check engine SUZUKI GRAND VITARA 1987 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 74 of 962

38) Remove oil seal housing.

Fig. 3-4-4 1

39) Remove crankshaft bearing caps, and take

out crankshaft.

Fig. 3-4-42

3-5. INSPECTION OF ENGINE

COMPONENTS

NOTE:

During and immediately after disassembly,

inspect cylinder block and head for evidence

of water leakage or damage and, after washing

them clean, inspect more closely.

Wash all disassembled parts clean, removing

grease,slime, carbon and scales, before

inspecting them to determine whether repair

is necessary or not. Be sure to de-scale water

jackets.

Use compressed air to clear internal oil holes

and passages.

Do not disturb set combinations of valves,

bearings and bearing caps, etc. Have the

sets segregated and identified.

Cylinder Head

l Remove all carbon from combustion cham-

bers.

NOTE:

Do not use any sharp-edged tool to scrape off

the carbon. Be careful not to scuff or nick

metal surfaces when decarboning. This applies

to valves and valve seats, too.

Fig. 3-5 1

l Check cylinder head for cracks in intake and

exhaust ports, combustion chambers, and

head surface.

3-17

Page 92 of 962

3-6. ENGINE REASSEMBLY

NOTE:

l All parts to be used in reassembly must be

perfectly clean.

l Oil sliding and rubbing surfaces of engine

parts just before using them in reassembly.

Use engine oil (Refer to page l-8).

l Have liquid packing ready for use. SUZUKI

BOND NO. 1215 is specified for it. Use it

wherever its use is specified in order to

ensure leak-free (oil and water) workmanship

of reassembly.

l There are many running clearances. During

the course of engine reassembly, be sure to

check these clearances, one after another,

as they form.

l Gaskets, “0” rings and similar sealing mem-

bers must be in perfect condition. For these

members, use replacement parts in stock.

l Tightening torque is specified for impor-

tant fasteners - mainly bolts and nuts -of

the engine and other components. Use torque

wrenches and constantly refer to the specified

values given on p. 3-58.

l Do not disregard match marks provided on

parts. Some of them are those given at the

time of disassembly.

l There are many sets of parts. Crankshaft

bearings, connecting rods, pistons, etc., are

in combination sets. Do not disturb such

combinations and make sure that each part

goes back to where it came from.

Engine reassembly is the reverse of engine disas-

sembly as far as sequence is concerned, but

there are many reassembling steps that involve

measures necessary for restoring engine as close

to factory-assembled condition as possible. Only

those steps will be dealt with here.

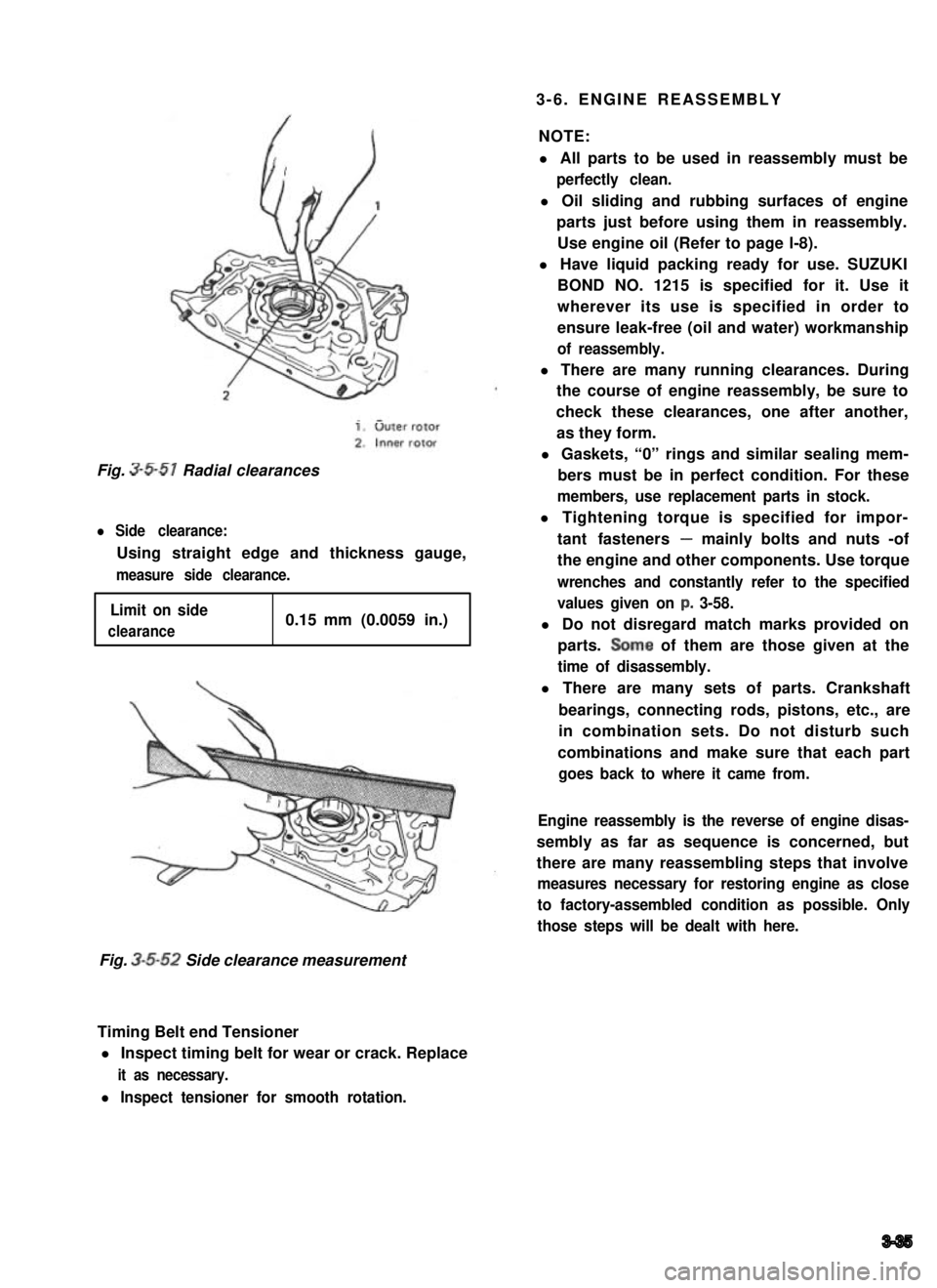

Fig. 3-5-51 Radial clearances

l Side clearance:

Using straight edge and thickness gauge,

measure side clearance.

Limit on side

clearance0.15 mm (0.0059 in.)

Fig. 3-5-52 Side clearance measurement

Timing Belt end Tensioner

l Inspect timing belt for wear or crack. Replace

it as necessary.

l Inspect tensioner for smooth rotation.

3-35

Page 94 of 962

n

U

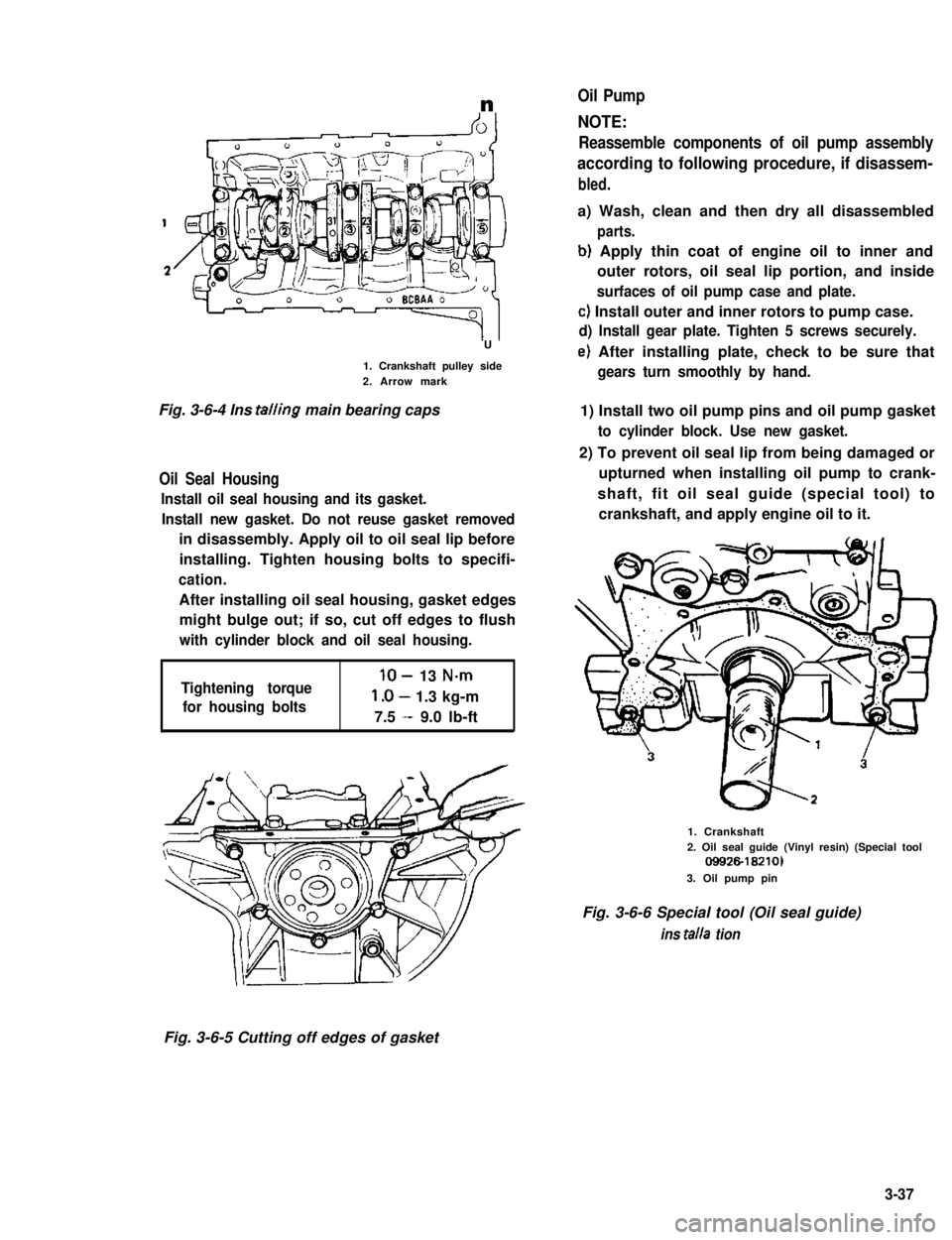

1. Crankshaft pulley side2. Arrow mark

Fig. 3-6-4 Ins tailing main bearing caps

Oil Seal Housing

Install oil seal housing and its gasket.

Install new gasket. Do not reuse gasket removed

in disassembly. Apply oil to oil seal lip before

installing. Tighten housing bolts to specifi-

cation.

After installing oil seal housing, gasket edges

might bulge out; if so, cut off edges to flush

with cylinder block and oil seal housing.

Tightening torque

for housing bolts

lo- 13 N-m

l.O- 1.3 kg-m

7.5 - 9.0 lb-ft

Oil Pump

NOTE:

Reassemble components of oil pump assembly

according to following procedure, if disassem-

bled.

a) Wash, clean and then dry all disassembled

parts.

b) Apply thin coat of engine oil to inner and

outer rotors, oil seal lip portion, and inside

surfaces of oil pump case and plate.

c) Install outer and inner rotors to pump case.

d) Install gear plate. Tighten 5 screws securely.

e) After installing plate, check to be sure that

gears turn smoothly by hand.

1) Install two oil pump pins and oil pump gasket

to cylinder block. Use new gasket.

2) To prevent oil seal lip from being damaged or

upturned when installing oil pump to crank-

shaft, fit oil seal guide (special tool) to

crankshaft, and apply engine oil to it.

1. Crankshaft2. Oil seal guide (Vinyl resin) (Special tool09926-18210)

3. Oil pump pin

Fig. 3-6-6 Special tool (Oil seal guide)

ins talla tion

Fig. 3-6-5 Cutting off edges of gasket

3-37

Page 101 of 962

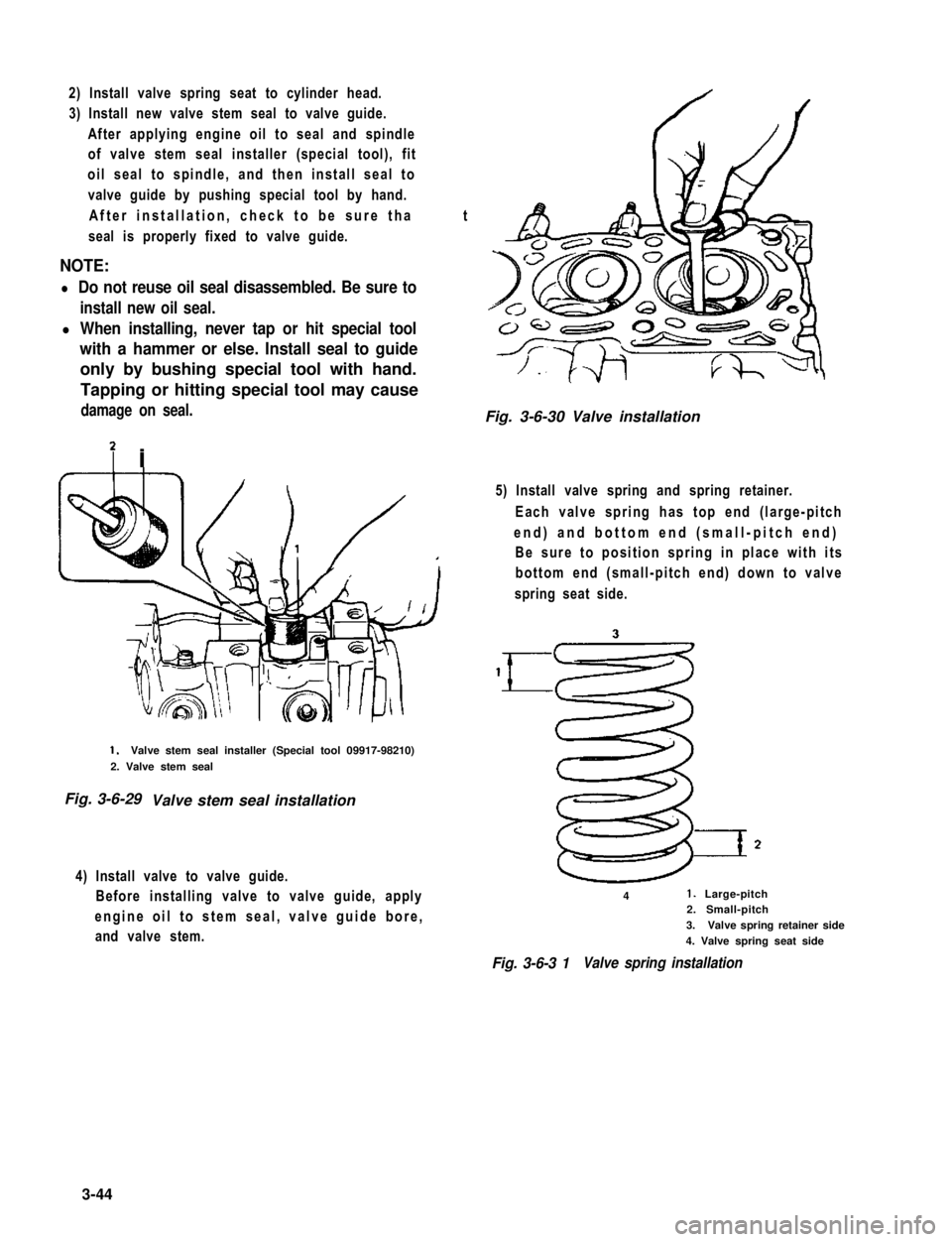

2) Install valve spring seat to cylinder head.

3) Install new valve stem seal to valve guide.

After applying engine oil to seal and spindle

of valve stem seal installer (special tool), fit

oil seal to spindle, and then install seal to

valve guide by pushing special tool by hand.

After installation, check to be sure that

seal is properly fixed to valve guide.

NOTE:

l Do not reuse oil seal disassembled. Be sure to

install new oil seal.

l When installing, never tap or hit special tool

with a hammer or else. Install seal to guide

only by bushing special tool with hand.

Tapping or hitting special tool may cause

damage on seal.

7 i

1.Valve stem seal installer (Special tool 09917-98210)

2. Valve stem seal

Fig. 3-6-29 Valve stem seal installation

4) Install valve to valve guide.

Before installing valve to valve guide, apply

engine oil to stem seal, valve guide bore,

and valve stem.

Fig. 3-6-30 Valve installation

5) Install valve spring and spring retainer.

Each valve spring has top end (large-pitch

end) and bottom end (small-pitch end)

Be sure to position spring in place with its

bottom end (small-pitch end) down to valve

spring seat side.

41. Large-pitch2. Small-pitch

3.Valve spring retainer side

4. Valve spring seat side

Fig. 3-6-3 1Valve spring installation

3-44

Page 109 of 962

Clutch Disc and Cover?

Install clutch disc and cover.

For installation, refer to p. 11-7 of SECTION 11

CLUTCH in this manual and torque each bolt to

specification.

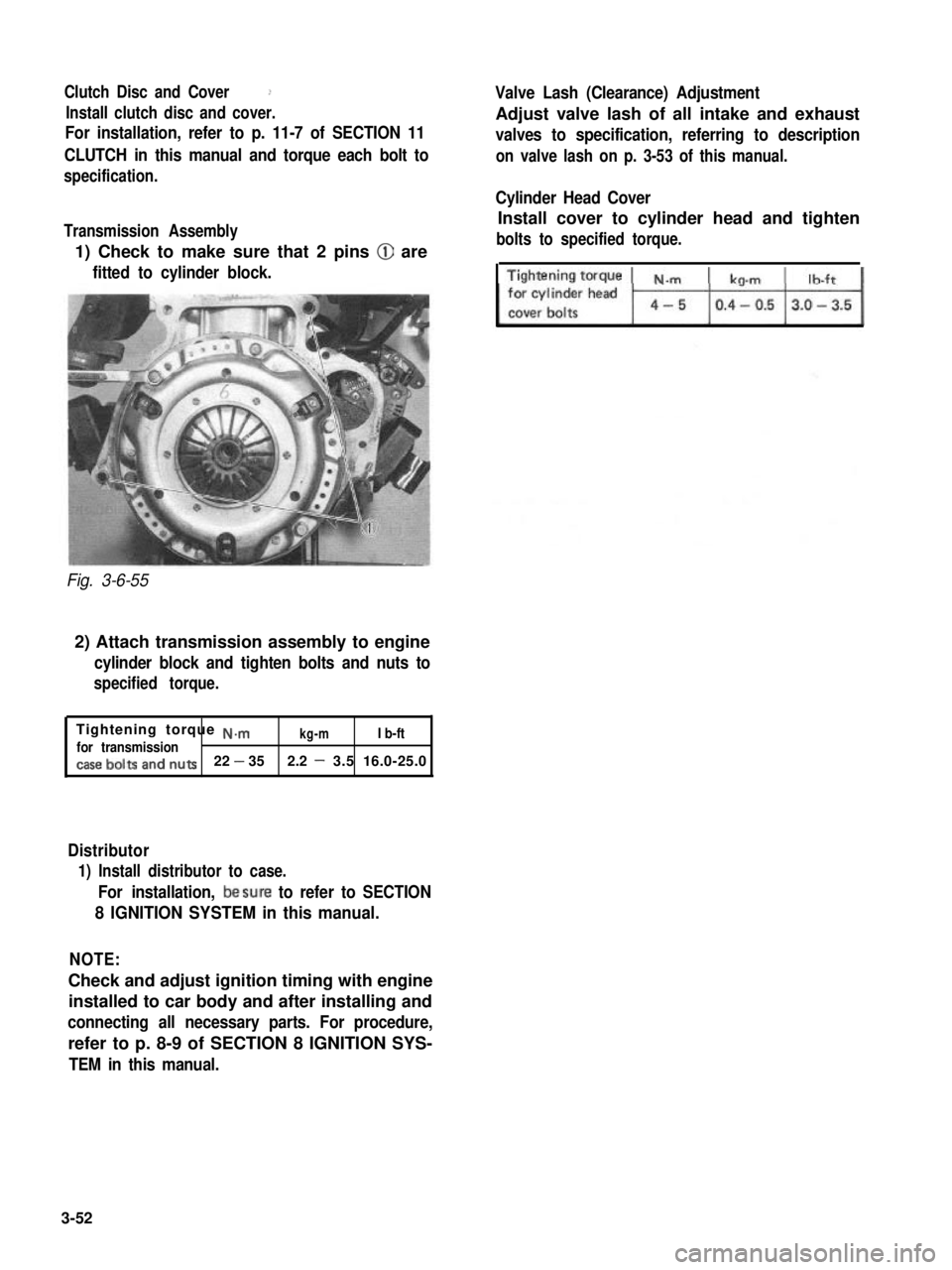

Transmission Assembly

1) Check to make sure that 2 pins @ are

fitted to cylinder block.

Fig. 3-6-55

2) Attach transmission assembly to engine

cylinder block and tighten bolts and nuts to

specified torque.

Tightening torque ~.mkg-mI b-ftfor transmission,.aSe bolts an,-j nutS22 - 352.2 - 3.5 16.0-25.0

Distributor

1) Install distributor to case.

For installation, besure to refer to SECTION

8 IGNITION SYSTEM in this manual.

Valve Lash (Clearance) Adjustment

Adjust valve lash of all intake and exhaust

valves to specification, referring to description

on valve lash on p. 3-53 of this manual.

Cylinder Head Cover

Install cover to cylinder head and tighten

bolts to specified torque.

NOTE:

Check and adjust ignition timing with engine

installed to car body and after installing and

connecting all necessary parts. For procedure,

refer to p. 8-9 of SECTION 8 IGNITION SYS-

TEM in this manual.

3-52

Page 110 of 962

3-7. ENGINE INSTALLATION

1) Lower engine with transmission into vehicle,

but do not remove lifting device.

2) Tighten engine mounting bracket bolts

(right and left) and transmission mounting

bolts to specification. Refer to p. 3-58.

3) Remove lifting device.

4) Reverse removal procedures for installation

of remainder.

5) Adjust accelerator cable play and clutch

cable play.

6) Connect vacuum hoses securely. Refer to

section 5 “EMISSION CONTROL SYSTEM”

for correct connection.

7) Connect wire harnesses and couplers secure-

IY.

8) Tighten bolts and nuts to specified torque.

For individual specification, refer to each

section.

9) Fill specified amount of specified trans-

mission oil and engine oil. For the detail,

refer to SECTION 1 PERIODIC MAINTE-

NANCE SERVICE of this manual.

10) After adjusting water pump belt tension to

specification, fill specified amount of engine

cooling water.

11) Before starting engine, check again to ensure

that all parts once disassembled or discon-

nected are back in place securely.

12)Start engine and check ignition timing. If

it is not to specified timing, adjust it, referr-

ing to SECTION 8 of this manual.

13) After engine is started, check for oil leak,

abnormal noise and other malcondition.

Also, check each part for operation.

3-8. ENGINE MAINTENANCE SERVICE

Fan Belt

Adjust belt tension as outlined in SECTION 6

ENGINE COOLING SYSTEM (p. 6-10).

Ignition Timing

Refer to IGNITION TIMING, Page 8-9.

Carburetor

fidjustments to be made are detailed in SEC-

TION 4 (p. 4-19).

Valve Lash (Clearance)

Valve lash specifications:

Valve lash refers to gap between rocker arm

adjusting screw and valve stem. Use a thickness

gauge to measure this gap @.

When coldWhen hot(Coolant tempe-(Coolant tempa-

Valve lashrature is 15 - 25%rature is 60 - 66’C

(gap A)or 69 - 77’F)or 140 - 154’F)

specif i-0.13 - 0.17 mm0.23 - 0.27 mmcationIntake(0.0051 - 0.0067 in) (0.009 - 0.011 in)

Exhaust0.16 -0.20 mm0.26 - 0.30 mm(0.0063 - 0.0079 in) (0.0102 - 0.0116 in)

Screw lock nut 15 - 19 N.m(1.5 - 1.9 kg-m, 11 .O - 13.5 lb-ft)

Adjusting screw

8

Valve stem

Fig. 3-8-l

Checking and adjusting procedures:

NOTE:

l Refer to Fig. 3-3-11 of SECTION 3 for

cylinder numbers (No. 1, No. 2, No. 3 and

No. 4) mentioned in this section.

l When adjustment becomes necessary in step

4), loosen adjusting screw lock nut and then

make adjustment by turning adjusting screw.

After adjustment, tighten lock nut to specifi-

ed torque while holding adjusting screw

stationary with straight headed screwdriver,

and then make sure again that gap @ is

within specification.

3-53

Page 111 of 962

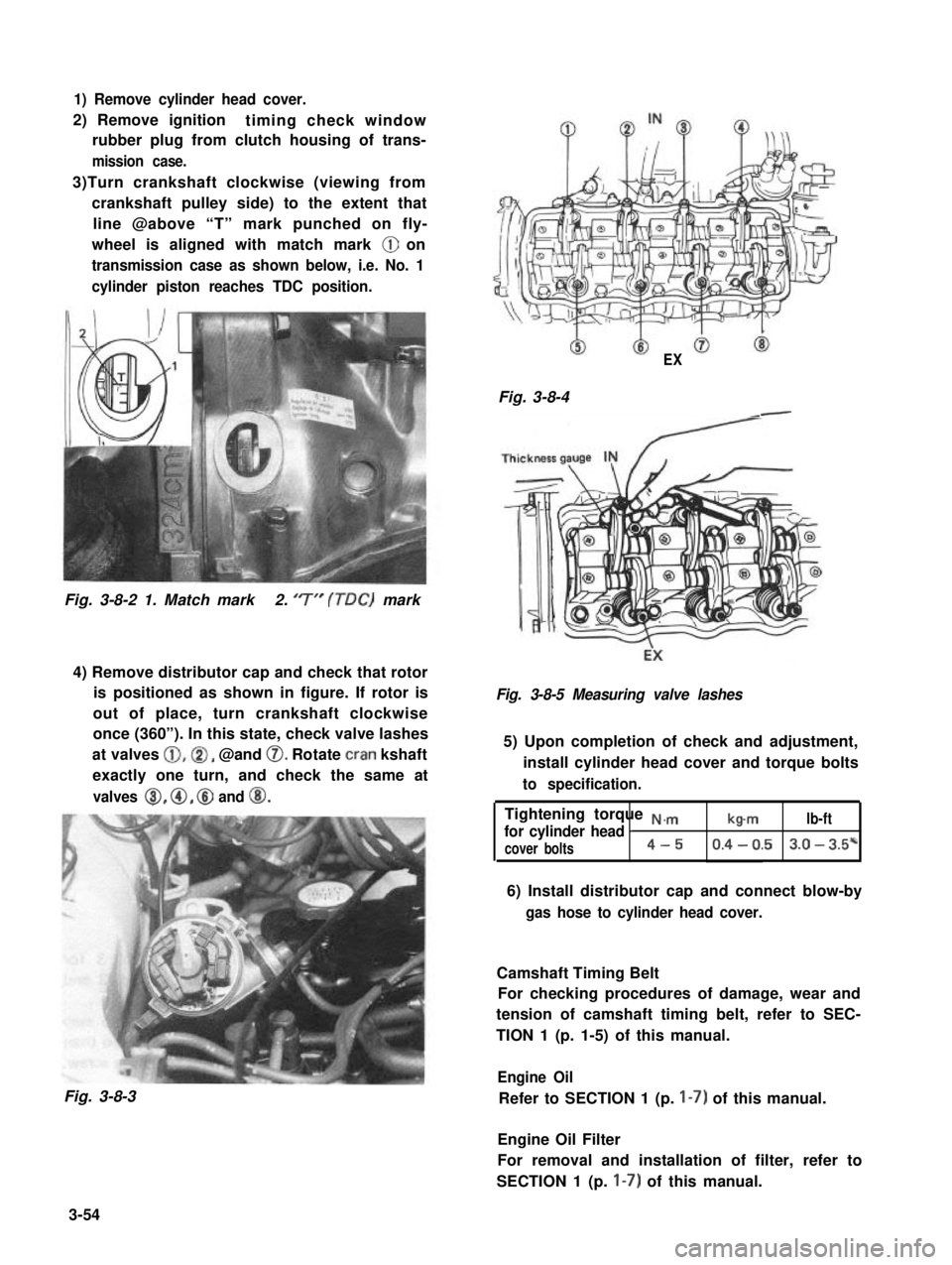

1) Remove cylinder head cover.

2) Remove ignitiontiming check window

rubber plug from clutch housing of trans-

mission case.

3)Turn crankshaft clockwise (viewing from

crankshaft pulley side) to the extent that

line @above “T” mark punched on fly-

wheel is aligned with match mark @ on

transmission case as shown below, i.e. No. 1

cylinder piston reaches TDC position.

Fig. 3-8-2 1. Match mark2. ‘7” (TDC) mark

4) Remove distributor cap and check that rotor

is positioned as shown in figure. If rotor is

out of place, turn crankshaft clockwise

once (360”). In this state, check valve lashes

at valves @,@I, @and 0. Rotate cran kshaft

exactly one turn, and check the same at

valves 8, @, @ and @I.

Fig. 3-8-3

EX

Fig. 3-8-4-

Fig. 3-8-5 Measuring valve lashes

5) Upon completion of check and adjustment,

install cylinder head cover and torque bolts

to specification.

Tightening torque N.,.,.,

for cylinder head Ib-mlb-ft

cover bolts4-50.4 - 0.53.0 - 3.5*

6) Install distributor cap and connect blow-by

gas hose to cylinder head cover.

Camshaft Timing Belt

For checking procedures of damage, wear and

tension of camshaft timing belt, refer to SEC-

TION 1 (p. 1-5) of this manual.

Engine Oil

Refer to SECTION 1 (p. I-7) of this manual.

Engine Oil Filter

For removal and installation of filter, refer to

SECTION 1 (p. I-7) of this manual.

3-54

Page 112 of 962

Engine Coolant

This subject is covered in SECTION 6 ENGINE

COOLING SYSTEM.

Exhaust Line and Muffler

Inspect each exhaust line connection for tight-

ness, and examine muffler and other parts for

evidence of breakage and leakage of gases.

Repair or replace defective parts, if any.

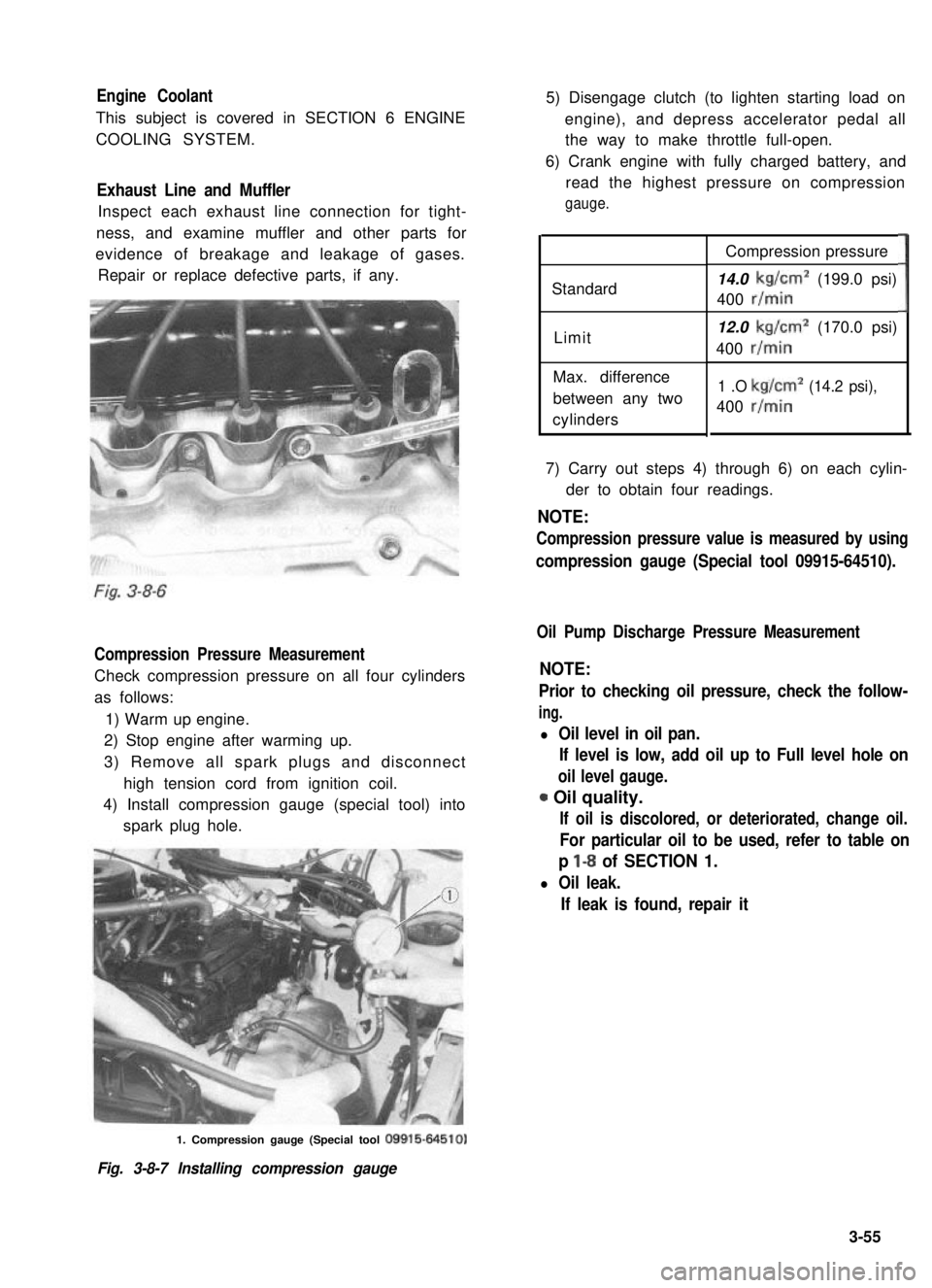

Compression Pressure Measurement

Check compression pressure on all four cylinders

as follows:

1) Warm up engine.

2) Stop engine after warming up.

3) Remove all spark plugs and disconnect

high tension cord from ignition coil.

4) Install compression gauge (special tool) into

spark plug hole.

5) Disengage clutch (to lighten starting load on

engine), and depress accelerator pedal all

the way to make throttle full-open.

6) Crank engine with fully charged battery, and

read the highest pressure on compression

gauge.

Standard

Limit

Max. difference

between any two

cylinders

Compression pressure

14.0 kg/cm2 (199.0 psi)

400 r/min

12.0 kg/cm2 (170.0 psi)

400 r/min

1 .O kg/cm2 (14.2 psi),

400 r/min

3

7) Carry out steps 4) through 6) on each cylin-

der to obtain four readings.

NOTE:

Compression pressure value is measured by using

compression gauge (Special tool 09915-64510).

Oil Pump Discharge Pressure Measurement

NOTE:

Prior to checking oil pressure, check the follow-

ing.

l Oil level in oil pan.

If level is low, add oil up to Full level hole on

oil level gauge.

0 Oil quality.

If oil is discolored, or deteriorated, change oil.

For particular oil to be used, refer to table on

p l-8 of SECTION 1.

l Oil leak.

If leak is found, repair it

1. Compression gauge (Special tool 09915-64510)

Fig. 3-8-7 Installing compression gauge

3-55

Page 113 of 962

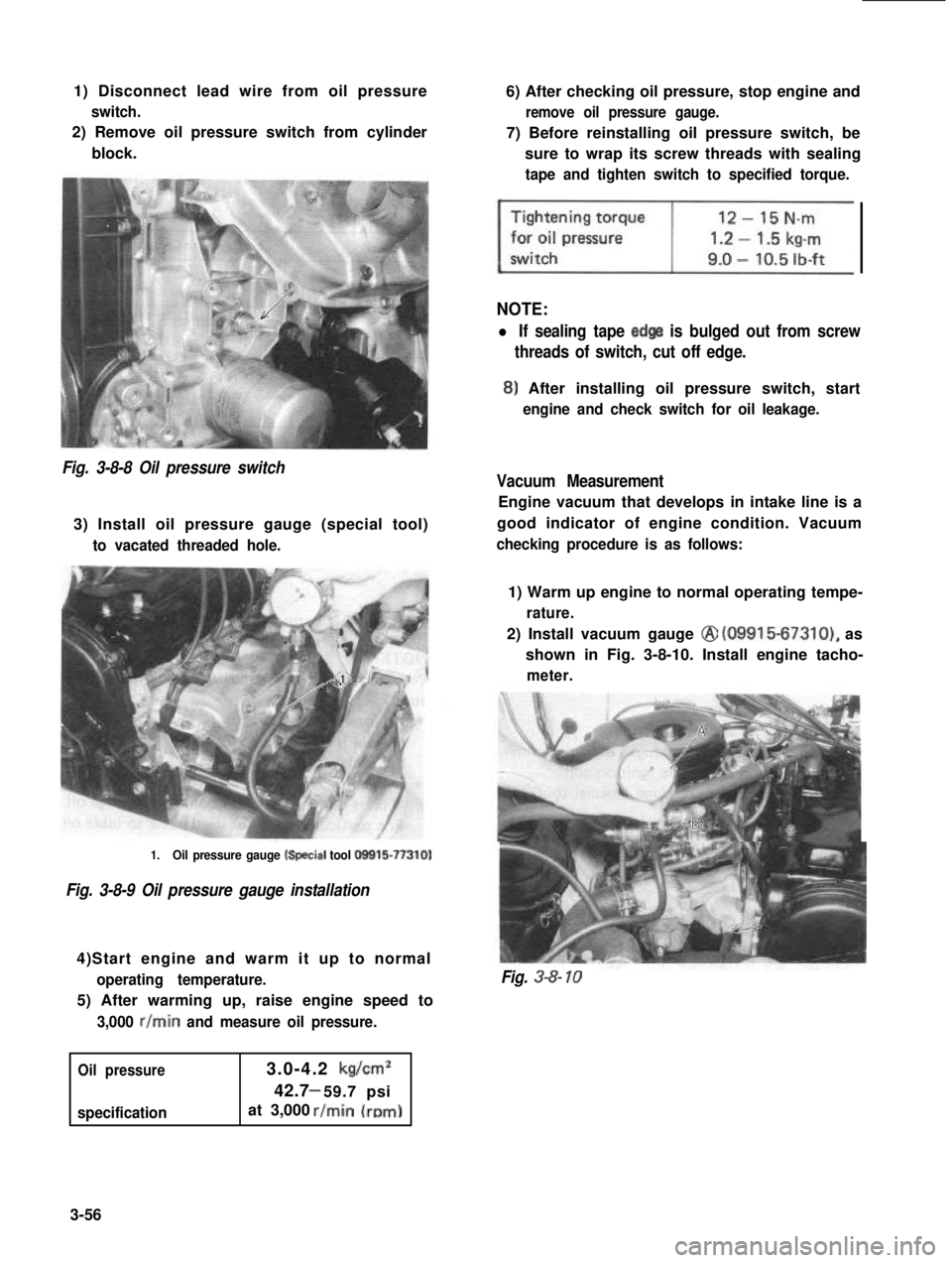

1) Disconnect lead wire from oil pressure

switch.

2) Remove oil pressure switch from cylinder

block.

6) After checking oil pressure, stop engine and

remove oil pressure gauge.

7) Before reinstalling oil pressure switch, be

sure to wrap its screw threads with sealing

tape and tighten switch to specified torque.

NOTE:

l If sealing tape edge is bulged out from screw

threads of switch, cut off edge.

8) After installing oil pressure switch, start

engine and check switch for oil leakage.

Fig. 3-8-8 Oil pressure switch

3) Install oil pressure gauge (special tool)

to vacated threaded hole.

Vacuum Measurement

Engine vacuum that develops in intake line is a

good indicator of engine condition. Vacuum

checking procedure is as follows:

1.Oil pressure gauge k+ecial tool O!Xil5-77310)

Fig. 3-8-9 Oil pressure gauge installation

4)Start engine and warm it up to normal

operating temperature.

5) After warming up, raise engine speed to

3,000 r/min and measure oil pressure.

Oil pressure

specification

3.0-4.2 kg/cm2

42.7 59.7 psi-

at 3,000

1) Warm up engine to normal operating tempe-

rature.

2) Install vacuum gauge @ (09915-67310), as

shown in Fig. 3-8-10. Install engine tacho-

meter.

Fig. 3-8- 10

3-56

Page 114 of 962

3) Run engine at specified idling speed and,

under this running condition, read vacuum

gauge. Vacuum should not be lower than

45 cm Hg (17.7 in. Hg).

A low vacuum reading means that any combi-

nation of following malconditions is the cause,

which must be corrected before releasing

machine to customer:

Oil Filler Cap

The cap has a packing. Be sure that packing is in

good condition, free of any damage and signs of

deterioration, and is tight In place: it is replacea-

ble.

(a) Leaky cylinder head gasket

(b) Leaky inlet manifold gasket

(c) Leaky valves

(d) Weakened valve springs

(e) Maladjusted valve clearance

(f) Valve timing out of adjustment

(g) Ignition mistimed

(h) Carburetor improperly adjusted

NOTE:

Should indicating hand of the vacuum gauge

oscillate violently, turn adjusting nut @I to

steady it

4

Standard vacuum45- 55cm Hg

(sea level)(17.7 - 21.6 in. Hg)

Idling speedBOO f 50 r/min (rpm)

specification(Take vacuum reading

at this speed.)L

4) After checking, remove vacuum gauge.

5) Before reinstalling vacuum checking plug,

be sure to wrap its screw threads with

sealing tape and tighten plug.

3-57