clock SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 22 of 962

5) Remove timing belt outside cover. Inspect

the belt for damage or wear. When any

damage or wear is found on the belt, replace

it.

If belt replacement is necessary, be sure to

install the belt properly.

6) Remove cylinder head cover and loosen all

valve adjusting screws all the way to permit

free rotation of camshaft.

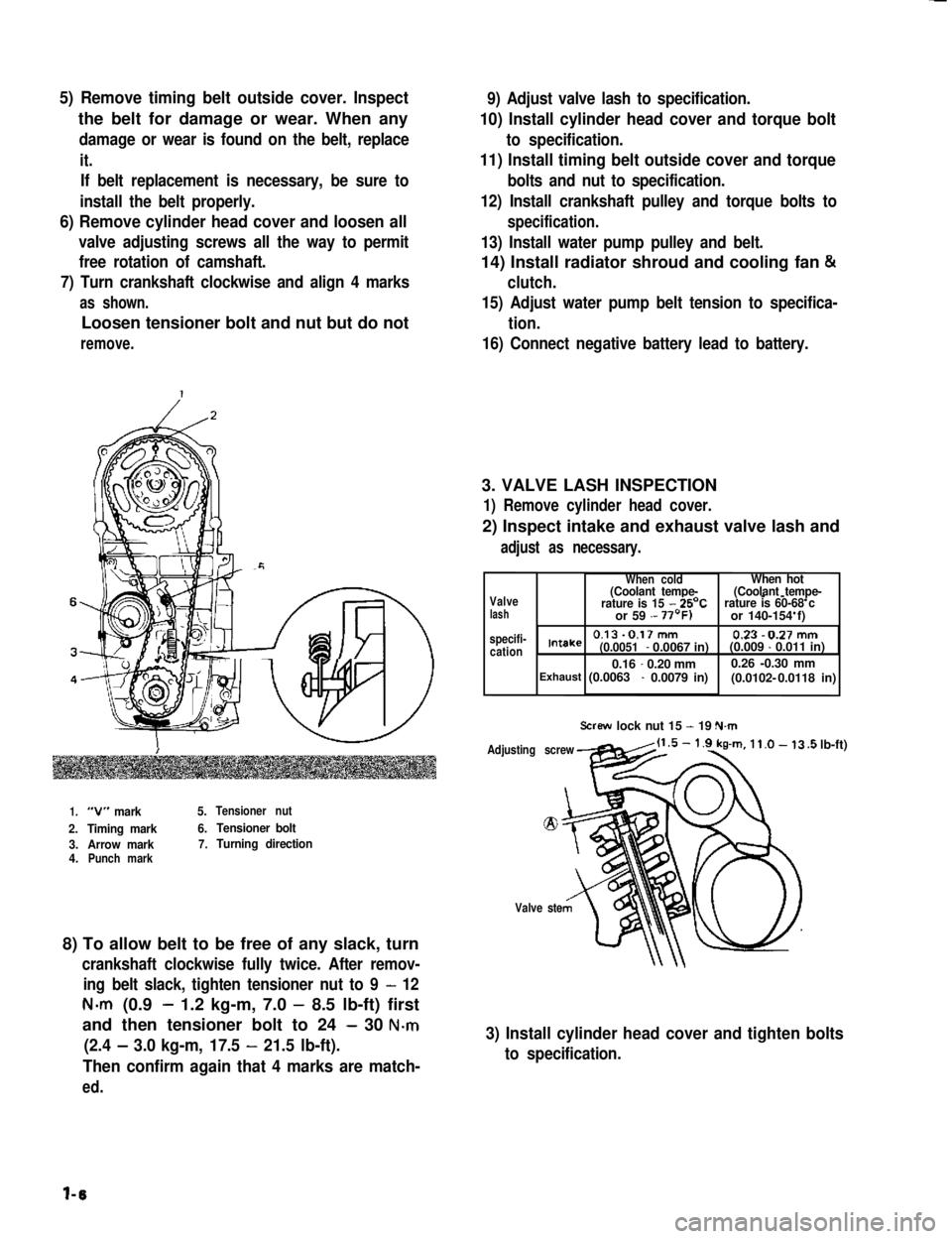

7) Turn crankshaft clockwise and align 4 marks

as shown.

Loosen tensioner bolt and nut but do not

remove.

9) Adjust valve lash to specification.

10) Install cylinder head cover and torque bolt

to specification.

11) Install timing belt outside cover and torque

bolts and nut to specification.

12) Install crankshaft pulley and torque bolts to

specification.

13) Install water pump pulley and belt.

14) Install radiator shroud and cooling fan &

clutch.

15) Adjust water pump belt tension to specifica-

tion.

16) Connect negative battery lead to battery.

3. VALVE LASH INSPECTION

1) Remove cylinder head cover.

2) Inspect intake and exhaust valve lash and

adjust as necessary.

1.“V” mark5.Tensioner nut

2.Timing mark6.Tensioner bolt

3.Arrow mark7.Turning direction4.Punch mark

8) To allow belt to be free of any slack, turn

crankshaft clockwise fully twice. After remov-

ing belt slack, tighten tensioner nut to 9 - 12

N-m (0.9- 1.2 kg-m, 7.0 - 8.5 lb-ft) first

and then tensioner bolt to 24 - 30 N-m

(2.4 - 3.0 kg-m, 17.5 - 21.5 lb-ft).

Then confirm again that 4 marks are match-

ed.

Valvelash specifi-cation

When coldWhen hot(Coolant tempe-(Coolant tempe---rature is 15 - 25’Crature is 60-68 c or 59 - or 140-154 f)

0.13-0.17mm 0.23-0.27mmIntake(0.0051- 0.0067 in)(0.009 - 0.011 in)

0.16-0.20 mm0.26 -0.30 mm(0.0102- Exhaust (0.0063 - 0.0079 in) 0.0118 in)

Screw lock nut 15 - 19 N.m

Adjusting screw

Valve ste

.5 lb-ft)

3) Install cylinder head cover and tighten bolts

to specification.

l-6

Page 106 of 962

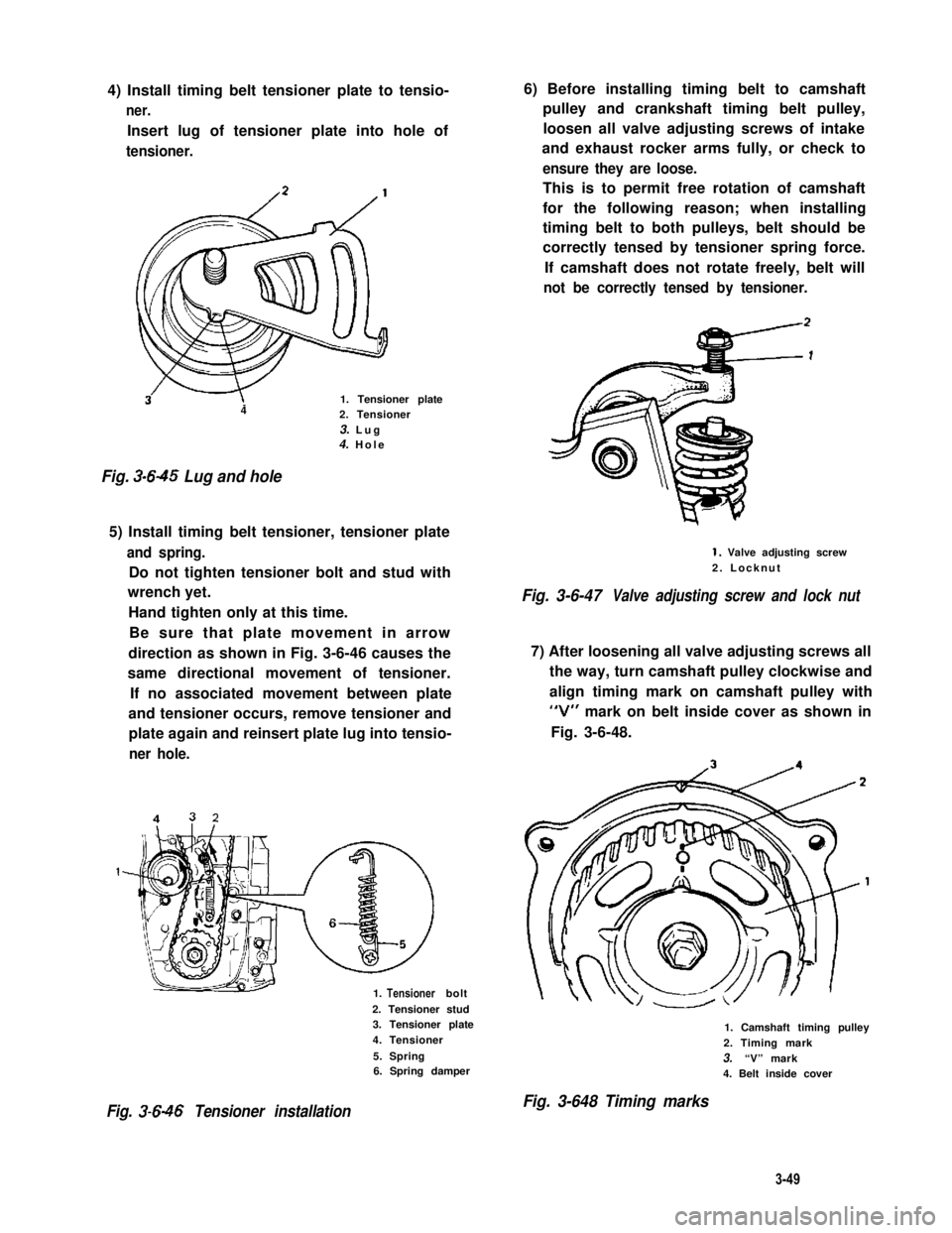

4) Install timing belt tensioner plate to tensio-

ner.

Insert lug of tensioner plate into hole of

tensioner.

3w1. Tensioner plate42. Tensioner

3. Lug4. Hole

Fig. 3-645 Lug and hole

5) Install timing belt tensioner, tensioner plate

and spring.

Do not tighten tensioner bolt and stud with

wrench yet.

Hand tighten only at this time.

Be sure that plate movement in arrow

direction as shown in Fig. 3-6-46 causes the

same directional movement of tensioner.

If no associated movement between plate

and tensioner occurs, remove tensioner and

plate again and reinsert plate lug into tensio-

ner hole.

1. bolt

2. Tensioner stud3. Tensioner plate

4. Tensioner

5. Spring6. Spring damper

Fig. 3-646 Tensioner installation

6) Before installing timing belt to camshaft

pulley and crankshaft timing belt pulley,

loosen all valve adjusting screws of intake

and exhaust rocker arms fully, or check to

ensure they are loose.

This is to permit free rotation of camshaft

for the following reason; when installing

timing belt to both pulleys, belt should be

correctly tensed by tensioner spring force.

If camshaft does not rotate freely, belt will

not be correctly tensed by tensioner.

1. Valve adjusting screw

2. Locknut

Fig. 3-6-47Valve adjusting screw and lock nut

7) After loosening all valve adjusting screws all

the way, turn camshaft pulley clockwise and

align timing mark on camshaft pulley with

“V” mark on belt inside cover as shown in

Fig. 3-6-48.

1. Camshaft timing pulley

2. Timing mark

3.“V” mark4. Belt inside cover

Fig. 3-648 Timing marks

3-49

Tensioner

Page 107 of 962

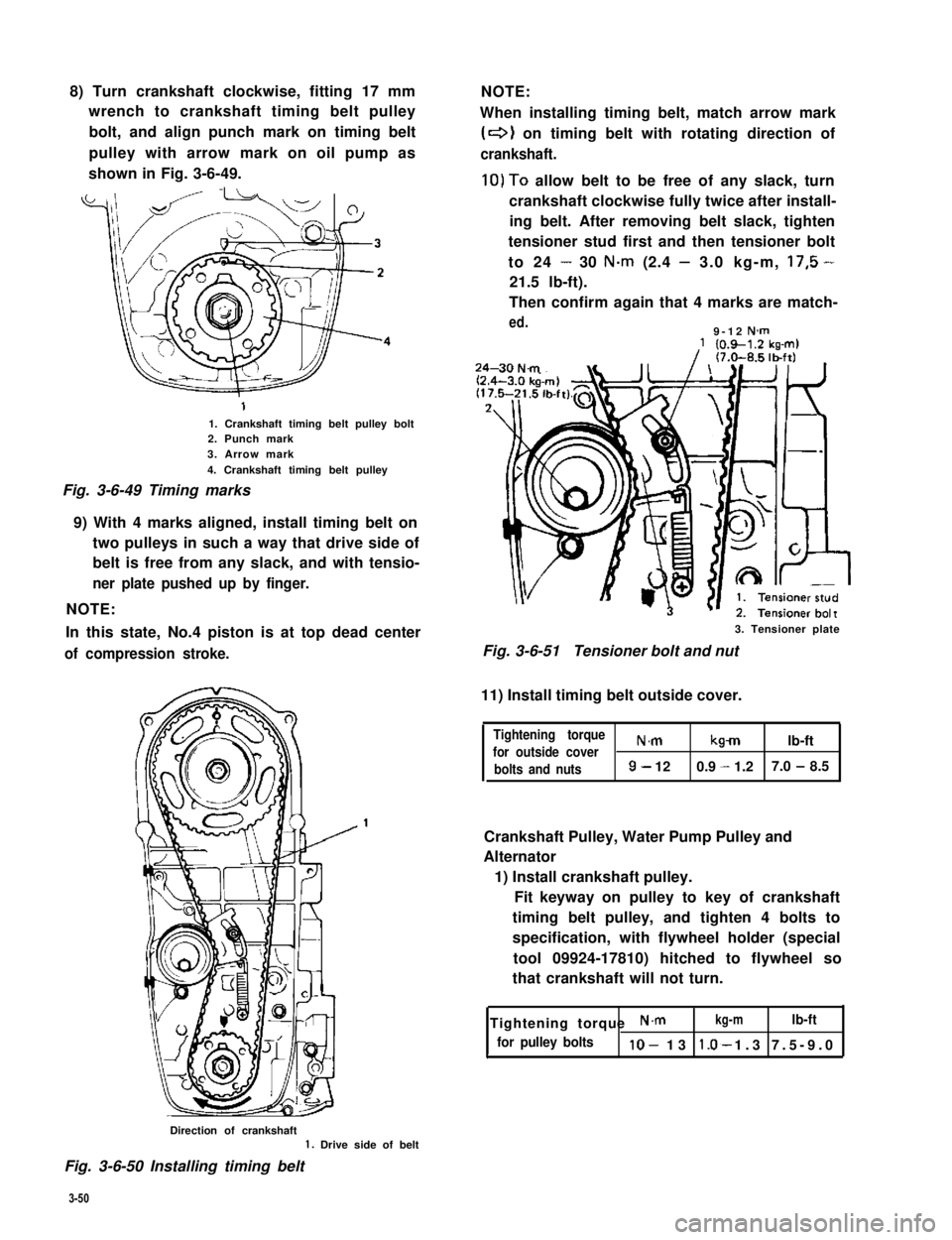

8) Turn crankshaft clockwise, fitting 17 mm

wrench to crankshaft timing belt pulley

bolt, and align punch mark on timing belt

pulley with arrow mark on oil pump as

shown in Fig. 3-6-49.

1. Crankshaft timing belt pulley bolt2. Punch mark3. Arrow mark

4. Crankshaft timing belt pulley

Fig. 3-6-49 Timing marks

9) With 4 marks aligned, install timing belt on

two pulleys in such a way that drive side of

belt is free from any slack, and with tensio-

ner plate pushed up by finger.

NOTE:

In this state, No.4 piston is at top dead center

of compression stroke.

NOTE:

When installing timing belt, match arrow mark

(+I on timing belt with rotating direction of

crankshaft.

10)To allow belt to be free of any slack, turn

crankshaft clockwise fully twice after install-

ing belt. After removing belt slack, tighten

tensioner stud first and then tensioner bolt

to 24 - 30 N.m (2.4 - 3.0 kg-m, 17,5 -

21.5 lb-ft).

Then confirm again that 4 marks are match-

ed.9-12 N-m

3. Tensioner plate

Fig. 3-6-51Tensioner bolt and nut

11) Install timing belt outside cover.

Tightening torque

for outside coverN.mkmlb-ft

bolts and nuts9- 120.9 - 1.27.0 - 8.5

Crankshaft Pulley, Water Pump Pulley and

Alternator

1) Install crankshaft pulley.

Fit keyway on pulley to key of crankshaft

timing belt pulley, and tighten 4 bolts to

specification, with flywheel holder (special

tool 09924-17810) hitched to flywheel so

that crankshaft will not turn.

Tightening torque N.mkg-mlb-ft

for pulley boltslo- 13 1.3 7.5-9.0*

Direction of crankshaft1. Drive side of belt

Fig. 3-6-50 Installing timing belt

3-50

Page 111 of 962

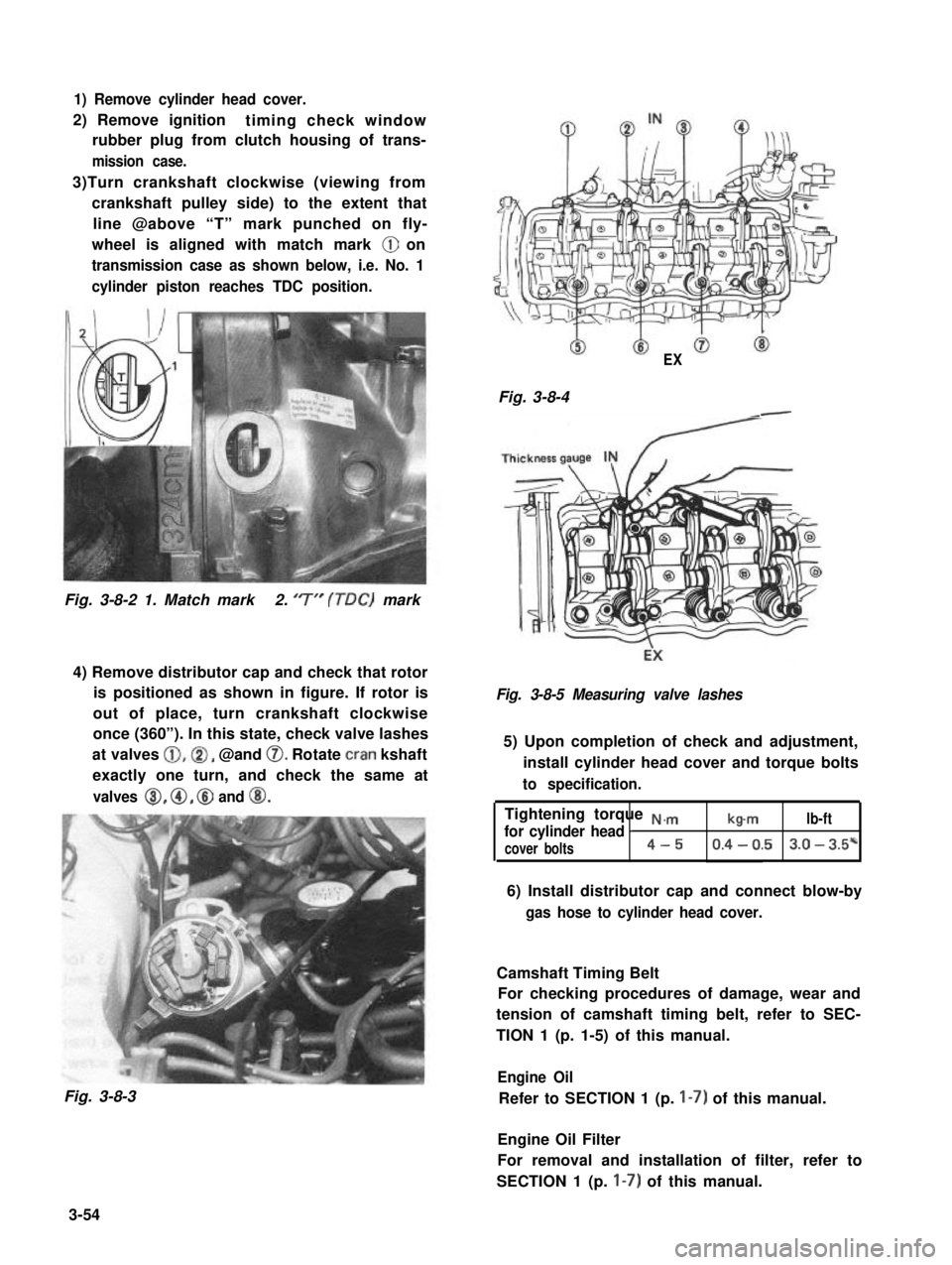

1) Remove cylinder head cover.

2) Remove ignitiontiming check window

rubber plug from clutch housing of trans-

mission case.

3)Turn crankshaft clockwise (viewing from

crankshaft pulley side) to the extent that

line @above “T” mark punched on fly-

wheel is aligned with match mark @ on

transmission case as shown below, i.e. No. 1

cylinder piston reaches TDC position.

Fig. 3-8-2 1. Match mark2. ‘7” (TDC) mark

4) Remove distributor cap and check that rotor

is positioned as shown in figure. If rotor is

out of place, turn crankshaft clockwise

once (360”). In this state, check valve lashes

at valves @,@I, @and 0. Rotate cran kshaft

exactly one turn, and check the same at

valves 8, @, @ and @I.

Fig. 3-8-3

EX

Fig. 3-8-4-

Fig. 3-8-5 Measuring valve lashes

5) Upon completion of check and adjustment,

install cylinder head cover and torque bolts

to specification.

Tightening torque N.,.,.,

for cylinder head Ib-mlb-ft

cover bolts4-50.4 - 0.53.0 - 3.5*

6) Install distributor cap and connect blow-by

gas hose to cylinder head cover.

Camshaft Timing Belt

For checking procedures of damage, wear and

tension of camshaft timing belt, refer to SEC-

TION 1 (p. 1-5) of this manual.

Engine Oil

Refer to SECTION 1 (p. I-7) of this manual.

Engine Oil Filter

For removal and installation of filter, refer to

SECTION 1 (p. I-7) of this manual.

3-54

Page 125 of 962

Choke System1) When coolant temperature is low:

This choke system is provided with a thermo-

wax which operates according to the heat from

the engine coolant, causing the choke valve to

open and close as well as the fast idle system to

operate automatically.

As the thermo-wax is contracted and the

plunger is retracted, the choke valve linked

with the fast idle cam is closed. When the

engine is started in this state, the intake

manifold vacuum pulls the diaphragm of the

choke piston to the left (below figure). The

choke piston rod also moves to the left and

acts on the choke valve to open. However,

the choke valve is restricted by the plunger of

the thermo-wax through the choke lever.

Therefore, the rod cannot move to the left

far enough to open the choke valve wide and

has .to stop at a position where the choke

valve opening is small as shown in the figure.

In this state, the diaphragm contracts the

bucking spring.

8

6

1.Choke piston2.Vacuum3.Therms wax

4.Plunger5. Fast idle cam

6.Cam follower7.Throttle valve8.Choke valve

Fig. 4- I- 11Choke system

[Operation of choke system]

As the thermo-wax is contracted at the low

coolant temperature, the plunger of the thermo-

wax is retracted (at the up position) and the fast

idle cam rotates clockwise by the spring force.

As a result, the cam follower pushed down by

the cam causes the primary throttle valve to

open and brings about the fast idle state.

The thermo-wax expands as the coolant tempe-

rature rises and the plunger position lowers,

causing the fast idle cam to rotate counterclock-

wise. As a result, the throttle valve starts moving

to close. In this way, the throttle valve closes

gradually as the coolant temperature rises until

it reaches the idling position at the normal

temperature. Refer to Fig. 4-l -11.

1.Choke piston

2.Intake manifoldvacuum

3.Diaphragm

4. Choke piston rod

5.Choke valve

6.Choke lever

7.Bucking spring

Fig. 4- I- 12 When coolant temp. is low

2) When the coolant temperature rises:

The plunger lowers due to the expansion of

the thermo-wax. Then the fast idle cam rotates

counterclockwise and consequently the choke

lever clockwise. This allow the rod to move

further to the left by the bucking spring force

(below figure). Thus a wide opening of the

choke valve is obtained.

Hereafter, the plunger of the thermo-wax

moves futher down in accordance with the

coolant temperature rise. The lower the

plunger moves, the wider the choke valve

opening becomes, and it becomes fully open

at the normal coolant temperature.

4-10

Page 128 of 962

0 Connect electric couplers securely.

l Connect accelerator cable to carburetor. With

the accelerator pedal released, adjust the cable

play to specification. This adjustment can be

made by turning the adjusting nut. After

adjustment, tighten the lock nut. Refer to

p. 4-19.

l Connect vacuum hoses securely.

l Refill cooling system.

l Connect negative cable at battery.

NOTE:

Upon completion of installation, be sure to

check each part for evidence of fuel leakage and

for proper operation. If defective, correct..

UNIT REPAIR OVERHAUL

This section outlines procedure to be used for

overhauling carburetor as removed from engine.

For removal and installation of carburetor from

and to engine, refer to the previous page.

NOTE:

l Be sure to replace gaskets as well as worn or

damaged parts.

l While disassembling and assembling carbure-

tor, use special care not to deform levers on

throttle valve shaft or cause damage to any

other parts.

l Don’t disassemble mixture control solenoid

valve and accelerator pump piston.

l Don’t remove idle and wide open micro

switches from the bracket where they are

installed.

Disassembly

1) Turn fast idle cam counterclockwise and

insert a pin avialable into holes on cam and

bracket to lock the cam.

Fig. 4- I- 19

1. Fast idle cam

2. Bracket3. Pin

4-13

Page 138 of 962

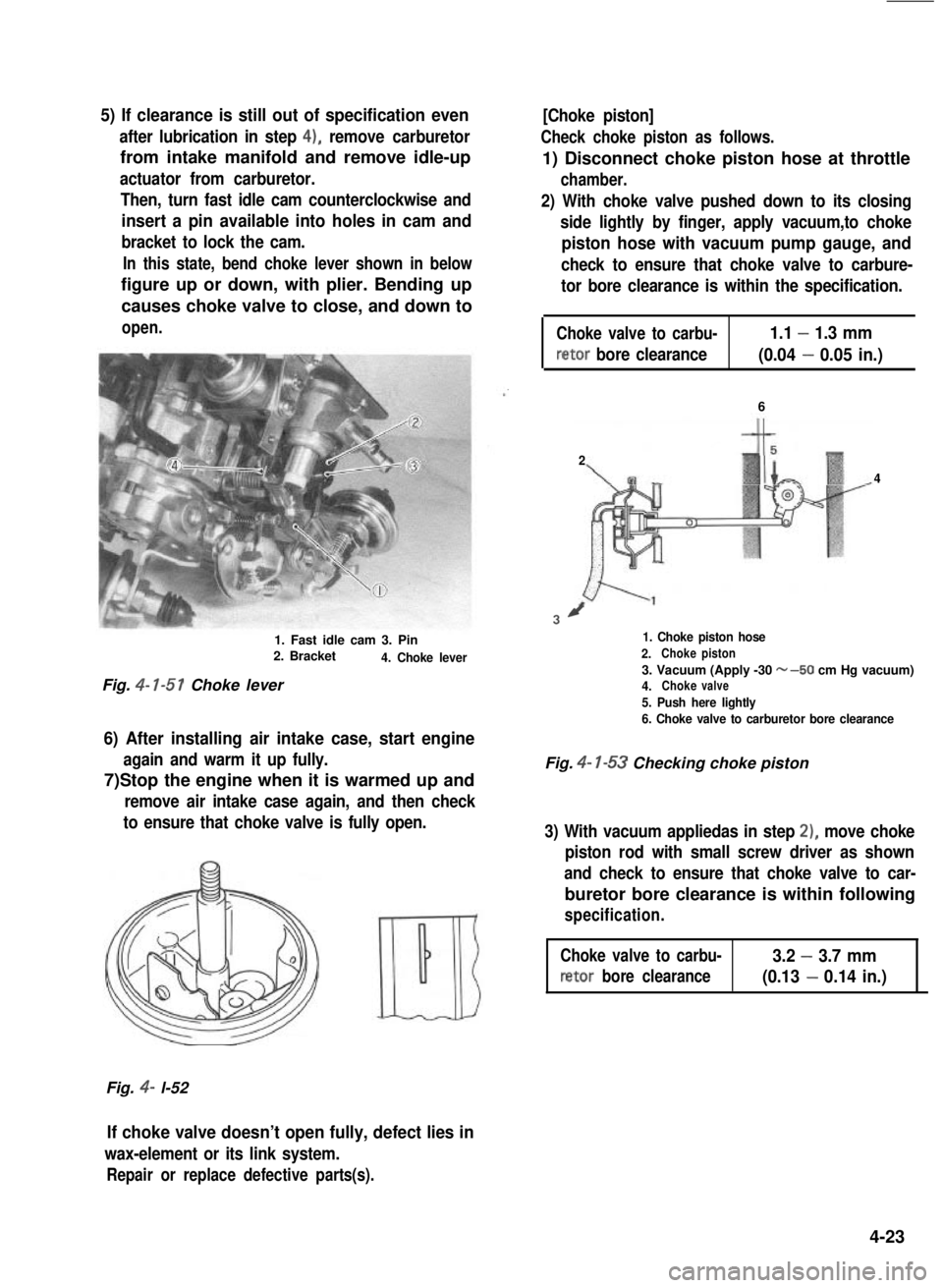

5) If clearance is still out of specification even

after lubrication in step 4), remove carburetor

from intake manifold and remove idle-up

actuator from carburetor.

Then, turn fast idle cam counterclockwise and

insert a pin available into holes in cam and

bracket to lock the cam.

In this state, bend choke lever shown in below

figure up or down, with plier. Bending up

causes choke valve to close, and down to

open.

1. Fast idle cam 3. Pin2. Bracket4. Choke lever

Fig. 4- l-51 Choke lever

6) After installing air intake case, start engine

again and warm it up fully.

7)Stop the engine when it is warmed up and

remove air intake case again, and then check

to ensure that choke valve is fully open.

Fig. 4- l-52

[Choke piston]

Check choke piston as follows.

1) Disconnect choke piston hose at throttle

chamber.

2) With choke valve pushed down to its closing

side lightly by finger, apply vacuum,to choke

piston hose with vacuum pump gauge, and

check to ensure that choke valve to carbure-

tor bore clearance is within the specification.

Choke valve to carbu-1.1 - 1.3 mm

retor bore clearance(0.04 - 0.05 in.)

6

2

4

3/

1. Choke piston hose

2.Chokepiston

3. Vacuum (Apply -30 w-50 cm Hg vacuum)4.Chokevalve

5. Push here lightly

6. Choke valve to carburetor bore clearance

Fig. 4- l-53 Checking choke piston

3) With vacuum appliedas in step 2), move choke

piston rod with small screw driver as shown

and check to ensure that choke valve to car-

buretor bore clearance is within following

specification.

Choke valve to carbu-3.2 - 3.7 mm

retor bore clearance(0.13 - 0.14 in.)

If choke valve doesn’t open fully, defect lies in

wax-element or its link system.

Repair or replace defective parts(s).

4-23

Page 175 of 962

THROTTLE VALVEINDICATOR

POSITIONMOVEMENT

Idle positionSwing

l/2 openStay after deflection

Full openSwing

NOTE:

If indicator doesn’t deflect at all, reverse above

connection, that is, negative prod to body and

positive one to check terminal, and carry out the

same check.

Fig. 53- 18

1. Check terminal

If check results are not satisfactory, check idle

and wide open micro switches as follows or their

circuits for continuity referring to item “check-

ing sensors and their lead wires ” (p. 5-32).

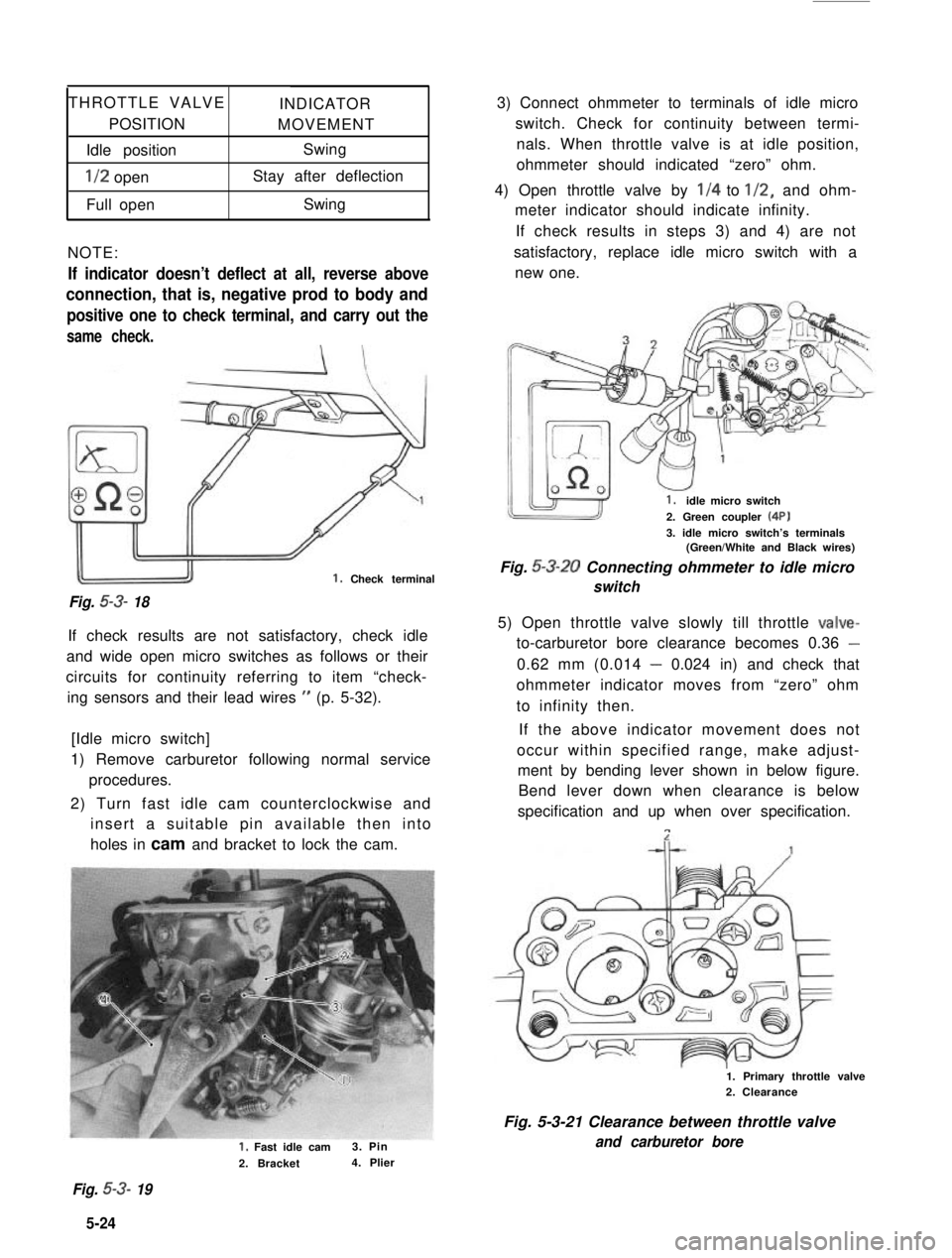

[Idle micro switch]

1) Remove carburetor following normal service

procedures.

2) Turn fast idle cam counterclockwise and

insert a suitable pin available then into

holes in cam and bracket to lock the cam.

1, Fast idle cam3. Pin

2. Bracket4. Plier

3) Connect ohmmeter to terminals of idle micro

switch. Check for continuity between termi-

nals. When throttle valve is at idle position,

ohmmeter should indicated “zero” ohm.

4) Open throttle valve by l/4 to l/2, and ohm-

meter indicator should indicate infinity.

If check results in steps 3) and 4) are not

satisfactory, replace idle micro switch with a

new one.

1.idle micro switch

2. Green coupler (4P)

3. idle micro switch’s terminals(Green/White and Black wires)

Fig. 5-3-20 Connecting ohmmeter to idle micro

switch

5) Open throttle valve slowly till throttle valve-

to-carburetor bore clearance becomes 0.36 -

0.62 mm (0.014 - 0.024 in) and check that

ohmmeter indicator moves from “zero” ohm

to infinity then.

If the above indicator movement does not

occur within specified range, make adjust-

ment by bending lever shown in below figure.

Bend lever down when clearance is below

specification and up when over specification.

n

1. Primary throttle valve2. Clearance

Fig. 5-3-21 Clearance between throttle valve

and carburetor bore

Fig. 5-3- 19

5-24 4

Page 213 of 962

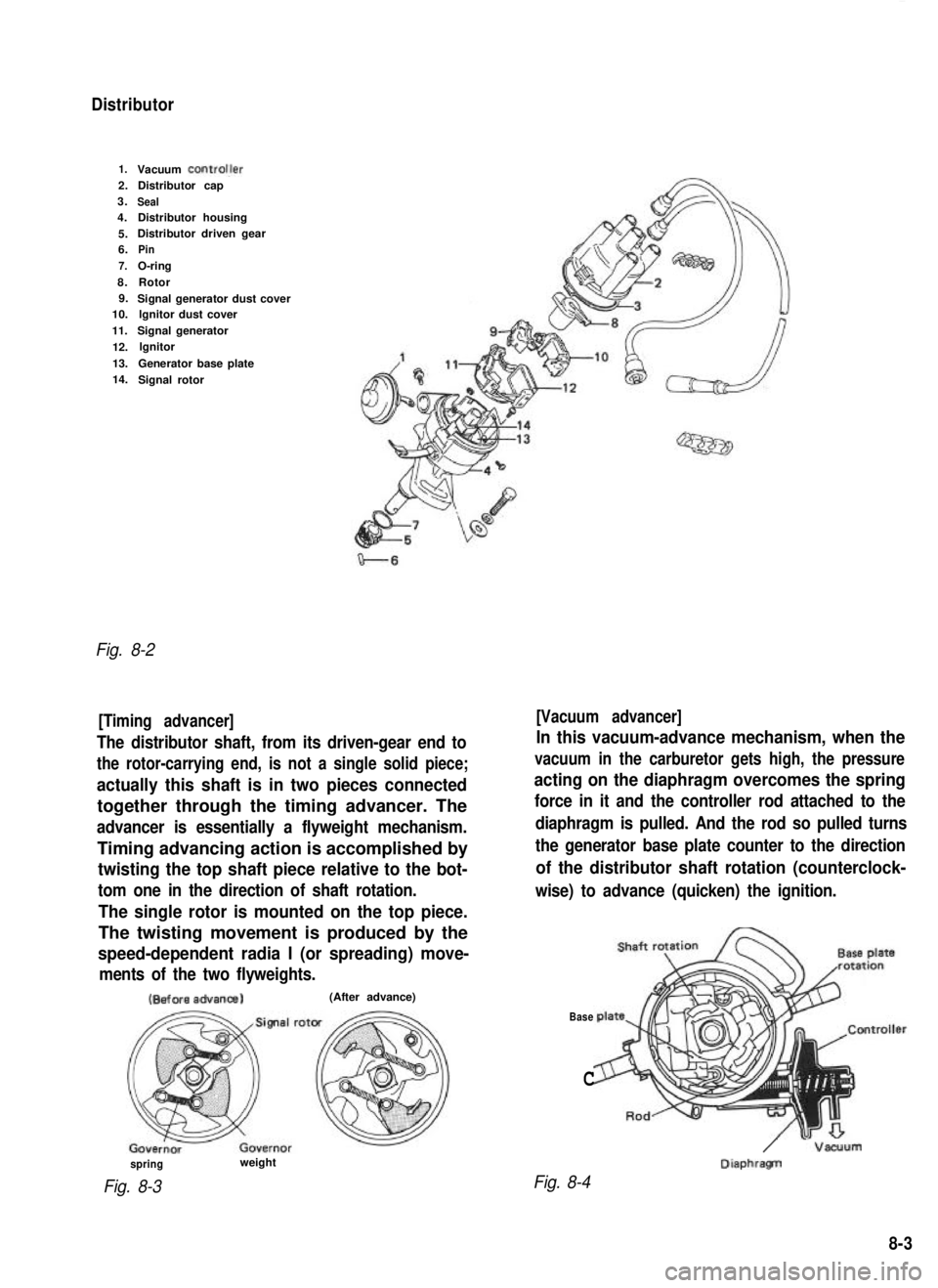

Distributor

1.Vacuum ControlJer2.Distributor cap

3.

Seal4. Distributor housing

5. Distributor driven gear

6.

Pin

7.

O-ring

8. Rotor

9. Signal generator dust cover

10. lgnitor dust cover

11. Signal generator

12. lgnitor

13. Generator base plate

14. Signal rotor

Fig. 8-2

[Timing advancer] [Vacuum advancer]

The distributor shaft, from its driven-gear end to

the rotor-carrying end, is not a single solid piece;

actually this shaft is in two pieces connected

together through the timing advancer. The

advancer is essentially a flyweight mechanism.

Timing advancing action is accomplished by

twisting the top shaft piece relative to the bot-

tom one in the direction of shaft rotation.

The single rotor is mounted on the top piece.

The twisting movement is produced by the

speed-dependent radia I (or spreading) move-

ments of the two flyweights.

In this vacuum-advance mechanism, when the

vacuum in the carburetor gets high, the pressure

acting on the diaphragm overcomes the spring

force in it and the controller rod attached to the

diaphragm is pulled. And the rod so pulled turns

the generator base plate counter to the direction

of the distributor shaft rotation (counterclock-

wise) to advance (quicken) the ignition. (Before

advanca)

(After advance)

Base

C

/ -Vacuum DiaphragTI

spring

Fig. 8-3

weight

Fig. 8-4

8-3

Page 219 of 962

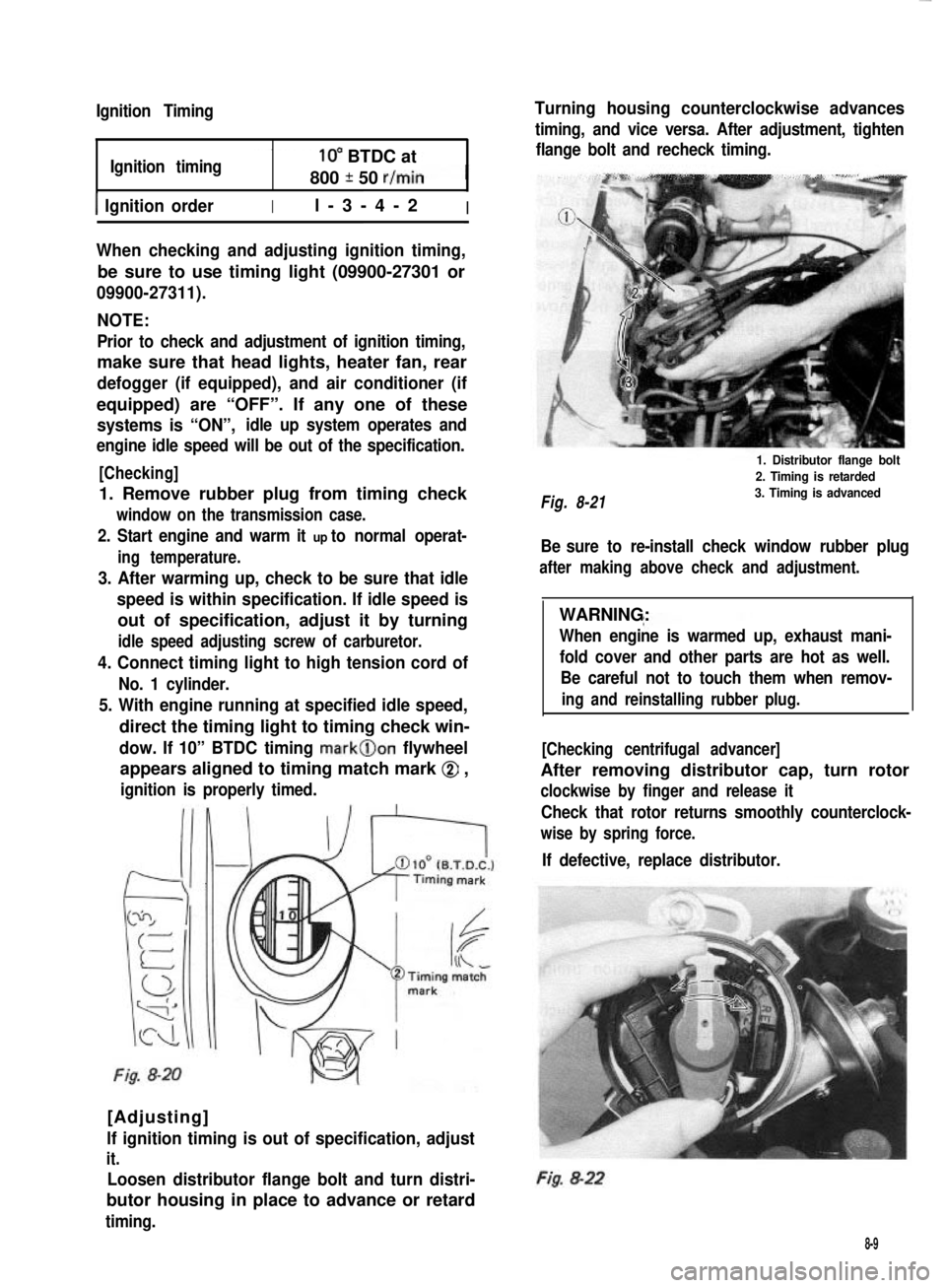

Ignition Timing

Ignition timing10” BTDC at

800 * 50 r/min

1 Ignition orderIl-3-4-2I

When checking and adjusting ignition timing,

be sure to use timing light (09900-27301 or

09900-27311).

NOTE:

Prior to check and adjustment of ignition timing,

make sure that head lights, heater fan, rear

defogger (if equipped), and air conditioner (if

equipped) are “OFF”. If any one of these

systems is “ON”,idle up system operates and

engine idle speed will be out of the specification.

[Checking]

1. Remove rubber plug from timing check

window on the transmission case.

2. Start engine and warm it up to normal operat-

ing temperature.

3. After warming up, check to be sure that idle

speed is within specification. If idle speed is

out of specification, adjust it by turning

idle speed adjusting screw of carburetor.

4. Connect timing light to high tension cord of

No. 1 cylinder.

5. With engine running at specified idle speed,

direct the timing light to timing check win-

dow. If 10” BTDC timing mark@on flywheel

appears aligned to timing match mark @ ,

ignition is properly timed.

Fig. 8-20

[Adjusting]

lf ignition timing is out of specification, adjust

it.

Loosen distributor flange bolt and turn distri-

butor housing in place to advance or retard

timing.

Turning housing counterclockwise advances

timing, and vice versa. After adjustment, tighten

flange bolt and recheck timing.

Fig. 8-21

1. Distributor flange bolt

2. Timing is retarded

3. Timing is advanced

Be sure to re-install check window rubber plug

after making above check and adjustment.

WARNING:

When engine is warmed up, exhaust mani-

fold cover and other parts are hot as well.

Be careful not to touch them when remov-

ing and reinstalling rubber plug.

[Checking centrifugal advancer]

After removing distributor cap, turn rotor

clockwise by finger and release it

Check that rotor returns smoothly counterclock-

wise by spring force.

If defective, replace distributor.

Fig. 8-22

8-9