turn signal bulb SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 185 of 962

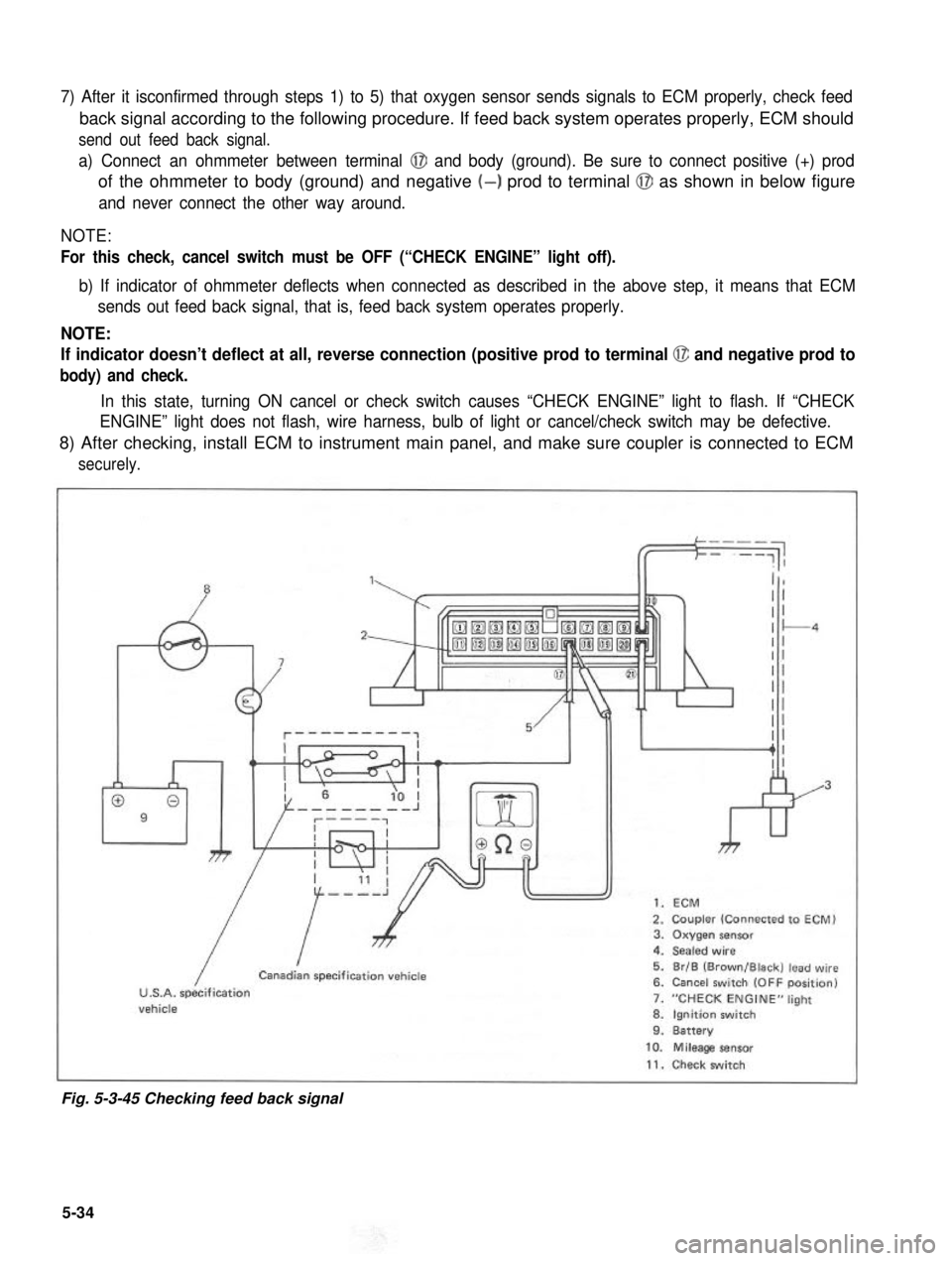

7) After it isconfirmed through steps 1) to 5) that oxygen sensor sends signals to ECM properly, check feed

back signal according to the following procedure. If feed back system operates properly, ECM should

send out feed back signal.

a) Connect an ohmmeter between terminal @I and body (ground). Be sure to connect positive (+) prod

of the ohmmeter to body (ground) and negative (-) prod to terminal @J as shown in below figure

and never connect the other way around.

NOTE:

For this check, cancel switch must be OFF (“CHECK ENGINE” light off).

b) If indicator of ohmmeter deflects when connected as described in the above step, it means that ECM

sends out feed back signal, that is, feed back system operates properly.

NOTE:

If indicator doesn’t deflect at all, reverse connection (positive prod to terminal @ and negative prod to

body) and check.

In this state, turning ON cancel or check switch causes “CHECK ENGINE” light to flash. If “CHECK

ENGINE” light does not flash, wire harness, bulb of light or cancel/check switch may be defective.

8) After checking, install ECM to instrument main panel, and make sure coupler is connected to ECM

securely.

”1,

009

7

kr

1. ECM

2. Coupler (Connected to ECM)3. Oxygen sensor4. Sealed wire

5. Br/B (Brown/Black) lead wire6. Cancel switch (OFF position)

7. “CHECK ENGINE” light

8. Ignition switch9. Battery

/

ICanadian specification vehicle

U.S.A. specificationvehicle

10. Mileage sensor

11. Check switch

Fig. 5-3-45 Checking feed back signal

5-34

Page 450 of 962

Wire color

G/R . . .Green/RedOr . Orange

0 . . . . .BlackBI/B . Blue/Black

0rlB . . .Brown/Blackw . White

Y/B . . .Yellow/BlackY/R . Yellow/Red

B/W . .Black/WhiteG/Y . .Green/Yellow

W/R .White/RedY/W . . Yellow/White

RIB .Red/BlackR/Y . Red/Yellow

G. . .GreenR/G . . .Red/Green

1.

2.

3.

4.

5.

6.7.

8.

9.

10.

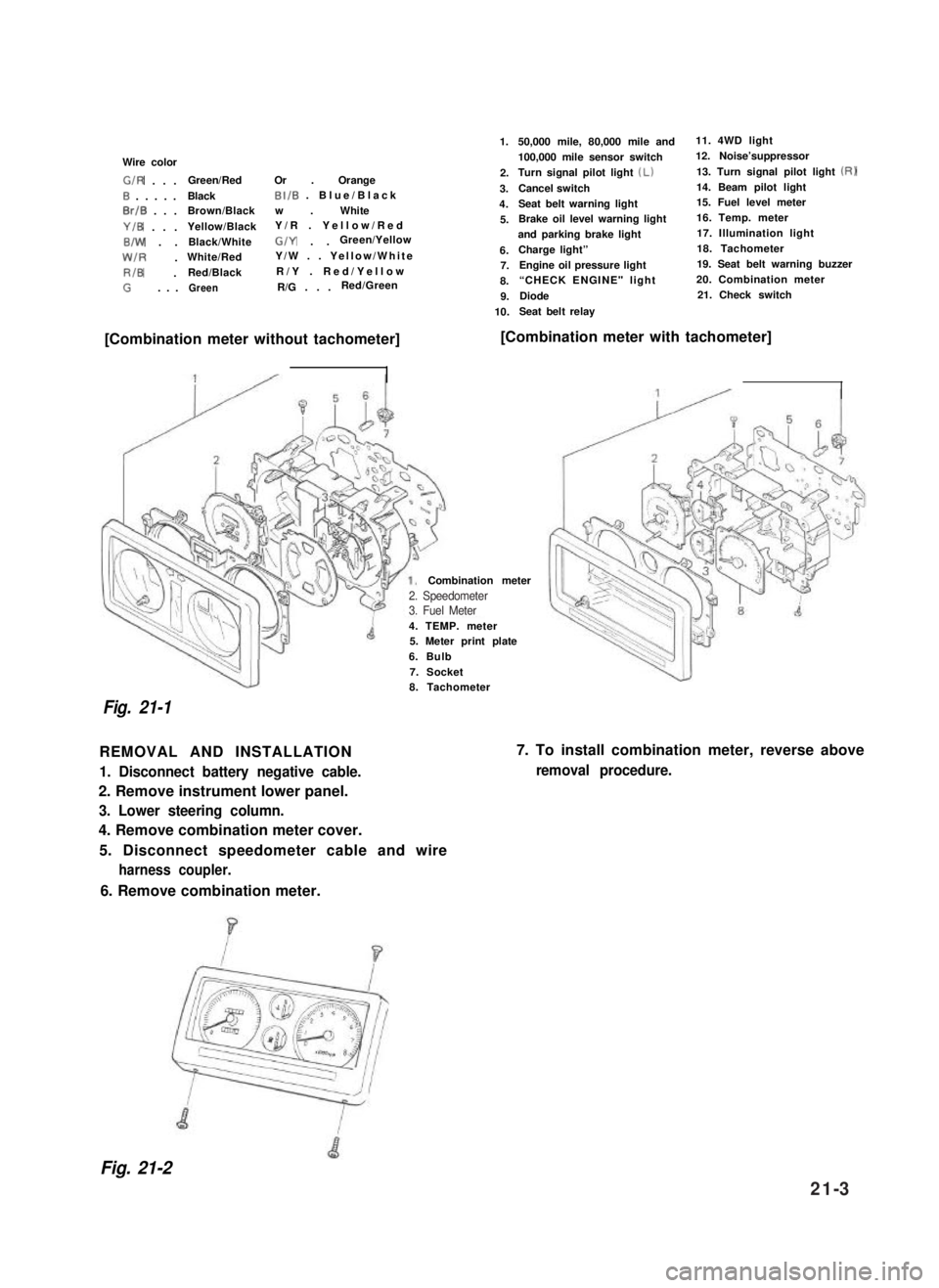

50,000 mile, 80,000 mile and11. 4WD light

100,000 mile sensor switch12. Noise’suppressor

Turn signal pilot light (Lb13. Turn signal pilot light (RI

Cancel switch14. Beam pilot light

Seat belt warning light15. Fuel level meter

Brake oil level warning light16. Temp. meter

and parking brake light17. Illumination light

Charge light”18. Tachometer

Engine oil pressure light19. Seat belt warning buzzer

“CHECK ENGINE" light 20. Combination meter

Diode21. Check switch

Seat belt relay

[Combination meter without tachometer][Combination meter with tachometer]

4. TEMP. meter5. Meter print plate

6. Bulb

7. Socket

Combination meter

Fig. 21-1

8. Tachometer

REMOVAL AND INSTALLATION

1. Disconnect battery negative cable.

2. Remove instrument lower panel.

3. Lower steering column.

4. Remove combination meter cover.

5. Disconnect speedometer cable and wire

harness coupler.

7. To install combination meter, reverse above

removal procedure.

6. Remove combination meter.

Fig. 21-2

2. Speedometer3. Fuel Meter

21-3

Page 455 of 962

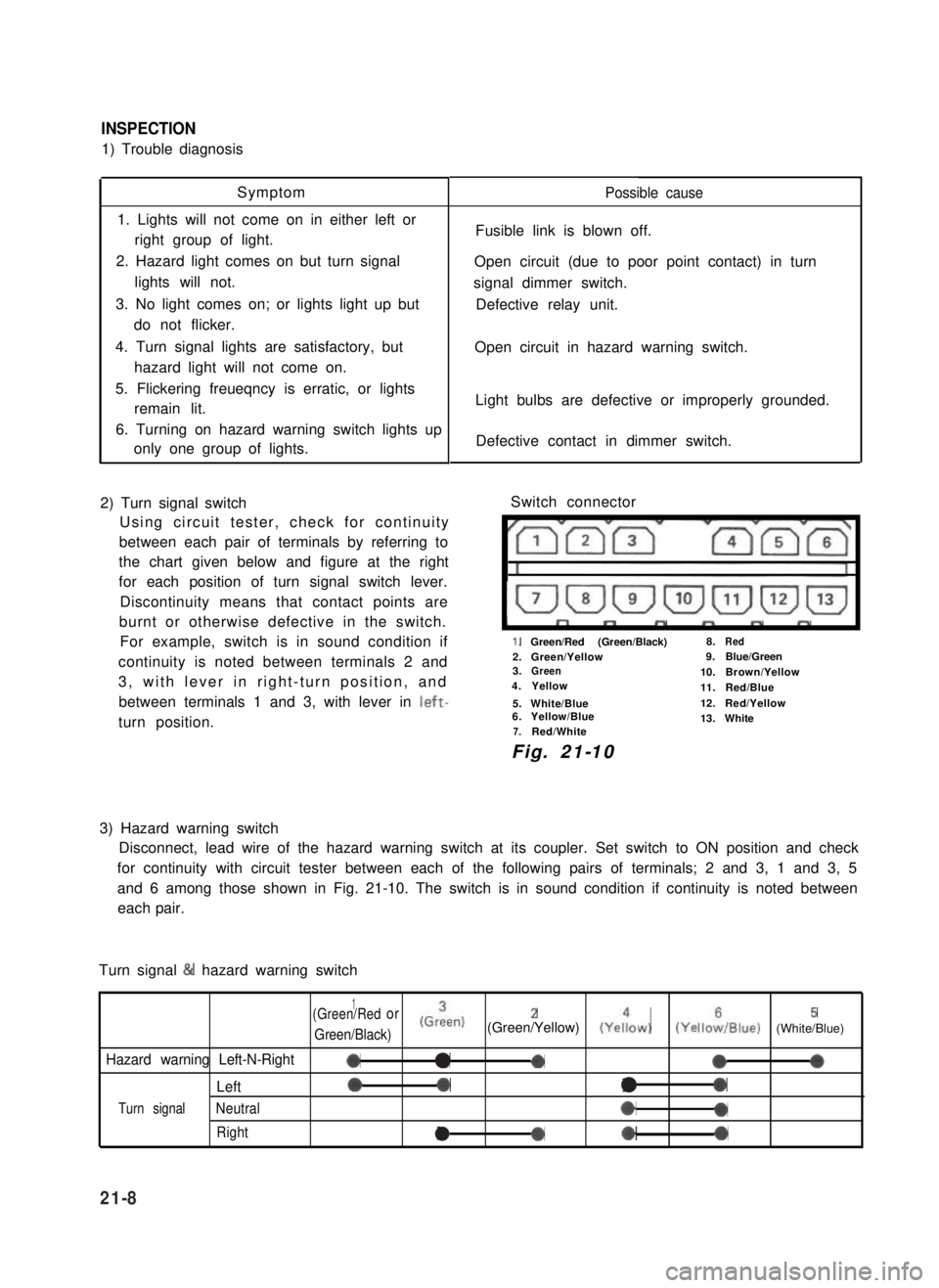

INSPECTION

1) Trouble diagnosis

Symptom

1. Lights will not come on in either left or

right group of light.

2. Hazard light comes on but turn signal

lights will not.

3. No light comes on; or lights light up but

do not flicker.

4. Turn signal lights are satisfactory, but

hazard light will not come on.

5. Flickering freueqncy is erratic, or lights

remain lit.

6. Turning on hazard warning switch lights up

only one group of lights.

2) Turn signal switch

Using circuit tester, check for continuity

between each pair of terminals by referring to

the chart given below and figure at the right

for each position of turn signal switch lever.

Discontinuity means that contact points are

burnt or otherwise defective in the switch.

For example, switch is in sound condition if

continuity is noted between terminals 2 and

3, with lever in right-turn position, and

between terminals 1 and 3, with lever in left-

turn position.

Possible cause

Fusible link is blown off.

Open circuit (due to poor point contact) in turn

signal dimmer switch.

Defective relay unit.

Open circuit in hazard warning switch.

Light bulbs are defective or improperly grounded.

Defective contact in dimmer switch.

Switch connector

I”””yrm-

1.Green/Red (Green/Black)8.Red

2.Green/Yellow9.Blue/Green3.Green10.Brown/Yellow4.Yellow11.Red/Blue

5.White/Blue12.Red/Yellow6.Yellow/Blue13.White7.Red/White

Fig. 21-10

3) Hazard warning switch

Disconnect, lead wire of the hazard warning switch at its coupler. Set switch to ON position and check

for continuity with circuit tester between each of the following pairs of terminals; 2 and 3, 1 and 3, 5

and 6 among those shown in Fig. 21-10. The switch is in sound condition if continuity is noted between

each pair.

Turn signal & hazard warning switch

1(Green/Redor

Green/Black)

(Grien)2(Green/Yellow) (Yeiow)5(YelloiIBlue) (White/Blue)

Hazard warning Left-N-Right0a-000

Left00l0

Turn signalNeutral*0

Rightla*0

21-8