ignition coil SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 189 of 2453

ET-3

Audio System

ENTERTAINMENT

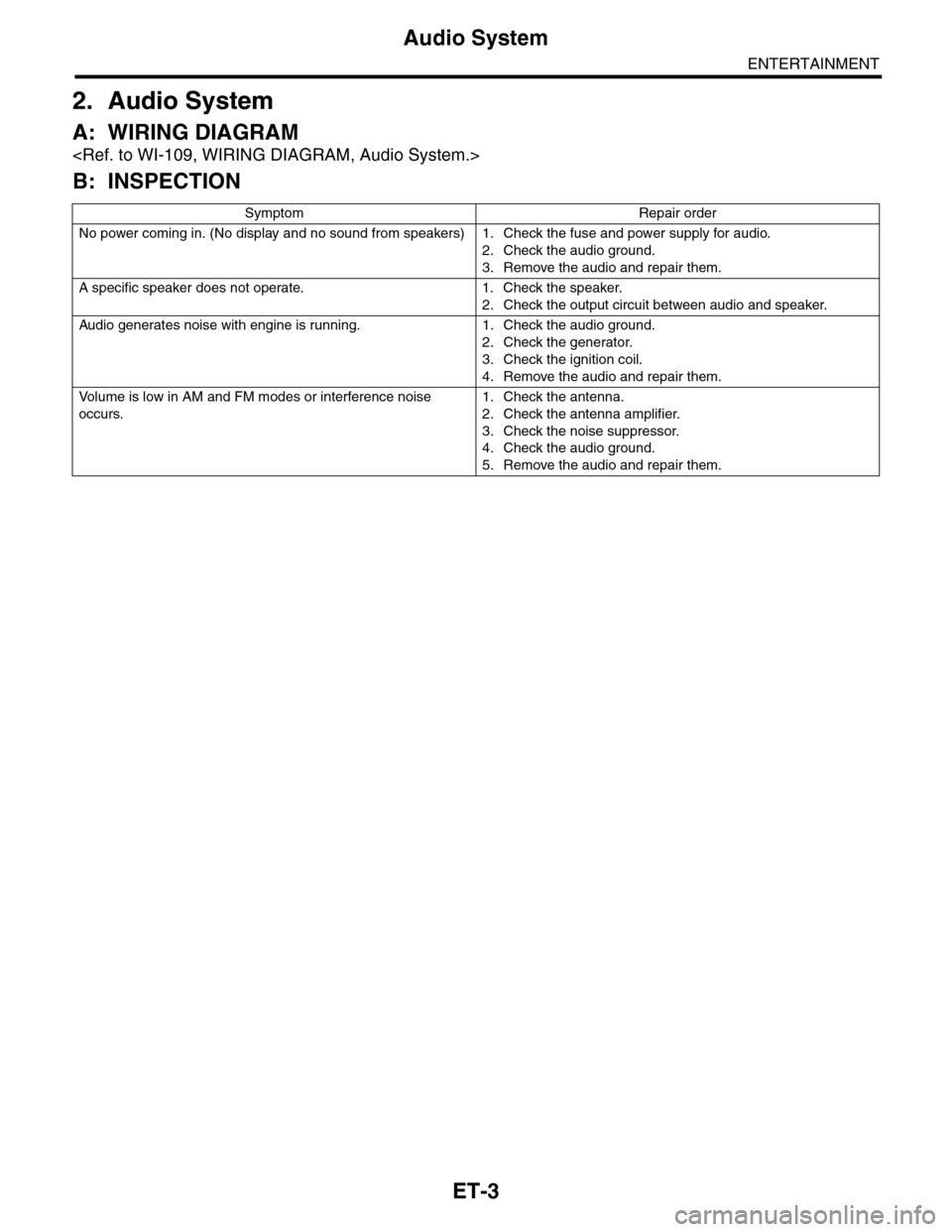

2. Audio System

A: WIRING DIAGRAM

B: INSPECTION

Symptom Repair order

No power coming in. (No display and no sound from speakers) 1. Check the fuse and power supply for audio.

2. Check the audio ground.

3. Remove the audio and repair them.

A specific speaker does not operate. 1. Check the speaker.

2. Check the output circuit between audio and speaker.

Audio generates noise with engine is r unning. 1. C heck the audio ground.

2. Check the generator.

3. Check the ignition coil.

4. Remove the audio and repair them.

Vo l u m e i s l o w i n A M a n d F M m o d e s o r i n t e r f e r e n c e n o i s e

occurs.

1. Check the antenna.

2. Check the antenna amplifier.

3. Check the noise suppressor.

4. Check the audio ground.

5. Remove the audio and repair them.

Page 1127 of 2453

CO(H6DO)-8

Radiator Fan System

COOLING

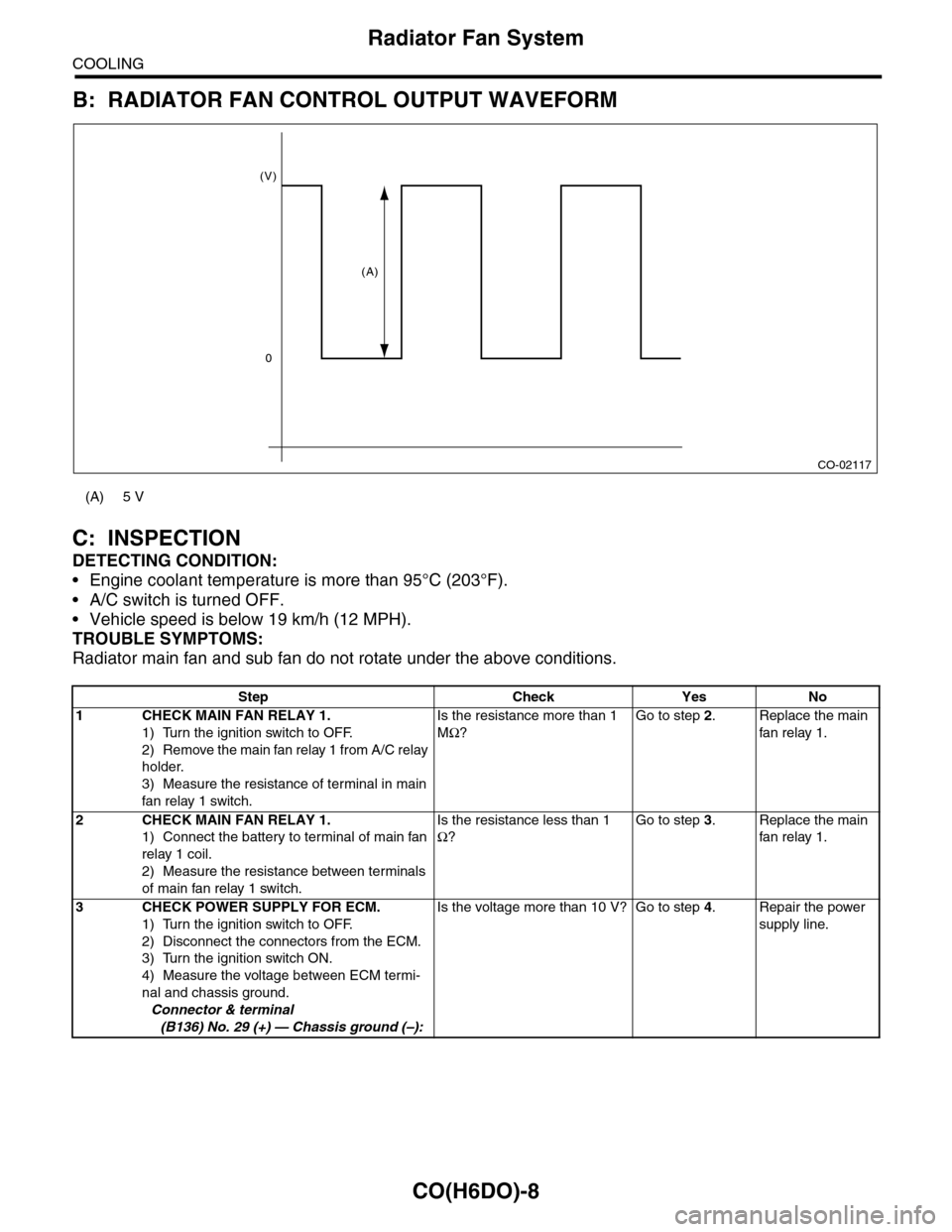

B: RADIATOR FAN CONTROL OUTPUT WAVEFORM

C: INSPECTION

DETECTING CONDITION:

•Engine coolant temperature is more than 95°C (203°F).

•A/C switch is turned OFF.

•Vehicle speed is below 19 km/h (12 MPH).

TROUBLE SYMPTOMS:

Radiator main fan and sub fan do not rotate under the above conditions.

(A) 5 V

Step Check Yes No

1CHECK MAIN FAN RELAY 1.

1) Turn the ignition switch to OFF.

2) Remove the main fan relay 1 from A/C relay

holder.

3) Measure the resistance of terminal in main

fan relay 1 switch.

Is the resistance more than 1

MΩ?

Go to step 2.Replace the main

fan relay 1.

2CHECK MAIN FAN RELAY 1.

1) Connect the battery to terminal of main fan

relay 1 coil.

2) Measure the resistance between terminals

of main fan relay 1 switch.

Is the resistance less than 1

Ω?

Go to step 3.Replace the main

fan relay 1.

3CHECK POWER SUPPLY FOR ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from the ECM.

3) Turn the ignition switch ON.

4) Measure the voltage between ECM termi-

nal and chassis ground.

Connector & terminal

(B136) No. 29 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Repair the power

supply line.

CO-02117

(V)

0

(A)

Page 1174 of 2453

EN(H6DO)(diag)-13

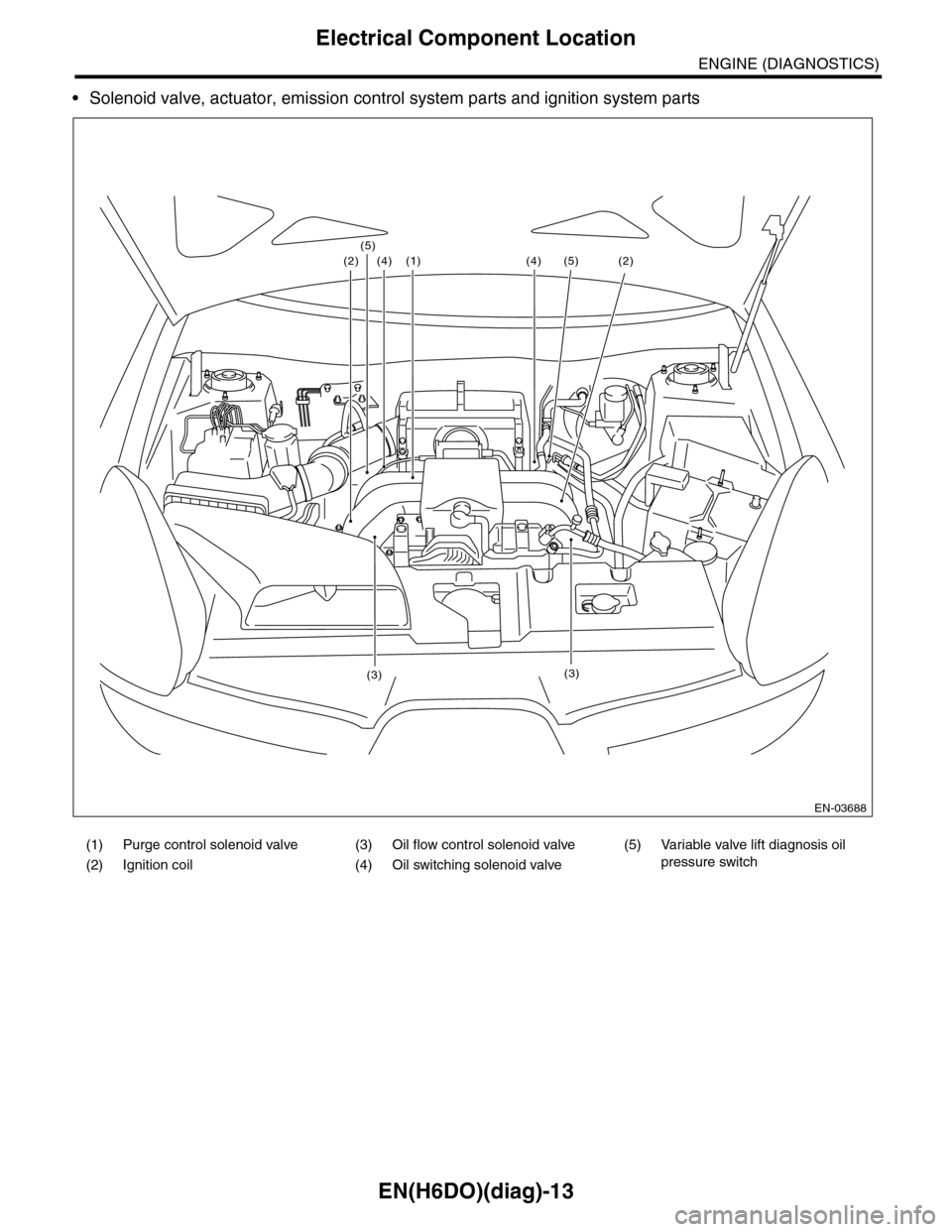

Electrical Component Location

ENGINE (DIAGNOSTICS)

•Solenoid valve, actuator, emission control system parts and ignition system parts

(1) Purge control solenoid valve (3) Oil flow control solenoid valve (5)

Va r i a b l e va l v e l i f t d i a g n o s i s o i l

pressure switch(2) Ignition coil (4) Oil switching solenoid valve

EN-03688

(5) (2)

(3)

(2) (1)

(3)

(4) (4)(5)

Page 1224 of 2453

EN(H6DO)(diag)-63

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

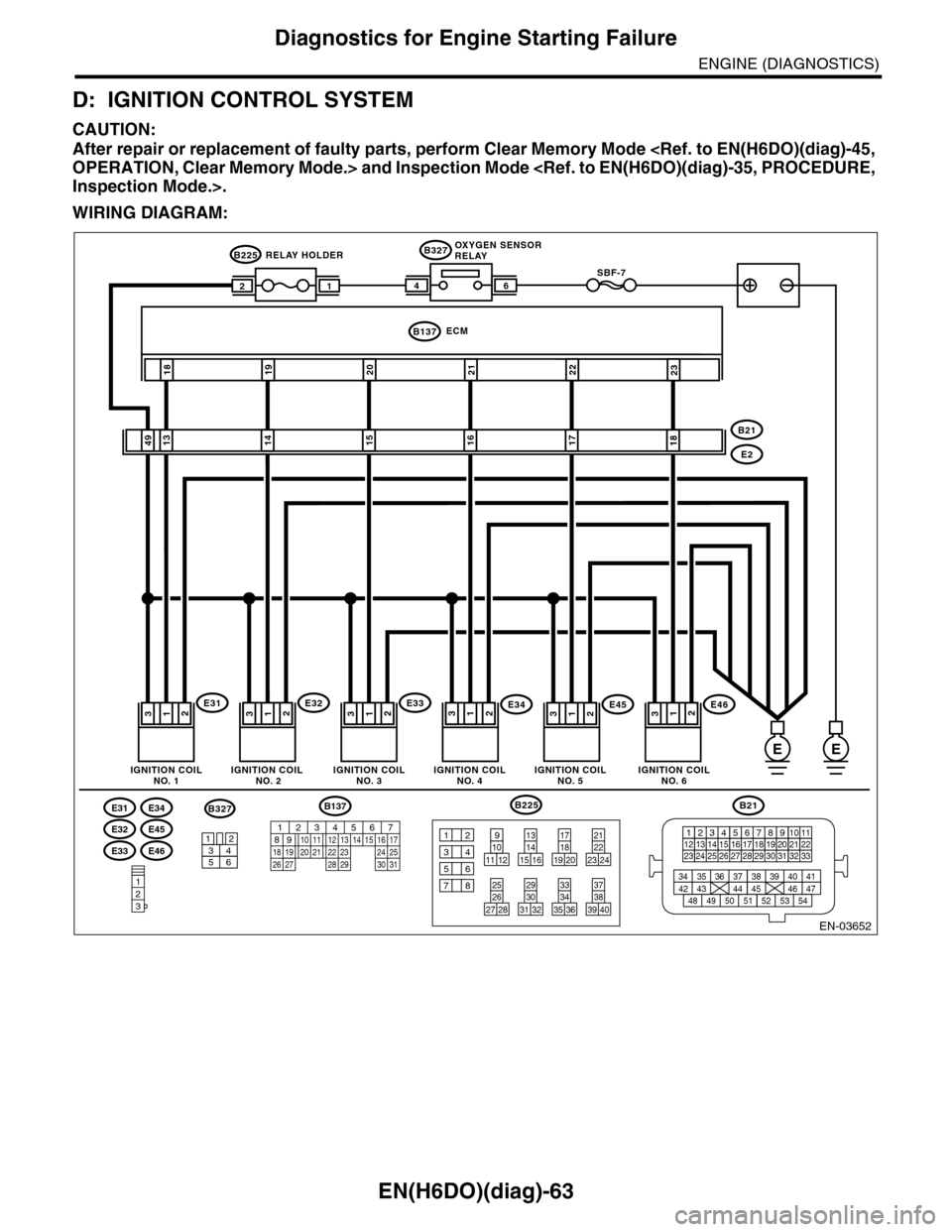

D: IGNITION CONTROL SYSTEM

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03652

E34

E45

E31

E32

E46E33

123

ECMB137

231918212220

SBF-746

B327

E46

E2

B21

E32

1814131617

32312E3432E4532

1549

111E31312E33312

12

B225

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

91012

34

56

78

11 121415 16

131819 20

172223 24

21

3839 40

373435 36

333031 32

292627 28

25

B225B327

3412

56

EE

OXYGEN SENSORRELAY

IGNITION COILNO. 1

RELAY HOLDER

IGNITION COIL NO. 2IGNITION COILNO. 3IGNITION COILNO. 4IGNITION COILNO. 5IGNITION COILNO. 6

B137

85610 11 12 13 14 157213416

3019 20 2228 29

91718 2521 23 243126 27

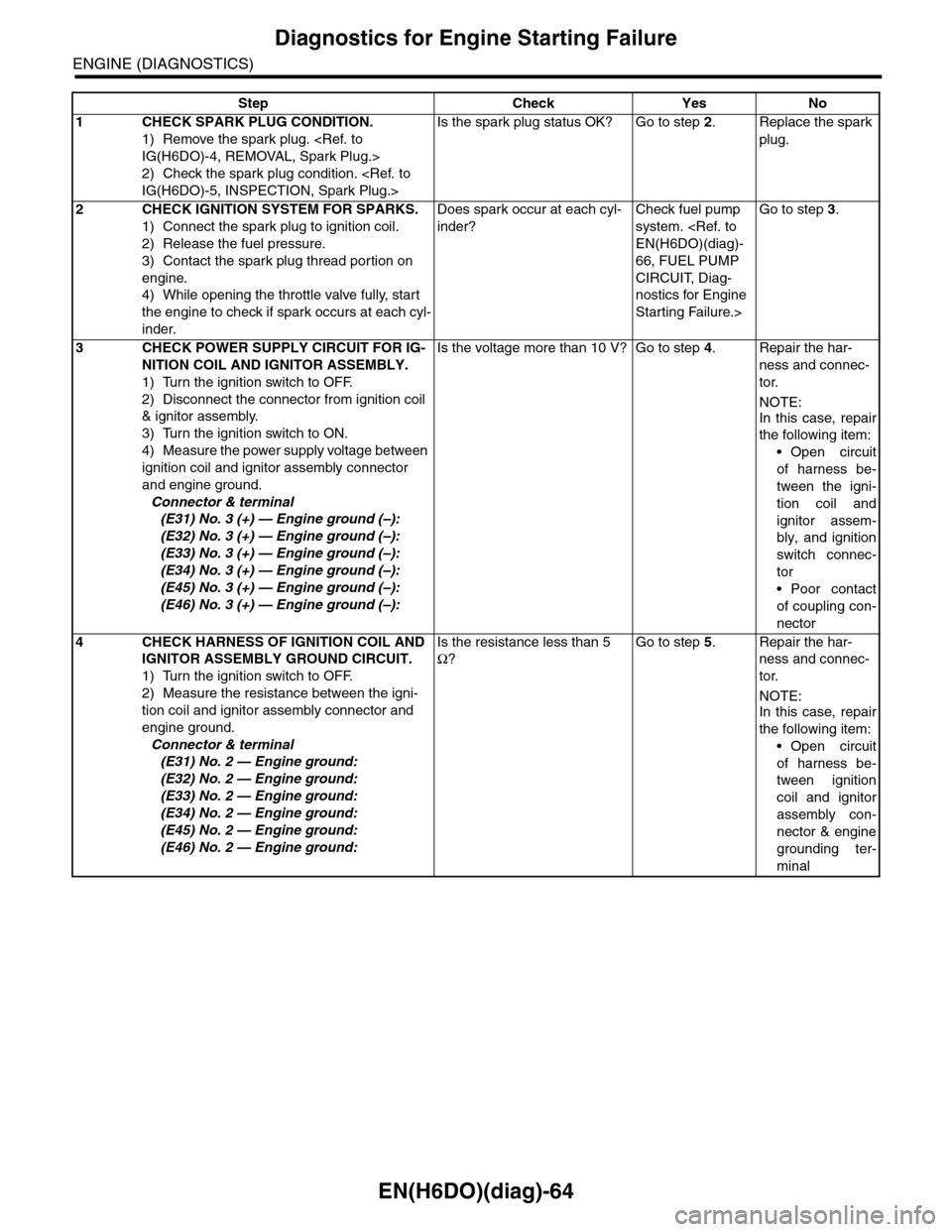

Page 1225 of 2453

EN(H6DO)(diag)-64

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK SPARK PLUG CONDITION.

1) Remove the spark plug.

2) Check the spark plug condition.

Is the spark plug status OK? Go to step 2.Replace the spark

plug.

2CHECK IGNITION SYSTEM FOR SPARKS.

1) Connect the spark plug to ignition coil.

2) Release the fuel pressure.

3) Contact the spark plug thread portion on

engine.

4) While opening the throttle valve fully, start

the engine to check if spark occurs at each cyl-

inder.

Does spark occur at each cyl-

inder?

Check fuel pump

system.

66, FUEL PUMP

CIRCUIT, Diag-

nostics for Engine

Starting Failure.>

Go to step 3.

3CHECK POWER SUPPLY CIRCUIT FOR IG-

NITION COIL AND IGNITOR ASSEMBLY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ignition coil

& ignitor assembly.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

ignition coil and ignitor assembly connector

and engine ground.

Connector & terminal

(E31) No. 3 (+) — Engine ground (–):

(E32) No. 3 (+) — Engine ground (–):

(E33) No. 3 (+) — Engine ground (–):

(E34) No. 3 (+) — Engine ground (–):

(E45) No. 3 (+) — Engine ground (–):

(E46) No. 3 (+) — Engine ground (–):

Is the voltage more than 10 V? Go to step 4.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween the igni-

tion coil and

ignitor assem-

bly, and ignition

switch connec-

tor

•Poor contact

of coupling con-

nector

4CHECK HARNESS OF IGNITION COIL AND

IGNITOR ASSEMBLY GROUND CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between the igni-

tion coil and ignitor assembly connector and

engine ground.

Connector & terminal

(E31) No. 2 — Engine ground:

(E32) No. 2 — Engine ground:

(E33) No. 2 — Engine ground:

(E34) No. 2 — Engine ground:

(E45) No. 2 — Engine ground:

(E46) No. 2 — Engine ground:

Is the resistance less than 5

Ω?

Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween ignition

coil and ignitor

assembly con-

nector & engine

grounding ter-

minal

Page 1226 of 2453

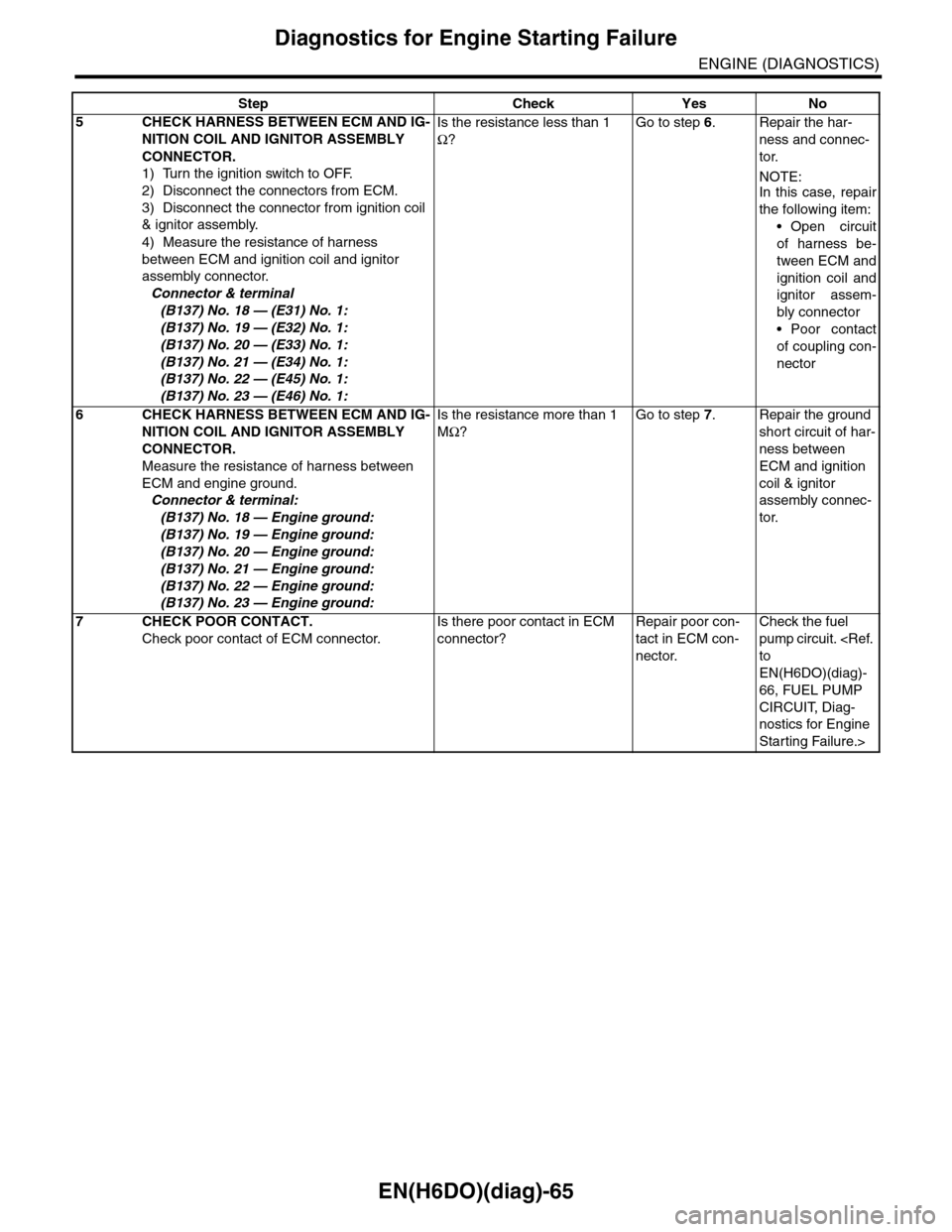

EN(H6DO)(diag)-65

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

5CHECK HARNESS BETWEEN ECM AND IG-

NITION COIL AND IGNITOR ASSEMBLY

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Disconnect the connector from ignition coil

& ignitor assembly.

4) Measure the resistance of harness

between ECM and ignition coil and ignitor

assembly connector.

Connector & terminal

(B137) No. 18 — (E31) No. 1:

(B137) No. 19 — (E32) No. 1:

(B137) No. 20 — (E33) No. 1:

(B137) No. 21 — (E34) No. 1:

(B137) No. 22 — (E45) No. 1:

(B137) No. 23 — (E46) No. 1:

Is the resistance less than 1

Ω?

Go to step 6.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

ignition coil and

ignitor assem-

bly connector

•Poor contact

of coupling con-

nector

6CHECK HARNESS BETWEEN ECM AND IG-

NITION COIL AND IGNITOR ASSEMBLY

CONNECTOR.

Measure the resistance of harness between

ECM and engine ground.

Connector & terminal:

(B137) No. 18 — Engine ground:

(B137) No. 19 — Engine ground:

(B137) No. 20 — Engine ground:

(B137) No. 21 — Engine ground:

(B137) No. 22 — Engine ground:

(B137) No. 23 — Engine ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the ground

short circuit of har-

ness between

ECM and ignition

coil & ignitor

assembly connec-

tor.

7CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Check the fuel

pump circuit.

EN(H6DO)(diag)-

66, FUEL PUMP

CIRCUIT, Diag-

nostics for Engine

Starting Failure.>

Step Check Yes No

Page 1408 of 2453

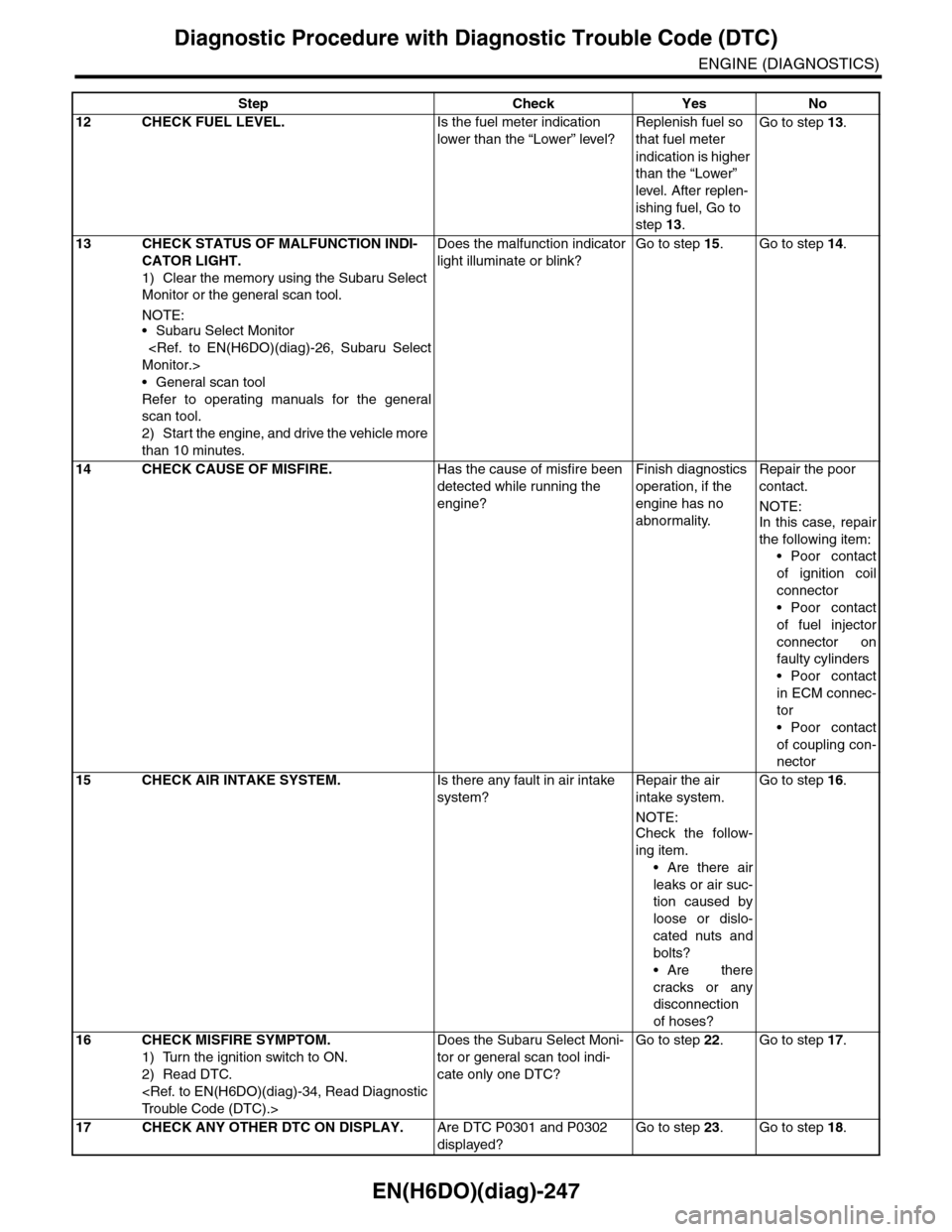

EN(H6DO)(diag)-247

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

12 CHECK FUEL LEVEL.Is the fuel meter indication

lower than the “Lower” level?

Replenish fuel so

that fuel meter

indication is higher

than the “Lower”

level. After replen-

ishing fuel, Go to

step 13.

Go to step 13.

13 CHECK STATUS OF MALFUNCTION INDI-

CATOR LIGHT.

1) Clear the memory using the Subaru Select

Monitor or the general scan tool.

NOTE:•Subaru Select Monitor

•General scan tool

Refer to operating manuals for the general

scan tool.

2) Start the engine, and drive the vehicle more

than 10 minutes.

Does the malfunction indicator

light illuminate or blink?

Go to step 15.Go to step 14.

14 CHECK CAUSE OF MISFIRE.Has the cause of misfire been

detected while running the

engine?

Finish diagnostics

operation, if the

engine has no

abnormality.

Repair the poor

contact.

NOTE:In this case, repair

the following item:

•Poor contact

of ignition coil

connector

•Poor contact

of fuel injector

connector on

faulty cylinders

•Poor contact

in ECM connec-

tor

•Poor contact

of coupling con-

nector

15 CHECK AIR INTAKE SYSTEM.Is there any fault in air intake

system?

Repair the air

intake system.

NOTE:

Check the follow-

ing item.

•Are there air

leaks or air suc-

tion caused by

loose or dislo-

cated nuts and

bolts?

•Are there

cracks or any

disconnection

of hoses?

Go to step 16.

16 CHECK MISFIRE SYMPTOM.

1) Turn the ignition switch to ON.

2) Read DTC.

Does the Subaru Select Moni-

tor or general scan tool indi-

cate only one DTC?

Go to step 22.Go to step 17.

17 CHECK ANY OTHER DTC ON DISPLAY.Are DTC P0301 and P0302

displayed?

Go to step 23.Go to step 18.

Step Check Yes No

Page 1409 of 2453

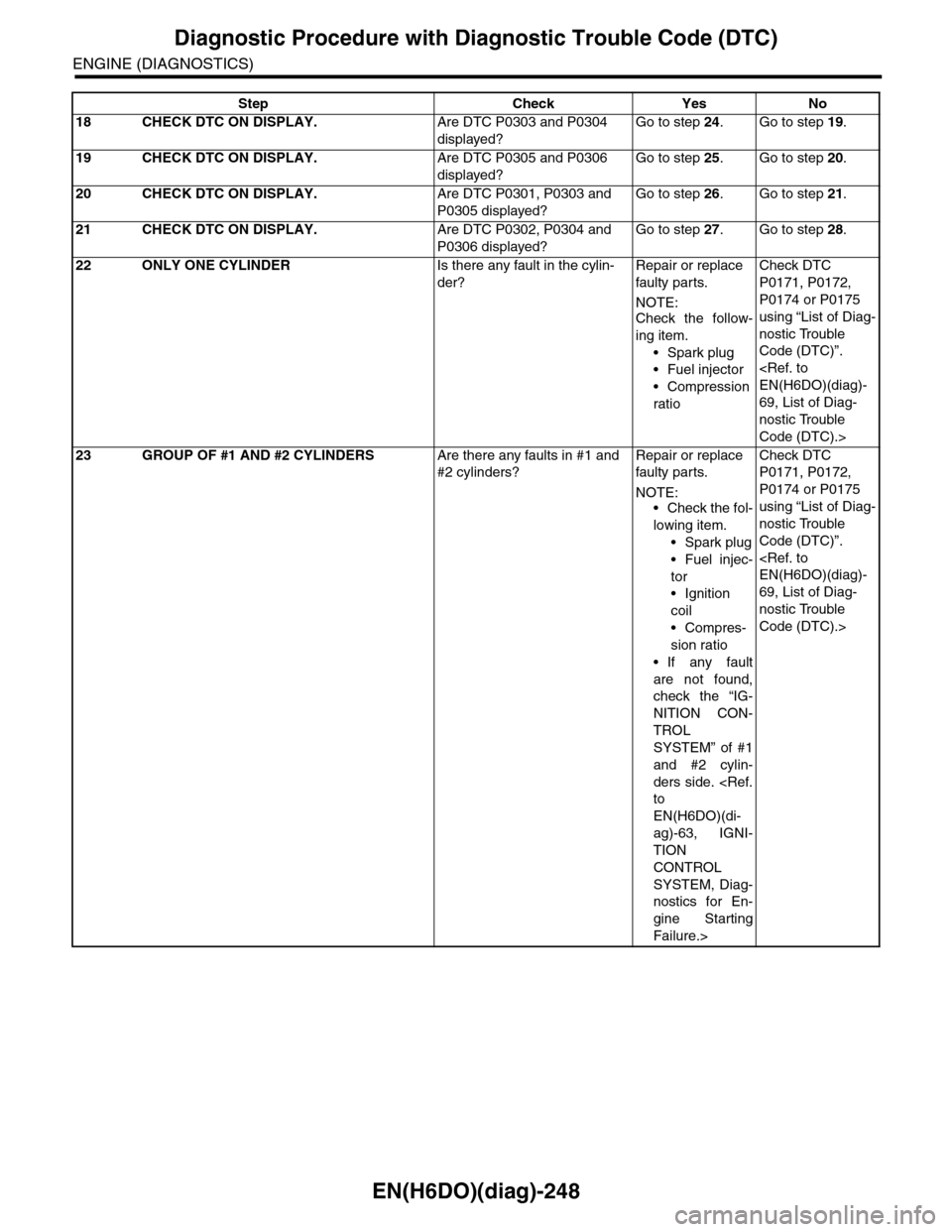

EN(H6DO)(diag)-248

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

18 CHECK DTC ON DISPLAY.Are DTC P0303 and P0304

displayed?

Go to step 24.Go to step 19.

19 CHECK DTC ON DISPLAY.Are DTC P0305 and P0306

displayed?

Go to step 25.Go to step 20.

20 CHECK DTC ON DISPLAY.Are DTC P0301, P0303 and

P0305 displayed?

Go to step 26.Go to step 21.

21 CHECK DTC ON DISPLAY.Are DTC P0302, P0304 and

P0306 displayed?

Go to step 27.Go to step 28.

22 ONLY ONE CYLINDERIs there any fault in the cylin-

der?

Repair or replace

faulty par ts.

NOTE:Check the follow-

ing item.

•Spark plug

•Fuel injector

•Compression

ratio

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

23 GROUP OF #1 AND #2 CYLINDERSAre there any faults in #1 and

#2 cylinders?

Repair or replace

faulty par ts.

NOTE:•Check the fol-

lowing item.

•Spark plug

•Fuel injec-

tor

•Ignition

coil

•Compres-

sion ratio

•If any fault

are not found,

check the “IG-

NITION CON-

TROL

SYSTEM” of #1

and #2 cylin-

ders side.

EN(H6DO)(di-

ag)-63, IGNI-

TION

CONTROL

SYSTEM, Diag-

nostics for En-

gine Starting

Failure.>

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Step Check Yes No

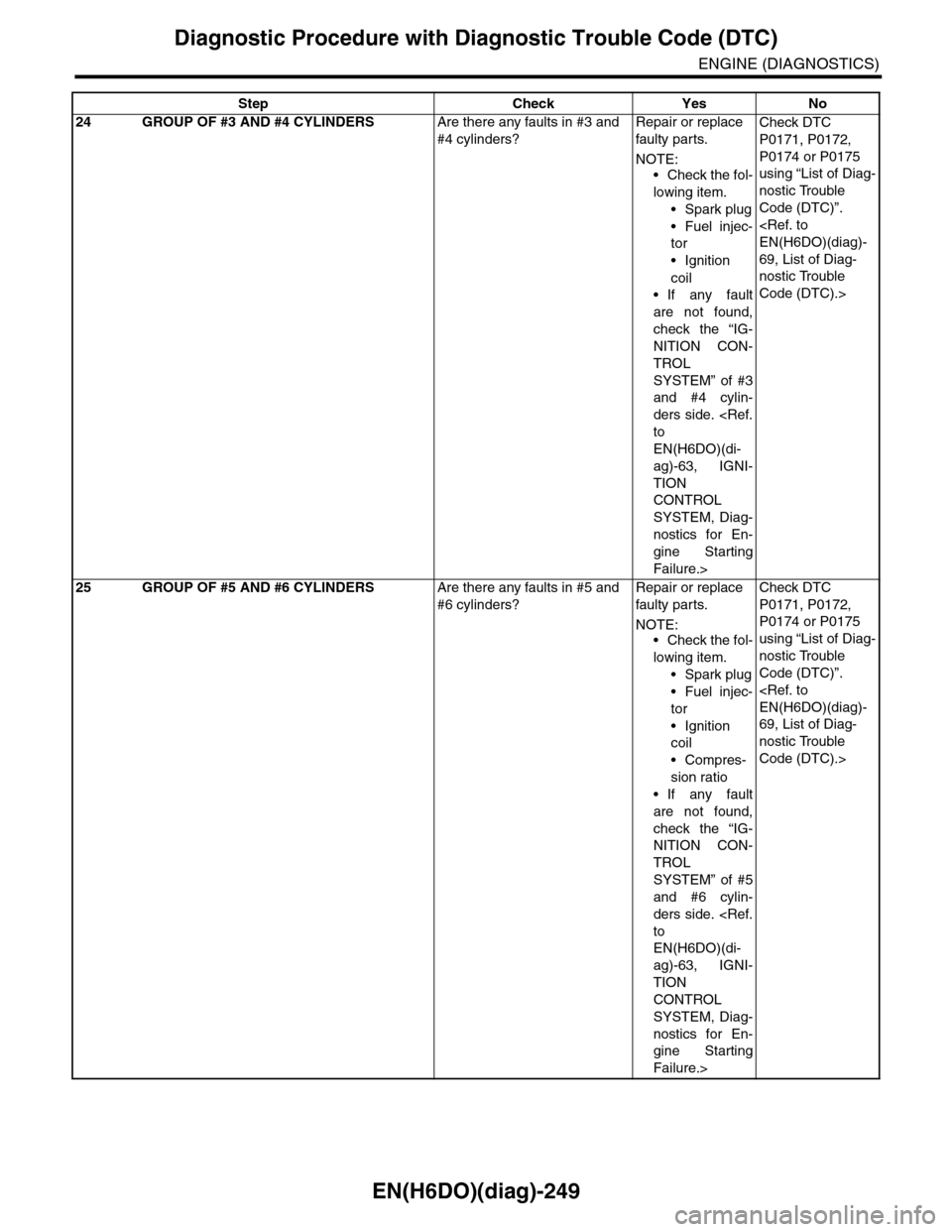

Page 1410 of 2453

EN(H6DO)(diag)-249

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

24 GROUP OF #3 AND #4 CYLINDERSAre there any faults in #3 and

#4 cylinders?

Repair or replace

faulty par ts.

NOTE:

•Check the fol-

lowing item.

•Spark plug

•Fuel injec-

tor

•Ignition

coil

•If any fault

are not found,

check the “IG-

NITION CON-

TROL

SYSTEM” of #3

and #4 cylin-

ders side.

EN(H6DO)(di-

ag)-63, IGNI-

TION

CONTROL

SYSTEM, Diag-

nostics for En-

gine Starting

Failure.>

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

25 GROUP OF #5 AND #6 CYLINDERSAre there any faults in #5 and

#6 cylinders?

Repair or replace

faulty par ts.

NOTE:•Check the fol-

lowing item.

•Spark plug

•Fuel injec-

tor

•Ignition

coil

•Compres-

sion ratio

•If any fault

are not found,

check the “IG-

NITION CON-

TROL

SYSTEM” of #5

and #6 cylin-

ders side.

EN(H6DO)(di-

ag)-63, IGNI-

TION

CONTROL

SYSTEM, Diag-

nostics for En-

gine Starting

Failure.>

Check DTC

P0171, P0172,

P0174 or P0175

using “List of Diag-

nostic Trouble

Code (DTC)”.

69, List of Diag-

nostic Trouble

Code (DTC).>

Step Check Yes No

Page 1554 of 2453

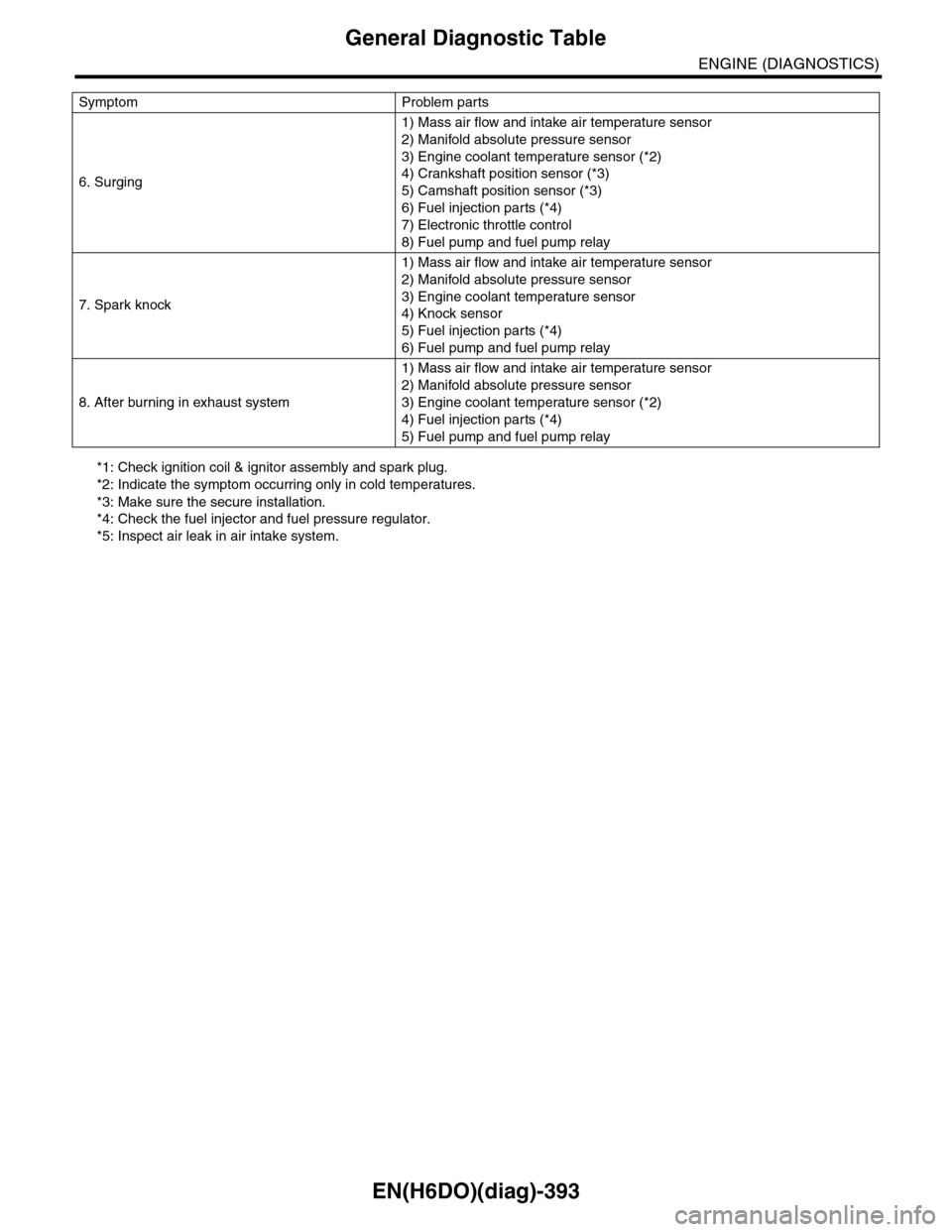

EN(H6DO)(diag)-393

General Diagnostic Table

ENGINE (DIAGNOSTICS)

*1: Check ignition coil & ignitor assembly and spark plug.

*2: Indicate the symptom occurring only in cold temperatures.

*3: Make sure the secure installation.

*4: Check the fuel injector and fuel pressure regulator.

*5: Inspect air leak in air intake system.

6. Surging

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Crankshaft position sensor (*3)

5) Camshaft position sensor (*3)

6) Fuel injection parts (*4)

7) Electronic throttle control

8) Fuel pump and fuel pump relay

7. Spark knock

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor

4) Knock sensor

5) Fuel injection parts (*4)

6) Fuel pump and fuel pump relay

8. After burning in exhaust system

1) Mass air flow and intake air temperature sensor

2) Manifold absolute pressure sensor

3) Engine coolant temperature sensor (*2)

4) Fuel injection parts (*4)

5) Fuel pump and fuel pump relay

Symptom Problem parts