SUZUKI GRAND VITARA 1999 2.G Owners Manual

Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 411 of 656

7B1-2 AUTOMATIC TRANSMISSION (4 A/T)

Stall Test ................................................... 7B1-38

Line Pressure Test .................................... 7B1-39

Road Test ................................................. 7B1-40

Manual Road Test..................................... 7B1-41

Time Lag Test ........................................... 7B1-41

Engine Brake Test .................................... 7B1-42

“P” Range Test.......................................... 7B1-42

On-Vehicle Service ..................................... 7B1-43

Maintenance Service ................................ 7B1-43

Fluid level .............................................. 7B1-43

Fluid change.......................................... 7B1-44

A/T Throttle Cable ..................................... 7B1-45Solenoid Valves (Shift Solenoid Valves

and TCC Solenoid Valve) ......................... 7B1-45

MANUAL SELECTOR ASSEMBLY .......... 7B1-46

SELECT CABLE ....................................... 7B1-48

Unit Repair .................................................. 7B1-49

Sub-Assembly Repair ............................... 7B1-49

Overdrive (case side) ............................ 7B1-49

Forward clutch ...................................... 7B1-50

Front upper valve body ......................... 7B1-54

Unit Assembly ........................................... 7B1-59

Tightening Torque Specification............... 7B1-60

Special Tool ................................................ 7B1-61

Page 412 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-3

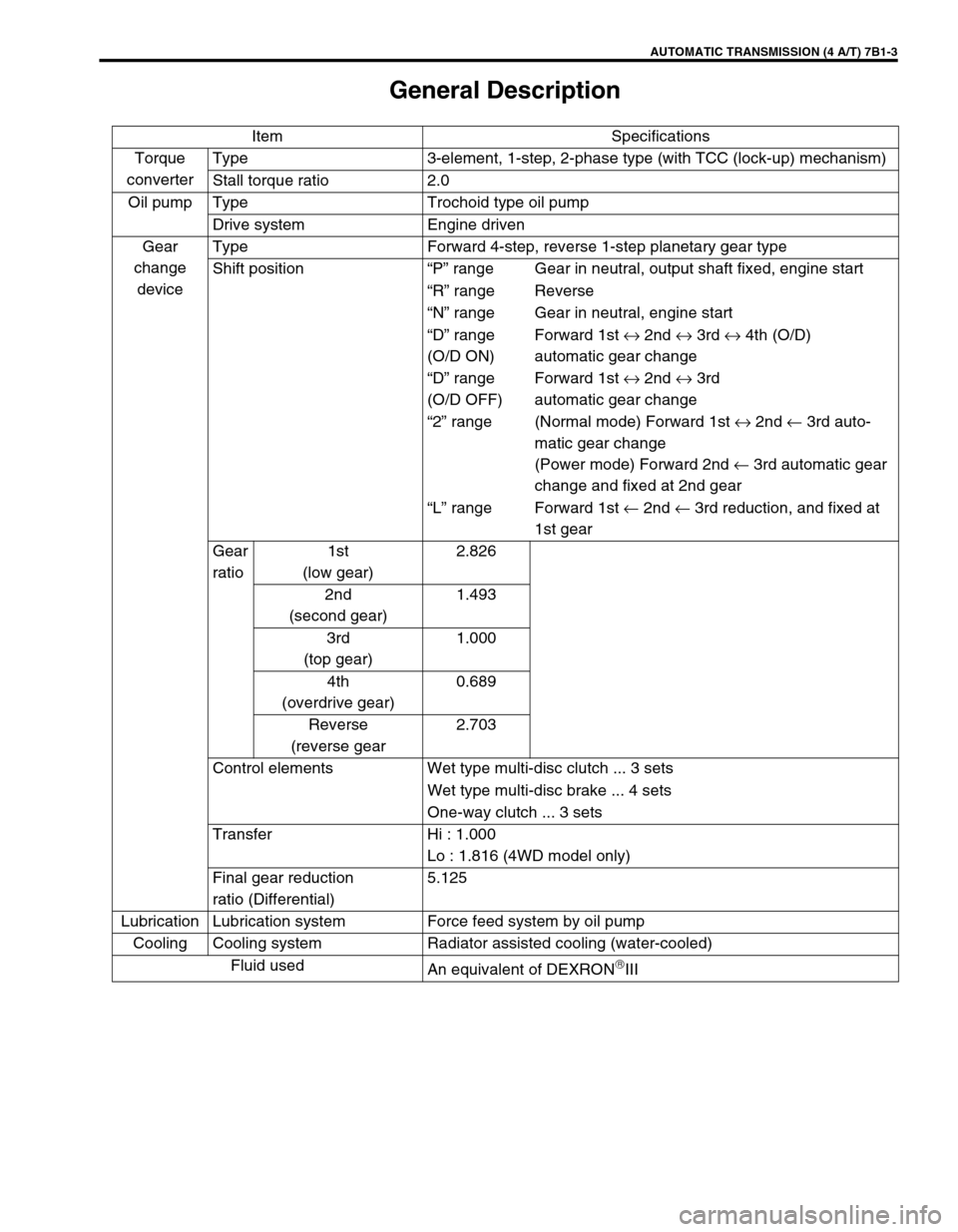

General Description

Item Specifications

Torque

converterType 3-element, 1-step, 2-phase type (with TCC (lock-up) mechanism)

Stall torque ratio 2.0

Oil pump Type Trochoid type oil pump

Drive system Engine driven

Gear

change

deviceType Forward 4-step, reverse 1-step planetary gear type

Shift position“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

(O/D ON)Forward 1st ↔ 2nd ↔ 3rd ↔ 4th (O/D)

automatic gear change

“D” range

(O/D OFF)Forward 1st ↔ 2nd ↔ 3rd

automatic gear change

“2” range (Normal mode) Forward 1st ↔ 2nd ← 3rd auto-

matic gear change

(Power mode) Forward 2nd ← 3rd automatic gear

change and fixed at 2nd gear

“L” range Forward 1st ← 2nd ← 3rd reduction, and fixed at

1st gear

Gear

ratio1st

(low gear)2.826

2nd

(second gear)1.493

3rd

(top gear)1.000

4th

(overdrive gear)0.689

Reverse

(reverse gear2.703

Control elements Wet type multi-disc clutch ... 3 sets

Wet type multi-disc brake ... 4 sets

One-way clutch ... 3 sets

Transfer Hi : 1.000

Lo : 1.816 (4WD model only)

Final gear reduction

ratio (Differential)5.125

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used

An equivalent of DEXRON

III

Page 413 of 656

7B1-4 AUTOMATIC TRANSMISSION (4 A/T)

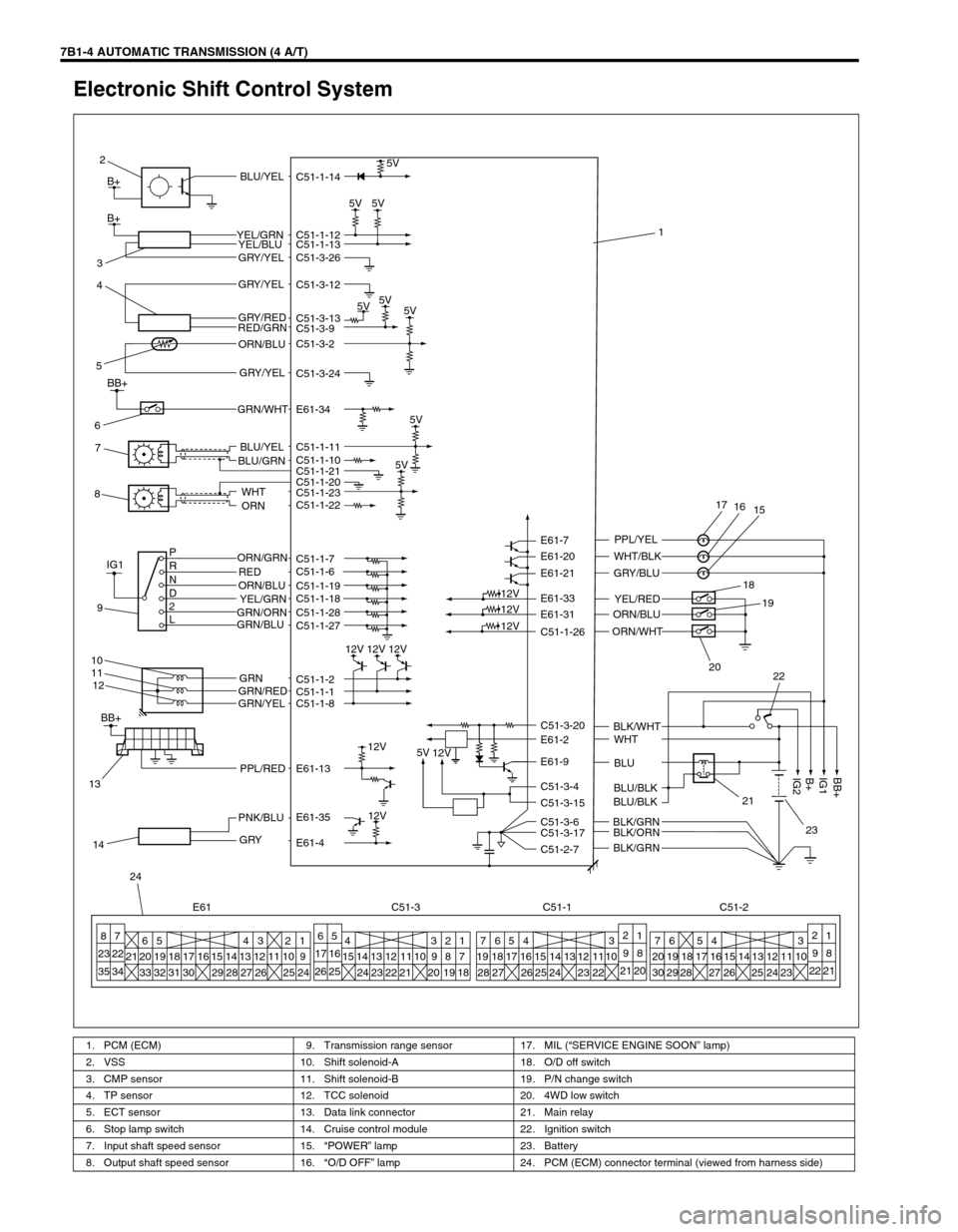

Electronic Shift Control System

1. PCM (ECM) 9. Transmission range sensor 17. MIL (“SERVICE ENGINE SOON” lamp)

2. VSS 10. Shift solenoid-A 18. O/D off switch

3. CMP sensor 11. Shift solenoid-B 19. P/N change switch

4. TP sensor 12. TCC solenoid 20. 4WD low switch

5. ECT sensor 13. Data link connector 21. Main relay

6. Stop lamp switch 14. Cruise control module 22. Ignition switch

7. Input shaft speed sensor 15.“POWER” lamp 23. Battery

8. Output shaft speed sensor 16.“O/D OFF” lamp 24. PCM (ECM) connector terminal (viewed from harness side)

5V

5V5V

5V5V

5V

5V 5V C51-1-14

C51-1-12

C51-1-13

C51-3-26

C51-3-12

C51-3-13

C51-3-9

C51-3-2

C51-3-24

C51-1-11

C51-1-10

C51-1-20 C51-1-21

C51-1-23

C51-1-22

C51-1-7

C51-1-6

C51-1-19

C51-1-18

C51-1-28

C51-1-27

C51-1-2

C51-1-1

C51-1-8

E61-13

E61-35

E61-4C51-1-26 E61-31 E61-33 E61-21 E61-20 E61-7

C51-3-20

E61-2

E61-9

C51-3-4

C51-3-15

C51-3-6

C51-3-17

C51-2-7

12V

12V 12V 12V

12V

12V

12V

12V

5V

12V

BLU/YEL

YEL/GRN

YEL/BLU

GRY/YEL

GRY/YEL

GRY/RED

RED/GRN

ORN/BLU

GRY/YEL

BLU/YEL

BLU/GRN

WHT

ORN

ORN/GRN

RED P

R

N

D

2

LORN/BLU

YEL/GRN

GRN/ORN

GRN/BLU

GRN

GRN/RED

GRN/YEL

PPL/RED

PNK/BLU

GRY

PPL/YEL

WHT/BLK

GRY/BLU

YEL/RED

ORN/BLU

WHT

BLU

BLU/BLK

BLU/BLK

BLK/GRN

BLK/ORN

BLK/GRNBLK/WHT ORN/WHT

8

7

23 22

35 346

20 21

335

19

3218

3117

3016 15

2914

284

13

273

12

26112

10

256

5

17 16

26 252

1

98

21 202

1

98

22 21 1

9

247

20

306

19

2918

27 17

2816 15

2614

25 5

13 4

12

24113

10

23 7

19

28654 3

18

2717 16

2615 14

2513

2412

2311

2210 4

15 14

2413

2312

2211 10 9 8 7

213

202

191

18

24

E61 C51-3 C51-1 C51-2 14

13

B+

B+

17

16

15

18

19

20

22

21

23

BB+

IG1

B+

IG2

1 2

3

4

5

7 6

8

IG1

9

10

11

12

BB+

E61-34 GRN/WHT

BB+

Page 414 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-5

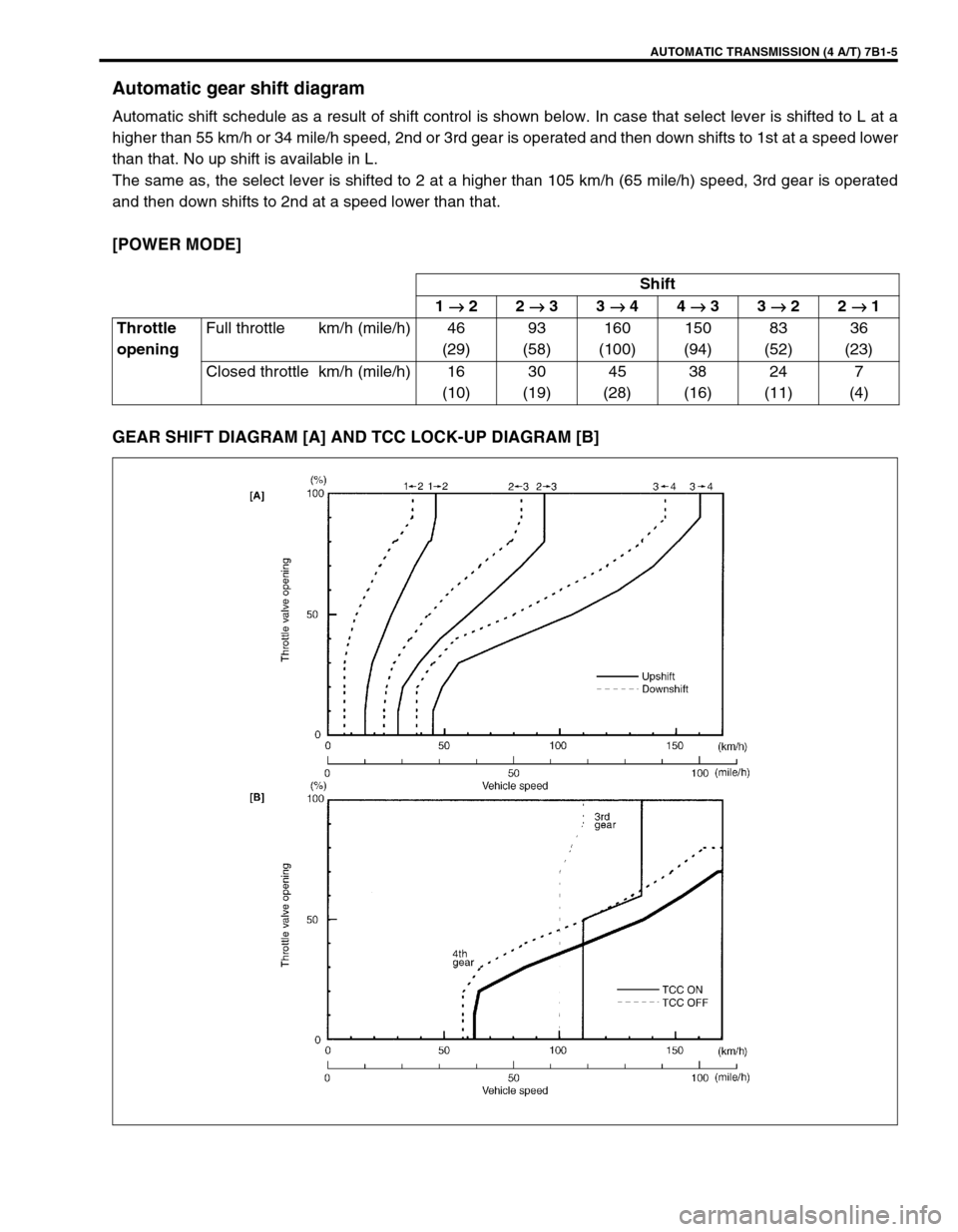

Automatic gear shift diagram

Automatic shift schedule as a result of shift control is shown below. In case that select lever is shifted to L at a

higher than 55 km/h or 34 mile/h speed, 2nd or 3rd gear is operated and then down shifts to 1st at a speed lower

than that. No up shift is available in L.

The same as, the select lever is shifted to 2 at a higher than 105 km/h (65 mile/h) speed, 3rd gear is operated

and then down shifts to 2nd at a speed lower than that.

[POWER MODE]

GEAR SHIFT DIAGRAM [A] AND TCC LOCK-UP DIAGRAM [B]

Shift

1 →

→→ → 22 →

→→ → 33 →

→→ → 44 →

→→ → 33 →

→→ → 22 →

→→ → 1

Throttle

openingFull throttle km/h (mile/h) 46

(29)93

(58)160

(100)150

(94)83

(52)36

(23)

Closed throttle km/h (mile/h) 16

(10)30

(19)45

(28)38

(16)24

(11)7

(4)

Page 415 of 656

![SUZUKI GRAND VITARA 1999 2.G Owners Manual 7B1-6 AUTOMATIC TRANSMISSION (4 A/T)

[NORMAL MODE]

GEAR SHIFT DIAGRAM [A] AND TCC LOCK-UP DIAGRAM [B]

Shift

1 →

→→ → 22 →

→→ → 33 →

→→ → 44 →

→→ → 33 →

→→ → 22 SUZUKI GRAND VITARA 1999 2.G Owners Manual 7B1-6 AUTOMATIC TRANSMISSION (4 A/T)

[NORMAL MODE]

GEAR SHIFT DIAGRAM [A] AND TCC LOCK-UP DIAGRAM [B]

Shift

1 →

→→ → 22 →

→→ → 33 →

→→ → 44 →

→→ → 33 →

→→ → 22](/img/20/7583/w960_7583-414.png)

7B1-6 AUTOMATIC TRANSMISSION (4 A/T)

[NORMAL MODE]

GEAR SHIFT DIAGRAM [A] AND TCC LOCK-UP DIAGRAM [B]

Shift

1 →

→→ → 22 →

→→ → 33 →

→→ → 44 →

→→ → 33 →

→→ → 22 →

→→ → 1

Throttle

openingFull throttle km/h (mile/h) 46

(29)93

(58)160

(100)150

(94)83

(52)36

(23)

Closed throttle km/h (mile/h) 11

(7)27

(17)40

(25)35

(22)21

(13)7

(4)

Page 416 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-7

Diagnosis

This vehicle is equipped with an electronic transmission control system, which control the automatic shift up and

shift down timing, TCC operation, etc. suitably to vehicle driving conditions.

PCM (ECM) has an On-Board Diagnosis system which detects a malfunction in this system and abnormality of

those parts that influence the engine exhaust emission.

When diagnosing a trouble in the transmission including this system, be sure to have full understanding of the

outline of “ON-BOARD DIAGNOSTIC SYSTEM” and each item in “PRECAUTION IN DIAGNOSING TROUBLE”

and execute diagnosis according to “AUTOMATIC TRANSMISSION DIAGNOSTIC FLOW TABLE” to obtain

correct result smoothly.

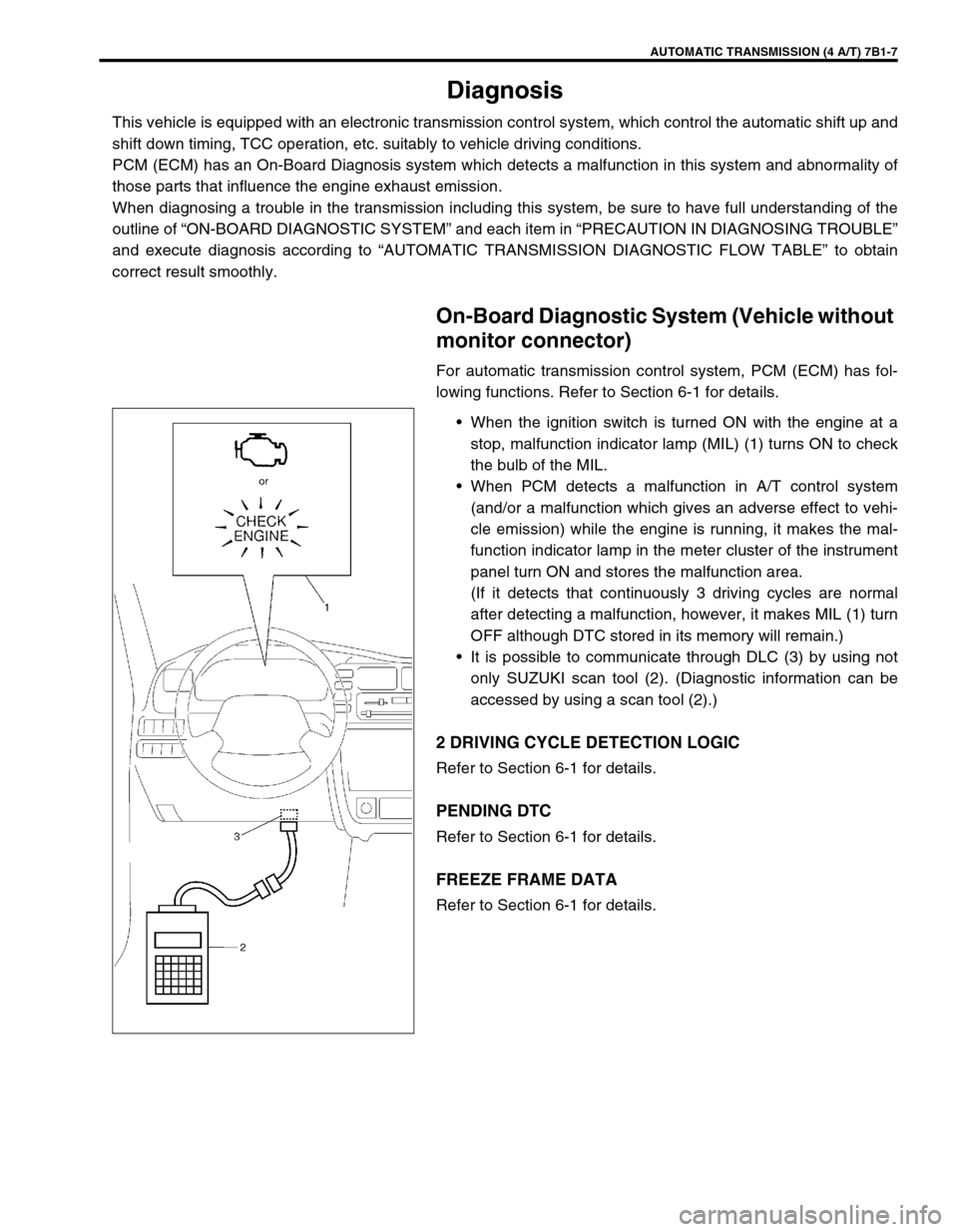

On-Board Diagnostic System (Vehicle without

monitor connector)

For automatic transmission control system, PCM (ECM) has fol-

lowing functions. Refer to Section 6-1 for details.

•When the ignition switch is turned ON with the engine at a

stop, malfunction indicator lamp (MIL) (1) turns ON to check

the bulb of the MIL.

•When PCM detects a malfunction in A/T control system

(and/or a malfunction which gives an adverse effect to vehi-

cle emission) while the engine is running, it makes the mal-

function indicator lamp in the meter cluster of the instrument

panel turn ON and stores the malfunction area.

(If it detects that continuously 3 driving cycles are normal

after detecting a malfunction, however, it makes MIL (1) turn

OFF although DTC stored in its memory will remain.)

•It is possible to communicate through DLC (3) by using not

only SUZUKI scan tool (2). (Diagnostic information can be

accessed by using a scan tool (2).)

2 DRIVING CYCLE DETECTION LOGIC

Refer to Section 6-1 for details.

PENDING DTC

Refer to Section 6-1 for details.

FREEZE FRAME DATA

Refer to Section 6-1 for details.

Page 417 of 656

7B1-8 AUTOMATIC TRANSMISSION (4 A/T)

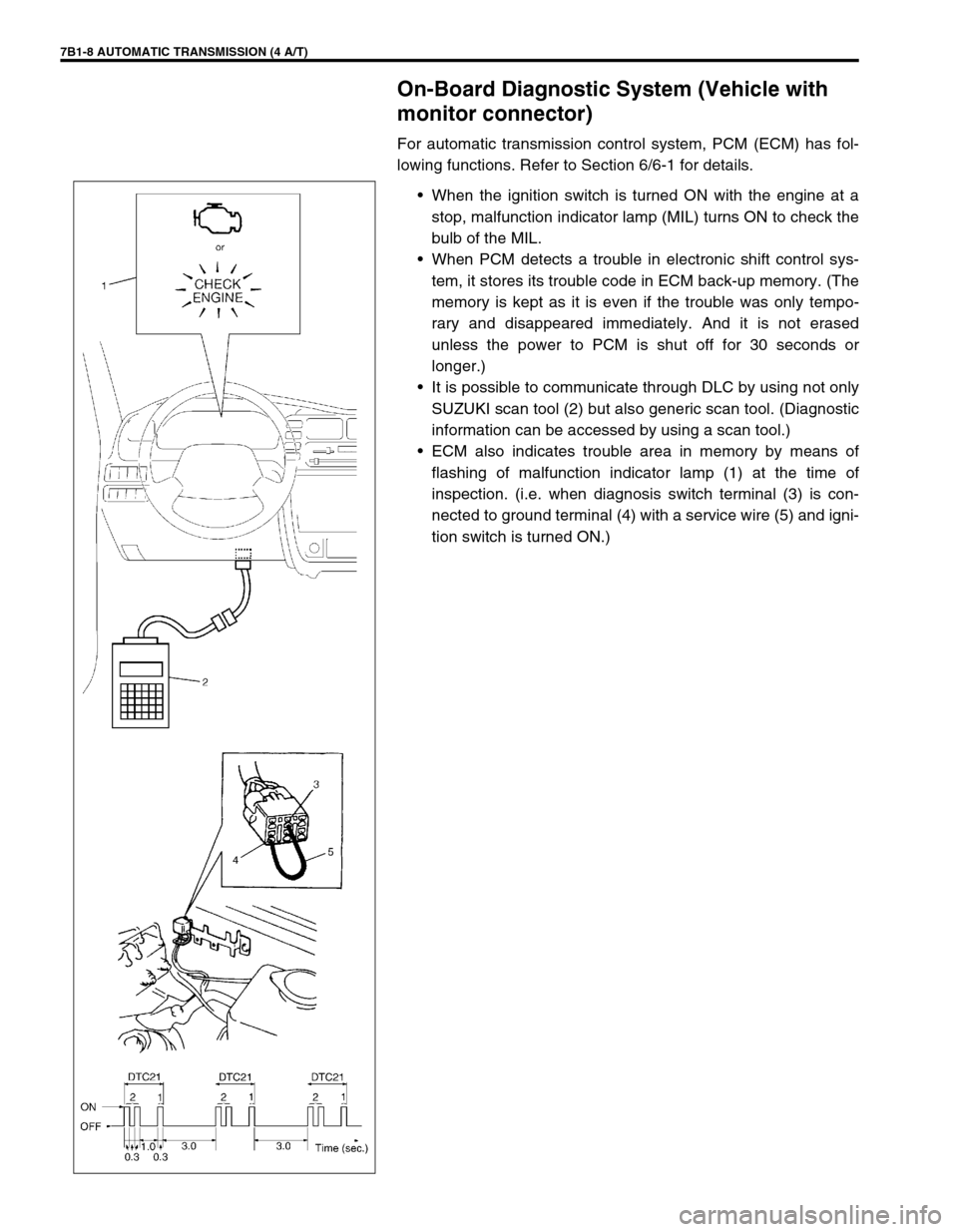

On-Board Diagnostic System (Vehicle with

monitor connector)

For automatic transmission control system, PCM (ECM) has fol-

lowing functions. Refer to Section 6/6-1 for details.

•When the ignition switch is turned ON with the engine at a

stop, malfunction indicator lamp (MIL) turns ON to check the

bulb of the MIL.

•When PCM detects a trouble in electronic shift control sys-

tem, it stores its trouble code in ECM back-up memory. (The

memory is kept as it is even if the trouble was only tempo-

rary and disappeared immediately. And it is not erased

unless the power to PCM is shut off for 30 seconds or

longer.)

•It is possible to communicate through DLC by using not only

SUZUKI scan tool (2) but also generic scan tool. (Diagnostic

information can be accessed by using a scan tool.)

•ECM also indicates trouble area in memory by means of

flashing of malfunction indicator lamp (1) at the time of

inspection. (i.e. when diagnosis switch terminal (3) is con-

nected to ground terminal (4) with a service wire (5) and igni-

tion switch is turned ON.)

Page 418 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-9

Precaution in Diagnosing Trouble

•Don’t disconnect couplers from PCM (ECM), battery cable

from battery, PCM ground wire harness from engine or main

fuse before checking the diagnosis information (DTC, freeze

frame data, etc.) stored in PCM memory. Such disconnec-

tion will clear memorized information in PCM memory.

•Using SUZUKI scan tool or also generic scan tool for vehicle

without monitor connector, the diagnostic information stored

in PCM memory can be checked and cleared as well. Before

its use, be sure to read Operator’s (Instruction) Manual sup-

plied with it carefully to have good understanding of its func-

tions and usage.

•Priorities for diagnosing troubles

If two or more diagnostic trouble codes (DTCs) are stored,

proceed to the flow table of the DTC which was detected

earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble

codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/

P0172/P0174/P0175 (Fuel system too lean/too rich), DTC

P0300/P0301/P0302/P0303/P0304/P0305/P0306 (Misfire

detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172/P0174/P0175 (Fuel system too lean/too

rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304/P0305/P0306

(Misfire detected)

•Be sure to read “PRECAUTIONS FOR ELECTRICAL CIR-

CUIT SERVICE” in Section 0A before inspection and

observe what is written there.

•PCM replacement

When substituting a known-good PCM, check for following

conditions.

Neglecting this check may result in damage to a good PCM.

–All relays and actuators have resistance of specified value.

–MAF sensor, MDP sensor, TP sensor and fuel tank pres-

sure sensor are in good condition. Also, the power circuit of

these sensors is not shorted to the ground.

Page 419 of 656

7B1-10 AUTOMATIC TRANSMISSION (4 A/T)

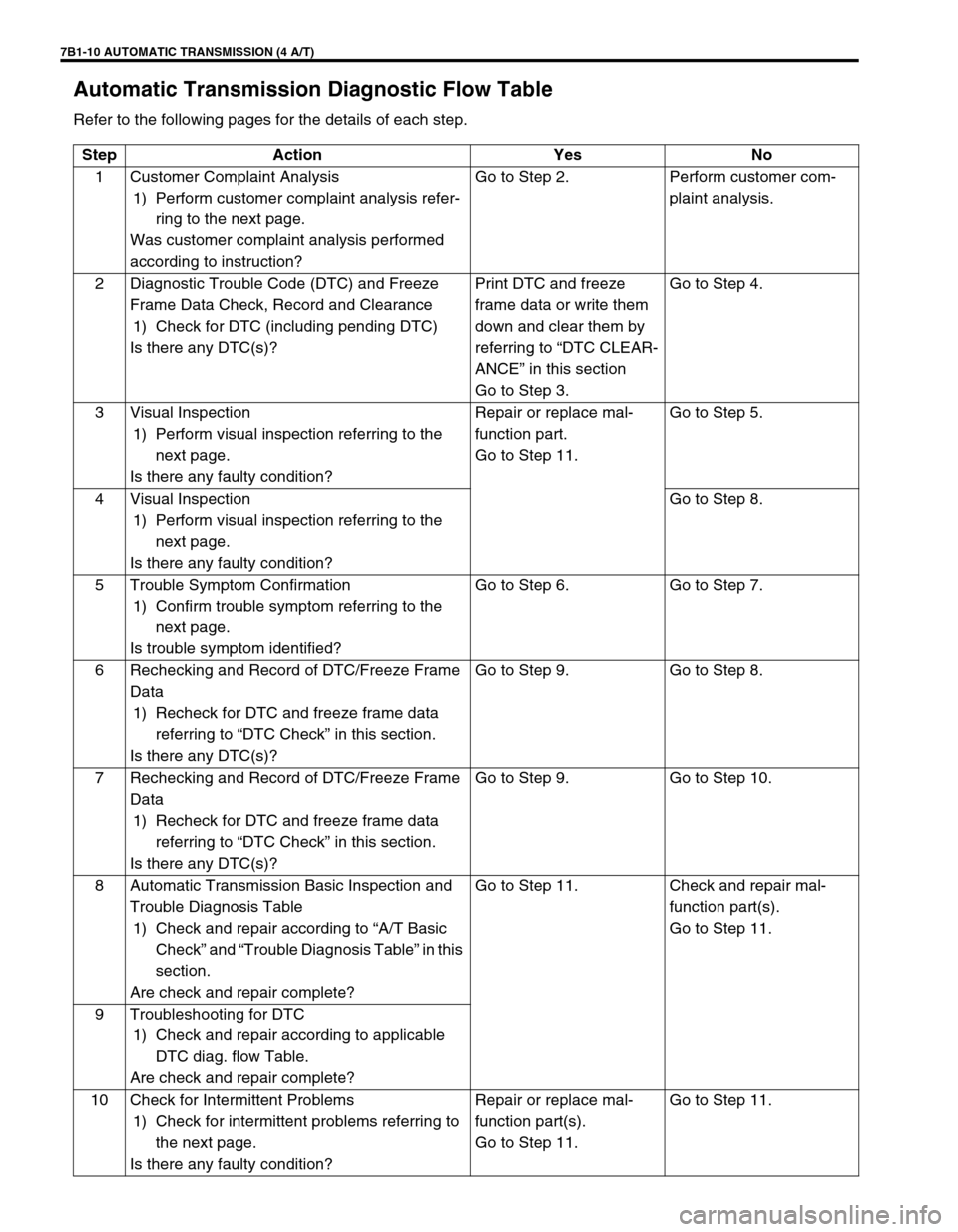

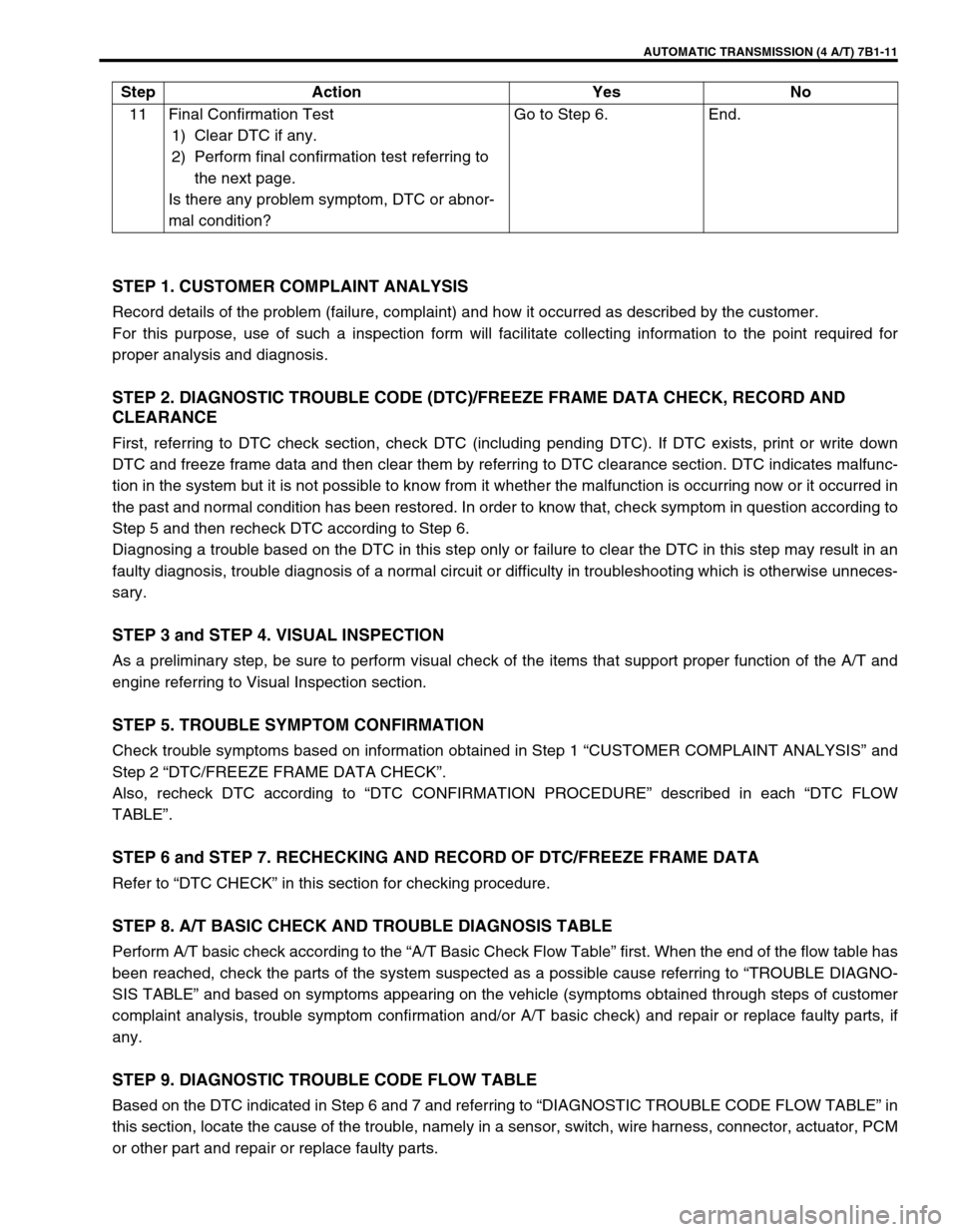

Automatic Transmission Diagnostic Flow Table

Refer to the following pages for the details of each step.

Step Action Yes No

1 Customer Complaint Analysis

1) Perform customer complaint analysis refer-

ring to the next page.

Was customer complaint analysis performed

according to instruction?Go to Step 2. Perform customer com-

plaint analysis.

2 Diagnostic Trouble Code (DTC) and Freeze

Frame Data Check, Record and Clearance

1) Check for DTC (including pending DTC)

Is there any DTC(s)?Print DTC and freeze

frame data or write them

down and clear them by

referring to “DTC CLEAR-

ANCE” in this section

Go to Step 3.Go to Step 4.

3 Visual Inspection

1) Perform visual inspection referring to the

next page.

Is there any faulty condition?Repair or replace mal-

function part.

Go to Step 11.Go to Step 5.

4 Visual Inspection

1) Perform visual inspection referring to the

next page.

Is there any faulty condition?Go to Step 8.

5 Trouble Symptom Confirmation

1) Confirm trouble symptom referring to the

next page.

Is trouble symptom identified?Go to Step 6. Go to Step 7.

6 Rechecking and Record of DTC/Freeze Frame

Data

1) Recheck for DTC and freeze frame data

referring to “DTC Check” in this section.

Is there any DTC(s)?Go to Step 9. Go to Step 8.

7 Rechecking and Record of DTC/Freeze Frame

Data

1) Recheck for DTC and freeze frame data

referring to “DTC Check” in this section.

Is there any DTC(s)?Go to Step 9. Go to Step 10.

8 Automatic Transmission Basic Inspection and

Trouble Diagnosis Table

1) Check and repair according to “A/T Basic

Check” and “Trouble Diagnosis Table” in this

section.

Are check and repair complete?Go to Step 11. Check and repair mal-

function part(s).

Go to Step 11.

9 Troubleshooting for DTC

1) Check and repair according to applicable

DTC diag. flow Table.

Are check and repair complete?

10 Check for Intermittent Problems

1) Check for intermittent problems referring to

the next page.

Is there any faulty condition?Repair or replace mal-

function part(s).

Go to Step 11.Go to Step 11.

Page 420 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-11

STEP 1. CUSTOMER COMPLAINT ANALYSIS

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a inspection form will facilitate collecting information to the point required for

proper analysis and diagnosis.

STEP 2. DIAGNOSTIC TROUBLE CODE (DTC)/FREEZE FRAME DATA CHECK, RECORD AND

CLEARANCE

First, referring to DTC check section, check DTC (including pending DTC). If DTC exists, print or write down

DTC and freeze frame data and then clear them by referring to DTC clearance section. DTC indicates malfunc-

tion in the system but it is not possible to know from it whether the malfunction is occurring now or it occurred in

the past and normal condition has been restored. In order to know that, check symptom in question according to

Step 5 and then recheck DTC according to Step 6.

Diagnosing a trouble based on the DTC in this step only or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or difficulty in troubleshooting which is otherwise unneces-

sary.

STEP 3 and STEP 4. VISUAL INSPECTION

As a preliminary step, be sure to perform visual check of the items that support proper function of the A/T and

engine referring to Visual Inspection section.

STEP 5. TROUBLE SYMPTOM CONFIRMATION

Check trouble symptoms based on information obtained in Step 1 “CUSTOMER COMPLAINT ANALYSIS” and

Step 2 “DTC/FREEZE FRAME DATA CHECK”.

Also, recheck DTC according to “DTC CONFIRMATION PROCEDURE” described in each “DTC FLOW

TABLE”.

STEP 6 and STEP 7. RECHECKING AND RECORD OF DTC/FREEZE FRAME DATA

Refer to “DTC CHECK” in this section for checking procedure.

STEP 8. A/T BASIC CHECK AND TROUBLE DIAGNOSIS TABLE

Perform A/T basic check according to the “A/T Basic Check Flow Table” first. When the end of the flow table has

been reached, check the parts of the system suspected as a possible cause referring to “TROUBLE DIAGNO-

SIS TABLE” and based on symptoms appearing on the vehicle (symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or A/T basic check) and repair or replace faulty parts, if

any.

STEP 9. DIAGNOSTIC TROUBLE CODE FLOW TABLE

Based on the DTC indicated in Step 6 and 7 and referring to “DIAGNOSTIC TROUBLE CODE FLOW TABLE” in

this section, locate the cause of the trouble, namely in a sensor, switch, wire harness, connector, actuator, PCM

or other part and repair or replace faulty parts.11 Final Confirmation Test

1) Clear DTC if any.

2) Perform final confirmation test referring to

the next page.

Is there any problem symptom, DTC or abnor-

mal condition?Go to Step 6. End. Step Action Yes No