wheel size SUZUKI GRAND VITARA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 71 of 962

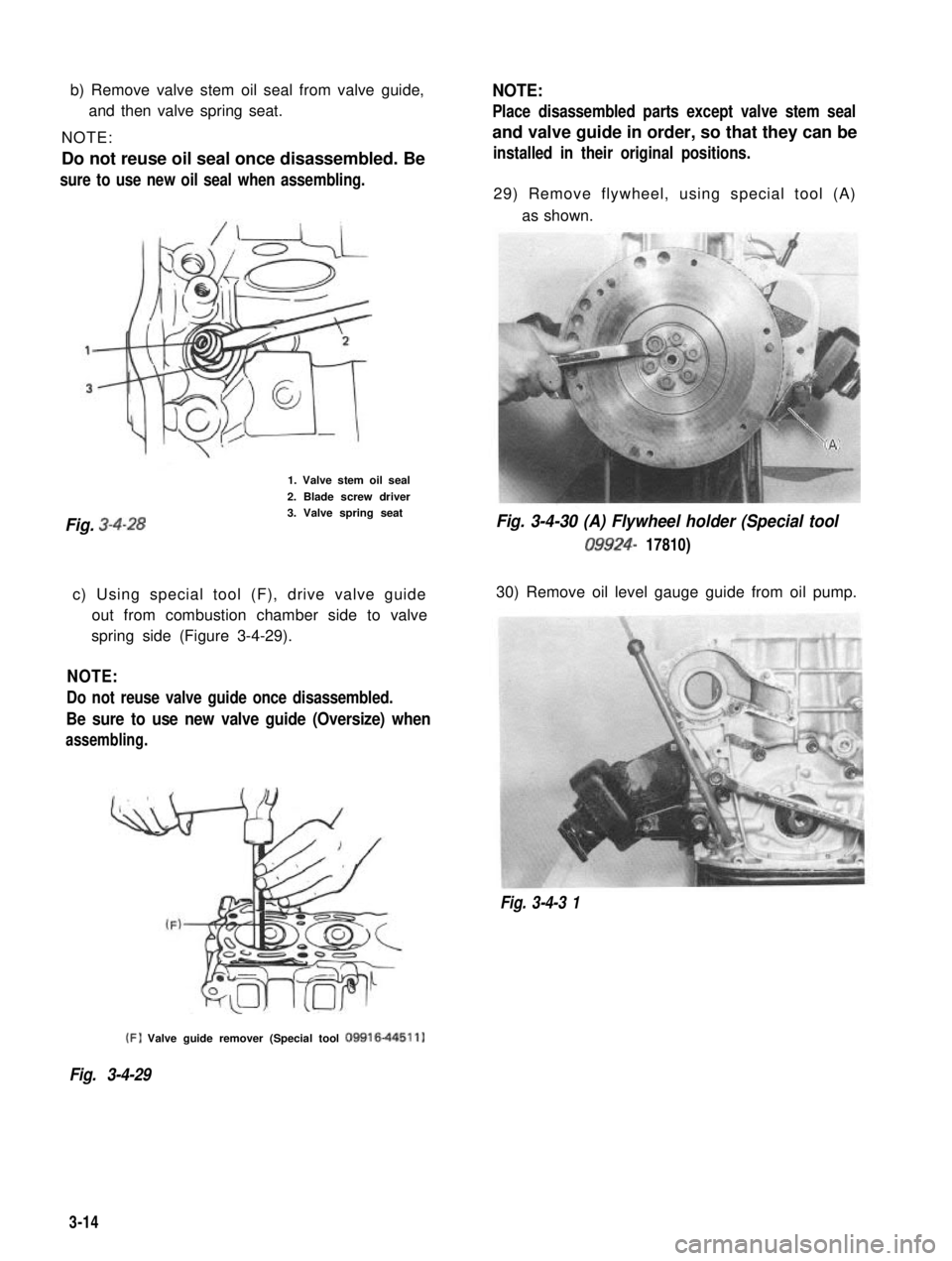

b) Remove valve stem oil seal from valve guide,

and then valve spring seat.

NOTE:

Do not reuse oil seal once disassembled. Besure to use new oil seal when assembling.

1. Valve stem oil seal

2. Blade screw driver

Fig. 3-4-283. Valve spring seat

c) Using special tool (F), drive valve guide out from combustion chamber side to valve

spring side (Figure 3-4-29).

NOTE:

Do not reuse valve guide once disassembled.

Be sure to use new valve guide (Oversize) when

assembling.

NOTE:

Place disassembled parts except valve stem seal

and valve guide in order, so that they can be

installed in their original positions.

29) Remove flywheel, using special tool (A)

as shown.

Fig. 3-4-30 (A) Flywheel holder (Special tool

09924- 17810)

30) Remove oil level gauge guide from oil pump.

Fig. 3-4-3 1 (F)

Valve guide remover (Special tool

09916-44511)

Fig. 3-4-29

3-14

Page 87 of 962

Crankshaft Main (Journal) Bearings

General informations:

l Service main bearings are available in standard-

size and 0.25 mm (0.0098 in) undersize, and

each of them has 5 kinds of bearings differ-

ing in tolerance.

l The upper half of bearing has oil groove as

indicated in Fig. 3~5-42. Install this half with

oil groove to cylinder block.

Fig. 3-5-40 Measuring thrust play of crankshaft

l Out-of-round and taper (uneven wear):

An unevenly worn crankshaft journal shows

up as a difference in diameter at a cross

section or along its length (or both). This

difference, if any, is to be determined from

micrometer readings.

If any of journals is badly damaged or if the

amount of uneven wear in the sense explained

above exceeds its limit, regrind or replace the

crankshaft.

I

Limit on out-of-round

and taper0.01 mm (0.0004 in.)

Fig. 3-5-4 1 Checking uneven wear

1. Cylinder block2. Upper half of bearing

3. Oil groove

Fig. 3-5-42 Upper half of bearing installation

l On each main bearing cap, arrow mark and

number are embossed as indicated in Fig.

3-5-43.

When installing each bearing cap to cylinder

block, point arrow mark toward crankshaft

pulley side and install each cap from crank-

shaft pulley side to flywheel side in ascending

order of numbers @,a, 0, @ and 0. Tigh-

ten cap bolts to specified torque.

3

2. Flywheel side

Fig. 3-5-43 Bearing caps ins talla tion

3-30

Page 91 of 962

Measured journal diameter

44.744 - 44.750 mm44.738 - 44.744 mm44.732 - 44.738 mm

(1.7616 - 1.7618 in.)(1.7614 - 1.7616 in.)(1.7612 - 1.7614 in.)

Alphabets stamped I AGreen & RedBlack & RedRed only

on mating surfaceBBlack & RedRed onlyYellow & Red

of cylinder blockCRed onlyYellow & RedBlue & Red

Undersize bearing to be installed.

Rear Oil Seal

Carefully inspect oil seal for wear or damage. If

its lip is worn or damaged, replace oil seal.

1. Rear oil seal

Fig. 3-5-49 Rear oil sealOil Pump

Flywheel

l If ring gear is damaged, cracked or worn,

replace flywheel.

l If surface contacting clutch disc is damaged,

or excessibly worn, replace flywheel.

l Check flywheel for face runout with a dial

wge.

If runout is out of limit, replace flywheel.

Limit on runout0.2 mm (0.0078 in.)

Fig. 3-5-50 Measuring runou t

1) Inspect oil seal lip for fault or other damage.

Replace as necessary.

2) Inspect outer and inner rotors, rotor plate,

and oil pump case for excessive wear or

damage.

l Radial clearance:

Check radial clearance between outer rotor

and case, using thickness gauge.

If clearance exceeds its limit, replace outer

rotor or case.

Outer rotor and case0.310 mm (0.0122 in.)

3-34

Page 100 of 962

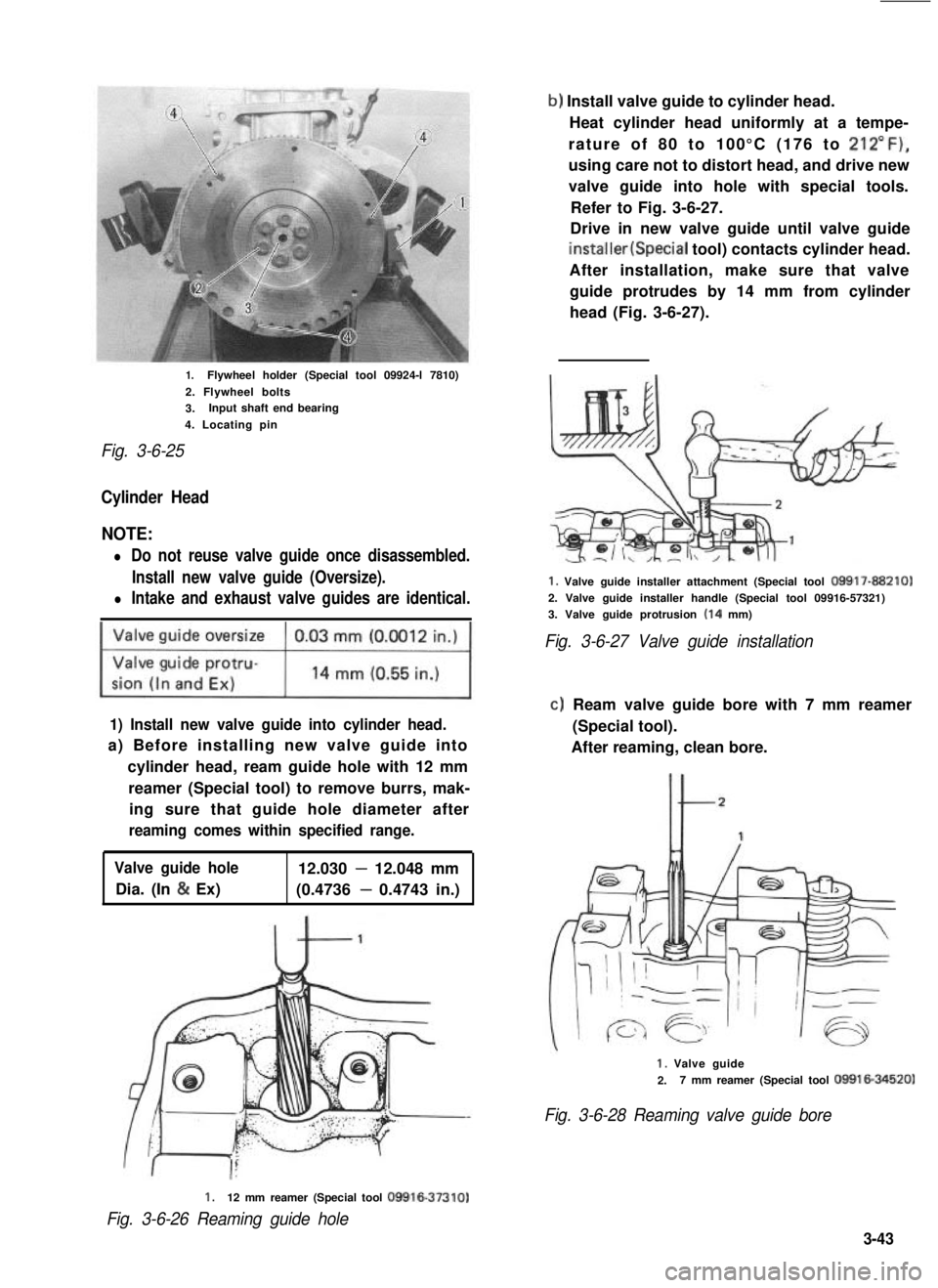

1.Flywheel holder (Special tool 09924-l 7810)

2. Flywheel bolts

3.Input shaft end bearing

4. Locating pin

Fig. 3-6-25

Cylinder Head

NOTE:

l Do not reuse valve guide once disassembled.

Install new valve guide (Oversize).

l Intake and exhaust valve guides are identical.

1) Install new valve guide into cylinder head.

a) Before installing new valve guide into

cylinder head, ream guide hole with 12 mm

reamer (Special tool) to remove burrs, mak-

ing sure that guide hole diameter after

reaming comes within specified range.

Valve guide hole12.030 - 12.048 mm

Dia. (In & Ex)(0.4736 - 0.4743 in.)

b) Install valve guide to cylinder head.

Heat cylinder head uniformly at a tempe-

rature of 80 to 100°C (176 to 212”F),

using care not to distort head, and drive new

valve guide into hole with special tools.

Refer to Fig. 3-6-27.

Drive in new valve guide until valve guide

installer(Special tool) contacts cylinder head.

After installation, make sure that valve

guide protrudes by 14 mm from cylinder

head (Fig. 3-6-27).

1. Valve guide installer attachment (Special tool 09917-88210)

2. Valve guide installer handle (Special tool 09916-57321)

3. Valve guide protrusion (14 mm)

Fig. 3-6-27 Valve guide installation

clReam valve guide bore with 7 mm reamer

(Special tool).

After reaming, clean bore.

1. Valve guide

2.7 mm reamer (Special tool 09916-34520)

Fig. 3-6-28 Reaming valve guide bore

1.12 mm reamer (Special tool 09916-37310)

Fig. 3-6-26 Reaming guide hole

3-43

Page 357 of 962

Before giving a test pull to knuckle arm with a

spring balance in the alternative method, in-

stall a large amount of shims on each kingpin to

lighten preload on tapered roller bearing.

Keep on reading the torque, each time decreas-

ing shim thickness a little, and continue this

process until specified torque value is obtained.

(This process protects kingpins because it ensure

that no excessive pull will be applied to bearings

at the onset.) If the process fails to produce

specified torque, that is, if desired torque

resistance does not occur even when shim

thickness has been reduced to zero on each

kingpin, it means that bearings or kingpins are

excessively worn and need replacement.

NOTE:

l Read spring balance indication when knuckle

arm begins to turn. In other words, you are

to read “starting torque.”

l When checking knuckle arm starting torque,

be sure to have axle hub oil seal removed

and tighten king pin bolts to specified torque.

Knuckle arm starting1 .O - 1.8 kg (2.20 - 3.96 lb)

torque (force)without oil seal

Available sizes of0.1,0.5 mm

shim for kingpins(0.004,0.02 in.)

/r--QzL- -\King pin shim

Fig. 17-3-13

Upon completion of this check and/or adjust-

ment, be sure to connect tie rod end to steering

knuckle and install oil seal retainer, oil seal,

felt packing oil seal cover and wheel.

Refer to “INSTALLATION” in this section.

Steering Knuckle Oil Seal

The oil seal used at the spherical sliding joint

between knuckle and inner case accomplishes

additional purposes of keeping out road dust

and of acting as the damper for steering hand-

wheel. As wear of this seal advances, its damping

effect decreases and thus makes front wheel

develop a tendency to “shimmy” not onI9 that

road dust begins to creep into sliding clearance

to promote wear of spherical sliding surfaces.

The oil seal is an expendable item, and must be

replaced at regular intervals.

Fig. 17-3-14

[How to replace oil seal]

1) Remove 8 bolts securing joint seat, and

displace oil seal cover and felt packing inward.

Fig. 17-3-15

17-23

Page 382 of 962

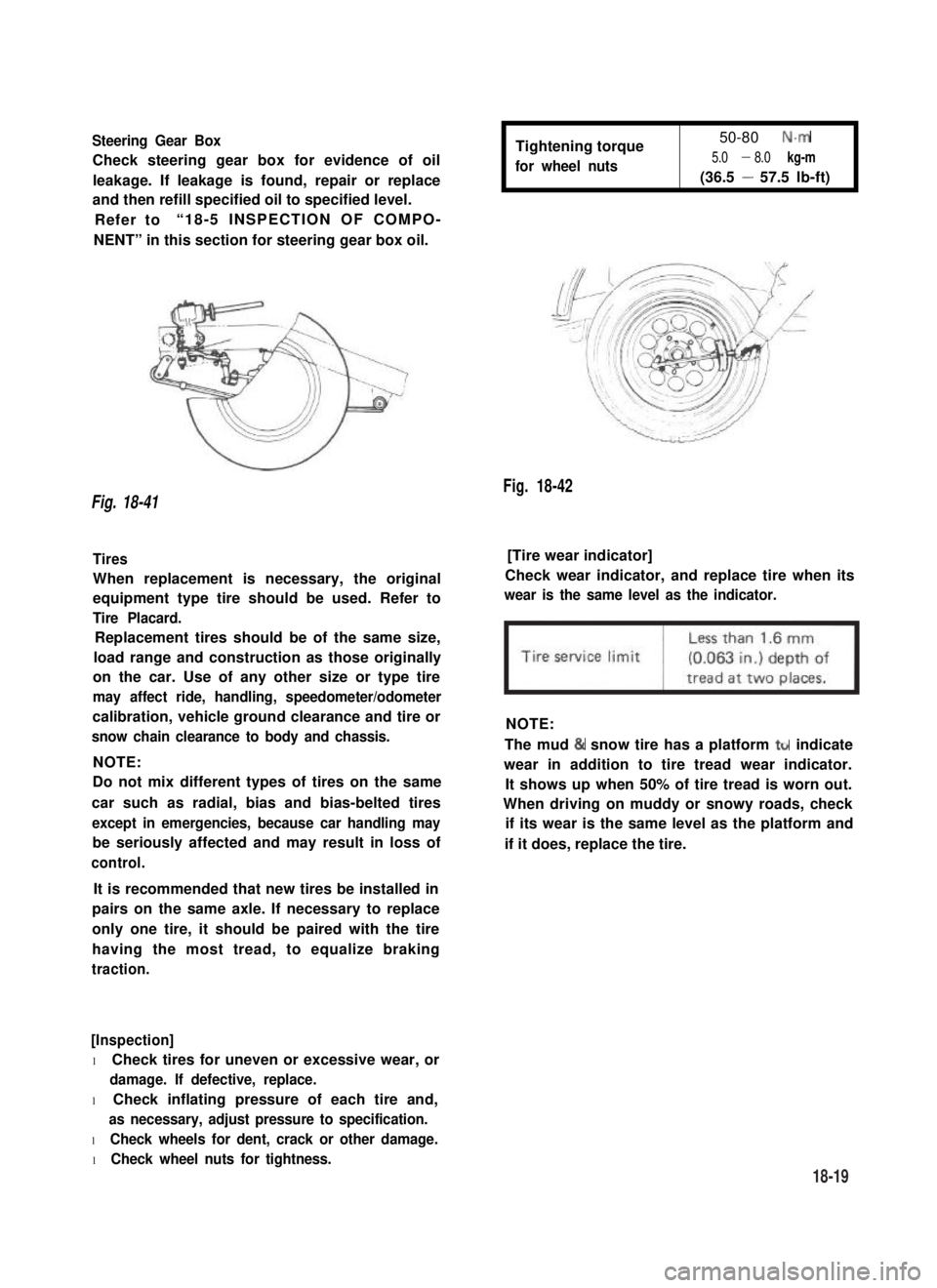

Steering Gear Box

Check steering gear box for evidence of oil

leakage. If leakage is found, repair or replace

and then refill specified oil to specified level.

Refer to“18-5 INSPECTION OF COMPO-

NENT” in this section for steering gear box oil.

Tightening torque

for wheel nuts

50-80 N.m

5.0 - 8.0 kg-m

(36.5 - 57.5 lb-ft)

Fig. 18-42

Fig. 18-41

Tires[Tire wear indicator]

When replacement is necessary, the original

equipment type tire should be used. Refer to

Tire Placard.

Check wear indicator, and replace tire when its

wear is the same level as the indicator.

Replacement tires should be of the same size,

load range and construction as those originally

on the car. Use of any other size or type tire

may affect ride, handling, speedometer/odometer

calibration, vehicle ground clearance and tire or

snow chain clearance to body and chassis.

NOTE:

NOTE:

Do not mix different types of tires on the same

car such as radial, bias and bias-belted tires

except in emergencies, because car handling may

be seriously affected and may result in loss of

control.

The mud & snow tire has a platform ttr indicate

wear in addition to tire tread wear indicator.

It shows up when 50% of tire tread is worn out.

When driving on muddy or snowy roads, check

if its wear is the same level as the platform and

if it does, replace the tire.

It is recommended that new tires be installed in

pairs on the same axle. If necessary to replace

only one tire, it should be paired with the tire

having the most tread, to equalize braking

traction.

[Inspection]

l Check tires for uneven or excessive wear, or

damage. If defective, replace.

l Check inflating pressure of each tire and,

as necessary, adjust pressure to specification.

l Check wheels for dent, crack or other damage.

l Check wheel nuts for tightness.

18-19

Page 383 of 962

![SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflati SUZUKI GRAND VITARA 1987 Service Repair Manual Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflati](/img/20/57437/w960_57437-382.png)

Fig. 18-43 @ Tire tread wear indicator

@ Wear indicating platform

[ Inflation of tires]

l Tire inflation pressures are listed on the

Tire Placard at driver’s side of instrument

panel.

l Tire inflation pressures should be checked

(including spare tire) at least monthly and

when significantly changing the load in the

car.

l Always check tire inflation pressures when

tires are “cold”.

l Always use tire pressure gauge when checking

inflation pressure.

l Be sure to reinstall tire inflation valve caps to

prevent dirt and moisture from getting into

valve core, as they may cause air leakage.

l If air loss occurs while driving, do not drive

on the deflated tire more than is needed to

stop safety. Driving even a short distance on a

deflated tire can damage a tire and wheel

beyond repair.

NOTE:

Before installing wheels, remove any build-up of

corrosion on the wheel mounting surface and

brake drum or disc mounting surface by scraping

and wire brushing. Installing wheels without

good metal-to-metal contact at the mounting

surfaces can cause wheel nuts to loosen, which

can later allow a wheel to come off while the

car is moving.

RADIAL TIRES

.i II

9T

\

I

4-wheels

Fig. 18-44

fT

u

[I

5-wheels

[Wheels]

Wheels must be replaced if they are bent, dented,

have excessive lateral or radial runout, leak air

through welds, have elongated bolt holes, if

lug nuts won’t stay tight, or if they are heavily

rusted. Wheels with greater runout than shown

in below figure may cause objectional vibrations.

Replacement wheels must be equivalent to the

original equipment wheels in load capacity,

diameter,rim width, offset and mounting

configuration. A wheel of improper size or type

may affect wheel and bearing life, brake cooling,

speedometer/odometer calibration, car ground

clearance and tire clearance to the body and

chassis.

[Tire rotation]

“Rotate” tires at the regular intervals in order to

equalize tire wear and thereby make full use of

each tire. Refer to below figure for the scheme

of rotation. Adherence to this scheme prolongs

tire life.

18-20

Page 472 of 962

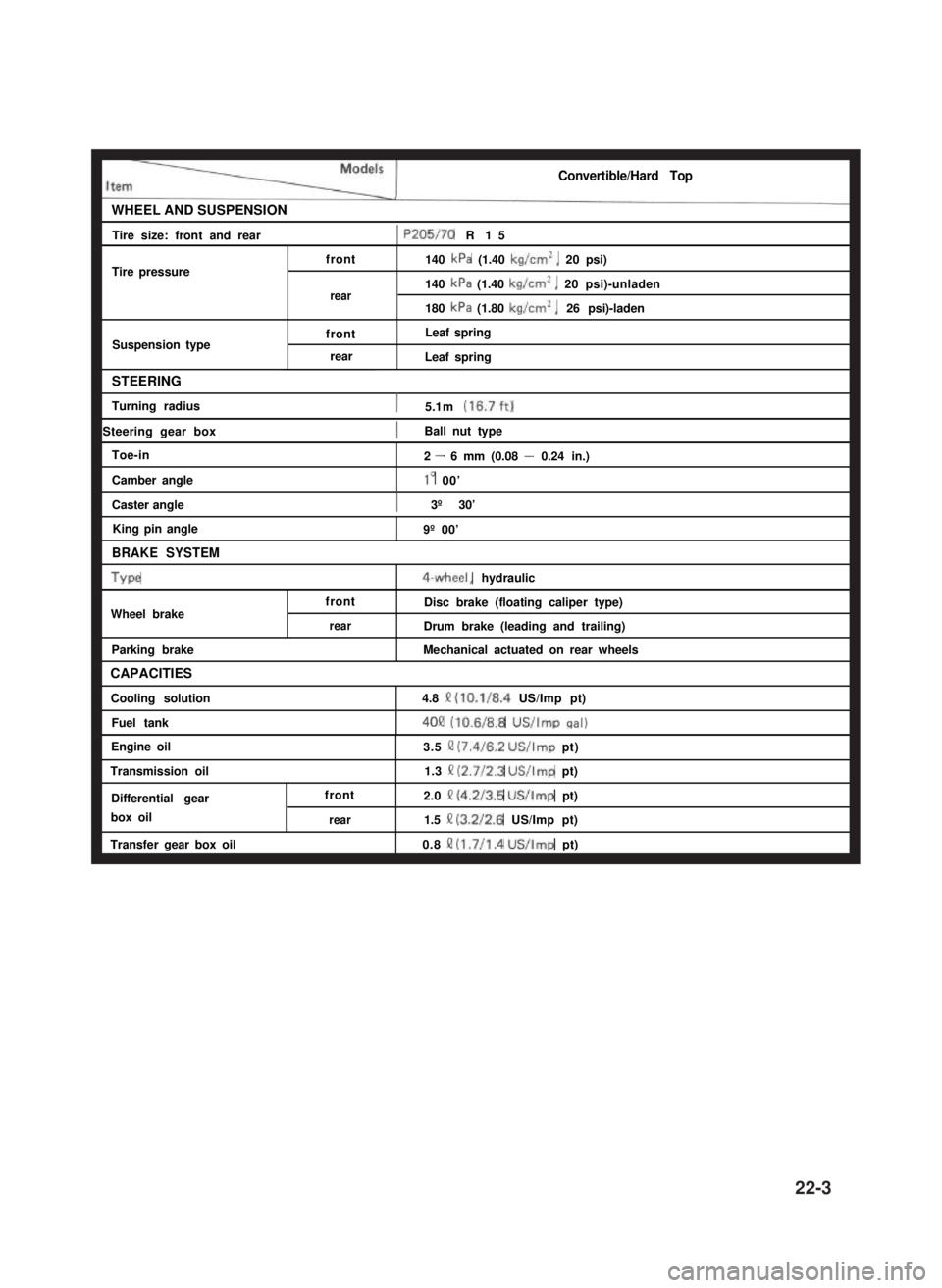

Convertible/Hard Top

WHEEL AND SUSPENSIONI

Tire size: front and rear1 P205/70 R15I

Tire pressurefront

rear

Suspension typefront

rear

140 kPa (1.40 kg/cm’, 20 psi)

140 kPa (1.40 kg/cm’, 20 psi)-unladen

180 kPa (1.80 kg/cm*, 26 psi)-laden

Leaf spring

Leaf spring

STEERING

Turning radius1 5.1 m (16.7ft)

1 Steering gear box1Ball nut typeI

Toe-in

Camber angle

Caster angle

King pin angle

BRAKE SYSTEM

Type

Wheel brake

Parking brake

CAPACITIES

Cooling solution

Fuel tank

2 - 6 mm (0.08 - 0.24 in.)

lo 00’

) 3º 30’I

front

rear

9º 00’

4-wheel, hydraulic

Disc brake (floating caliper type)

Drum brake (leading and trailing)

Mechanical actuated on rear wheels

4.8 Q (10.1/8.4 US/Imp pt)

4OQ (10.6/8.8 US/Imp cral)

Engine oil

Transmission oil

Differential gear

box oil

Transfer gear box oil

front

rear

3.5 II (7.4/6.2 US/Imp pt)

1.3 II (2.7/2.3 US/Imp pt)

2.0 Q (4.2/3.5 US/Imp pt)

1.5 II (3.2/2.6 US/Imp pt)

0.8 !? (1.7/l .4 US/Imp pt)

22-3