check engine SUZUKI GRAND VITARA 1987 Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 143 of 962

3) Reinstall carburetor following normal service

procedures.

Connect emission control system hoses and

lead wires. Make specified play on accelerator

cable and refill cooling system.

4) Place transaxle gear shift lever in “Neutral”,

set parking brake and block drive wheels.

5) Start engine, and warm it up to normal

operating temperature, stop engine.

6) Be sure to check the following before idle

mixture adjustment.

l Fuel level is within round mark at the

center of level gauge.

l Valve lash is checked and adjusted accord-

ing to the maintenance schedule.

l Air cleaner has been properly installed

and is in good condition.

l All accessories (wipers, heater, lights etc)

are out of service.

l Ignition timing is within specification.

l Choke valve opens fully.

l Idle-up actuator does not operate.

7) Check and adjust idle speed to specification

if necessary.

8) Remove seal rubber of duty check coupler

and connect positive terminal of duty

meter to“Blue/Red” wire and negative

terminal to “Black/Green” wire.

9) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

10) With engine running at idle speed, adjust idle

mixture adjusting screw slowly in small incre-

ment allowing time for duty to stabilize after

turning screw to obtain duty of 10 - 50.

If duty is too low, back screw out; if too

high, screw it in. After obtaining duty of

10 - 50, recheck idle speed, and adjust if

necessary.

NOTE:

If adjustment can’t be made because duty meter

indicator does not deflect, check feed back

system according to the checking procedure of

system described in section of Emission Control

System.

11) After adjustment, install seal rubber to duty

check coupler and drive in idle mixture

adjusting screw pin.

4-28

Page 144 of 962

4-2. AIR CLEANER

GENERAL DESCRIPTION

In the air cleaner case, a dry-type air cleaner element is provided for filtering.out dirt and dust from air

being drawn into the engine for combustion.

A damaged element must be replaced with a new one, since it allows dust particles to enter the engine if

used as it is. Such dust particles could cause wear to the engine inner parts and this further results in

decreased output.

Also, the element must be cleaned periodically. Dusty and dirty element causes decrease in output and

increase in fuel consumption. The dusty element even after cleaning should be replaced with a new one.

Fig. 4-2-l

1. Air cleaner case

2. Air cleaner case cap

3. Air cleaner element4. Air cleaner inlet hose

5. Air cleaner outlet hose

6. Warm air hose

7. Carburetor air intake case

8. Check valve

9. Therm0 sensor (valve)10. Air control actuator

MAINTENANCE SERVICES

Air Cleaner Element

[Cleaning]

1) Remove air cleaner outlet hose and case cap.

Fig. 4-2-21. Air cleaner outlet hose2. Air cleaner case cap3. Clamp

4-29

Page 149 of 962

![SUZUKI GRAND VITARA 1987 Service Service Manual ,Fuel Pump

[ Rem’oval]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap from fuel filler neck to

release fuel vapor pressure in fuel tank. After

releasing, reinstall the cap.

3) SUZUKI GRAND VITARA 1987 Service Service Manual ,Fuel Pump

[ Rem’oval]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap from fuel filler neck to

release fuel vapor pressure in fuel tank. After

releasing, reinstall the cap.

3)](/img/20/57437/w960_57437-148.png)

,Fuel Pump

[ Rem’oval]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap from fuel filler neck to

release fuel vapor pressure in fuel tank. After

releasing, reinstall the cap.

3) Disconnect fuel inlet, outlet and return hoses

from fuel pump.

Fuel Filter

[Removal]

1) Disconnect negative cable from battery.

2) Remove fuel filler cap to release fuel vapor

pressure in fuel tank. After releasing, reinstall

the cap.

3) Disconnect inlet and outlet hoses from fuel

filter.

4) Remove fuel filter with clamp.

[Installation]

1) Install filter and clamp, and connect inlet

and outlet hoses to fuel filter.

NOTE:.

The top connection is for outlet hose, the

lower one for inlet hose.

1. Fuel pump

2. Inlet hose3. Outlet hose

4. Return hose

Fig. 4-2-l 1

4) Remove fuel pump from cylinder head.

5) Remove fuel pump rod from cylinder head.

2

1. Fuel pump rod

2. Cylinder head

[Installation]

Reverse removal procedure for installation

using care for the following.

l After oiling it,install fuel pump rod to

cylinder head.

0 Use new fuel pump gasket.

l Make sure for proper hose connection.

0 Upon completion of installation, start engine

and check fuel hose or its joints for leaks.

1.Fuel filter3.From fueltank

2.To fuel pump4.Clamp

Fig.4-2-13

2) Connect negative cable to battery.

3) After installation, start engine and check it

for leaks.

Fuel Tank

[Removal]

1) Disconnect negative cable from battery.

2) Disconnect fuel level gauge lead wire.

3) To release the pressure in fuel tank, remove

fuel filler cap and then, reinstall it.

4) Raise car on hoist.

5) Drain fuel by removing drain plug.

6) Remove filler hose protector.

7) Disconnect filler hose from fuel tank.

.8) Disconnect fuel hosesand pipe from fuel tank.

9) Remove fuel tank.

4-34

Page 150 of 962

![SUZUKI GRAND VITARA 1987 Service Service Manual [Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal i SUZUKI GRAND VITARA 1987 Service Service Manual [Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal i](/img/20/57437/w960_57437-149.png)

[Fuel tank purging procedure]

WARNING:

This purging procedure will NOT remove

all fuel vapor. Do not attempt any repair

on tank where heat or flame is required, as

an explosion resulting in personal injury

cou Id occur.J

The following procedure is used for purging the

fuel tank.

1) After removing fuel tank, remove all hoses,

fuel level gauge from fuel tank.

2) Drain all remaining fuel from tank.

3) Move tank to flushing area.

4) Fill tank with warm water or tap water, and

agitate vigorously and drain. Repeat this

washing until inside of tank is clean.

Replace tank if inside is rusty.

5) Completely flush out remaining water after

washing.

[ Installation]

Reverse removal procedure for installation using

care for the following.

Tightening torque30-45 Nm

for fuel tank(3.0- 4.5 kg-m)

drain plug(22.0 - 32.5 lb-ft)

Refer to Fig. 4-2-5 for piping and clamp posi-

tions.

l Make sure for correct hose-to-pipe connec-

tion.

l Clamp hoses securely.

l Upon completion of installation, start engine

and check hose joints for leaks.

MAINTENANCE SERVICES

Fuel Lines

Visually inspect fuel lines and connections for

evidence of fuel leakage, hose cracking, and

damage. Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being crack-

ed.

Fig. 4-2-14

Fuel Filler (tank) Cap

Visually inspect gasket of fuel filler cap.

If it is damaged or deteriorated, replace filler cap

with new one.

NOTE:

If cap requires replacement, only a cap with

the same features should be used. Failure to

use correct cap can result in a serious malfunc-

tion of the system.

Fig. 4-2-15

1. Fuel filler cap

2. Fuel filler capgasket

Fuel Filter

As said before, this filter does not permit dis-

assembly: it is to be replaced with a new one

periodically.

Replace fuel filter referring to previous item of

“Fuel Filter Removal and Installation”.

This servicing must be performed in a well

ventilated area and away from any open

flames (such as gas hot water heaters).

4-35

Page 155 of 962

5-l. GENERAL DESCRIPTION

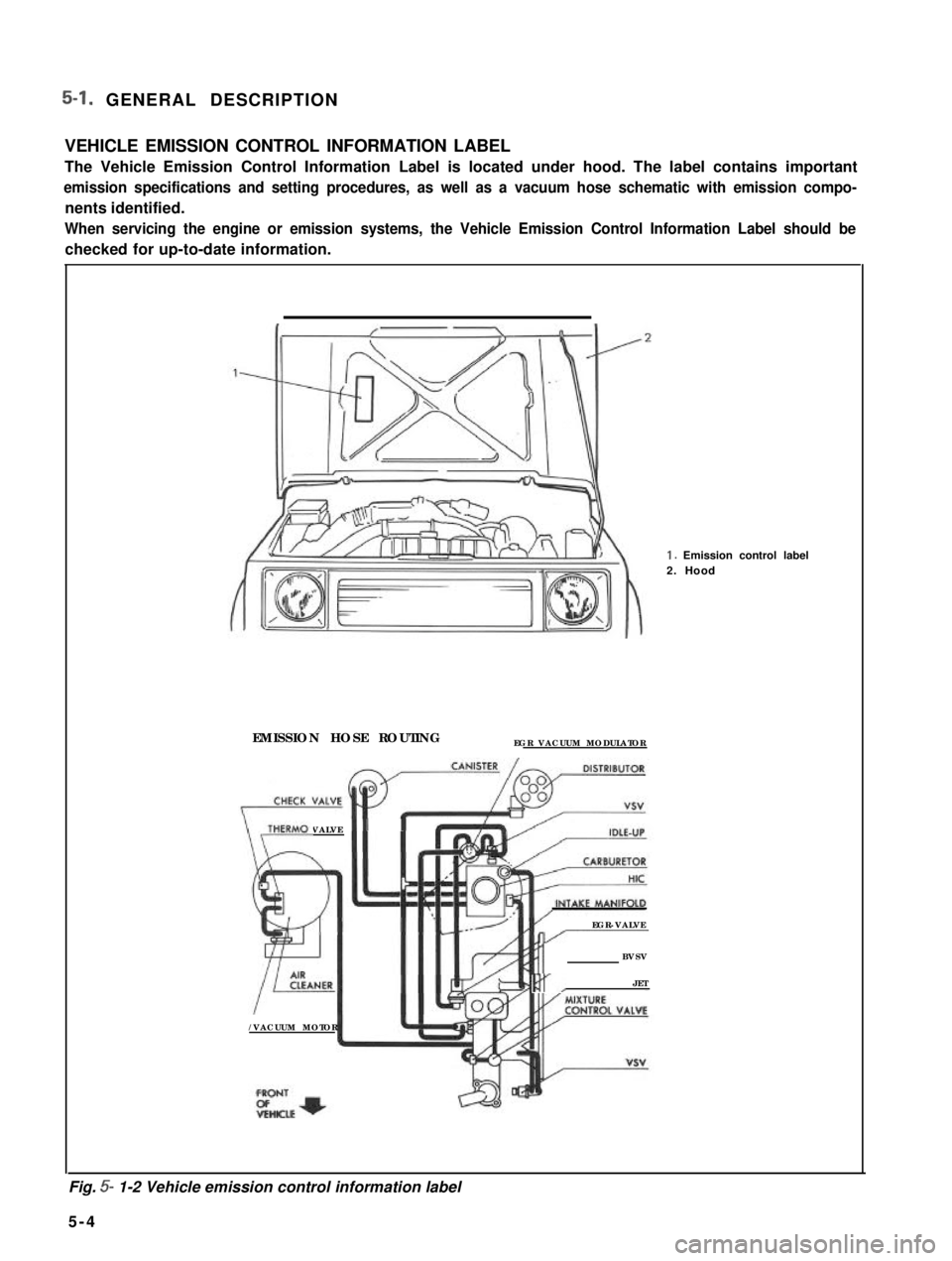

VEHICLE EMISSION CONTROL INFORMATION LABEL

The Vehicle Emission Control Information Label is located under hood. The label contains important

emission specifications and setting procedures, as well as a vacuum hose schematic with emission compo-

nents identified.

When servicing the engine or emission systems, the Vehicle Emission Control Information Label should be

checked for up-to-date information. 1.

Emission control label

2. Hood

EMISSION HOSE ROUTING EGR VACUUM MODULATOR

THERM0 VALVE

\/-

I I

EGR-VALVE-/------

BVSV

Rr,JET

/VACUUM MOTOR

Fig.

5- 1-2 Vehicle emission control information label

5- 4

Page 157 of 962

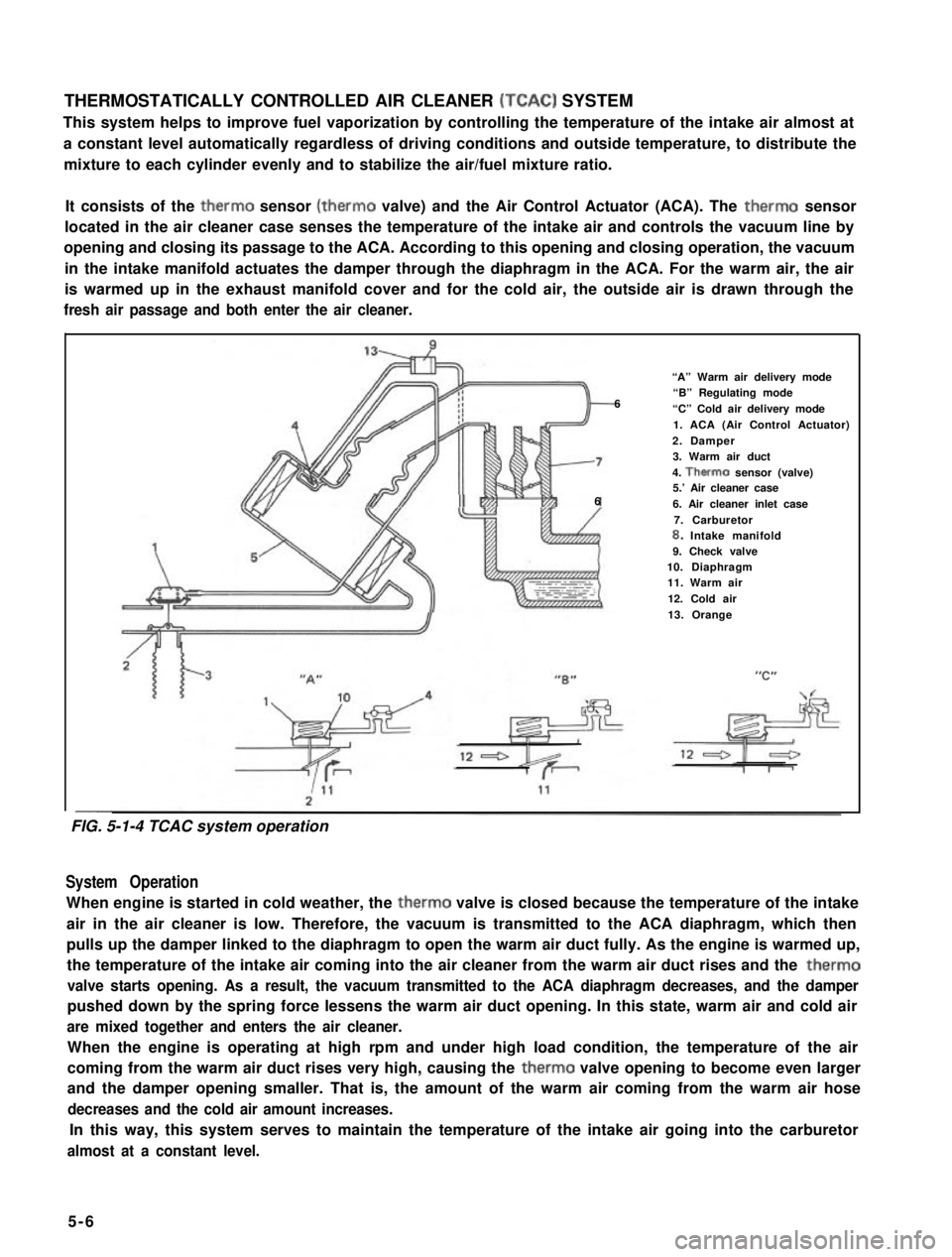

THERMOSTATICALLY CONTROLLED AIR CLEANER (TCAC) SYSTEM

This system helps to improve fuel vaporization by controlling the temperature of the intake air almost at

a constant level automatically regardless of driving conditions and outside temperature, to distribute the

mixture to each cylinder evenly and to stabilize the air/fuel mixture ratio.

It consists of the therm0 sensor (therm0 valve) and the Air Control Actuator (ACA). The therm0 sensor

located in the air cleaner case senses the temperature of the intake air and controls the vacuum line by

opening and closing its passage to the ACA. According to this opening and closing operation, the vacuum

in the intake manifold actuates the damper through the diaphragm in the ACA. For the warm air, the air

is warmed up in the exhaust manifold cover and for the cold air, the outside air is drawn through the

fresh air passage and both enter the air cleaner.

“A” Warm air delivery mode

6“B” Regulating mode

“C” Cold air delivery mode

1. ACA (Air Control Actuator)

2. Damper3. Warm air duct

4. Therm0 sensor (valve)5.’ Air cleaner case66. Air cleaner inlet case

7. Carburetor8. Intake manifold9. Check valve10. Diaphragm11. Warm air

12. Cold air

13. Orange

--

System Operation

When engine is started in cold weather, the therm0 valve is closed because the temperature of the intake

air in the air cleaner is low. Therefore, the vacuum is transmitted to the ACA diaphragm, which then

pulls up the damper linked to the diaphragm to open the warm air duct fully. As the engine is warmed up,

the temperature of the intake air coming into the air cleaner from the warm air duct rises and the therm0

valve starts opening. As a result, the vacuum transmitted to the ACA diaphragm decreases, and the damper

pushed down by the spring force lessens the warm air duct opening. In this state, warm air and cold air

are mixed together and enters the air cleaner.

When the engine is operating at high rpm and under high load condition, the temperature of the air

coming from the warm air duct rises very high, causing the therm0 valve opening to become even larger

and the damper opening smaller. That is, the amount of the warm air coming from the warm air hose

decreases and the cold air amount increases.

In this way, this system serves to maintain the temperature of the intake air going into the carburetor

almost at a constant level.

5-6

FIG. 5-1-4 TCAC system operation

Page 167 of 962

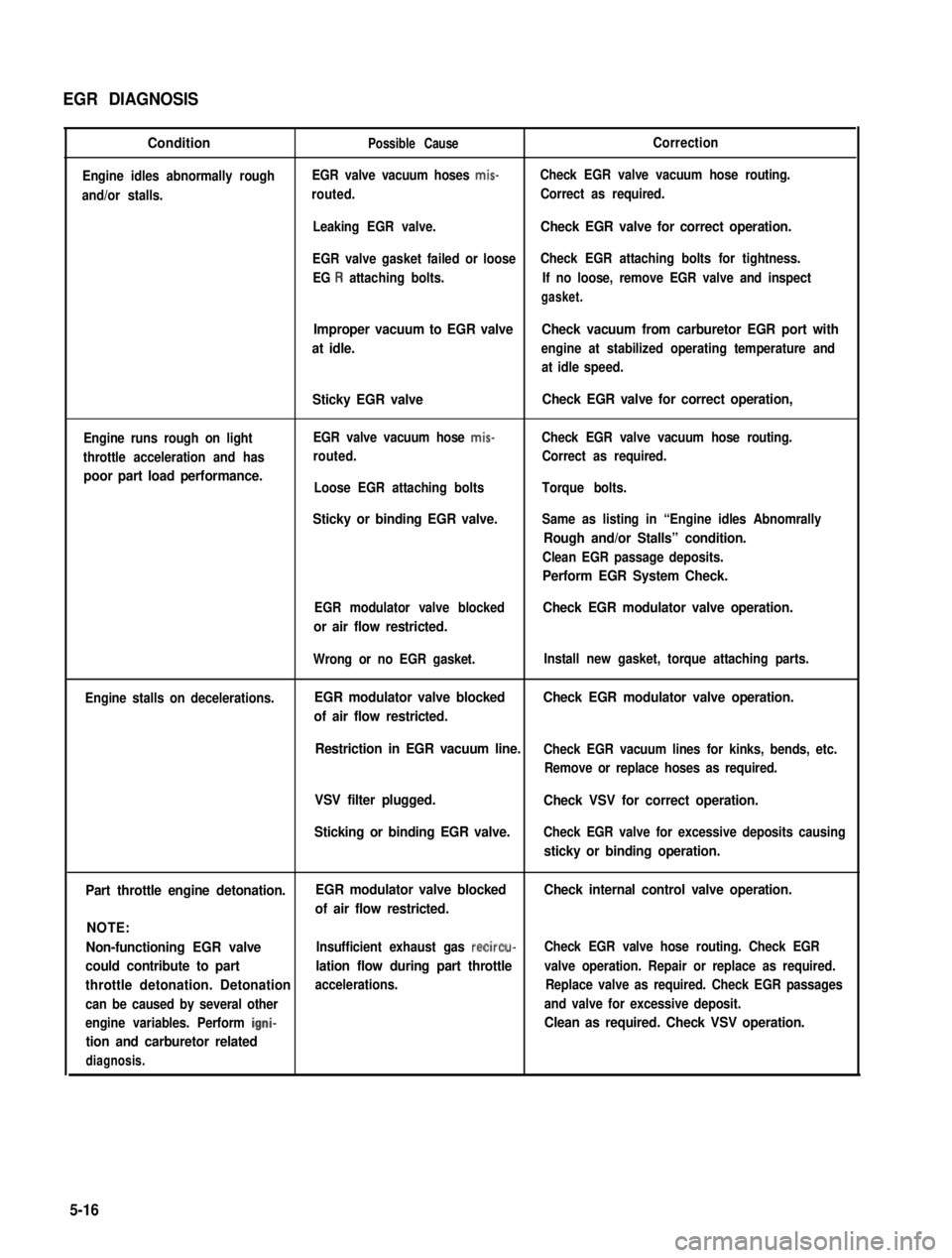

EGR DIAGNOSIS

Condition

Engine idles abnormally rough

and/or stalls.

Possible CauseCorrection

EGR valve vacuum hoses mis-Check EGR valve vacuum hose routing.

routed.Correct as required.

Leaking EGR valve.Check EGR valve for correct operation.

EGR valve gasket failed or looseCheck EGR attaching bolts for tightness.

EG R attaching bolts.If no loose, remove EGR valve and inspect

gasket.

Improper vacuum to EGR valveCheck vacuum from carburetor EGR port with

at idle.engine at stabilized operating temperature and

at idle speed.

Engine runs rough on light

throttle acceleration and has

poor part load performance.

Sticky EGR valve

EGR valve vacuum hose mis-

routed.

Loose EGR attaching bolts

Sticky or binding EGR valve.

Check EGR valve for correct operation,

Check EGR valve vacuum hose routing.

Correct as required.

Torque bolts.

Same as listing in “Engine idles Abnomrally

Rough and/or Stalls” condition.

Clean EGR passage deposits.

Perform EGR System Check.

EGR modulator valve blocked

or air flow restricted.

Check EGR modulator valve operation.

Engine stalls on decelerations.

Wrong or no EGR gasket.

EGR modulator valve blocked

of air flow restricted.

Install new gasket, torque attaching parts.

Check EGR modulator valve operation.

Restriction in EGR vacuum line.Check EGR vacuum lines for kinks, bends, etc.

Remove or replace hoses as required.

VSV filter plugged.

Sticking or binding EGR valve.

Check VSV for correct operation.

Check EGR valve for excessive deposits causing

sticky or binding operation.

Part throttle engine detonation.EGR modulator valve blockedCheck internal control valve operation.

of air flow restricted.

NOTE:

Non-functioning EGR valveInsufficient exhaust gas recircu-Check EGR valve hose routing. Check EGR

could contribute to partlation flow during part throttlevalve operation. Repair or replace as required.

throttle detonation. Detonationaccelerations.Replace valve as required. Check EGR passages

can be caused by several otherand valve for excessive deposit.

engine variables. Perform igni-Clean as required. Check VSV operation.

tion and carburetor related

diagnosis.

5-16

Page 168 of 962

Condition

Engine starts but immediately

stalls when cold.

NOTE:

Stalls after start can also be

caused by carburetor problems.

PCV SYSTEM DIAGNOSIS

Condition

Unstable idle, frequent stalling.

Oil in air cleaner.

Possible Cause

EGR valve hoses misrouted.

BVSV is out of order.

Possible Cause

PCV valve completely stuck.

Hose plugged.

PCV system plugged.

Correction

Check EGR valve hose routings.

Check BVSV. Replace as necessary.

Correction

Replace valve.

Check hoses.

Replace valve.

5-17

Page 169 of 962

5-3. MAINTENANCE SERVICE

GENERAL

If the emission control hoses were disconnected

and any system component was removed for

service,be sure to reinstall the component

properly and route and connect hoses correctly

after service. Refer to Fig. 5-l-l for hose con-

nection.

PCV SYSTEM

Checking PCV System

NOTE:

If the engine is idling rough, this may be caused

by a stuck PCV valve, plugged hoses or vacuum

leakage of PCV line, therefore, never adjust the

carburetor idle without first checking the PCV

valve and hoses.

[ PCV hoses]

Check hoses for connection, leakage, clog, and

deterioration. Replace as necessary.

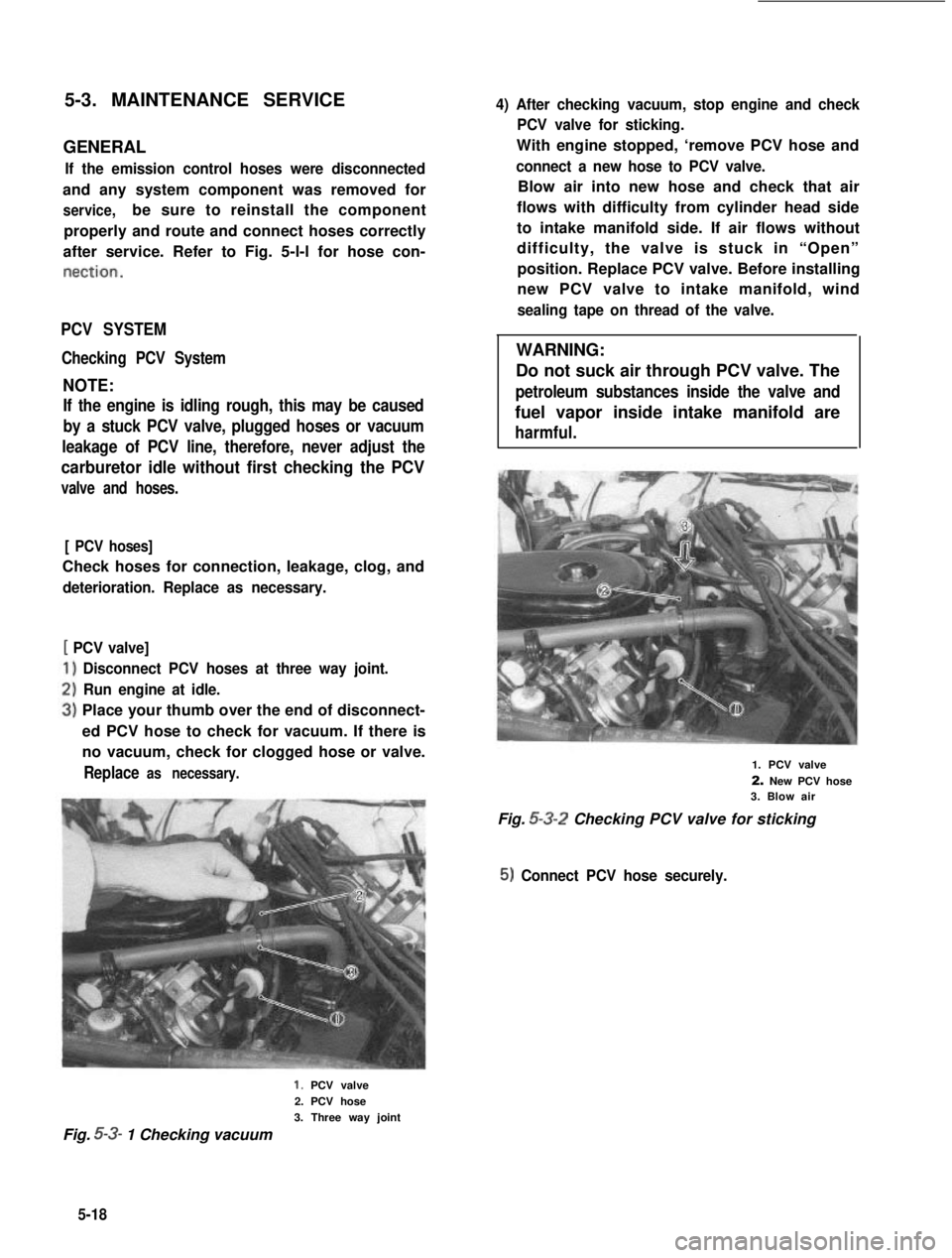

[ PCV valve]

Disconnect PCV hoses at three way joint.

Run engine at idle.

Place your thumb over the end of disconnect-

ed PCV hose to check for vacuum. If there is

no vacuum, check for clogged hose or valve.

Replace as necessary.

4) After checking vacuum, stop engine and check

PCV valve for sticking.

With engine stopped, ‘remove PCV hose and

connect a new hose to PCV valve.

Blow air into new hose and check that air

flows with difficulty from cylinder head side

to intake manifold side. If air flows without

difficulty, the valve is stuck in “Open”

position. Replace PCV valve. Before installing

new PCV valve to intake manifold, wind

sealing tape on thread of the valve.

WARNING:

Do not suck air through PCV valve. The

petroleum substances inside the valve and

fuel vapor inside intake manifold are

harmful.

1. PCV valve

2. New PCV hose3. Blow air

Fig. 5-3-2 Checking PCV valve for sticking

5) Connect PCV hose securely.

1. PCV valve

2. PCV hose

3. Three way joint

Fig. 5-3- 1 Checking vacuum

5-18

Page 170 of 962

TCAC SYSTEM

Checking TCAC System

1) Check vacuum hose for connection, deterio-

ration or damage. Replace as necessary.

4 3

3) Check that when engine is started (and run at

idle speed) under the condition that air

cleaner is cool, valve on warm air side becomes

fully open and one on fresh air inhaling side

is completely closed.

4) If nothing was found faulty in the above step,

connect warm air hose.

1. Air control actuator

2. Therm0 sensor3. Check valve

4. Orange side

Fig, 5-3-3TCA C sys tern

2) With engine at a stop, make sure that the

valve indicated in figure is completely closed

(closing warm air side). This check should be

carried out by putting finger into duct after

removing warm air hose from it.

Fig. 5-3-4Checking TCA C sys tern

If found defective in above step 2) or 3),

inspect following parts according to each

procedure.

[Air control actuator]

1) Disconnect vacuum hose from therm0 sensor.

2) Make sure that damper opens fully when

more than 20 cmHg (7.87 in.Hg) vacuum is

applied to ACA.

Also, make sure that damper is held at the

same position when a constant vacuum is

applied to it.

If damper doesn’t open or close smoothly, or

it isn’t held at the same position, replace ACA.

Fig. 5-3-5 Checking A CA

3

4

1. Air cleaner

2. ACA3. Damper valve

4. Warm air5. Fresh air

[Thermo sensor]

1) Remove air cleaner case cap.

2) Disconnect two vacuum hoses from therm0

sensor.

I) Measure the temperature around therm0

sensor.

.) Close a nozzle with finger and then blow air

into nozzle. If measured temperature is above

40°C (104” F), air should come out of therm0

sensor valve (valve is open) as shown in Fig.

5-3-6.

If the temperature is below 25°C (77”F), air

should not come out (valve is closed).

Replace defective parts.5-19