ECU SUZUKI GRAND VITARA 1987 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 108 of 962

-1. Key

‘32. Crankshaft pulley3. Pulley bolt

Fig. 3-6-52 Installing crankshaft pulley

2) Install alternator assembly.

Tighten alternator ass’y securing bolts (3pcs)

only to the extent to allow alternator to be

moved by hand. Don’t torque them tight.

NOTE:

Adjust water pump belt tension to specification

upon completion of installing engine ass’y to

body and then cooling fan and water pump

pulley. Make sure to refer to p. 1-5 of this

manual for adjusting procedure.

Distributor Case

1) Install distributor case O-ring to cylinder

head.

2) Install distributor case.

3) Tighten bolts to specified torque.

Tightening torque N.mkg-mlb-ft

forcasebolts8-120.8-1.26.0-8.5

Fig. 3-6-53

Fuel Pump

Install fuel pump rod, gasket and fuel pump to

cylinder head.

Apply engine oil to rod @ before installation.

Use new gasket.

Fig. 3-6-54 Fuel pump rod installation

case with about 3Occ (1.02/1.05 US/Imp

3-51

Page 110 of 962

3-7. ENGINE INSTALLATION

1) Lower engine with transmission into vehicle,

but do not remove lifting device.

2) Tighten engine mounting bracket bolts

(right and left) and transmission mounting

bolts to specification. Refer to p. 3-58.

3) Remove lifting device.

4) Reverse removal procedures for installation

of remainder.

5) Adjust accelerator cable play and clutch

cable play.

6) Connect vacuum hoses securely. Refer to

section 5 “EMISSION CONTROL SYSTEM”

for correct connection.

7) Connect wire harnesses and couplers secure-

IY.

8) Tighten bolts and nuts to specified torque.

For individual specification, refer to each

section.

9) Fill specified amount of specified trans-

mission oil and engine oil. For the detail,

refer to SECTION 1 PERIODIC MAINTE-

NANCE SERVICE of this manual.

10) After adjusting water pump belt tension to

specification, fill specified amount of engine

cooling water.

11) Before starting engine, check again to ensure

that all parts once disassembled or discon-

nected are back in place securely.

12)Start engine and check ignition timing. If

it is not to specified timing, adjust it, referr-

ing to SECTION 8 of this manual.

13) After engine is started, check for oil leak,

abnormal noise and other malcondition.

Also, check each part for operation.

3-8. ENGINE MAINTENANCE SERVICE

Fan Belt

Adjust belt tension as outlined in SECTION 6

ENGINE COOLING SYSTEM (p. 6-10).

Ignition Timing

Refer to IGNITION TIMING, Page 8-9.

Carburetor

fidjustments to be made are detailed in SEC-

TION 4 (p. 4-19).

Valve Lash (Clearance)

Valve lash specifications:

Valve lash refers to gap between rocker arm

adjusting screw and valve stem. Use a thickness

gauge to measure this gap @.

When coldWhen hot(Coolant tempe-(Coolant tempa-

Valve lashrature is 15 - 25%rature is 60 - 66’C

(gap A)or 69 - 77’F)or 140 - 154’F)

specif i-0.13 - 0.17 mm0.23 - 0.27 mmcationIntake(0.0051 - 0.0067 in) (0.009 - 0.011 in)

Exhaust0.16 -0.20 mm0.26 - 0.30 mm(0.0063 - 0.0079 in) (0.0102 - 0.0116 in)

Screw lock nut 15 - 19 N.m(1.5 - 1.9 kg-m, 11 .O - 13.5 lb-ft)

Adjusting screw

8

Valve stem

Fig. 3-8-l

Checking and adjusting procedures:

NOTE:

l Refer to Fig. 3-3-11 of SECTION 3 for

cylinder numbers (No. 1, No. 2, No. 3 and

No. 4) mentioned in this section.

l When adjustment becomes necessary in step

4), loosen adjusting screw lock nut and then

make adjustment by turning adjusting screw.

After adjustment, tighten lock nut to specifi-

ed torque while holding adjusting screw

stationary with straight headed screwdriver,

and then make sure again that gap @ is

within specification.

3-53

Page 128 of 962

0 Connect electric couplers securely.

l Connect accelerator cable to carburetor. With

the accelerator pedal released, adjust the cable

play to specification. This adjustment can be

made by turning the adjusting nut. After

adjustment, tighten the lock nut. Refer to

p. 4-19.

l Connect vacuum hoses securely.

l Refill cooling system.

l Connect negative cable at battery.

NOTE:

Upon completion of installation, be sure to

check each part for evidence of fuel leakage and

for proper operation. If defective, correct..

UNIT REPAIR OVERHAUL

This section outlines procedure to be used for

overhauling carburetor as removed from engine.

For removal and installation of carburetor from

and to engine, refer to the previous page.

NOTE:

l Be sure to replace gaskets as well as worn or

damaged parts.

l While disassembling and assembling carbure-

tor, use special care not to deform levers on

throttle valve shaft or cause damage to any

other parts.

l Don’t disassemble mixture control solenoid

valve and accelerator pump piston.

l Don’t remove idle and wide open micro

switches from the bracket where they are

installed.

Disassembly

1) Turn fast idle cam counterclockwise and

insert a pin avialable into holes on cam and

bracket to lock the cam.

Fig. 4- I- 19

1. Fast idle cam

2. Bracket3. Pin

4-13

Page 134 of 962

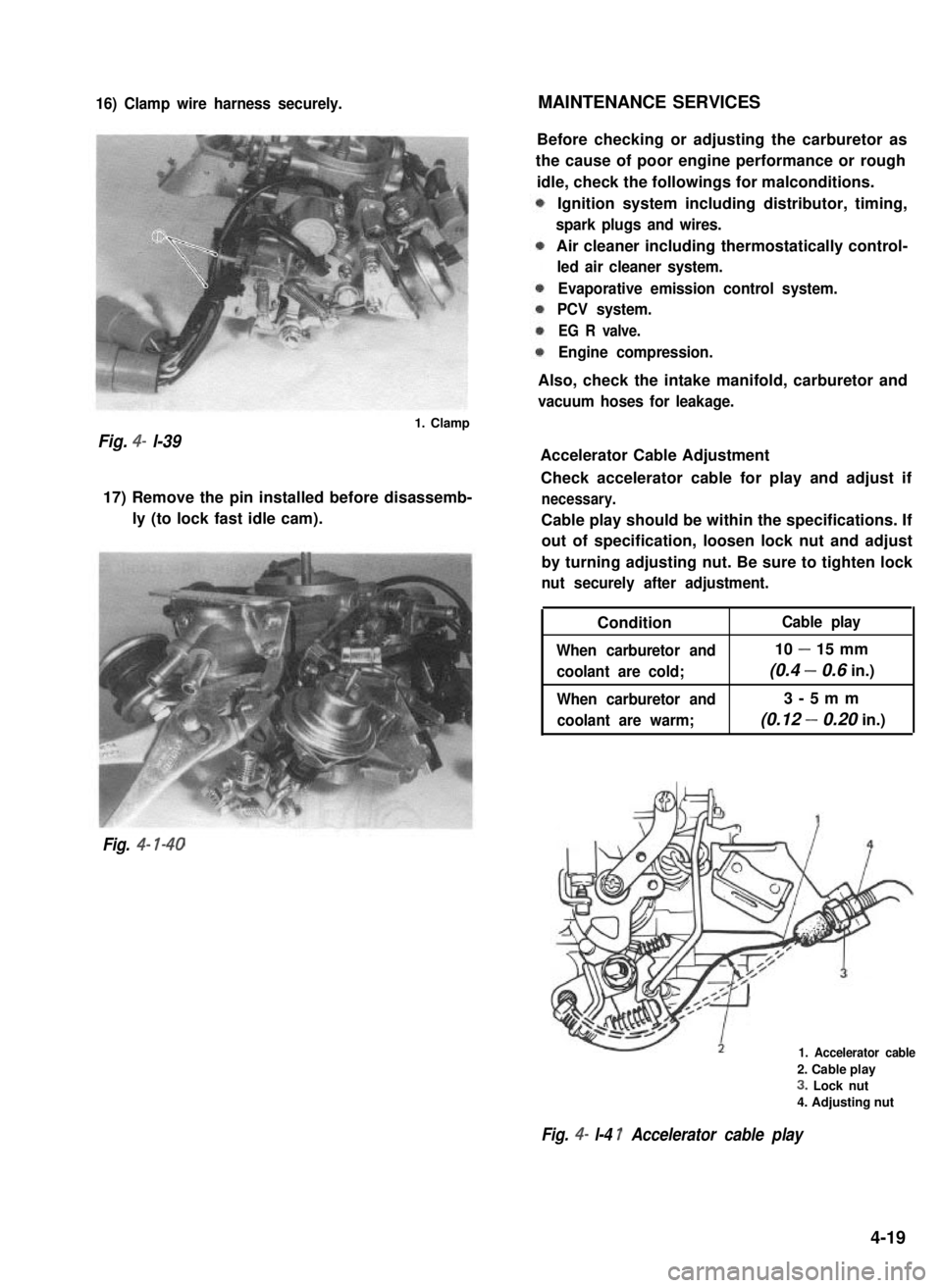

16) Clamp wire harness securely.MAINTENANCE SERVICES

Fig. 4- l-39

1. Clamp

17) Remove the pin installed before disassemb-

ly (to lock fast idle cam).

Fig. 4- l-40

Before checking or adjusting the carburetor as

the cause of poor engine performance or rough

idle, check the followings for malconditions.

Ignition system including distributor, timing,

spark plugs and wires.

Air cleaner including thermostatically control-

led air cleaner system.

Evaporative emission control system.

PCV system.

EG R valve.

Engine compression.

Also, check the intake manifold, carburetor and

vacuum hoses for leakage.

Accelerator Cable Adjustment

Check accelerator cable for play and adjust if

necessary.

Cable play should be within the specifications. If

out of specification, loosen lock nut and adjust

by turning adjusting nut. Be sure to tighten lock

nut securely after adjustment.

Condition

When carburetor and

coolant are cold;

When carburetor and

coolant are warm;

Cable play

10 - 15 mm

(0.4 - 0.6 in.)

3-5mm

(0.12 - 0.20 in.)

1. Accelerator cable

2. Cable play

3. Lock nut

4. Adjusting nut

Fig. 4- l-4 1 Accelerator cable play

4-19

Page 141 of 962

With vacuum pump gauge set at Black side of

VTV, when pump is operated, pointer moves

considerably but moves back to zero position as

soon as pump operation is stopped.

Brown side

(Actuator side) Black side

Fig. 4-l-60

1. VTV

2. Vacuum pump gauge

install VTV. Refer to Fig. 4-l -2 for installation.

[ VSV (Vacuum Switching Valve)]

1) Disconnect VSV vacuum hoses from 3 way

joint and secondary actuator and while

blowing either hose, check that air doesn’t

come out of the other hose.

2) Turn on ignition switch and depress accelera-

tor pedal fully. 5 or 6 seconds later, while

blowing either vacuum hose, check that air

comes out of the other hose.

J5

Fig. 4- l-61

1I

1. vsv4. WOTS

2. Ignition switch5. ECM

3. Battery6. Blow air

If check results in steps 1) and 2)are not satisfac-

tory, either replace VSV or check WOTS and its

circuit referring to SECTION5 “EMISSION

CONTROL SYSTEM”.

Idle Speed Adjustment

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

Before idle speed check and adjustment, make

sure of the following.

l Lead wires and hoses of engine emission

control systems are connected securely.

l Accelerator cable has some play, that is, it is

not tight.

l All vacuum hoses are connected securely.

l Fuel level should be within round mark at the

center of level gauge.

l Valve lash is checked and adjusted according

to the maintenance schedule.

l Air cleaner has been properly installed and is

in good condition.

l All accessories (wipers, heater, lights, etc) are

out of service.

l Ignition timing is within specification.

l Idle up actuator is not operating when engine

is running at idle speed.

NOTE:

In areas above 4,00Ofeet( 1,220m) elevation

(high altitude), idle up system will be normally

in operation. Do not attempt to adjust the idle

speed.

After above items are all confirmed, adjust idle

speed as follows.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust by turning idle speed adjusting screw.

If idle speed can not be adjusted to the speci-

fication by turning the adjusting screw, it can

be due to faulty return of throttle valve or

some other reason. Determine cause and

repair, and then adjust idle speed to specifica-

tion.

4-26

Page 145 of 962

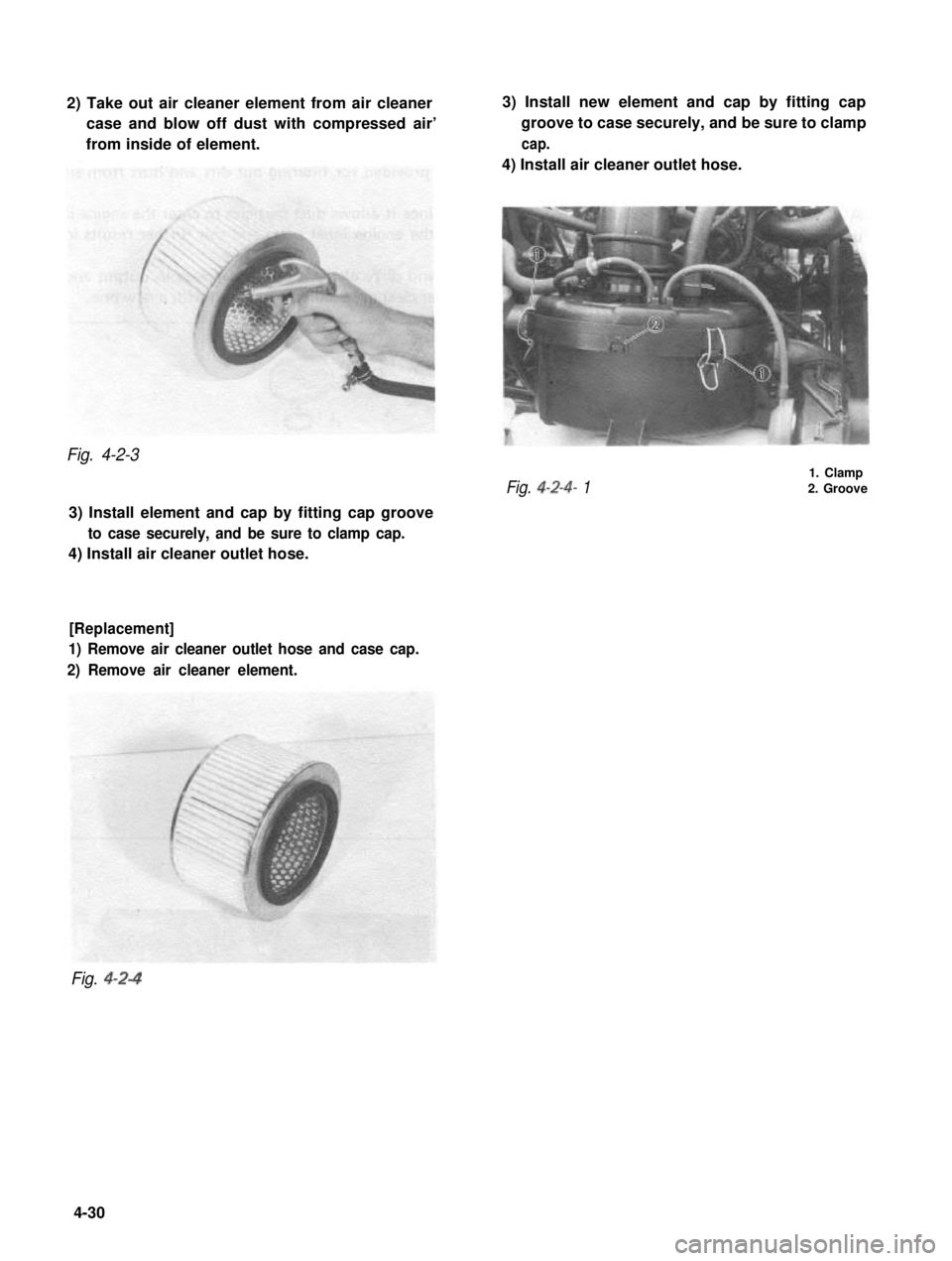

2) Take out air cleaner element from air cleaner

case and blow off dust with compressed air’

from inside of element.

3) Install new element and cap by fitting cap

groove to case securely, and be sure to clamp

cap.

4) Install air cleaner outlet hose.

Fig. 4-2-3

Fig. 4-2-4- 1

1. Clamp2. Groove

3) Install element and cap by fitting cap groove

to case securely, and be sure to clamp cap.

4) Install air cleaner outlet hose.

[Replacement]

1) Remove air cleaner outlet hose and case cap.

2) Remove air cleaner element.

Fig. 4-2-4

4-30

Page 148 of 962

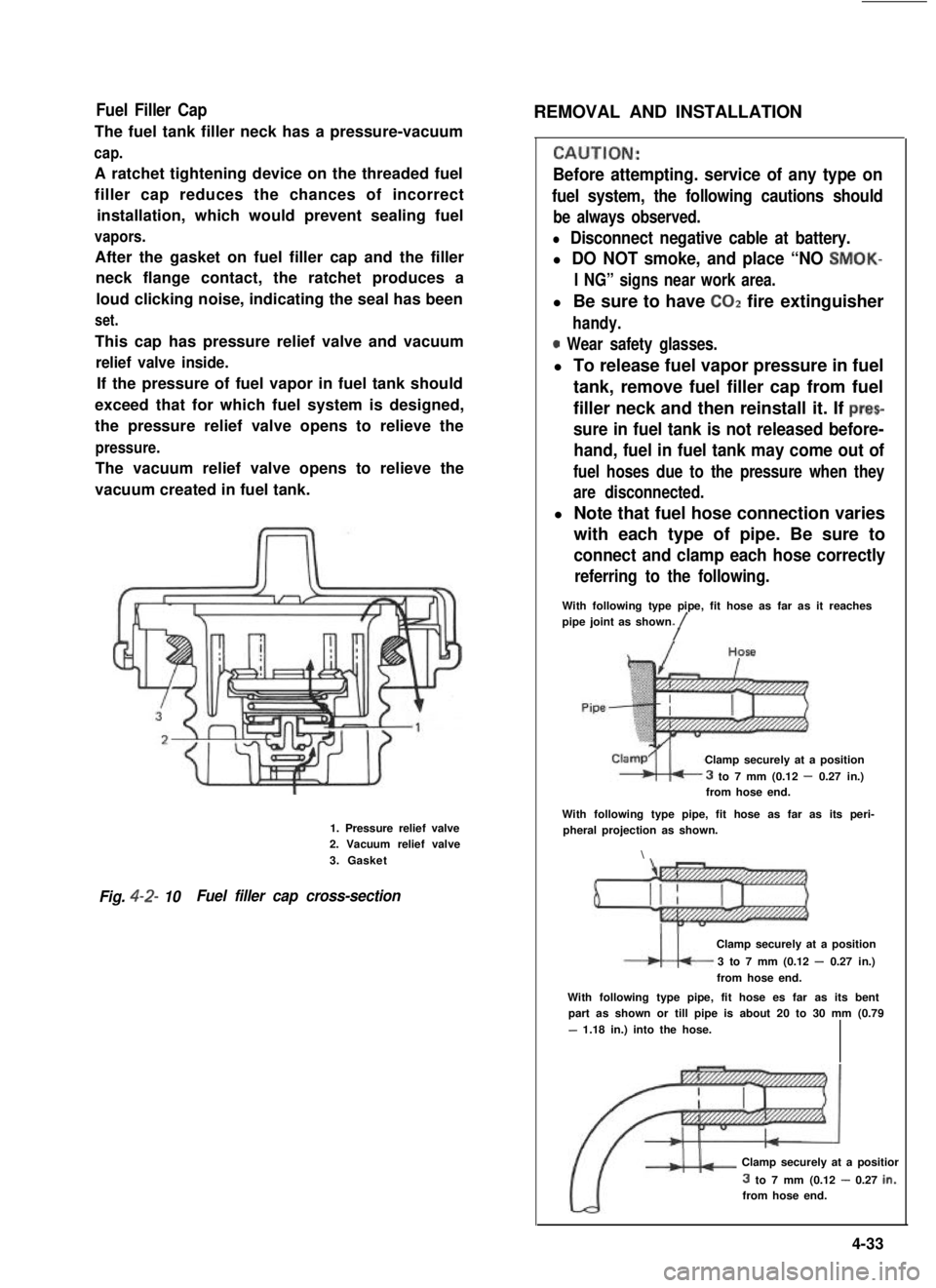

Fuel Filler Cap

The fuel tank filler neck has a pressure-vacuum

cap.

A ratchet tightening device on the threaded fuel

filler cap reduces the chances of incorrect

installation, which would prevent sealing fuel

vapors.

After the gasket on fuel filler cap and the filler

neck flange contact, the ratchet produces a

loud clicking noise, indicating the seal has been

set.

This cap has pressure relief valve and vacuum

relief valve inside.

If the pressure of fuel vapor in fuel tank should

exceed that for which fuel system is designed,

the pressure relief valve opens to relieve the

pressure.

The vacuum relief valve opens to relieve the

vacuum created in fuel tank.

1. Pressure relief valve2. Vacuum relief valve

3. Gasket

Fig. 4-2- 10Fuel filler cap cross-section

REMOVAL AND INSTALLATION

CALJTION:

Before attempting. service of any type on

fuel system, the following cautions should

be always observed.

l Disconnect negative cable at battery.

l DO NOT smoke, and place “NO SMOK-

I NG” signs near work area.

l Be sure to have COZ fire extinguisher

handy.

0 Wear safety glasses.

l To release fuel vapor pressure in fuel

tank, remove fuel filler cap from fuel

filler neck and then reinstall it. If prec

sure in fuel tank is not released before-

hand, fuel in fuel tank may come out of

fuel hoses due to the pressure when they

are disconnected.

l Note that fuel hose connection varies

with each type of pipe. Be sure to

connect and clamp each hose correctly

referring to the following.

With following type pipe, fit hose as far as it reachespipe joint as shown./

Clamp securely at a position

3 to 7 mm (0.12 - 0.27 in.)from hose end.

With following type pipe, fit hose as far as its peri-pheral projection as shown.

\

Clamp securely at a position

3 to 7 mm (0.12 - 0.27 in.)

from hose end.

With following type pipe, fit hose es far as its bentpart as shown or till pipe is about 20 to 30 mm (0.79

- 1.18 in.) into the hose.

Clamp securely at a positior

3 to 7 mm (0.12 - 0.27 in.:from hose end.

4-33

Page 150 of 962

![SUZUKI GRAND VITARA 1987 Service Owners Manual [Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal i SUZUKI GRAND VITARA 1987 Service Owners Manual [Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal i](/img/20/57437/w960_57437-149.png)

[Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal injury

cou Id occur.J

The following procedure is used for purging the

fuel tank.

1) After removing fuel tank, remove all hoses,

fuel level gauge from fuel tank.

2) Drain all remaining fuel from tank.

3) Move tank to flushing area.

4) Fill tank with warm water or tap water, and

agitate vigorously and drain. Repeat this

washing until inside of tank is clean.

Replace tank if inside is rusty.

5) Completely flush out remaining water after

washing.

[ Installation]

Reverse removal procedure for installation using

care for the following.

Tightening torque30-45 Nm

for fuel tank(3.0- 4.5 kg-m)

drain plug(22.0 - 32.5 lb-ft)

Refer to Fig. 4-2-5 for piping and clamp posi-

tions.

l Make sure for correct hose-to-pipe connec-

tion.

l Clamp hoses securely.

l Upon completion of installation, start engine

and check hose joints for leaks.

MAINTENANCE SERVICES

Fuel Lines

Visually inspect fuel lines and connections for

evidence of fuel leakage, hose cracking, and

damage. Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being crack-

ed.

Fig. 4-2-14

Fuel Filler (tank) Cap

Visually inspect gasket of fuel filler cap.

If it is damaged or deteriorated, replace filler cap

with new one.

NOTE:

If cap requires replacement, only a cap with

the same features should be used. Failure to

use correct cap can result in a serious malfunc-

tion of the system.

Fig. 4-2-15

1. Fuel filler cap

2. Fuel filler capgasket

Fuel Filter

As said before, this filter does not permit dis-

assembly: it is to be replaced with a new one

periodically.

Replace fuel filter referring to previous item of

“Fuel Filter Removal and Installation”.

This servicing must be performed in a well

ventilated area and away from any open

flames (such as gas hot water heaters).

4-35

Page 151 of 962

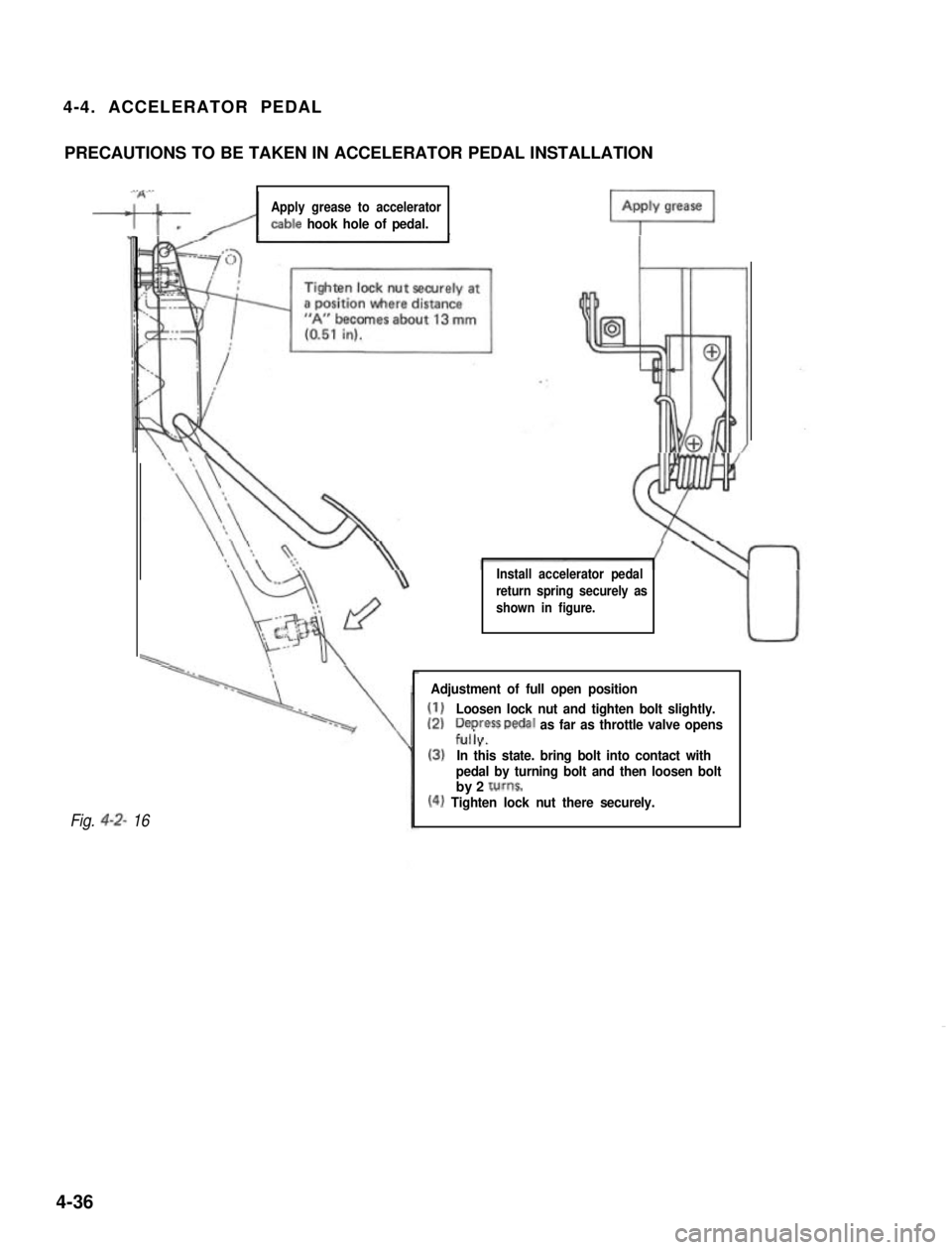

4-4. ACCELERATOR PEDAL

PRECAUTIONS TO BE TAKEN IN ACCELERATOR PEDAL INSTALLATION

“A’,

-w/i

Apply grease to accelerator

cable hook hole of pedal.

Install accelerator pedal

return spring securely as

shown in figure.

Fig. 4-2- 16

Adjustment of full open position

(1)Loosen lock nut and tighten bolt slightly.

(2)Depress Dedal as far as throttle valve opensf&

(3)In this state. bring bolt into contact with

pedal by turning bolt and then loosen boltby 2 tums.

(4) Tighten lock nut there securely.

4-36

Page 169 of 962

5-3. MAINTENANCE SERVICE

GENERAL

If the emission control hoses were disconnected

and any system component was removed for

service,be sure to reinstall the component

properly and route and connect hoses correctly

after service. Refer to Fig. 5-l-l for hose con-

nection.

PCV SYSTEM

Checking PCV System

NOTE:

If the engine is idling rough, this may be caused

by a stuck PCV valve, plugged hoses or vacuum

leakage of PCV line, therefore, never adjust the

carburetor idle without first checking the PCV

valve and hoses.

[ PCV hoses]

Check hoses for connection, leakage, clog, and

deterioration. Replace as necessary.

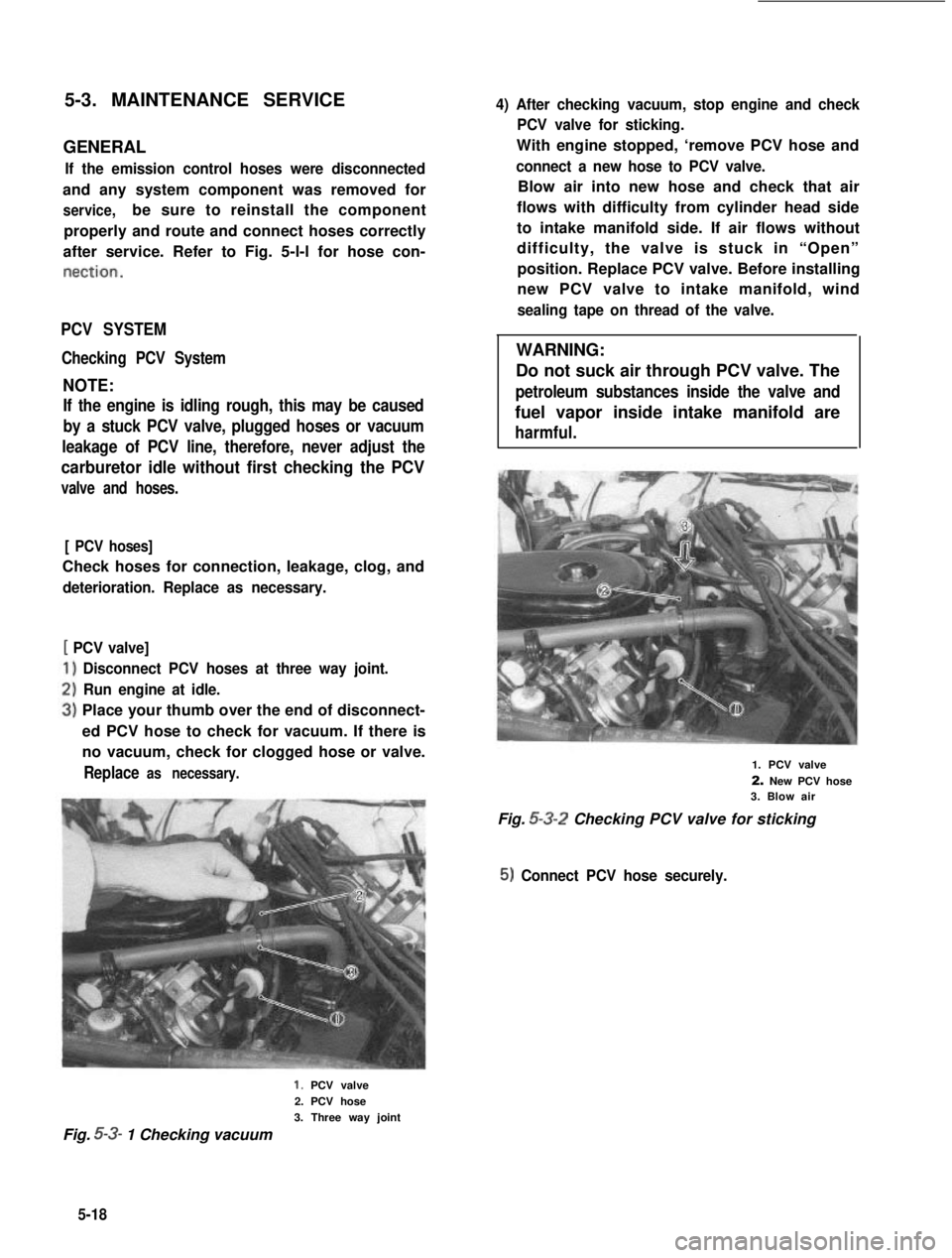

[ PCV valve]

Disconnect PCV hoses at three way joint.

Run engine at idle.

Place your thumb over the end of disconnect-

ed PCV hose to check for vacuum. If there is

no vacuum, check for clogged hose or valve.

Replace as necessary.

4) After checking vacuum, stop engine and check

PCV valve for sticking.

With engine stopped, ‘remove PCV hose and

connect a new hose to PCV valve.

Blow air into new hose and check that air

flows with difficulty from cylinder head side

to intake manifold side. If air flows without

difficulty, the valve is stuck in “Open”

position. Replace PCV valve. Before installing

new PCV valve to intake manifold, wind

sealing tape on thread of the valve.

WARNING:

Do not suck air through PCV valve. The

petroleum substances inside the valve and

fuel vapor inside intake manifold are

harmful.

1. PCV valve

2. New PCV hose3. Blow air

Fig. 5-3-2 Checking PCV valve for sticking

5) Connect PCV hose securely.

1. PCV valve

2. PCV hose

3. Three way joint

Fig. 5-3- 1 Checking vacuum

5-18