Temperature SUZUKI GRAND VITARA 1999 2.G Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1999, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1999 2.GPages: 656, PDF Size: 14.31 MB

Page 452 of 656

AUTOMATIC TRANSMISSION (4 A/T) 7B1-43

On-Vehicle Service

Maintenance Service

Fluid level

LEVEL CHECK AT NORMAL OPERATING TEMPERATURE

1) Stop vehicle and place it level.

2) Apply parking brake and place chocks against wheels.

3) With selector at P position, start engine.

4) Warm up engine till fluid temperature reaches normal oper-

ating temperature (70 – 80 °C (158 – 176 °F)). As a guide to

check fluid temperature, warm up engine till engine coolant

temperature meter indicated around 1 unit above “C” point.

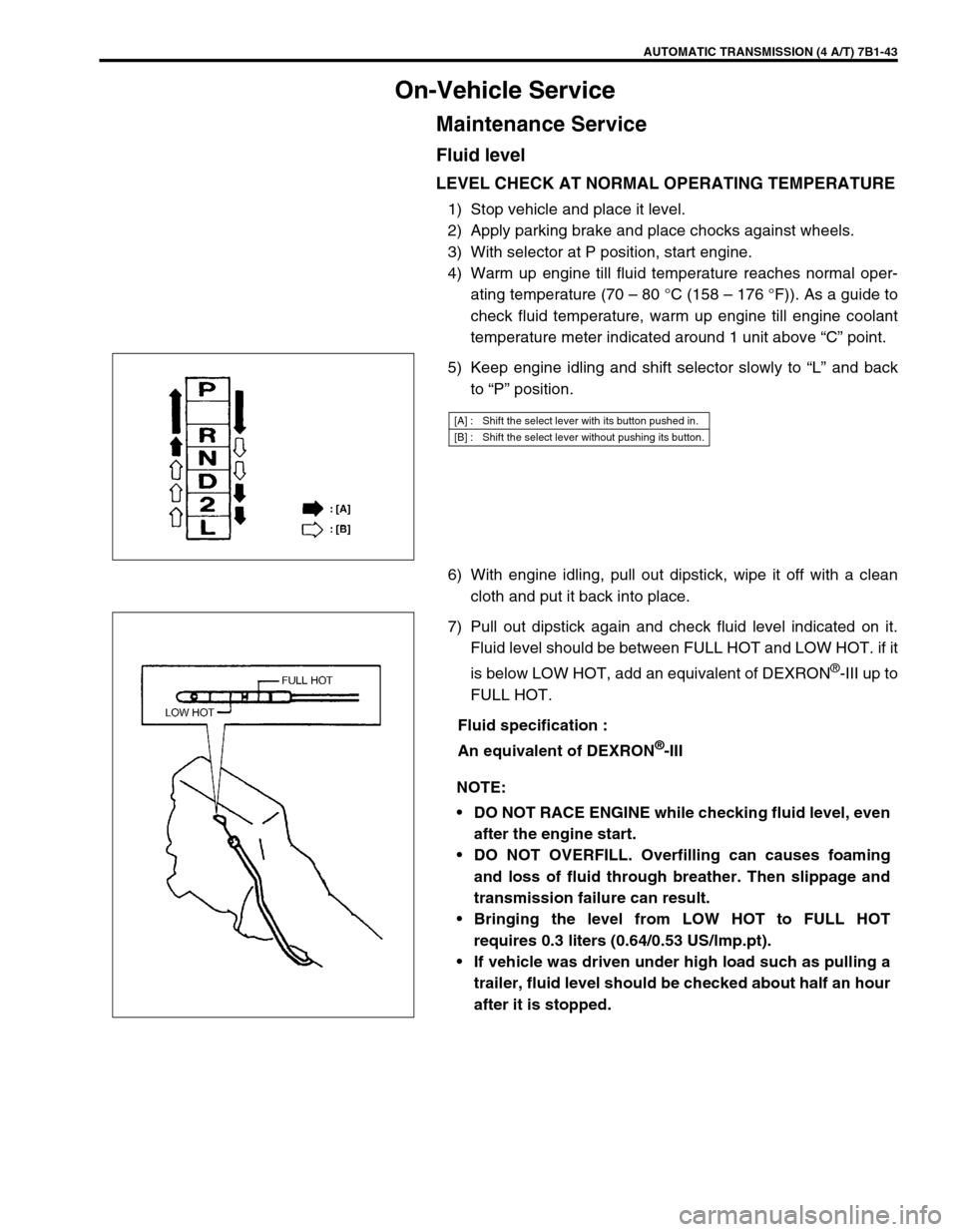

5) Keep engine idling and shift selector slowly to “L” and back

to “P” position.

6) With engine idling, pull out dipstick, wipe it off with a clean

cloth and put it back into place.

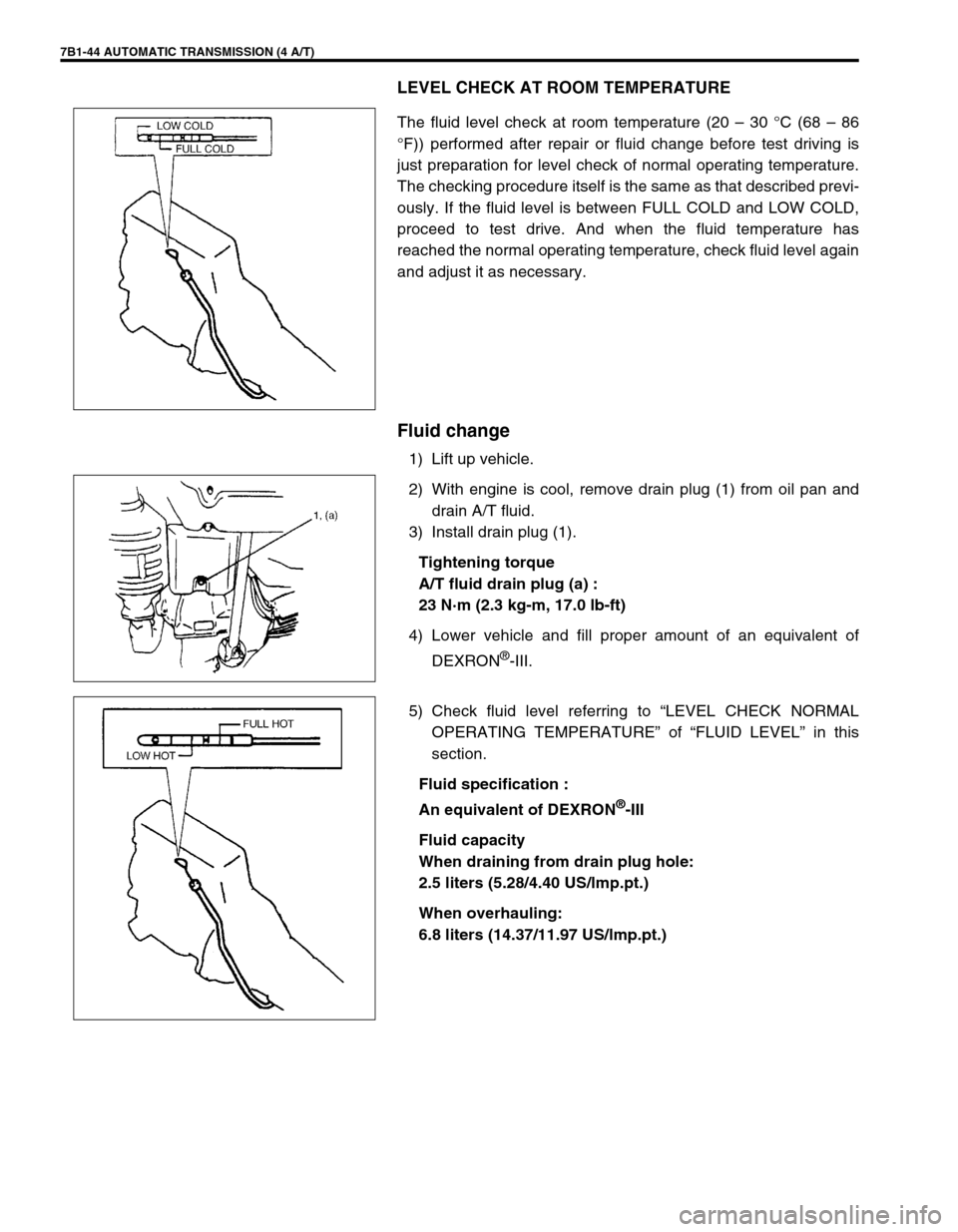

7) Pull out dipstick again and check fluid level indicated on it.

Fluid level should be between FULL HOT and LOW HOT. if it

is below LOW HOT, add an equivalent of DEXRON

®-III up to

FULL HOT.

Fluid specification :

An equivalent of DEXRON

®-III

[A] : Shift the select lever with its button pushed in.

[B] : Shift the select lever without pushing its button.

NOTE:

DO NOT RACE ENGINE while checking fluid level, even

after the engine start.

DO NOT OVERFILL. Overfilling can causes foaming

and loss of fluid through breather. Then slippage and

transmission failure can result.

Bringing the level from LOW HOT to FULL HOT

requires 0.3 liters (0.64/0.53 US/lmp.pt).

If vehicle was driven under high load such as pulling a

trailer, fluid level should be checked about half an hour

after it is stopped.

Page 453 of 656

7B1-44 AUTOMATIC TRANSMISSION (4 A/T)

LEVEL CHECK AT ROOM TEMPERATURE

The fluid level check at room temperature (20 – 30 °C (68 – 86

°F)) performed after repair or fluid change before test driving is

just preparation for level check of normal operating temperature.

The checking procedure itself is the same as that described previ-

ously. If the fluid level is between FULL COLD and LOW COLD,

proceed to test drive. And when the fluid temperature has

reached the normal operating temperature, check fluid level again

and adjust it as necessary.

Fluid change

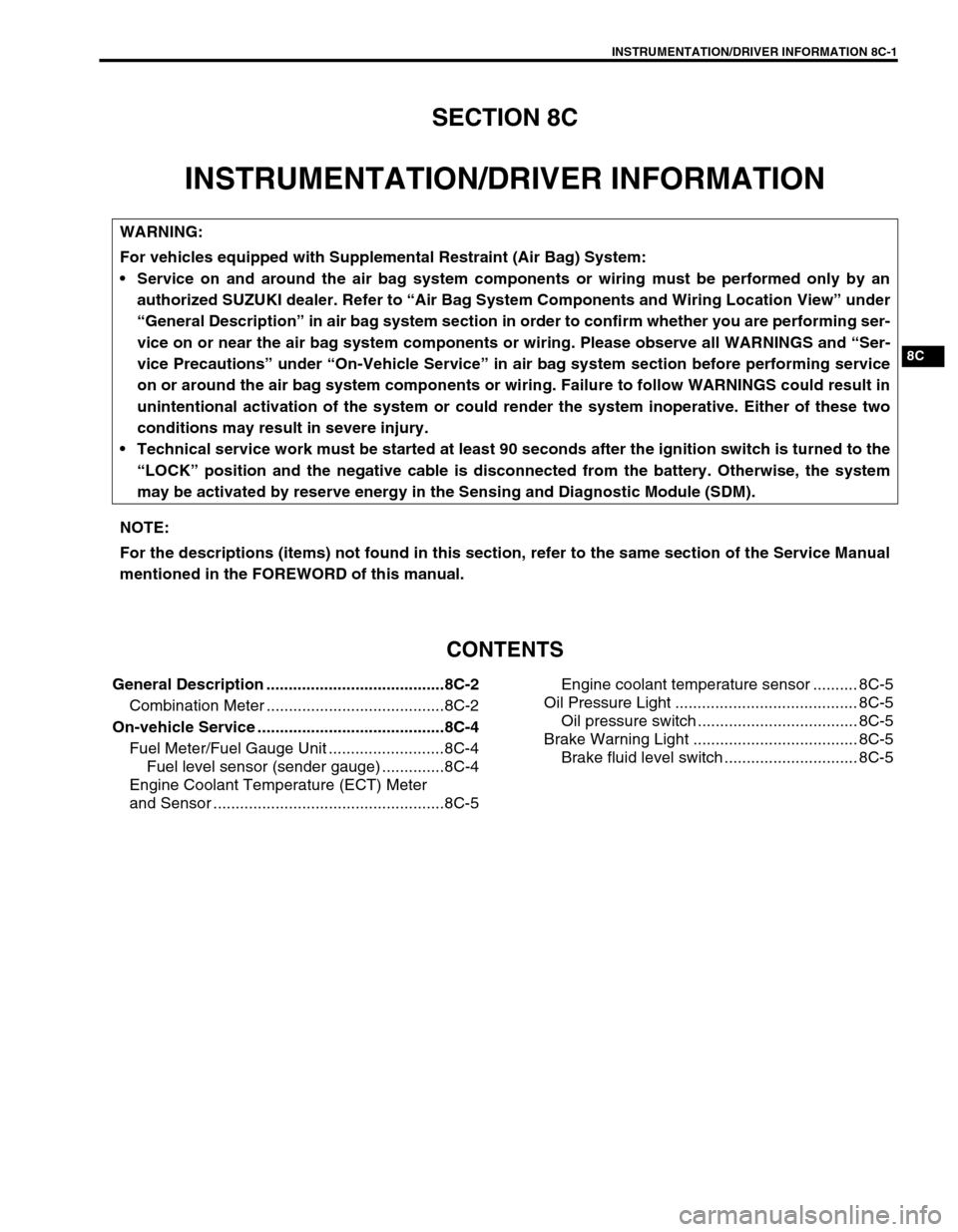

1) Lift up vehicle.

2) With engine is cool, remove drain plug (1) from oil pan and

drain A/T fluid.

3) Install drain plug (1).

Tightening torque

A/T fluid drain plug (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

4) Lower vehicle and fill proper amount of an equivalent of

DEXRON

®-III.

5) Check fluid level referring to “LEVEL CHECK NORMAL

OPERATING TEMPERATURE” of “FLUID LEVEL” in this

section.

Fluid specification :

An equivalent of DEXRON

®-III

Fluid capacity

When draining from drain plug hole:

2.5 liters (5.28/4.40 US/lmp.pt.)

When overhauling:

6.8 liters (14.37/11.97 US/lmp.pt.)

Page 512 of 656

INSTRUMENTATION/DRIVER INFORMATION 8C-1

8C

SECTION 8C

INSTRUMENTATION/DRIVER INFORMATION

CONTENTS

General Description ........................................8C-2

Combination Meter ........................................8C-2

On-vehicle Service ..........................................8C-4

Fuel Meter/Fuel Gauge Unit ..........................8C-4

Fuel level sensor (sender gauge) ..............8C-4

Engine Coolant Temperature (ECT) Meter

and Sensor ....................................................8C-5Engine coolant temperature sensor .......... 8C-5

Oil Pressure Light ......................................... 8C-5

Oil pressure switch .................................... 8C-5

Brake Warning Light ..................................... 8C-5

Brake fluid level switch .............................. 8C-5

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the descriptions (items) not found in this section, refer to the same section of the Service Manual

mentioned in the FOREWORD of this manual.

Page 513 of 656

8C-2 INSTRUMENTATION/DRIVER INFORMATION

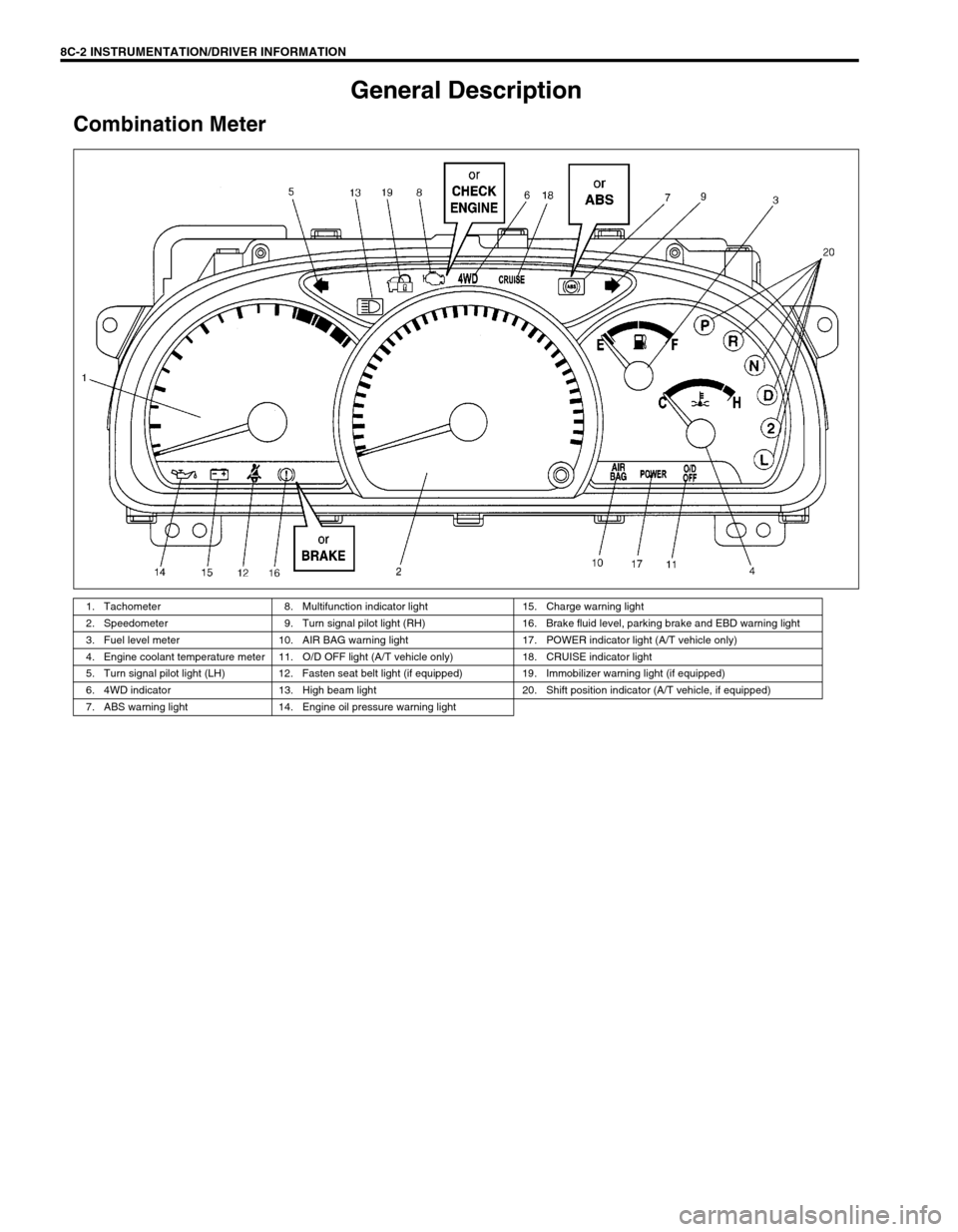

General Description

Combination Meter

1. Tachometer 8. Multifunction indicator light 15. Charge warning light

2. Speedometer 9. Turn signal pilot light (RH) 16. Brake fluid level, parking brake and EBD warning light

3. Fuel level meter 10. AIR BAG warning light 17. POWER indicator light (A/T vehicle only)

4. Engine coolant temperature meter 11. O/D OFF light (A/T vehicle only) 18. CRUISE indicator light

5. Turn signal pilot light (LH) 12. Fasten seat belt light (if equipped) 19. Immobilizer warning light (if equipped)

6. 4WD indicator 13. High beam light 20. Shift position indicator (A/T vehicle, if equipped)

7. ABS warning light 14. Engine oil pressure warning light

Page 516 of 656

INSTRUMENTATION/DRIVER INFORMATION 8C-5

Engine Coolant Temperature (ECT) Meter and

Sensor

Engine coolant temperature sensor

REMOVAL AND INSTALLATION

Refer to “ECT SENSOR” in Section 6E2.

Oil Pressure Light

Oil pressure switch

REMOVAL AND INSTALLATION

Refer to “OIL PRESSURE CHECK” in Section 6A2.

Brake Warning Light

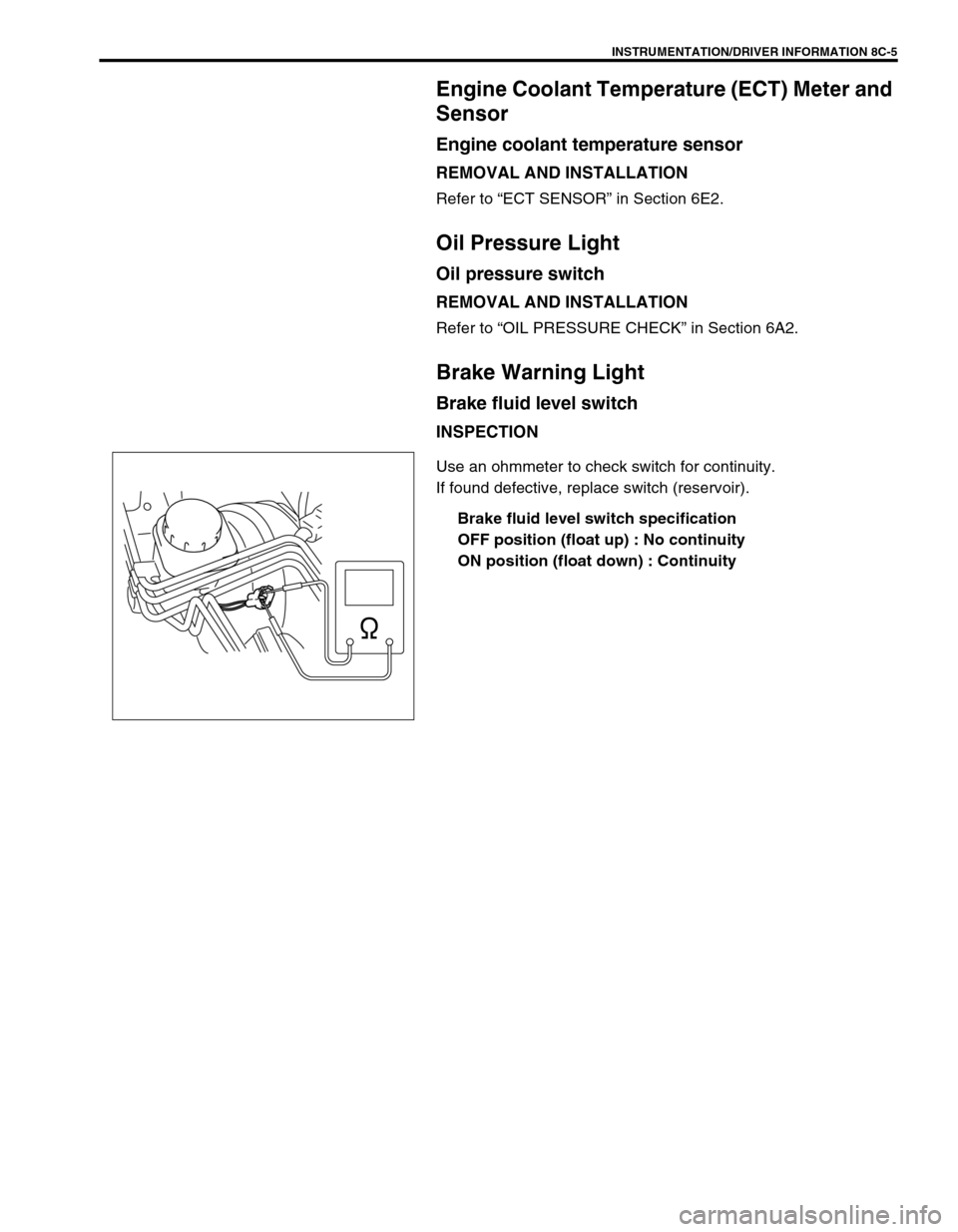

Brake fluid level switch

INSPECTION

Use an ohmmeter to check switch for continuity.

If found defective, replace switch (reservoir).

Brake fluid level switch specification

OFF position (float up) : No continuity

ON position (float down) : Continuity

Page 626 of 656

AIR BAG SYSTEM 10B-49

On-Vehicle Service

Service Precautions

Service and diagnosis

WARNING/CAUTION labels are attached on each part of air bag system components (SDM, air bag (inflator)

modules and seat belt pretensioners). Be sure to follow the instructions.

•Many of service procedures require disconnection of “AIR BAG” fuse and air bag (inflator) module(s) (driver

and passenger) from initiator circuit to avoid an accidental deployment.

•Do not apply power to the air bag system unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble code (DTC).

•The “AIR BAG DIAGNOSTIC SYSTEM CHECK” must be the starting point of any air bag diagnostics. The

“AIR BAG DIAGNOSTIC SYSTEM CHECK” will verify proper “AIR BAG” warning lamp operation and will

lead you to the correct table to diagnose any air bag malfunctions. Bypassing these procedures may result in

extended diagnostic time, incorrect diagnosis, and incorrect parts replacements.

•Never use air bag component parts from another vehicle.

•If the vehicle will be exposed to temperatures over 93°C (200°F) (for example, during a paint baking pro-

cess), remove the air bag system components beforehand to avoid component damage or unintended sys-

tem activation.

•When handling the air bag (inflator) modules (driver and passenger), seat belt pretensioners (driver and

passenger) or SDM, be careful not to drop it or apply an impact to it. If an excessive impact was applied

(e.g., SDM is dropped, air bag (inflator) module is dropped from a height of 90 cm (3 ft) or more, seat belt

pretensioner (retractor assembly) is dropped from a height of 30 cm (1 ft) or more), never attempt disassem-

bly or repair but replace it with a new one.

•When using electric welding, be sure to disconnect air bag (inflator) module connectors (driver and passen-

ger) and seat belt pretensioner connectors (driver and passenger) respectively.

•When applying paint around the air bag system related parts, use care so that the harness or connector will

not be exposed to the paint mist.

•Never expose air bag system component parts directly to hot air (drying or baking the vehicle after painting)

or flames. WARNING:

If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

Do not modify the steering wheel, dashboard or any other on or around air bag system compo-

nents. Modifications can adversely affect air bag system performance and lead to injury.

Failure to follow procedures could result in possible air bag system activation, personal injury or

unneeded air bag system repairs.

WARNING:

When performing service on or around air bag system components or air bag wiring, follow the proce-

dures listed in the following pages to temporarily disable the air bag system.

Failure to follow procedures could result in possible air bag system activation, personal injury or

unneeded air bag system repairs.

Page 629 of 656

10B-52 AIR BAG SYSTEM

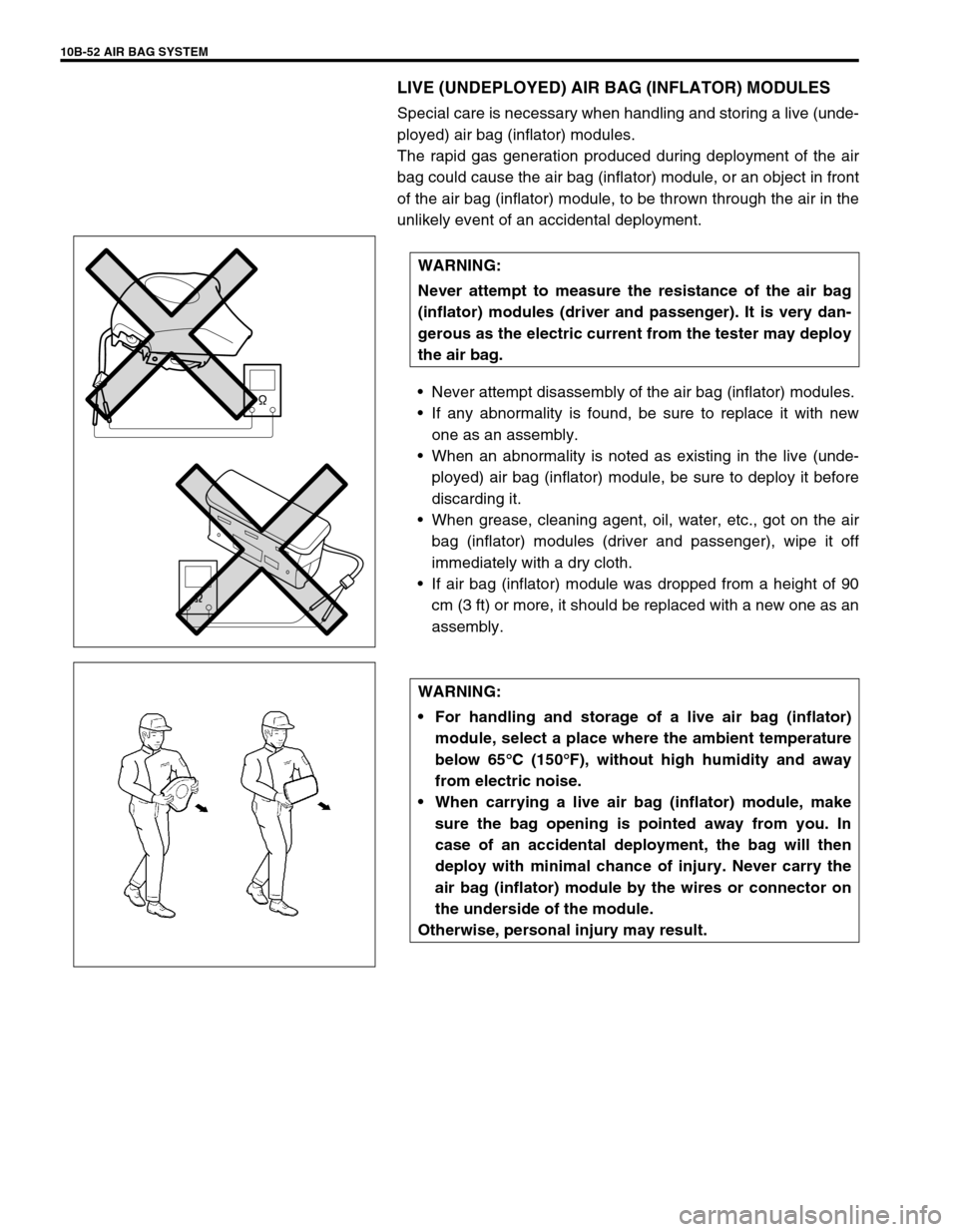

LIVE (UNDEPLOYED) AIR BAG (INFLATOR) MODULES

Special care is necessary when handling and storing a live (unde-

ployed) air bag (inflator) modules.

The rapid gas generation produced during deployment of the air

bag could cause the air bag (inflator) module, or an object in front

of the air bag (inflator) module, to be thrown through the air in the

unlikely event of an accidental deployment.

•Never attempt disassembly of the air bag (inflator) modules.

•If any abnormality is found, be sure to replace it with new

one as an assembly.

•When an abnormality is noted as existing in the live (unde-

ployed) air bag (inflator) module, be sure to deploy it before

discarding it.

•When grease, cleaning agent, oil, water, etc., got on the air

bag (inflator) modules (driver and passenger), wipe it off

immediately with a dry cloth.

•If air bag (inflator) module was dropped from a height of 90

cm (3 ft) or more, it should be replaced with a new one as an

assembly. WARNING:

Never attempt to measure the resistance of the air bag

(inflator) modules (driver and passenger). It is very dan-

gerous as the electric current from the tester may deploy

the air bag.

WARNING:

For handling and storage of a live air bag (inflator)

module, select a place where the ambient temperature

below 65°

°° °C (150°

°° °F), without high humidity and away

from electric noise.

When carrying a live air bag (inflator) module, make

sure the bag opening is pointed away from you. In

case of an accidental deployment, the bag will then

deploy with minimal chance of injury. Never carry the

air bag (inflator) module by the wires or connector on

the underside of the module.

Otherwise, personal injury may result.

Page 631 of 656

10B-54 AIR BAG SYSTEM

DEPLOYED AIR BAG (INFLATOR) MODULE AND ACTI-

VATED SEAT BELT PRETENSIONER

Refer to the procedure described under “DEPLOYED AIR BAG

(INFLATOR) MODULE AND ACTIVATED SEAT BELT PRETEN-

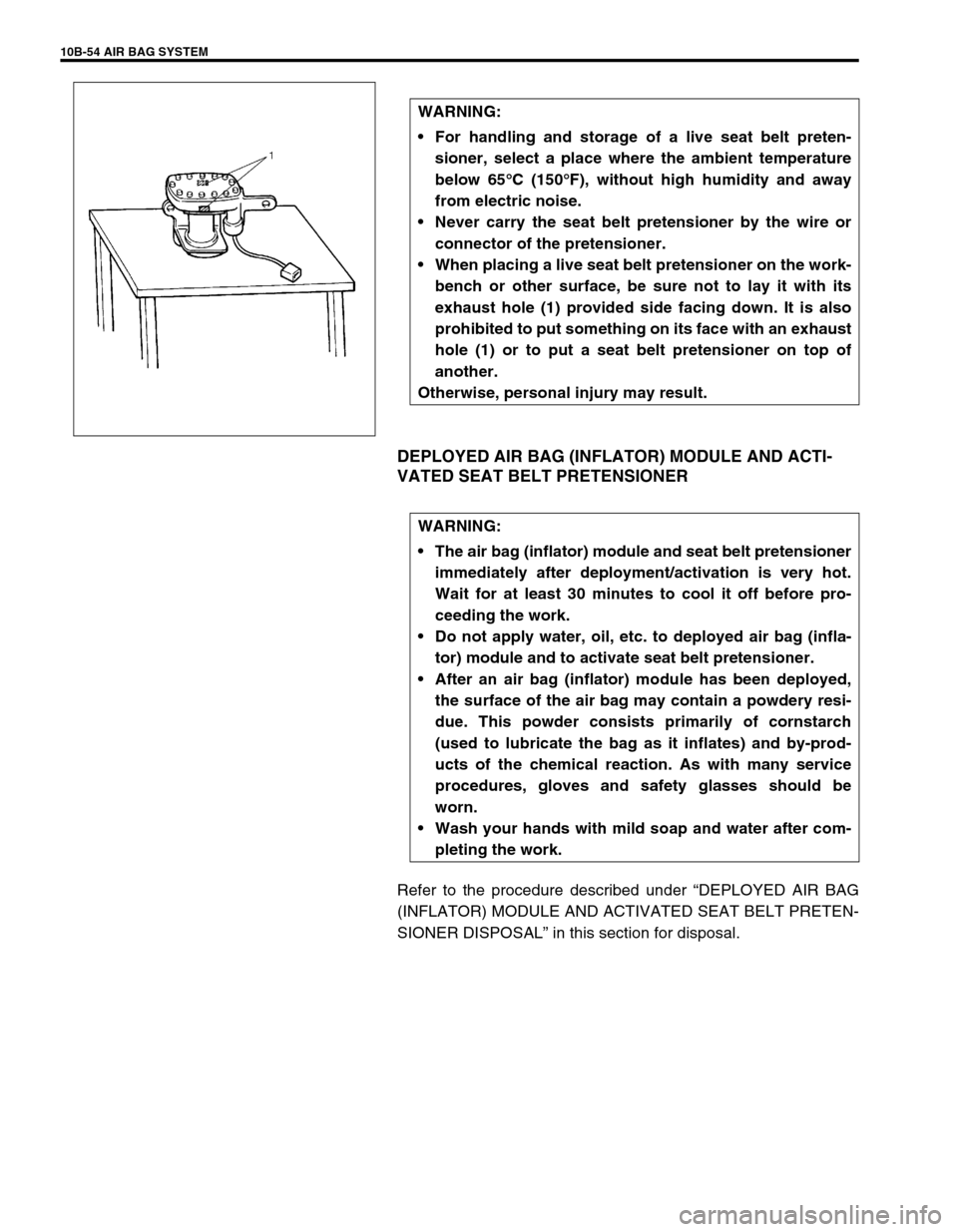

SIONER DISPOSAL” in this section for disposal. WARNING:

For handling and storage of a live seat belt preten-

sioner, select a place where the ambient temperature

below 65°

°° °C (150°

°° °F), without high humidity and away

from electric noise.

Never carry the seat belt pretensioner by the wire or

connector of the pretensioner.

When placing a live seat belt pretensioner on the work-

bench or other surface, be sure not to lay it with its

exhaust hole (1) provided side facing down. It is also

prohibited to put something on its face with an exhaust

hole (1) or to put a seat belt pretensioner on top of

another.

Otherwise, personal injury may result.

WARNING:

The air bag (inflator) module and seat belt pretensioner

immediately after deployment/activation is very hot.

Wait for at least 30 minutes to cool it off before pro-

ceeding the work.

Do not apply water, oil, etc. to deployed air bag (infla-

tor) module and to activate seat belt pretensioner.

After an air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery resi-

due. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-prod-

ucts of the chemical reaction. As with many service

procedures, gloves and safety glasses should be

worn.

Wash your hands with mild soap and water after com-

pleting the work.

Page 644 of 656

![SUZUKI GRAND VITARA 1999 2.G Workshop Manual AIR BAG SYSTEM 10B-67

5) Set air bag (inflator) module or seat belt pretensioner as fol-

lows.

[In case of driver air bag (inflator) module]

a) Clear a space on the ground about 185 cm (6 ft) (3) in

d SUZUKI GRAND VITARA 1999 2.G Workshop Manual AIR BAG SYSTEM 10B-67

5) Set air bag (inflator) module or seat belt pretensioner as fol-

lows.

[In case of driver air bag (inflator) module]

a) Clear a space on the ground about 185 cm (6 ft) (3) in

d](/img/20/7583/w960_7583-643.png)

AIR BAG SYSTEM 10B-67

5) Set air bag (inflator) module or seat belt pretensioner as fol-

lows.

[In case of driver air bag (inflator) module]

a) Clear a space on the ground about 185 cm (6 ft) (3) in

diameter where the driver air bag (inflator) module (1) is to

be deployed. A paved, outdoor location where there is no

activity is preferred. If an outdoor location is not available, a

space on the shop floor where there is no activity and suffi-

cient ventilation is recommended.

Ensure no loose or flammable objects are within the

deployment area.

b) Place the driver air bag (inflator) module (1), with its vinyl

trim cover facing up (2), on the ground in the space just

cleared.

[In case of passenger air bag (inflator) module]

a) Clear a space on the ground about 185 cm (6 ft) (2) in

diameter where the fixture (special tool) with attached air

bag (inflator) module (1) is to be placed for deployment. A

paved outdoor location where there is no activity is pre-

ferred. If an outdoor location is not available, a space on the

shop floor where there is no activity and sufficient ventila-

tion is recommended. Ensure that no loose or flammable

objects are within the deployment area.

b) Place special tool (passenger air bag (inflator) module

deployment fixture) on the ground in the space cleared in

step a), if it has not already been placed there.

Special tool

(B) : 09932-75041 WARNING:

For handing and storage of a live seat belt preten-

sioner, select a place where the ambient temperature

below 65°

°° °C (150°

°° °F), without high humidity and away

from electric noise.

Never carry the seat belt pretensioner by the wire or

connector of the pretensioner.

When placing a live seat belt pretensioner on the work-

bench or other surface, be sure not to lay it with its

exhaust hole (1) provided side facing down. It is also

prohibited to put something on its face with an exhaust

hole (1) or to put a seat belt pretensioner on top of

another.

Otherwise, personal injury may result.