ignition coil SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1837 of 2453

IG(H6DO)-2

General Description

IGNITION

1. General Description

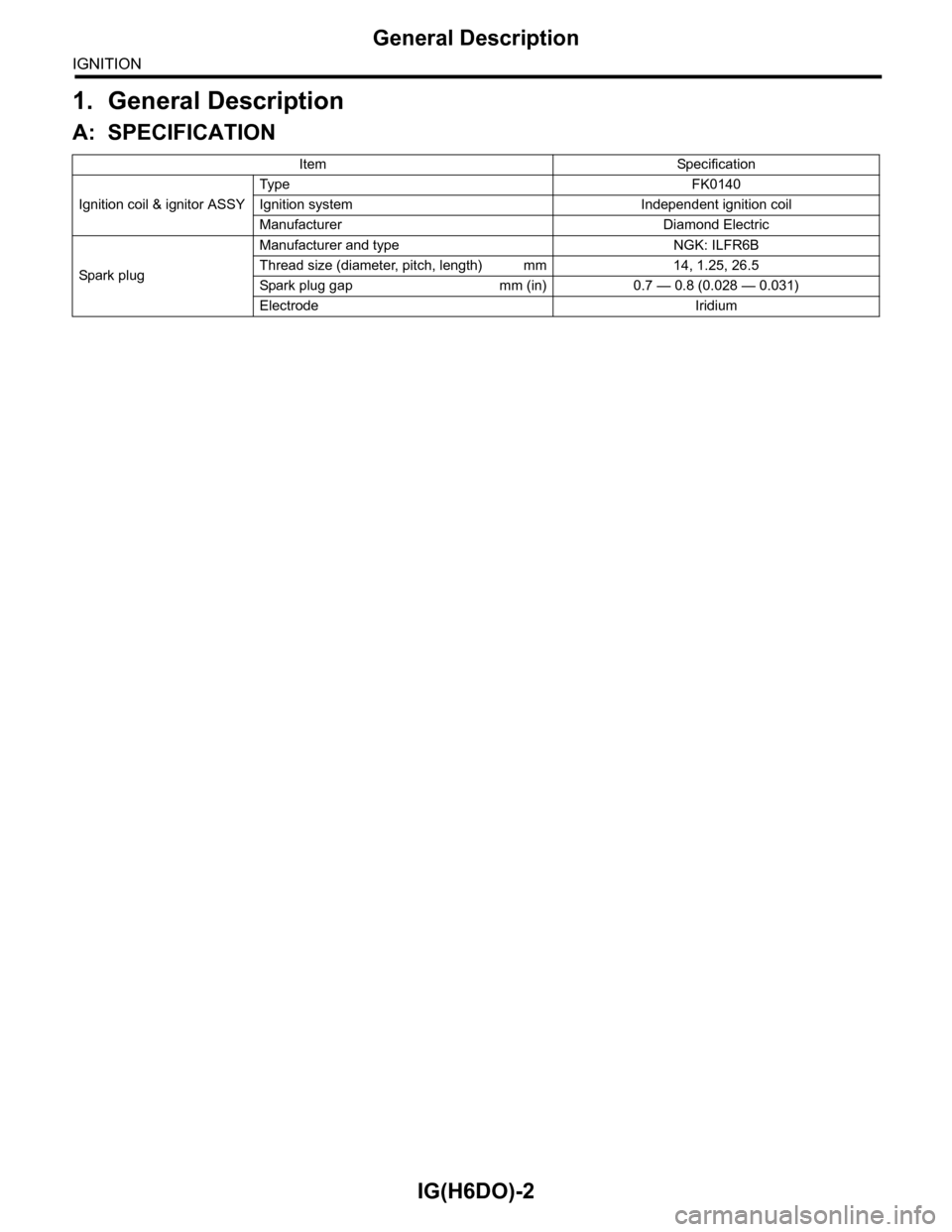

A: SPECIFICATION

Item Specification

Ignition coil & ignitor ASSY

Typ e F K 0 14 0

Ignition system Independent ignition coil

Manufacturer Diamond Electric

Spar k p l ug

Manufacturer and type NGK: ILFR6B

Thread size (diameter, pitch, length) mm 14, 1.25, 26.5

Spark plug gap mm (in) 0.7 — 0.8 (0.028 — 0.031)

Electrode Iridium

Page 1838 of 2453

IG(H6DO)-3

General Description

IGNITION

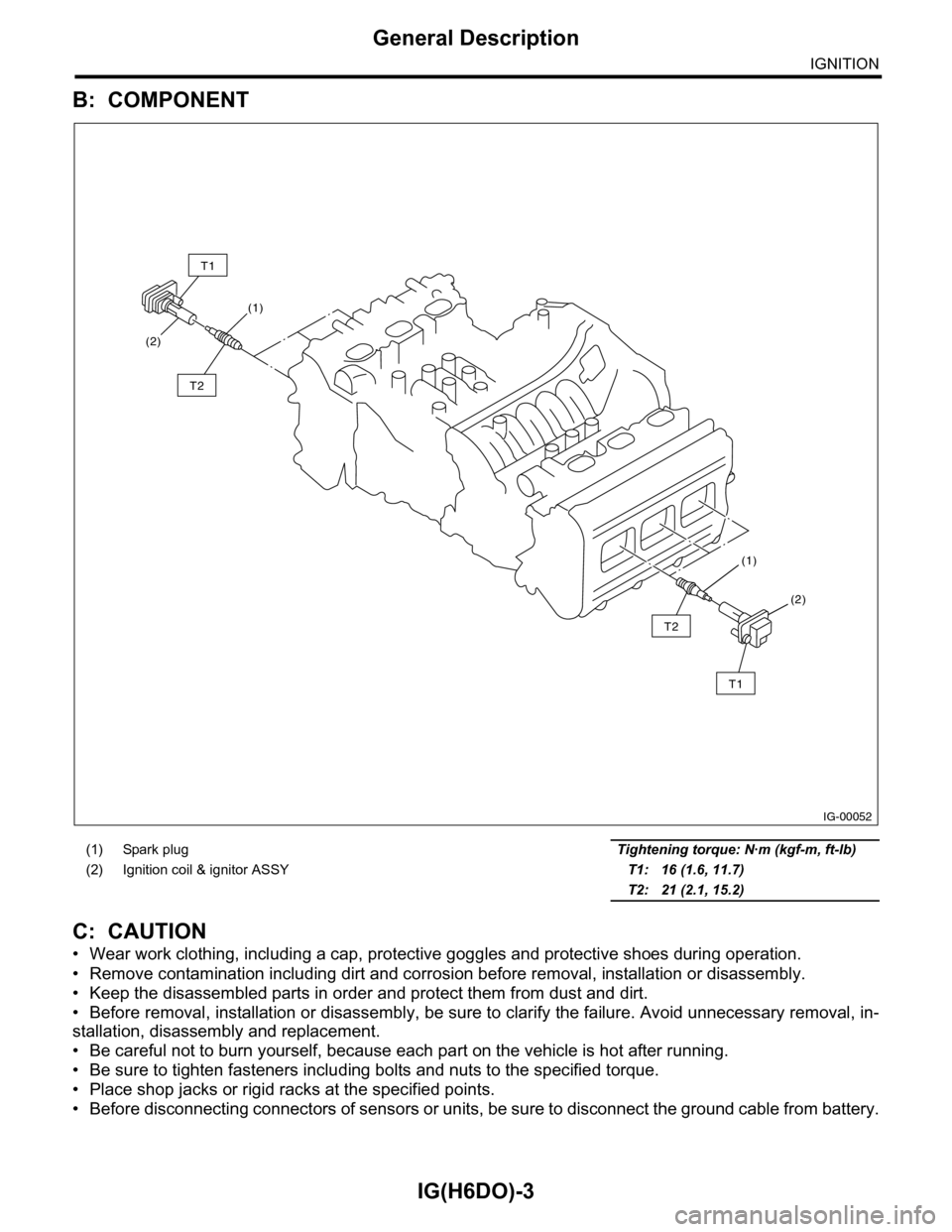

B: COMPONENT

C: CAUTION

•Wear work clothing, including a cap, protective goggles and protective shoes during operation.

•Remove contamination including dirt and corrosion before removal, installation or disassembly.

•Keep the disassembled parts in order and protect them from dust and dirt.

•Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, in-

stallation, disassembly and replacement.

•Be careful not to burn yourself, because each part on the vehicle is hot after running.

•Be sure to tighten fasteners including bolts and nuts to the specified torque.

•Place shop jacks or rigid racks at the specified points.

•Before disconnecting connectors of sensors or units, be sure to disconnect the ground cable from battery.

(1) Spark plug Tightening torque: N·m (kgf-m, ft-lb)

(2) Ignition coil & ignitor ASSY T1: 16 (1.6, 11.7)

T2: 21 (2.1, 15.2)

IG-00052

(1)

(1)

(2)

(2)

T1

T2

T2

T1

Page 1839 of 2453

IG(H6DO)-4

Spark Plug

IGNITION

2. Spark Plug

A: REMOVAL

CAUTION:

All spark plugs installed on an engine must be

of the same heat range.

Spark plug:

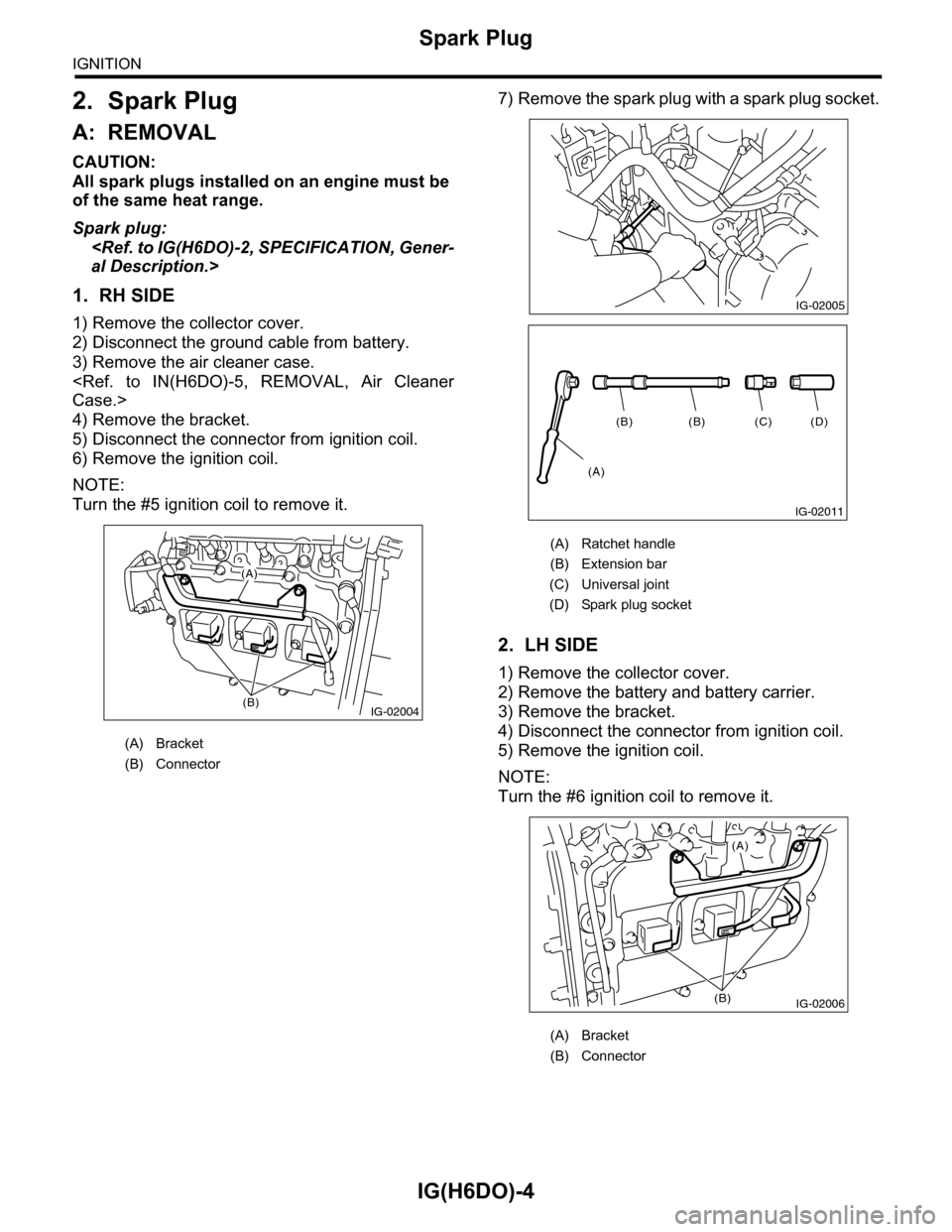

1. RH SIDE

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air cleaner case.

4) Remove the bracket.

5) Disconnect the connector from ignition coil.

6) Remove the ignition coil.

NOTE:

Turn the #5 ignition coil to remove it.

7) Remove the spark plug with a spark plug socket.

2. LH SIDE

1) Remove the collector cover.

2) Remove the battery and battery carrier.

3) Remove the bracket.

4) Disconnect the connector from ignition coil.

5) Remove the ignition coil.

NOTE:

Turn the #6 ignition coil to remove it.

(A) Bracket

(B) Connector

IG-02004(B)

(A)

(A) Ratchet handle

(B) Extension bar

(C) Universal joint

(D) Spark plug socket

(A) Bracket

(B) Connector

IG-02005

(D)(C)(B)(B)

(A)

IG-02011

IG-02006

(A)

(B)

Page 1840 of 2453

IG(H6DO)-5

Spark Plug

IGNITION

6) Remove the spark plug with a spark plug socket.

B: INSTALLATION

1. RH SIDE

Install in the reverse order of removal.

Tightening torque (Spark plug):

21 N·m (2.1 kgf-m, 15.2 ft-lb)

Tightening torque (Ignition coil):

16 N·m (1.6 kgf-m, 11.7 ft-lb)

NOTE:

The tightening torque described above should be

applied to only new spark plugs without oil on their

threads.

In case their threads are lubricated, the torque

should be reduced by approx. 1/3 of the specified

torque in order to avoid over-stressing.

2. LH SIDE

Install in the reverse order of removal.

Tightening torque (Spark plug):

21 N·m (2.1 kgf-m, 15.2 ft-lb)

Tightening torque (Ignition coil):

16 N·m (1.6 kgf-m, 11.7 ft-lb)

NOTE:

The tightening torque described above should be

applied to only new spark plugs without oil on their

threads. In case their threads are lubricated, the

torque should be reduced by approx. 1/3 of the

specified torque in order to avoid over-stressing.

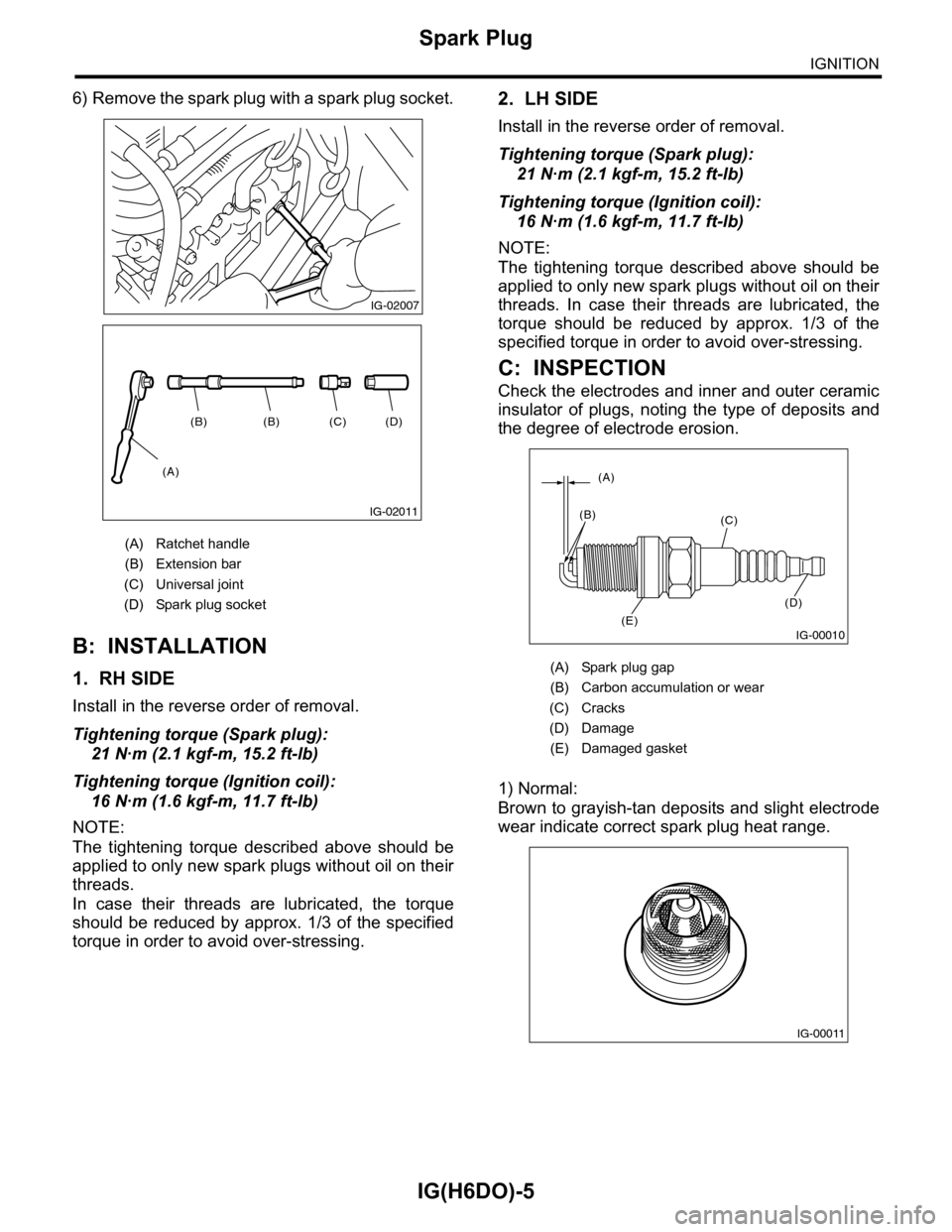

C: INSPECTION

Check the electrodes and inner and outer ceramic

insulator of plugs, noting the type of deposits and

the degree of electrode erosion.

1) Normal:

Brown to grayish-tan deposits and slight electrode

wear indicate correct spark plug heat range.

(A) Ratchet handle

(B) Extension bar

(C) Universal joint

(D) Spark plug socket

IG-02007

(D)(C)(B)(B)

(A)

IG-02011

(A) Spark plug gap

(B) Carbon accumulation or wear

(C) Cracks

(D) Damage

(E) Damaged gasket

IG-00010

(A)

(B)(C)

(D)

(E)

IG-00011

Page 1842 of 2453

IG(H6DO)-7

Ignition Coil & Ignitor Assembly

IGNITION

3. Ignition Coil & Ignitor Assem-

bly

A: REMOVAL

Direct ignition type has been adopted. Refer to

“Spark Plug” for removal procedure.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

16 N·m (1.6 kgf-m, 11.7 ft-lb)

C: INSPECTION

For inspection procedure, refer to “Diagnostics for

Engine Starting Failure.”

for Engine Starting Failure.>

Page 1843 of 2453

IG(H6DO)-8

Ignition Coil & Ignitor Assembly

IGNITION

Page 1893 of 2453

ME(H6DO)-27

Valve Clearance

MECHANICAL

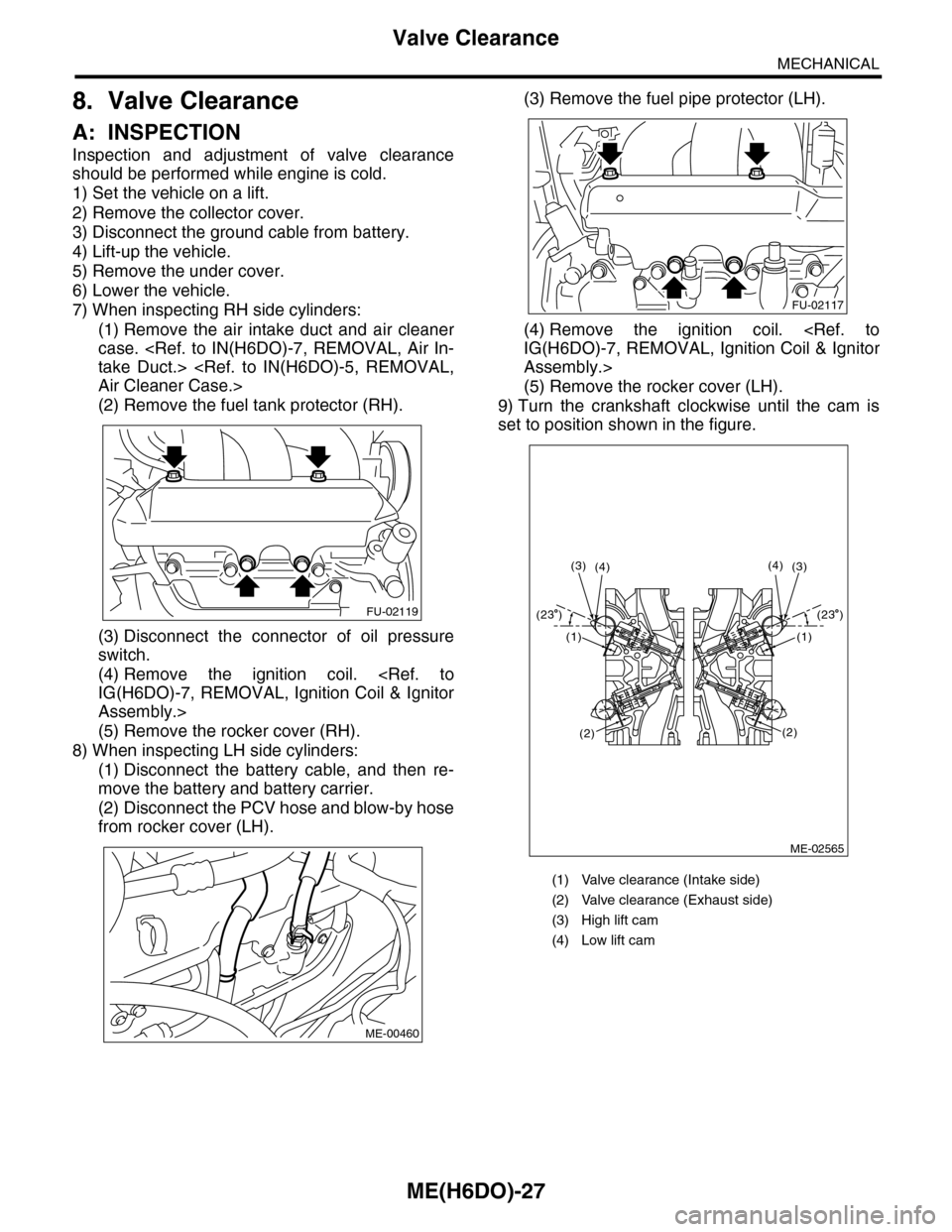

8. Valve Clearance

A: INSPECTION

Inspection and adjustment of valve clearance

should be performed while engine is cold.

1) Set the vehicle on a lift.

2) Remove the collector cover.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Remove the under cover.

6) Lower the vehicle.

7) When inspecting RH side cylinders:

(1) Remove the air intake duct and air cleaner

case.

(2) Remove the fuel tank protector (RH).

(3) Disconnect the connector of oil pressure

switch.

(4) Remove the ignition coil.

Assembly.>

(5) Remove the rocker cover (RH).

8) When inspecting LH side cylinders:

(1) Disconnect the battery cable, and then re-

move the battery and battery carrier.

(2) Disconnect the PCV hose and blow-by hose

from rocker cover (LH).

(3) Remove the fuel pipe protector (LH).

(4) Remove the ignition coil.

Assembly.>

(5) Remove the rocker cover (LH).

9) Turn the crankshaft clockwise until the cam is

set to position shown in the figure.

FU-02119

ME-00460

(1) Valve clearance (Intake side)

(2) Valve clearance (Exhaust side)

(3) High lift cam

(4) Low lift cam

FU-02117

ME-02565

(4)(3)(3)(4)

(1)

(2)

(1)

(2)

(23 )(23 )

Page 1992 of 2453

PM-9

Spark Plug

PERIODIC MAINTENANCE SERVICES

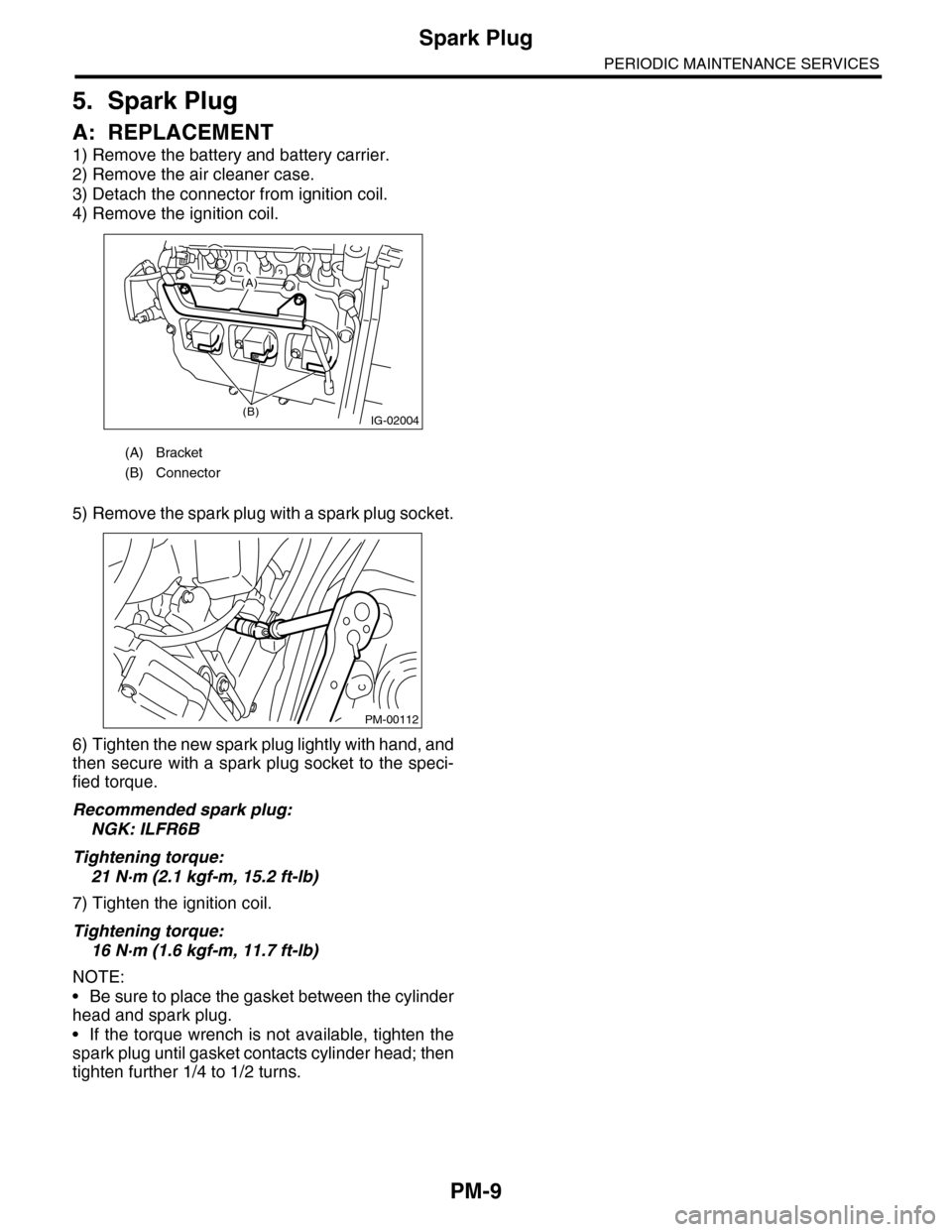

5. Spark Plug

A: REPLACEMENT

1) Remove the battery and battery carrier.

2) Remove the air cleaner case.

3) Detach the connector from ignition coil.

4) Remove the ignition coil.

5) Remove the spark plug with a spark plug socket.

6) Tighten the new spark plug lightly with hand, and

then secure with a spark plug socket to the speci-

fied torque.

Recommended spark plug:

NGK: ILFR6B

Tightening torque:

21 N·m (2.1 kgf-m, 15.2 ft-lb)

7) Tighten the ignition coil.

Tightening torque:

16 N·m (1.6 kgf-m, 11.7 ft-lb)

NOTE:

•Be sure to place the gasket between the cylinder

head and spark plug.

•If the torque wrench is not available, tighten the

spark plug until gasket contacts cylinder head; then

tighten further 1/4 to 1/2 turns.

(A) Bracket

(B) Connector

IG-02004(B)

(A)

PM-00112

Page 2314 of 2453

WI-30

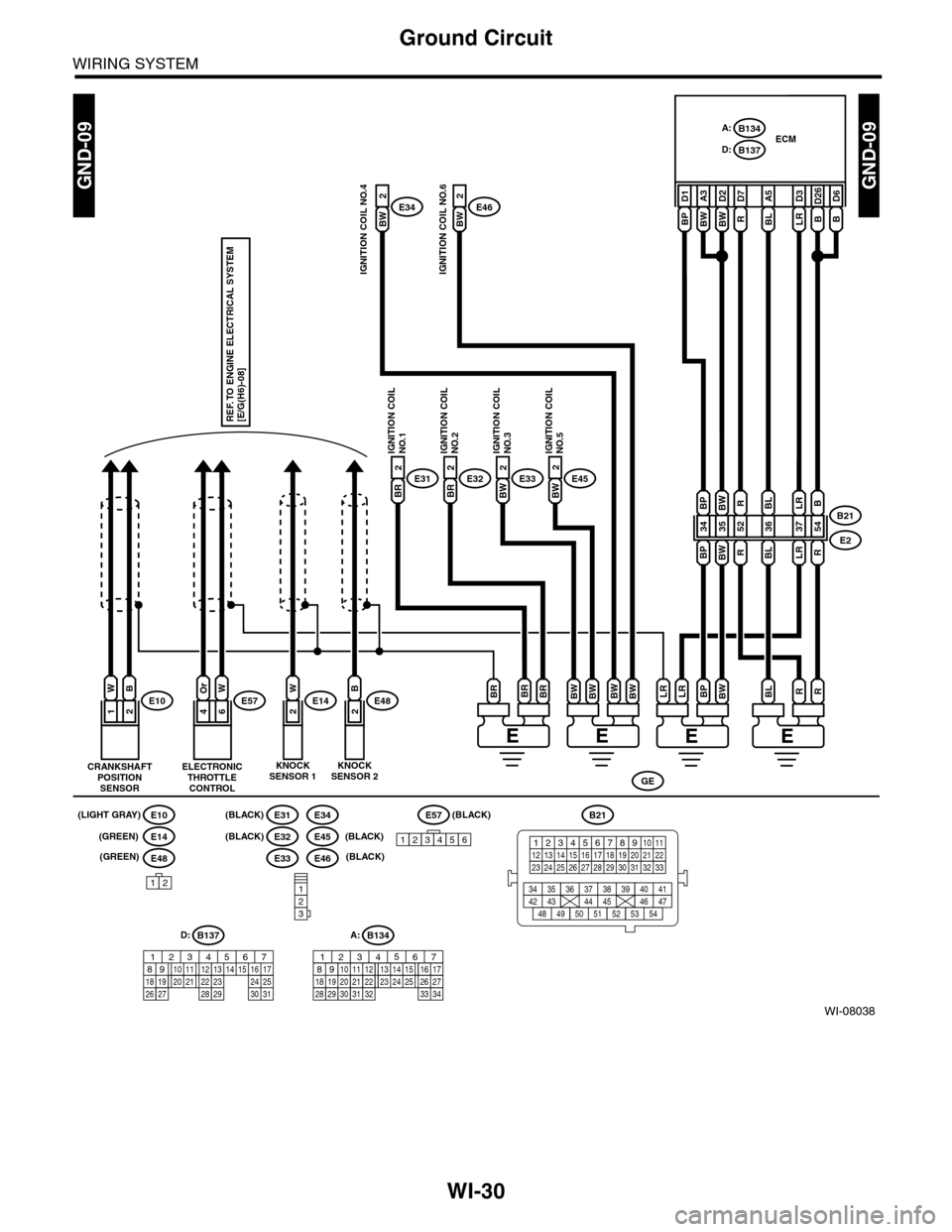

Ground Circuit

WIRING SYSTEM

WI-08038

GND-09GND-09

BL A5B D26B

D6

R 54

BW

LR 37

LR

BL 36

BL

BW 35

BW

BP 34

BPBB21

E2

E452

LR D3BP D1BW A3BW

D2

(BLACK)

(GREEN)

(GREEN)

B134A:

B137D:ECM

BW

E332

BRE322

BRE312

IGNITION COILNO.1IGNITION COILNO.2IGNITION COILNO.3IGNITION COILNO.5

E57

ELECTRONICTHROTTLECONTROL

46

OrWE10

CRANKSHAFTPOSITIONSENSOR

12

WBE14

KNOCKSENSOR 1

2

WE482

B

12

D: A:B137

85610 11 12 13 14 157213416

3019 20 2228 29

91718 2521 23 243126 27

B134

85610 11 12 13 14 157213416

3019 20 2228 29

91718252123 24323126 2733 34

RBLBWBPLRLRBRBR

REF. TO ENGINE ELECTRICAL SYSTEM[E/G(H6)-08]

E33

E31E34

E32

E48

E10

E14

B21

12345678910 1112 13 14 15 16 17 18 19 20 21 2223 24 25 26 27 28 29 30 31 32 33

34 3542 4336 3738 39

48 4950 5152 5354

40 41444546 47123

E57

123456

GE

BWBWBRBWBW

BW

E462

BW

E342

R

R

52

R

R D7

IGNITION COIL NO.4IGNITION COIL NO.6

KNOCKSENSOR 2

(LIGHT GRAY) (BLACK)

(BLACK) (BLACK)

(BLACK)

E45

E46

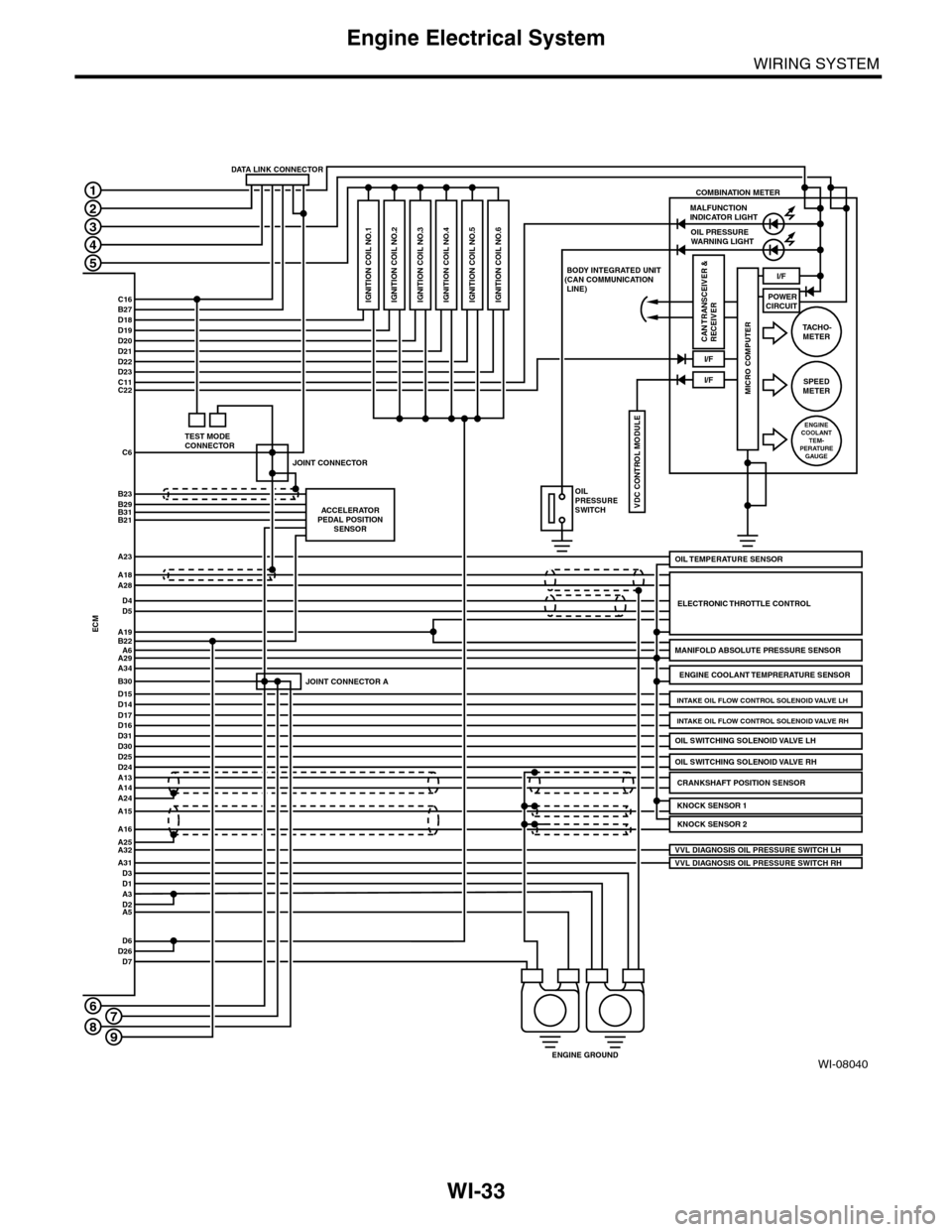

Page 2317 of 2453

WI-33

Engine Electrical System

WIRING SYSTEM

WI-08040

A3D2

D22D23

POWERCIRCUIT

COMBINATION METER

C16B27D18D19D20D21

C11C22

C6

B23B29B31B21

1

2

3

4

5

6

ACCELERATORPEDAL POSITIONSENSOR

JOINT CONNECTOR A

JOINT CONNECTOR

MALFUNCTION INDICATOR LIGHTOIL PRESSUREWARNING LIGHT

I/F

I/F

I/F

VDC CONTROL MODULE

IGNITION COIL NO.1

BODY INTEGRATED UNIT(CAN COMMUNICATION LINE)

OILPRESSURESWITCH

CRANKSHAFT POSITION SENSORA13A14

ENGINE GROUND

ECM

A18A28

D4D5

A19B22A6A29A34

D15B30

D14D17D16D31D30

ELECTRONIC THROTTLE CONTROL

A24

A25A16

A15

A32

D1

MANIFOLD ABSOLUTE PRESSURE SENSOR

ENGINE COOLANT TEMPRERATURE SENSOR

VVL DIAGNOSIS OIL PRESSURE SWITCH RH

D25D24

KNOCK SENSOR 2

D6D26D7

A5

MICRO COMPUTER

CAN TRANSCEIVER &RECEIVER

OIL SWITCHING SOLENOID VALVE RH

TA C H O -METER

SPEEDMETER

ENGINECOOLANTTEM-PERATUREGAUGE

DATA LINK CONNECTOR

TEST MODECONNECTOR

OIL TEMPERATURE SENSORA23

A31D3

VVL DIAGNOSIS OIL PRESSURE SWITCH LH

KNOCK SENSOR 1

OIL SWITCHING SOLENOID VALVE LH

INTAKE OIL FLOW CONTROL SOLENOID VALVE RH

INTAKE OIL FLOW CONTROL SOLENOID VALVE LH

IGNITION COIL NO.2 IGNITION COIL NO.3 IGNITION COIL NO.4 IGNITION COIL NO.5 IGNITION COIL NO.6

789