diagram SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 206 of 962

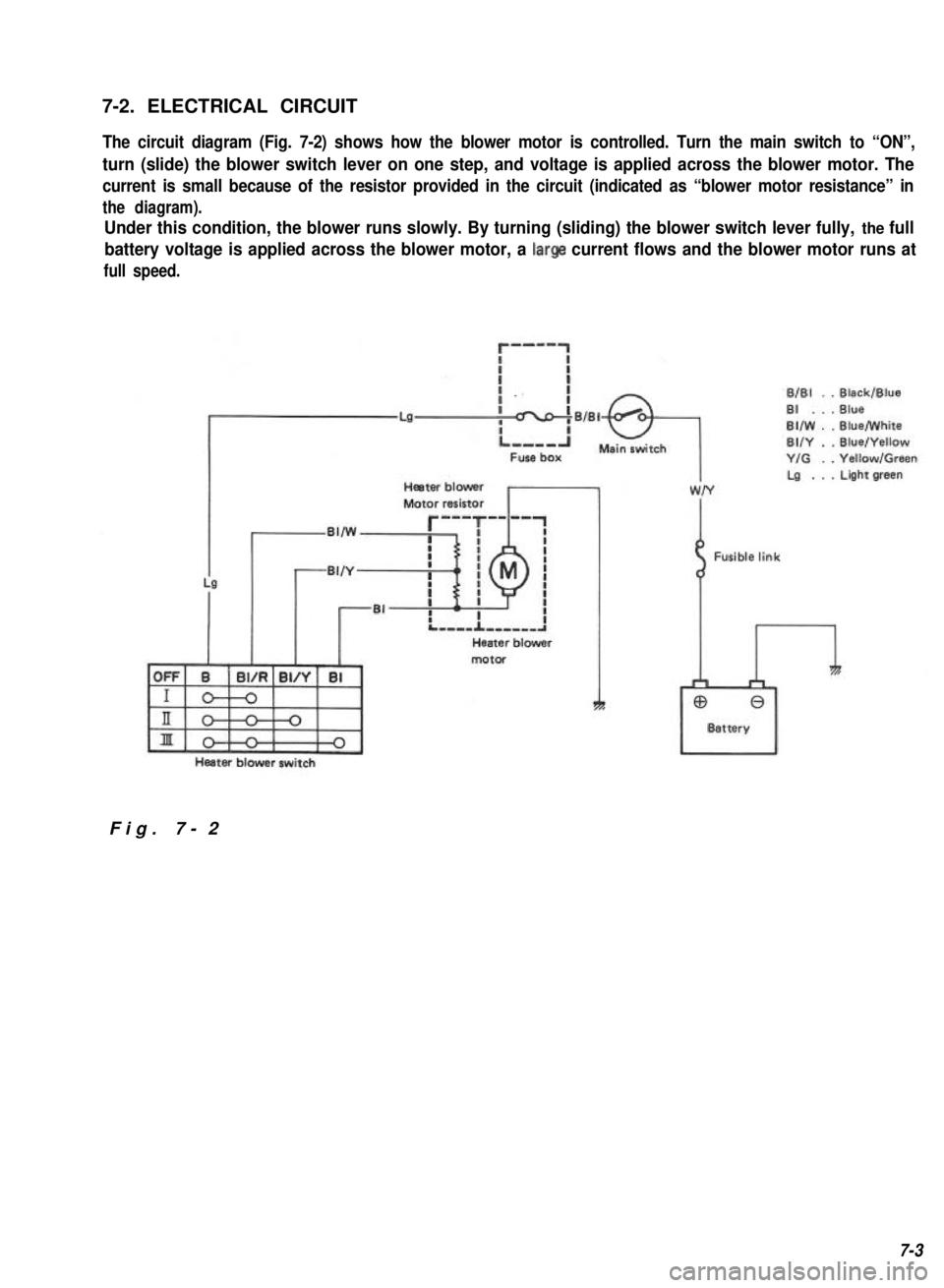

7-2. ELECTRICAL CIRCUIT

The circuit diagram (Fig. 7-2) shows how the blower motor is controlled. Turn the main switch to “ON”,

turn (slide) the blower switch lever on one step, and voltage is applied across the blower motor. The

current is small because of the resistor provided in the circuit (indicated as “blower motor resistance” in

the diagram).

Under this condition, the blower runs slowly. By turning (sliding) the blower switch lever fully, the full

battery voltage is applied across the blower motor, a large current flows and the blower motor runs at

full speed.

r-mm-1

ri

BlBl . .Black/Blue

LaBI . . . Blue

BIIW . .Blue/White

BUY . .Blue/Yellow

Y/G . .Yellow/Green

Heater blowerLa . . . Light green

Motor resistor

,,w~

motor

Heater blower switch

Fusible link

I

Fig. 7-2

7-3

Page 212 of 962

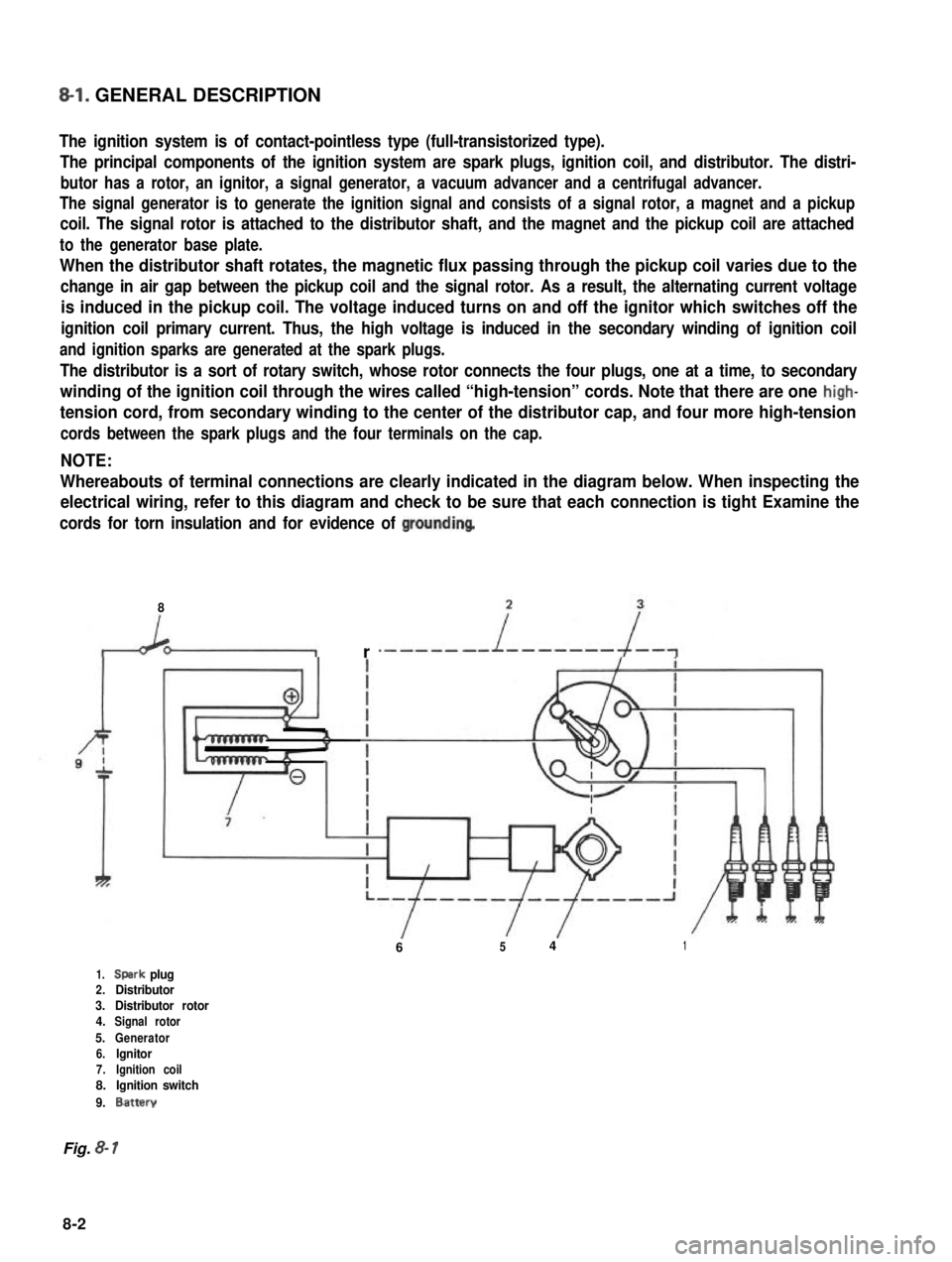

8-l. GENERAL DESCRIPTION

The ignition system is of contact-pointless type (full-transistorized type).

The principal components of the ignition system are spark plugs, ignition coil, and distributor. The distri-

butor has a rotor, an ignitor, a signal generator, a vacuum advancer and a centrifugal advancer.

The signal generator is to generate the ignition signal and consists of a signal rotor, a magnet and a pickup

coil. The signal rotor is attached to the distributor shaft, and the magnet and the pickup coil are attached

to the generator base plate.

When the distributor shaft rotates, the magnetic flux passing through the pickup coil varies due to the

change in air gap between the pickup coil and the signal rotor. As a result, the alternating current voltage

is induced in the pickup coil. The voltage induced turns on and off the ignitor which switches off the

ignition coil primary current. Thus, the high voltage is induced in the secondary winding of ignition coil

and ignition sparks are generated at the spark plugs.

The distributor is a sort of rotary switch, whose rotor connects the four plugs, one at a time, to secondary

winding of the ignition coil through the wires called “high-tension” cords. Note that there are one high-

tension cord, from secondary winding to the center of the distributor cap, and four more high-tension

cords between the spark plugs and the four terminals on the cap.

NOTE:

Whereabouts of terminal connections are clearly indicated in the diagram below. When inspecting the

electrical wiring, refer to this diagram and check to be sure that each connection is tight Examine the

cords for torn insulation and for evidence of groundinq

8

r

6541

1.Spark plug2.Distributor3.Distributor rotor4.Signal rotor

5.Generator6.lgnitor7.Ignition coil8.Ignition switch

9.Battery

Fig. 8- 1

8-2

Page 236 of 962

The alternator features a solid state regulator

that is mounted inside the alternator. All regula-

tor components are enclosed into a solid mold,

and this unit along with the brush holder assemb-

ly is attached to the slip ring end frame. The

regulator voltage setting cannot be adjusted.

The alternator rotor bearings contain enough

grease to eliminate the need for periodic lubri-

cation. Two brushes carry current through the

two slip rings to the field coil mounted on the

rotor, and under normal conditions will provide

long period of attention-free service.

The stator windings are assembled on the inside

of a laminated core that forms part of the

alternator frame. A rectifier bridge connected

to the stator windings contains six diodes,

and electrically changes the stator A.C. voltages

to a D.C. voltage which appears at the generator

output terminal.

The neutral diodes serve to convert the voltage

fluctuation at the neutral point to direct current

for increasing the alternator output.

A condenser mounted in the end frame protects

the diodes from high voltages and suppresses

radio noise.

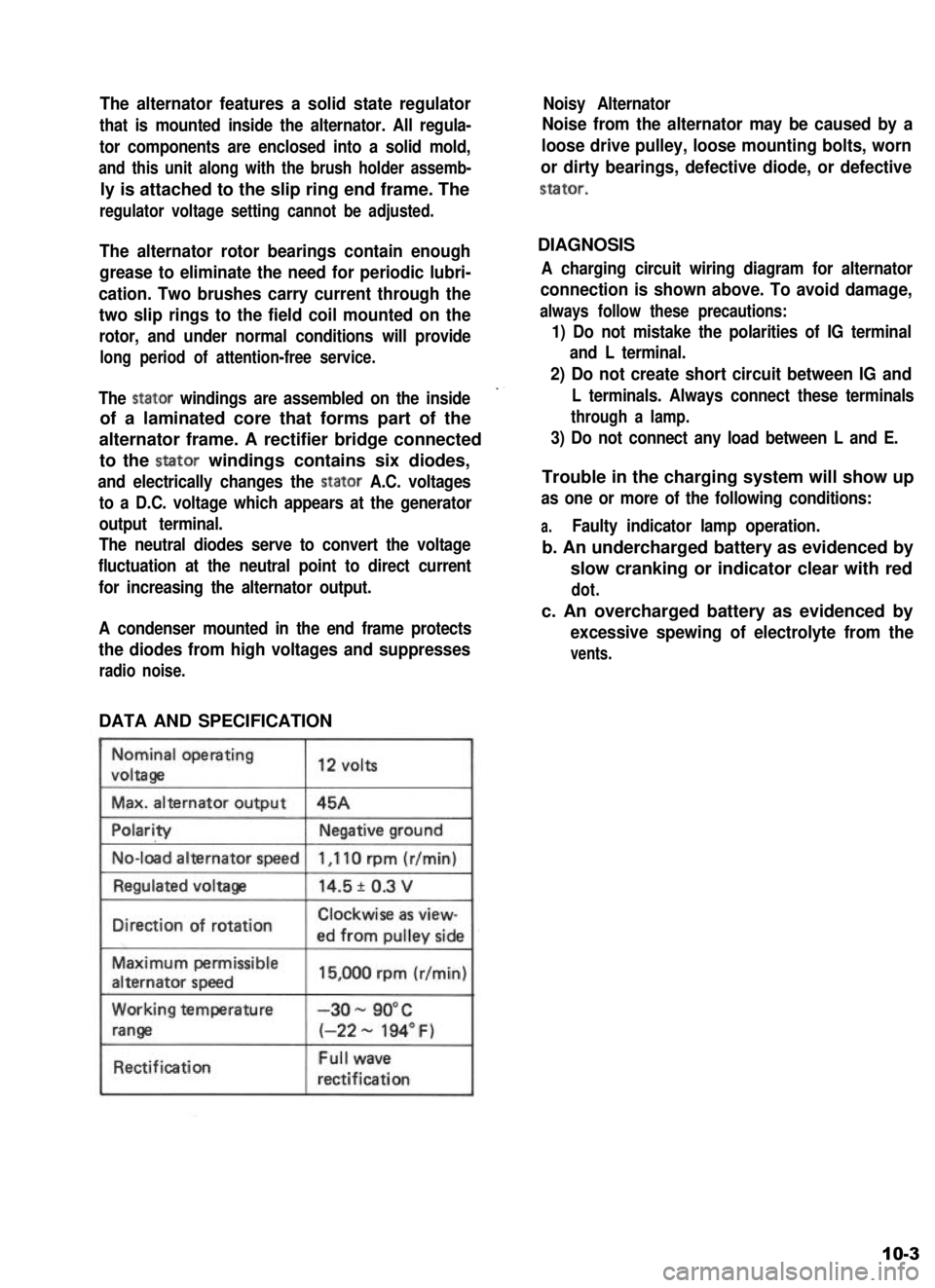

DATA AND SPECIFICATION

Nominal operating

voltaga

Max. alternator output

12 volts

45A

No-load alternator speed

IDirection of rotationClockwise as view-

ed from oullev side

Maximum permissible

alternator speed

Working temperature

range

Rectification

15,000 rpm (r/min)

-3o- 90°C

(-22 - 194” F)

Full wave

rectification

Noisy Alternator

Noise from the alternator may be caused by a

loose drive pulley, loose mounting bolts, worn

or dirty bearings, defective diode, or defective

stator.

DIAGNOSIS

A charging circuit wiring diagram for alternator

connection is shown above. To avoid damage,

always follow these precautions:

1) Do not mistake the polarities of IG terminal

and L terminal.

2) Do not create short circuit between IG and

L terminals. Always connect these terminals

through a lamp.

3) Do not connect any load between L and E.

Trouble in the charging system will show up

as one or more of the following conditions:

a.Faulty indicator lamp operation.

b. An undercharged battery as evidenced by

slow cranking or indicator clear with red

dot.

c. An overcharged battery as evidenced by

excessive spewing of electrolyte from the

vents.

10-3

Page 237 of 962

A. Faulty Indicator Lamp Operation

Problem

Charge light does not light

with ignition ON and engine

off

Charge light does not go out

with engine running

(battery requires frequent

re-

charging) Possible cause

Correcti on

Fuse blown

Check fuse

Light burned outReplace light

Wiring connection loose Tighten loose connections

IC regulator faultyReplace IC regulator

Drive belt loose or worn Adjust or replace drive belt

Battery cables loose, corroded or worn Repair or replace cables

IC regulator or alternator faultyCheck charging system

Wiring faulty.Repair wiring

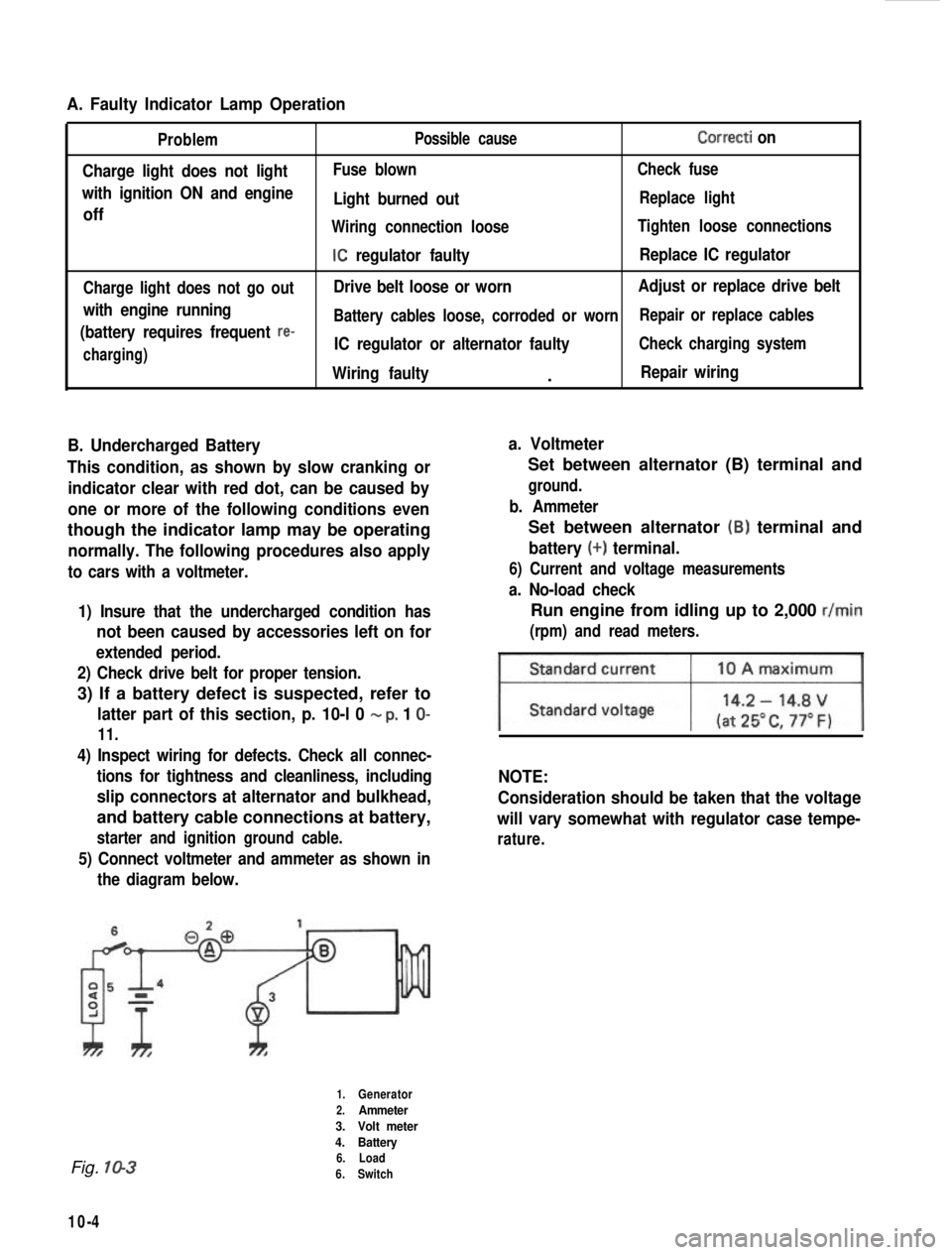

B. Undercharged Battery a. Voltmeter

This condition, as shown by slow cranking or indicator clear with red dot, can be caused by

one or more of the following conditions even

though the indicator lamp may be operating

normally. The following procedures also apply

to cars with a voltmeter.

1) Insure that the undercharged condition has

not been caused by accessories left on for

extended period.

2) Check drive belt for proper tension.

3) If a battery defect is suspected, refer to

latter part of this section, p. 10-l 0 - p, 1 O-

11.

4) Inspect wiring for defects. Check all connec- tions for tightness and cleanliness, including

slip connectors at alternator and bulkhead,

and battery cable connections at battery,

starter and ignition ground cable.

5) Connect voltmeter and ammeter as shown inthe diagram below.

Set between alternator (B) terminal and

ground.

b. Ammeter

Set between alternator (B) terminal and

battery (+) terminal.

6) Current and voltage measurements

a. No-load check

Run engine from idling up to 2,000 r/min

(rpm) and read meters.

NOTE:

Consideration should be taken that the voltage

will vary somewhat with regulator case tempe-

rature.

Fig. 10-3

10-4

1.Generator

2.Ammeter

3. Volt meter

4. Battery

6. Load

6. Switch

Page 443 of 962

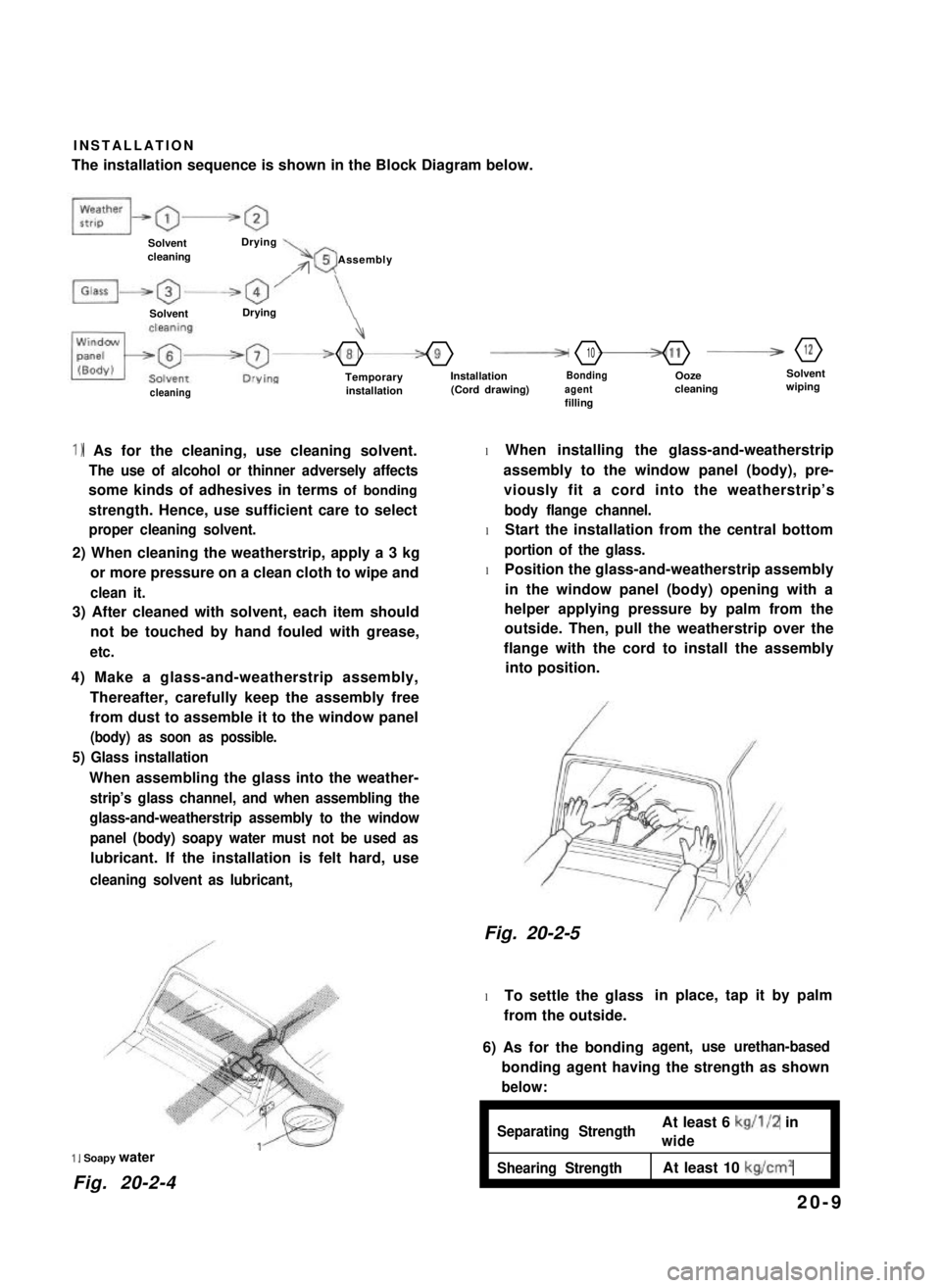

INSTALLATION

The installation sequence is shown in the Block Diagram below.

SolventcleaningDrying\rr05 Assembly

SolventDrying

4

-8-9F10-11B12

TemporaryinstallationInstallation(Cord drawing)Bondingagentfilling

Oozecleaning

Solventwipingcleaning

1) As for the cleaning, use cleaning solvent.

The use of alcohol or thinner adversely affects

some kinds of adhesives in terms of bonding

strength. Hence, use sufficient care to select

proper cleaning solvent.

2) When cleaning the weatherstrip, apply a 3 kg

or more pressure on a clean cloth to wipe and

clean it.

3) After cleaned with solvent, each item should

not be touched by hand fouled with grease,

etc.

4) Make a glass-and-weatherstrip assembly,

Thereafter, carefully keep the assembly free

from dust to assemble it to the window panel

(body) as soon as possible.

5) Glass installation

When assembling the glass into the weather-

strip’s glass channel, and when assembling the

glass-and-weatherstrip assembly to the window

panel (body) soapy water must not be used as

lubricant. If the installation is felt hard, use

cleaning solvent as lubricant,

1, Soapy water

Fig. 20-2-4

l When installing the glass-and-weatherstrip

assembly to the window panel (body), pre-

viously fit a cord into the weatherstrip’s

body flange channel.

l Start the installation from the central bottom

portion of the glass.

l Position the glass-and-weatherstrip assembly

in the window panel (body) opening with a

helper applying pressure by palm from the

outside. Then, pull the weatherstrip over the

flange with the cord to install the assembly

into position.

Fig. 20-2-5

l To settle the glass

from the outside.

in place, tap it by palm

6) As for the bondingagent, use urethan-based

bonding agent having the strength as shown

below:

ISeparating StrengthAt least 6 kg/l/2 in

wideI

Shearing StrengthAt least 10 kg/cm2I

20-9

Page 448 of 962

21-1.COMBINATION METER..................................

21-2.HEAD LIGHT..........................................

21-3.TURN SIGNAL LIGHT AND HAZARD WARNING LIGHT.......

21-4.WINDSHIELD WIPER MOTOR.............................

21-5.WATER TEMPERATURE METER AND GAUGE...............

21-6.FUEL LEVEL METER AND GAUGE........................

21-7.BRAKE WARNING LAMP ...............................

21-8.OIL PRESSURE LAMP..................................

4 WHEEL DRIVE LAMP.................................

21-10. SEAT BELT WARNING LAMP/BUZZER.....................

...................

...~I-I

.....

21-14. .............................................

21-15. WIRING HARNESS ROUTING............................

21-16. WIRING DIAGRAM....................................

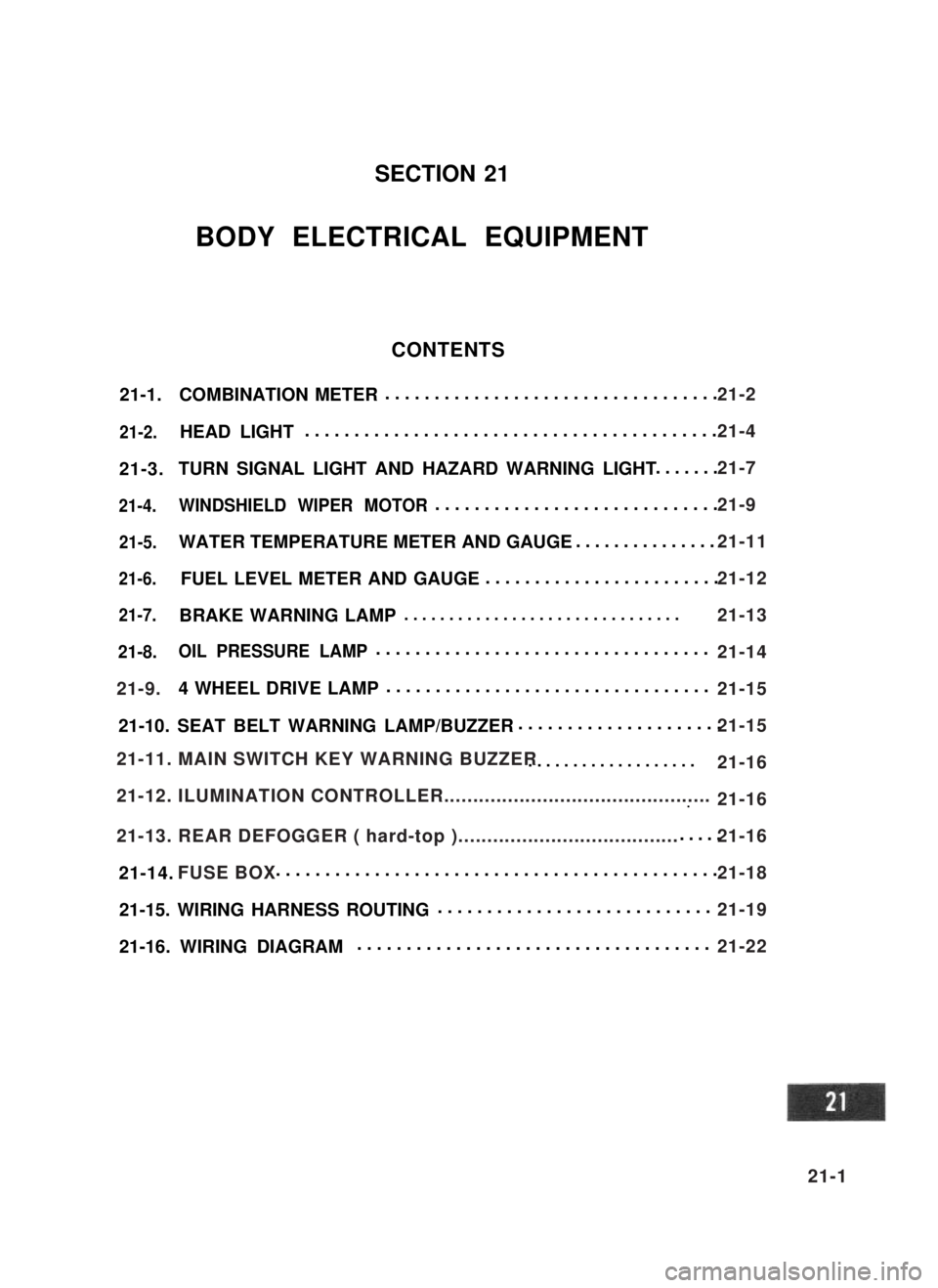

SECTION 21

BODY ELECTRICAL EQUIPMENT

CONTENTS

21-9.

21-11. MAIN SWITCH KEY WARNING BUZZER

21-12. ILUMINATION CONTROLLER..............................................

21-13. REAR DEFOGGER ( hard-top )......................................

FUSE BOX

21-2

21-4

21-7

21-9

21-11

21-12

21-13

21-14

21-15

21-15

21-16

21-16

21-16

21-18

21-19

21-22

21-1

Page 460 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual [Gauge unit]21-7. BRAKE WARNING LAMP

Use ohmmeter to confirm that level gauge unit

changes in resistance with change of the float

position. Float position-to-resistance relation-

ship can be plotted i SUZUKI GRAND VITARA 1987 Service Repair Manual [Gauge unit]21-7. BRAKE WARNING LAMP

Use ohmmeter to confirm that level gauge unit

changes in resistance with change of the float

position. Float position-to-resistance relation-

ship can be plotted i](/img/20/57437/w960_57437-459.png)

[Gauge unit]21-7. BRAKE WARNING LAMP

Use ohmmeter to confirm that level gauge unit

changes in resistance with change of the float

position. Float position-to-resistance relation-

ship can be plotted in a graph as shown below.

The brake warning lamp system consists of the

brake fluid level switch installed to the master

cylinder reservoir and the lamp inside the

combination meter.

This circuit includes a parking brake switch

which gives a warning for unreleased parking

brake.

F-E

Fig. 21-20 Resistance-Fuel Level Relationship

Fig. 21-21

F : Full

E : Empty

OPERATION

Brake fluid level warning lamp circuit consists of

brake fluid level switch installed in master

cylinder reservoir, brake fluid level warning lamp

in gage cluster and check relay.

Also, this circuit is additionally provided with

parking brake switch which warns that parking

brake is applied.when engine is stopped,

warning lamp comes on, if ignition switch is

turned ON and parking brake is applied.

For bulb check, warning lamp comes on briefly

during engine starting regardless of brake fluid

level position and parking brake operation.

Because point of check relay is closed.

After engine is started, release parking brake.

If lamp gose off, brake fluid level is adequate.

When warning lamp dose not operate, use circuit

diagram as reference to check bulb, wiring, etc.

r---i

check relayl-2-l

B/Y : Black/Yellow1. Fluid level switch

R/B : Red/Black2. Warning lamp

B: Black3. Parking brake switch

B/W : Black/White4. Main switch

B/BI : Black/Blue5. Battery

Fig. 27-22

21-13

Page 462 of 962

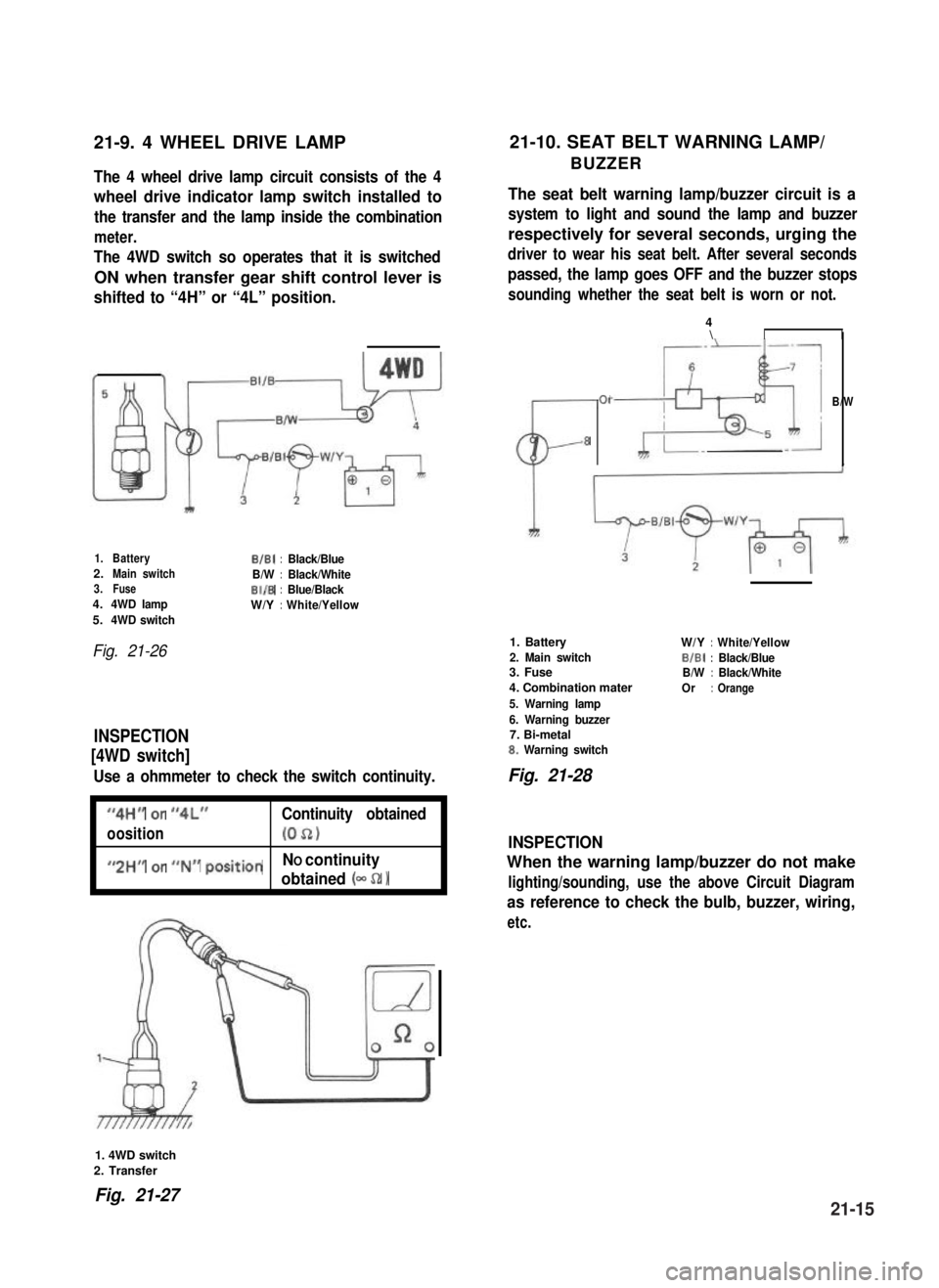

21-9. 4 WHEEL DRIVE LAMP21-10. SEAT BELT WARNING LAMP/

BUZZERThe 4 wheel drive lamp circuit consists of the 4

wheel drive indicator lamp switch installed to

the transfer and the lamp inside the combination

meter.

The 4WD switch so operates that it is switched

ON when transfer gear shift control lever is

shifted to “4H” or “4L” position.

The seat belt warning lamp/buzzer circuit is a

system to light and sound the lamp and buzzer

respectively for several seconds, urging the

driver to wear his seat belt. After several seconds

passed, the lamp goes OFF and the buzzer stops

sounding whether the seat belt is worn or not.

1.BatteryB/B1:Black/Blue2.Main switchB/W:Black/White3.FuseBI/B:Blue/Black4.4WD lampW/Y:White/Yellow5.4WD switch

Fig. 21-26

INSPECTION

[4WD switch]

Use a ohmmeter to check the switch continuity.

I

“4H” or “4L”Continuity obtained

oosition(052)I

I

#,2HM or ##N## positionNO continuity

obtained (- 52 1I

CL-

01

8

4\II

B/W

1. Battery

2. Main switch3. Fuse

4. Combination mater

5. Warning lamp

6. Warning buzzer7. Bi-metal8. Warning switch

W/Y:White/Yellow

BIBI:Black/BlueB/W:Black/White

Or:Orange

Fig. 21-28

INSPECTION

When the warning lamp/buzzer do not make

lighting/sounding, use the above Circuit Diagram

as reference to check the bulb, buzzer, wiring,

etc.

1. 4WD switch

2. Transfer

Fig. 21-2721-15

Page 463 of 962

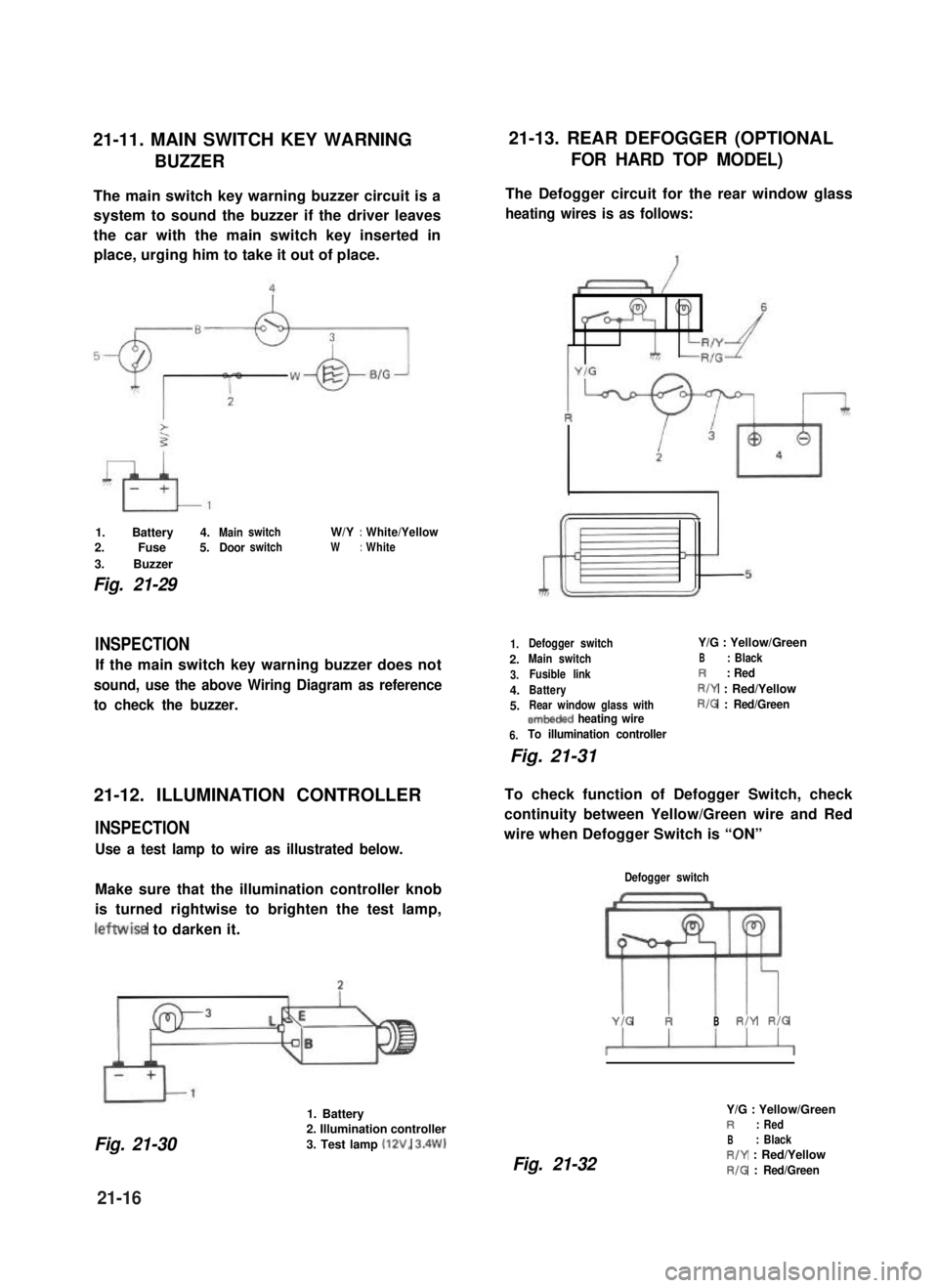

21-11. MAIN SWITCH KEY WARNING21-13. REAR DEFOGGER (OPTIONAL

BUZZERFOR HARD TOP MODEL)

The main switch key warning buzzer circuit is a

system to sound the buzzer if the driver leaves

the car with the main switch key inserted in

place, urging him to take it out of place.

1. Battery 4.MainswitchW/Y:White/Yellow

2. Fuse 5.DoorswitchW:White

3. Buzzer

Fig. 21-29

INSPECTION

If the main switch key warning buzzer does not

sound, use the above Wiring Diagram as reference

to check the buzzer.

21-12. ILLUMINATION CONTROLLER

INSPECTION

Use a test lamp to wire as illustrated below.

Make sure that the illumination controller knob

is turned rightwise to brighten the test lamp,

leftwise to darken it.

1. Battery

Fig. 21-30

2. Illumination controller

3. Test lamp (12V, 3.4W)

The Defogger circuit for the rear window glass

heating wires is as follows:

1.

2.

3.

4.

5.

6.

Defogger switchY/G : Yellow/Green

Main switchB: Black

Fusible linkR: Red

BatteryR/Y : Red/Yellow

Rear window glass withR/G : Red/Greenembeded heating wire

To illumination controller

Fig. 21-31

To check function of Defogger Switch, check

continuity between Yellow/Green wire and Red

wire when Defogger Switch is “ON”

Defogger switch

YIG RBR/Y RIG

Fig. 21-32

Y/G : Yellow/GreenR: Red

B: BlackR/Y : Red/Yellow

R/G : Red/Green

21-16

Page 469 of 962

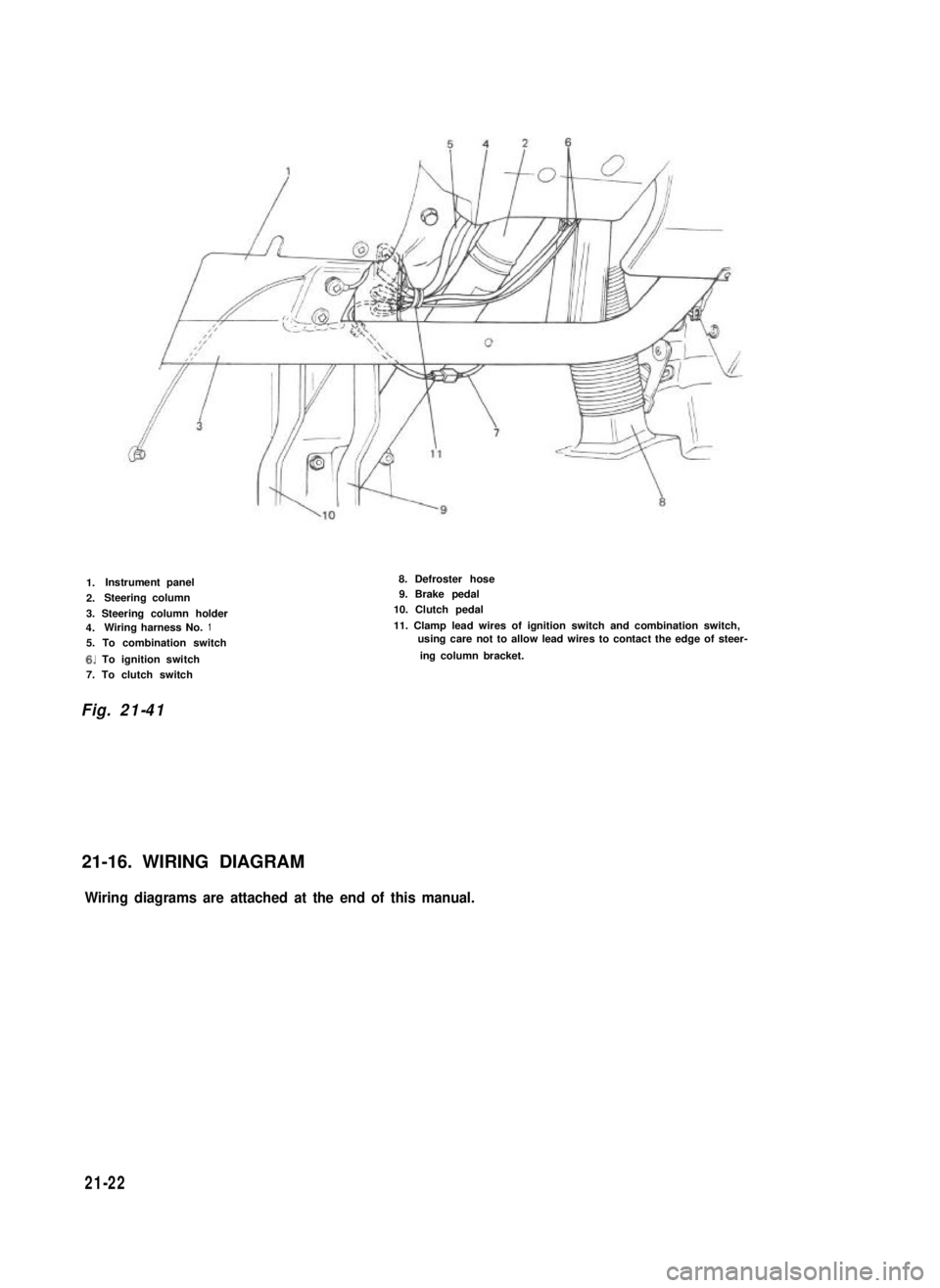

1.Instrument panel

2.Steering column

3. Steering column holder4.Wiring harness No.1

5. To combination switch

6. To ignition switch

7. To clutch switch

8. Defroster hose9. Brake pedal

10. Clutch pedal

11. Clamp lead wires of ignition switch and combination switch,using care not to allow lead wires to contact the edge of steer-

ing column bracket.

Fig. 21-41

21-16. WIRING DIAGRAM

Wiring diagrams are attached at the end of this manual.

21-22