SUZUKI GRAND VITARA 1999 2.G Owners Manual

GRAND VITARA 1999 2.G

SUZUKI

SUZUKI

https://www.carmanualsonline.info/img/20/7583/w960_7583-0.png

SUZUKI GRAND VITARA 1999 2.G Owners Manual

Trending: engine oil capacity, oil level, speed, windshield wipers, Temperature, Security, rims

Page 391 of 656

6F2-8 IGNITION SYSTEM (FOR H27 ENGINE)

On-Vehicle Service

Ignition Coil Assembly (Igniter and Ignition

Coil)

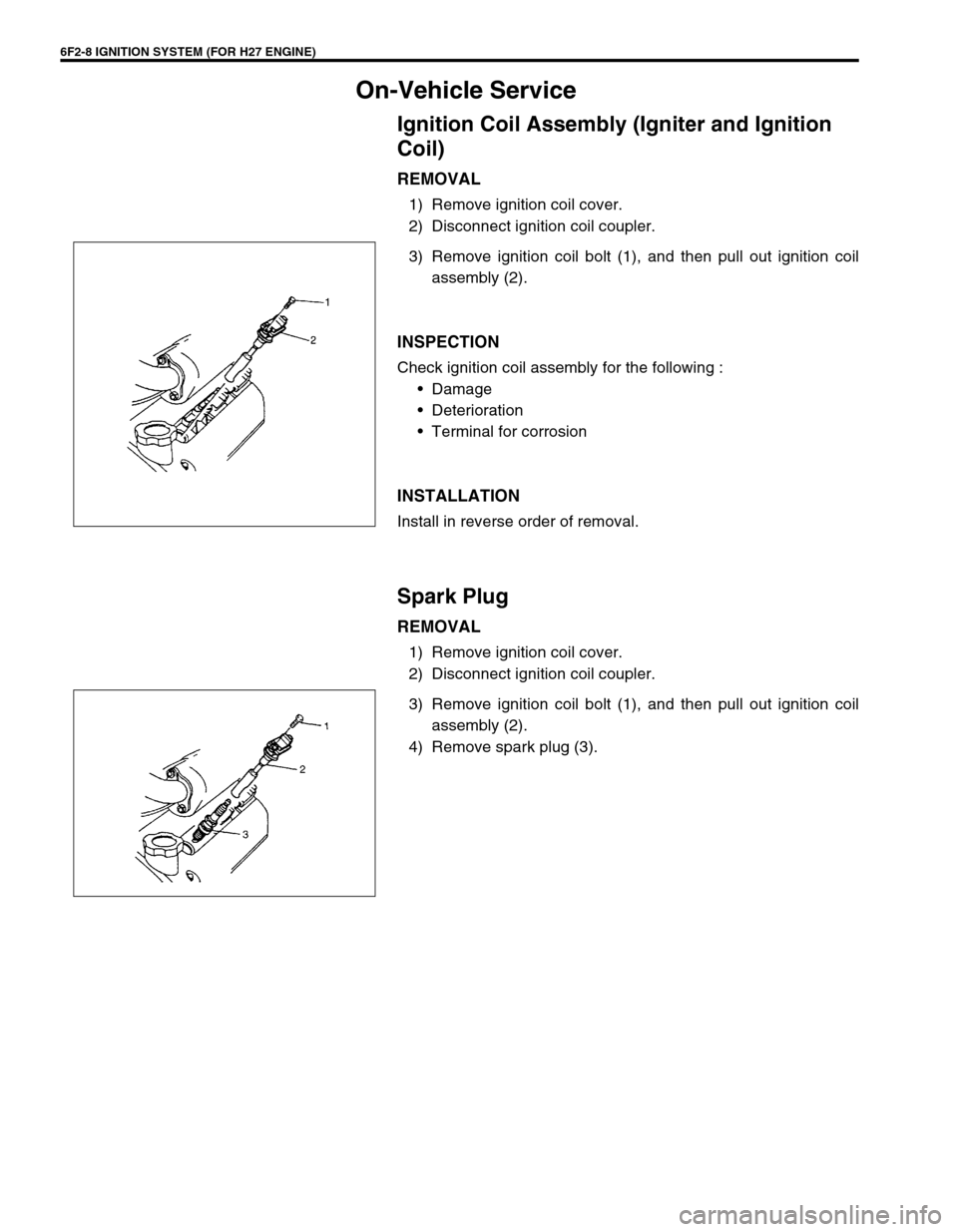

REMOVAL

1) Remove ignition coil cover.

2) Disconnect ignition coil coupler.

3) Remove ignition coil bolt (1), and then pull out ignition coil

assembly (2).

INSPECTION

Check ignition coil assembly for the following :

•Damage

•Deterioration

•Terminal for corrosion

INSTALLATION

Install in reverse order of removal.

Spark Plug

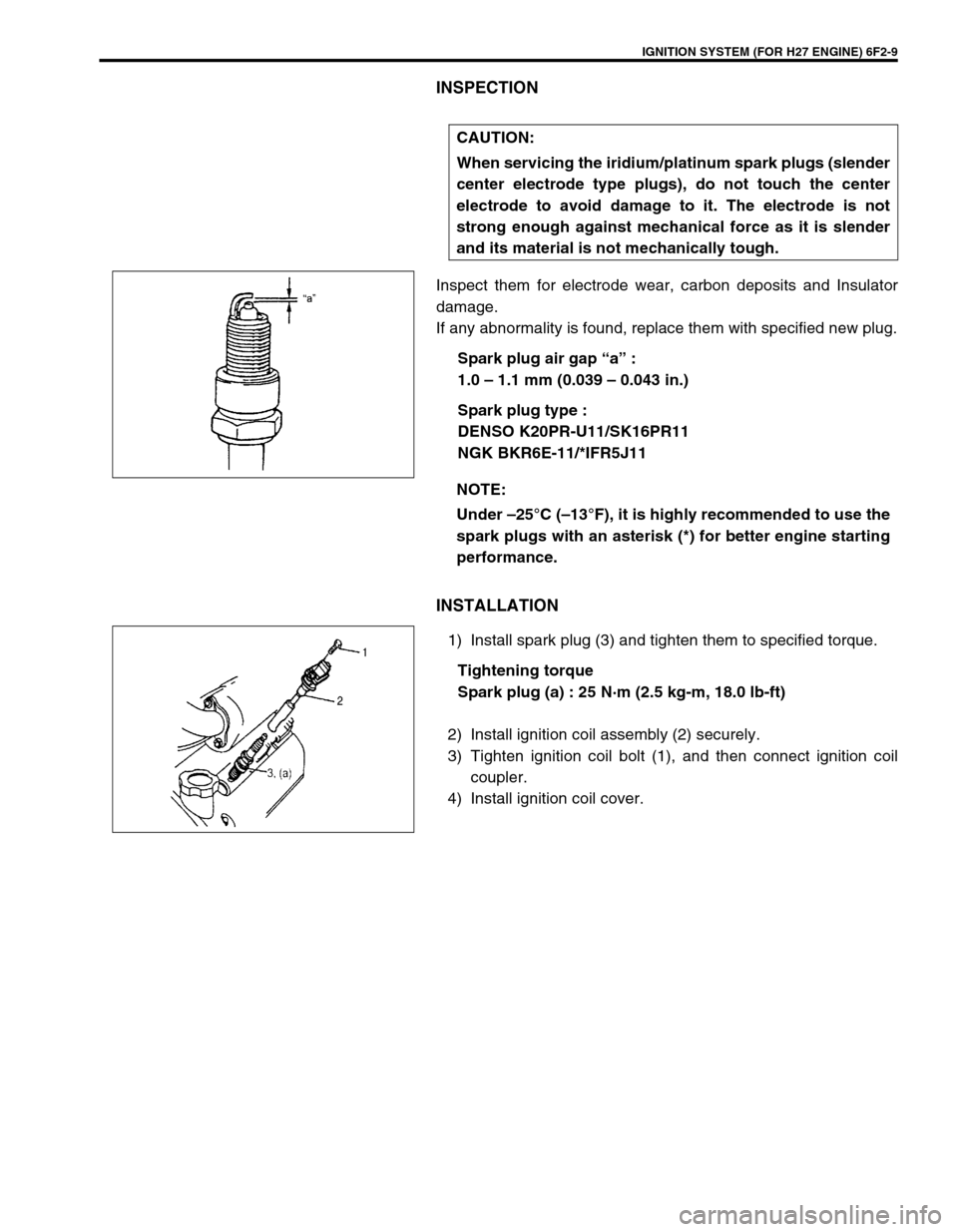

REMOVAL

1) Remove ignition coil cover.

2) Disconnect ignition coil coupler.

3) Remove ignition coil bolt (1), and then pull out ignition coil

assembly (2).

4) Remove spark plug (3).

Page 392 of 656

IGNITION SYSTEM (FOR H27 ENGINE) 6F2-9

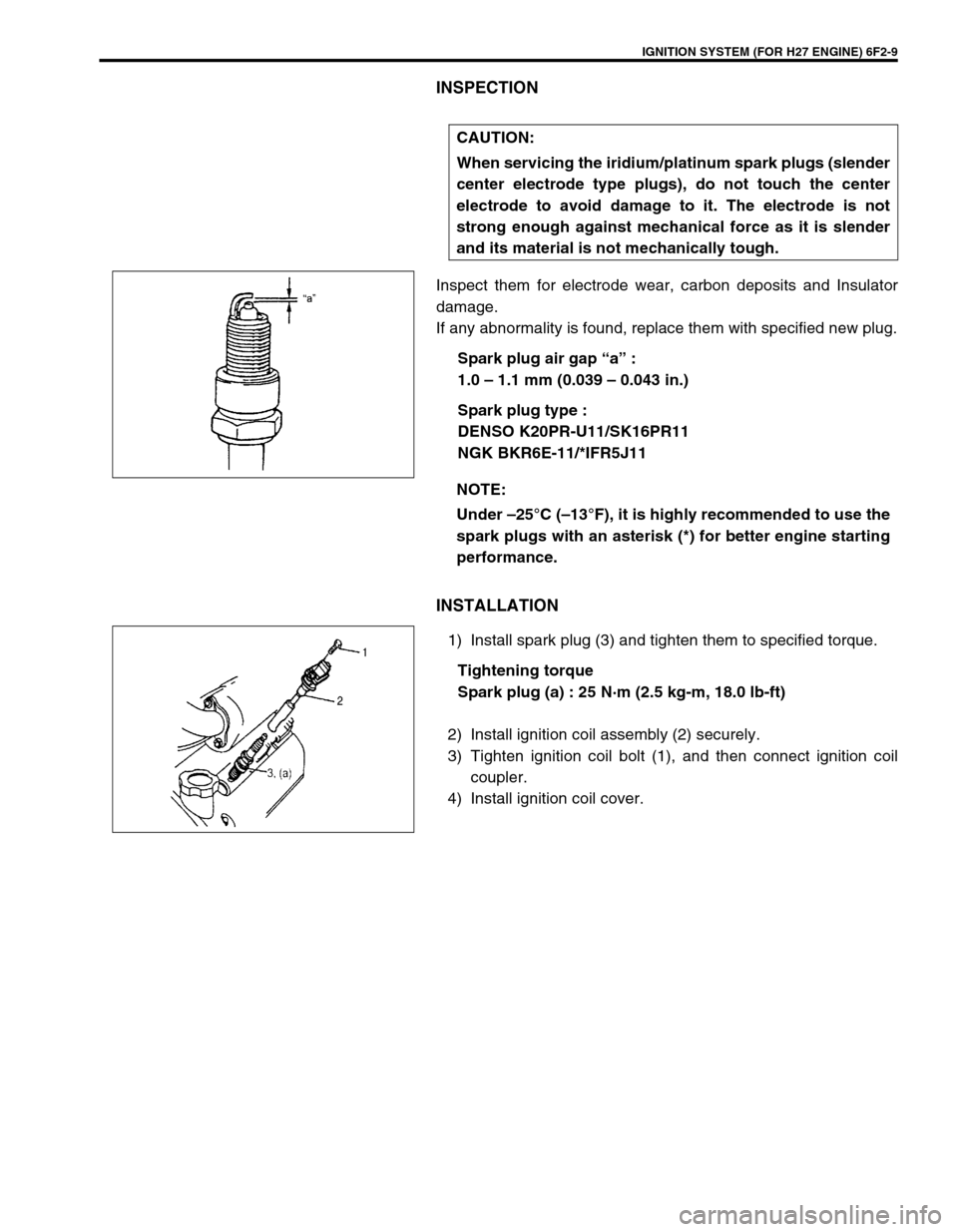

INSPECTION

Inspect them for electrode wear, carbon deposits and Insulator

damage.

If any abnormality is found, replace them with specified new plug.

Spark plug air gap “a” :

1.0 – 1.1 mm (0.039 – 0.043 in.)

Spark plug type :

DENSO K20PR-U11/SK16PR11

NGK BKR6E-11/*IFR5J11

INSTALLATION

1) Install spark plug (3) and tighten them to specified torque.

Tightening torque

Spark plug (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

2) Install ignition coil assembly (2) securely.

3) Tighten ignition coil bolt (1), and then connect ignition coil

coupler.

4) Install ignition coil cover.CAUTION:

When servicing the iridium/platinum spark plugs (slender

center electrode type plugs), do not touch the center

electrode to avoid damage to it. The electrode is not

strong enough against mechanical force as it is slender

and its material is not mechanically tough.

NOTE:

Under –25°C (–13°F), it is highly recommended to use the

spark plugs with an asterisk (*) for better engine starting

performance.

Page 393 of 656

6F2-10 IGNITION SYSTEM (FOR H27 ENGINE)

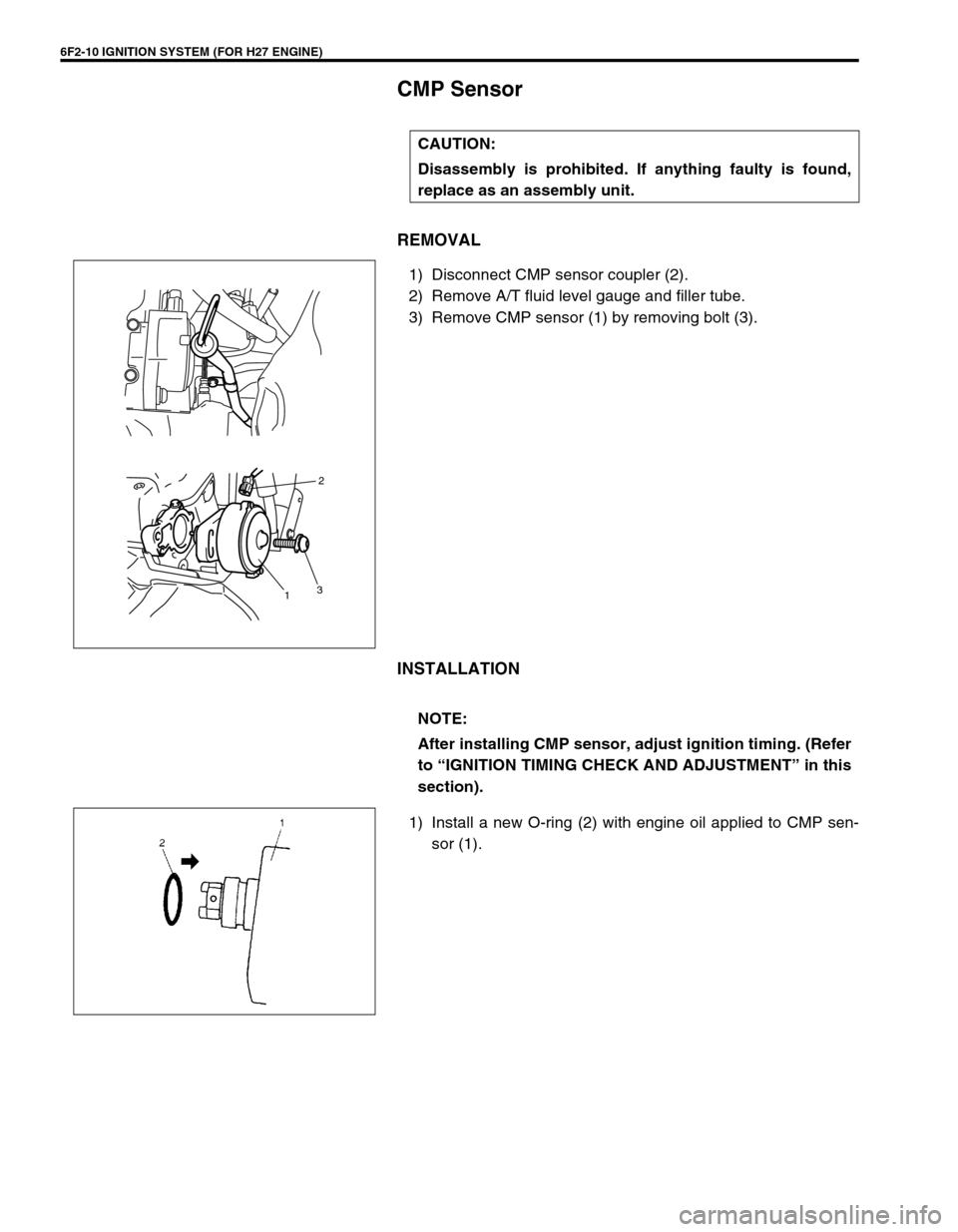

CMP Sensor

REMOVAL

1) Disconnect CMP sensor coupler (2).

2) Remove A/T fluid level gauge and filler tube.

3) Remove CMP sensor (1) by removing bolt (3).

INSTALLATION

1) Install a new O-ring (2) with engine oil applied to CMP sen-

sor (1). CAUTION:

Disassembly is prohibited. If anything faulty is found,

replace as an assembly unit.

2

3

1

NOTE:

After installing CMP sensor, adjust ignition timing. (Refer

to “IGNITION TIMING CHECK AND ADJUSTMENT” in this

section).

Page 394 of 656

IGNITION SYSTEM (FOR H27 ENGINE) 6F2-11

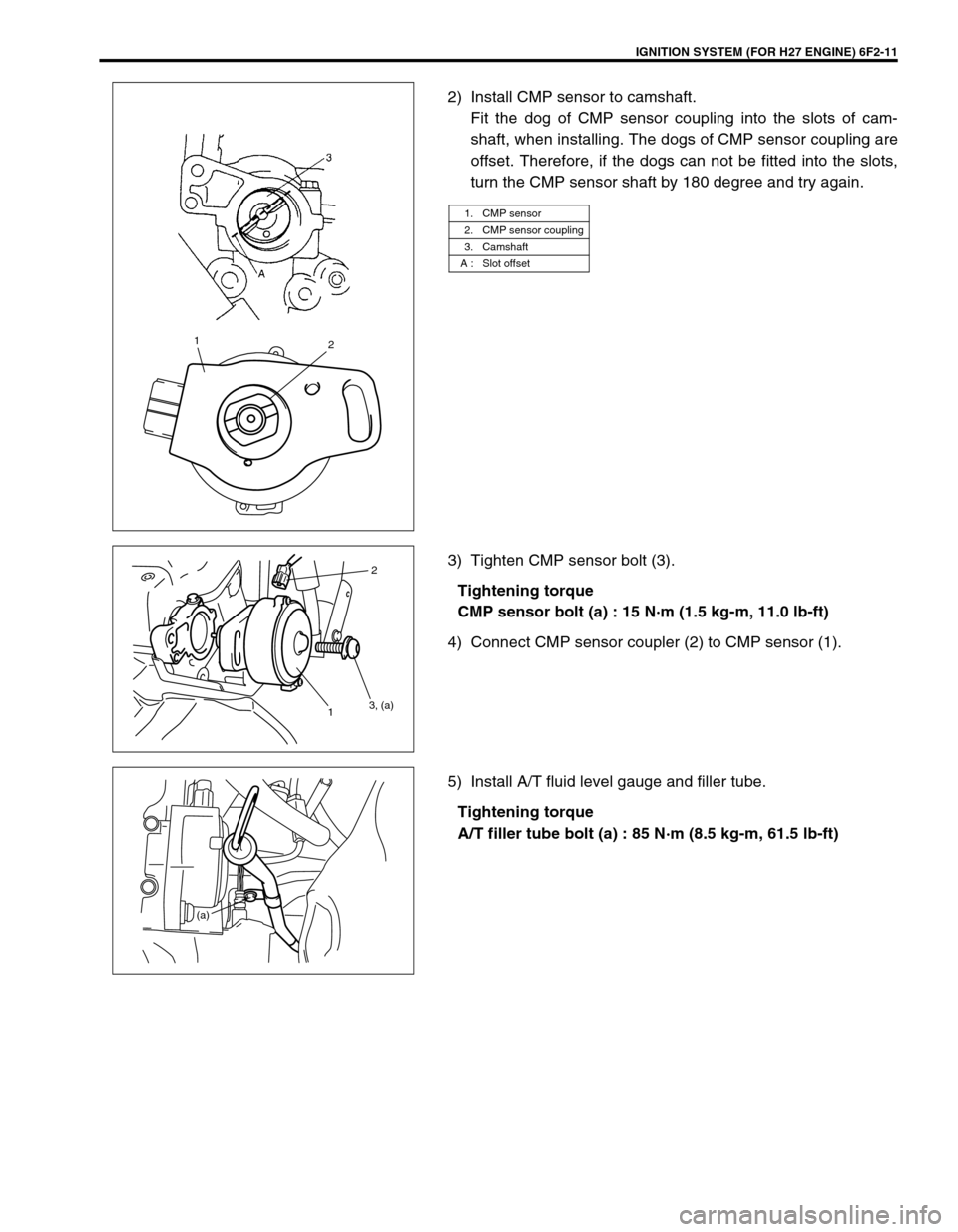

2) Install CMP sensor to camshaft.

Fit the dog of CMP sensor coupling into the slots of cam-

shaft, when installing. The dogs of CMP sensor coupling are

offset. Therefore, if the dogs can not be fitted into the slots,

turn the CMP sensor shaft by 180 degree and try again.

3) Tighten CMP sensor bolt (3).

Tightening torque

CMP sensor bolt (a) : 15 N·m (1.5 kg-m, 11.0 lb-ft)

4) Connect CMP sensor coupler (2) to CMP sensor (1).

5) Install A/T fluid level gauge and filler tube.

Tightening torque

A/T filler tube bolt (a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

1. CMP sensor

2. CMP sensor coupling

3. Camshaft

A : Slot offset

12

2

3, (a)

1

(a)

Page 395 of 656

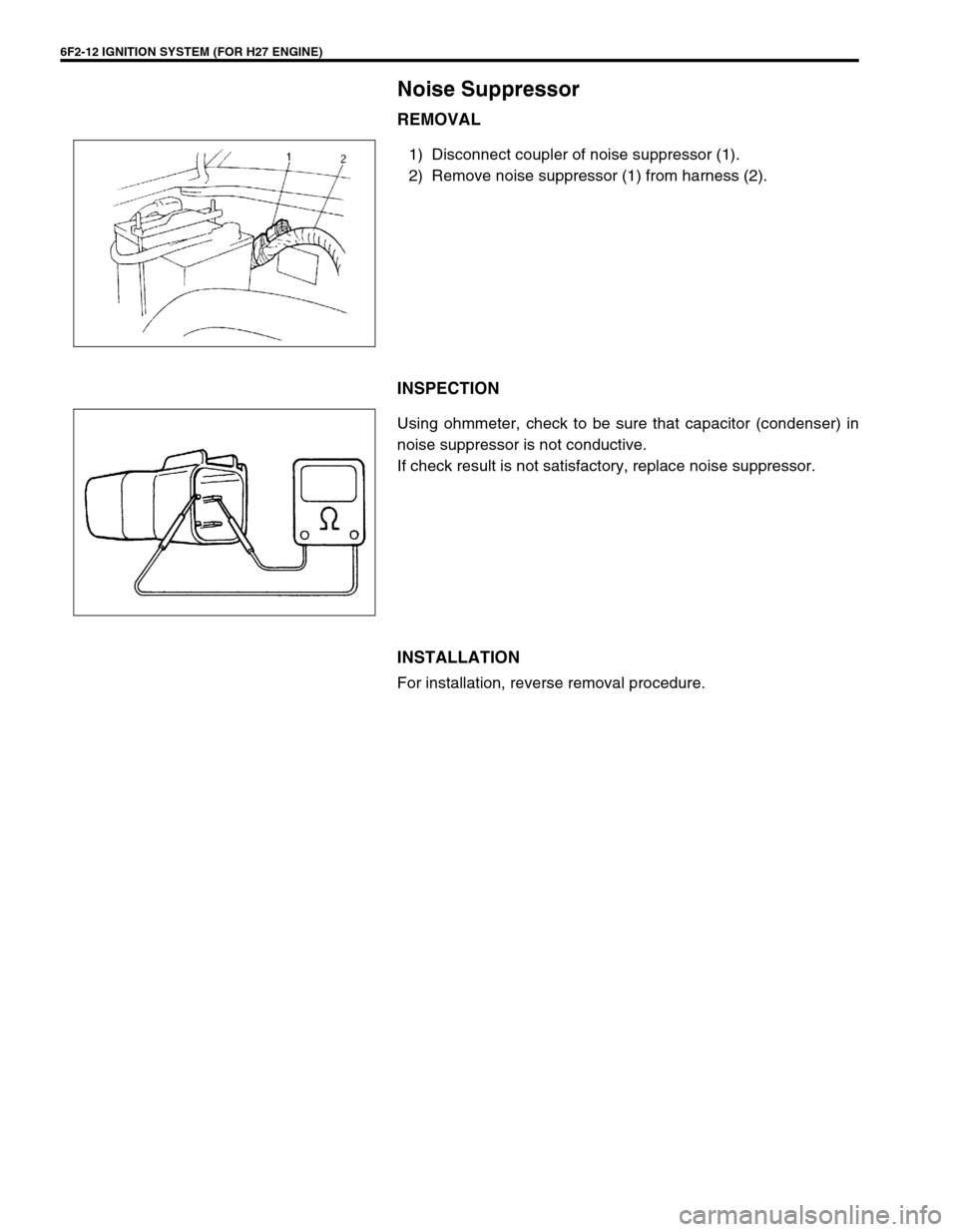

6F2-12 IGNITION SYSTEM (FOR H27 ENGINE)

Noise Suppressor

REMOVAL

1) Disconnect coupler of noise suppressor (1).

2) Remove noise suppressor (1) from harness (2).

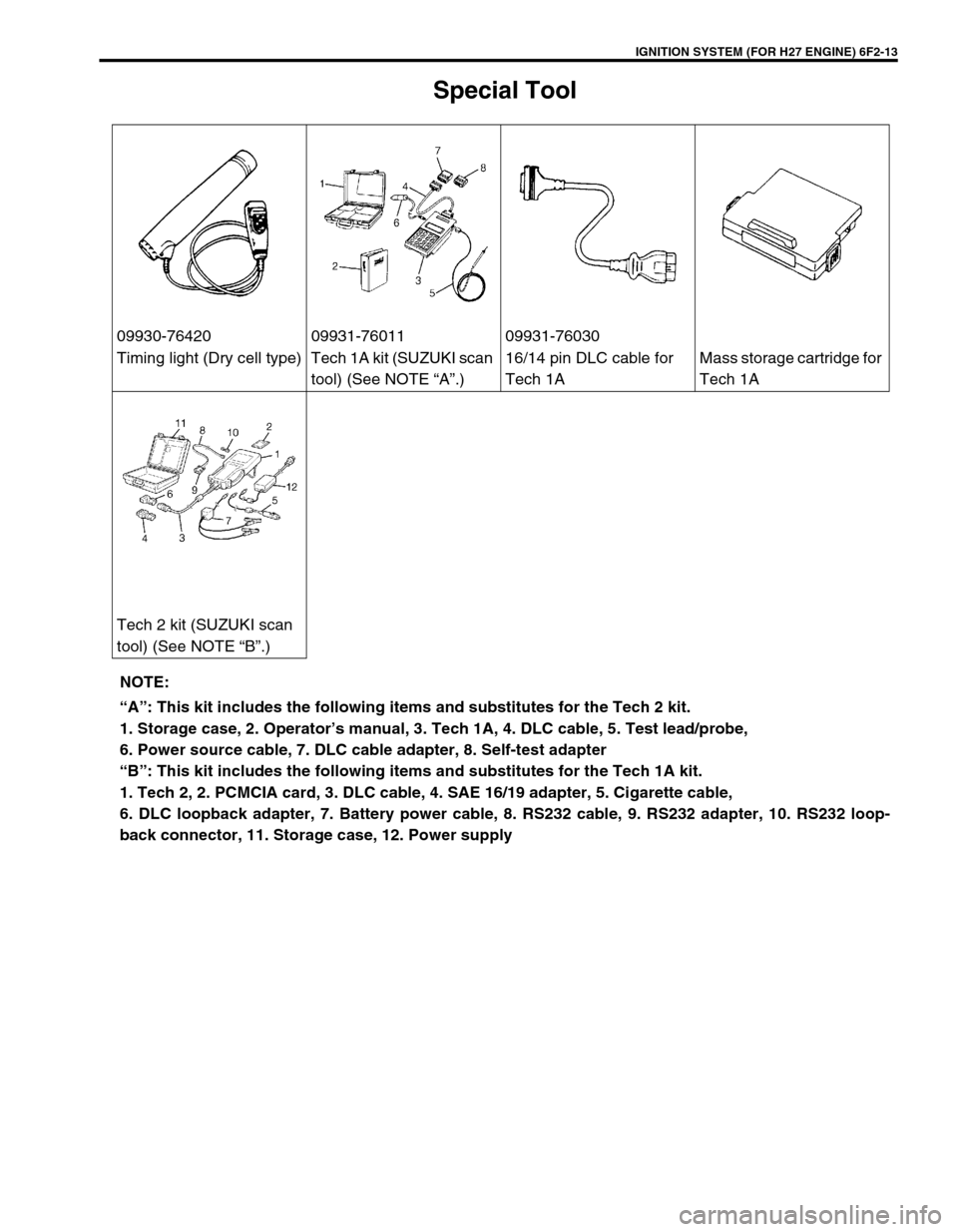

INSPECTION

Using ohmmeter, check to be sure that capacitor (condenser) in

noise suppressor is not conductive.

If check result is not satisfactory, replace noise suppressor.

INSTALLATION

For installation, reverse removal procedure.

Page 396 of 656

IGNITION SYSTEM (FOR H27 ENGINE) 6F2-13

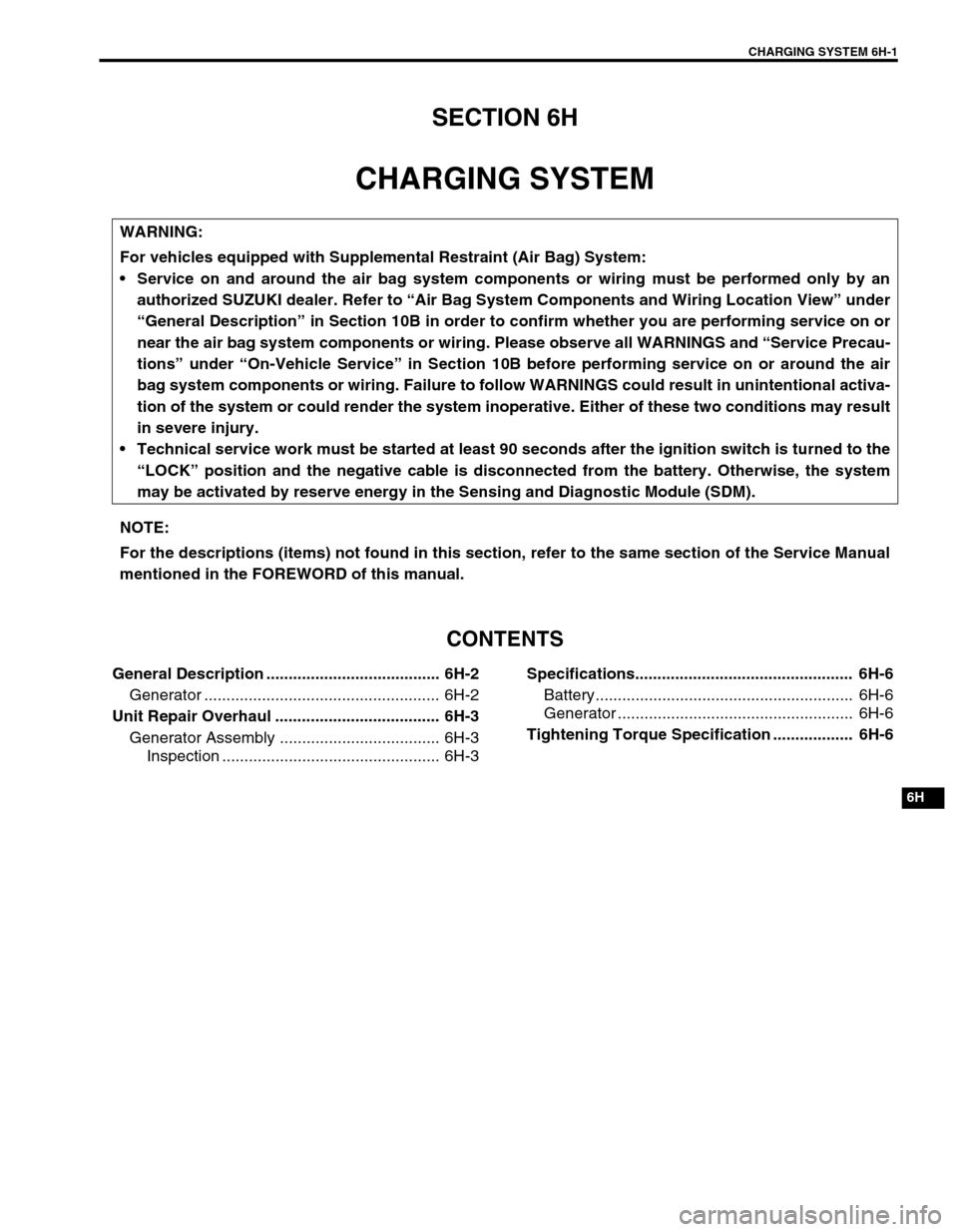

Special Tool

09930-76420 09931-76011 09931-76030

Timing light (Dry cell type) Tech 1A kit (SUZUKI scan

tool) (See NOTE “A”.)16/14 pin DLC cable for

Tech 1AMass storage cartridge for

Tech 1A

Tech 2 kit (SUZUKI scan

tool) (See NOTE “B”.)

NOTE:

“A”: This kit includes the following items and substitutes for the Tech 2 kit.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable, 5. Test lead/probe,

6. Power source cable, 7. DLC cable adapter, 8. Self-test adapter

“B”: This kit includes the following items and substitutes for the Tech 1A kit.

1. Tech 2, 2. PCMCIA card, 3. DLC cable, 4. SAE 16/19 adapter, 5. Cigarette cable,

6. DLC loopback adapter, 7. Battery power cable, 8. RS232 cable, 9. RS232 adapter, 10. RS232 loop-

back connector, 11. Storage case, 12. Power supply

Page 397 of 656

6F2-14 IGNITION SYSTEM (FOR H27 ENGINE)

Page 398 of 656

CHARGING SYSTEM 6H-1

6H

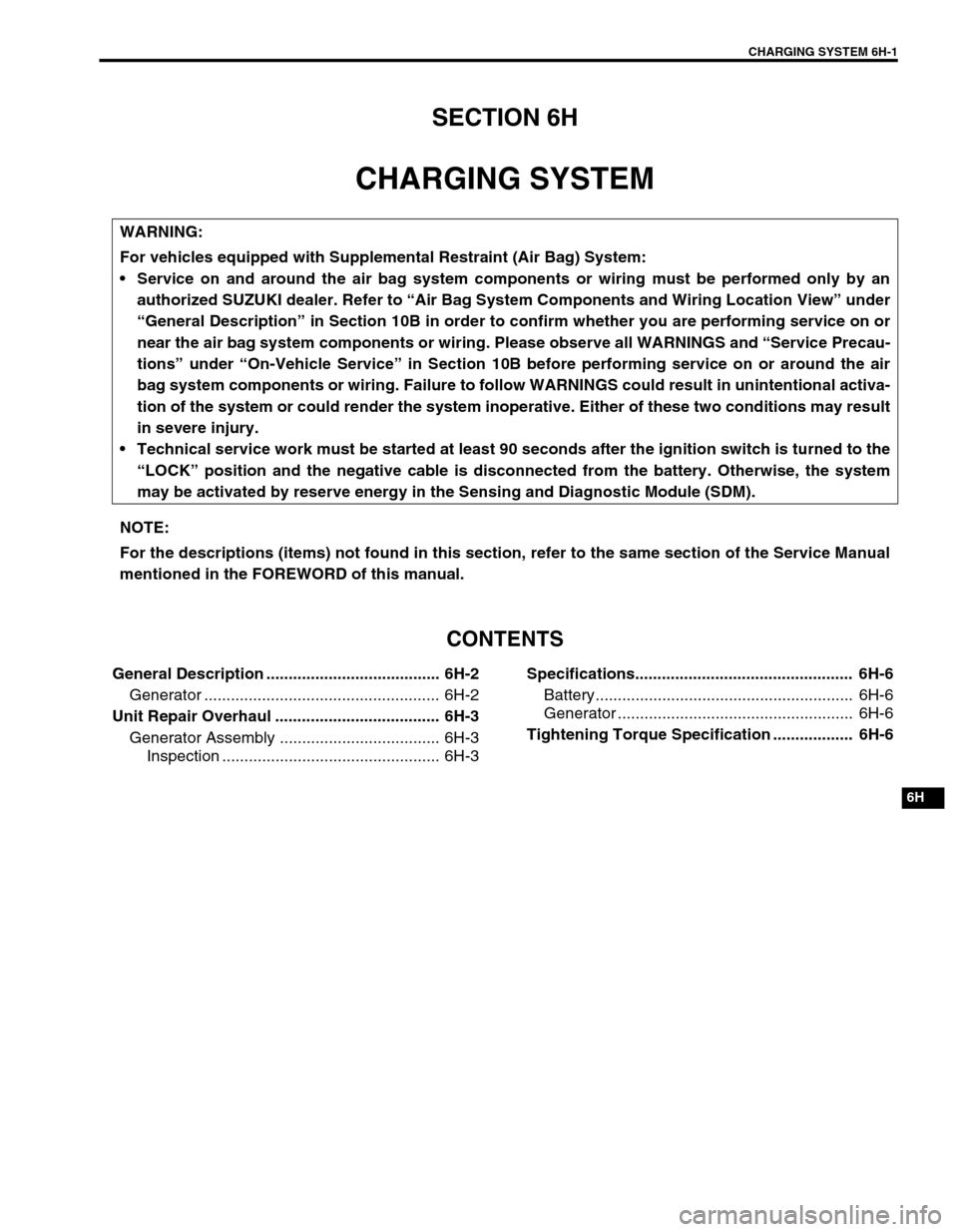

SECTION 6H

CHARGING SYSTEM

CONTENTS

General Description ....................................... 6H-2

Generator ..................................................... 6H-2

Unit Repair Overhaul ..................................... 6H-3

Generator Assembly .................................... 6H-3

Inspection ................................................. 6H-3Specifications................................................. 6H-6

Battery.......................................................... 6H-6

Generator ..................................................... 6H-6

Tightening Torque Specification .................. 6H-6

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in Section 10B in order to confirm whether you are performing service on or

near the air bag system components or wiring. Please observe all WARNINGS and “Service Precau-

tions” under “On-Vehicle Service” in Section 10B before performing service on or around the air

bag system components or wiring. Failure to follow WARNINGS could result in unintentional activa-

tion of the system or could render the system inoperative. Either of these two conditions may result

in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in the FOREWORD of this manual.

Page 399 of 656

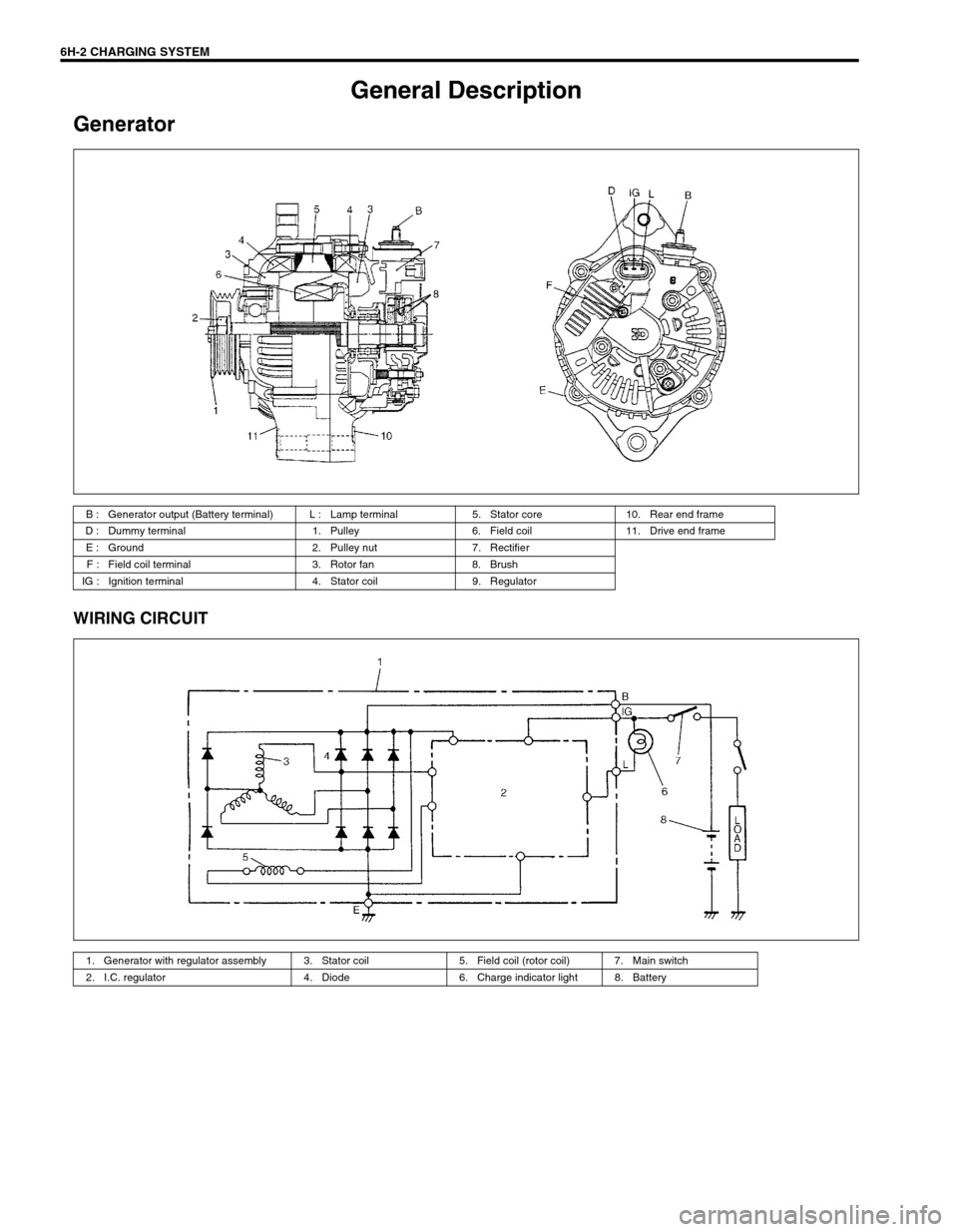

6H-2 CHARGING SYSTEM

General Description

Generator

WIRING CIRCUIT

B : Generator output (Battery terminal) L : Lamp terminal 5. Stator core 10. Rear end frame

D : Dummy terminal 1. Pulley 6. Field coil 11. Drive end frame

E : Ground 2. Pulley nut 7. Rectifier

F : Field coil terminal 3. Rotor fan 8. Brush

IG : Ignition terminal 4. Stator coil 9. Regulator

1. Generator with regulator assembly 3. Stator coil 5. Field coil (rotor coil) 7. Main switch

2. I.C. regulator 4. Diode 6. Charge indicator light 8. Battery

Page 400 of 656

CHARGING SYSTEM 6H-3

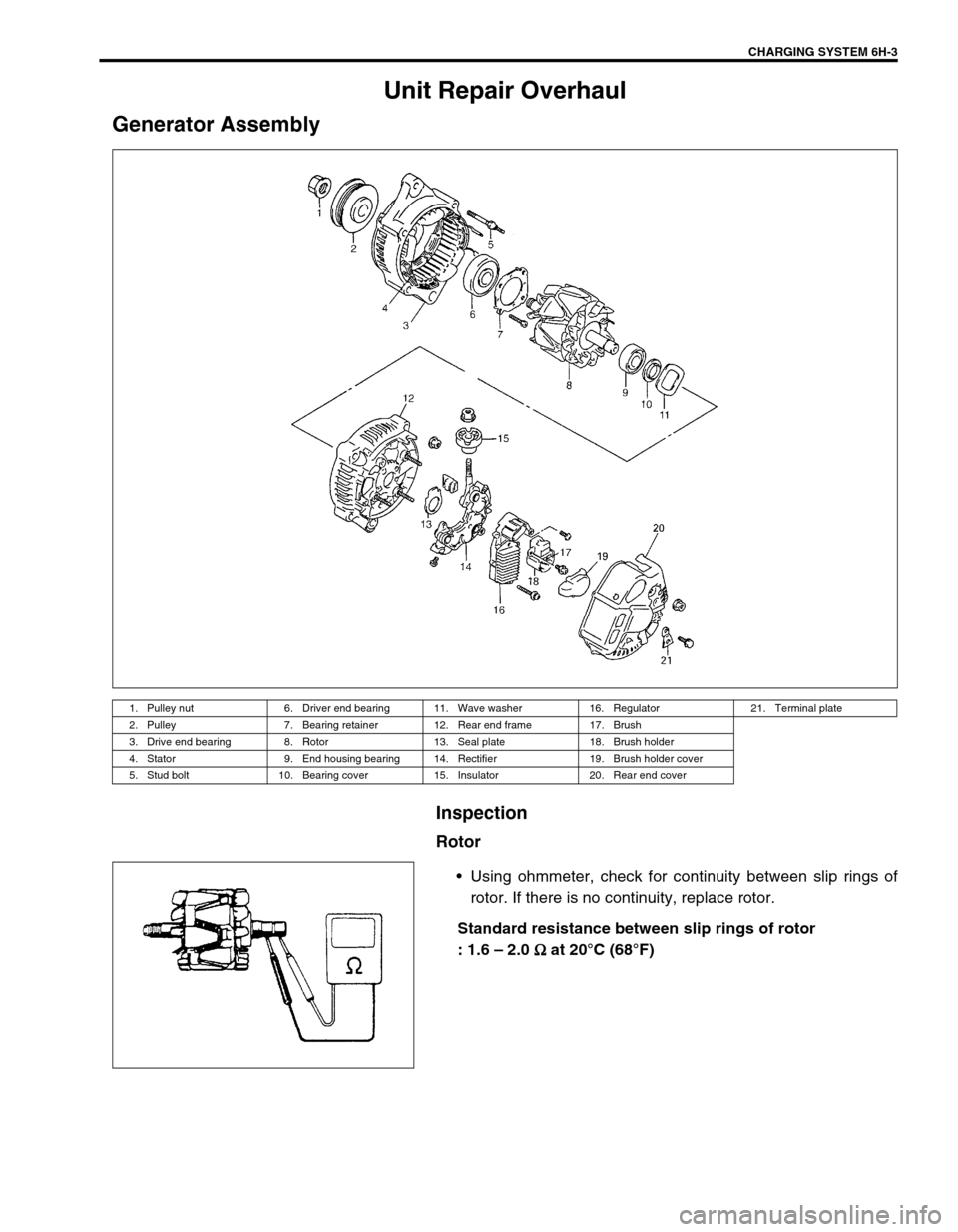

Unit Repair Overhaul

Generator Assembly

Inspection

Rotor

•Using ohmmeter, check for continuity between slip rings of

rotor. If there is no continuity, replace rotor.

Standard resistance between slip rings of rotor

: 1.6 – 2.0 Ω

ΩΩ Ω at 20°C (68°F)

1. Pulley nut 6. Driver end bearing 11. Wave washer 16. Regulator 21. Terminal plate

2. Pulley 7. Bearing retainer 12. Rear end frame 17. Brush

3. Drive end bearing 8. Rotor 13. Seal plate 18. Brush holder

4. Stator 9. End housing bearing 14. Rectifier 19. Brush holder cover

5. Stud bolt 10. Bearing cover 15. Insulator 20. Rear end cover

Trending: window switch, front, air filter, reset, heater, engine, Pcm