check engine light SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 26 of 962

8. PCV VALVE REPLACEMENT

1) Disconnect crankcase ventilation hose from

PCV valve.

2) Remove PCV valve from intake manifold.

3) Wind sealing tape on thread of the new valve

and install it securely.

Tightenlng torque

for PCV valve

15-25 N.m

1.5-2.5 kg-m,

11 .O-18.0 lb-ft

4) Install hose and clamp it securely.

9. OXYGEN SENSOR REPLACEMENT

[Canadian specification vehicle]

When the odometer indicates 50,000 and 100,000

miles, replace oxygen sensor as follows.

CAUTION:

To avoid the danger of being burned, do

not touch the exhaust system when the

system is hot. This work should be perform-

ed when the system is cool.

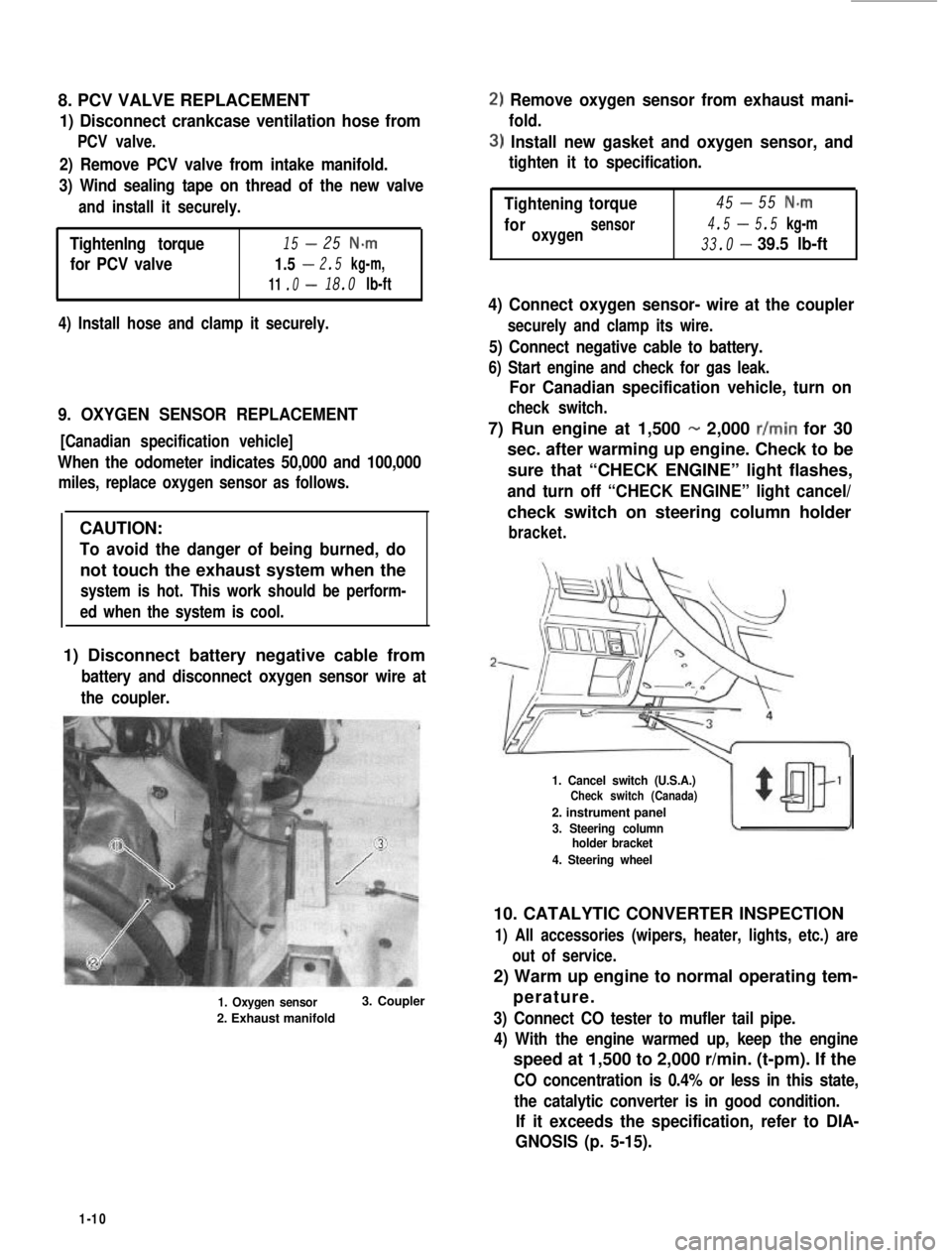

1) Disconnect battery negative cable from

battery and disconnect oxygen sensor wire at

the coupler.

1. Oxygen sensor

2. Exhaust manifold

3. Coupler

2) Remove oxygen sensor from exhaust mani-

fold.

3) Install new gasket and oxygen sensor, and

tighten it to specification.

-Tightening45torque55 N-m

4.5-foroxygensensor5.5 kg-m

33.0-39.5 lb-ft

4) Connect oxygen sensor- wire at the coupler

securely and clamp its wire.

5) Connect negative cable to battery.

6) Start engine and check for gas leak.

For Canadian specification vehicle, turn on

check switch.

7) Run engine at 1,500 - 2,000 r/min for 30

sec. after warming up engine. Check to be

sure that “CHECK ENGINE” light flashes,

and turn off “CHECK ENGINE” light cancel/

check switch on steering column holder

bracket.

1. Cancel switch (U.S.A.)Check switch (Canada)

2. instrument panel

3. Steering columnholder bracket

4. Steering wheel

10. CATALYTIC CONVERTER INSPECTION

1) All accessories (wipers, heater, lights, etc.) are

out of service.

2) Warm up engine to normal operating tem-

perature.

3) Connect CO tester to mufler tail pipe.

4) With the engine warmed up, keep the engine

speed at 1,500 to 2,000 r/min. (t-pm). If the

CO concentration is 0.4% or less in this state,

the catalytic converter is in good condition.

If it exceeds the specification, refer to DIA-

GNOSIS (p. 5-15).

1-10

Page 28 of 962

1. During acceleration

2. During deceleration

3. Diaphragm

Movement of EGR valve diaphragm

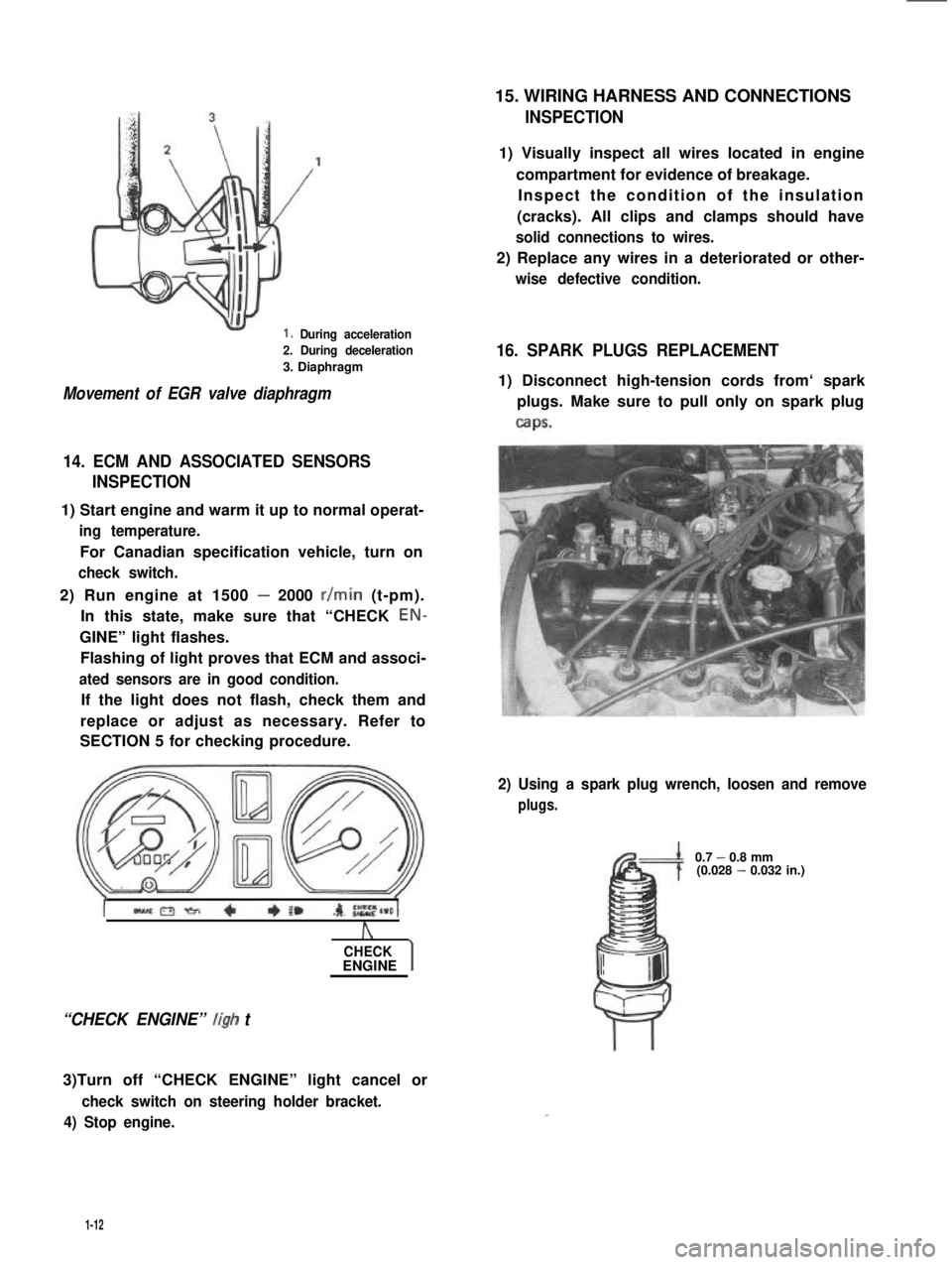

14. ECM AND ASSOCIATED SENSORS

INSPECTION

1) Start engine and warm it up to normal operat-

ing temperature.

For Canadian specification vehicle, turn on

check switch.

2) Run engine at 1500 - 2000 r/min (t-pm).

In this state, make sure that “CHECK EON-

GINE” light flashes.

Flashing of light proves that ECM and associ-

ated sensors are in good condition.

If the light does not flash, check them and

replace or adjust as necessary. Refer to

SECTION 5 for checking procedure.

A

CHECKENGINE

“CHECK ENGINE” ligh t

3)Turn off “CHECK ENGINE” light cancel or

check switch on steering holder bracket.

4) Stop engine.

15. WIRING HARNESS AND CONNECTIONS

INSPECTION

1) Visually inspect all wires located in engine

compartment for evidence of breakage.

Inspect the condition of the insulation

(cracks). All clips and clamps should have

solid connections to wires.

2) Replace any wires in a deteriorated or other-

wise defective condition.

16. SPARK PLUGS REPLACEMENT

1) Disconnect high-tension cords from‘ spark

plugs. Make sure to pull only on spark plug

caps.

2) Using a spark plug wrench, loosen and remove

plugs.

0.7 - 0.8 mm(0.028 - 0.032 in.)

1-12

Page 32 of 962

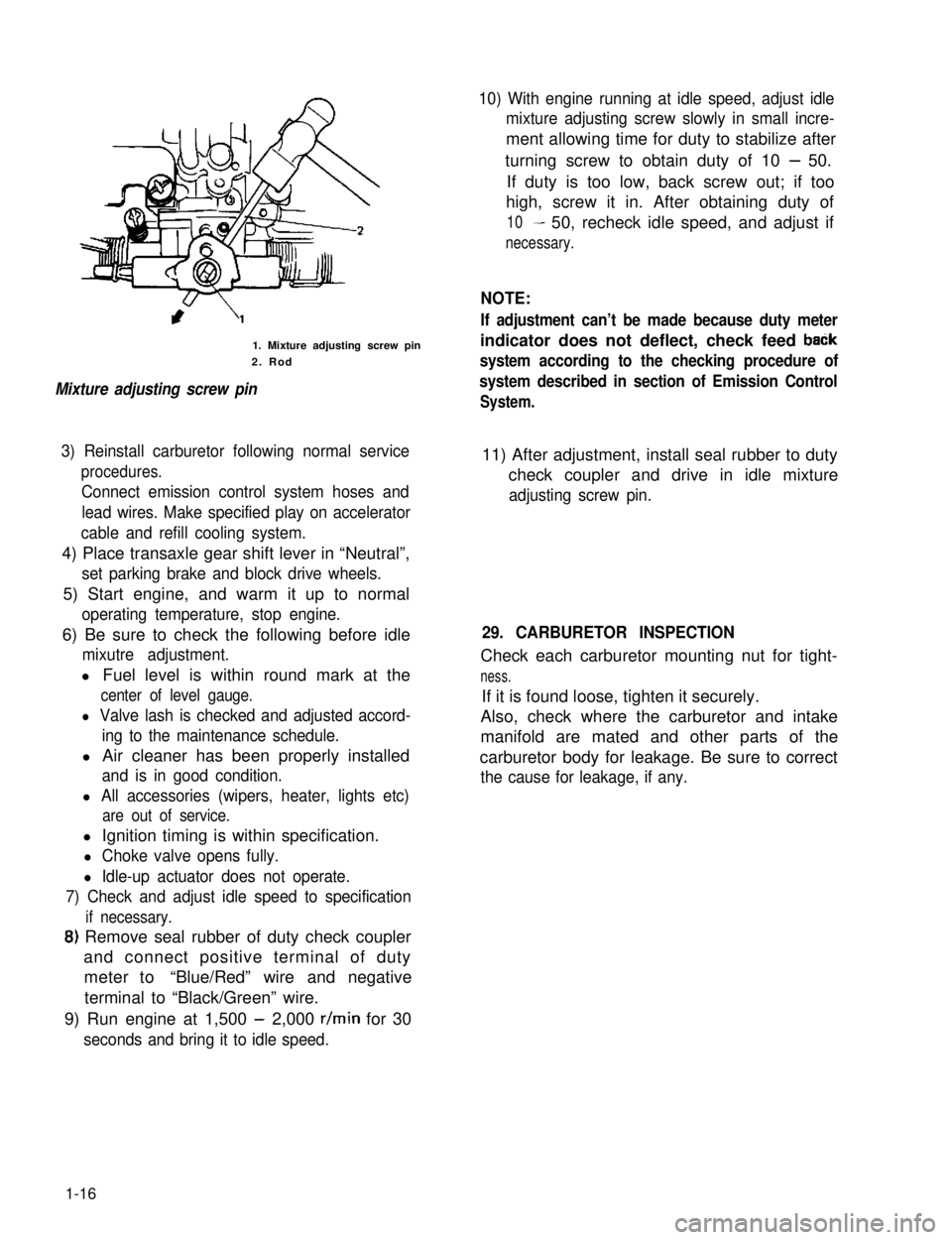

1. Mixture adjusting screw pin

2. Rod

Mixture adjusting screw pin

10) With engine running at idle speed, adjust idle

mixture adjusting screw slowly in small incre-

ment allowing time for duty to stabilize after

turning screw to obtain duty of 10 - 50.

If duty is too low, back screw out; if too

high, screw it in. After obtaining duty of

10- 50, recheck idle speed, and adjust if

necessary.

NOTE:

If adjustment can’t be made because duty meter

indicator does not deflect, check feed baCk

system according to the checking procedure of

system described in section of Emission Control

System.

3) Reinstall carburetor following normal service

procedures.

Connect emission control system hoses and

lead wires. Make specified play on accelerator

cable and refill cooling system.

11) After adjustment, install seal rubber to duty

check coupler and drive in idle mixture

adjusting screw pin.

4) Place transaxle gear shift lever in “Neutral”,

set parking brake and block drive wheels.

5) Start engine, and warm it up to normal

operating temperature, stop engine.

6) Be sure to check the following before idle

mixutre adjustment.

l Fuel level is within round mark at the

center of level gauge.

l Valve lash is checked and adjusted accord-

ing to the maintenance schedule.

l Air cleaner has been properly installed

and is in good condition.

l All accessories (wipers, heater, lights etc)

are out of service.

29. CARBURETOR INSPECTION

Check each carburetor mounting nut for tight-

ness.

If it is found loose, tighten it securely.

Also, check where the carburetor and intake

manifold are mated and other parts of the

carburetor body for leakage. Be sure to correct

the cause for leakage, if any.

l Ignition timing is within specification.

l Choke valve opens fully.

l Idle-up actuator does not operate.

7) Check and adjust idle speed to specification

if necessary.

8) Remove seal rubber of duty check coupler

and connect positive terminal of duty

meter to“Blue/Red” wire and negative

terminal to “Black/Green” wire.

9) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

1-16

Page 55 of 962

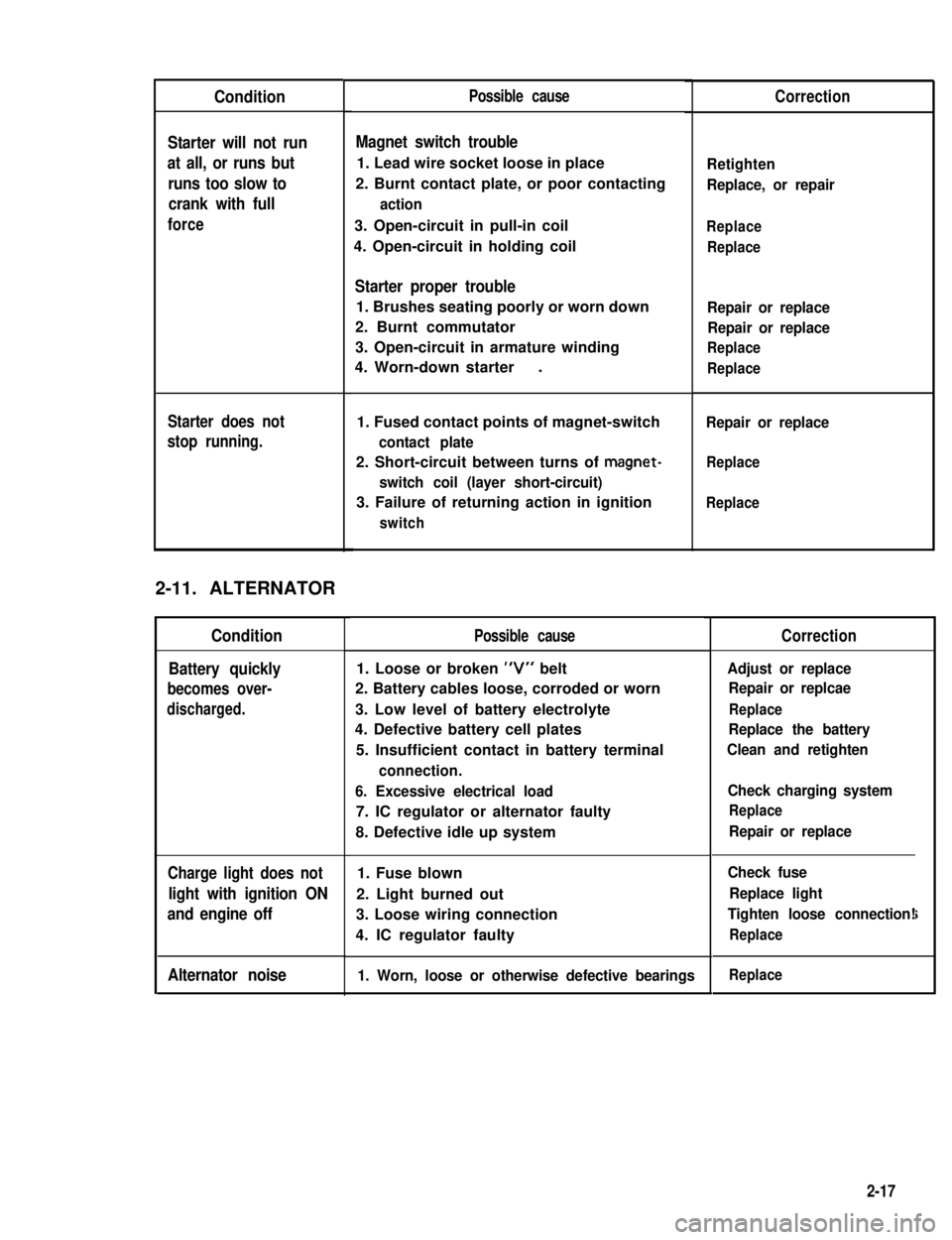

Condition

Starter will not run

at all, or runs but

runs too slow to

crank with full

force

Starter does not

stop running.

2-11. ALTERNATOR

Condition

Battery quickly

becomes over-

discharged.

Charge light does not

light with ignition ON

and engine off

Alternator noise

Possible cause

Magnet switch trouble

1. Lead wire socket loose in place

2. Burnt contact plate, or poor contacting

action

3. Open-circuit in pull-in coil

4. Open-circuit in holding coil

Starter proper trouble

1. Brushes seating poorly or worn down

2. Burnt commutator

3. Open-circuit in armature winding

4. Worn-down starter.

1. Fused contact points of magnet-switch

contact plate

2. Short-circuit between turns of magnet-

switch coil (layer short-circuit)

3. Failure of returning action in ignition

switch

Possible cause

1. Loose or broken “V” belt

2. Battery cables loose, corroded or worn

3. Low level of battery electrolyte

4. Defective battery cell plates

5. Insufficient contact in battery terminal

connection.

6. Excessive electrical load

7. IC regulator or alternator faulty

8. Defective idle up system

1. Fuse blown

2. Light burned out

3. Loose wiring connection

4. IC regulator faulty

1. Worn, loose or otherwise defective bearings

Correction

Retighten

Replace, or repair

Replace

Replace

Repair or replace

Repair or replace

Replace

Replace

Repair or replace

Replace

Replace

Correction

Adjust or replace

Repair or replcae

Replace

Replace the battery

Clean and retighten

Check charging system

Replace

Repair or replace

Check fuse

Replace light

Tighten loose connection!

Replace

i

Replace

2-17

Page 112 of 962

Engine Coolant

This subject is covered in SECTION 6 ENGINE

COOLING SYSTEM.

Exhaust Line and Muffler

Inspect each exhaust line connection for tight-

ness, and examine muffler and other parts for

evidence of breakage and leakage of gases.

Repair or replace defective parts, if any.

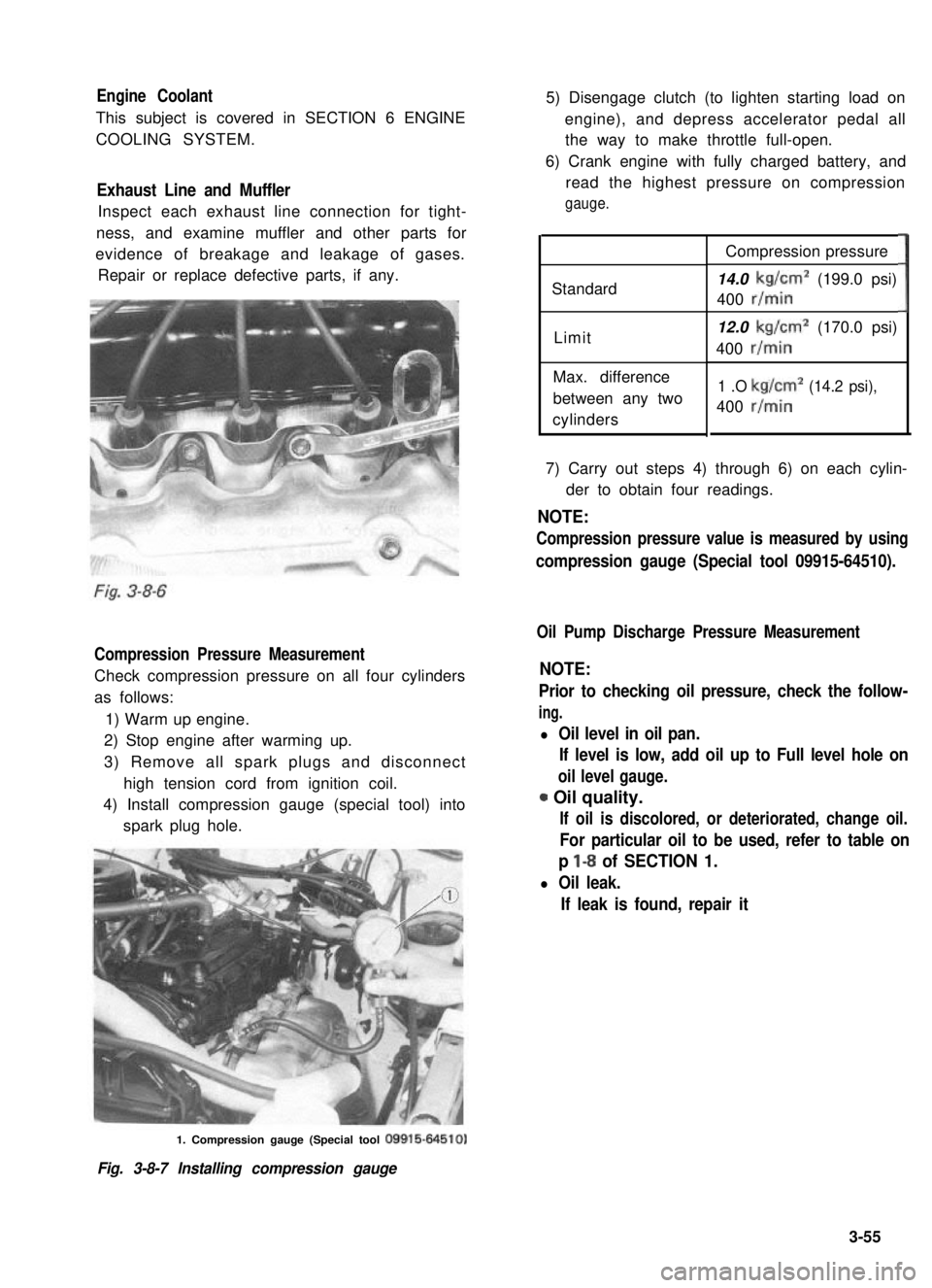

Compression Pressure Measurement

Check compression pressure on all four cylinders

as follows:

1) Warm up engine.

2) Stop engine after warming up.

3) Remove all spark plugs and disconnect

high tension cord from ignition coil.

4) Install compression gauge (special tool) into

spark plug hole.

5) Disengage clutch (to lighten starting load on

engine), and depress accelerator pedal all

the way to make throttle full-open.

6) Crank engine with fully charged battery, and

read the highest pressure on compression

gauge.

Standard

Limit

Max. difference

between any two

cylinders

Compression pressure

14.0 kg/cm2 (199.0 psi)

400 r/min

12.0 kg/cm2 (170.0 psi)

400 r/min

1 .O kg/cm2 (14.2 psi),

400 r/min

3

7) Carry out steps 4) through 6) on each cylin-

der to obtain four readings.

NOTE:

Compression pressure value is measured by using

compression gauge (Special tool 09915-64510).

Oil Pump Discharge Pressure Measurement

NOTE:

Prior to checking oil pressure, check the follow-

ing.

l Oil level in oil pan.

If level is low, add oil up to Full level hole on

oil level gauge.

0 Oil quality.

If oil is discolored, or deteriorated, change oil.

For particular oil to be used, refer to table on

p l-8 of SECTION 1.

l Oil leak.

If leak is found, repair it

1. Compression gauge (Special tool 09915-64510)

Fig. 3-8-7 Installing compression gauge

3-55

Page 135 of 962

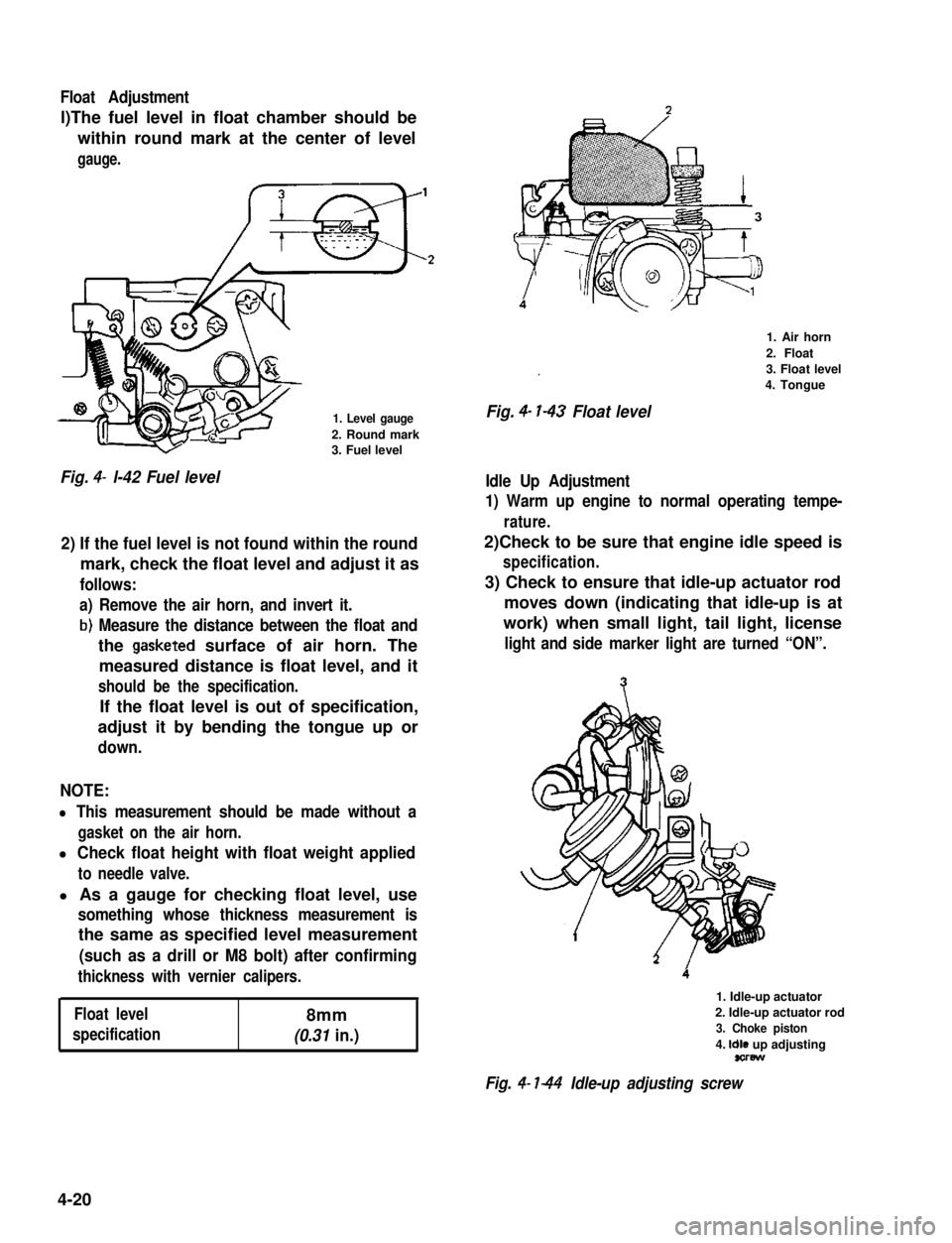

Float Adjustment

l)The fuel level in float chamber should be

within round mark at the center of level

gauge.

1. Level gauge

2. Round mark3. Fuel level

Fig. 4- l-42 Fuel level

2) If the fuel level is not found within the round

mark, check the float level and adjust it as

follows:

a) Remove the air horn, and invert it.

b) Measure the distance between the float and

the gasketed surface of air horn. The

measured distance is float level, and it

should be the specification.

If the float level is out of specification,

adjust it by bending the tongue up or

down.

NOTE:

l This measurement should be made without a

gasket on the air horn.

l Check float height with float weight applied

to needle valve.

l As a gauge for checking float level, use

something whose thickness measurement is

the same as specified level measurement

(such as a drill or M8 bolt) after confirming

thickness with vernier calipers.

Float level8mm

specification(0.31 in.)

.

Fig. 4- l-43 Float level

1. Air horn

2. Float

3. Float level

4. Tongue

Idle Up Adjustment

1) Warm up engine to normal operating tempe-

rature.

2)Check to be sure that engine idle speed is

specification.

3) Check to ensure that idle-up actuator rod

moves down (indicating that idle-up is at

work) when small light, tail light, license

light and side marker light are turned “ON”.

1. Idle-up actuator

2. Idle-up actuator rod

3. Choke piston

4. Idle up adjustingsorew

Fig. 4- l-44 Idle-up adjusting screw

4-20

Page 136 of 962

4) With lights (head light) turned “ON”, check

engine rpm (idle-up speed). Be sure that

heater fan, rear defogger (if equipped), and

air conditioner (if equipped) are all turned

“OFF”.

Idle-up speed900 - 1,000 r/min.

If idle-up speed is not within specification,

adjust by turning adjusting screw.

5) After idle-up adjustment, check to ensure that

idle-up adjusting screw moves as in step 3)

when only heater fan is operated and then

only rear defogger is operated (small light, tail

light, side marker light and license light should

be “OFF” in this cases).

If found faulty in step 3), check following parts

individually according to each procedure.

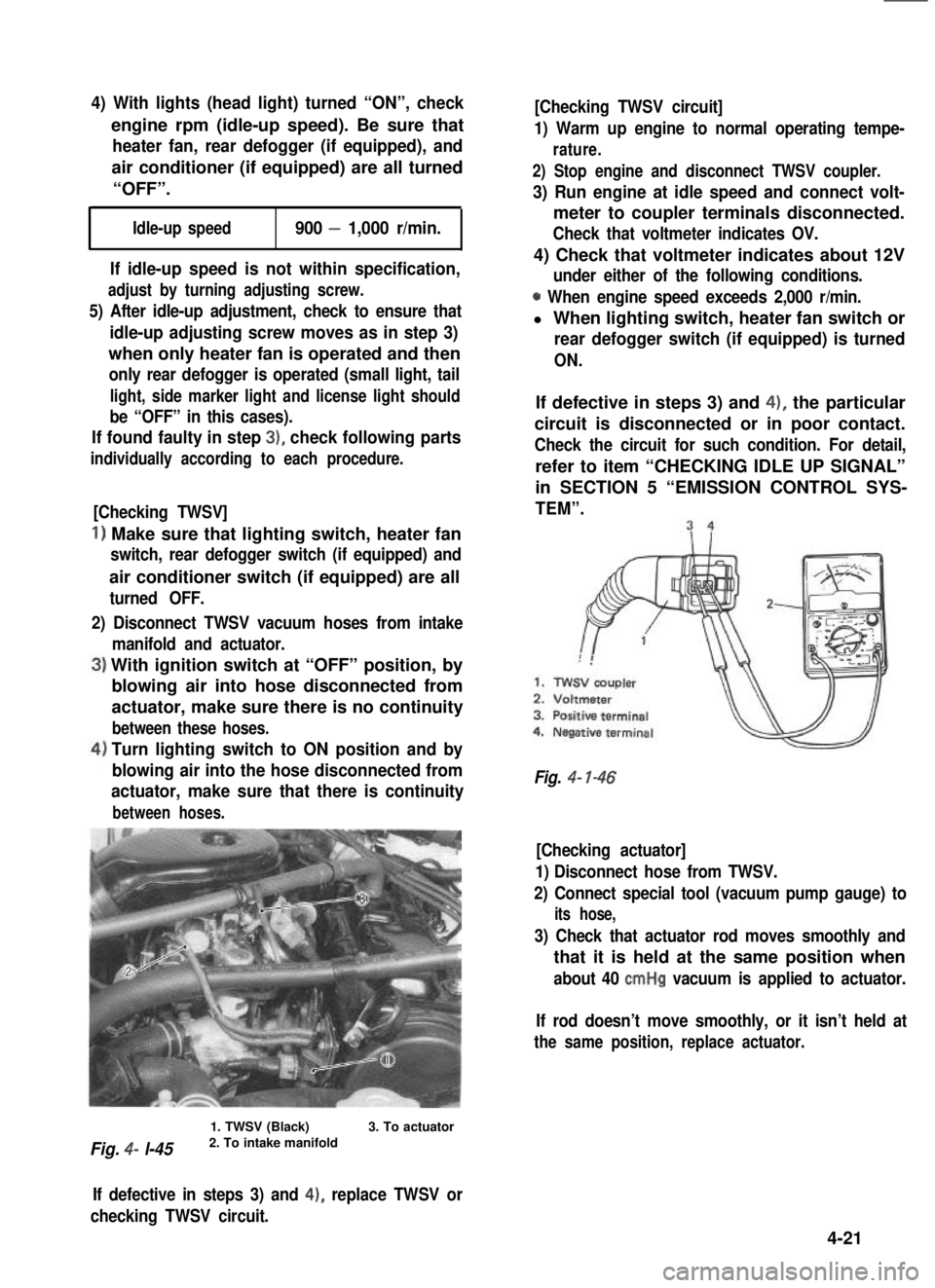

[Checking TWSV]

1) Make sure that lighting switch, heater fan

switch, rear defogger switch (if equipped) and

air conditioner switch (if equipped) are all

turned OFF.

2) Disconnect TWSV vacuum hoses from intake

manifold and actuator.

With ignition switch at “OFF” position, by

blowing air into hose disconnected from

actuator, make sure there is no continuity

between these hoses.

Turn lighting switch to ON position and by

blowing air into the hose disconnected from

actuator, make sure that there is continuity

between hoses.

Fig. 4- l-45

1. TWSV (Black)2. To intake manifold3. To actuator

[Checking TWSV circuit]

1) Warm up engine to normal operating tempe-

rature.

2) Stop engine and disconnect TWSV coupler.

3) Run engine at idle speed and connect volt-

meter to coupler terminals disconnected.

Check that voltmeter indicates OV.

4) Check that voltmeter indicates about 12V

under either of the following conditions.

0 When engine speed exceeds 2,000 r/min.

l When lighting switch, heater fan switch or

rear defogger switch (if equipped) is turned

ON.

If defective in steps 3) and 4), the particular

circuit is disconnected or in poor contact.

Check the circuit for such condition. For detail,

refer to item “CHECKING IDLE UP SIGNAL”

in SECTION 5 “EMISSION CONTROL SYS-

TEM”.

Fig. 4- l-46

[Checking actuator]

1) Disconnect hose from TWSV.

2) Connect special tool (vacuum pump gauge) to

its hose,

3) Check that actuator rod moves smoothly and

that it is held at the same position when

about 40 cmHg vacuum is applied to actuator.

If rod doesn’t move smoothly, or it isn’t held at

the same position, replace actuator.

If defective in steps 3) and 4), replace TWSV or

checking TWSV circuit.

4-21

Page 138 of 962

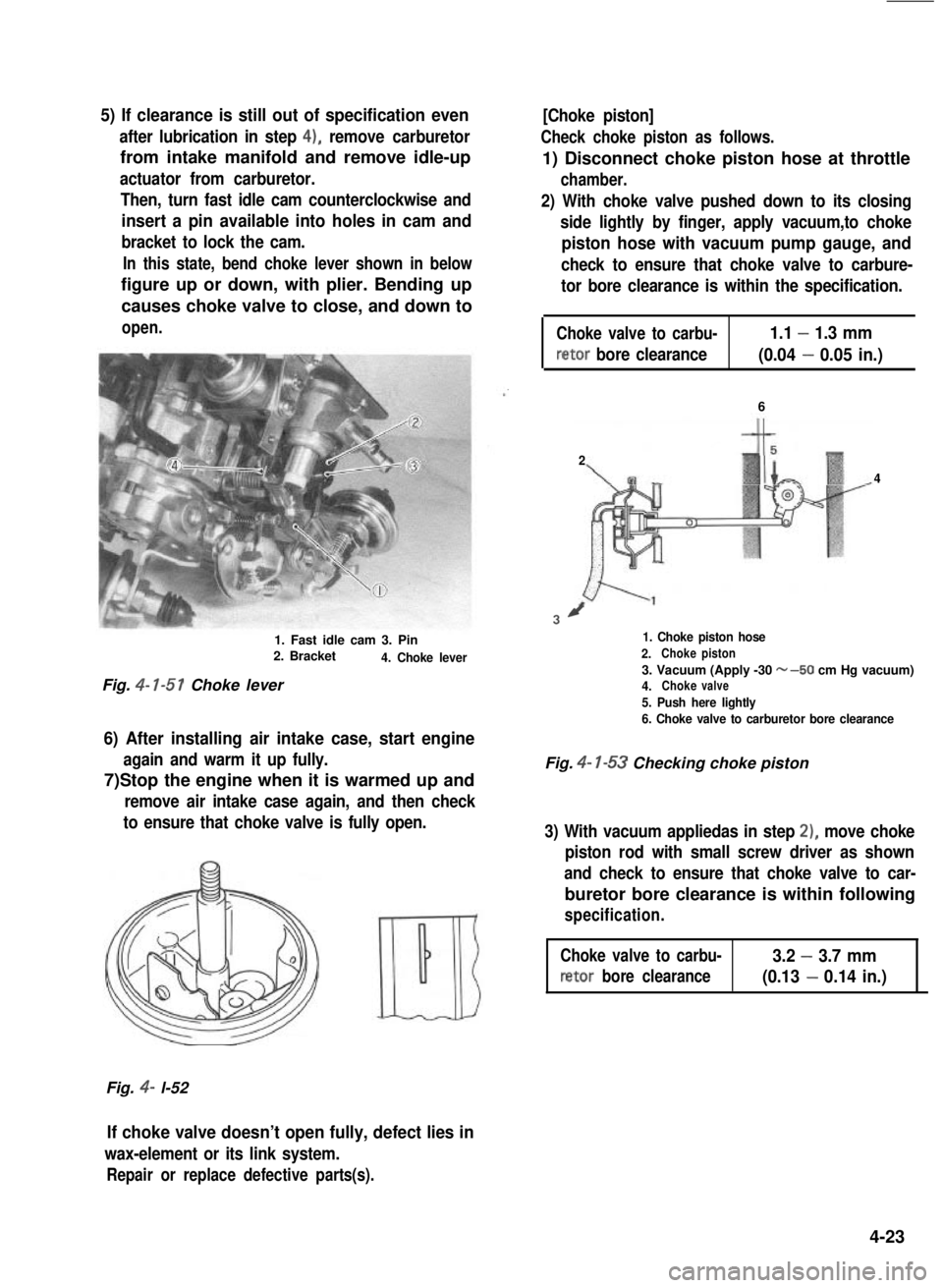

5) If clearance is still out of specification even

after lubrication in step 4), remove carburetor

from intake manifold and remove idle-up

actuator from carburetor.

Then, turn fast idle cam counterclockwise and

insert a pin available into holes in cam and

bracket to lock the cam.

In this state, bend choke lever shown in below

figure up or down, with plier. Bending up

causes choke valve to close, and down to

open.

1. Fast idle cam 3. Pin2. Bracket4. Choke lever

Fig. 4- l-51 Choke lever

6) After installing air intake case, start engine

again and warm it up fully.

7)Stop the engine when it is warmed up and

remove air intake case again, and then check

to ensure that choke valve is fully open.

Fig. 4- l-52

[Choke piston]

Check choke piston as follows.

1) Disconnect choke piston hose at throttle

chamber.

2) With choke valve pushed down to its closing

side lightly by finger, apply vacuum,to choke

piston hose with vacuum pump gauge, and

check to ensure that choke valve to carbure-

tor bore clearance is within the specification.

Choke valve to carbu-1.1 - 1.3 mm

retor bore clearance(0.04 - 0.05 in.)

6

2

4

3/

1. Choke piston hose

2.Chokepiston

3. Vacuum (Apply -30 w-50 cm Hg vacuum)4.Chokevalve

5. Push here lightly

6. Choke valve to carburetor bore clearance

Fig. 4- l-53 Checking choke piston

3) With vacuum appliedas in step 2), move choke

piston rod with small screw driver as shown

and check to ensure that choke valve to car-

buretor bore clearance is within following

specification.

Choke valve to carbu-3.2 - 3.7 mm

retor bore clearance(0.13 - 0.14 in.)

If choke valve doesn’t open fully, defect lies in

wax-element or its link system.

Repair or replace defective parts(s).

4-23

Page 141 of 962

With vacuum pump gauge set at Black side of

VTV, when pump is operated, pointer moves

considerably but moves back to zero position as

soon as pump operation is stopped.

Brown side

(Actuator side) Black side

Fig. 4-l-60

1. VTV

2. Vacuum pump gauge

install VTV. Refer to Fig. 4-l -2 for installation.

[ VSV (Vacuum Switching Valve)]

1) Disconnect VSV vacuum hoses from 3 way

joint and secondary actuator and while

blowing either hose, check that air doesn’t

come out of the other hose.

2) Turn on ignition switch and depress accelera-

tor pedal fully. 5 or 6 seconds later, while

blowing either vacuum hose, check that air

comes out of the other hose.

J5

Fig. 4- l-61

1I

1. vsv4. WOTS

2. Ignition switch5. ECM

3. Battery6. Blow air

If check results in steps 1) and 2)are not satisfac-

tory, either replace VSV or check WOTS and its

circuit referring to SECTION5 “EMISSION

CONTROL SYSTEM”.

Idle Speed Adjustment

NOTE:

Before starting engine, place transmission gear

shift lever in “Neutral”, and set parking brake

and block drive wheels.

Before idle speed check and adjustment, make

sure of the following.

l Lead wires and hoses of engine emission

control systems are connected securely.

l Accelerator cable has some play, that is, it is

not tight.

l All vacuum hoses are connected securely.

l Fuel level should be within round mark at the

center of level gauge.

l Valve lash is checked and adjusted according

to the maintenance schedule.

l Air cleaner has been properly installed and is

in good condition.

l All accessories (wipers, heater, lights, etc) are

out of service.

l Ignition timing is within specification.

l Idle up actuator is not operating when engine

is running at idle speed.

NOTE:

In areas above 4,00Ofeet( 1,220m) elevation

(high altitude), idle up system will be normally

in operation. Do not attempt to adjust the idle

speed.

After above items are all confirmed, adjust idle

speed as follows.

1) Warm up engine to normal operating tempe-

rature.

2) Check to ensure that idle speed is within

750 - 850 r/min (rpm).

3) If idle speed is not within specified range,

adjust by turning idle speed adjusting screw.

If idle speed can not be adjusted to the speci-

fication by turning the adjusting screw, it can

be due to faulty return of throttle valve or

some other reason. Determine cause and

repair, and then adjust idle speed to specifica-

tion.

4-26

Page 142 of 962

1. Idle speed adjusting screw

Fig. 4- l-62 Idle speed adjusting screw

4) After idle speed adjustment, check idle-up for

operation with lights (small light, tail light,

side marker light and license light), heater fan

and rear defogger (if equipped) turned “ON”,

only one at a time. Refer to item “Idle Up

Adjustment”. (p. 4-20).

5) Stop engine and check to ensure that accelera-

tor cable play is within the specification as

previously outlined. If play is out of specifica-

tion, adjust it.

Idle Mixture Inspection and Adjustment

[Inspection]

1) Warm up engine to normal operating tem-

perature.

2) Remove seal rubber of duty check coupler

and connect positive terminal of duty meter

to “Blue/Red” wire and negative terminal to

“Black/Green” wire.

1

1. Duty check

3) Set tachometer.

4) Run engine at 1,500 - 2,000 r/min for 30

seconds and bring it to idle speed.

5) Check duty at specified idle speed. If it is out

of specification, adjust it to specification ac-

cording to following adjustment procedure.

Specified DutyIO-50

at 750 - 850 r/min.

After inspection, install seal rubber to duty

check coupler.

[Idle Mixture Adjustment]

The carburetor has been calibrated at the facto-

ry and. should not normally need adjustment in

the field. For this reason, the mixture adjust-

ment should never be changed from the original

factory setting. However, if during diagnosis, the

check indicates the carburetor to be the cause of

a driver performance complaint or emission

failure, or the carburetor is overhauled or

replaced, the idle mixture can be adjusted using

the following procedure.

After adjustment, mixture adjusting screw pin

must be installed.

Idle mixture adjustment procedure is as follows:

1) Remove carburetor from intake manifold

following normal service procedure to gain

access to mixture adjusting screw pin covering

mixture adjusting screw.

2) Drive out mixture adjusting screw pin using

about 4.5 mm (0.18 in) thick iron rod as

shown below.

1. Mixture adjusting screw pin2. Rod

Fig. 4- l-64 Mixture adjusting screw pin

2. Air intake case

Fig. 4- l-63

4-27