SUBARU TRIBECA 2014 1.G Owners Manual

Manufacturer: SUBARU, Model Year: 2014, Model line: TRIBECA, Model: SUBARU TRIBECA 2014 1.GPages: 426, PDF Size: 6.37 MB

Page 391 of 426

12-14Specifications

CAUTION

Replace any bulb only with a newbulb of the specified wattage. Usinga bulb of different wattage couldresult in a fire.

Page 392 of 426

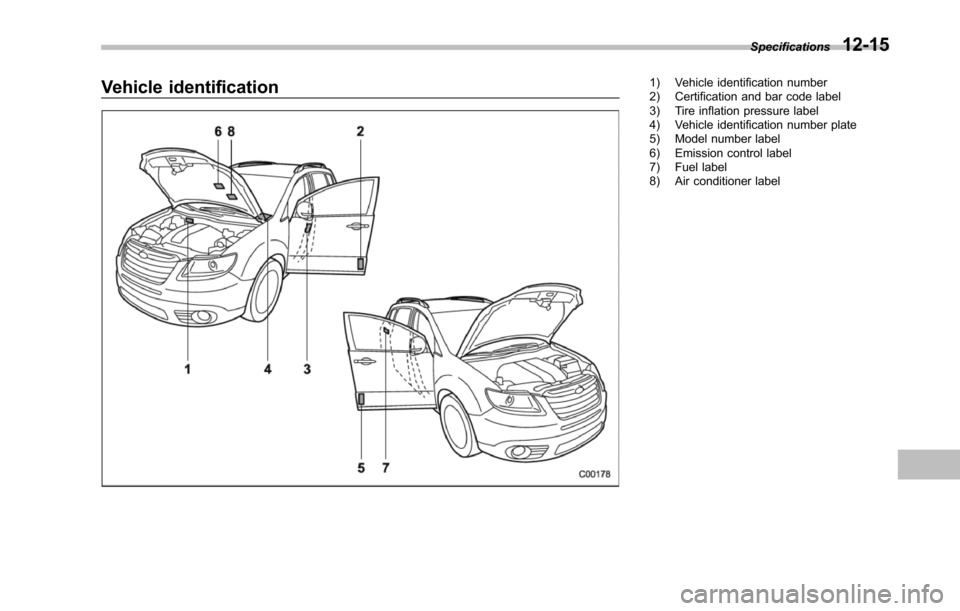

Vehicle identification1) Vehicle identification number2) Certification and bar code label3) Tire inflation pressure label4) Vehicle identification number plate5) Model number label6) Emission control label7) Fuel label8) Air conditioner label

Specifications12-15

Page 393 of 426

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

————————————————————————————————————————

Page 394 of 426

For U.S.A............................................................ 13-2

Tire information.................................................. 13-2Tire labeling....................................................... 13-2Recommended tire inflation pressure.................. 13-4Glossary of tire terminology............................... 13-5Tire care–maintenance and safety practices...... 13-9Vehicle load limit–how to determine................ 13-10Determining compatibility of tire and vehicleload capacities............................................... 13-13

Adverse safety consequences of overloadingon handling and stopping and on tires........... 13-13Steps for Determining Correct Load Limit......... 13-13

Uniform tire quality grading standards.......... 13-14Treadwear....................................................... 13-14Traction AA, A, B, C......................................... 13-14Temperature A, B, C......................................... 13-15

Reporting safety defects (U.S.A.)................... 13-15

Consumer information and Reporting safety defects

13

Page 395 of 426

13-2Consumer information and Reporting safety defects

For U.S.A.

The following information has been

compiled according to Code of

Federal Regulations“Title 49, Part

575”.

Tire information

&Tire labeling

Many markings (e.g. Tire size, Tire

Identification Number or TIN) are

placed on the sidewall of a tire by

tire manufacturers. These markings

can provide you with useful infor-

mation on the tire.

!Tire size

Your vehicle comes equipped with

P-Metric tire size. It is important to

understand the sizing system in

selecting the proper tire for your

vehicle. Here is a brief review of the

tire sizing system with a breakdown

of its individual elements.

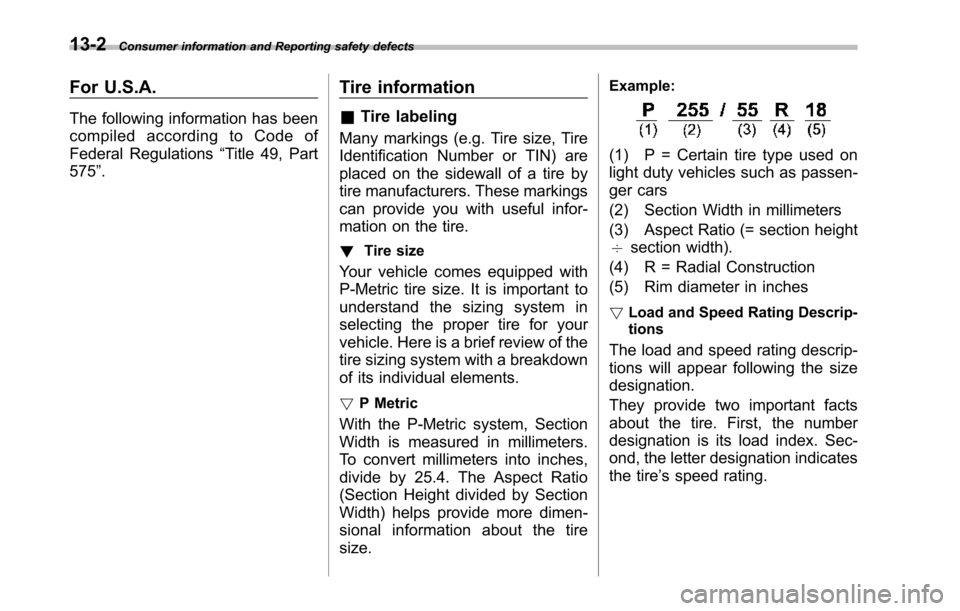

!P Metric

With the P-Metric system, Section

Width is measured in millimeters.

To convert millimeters into inches,

divide by 25.4. The Aspect Ratio

(Section Height divided by Section

Width) helps provide more dimen-

sional information about the tire

size.

Example:

(1) P = Certain tire type used on

light duty vehicles such as passen-

ger cars

(2) Section Width in millimeters

(3) Aspect Ratio (= section height

7section width).

(4) R = Radial Construction

(5) Rim diameter in inches

!Load and Speed Rating Descrip-

tions

The load and speed rating descrip-

tions will appear following the size

designation.

They provide two important facts

about the tire. First, the number

designation is its load index. Sec-

ond, the letter designation indicates

the tire’s speed rating.

Page 396 of 426

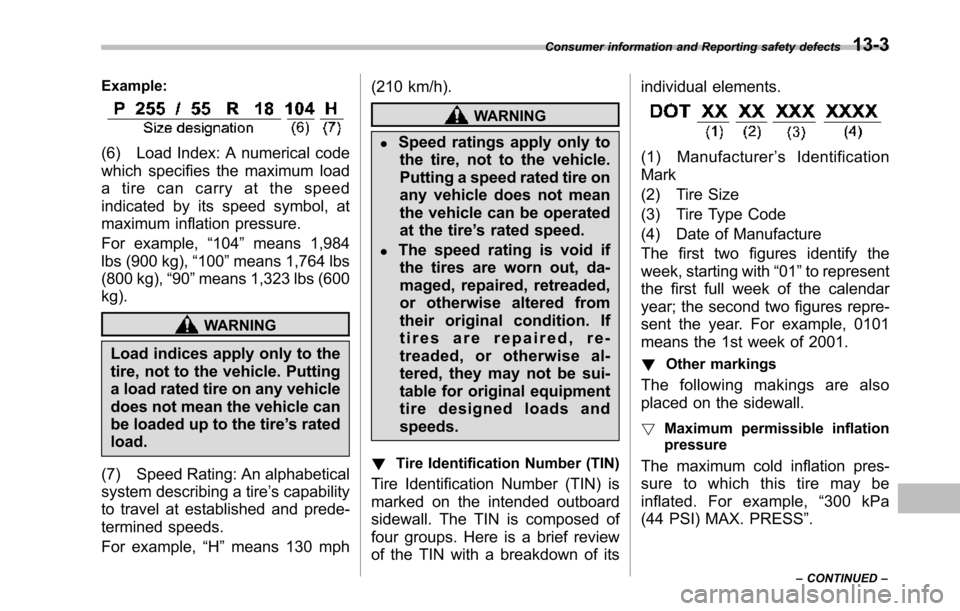

Example:

(6) Load Index: A numerical code

which specifies the maximum load

atirecancarryatthespeed

indicated by its speed symbol, at

maximum inflation pressure.

For example,“104”means 1,984

lbs (900 kg),“100”means 1,764 lbs

(800 kg),“90”means 1,323 lbs (600

kg).

WARNING

Load indices apply only to the

tire, not to the vehicle. Putting

a load rated tire on any vehicle

does not mean the vehicle can

be loaded up to the tire’s rated

load.

(7) Speed Rating: An alphabetical

system describing a tire’s capability

to travel at established and prede-

termined speeds.

For example,“H”means 130 mph

(210 km/h).

WARNING

.Speed ratings apply only to

the tire, not to the vehicle.

Putting a speed rated tire on

any vehicle does not mean

the vehicle can be operated

at the tire’s rated speed.

.The speed rating is void if

the tires are worn out, da-

maged, repaired, retreaded,

or otherwise altered from

their original condition. If

tires are repaired, re-

treaded, or otherwise al-

tered, they may not be sui-

table for original equipment

tire designed loads and

speeds.

!Tire Identification Number (TIN)

Tire Identification Number (TIN) is

marked on the intended outboard

sidewall. The TIN is composed of

four groups. Here is a brief review

of the TIN with a breakdown of its

individual elements.

(1) Manufacturer’sIdentification

Mark

(2) Tire Size

(3) Tire Type Code

(4) Date of Manufacture

The first two figures identify the

week, starting with“01”to represent

the first full week of the calendar

year; the second two figures repre-

sent the year. For example, 0101

means the 1st week of 2001.

!Other markings

The following makings are also

placed on the sidewall.

!Maximum permissible inflation

pressure

The maximum cold inflation pres-

sure to which this tire may be

inflated. For example,“300 kPa

(44 PSI) MAX. PRESS”.

Consumer information and Reporting safety defects13-3

–CONTINUED–

Page 397 of 426

13-4Consumer information and Reporting safety defects

!Maximum load rating

The load rating at the maximum

permissible weight load for this tire.

For example,“MAX. LOAD 730 kg

(1609 LBS) @ 300 kPa (44 PSI)

MAX. PRESS.”

WARNING

Maximum load rating applies

only to the tire, not to the

vehicle. Putting a load rated

tire on any vehicle does not

mean the vehicle can be

loaded up to the tire’s rated

load.

!Construction type

Applicable construction of this tire.

For example,“TUBELESS STEEL

BELTED RADIAL”

!Construction

The generic name of each cord

material used in the plies (both

sidewall and tread area) of this tire.

For example,“PLIES: TREAD 2

STEEL + 2 POLYESTER + 1

NYLON SIDEWALL 2 POLYE-

STER”

!Uniform Tire Quality Grading

(UTQG)

For details, refer to“Uniform tire

quality grading standards”F13-14.

&Recommended tire inflation

pressure

!Recommended cold tire infla-

tion pressure

For the recommended cold tire

inflation pressure for your vehicle’s

tires, refer to“Tires”F12-8.

!Vehicle placard

The vehicle placard is affixed to the

driver’s side B-pillar.

Page 398 of 426

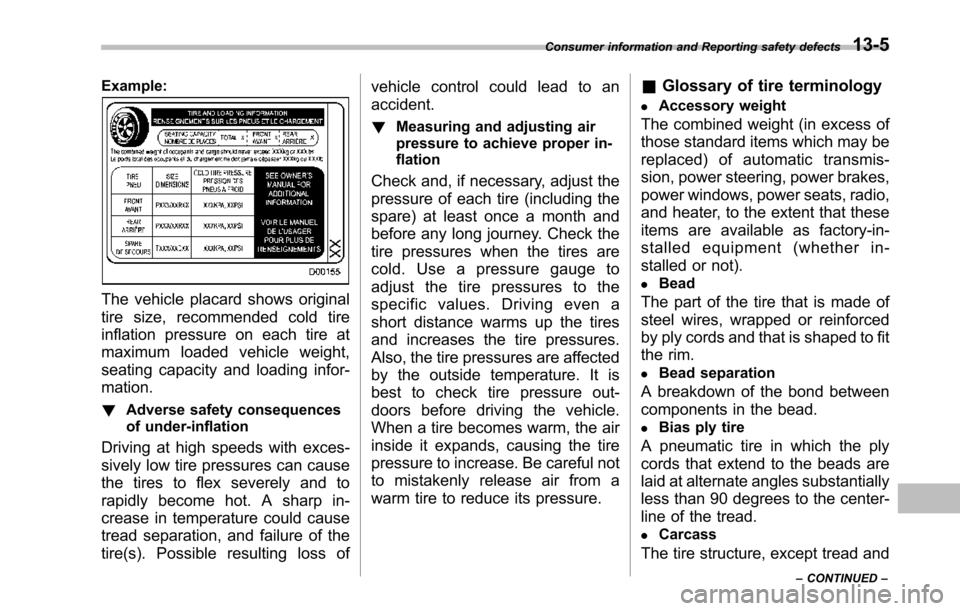

Example:

The vehicle placard shows original

tire size, recommended cold tire

inflation pressure on each tire at

maximum loaded vehicle weight,

seating capacity and loading infor-

mation.

!Adverse safety consequences

of under-inflation

Driving at high speeds with exces-

sively low tire pressures can cause

the tires to flex severely and to

rapidly become hot. A sharp in-

crease in temperature could cause

tread separation, and failure of the

tire(s). Possible resulting loss of

vehicle control could lead to an

accident.

!Measuring and adjusting air

pressure to achieve proper in-

flation

Check and, if necessary, adjust the

pressure of each tire (including the

spare) at least once a month and

before any long journey. Check the

tire pressures when the tires are

cold. Use a pressure gauge to

adjust the tire pressures to the

specific values. Driving even a

short distance warms up the tires

and increases the tire pressures.

Also, the tire pressures are affected

by the outside temperature. It is

best to check tire pressure out-

doors before driving the vehicle.

When a tire becomes warm, the air

inside it expands, causing the tire

pressure to increase. Be careful not

to mistakenly release air from a

warm tire to reduce its pressure.

&Glossary of tire terminology

.Accessory weight

The combined weight (in excess of

those standard items which may be

replaced) of automatic transmis-

sion, power steering, power brakes,

power windows, power seats, radio,

and heater, to the extent that these

items are available as factory-in-

stalled equipment (whether in-

stalled or not).

.Bead

The part of the tire that is made of

steel wires, wrapped or reinforced

by ply cords and that is shaped to fit

the rim.

.Bead separation

A breakdown of the bond between

components in the bead.

.Bias ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at alternate angles substantially

less than 90 degrees to the center-

line of the tread.

.Carcass

The tire structure, except tread and

Consumer information and Reporting safety defects13-5

–CONTINUED–

Page 399 of 426

13-6Consumer information and Reporting safety defects

sidewall rubber which, when in-

flated, bears the load.

.Chunking

The breaking away of pieces of the

tread or sidewall.

.Cold tire pressure

The pressure in a tire that has been

driven less than 1 mile or has been

standing for three hours or more.

.Cord

The strands forming the plies in the

tire.

.Cordseparation

The parting of cords from adjacent

rubber compounds.

.Cracking

Any parting within the tread, side-

wall, or inner liner of the tire

extending to cord material.

.Curb weight

The weight of a motor vehicle with

standard equipment including the

maximum capacity of fuel, oil and

coolant, and if so equipped, air

conditioning and additional weight

optional engine.

.Extra load tire

A tire designed to operate at higher

loads and higher inflation pressure

than the corresponding standard

tire.

.Groove

The space between two adjacent

tread ribs.

.Innerliner

The layer(s) forming the inside sur-

face of a tubeless tire that contains

the inflating medium within the tire.

.Innerliner separation

The parting of the innerliner from

cord material in the carcass.

.Intended outboard sidewall(1)The sidewall that contains a

whitewall, bears white lettering

or bears manufacturer, brand,

and/or model name molding that

is higher or deeper than the

same molding on the other side-

wall of the tire, or

(2)The outward facing sidewall

of an asymmetrical tire that has

a particular side that must al-

ways face outward when mount-

ing on a vehicle.

.Light truck (LT) tire

A tire designated by its manufac-

turer as primarily intended for use

on lightweight trucks or multipur-

pose passenger vehicles.

.Load rating

The maximum load that a tire is

rated to carry for a given inflation

pressure.

.Maximum inflation pressure

The maximum cold inflation pres-

sure to which a tire may be inflated.

.Maximum load rating

The load rating for a tire at the

maximum permissible inflation

pressure for that tire.

.Maximum loaded vehicle weight

The sum of:

(a)Curb weight(b)Accessory weight(c)Vehicle capacity weight(d)Production options weight.Maximum permissible inflation

pressure

The maximum cold inflation pres-

sure to which a tire may be inflated.

Page 400 of 426

.Measuring rim

The rim on which a tire is fitted for

physical dimension requirements.

.Normal occupant weight

150 lbs (68 kg) times the number of

occupants specified in the second

column of Table 1 that is appended

to the end of this section.

.Occupant distribution

Distribution of occupants in a vehi-

cle as specified in the third column

of Table 1 that is appended to the

end of this section.

.Open splice

Any parting at any junction of tread,

sidewall, or innerliner that extends

to cord material.

.Outer diameter

The overall diameter of an inflated

new tire.

.Overall width

The linear distance between the

exteriors of the sidewalls of an

inflated tire, including elevations

due to labeling, decorations, or

protective bands or ribs.

.Passenger car tire

A tire intended for use on passen-

ger cars, multipurpose passenger

vehicles, and trucks, that have a

gross vehicle weight rating (GVWR)

of 10,000 lbs (4,535 kg) or less.

.Ply

A layer of rubber-coated parallel

cords.

.Ply separation

Apartingofrubbercompound

between adjacent plies.

.Pneumatic tire

A mechanical device made of rub-

ber, chemicals, fabric and steel or

other materials, that, when

mounted on an automotive wheel,

provides the traction and contains

the gas or fluid that sustains the

load.

.Production options weight

The combined weight of those

installed regular production options

weighing over 5.1 lbs (2.3 kg) in

excess of those standard items

which they replace, not previously

considered in curb weight or acces-

sory weight, including heavy duty

brakes, ride levelers, roof rack,

heavy duty battery, and special

trim.

.Radial ply tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at substantially 90 degrees to

the centerline of the tread.

.Recommended inflation pres-

sure

The cold inflation pressure recom-

mended by a vehicle manufacturer.

.Reinforced tire

A tire designed to operate at higher

loads and at higher inflation pres-

sures than the corresponding stan-

dard tire.

.Rim

A metal support for a tire or a tire

and tube assembly upon which the

tire beads are seated.

.Rim diameter

Nominal diameter of the bead seat.

.Rim size designation

Rim diameter and width.

Consumer information and Reporting safety defects13-7

–CONTINUED–