Rear diff SUBARU TRIBECA 2009 1.G Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2087 of 2453

5AT-71

Center Differential Carrier

AUTOMATIC TRANSMISSION

28.Center Differential Carrier

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Remove the rear wheel speed sensor, and sep-

arate the extension case from transmission case.

3) Extract the rear drive shaft.

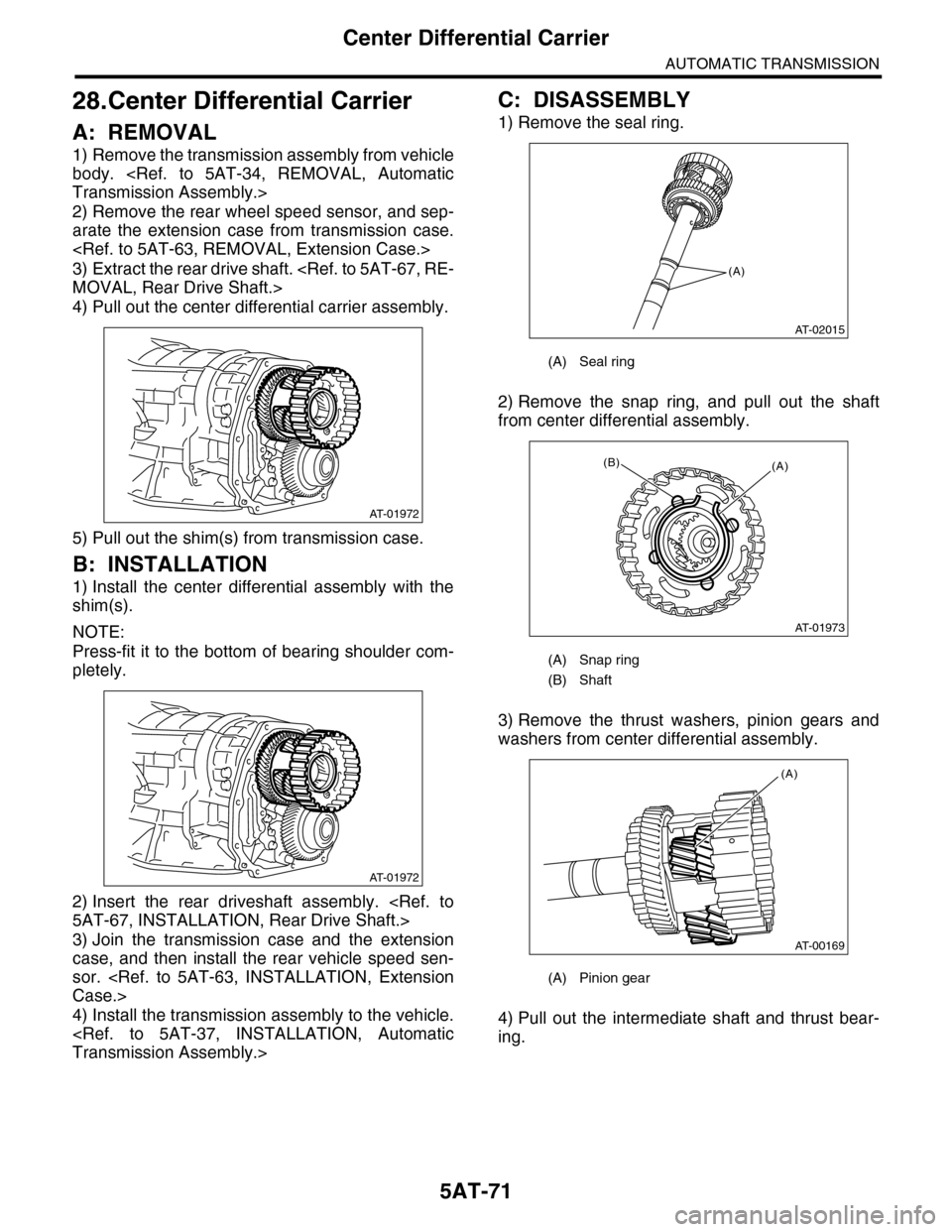

4) Pull out the center differential carrier assembly.

5) Pull out the shim(s) from transmission case.

B: INSTALLATION

1) Install the center differential assembly with the

shim(s).

NOTE:

Press-fit it to the bottom of bearing shoulder com-

pletely.

2) Insert the rear driveshaft assembly.

3) Join the transmission case and the extension

case, and then install the rear vehicle speed sen-

sor.

4) Install the transmission assembly to the vehicle.

C: DISASSEMBLY

1) Remove the seal ring.

2) Remove the snap ring, and pull out the shaft

from center differential assembly.

3) Remove the thrust washers, pinion gears and

washers from center differential assembly.

4) Pull out the intermediate shaft and thrust bear-

ing.

AT-01972

AT-01972

(A) Seal ring

(A) Snap ring

(B) Shaft

(A) Pinion gear

(A)

AT-02015

AT-01973

(A)(B)

AT-00169

(A)

Page 2097 of 2453

5AT-81

Drive Pinion Shaft Assembly

AUTOMATIC TRANSMISSION

32.Drive Pinion Shaft Assembly

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Disconnect the air breather hose.

5) Remove the oil charge pipe.

6) Remove the ATF filter inlet and outlet pipes.

7) Separate the converter case and transmission

case.

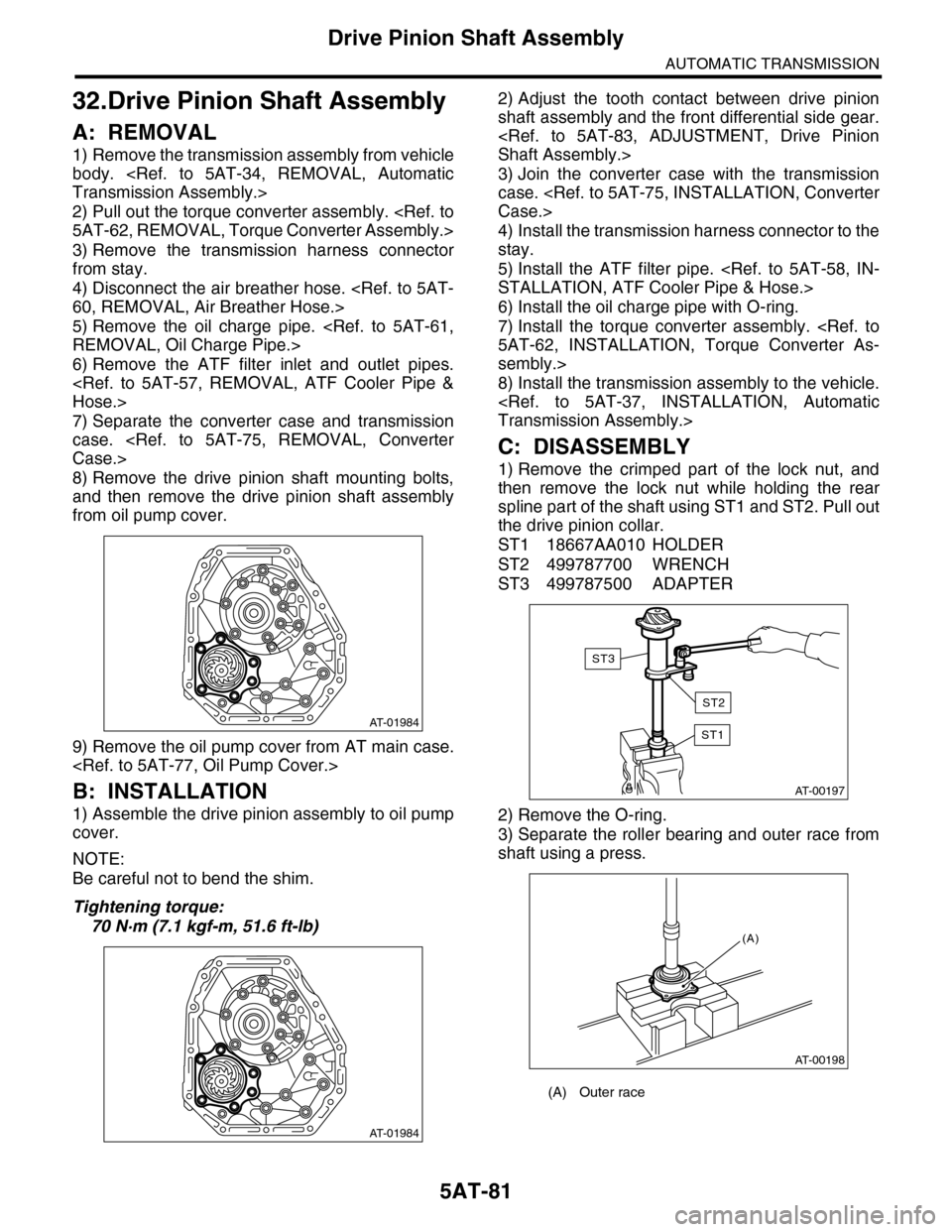

8) Remove the drive pinion shaft mounting bolts,

and then remove the drive pinion shaft assembly

from oil pump cover.

9) Remove the oil pump cover from AT main case.

B: INSTALLATION

1) Assemble the drive pinion assembly to oil pump

cover.

NOTE:

Be careful not to bend the shim.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

2) Adjust the tooth contact between drive pinion

shaft assembly and the front differential side gear.

3) Join the converter case with the transmission

case.

4) Install the transmission harness connector to the

stay.

5) Install the ATF filter pipe.

6) Install the oil charge pipe with O-ring.

7) Install the torque converter assembly.

sembly.>

8) Install the transmission assembly to the vehicle.

C: DISASSEMBLY

1) Remove the crimped part of the lock nut, and

then remove the lock nut while holding the rear

spline part of the shaft using ST1 and ST2. Pull out

the drive pinion collar.

ST1 18667AA010 HOLDER

ST2 499787700 WRENCH

ST3 499787500 ADAPTER

2) Remove the O-ring.

3) Separate the roller bearing and outer race from

shaft using a press.

AT-01984

AT-01984

(A) Outer race

AT-00197

ST1

ST3

ST2

AT-00198

(A)

Page 2107 of 2453

5AT-91

AT Main Case

AUTOMATIC TRANSMISSION

34.AT Main Case

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Disconnect the air breather hose.

5) Remove the oil charge pipe.

6) Remove the ATF filter inlet and outlet pipes.

7) Remove the extension case.

8) Remove the center differential carrier.

9) Remove the reduction driven gear.

10) Separate the converter case from the transmis-

sion case.

11) Remove the control valve body.

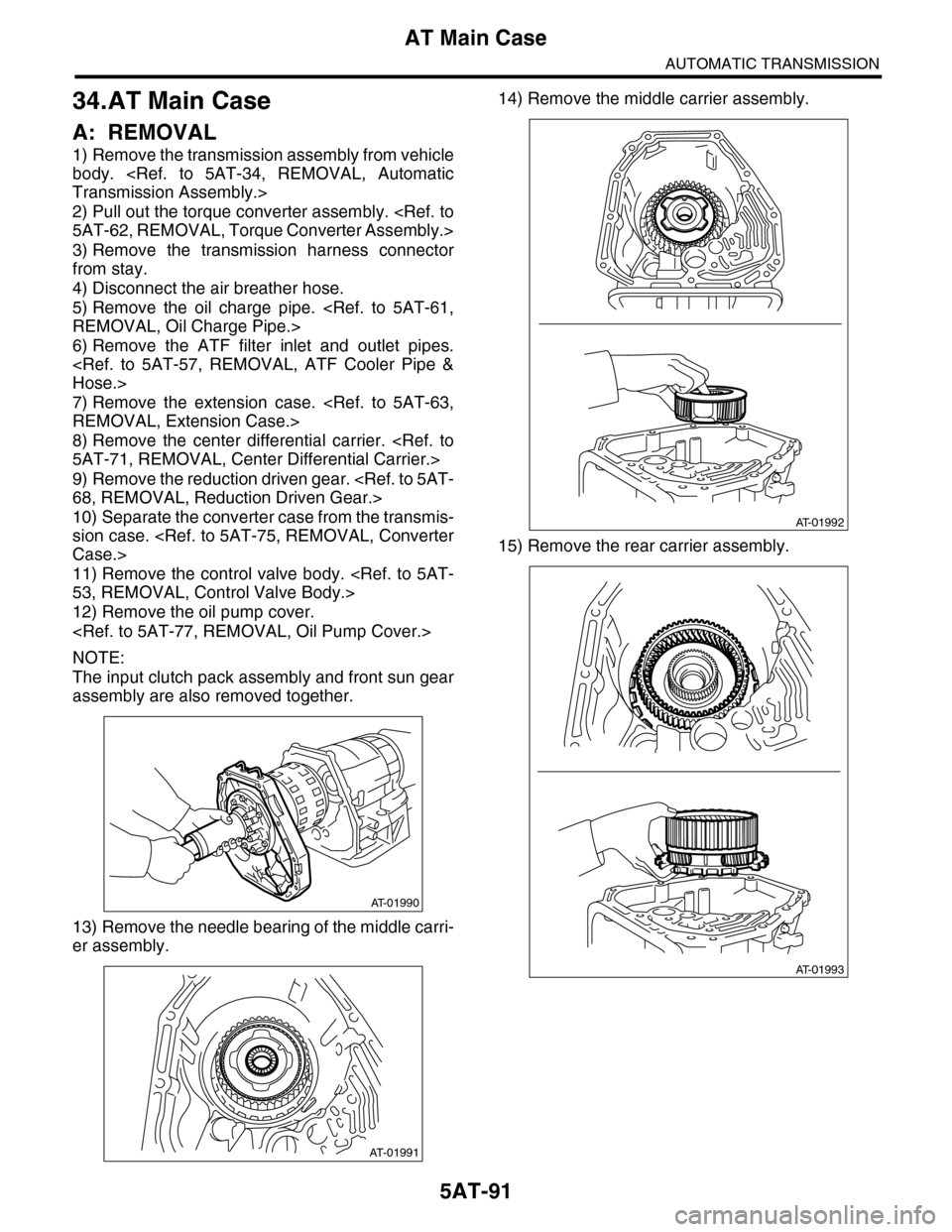

12) Remove the oil pump cover.

NOTE:

The input clutch pack assembly and front sun gear

assembly are also removed together.

13) Remove the needle bearing of the middle carri-

er assembly.

14) Remove the middle carrier assembly.

15) Remove the rear carrier assembly.

AT-01990

AT-01991

AT-01992

AT-01993

Page 2112 of 2453

5AT-96

AT Main Case

AUTOMATIC TRANSMISSION

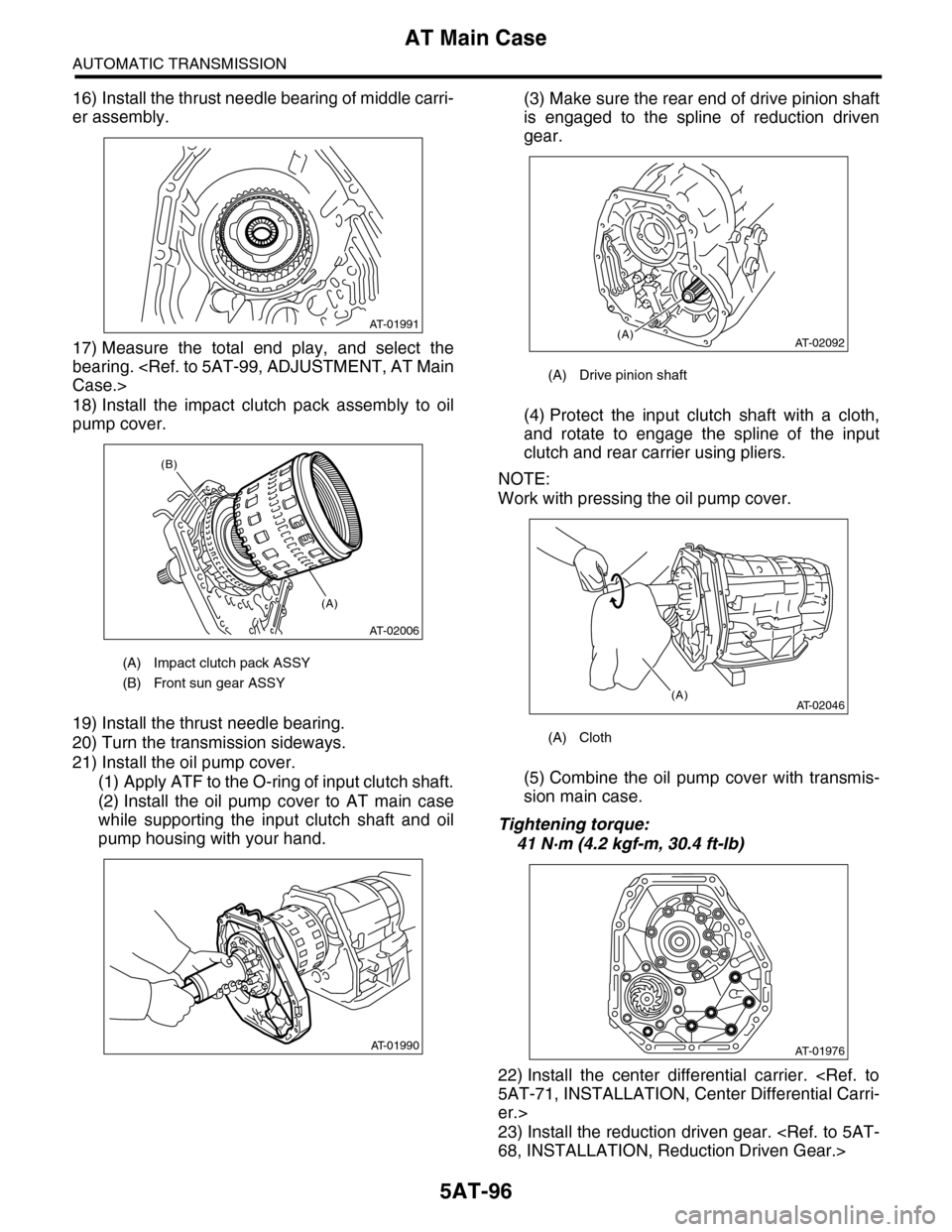

16) Install the thrust needle bearing of middle carri-

er assembly.

17) Measure the total end play, and select the

bearing.

18) Install the impact clutch pack assembly to oil

pump cover.

19) Install the thrust needle bearing.

20) Turn the transmission sideways.

21) Install the oil pump cover.

(1) Apply ATF to the O-ring of input clutch shaft.

(2) Install the oil pump cover to AT main case

while supporting the input clutch shaft and oil

pump housing with your hand.

(3) Make sure the rear end of drive pinion shaft

is engaged to the spline of reduction driven

gear.

(4) Protect the input clutch shaft with a cloth,

and rotate to engage the spline of the input

clutch and rear carrier using pliers.

NOTE:

Work with pressing the oil pump cover.

(5) Combine the oil pump cover with transmis-

sion main case.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

22) Install the center differential carrier.

er.>

23) Install the reduction driven gear.

(A) Impact clutch pack ASSY

(B) Front sun gear ASSY

AT-01991

AT-02006

(A)

(B)

AT-01990

(A) Drive pinion shaft

(A) Cloth

AT-02092(A)

AT-02046(A)

AT-01976

Page 2160 of 2453

5AT(diag)-43

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

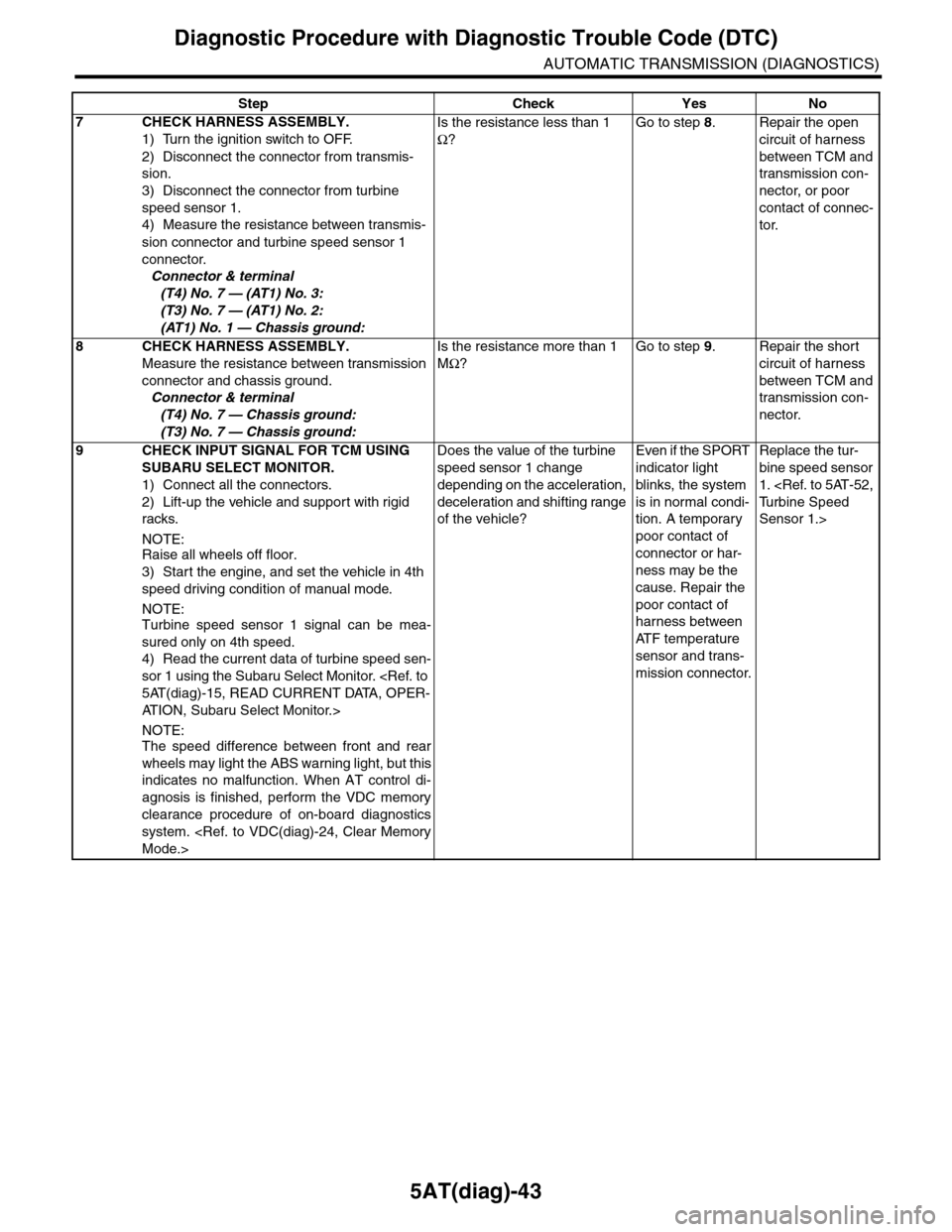

7CHECK HARNESS ASSEMBLY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Disconnect the connector from turbine

speed sensor 1.

4) Measure the resistance between transmis-

sion connector and turbine speed sensor 1

connector.

Connector & terminal

(T4) No. 7 — (AT1) No. 3:

(T3) No. 7 — (AT1) No. 2:

(AT1) No. 1 — Chassis ground:

Is the resistance less than 1

Ω?

Go to step 8.Repair the open

circuit of harness

between TCM and

transmission con-

nector, or poor

contact of connec-

tor.

8CHECK HARNESS ASSEMBLY.

Measure the resistance between transmission

connector and chassis ground.

Connector & terminal

(T4) No. 7 — Chassis ground:

(T3) No. 7 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 9.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

9CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:Raise all wheels off floor.

3) Start the engine, and set the vehicle in 4th

speed driving condition of manual mode.

NOTE:Turbine speed sensor 1 signal can be mea-

sured only on 4th speed.

4) Read the current data of turbine speed sen-

sor 1 using the Subaru Select Monitor.

AT I O N , S u b a r u S e l e c t M o n i t o r . >

NOTE:The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Does the value of the turbine

speed sensor 1 change

depending on the acceleration,

deceleration and shifting range

of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness between

AT F t e m p e r a t u r e

sensor and trans-

mission connector.

Replace the tur-

bine speed sensor

1.

Sensor 1.>

Step Check Yes No

Page 2165 of 2453

5AT(diag)-48

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

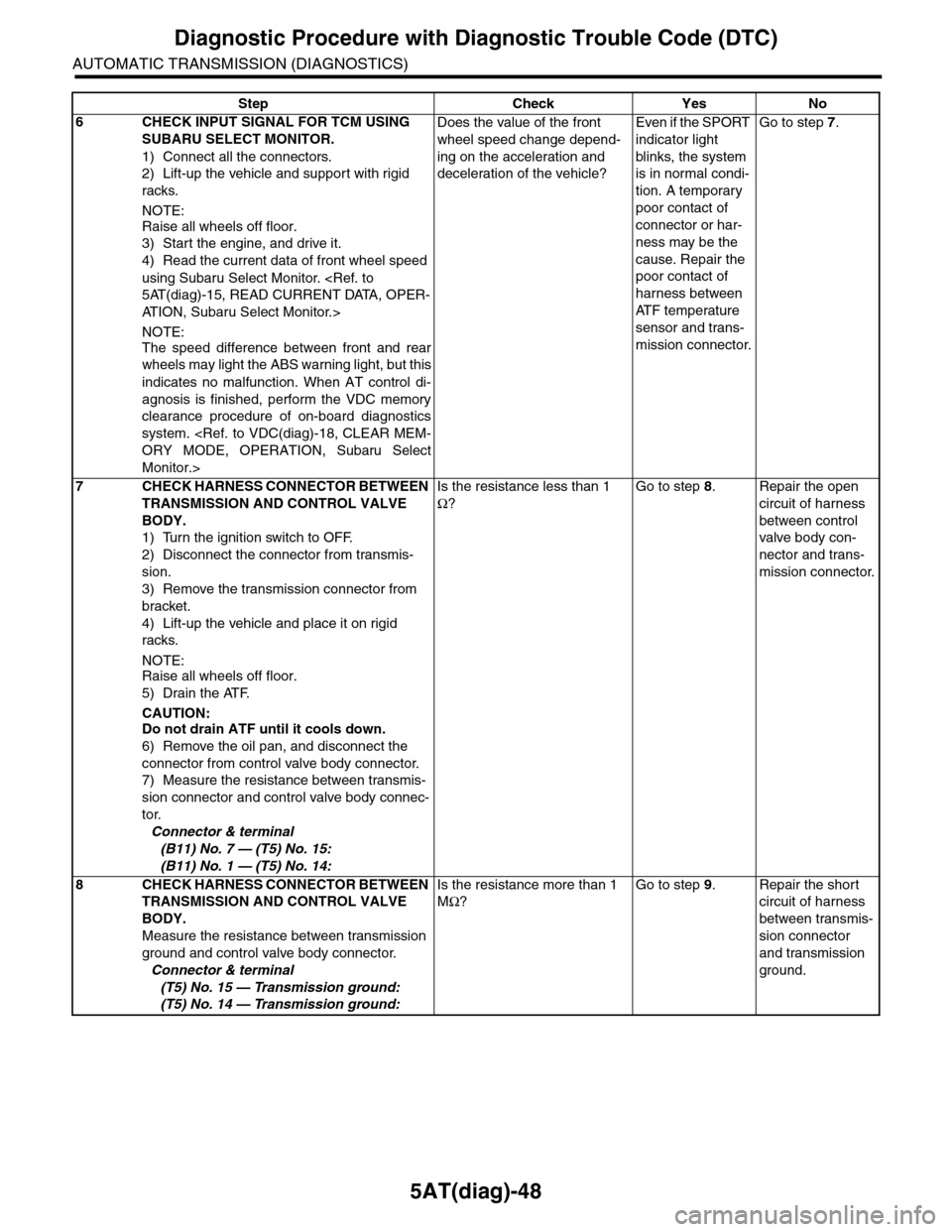

6CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:

Raise all wheels off floor.

3) Start the engine, and drive it.

4) Read the current data of front wheel speed

using Subaru Select Monitor.

AT I O N , S u b a r u S e l e c t M o n i t o r . >

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the value of the front

wheel speed change depend-

ing on the acceleration and

deceleration of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness between

AT F t e m p e r a t u r e

sensor and trans-

mission connector.

Go to step 7.

7CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:Raise all wheels off floor.

5) Drain the ATF.

CAUTION:Do not drain ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmis-

sion connector and control valve body connec-

tor.

Connector & terminal

(B11) No. 7 — (T5) No. 15:

(B11) No. 1 — (T5) No. 14:

Is the resistance less than 1

Ω?

Go to step 8.Repair the open

circuit of harness

between control

valve body con-

nector and trans-

mission connector.

8CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

Measure the resistance between transmission

ground and control valve body connector.

Connector & terminal

(T5) No. 15 — Transmission ground:

(T5) No. 14 — Transmission ground:

Is the resistance more than 1

MΩ?

Go to step 9.Repair the short

circuit of harness

between transmis-

sion connector

and transmission

ground.

Step Check Yes No

Page 2170 of 2453

5AT(diag)-53

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

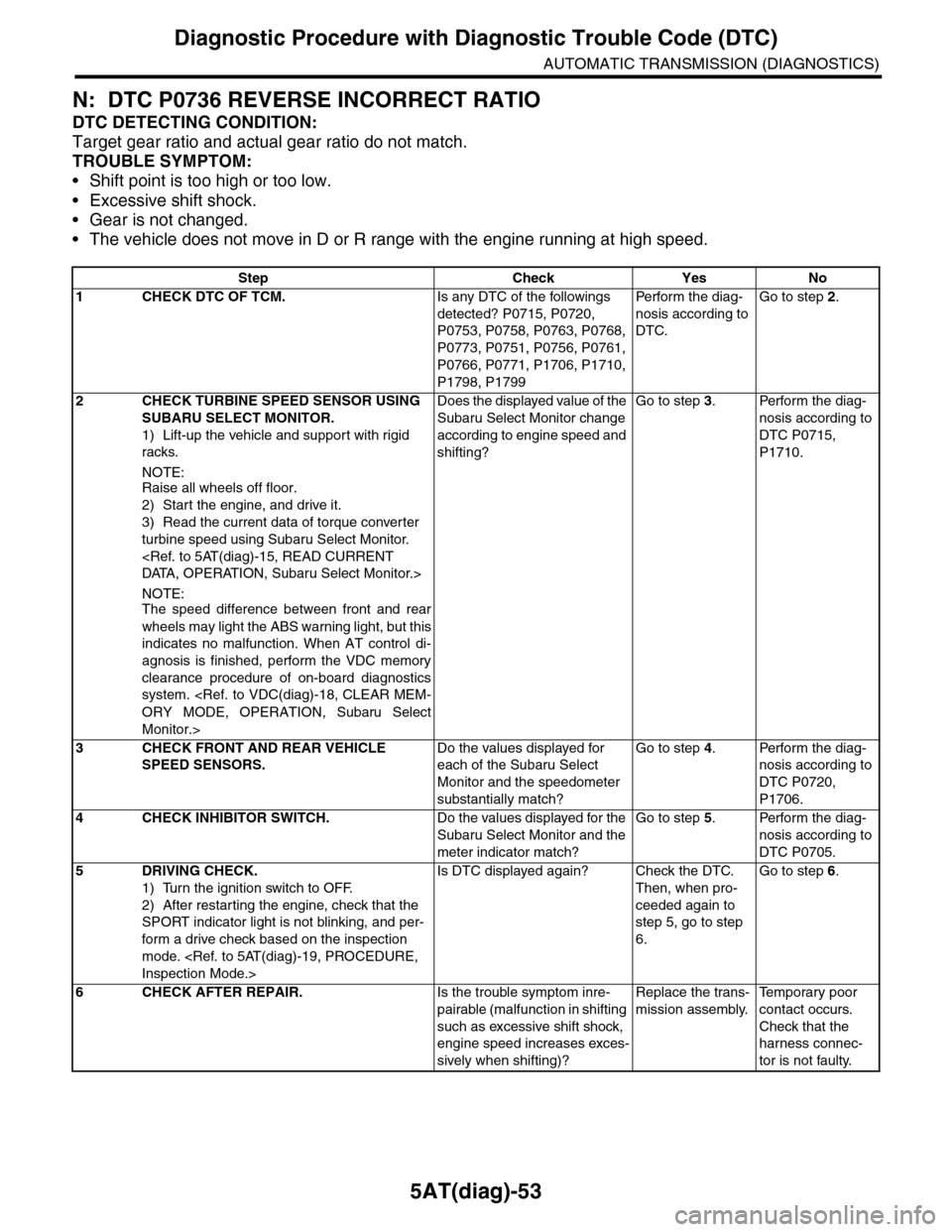

N: DTC P0736 REVERSE INCORRECT RATIO

DTC DETECTING CONDITION:

Target gear ratio and actual gear ratio do not match.

TROUBLE SYMPTOM:

•Shift point is too high or too low.

•Excessive shift shock.

•Gear is not changed.

•The vehicle does not move in D or R range with the engine running at high speed.

Step Check Yes No

1CHECK DTC OF TCM.Is any DTC of the followings

detected? P0715, P0720,

P0753, P0758, P0763, P0768,

P0773, P0751, P0756, P0761,

P0766, P0771, P1706, P1710,

P1798, P1799

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK TURBINE SPEED SENSOR USING

SUBARU SELECT MONITOR.

1) Lift-up the vehicle and support with rigid

racks.

NOTE:Raise all wheels off floor.

2) Start the engine, and drive it.

3) Read the current data of torque converter

turbine speed using Subaru Select Monitor.

NOTE:The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the displayed value of the

Subaru Select Monitor change

according to engine speed and

shifting?

Go to step 3.Perform the diag-

nosis according to

DTC P0715,

P1710.

3CHECK FRONT AND REAR VEHICLE

SPEED SENSORS.

Do the values displayed for

each of the Subaru Select

Monitor and the speedometer

substantially match?

Go to step 4.Perform the diag-

nosis according to

DTC P0720,

P1706.

4CHECK INHIBITOR SWITCH.Do the values displayed for the

Subaru Select Monitor and the

meter indicator match?

Go to step 5.Perform the diag-

nosis according to

DTC P0705.

5DRIVING CHECK.

1) Turn the ignition switch to OFF.

2) After restarting the engine, check that the

SPORT indicator light is not blinking, and per-

form a drive check based on the inspection

mode.

Is DTC displayed again? Check the DTC.

Then, when pro-

ceeded again to

step 5, go to step

6.

Go to step 6.

6CHECK AFTER REPAIR.Is the trouble symptom inre-

pairable (malfunction in shifting

such as excessive shift shock,

engine speed increases exces-

sively when shifting)?

Replace the trans-

mission assembly.

Te m p o r a r y p o o r

contact occurs.

Check that the

harness connec-

tor is not faulty.

Page 2207 of 2453

5AT(diag)-90

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

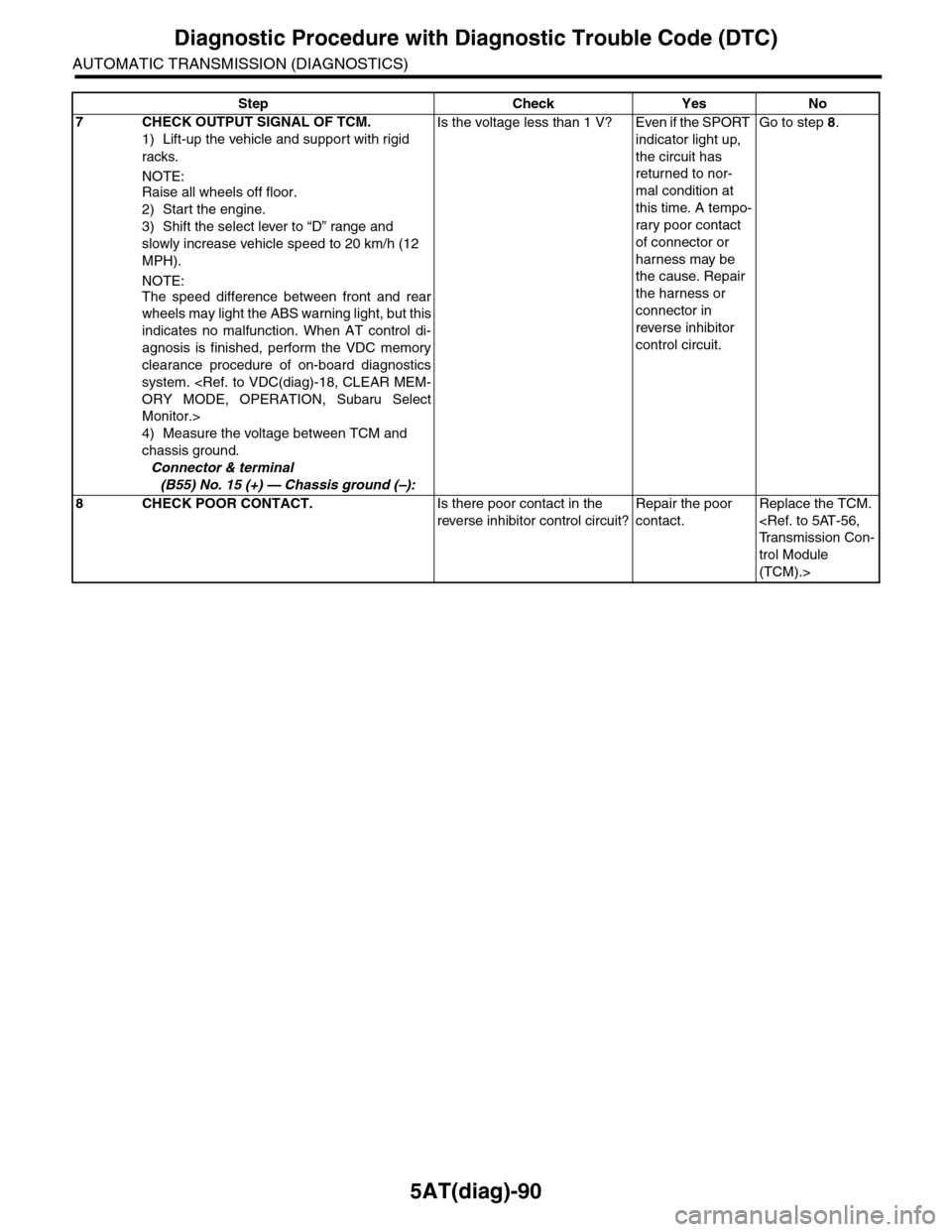

7CHECK OUTPUT SIGNAL OF TCM.

1) Lift-up the vehicle and support with rigid

racks.

NOTE:Raise all wheels off floor.

2) Start the engine.

3) Shift the select lever to “D” range and

slowly increase vehicle speed to 20 km/h (12

MPH).

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

4) Measure the voltage between TCM and

chassis ground.

Connector & terminal

(B55) No. 15 (+) — Chassis ground (–):

Is the voltage less than 1 V? Even if the SPORT

indicator light up,

the circuit has

returned to nor-

mal condition at

this time. A tempo-

rary poor contact

of connector or

harness may be

the cause. Repair

the harness or

connector in

reverse inhibitor

control circuit.

Go to step 8.

8CHECK POOR CONTACT.Is there poor contact in the

reverse inhibitor control circuit?

Repair the poor

contact.

Replace the TCM.

trol Module

(TCM).>

Step Check Yes No

Page 2220 of 2453

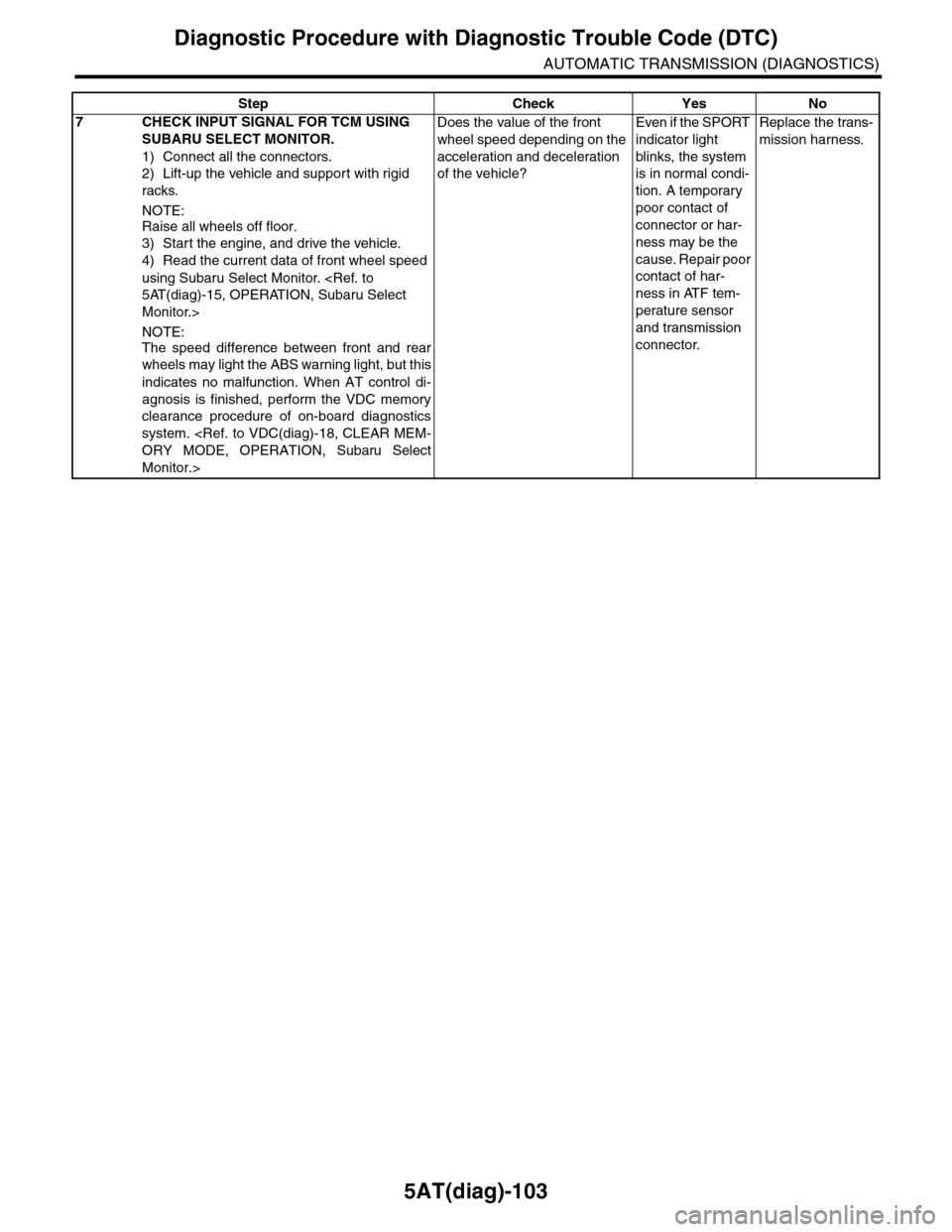

5AT(diag)-103

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

7CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:

Raise all wheels off floor.

3) Start the engine, and drive the vehicle.

4) Read the current data of front wheel speed

using Subaru Select Monitor.

Monitor.>

NOTE:

The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the value of the front

wheel speed depending on the

acceleration and deceleration

of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair poor

contact of har-

ness in ATF tem-

perature sensor

and transmission

connector.

Replace the trans-

mission harness.

Step Check Yes No

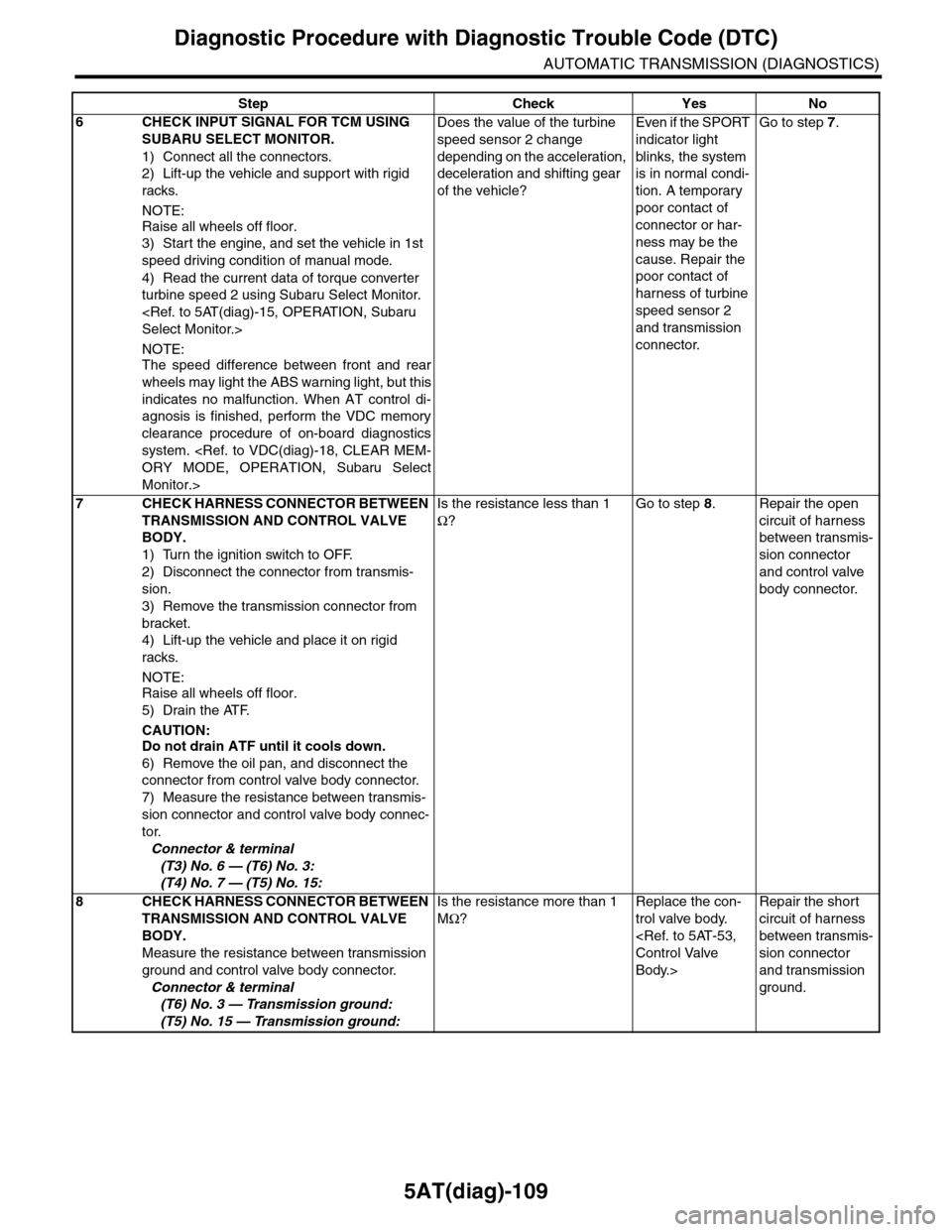

Page 2226 of 2453

5AT(diag)-109

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

6CHECK INPUT SIGNAL FOR TCM USING

SUBARU SELECT MONITOR.

1) Connect all the connectors.

2) Lift-up the vehicle and support with rigid

racks.

NOTE:

Raise all wheels off floor.

3) Start the engine, and set the vehicle in 1st

speed driving condition of manual mode.

4) Read the current data of torque converter

turbine speed 2 using Subaru Select Monitor.

NOTE:The speed difference between front and rear

wheels may light the ABS warning light, but this

indicates no malfunction. When AT control di-

agnosis is finished, perform the VDC memory

clearance procedure of on-board diagnostics

system.

Monitor.>

Does the value of the turbine

speed sensor 2 change

depending on the acceleration,

deceleration and shifting gear

of the vehicle?

Even if the SPORT

indicator light

blinks, the system

is in normal condi-

tion. A temporary

poor contact of

connector or har-

ness may be the

cause. Repair the

poor contact of

harness of turbine

speed sensor 2

and transmission

connector.

Go to step 7.

7CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from transmis-

sion.

3) Remove the transmission connector from

bracket.

4) Lift-up the vehicle and place it on rigid

racks.

NOTE:

Raise all wheels off floor.

5) Drain the ATF.

CAUTION:Do not drain ATF until it cools down.

6) Remove the oil pan, and disconnect the

connector from control valve body connector.

7) Measure the resistance between transmis-

sion connector and control valve body connec-

tor.

Connector & terminal

(T3) No. 6 — (T6) No. 3:

(T4) No. 7 — (T5) No. 15:

Is the resistance less than 1

Ω?

Go to step 8.Repair the open

circuit of harness

between transmis-

sion connector

and control valve

body connector.

8CHECK HARNESS CONNECTOR BETWEEN

TRANSMISSION AND CONTROL VALVE

BODY.

Measure the resistance between transmission

ground and control valve body connector.

Connector & terminal

(T6) No. 3 — Transmission ground:

(T5) No. 15 — Transmission ground:

Is the resistance more than 1

MΩ?

Replace the con-

trol valve body.

Body.>

Repair the short

circuit of harness

between transmis-

sion connector

and transmission

ground.

Step Check Yes No