A) Cloth

AT-02092(A)

AT-02046(A)

AT-01976