Power SUZUKI GRAND VITARA 2001 2.G Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 171 of 656

6-1-10 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

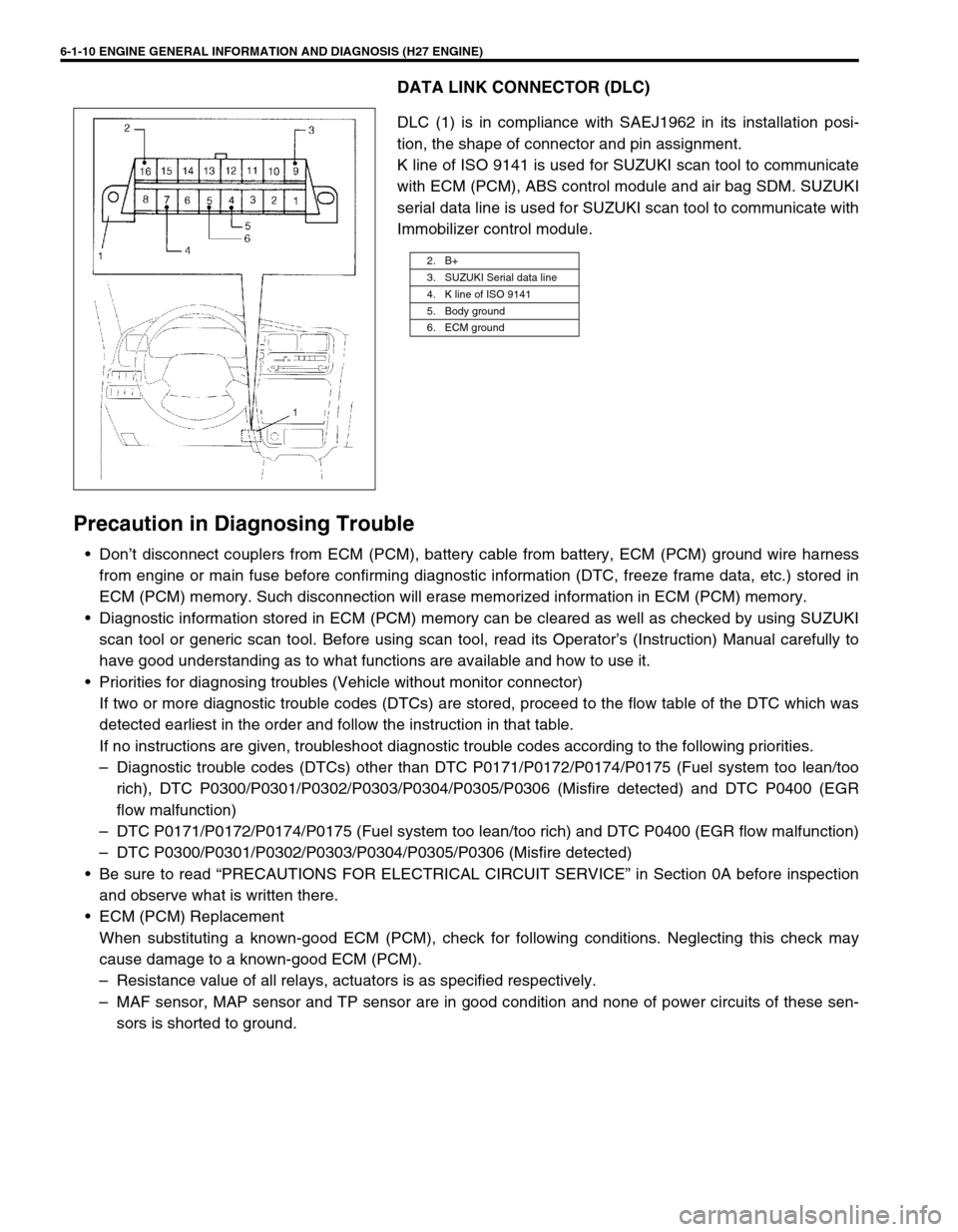

DATA LINK CONNECTOR (DLC)

DLC (1) is in compliance with SAEJ1962 in its installation posi-

tion, the shape of connector and pin assignment.

K line of ISO 9141 is used for SUZUKI scan tool to communicate

with ECM (PCM), ABS control module and air bag SDM. SUZUKI

serial data line is used for SUZUKI scan tool to communicate with

Immobilizer control module.

Precaution in Diagnosing Trouble

• Don’t disconnect couplers from ECM (PCM), battery cable from battery, ECM (PCM) ground wire harness

from engine or main fuse before confirming diagnostic information (DTC, freeze frame data, etc.) stored in

ECM (PCM) memory. Such disconnection will erase memorized information in ECM (PCM) memory.

• Diagnostic information stored in ECM (PCM) memory can be cleared as well as checked by using SUZUKI

scan tool or generic scan tool. Before using scan tool, read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are available and how to use it.

• Priorities for diagnosing troubles (Vehicle without monitor connector)

If two or more diagnostic trouble codes (DTCs) are stored, proceed to the flow table of the DTC which was

detected earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble codes according to the following priorities.

– Diagnostic trouble codes (DTCs) other than DTC P0171/P0172/P0174/P0175 (Fuel system too lean/too

rich), DTC P0300/P0301/P0302/P0303/P0304/P0305/P0306 (Misfire detected) and DTC P0400 (EGR

flow malfunction)

– DTC P0171/P0172/P0174/P0175 (Fuel system too lean/too rich) and DTC P0400 (EGR flow malfunction)

– DTC P0300/P0301/P0302/P0303/P0304/P0305/P0306 (Misfire detected)

• Be sure to read “PRECAUTIONS FOR ELECTRICAL CIRCUIT SERVICE” in Section 0A before inspection

and observe what is written there.

• ECM (PCM) Replacement

When substituting a known-good ECM (PCM), check for following conditions. Neglecting this check may

cause damage to a known-good ECM (PCM).

– Resistance value of all relays, actuators is as specified respectively.

– MAF sensor, MAP sensor and TP sensor are in good condition and none of power circuits of these sen-

sors is shorted to ground.

2. B+

3. SUZUKI Serial data line

4. K line of ISO 9141

5. Body ground

6. ECM ground

Page 178 of 656

![SUZUKI GRAND VITARA 2001 2.G Owners Manual ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-17

[Without Using SUZUKI Scan Tool] (Vehicle with Monitor

Connector)

1) Check malfunction indicator lamp referring to “Malfunction

Indicato SUZUKI GRAND VITARA 2001 2.G Owners Manual ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-17

[Without Using SUZUKI Scan Tool] (Vehicle with Monitor

Connector)

1) Check malfunction indicator lamp referring to “Malfunction

Indicato](/img/20/7584/w960_7584-177.png)

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-17

[Without Using SUZUKI Scan Tool] (Vehicle with Monitor

Connector)

1) Check malfunction indicator lamp referring to “Malfunction

Indicator Lamp Check” in this section.

2) With the ignition switch OFF position, disconnect SUZUKI

scan tool if connected and using service wire (4), connect

diagnosis switch terminal (1) to ground terminal (2) in moni-

tor connector (3).

3) With the ignition switch ON position and leaving engine OFF,

read DTC from flashing pattern of malfunction indicator

lamp. Refer to “Diagnostic Trouble Code Table”.

If lamp remains ON, go to “Diagnostic Flow Table A-4”.

4) After completing the check, turn the ignition switch OFF posi-

tion and disconnect service wire from monitor coupler.

Diagnostic Trouble Code (DTC) Clearance

[Using scan tool]

1) With ignition switch OFF, connect generic scan tool or

SUZUKI scan tool to data link connector (DLC).

2) Turn ignition switch ON.

3) Erase DTC according to instructions displayed on scan tool.

Freeze frame data is cleared with the DTC. Refer to scan tool

operator’s manual for further details.

4) After completing the clearance, turn ignition switch off and

disconnect scan tool from data link connector. NOTE:

If abnormality or malfunction lies in two or more areas,

malfunction indicator lamp indicates applicable codes

three times each.

And flashing of these codes is repeated as long as

diagnosis terminal is grounded and ignition switch is

held at ON position.

Take a note of diagnostic trouble code indicated first.

NOTE:

DTC and freeze frame data stored in ECM (PCM) memory

are also cleared in following cases. Be careful not to

clear them before keeping their record.

When power to ECM (PCM) is cut off (by disconnecting

battery cable, removing fuse or disconnecting ECM

(PCM) connectors)

When the same malfunction (DTC) is not detected

again during 40 engine warm-up cycles (refer to

“WARM-UP CYCLE” of “ON-BOARD DIAGNOSTIC SYS-

TEM” in this section) (Vehicle without monitor connec-

tor)

Page 179 of 656

![SUZUKI GRAND VITARA 2001 2.G Owners Manual 6-1-18 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

[Without using scan tool]

1) Turn the ignition switch OFF position.

2) Disconnect battery negative cable for specified time below to

erase SUZUKI GRAND VITARA 2001 2.G Owners Manual 6-1-18 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

[Without using scan tool]

1) Turn the ignition switch OFF position.

2) Disconnect battery negative cable for specified time below to

erase](/img/20/7584/w960_7584-178.png)

6-1-18 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

[Without using scan tool]

1) Turn the ignition switch OFF position.

2) Disconnect battery negative cable for specified time below to

erase diagnostic trouble code stored in ECM memory and

reconnect it.

Time required to erase DTC:

Diagnostic Trouble Code (DTC) Table

Ambient

temperatureTime to cut power to ECM

Over 0°C (32°F) 30 sec. or longer

Under 0°C

(32°F)Not specifiable.

Select a place with higher than 0°C

(32°F) temperature.

DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

P0100

(No.34)

Mass air flow circuit malfunc-

tionSensor output too low

1 driving

cycle1 driving

cycle

P0100

(No.33)Sensor output too high

P0110

(No.25)

Intake air temp. circuit mal-

functionIntake air temp. circuit low input

1 driving

cycle1 driving

cycle

P0110

(No.23)Intake air temp. circuit high input

P0115

(No.15)

Engine coolant temp. circuit

malfunctionEngine coolant temp. circuit low input

1 driving

cycle1 driving

cycle

P0115

(No.14)Engine coolant temp. circuit high input

P0120

(No.22)

Throttle position circuit mal-

functionThrottle position circuit low input

1 driving

cycle1 driving

cycle

P0120

(No.21)Throttle position circuit high input

P0121Throttle position circuit perfor-

mance problemPoor performance of TP sensor2 driving

cyclesNot

applicable

*P0130HO2S circuit malfunction

(Bank 1 - Sensor 1)Min. output voltage of HO2S-1 is

higher than specification.

2 driving

cyclesNot

applicable Min. output voltage of HO2S-1 is

lower than specification.

Output voltage of HO2S-1 fails to go

above specification.

**P0130

(No.13)HO2S (Bank 1 - Sensor 1) no

activity detectedOutput voltage of HO2S-1 fails to go

above specification (or HO2S-1 cir-

cuit open).2 driving

cycles2 driving

cycles

Page 182 of 656

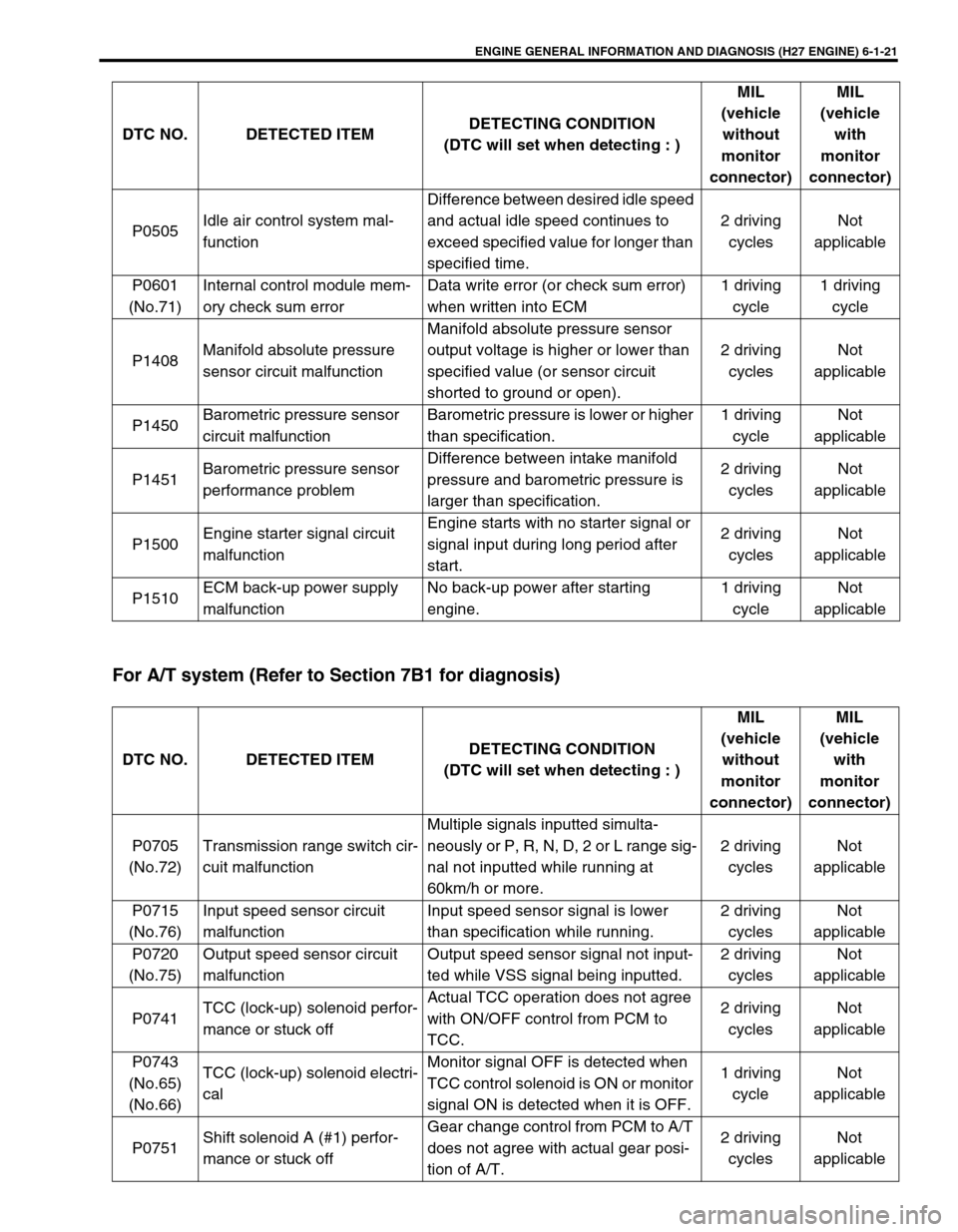

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-21

For A/T system (Refer to Section 7B1 for diagnosis)

P0505Idle air control system mal-

functionDifference between desired idle speed

and actual idle speed continues to

exceed specified value for longer than

specified time.2 driving

cyclesNot

applicable

P0601

(No.71)Internal control module mem-

ory check sum errorData write error (or check sum error)

when written into ECM1 driving

cycle1 driving

cycle

P1408Manifold absolute pressure

sensor circuit malfunctionManifold absolute pressure sensor

output voltage is higher or lower than

specified value (or sensor circuit

shorted to ground or open).2 driving

cyclesNot

applicable

P1450Barometric pressure sensor

circuit malfunctionBarometric pressure is lower or higher

than specification.1 driving

cycleNot

applicable

P1451Barometric pressure sensor

performance problemDifference between intake manifold

pressure and barometric pressure is

larger than specification.2 driving

cyclesNot

applicable

P1500Engine starter signal circuit

malfunctionEngine starts with no starter signal or

signal input during long period after

start.2 driving

cyclesNot

applicable

P1510ECM back-up power supply

malfunctionNo back-up power after starting

engine.1 driving

cycleNot

applicable DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

DTC NO. DETECTED ITEMDETECTING CONDITION

(DTC will set when detecting : )MIL

(vehicle

without

monitor

connector)MIL

(vehicle

with

monitor

connector)

P0705

(No.72)Transmission range switch cir-

cuit malfunctionMultiple signals inputted simulta-

neously or P, R, N, D, 2 or L range sig-

nal not inputted while running at

60km/h or more.2 driving

cyclesNot

applicable

P0715

(No.76)Input speed sensor circuit

malfunctionInput speed sensor signal is lower

than specification while running.2 driving

cyclesNot

applicable

P0720

(No.75)Output speed sensor circuit

malfunctionOutput speed sensor signal not input-

ted while VSS signal being inputted.2 driving

cyclesNot

applicable

P0741TCC (lock-up) solenoid perfor-

mance or stuck offActual TCC operation does not agree

with ON/OFF control from PCM to

TCC.2 driving

cyclesNot

applicable

P0743

(No.65)

(No.66)TCC (lock-up) solenoid electri-

calMonitor signal OFF is detected when

TCC control solenoid is ON or monitor

signal ON is detected when it is OFF.1 driving

cycleNot

applicable

P0751Shift solenoid A (#1) perfor-

mance or stuck offGear change control from PCM to A/T

does not agree with actual gear posi-

tion of A/T.2 driving

cyclesNot

applicable

Page 187 of 656

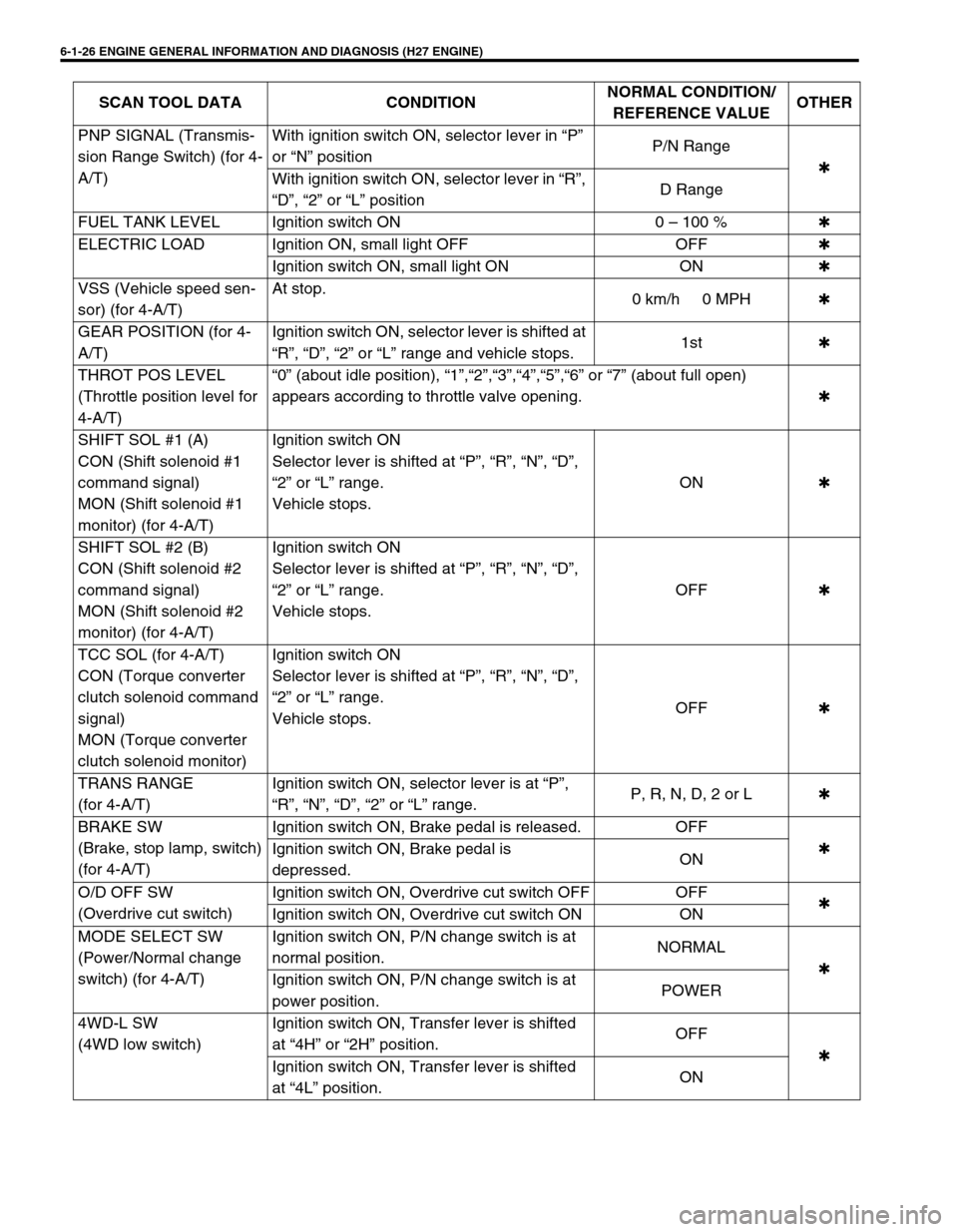

6-1-26 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

PNP SIGNAL (Transmis-

sion Range Switch) (for 4-

A/T)With ignition switch ON, selector lever in “P”

or “N” positionP/N Range

✱

With ignition switch ON, selector lever in “R”,

“D”, “2” or “L” positionD Range

FUEL TANK LEVEL Ignition switch ON 0 – 100 %✱

ELECTRIC LOAD Ignition ON, small light OFF OFF✱

Ignition switch ON, small light ON ON✱

VSS (Vehicle speed sen-

sor) (for 4-A/T)At stop.

0 km/h 0 MPH✱

GEAR POSITION (for 4-

A/T)Ignition switch ON, selector lever is shifted at

“R”, “D”, “2” or “L” range and vehicle stops.1st✱

THROT POS LEVEL

(Throttle position level for

4-A/T)“0” (about idle position), “1”,“2”,“3”,“4”,“5”,“6” or “7” (about full open)

appears according to throttle valve opening.✱

SHIFT SOL #1 (A)

CON (Shift solenoid #1

command signal)

MON (Shift solenoid #1

monitor) (for 4-A/T)Ignition switch ON

Selector lever is shifted at “P”, “R”, “N”, “D”,

“2” or “L” range.

Vehicle stops.ON✱

SHIFT SOL #2 (B)

CON (Shift solenoid #2

command signal)

MON (Shift solenoid #2

monitor) (for 4-A/T)Ignition switch ON

Selector lever is shifted at “P”, “R”, “N”, “D”,

“2” or “L” range.

Vehicle stops.OFF✱

TCC SOL (for 4-A/T)

CON (Torque converter

clutch solenoid command

signal)

MON (Torque converter

clutch solenoid monitor)Ignition switch ON

Selector lever is shifted at “P”, “R”, “N”, “D”,

“2” or “L” range.

Vehicle stops.OFF✱

TRANS RANGE

(for 4-A/T)Ignition switch ON, selector lever is at “P”,

“R”, “N”, “D”, “2” or “L” range.P, R, N, D, 2 or L✱

BRAKE SW

(Brake, stop lamp, switch)

(for 4-A/T)Ignition switch ON, Brake pedal is released. OFF

✱

Ignition switch ON, Brake pedal is

depressed.ON

O/D OFF SW

(Overdrive cut switch)Ignition switch ON, Overdrive cut switch OFF OFF

✱

Ignition switch ON, Overdrive cut switch ON ON

MODE SELECT SW

(Power/Normal change

switch) (for 4-A/T)Ignition switch ON, P/N change switch is at

normal position.NORMAL

✱

Ignition switch ON, P/N change switch is at

power position.POWER

4WD-L SW

(4WD low switch)Ignition switch ON, Transfer lever is shifted

at “4H” or “2H” position.OFF

✱

Ignition switch ON, Transfer lever is shifted

at “4L” position.ON SCAN TOOL DATA CONDITIONNORMAL CONDITION/

REFERENCE VALUEOTHER

Page 189 of 656

6-1-28 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

TP SENSOR VOLT (TP Sensor Output Voltage, V)

Throttle Position Sensor reading provides throttle valve opening information in the from of voltage.

O2S B1 S1 (HO2S Bank 1 Sensor 1 Output Voltage, V) / O2S B2 S1 (HO2S Bank 2 Sensor 1 Output

Voltage, V)

It indicates output voltage of HO2S SENSOR 1 installed on exhaust manifold (pre-catalyst).

O2S B1 S2 (HO2S Bank 1 Sensor 2 Output Voltage, V) / O2S B2 S2 (HO2S Bank 2 Sensor 2 Output

Voltage, V)

If indicates output voltage of HO2S SENSOR 2 installed on exhaust pipe (post-catalyst). It is used to detect cat-

alyst deterioration.

FUEL SYSTEM B1 (Fuel System Bank 1 Status) / Fuel System B2 (Fuel System Bank 2 Status)

Air/fuel ratio feedback loop status displayed as one of the followings.

OPEN : Open loop-has not yet satisfied conditions to go closed loop.

CLOSED : Closed loop-using oxygen sensor(s) as feedback for fuel control.

OPEN-DRIVE COND : Open loop due to driving conditions (Power enrichment, etc.).

OPEN SYS FAULT : Open loop due to detected system fault.

CLOSED-ONE O2S : Closed loop, but fault with at least one oxygen sensor may be using single oxygen sensor

for fuel control.

CALC LOAD (Calculated Load Value, %)

Engine load displayed as a percentage of maximum possible load. Value is calculated mathematically using the

formula : actual (current) intake air volume ÷ maximum possible intake air volume x 100%.

TOTAL FUEL TRIM (%)

The value of total fuel trim is obtained by putting values of short term fuel trim and long term fuel trim together.

This value indicates how much correction is necessary to keep the air/fuel mixture stoichiometrical.

CANIST PRG DUTY (EVAP Canister Purge Flow Duty, %)

This parameter indicates valve ON (valve open) time rate within a certain set cycle of EVAP canister purge valve

which controls the amount of EVAP purge.

VEHICLE SPEED (km/h, MPH)

It is computed based on pulse signals from vehicle speed sensor on transfer or transmission.

FUEL CUT (ON/OFF)

ON : Fuel being cut (output signal to injector is stopped).

OFF : Fuel not being cut.

MAP (Manifold Absolute Pressure, mmHg, kPa)

This parameter indicates the pressure in the intake manifold absolute pressure.

A/C CONDENSER FAN (ON/OFF)

This parameter indicates the state of the A/C Condenser Fan control signal.

BLOWER FAN (ON/OFF)

This parameter indicates the state of the blower fan motor switch.

Page 191 of 656

6-1-30 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

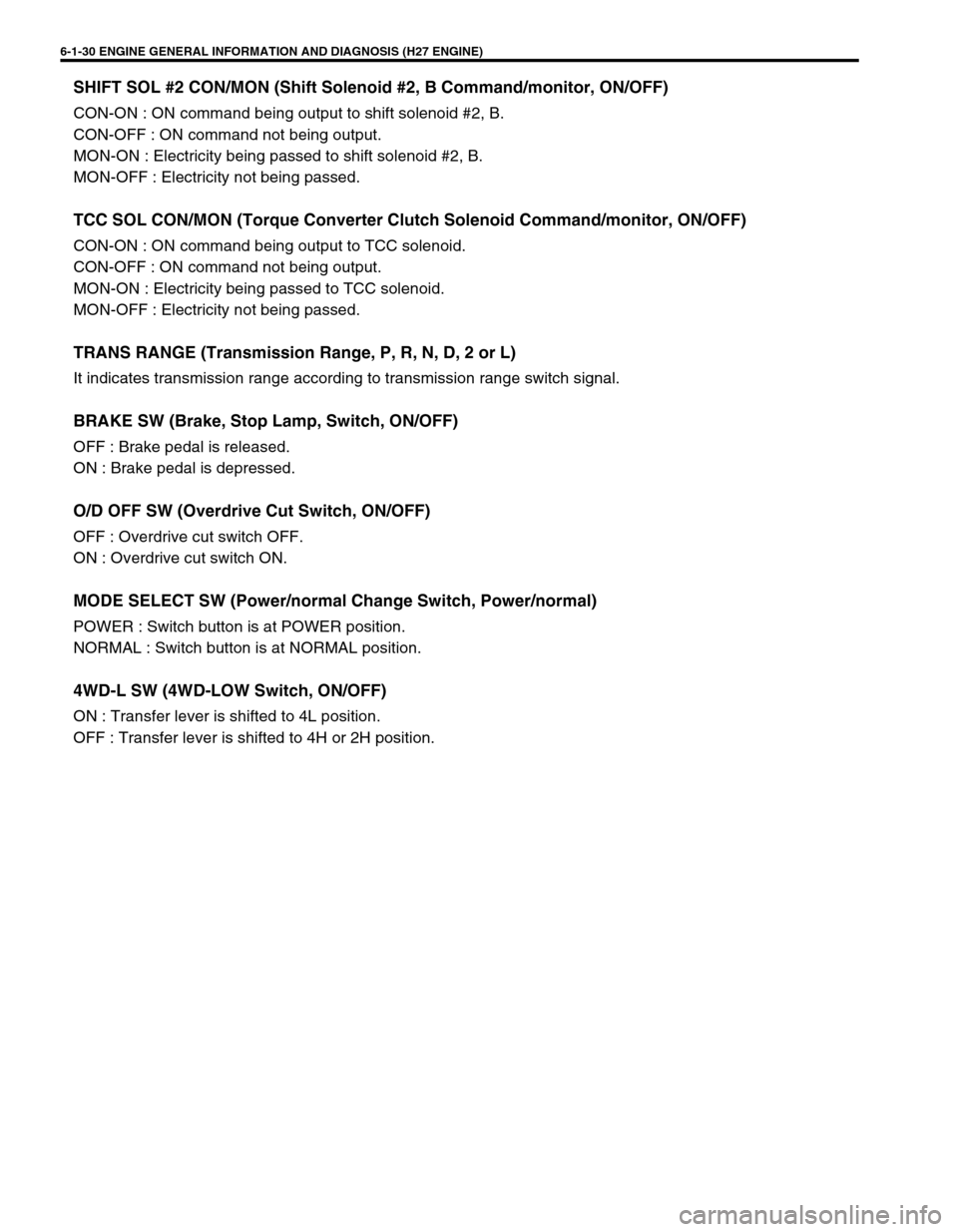

SHIFT SOL #2 CON/MON (Shift Solenoid #2, B Command/monitor, ON/OFF)

CON-ON : ON command being output to shift solenoid #2, B.

CON-OFF : ON command not being output.

MON-ON : Electricity being passed to shift solenoid #2, B.

MON-OFF : Electricity not being passed.

TCC SOL CON/MON (Torque Converter Clutch Solenoid Command/monitor, ON/OFF)

CON-ON : ON command being output to TCC solenoid.

CON-OFF : ON command not being output.

MON-ON : Electricity being passed to TCC solenoid.

MON-OFF : Electricity not being passed.

TRANS RANGE (Transmission Range, P, R, N, D, 2 or L)

It indicates transmission range according to transmission range switch signal.

BRAKE SW (Brake, Stop Lamp, Switch, ON/OFF)

OFF : Brake pedal is released.

ON : Brake pedal is depressed.

O/D OFF SW (Overdrive Cut Switch, ON/OFF)

OFF : Overdrive cut switch OFF.

ON : Overdrive cut switch ON.

MODE SELECT SW (Power/normal Change Switch, Power/normal)

POWER : Switch button is at POWER position.

NORMAL : Switch button is at NORMAL position.

4WD-L SW (4WD-LOW Switch, ON/OFF)

ON : Transfer lever is shifted to 4L position.

OFF : Transfer lever is shifted to 4H or 2H position.

Page 192 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-31

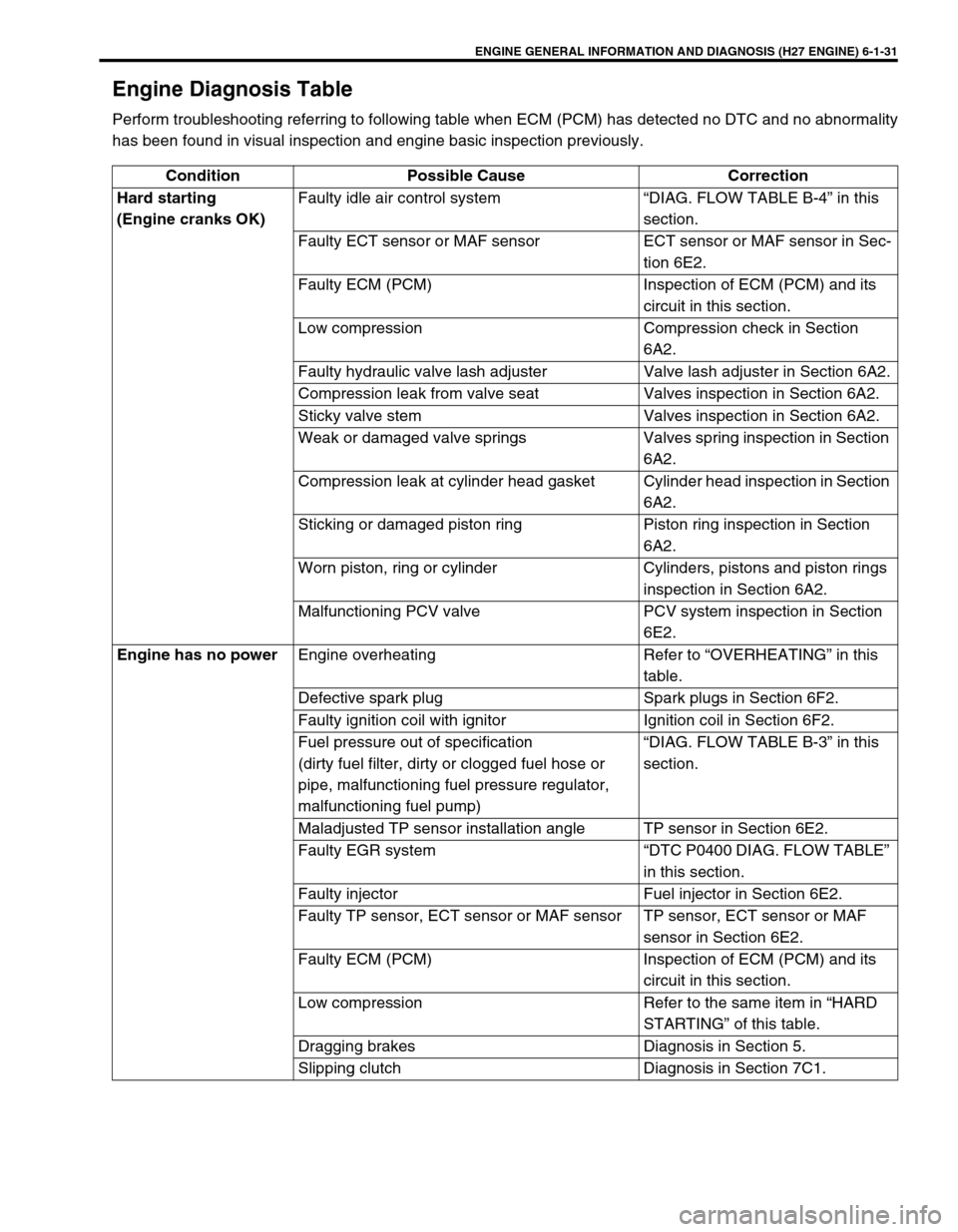

Engine Diagnosis Table

Perform troubleshooting referring to following table when ECM (PCM) has detected no DTC and no abnormality

has been found in visual inspection and engine basic inspection previously.

Condition Possible Cause Correction

Hard starting

(Engine cranks OK)Faulty idle air control system “DIAG. FLOW TABLE B-4” in this

section.

Faulty ECT sensor or MAF sensor ECT sensor or MAF sensor in Sec-

tion 6E2.

Faulty ECM (PCM) Inspection of ECM (PCM) and its

circuit in this section.

Low compression Compression check in Section

6A2.

Faulty hydraulic valve lash adjuster Valve lash adjuster in Section 6A2.

Compression leak from valve seat Valves inspection in Section 6A2.

Sticky valve stem Valves inspection in Section 6A2.

Weak or damaged valve springs Valves spring inspection in Section

6A2.

Compression leak at cylinder head gasket Cylinder head inspection in Section

6A2.

Sticking or damaged piston ring Piston ring inspection in Section

6A2.

Worn piston, ring or cylinder Cylinders, pistons and piston rings

inspection in Section 6A2.

Malfunctioning PCV valve PCV system inspection in Section

6E2.

Engine has no power

Engine overheating Refer to “OVERHEATING” in this

table.

Defective spark plug Spark plugs in Section 6F2.

Faulty ignition coil with ignitor Ignition coil in Section 6F2.

Fuel pressure out of specification

(dirty fuel filter, dirty or clogged fuel hose or

pipe, malfunctioning fuel pressure regulator,

malfunctioning fuel pump)“DIAG. FLOW TABLE B-3” in this

section.

Maladjusted TP sensor installation angle TP sensor in Section 6E2.

Faulty EGR system “DTC P0400 DIAG. FLOW TABLE”

in this section.

Faulty injector Fuel injector in Section 6E2.

Faulty TP sensor, ECT sensor or MAF sensor TP sensor, ECT sensor or MAF

sensor in Section 6E2.

Faulty ECM (PCM) Inspection of ECM (PCM) and its

circuit in this section.

Low compression Refer to the same item in “HARD

STARTING” of this table.

Dragging brakes Diagnosis in Section 5.

Slipping clutch Diagnosis in Section 7C1.

Page 194 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-33

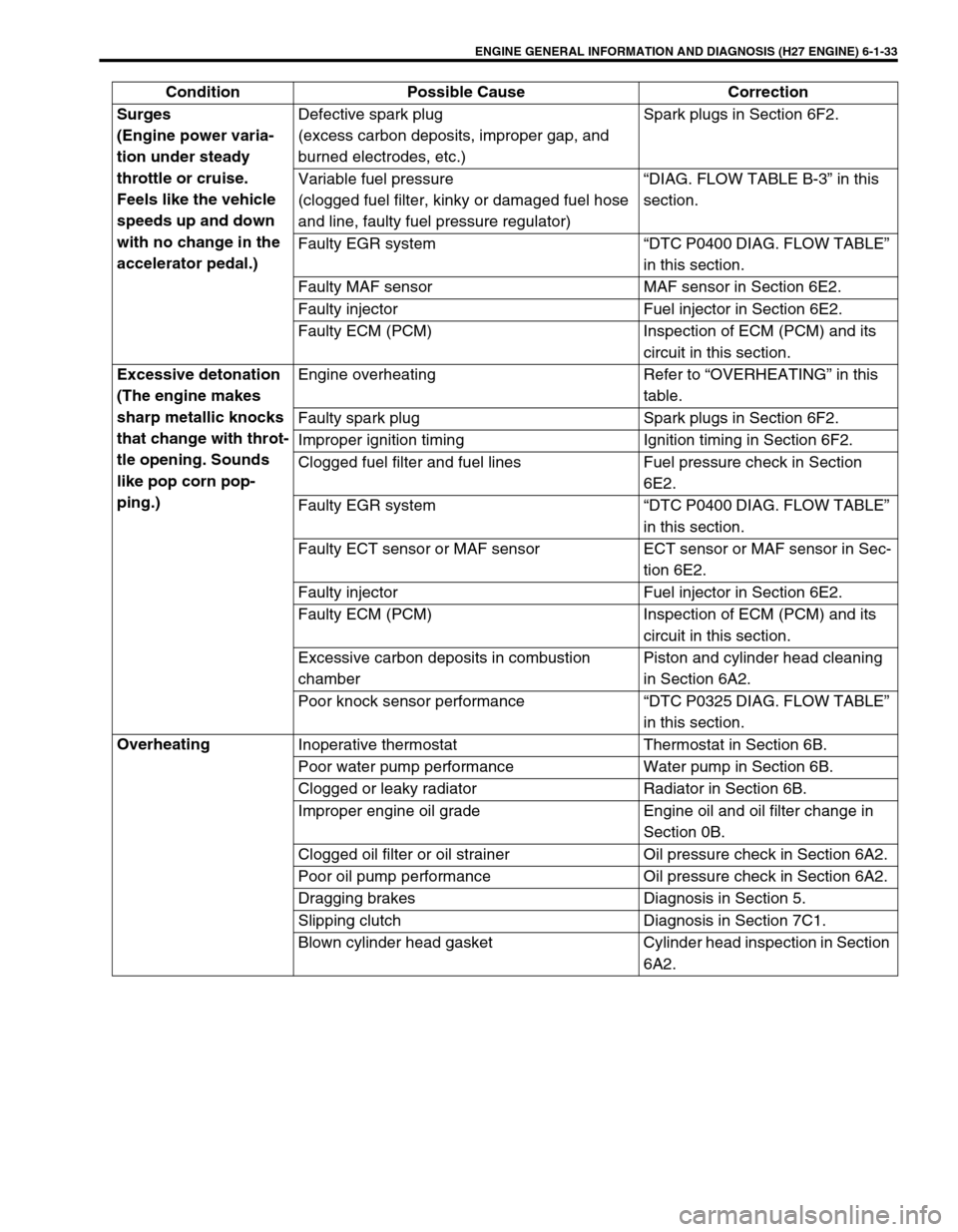

Surges

(Engine power varia-

tion under steady

throttle or cruise.

Feels like the vehicle

speeds up and down

with no change in the

accelerator pedal.)Defective spark plug

(excess carbon deposits, improper gap, and

burned electrodes, etc.)Spark plugs in Section 6F2.

Variable fuel pressure

(clogged fuel filter, kinky or damaged fuel hose

and line, faulty fuel pressure regulator)“DIAG. FLOW TABLE B-3” in this

section.

Faulty EGR system “DTC P0400 DIAG. FLOW TABLE”

in this section.

Faulty MAF sensor MAF sensor in Section 6E2.

Faulty injector Fuel injector in Section 6E2.

Faulty ECM (PCM) Inspection of ECM (PCM) and its

circuit in this section.

Excessive detonation

(The engine makes

sharp metallic knocks

that change with throt-

tle opening. Sounds

like pop corn pop-

ping.)Engine overheating Refer to “OVERHEATING” in this

table.

Faulty spark plug Spark plugs in Section 6F2.

Improper ignition timing Ignition timing in Section 6F2.

Clogged fuel filter and fuel lines Fuel pressure check in Section

6E2.

Faulty EGR system “DTC P0400 DIAG. FLOW TABLE”

in this section.

Faulty ECT sensor or MAF sensor ECT sensor or MAF sensor in Sec-

tion 6E2.

Faulty injector Fuel injector in Section 6E2.

Faulty ECM (PCM) Inspection of ECM (PCM) and its

circuit in this section.

Excessive carbon deposits in combustion

chamberPiston and cylinder head cleaning

in Section 6A2.

Poor knock sensor performance “DTC P0325 DIAG. FLOW TABLE”

in this section.

Overheating

Inoperative thermostat Thermostat in Section 6B.

Poor water pump performance Water pump in Section 6B.

Clogged or leaky radiator Radiator in Section 6B.

Improper engine oil grade Engine oil and oil filter change in

Section 0B.

Clogged oil filter or oil strainer Oil pressure check in Section 6A2.

Poor oil pump performance Oil pressure check in Section 6A2.

Dragging brakes Diagnosis in Section 5.

Slipping clutch Diagnosis in Section 7C1.

Blown cylinder head gasket Cylinder head inspection in Section

6A2. Condition Possible Cause Correction

Page 198 of 656

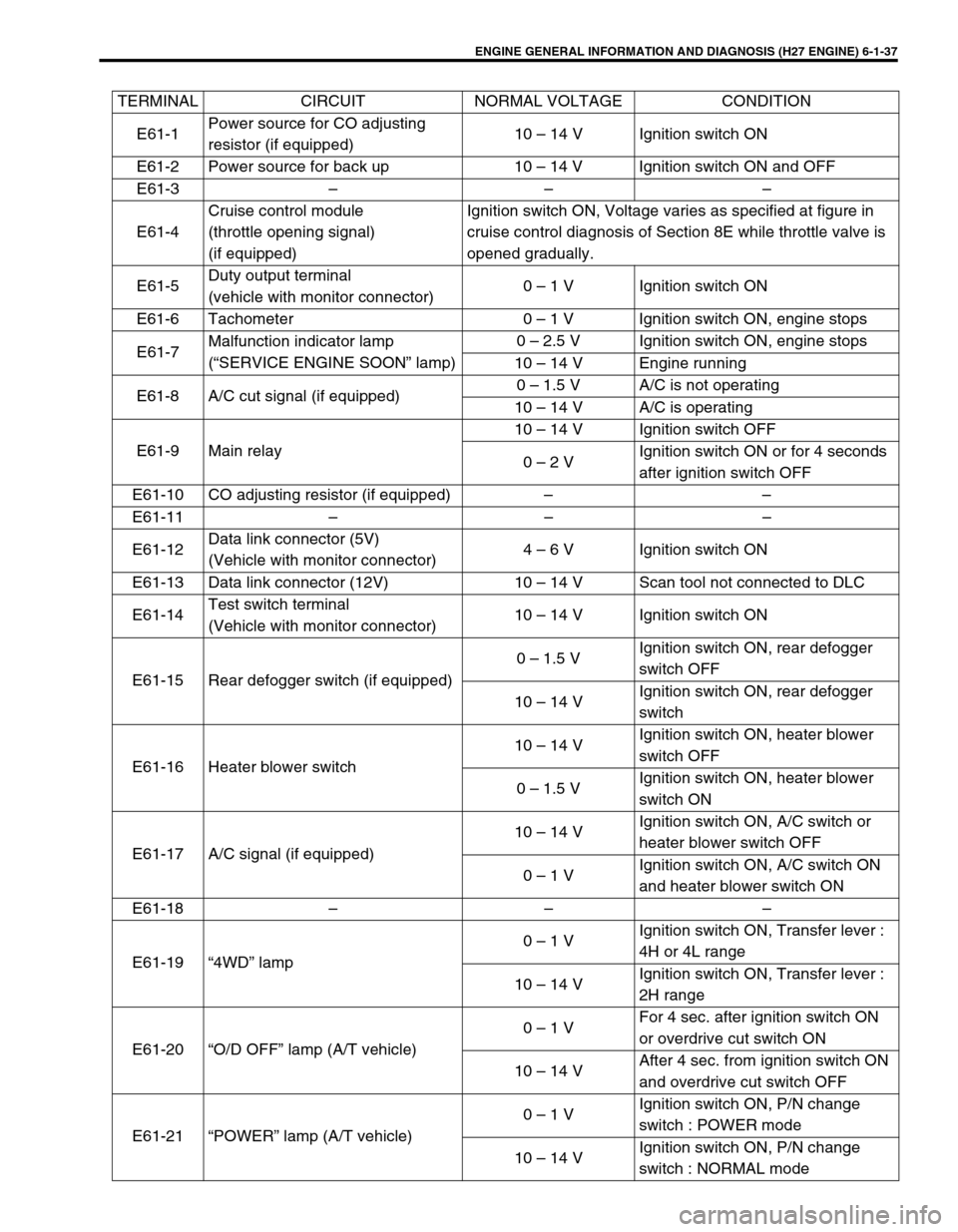

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-37

TERMINAL CIRCUIT NORMAL VOLTAGE CONDITION

E61-1Power source for CO adjusting

resistor (if equipped)10 – 14 V Ignition switch ON

E61-2 Power source for back up 10 – 14 V Ignition switch ON and OFF

E61-3 – – –

E61-4Cruise control module

(throttle opening signal)

(if equipped)Ignition switch ON, Voltage varies as specified at figure in

cruise control diagnosis of Section 8E while throttle valve is

opened gradually.

E61-5Duty output terminal

(vehicle with monitor connector)0 – 1 V Ignition switch ON

E61-6 Tachometer 0 – 1 V Ignition switch ON, engine stops

E61-7Malfunction indicator lamp

(“SERVICE ENGINE SOON” lamp)0 – 2.5 V Ignition switch ON, engine stops

10 – 14 V Engine running

E61-8 A/C cut signal (if equipped)0 – 1.5 V A/C is not operating

10 – 14 V A/C is operating

E61-9 Main relay10 – 14 V Ignition switch OFF

0 – 2 VIgnition switch ON or for 4 seconds

after ignition switch OFF

E61-10 CO adjusting resistor (if equipped) – –

E61-11 – – –

E61-12Data link connector (5V)

(Vehicle with monitor connector)4 – 6 V Ignition switch ON

E61-13 Data link connector (12V) 10 – 14 V Scan tool not connected to DLC

E61-14Test switch terminal

(Vehicle with monitor connector)10 – 14 V Ignition switch ON

E61-15 Rear defogger switch (if equipped)0 – 1.5 VIgnition switch ON, rear defogger

switch OFF

10 – 14 VIgnition switch ON, rear defogger

switch

E61-16 Heater blower switch10 – 14 VIgnition switch ON, heater blower

switch OFF

0 – 1.5 VIgnition switch ON, heater blower

switch ON

E61-17 A/C signal (if equipped)10 – 14 VIgnition switch ON, A/C switch or

heater blower switch OFF

0 – 1 VIgnition switch ON, A/C switch ON

and heater blower switch ON

E61-18 – – –

E61-19 “4WD” lamp0 – 1 VIgnition switch ON, Transfer lever :

4H or 4L range

10 – 14 VIgnition switch ON, Transfer lever :

2H range

E61-20 “O/D OFF” lamp (A/T vehicle)0 – 1 VFor 4 sec. after ignition switch ON

or overdrive cut switch ON

10 – 14 VAfter 4 sec. from ignition switch ON

and overdrive cut switch OFF

E61-21 “POWER” lamp (A/T vehicle)0 – 1 VIgnition switch ON, P/N change

switch : POWER mode

10 – 14 VIgnition switch ON, P/N change

switch : NORMAL mode