Power SUZUKI GRAND VITARA 2001 2.G Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2001, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2001 2.GPages: 656, PDF Size: 14.31 MB

Page 222 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-61

DTC P0135 HO2S-1 (Bank 1) Heater Circuit Malfunction

WIRING DIAGRAM

Refer to DTC P0130.

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and run

engine at idle speed for 5 min.

3) Check pending DTC by using scan tool.

TROUBLESHOOTING

DTC DETECTING CONDITION TROUBLE AREA

Following condition is detected when HO2S heater is

electrically live (2 driving cycle detection logic).

• Current of HO2S heater is 5.3 A or more or less than

0.09 A, or

• Voltage of HO2S heater is 14.0 V or higher or lower

than 11.7 V.HO2S-1 heater circuit

HO2S-1 heater

ECM (PCM)

HO2S heater relay

NOTE:

Check to make sure that following conditions are satisfied when using this “DTC CONFIRMATION

PROCEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE

DIAG. FLOW TABLE” in

this section.

2 HO2S-1 heater check :

1) Disconnect HO2S-1 coupler with ignition

switch OFF.

2) Check resistance between “3” and “4” termi-

nal of HO2S-1 coupler.

HO2S-1 heater resistance :

5.0 – 6.4

Ω

ΩΩ Ω (at 20°C (68°F))

Is it within above specification?Go to Step 3. Replace HO2S-1.

3 HO2S heater power supply check :

1) With ignition switch ON leaving engine OFF,

check voltage between E139-3 and ground,

E139-1 and ground. (See Fig.)

Is each voltage 10 – 14 V?Go to Step 4. “HO2S”, and/or “IG

METER” fuse blown.

If OK, faulty “BLK/WHT”

wire or “BLU/WHT” wire.

Page 224 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-63

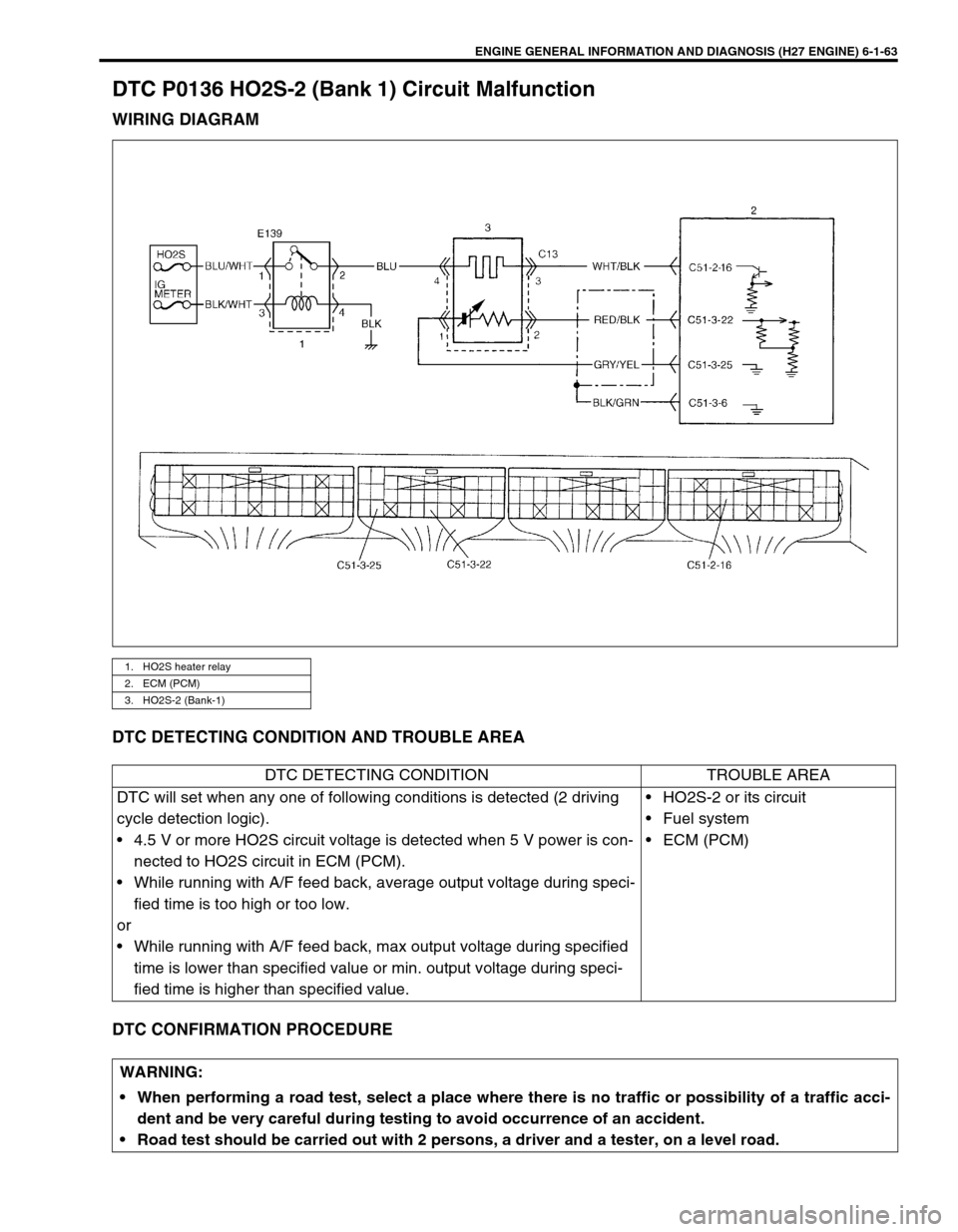

DTC P0136 HO2S-2 (Bank 1) Circuit Malfunction

WIRING DIAGRAM

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1. HO2S heater relay

2. ECM (PCM)

3. HO2S-2 (Bank-1)

DTC DETECTING CONDITION TROUBLE AREA

DTC will set when any one of following conditions is detected (2 driving

cycle detection logic).

• 4.5 V or more HO2S circuit voltage is detected when 5 V power is con-

nected to HO2S circuit in ECM (PCM).

• While running with A/F feed back, average output voltage during speci-

fied time is too high or too low.

or

• While running with A/F feed back, max output voltage during specified

time is lower than specified value or min. output voltage during speci-

fied time is higher than specified value.• HO2S-2 or its circuit

• Fuel system

•ECM (PCM)

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 227 of 656

6-1-66 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

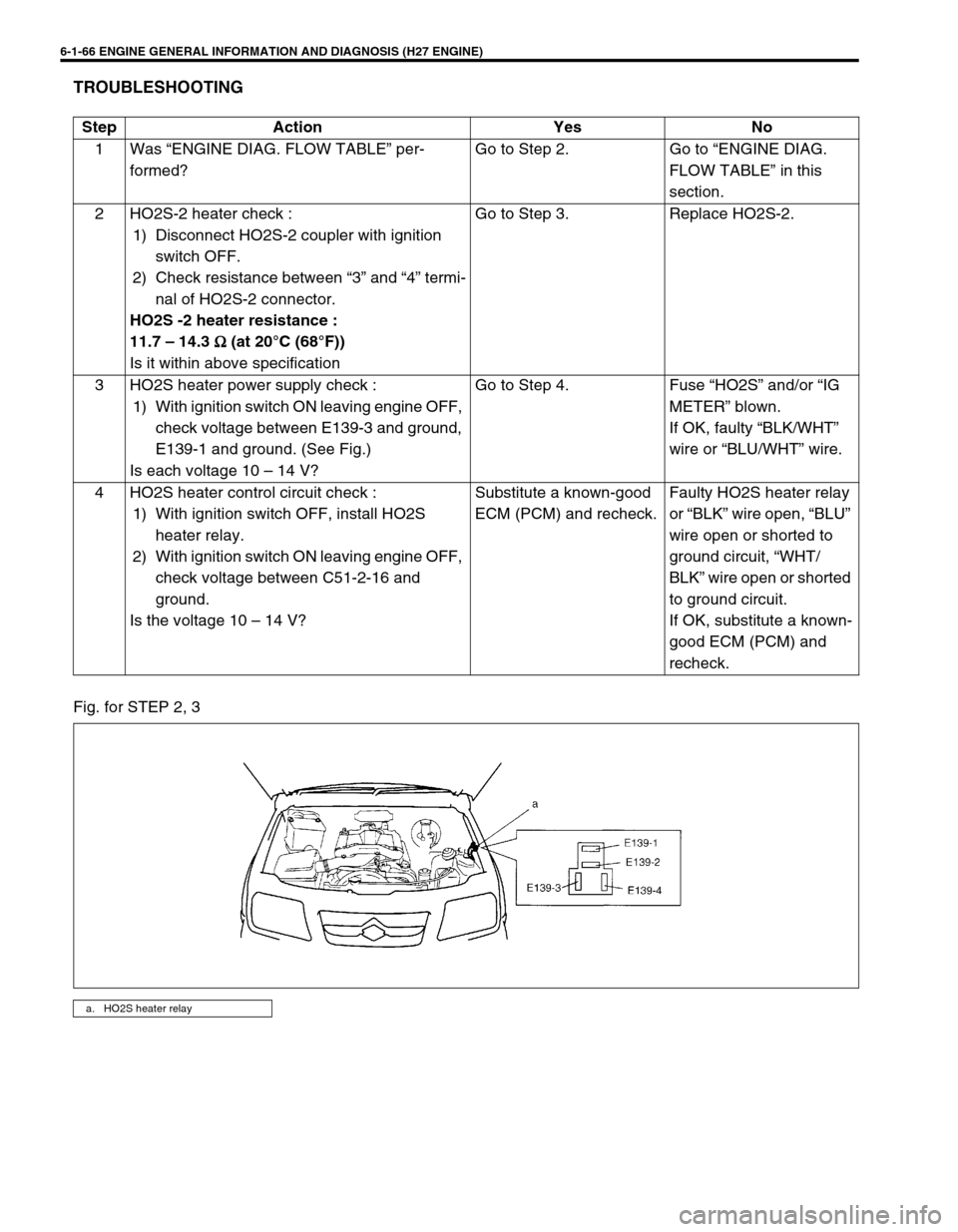

TROUBLESHOOTING

Fig. for STEP 2, 3Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 HO2S-2 heater check :

1) Disconnect HO2S-2 coupler with ignition

switch OFF.

2) Check resistance between “3” and “4” termi-

nal of HO2S-2 connector.

HO2S -2 heater resistance :

11.7 – 14.3

Ω

ΩΩ Ω (at 20°C (68°F))

Is it within above specificationGo to Step 3. Replace HO2S-2.

3 HO2S heater power supply check :

1) With ignition switch ON leaving engine OFF,

check voltage between E139-3 and ground,

E139-1 and ground. (See Fig.)

Is each voltage 10 – 14 V?Go to Step 4. Fuse “HO2S” and/or “IG

METER” blown.

If OK, faulty “BLK/WHT”

wire or “BLU/WHT” wire.

4 HO2S heater control circuit check :

1) With ignition switch OFF, install HO2S

heater relay.

2) With ignition switch ON leaving engine OFF,

check voltage between C51-2-16 and

ground.

Is the voltage 10 – 14 V?Substitute a known-good

ECM (PCM) and recheck.Faulty HO2S heater relay

or “BLK” wire open, “BLU”

wire open or shorted to

ground circuit, “WHT/

BLK” wire open or shorted

to ground circuit.

If OK, substitute a known-

good ECM (PCM) and

recheck.

a. HO2S heater relay

Page 228 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-67

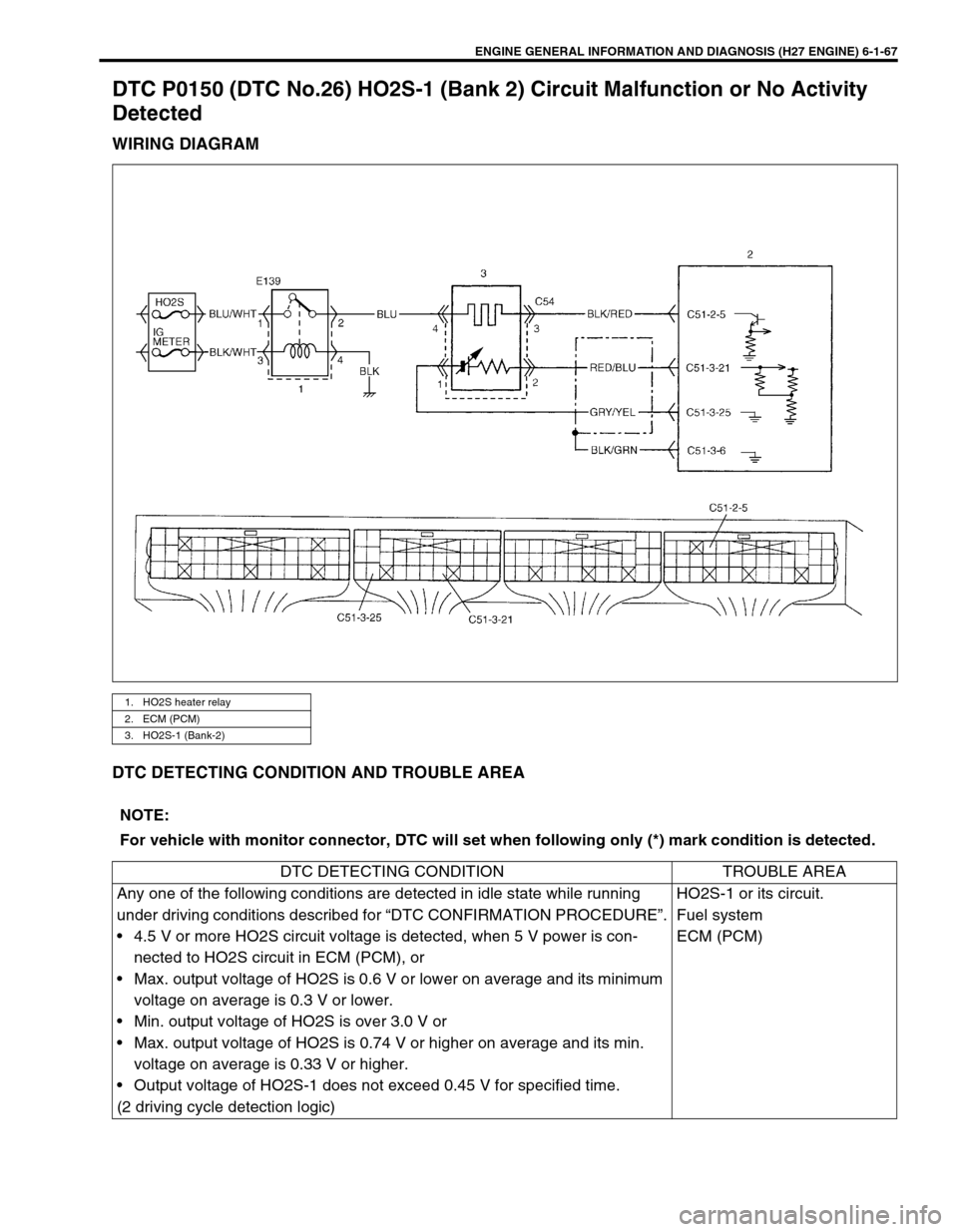

DTC P0150 (DTC No.26) HO2S-1 (Bank 2) Circuit Malfunction or No Activity

Detected

WIRING DIAGRAM

DTC DETECTING CONDITION AND TROUBLE AREA

1. HO2S heater relay

2. ECM (PCM)

3. HO2S-1 (Bank-2)

NOTE:

For vehicle with monitor connector, DTC will set when following only (*) mark condition is detected.

DTC DETECTING CONDITION TROUBLE AREA

Any one of the following conditions are detected in idle state while running

under driving conditions described for “DTC CONFIRMATION PROCEDURE”.

• 4.5 V or more HO2S circuit voltage is detected, when 5 V power is con-

nected to HO2S circuit in ECM (PCM), or

• Max. output voltage of HO2S is 0.6 V or lower on average and its minimum

voltage on average is 0.3 V or lower.

• Min. output voltage of HO2S is over 3.0 V or

• Max. output voltage of HO2S is 0.74 V or higher on average and its min.

voltage on average is 0.33 V or higher.

• Output voltage of HO2S-1 does not exceed 0.45 V for specified time.

(2 driving cycle detection logic)HO2S-1 or its circuit.

Fuel system

ECM (PCM)

Page 231 of 656

6-1-70 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

DTC P0155 HO2S-1 (Bank 2) Heater Circuit Malfunction

WIRING DIAGRAM

Refer to DTC P0150.

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and run

engine at idle speed for 5 min.

3) Check pending DTC by using scan tool.

TROUBLESHOOTING

DTC DETECTING CONDITION TROUBLE AREA

Following condition is detected when HO2S heater is

electrically live (2 driving cycle detection logic).

• Current of HO2S heater is 5.3 A or more or less than

0.09 A, or

• Voltage of HO2S heater is 14.0 V or higher or lower

than 11.7 V.HO2S-1 heater circuit

HO2S-1 heater

ECM (PCM)

NOTE:

Check to make sure that following conditions are satisfied when using this “DTC CONFIRMATION

PROCEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE

DIAG. FLOW TABLE” in

this section.

2 HO2S-1 heater check :

1) Disconnect HO2S-1 coupler with ignition

switch OFF.

2) Check resistance between “3” and “4” termi-

nal of HO2S-1 coupler.

HO2S-1 heater resistance :

5.0 – 6.4

Ω

ΩΩ Ω (at 20°C (68°F))

Is it within above specification?Go to Step 3. Replace HO2S-1.

3 HO2S heater power supply check :

1) With ignition switch ON leaving engine OFF,

check voltage between E139-3 and ground,

E139-1 and ground. (See Fig.)

Is each voltage 10 – 14 V?Go to Step 4. “HO2S”, and/or “IG

METER” fuse blown.

If OK, faulty “BLK/WHT”

wire or “BLU/WHT” wire.

Page 233 of 656

6-1-72 ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE)

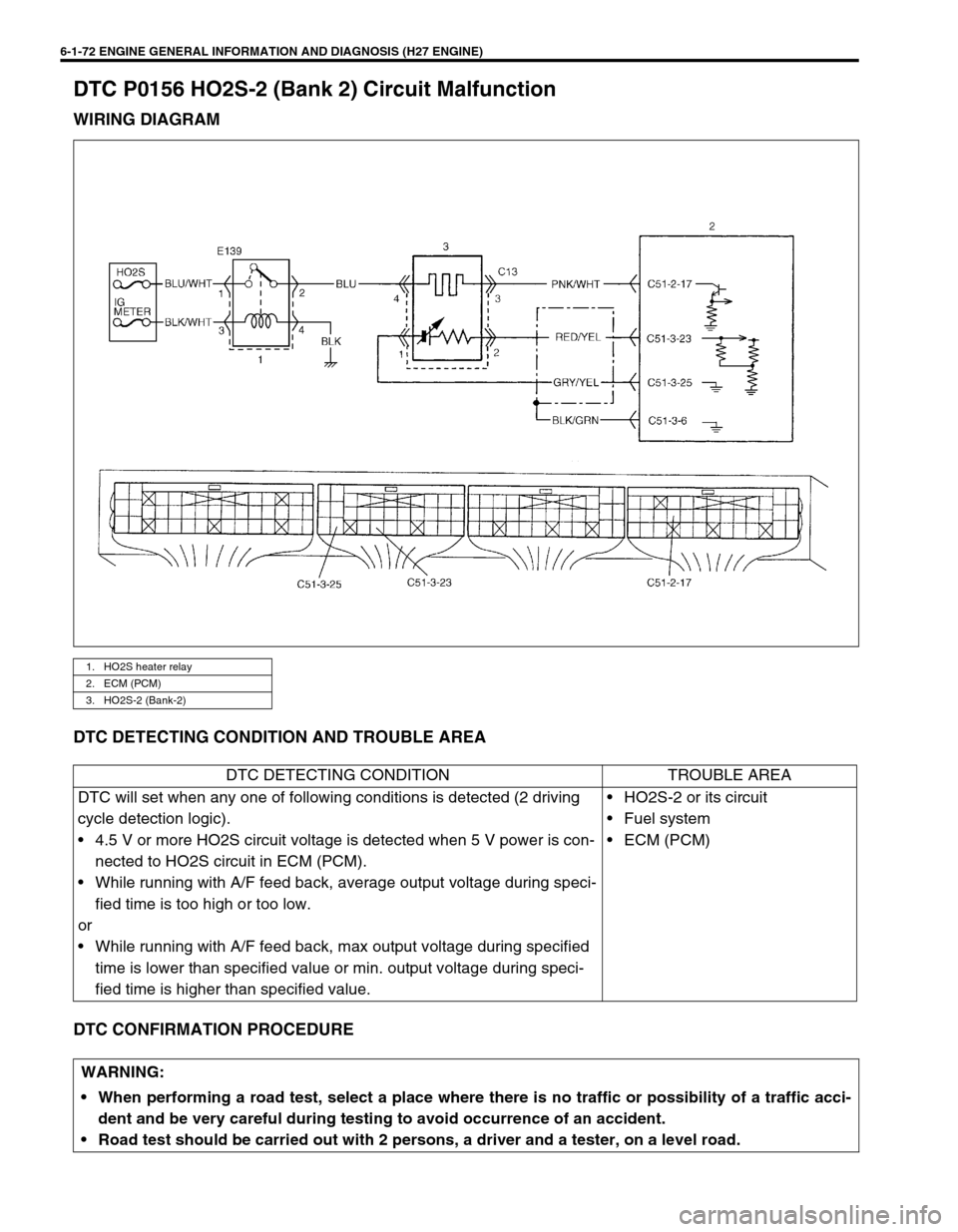

DTC P0156 HO2S-2 (Bank 2) Circuit Malfunction

WIRING DIAGRAM

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1. HO2S heater relay

2. ECM (PCM)

3. HO2S-2 (Bank-2)

DTC DETECTING CONDITION TROUBLE AREA

DTC will set when any one of following conditions is detected (2 driving

cycle detection logic).

• 4.5 V or more HO2S circuit voltage is detected when 5 V power is con-

nected to HO2S circuit in ECM (PCM).

• While running with A/F feed back, average output voltage during speci-

fied time is too high or too low.

or

• While running with A/F feed back, max output voltage during specified

time is lower than specified value or min. output voltage during speci-

fied time is higher than specified value.• HO2S-2 or its circuit

• Fuel system

• ECM (PCM)

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 236 of 656

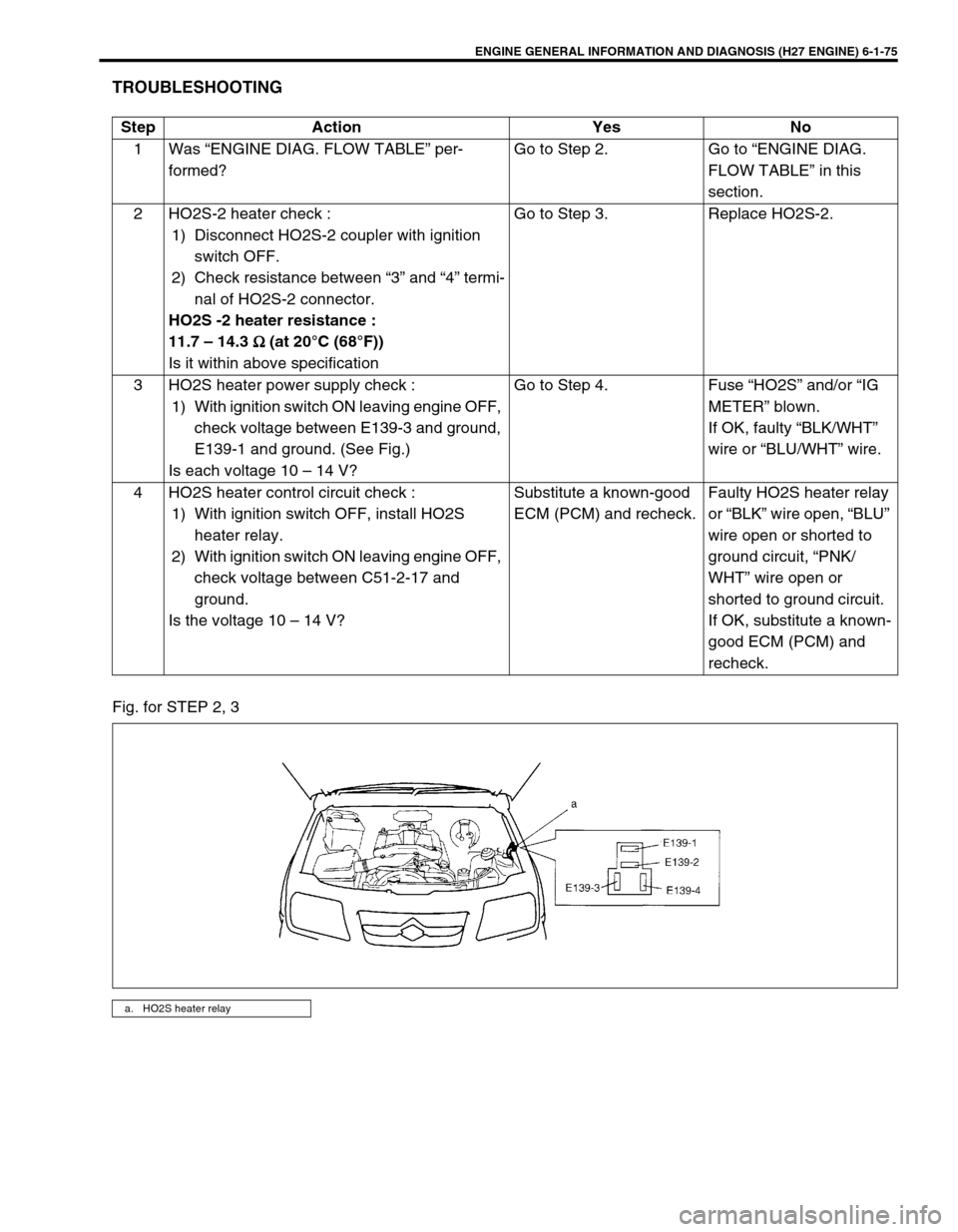

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-75

TROUBLESHOOTING

Fig. for STEP 2, 3Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 HO2S-2 heater check :

1) Disconnect HO2S-2 coupler with ignition

switch OFF.

2) Check resistance between “3” and “4” termi-

nal of HO2S-2 connector.

HO2S -2 heater resistance :

11.7 – 14.3

Ω

ΩΩ Ω (at 20°C (68°F))

Is it within above specificationGo to Step 3. Replace HO2S-2.

3 HO2S heater power supply check :

1) With ignition switch ON leaving engine OFF,

check voltage between E139-3 and ground,

E139-1 and ground. (See Fig.)

Is each voltage 10 – 14 V?Go to Step 4. Fuse “HO2S” and/or “IG

METER” blown.

If OK, faulty “BLK/WHT”

wire or “BLU/WHT” wire.

4 HO2S heater control circuit check :

1) With ignition switch OFF, install HO2S

heater relay.

2) With ignition switch ON leaving engine OFF,

check voltage between C51-2-17 and

ground.

Is the voltage 10 – 14 V?Substitute a known-good

ECM (PCM) and recheck.Faulty HO2S heater relay

or “BLK” wire open, “BLU”

wire open or shorted to

ground circuit, “PNK/

WHT” wire open or

shorted to ground circuit.

If OK, substitute a known-

good ECM (PCM) and

recheck.

a. HO2S heater relay

Page 244 of 656

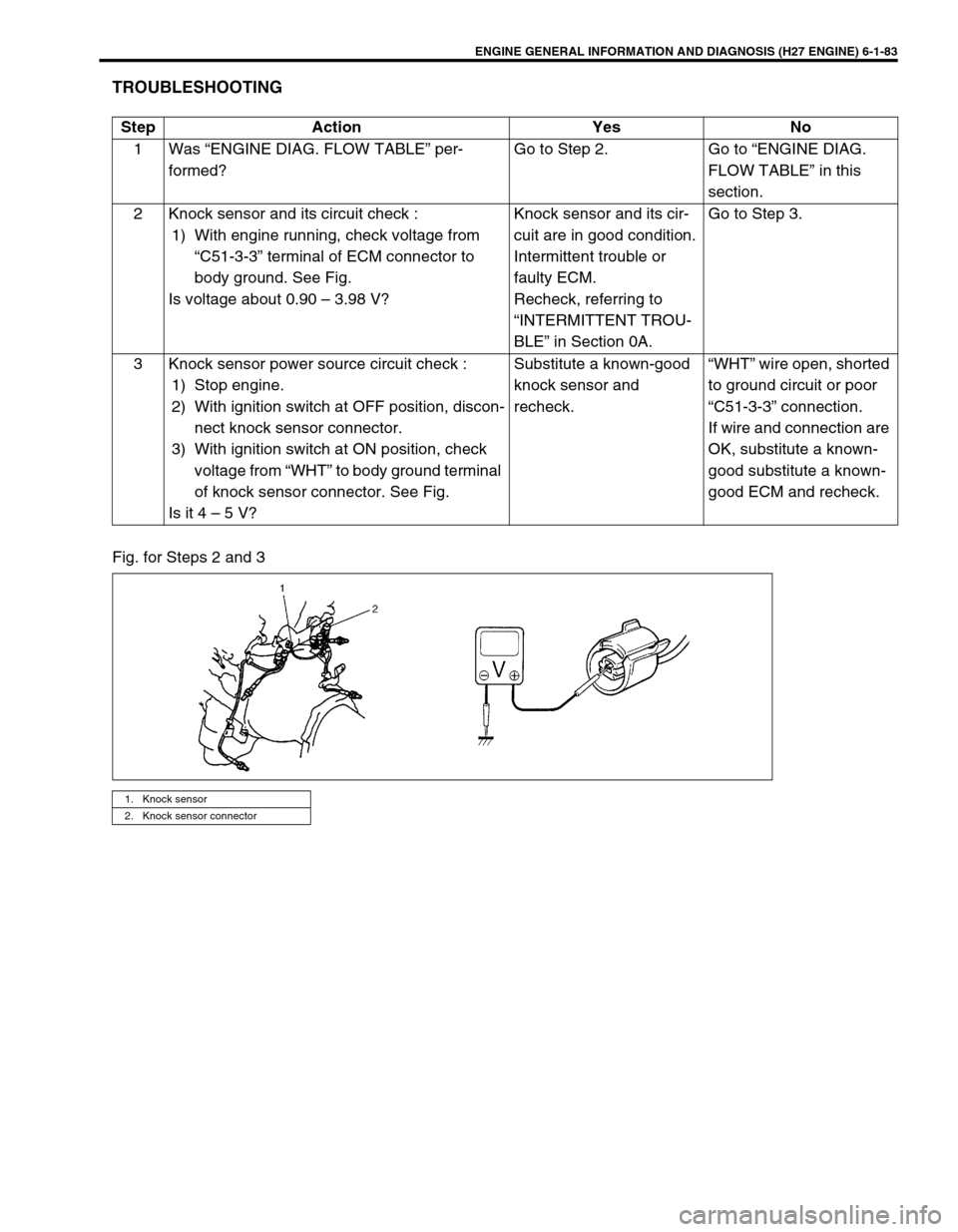

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-83

TROUBLESHOOTING

Fig. for Steps 2 and 3Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Knock sensor and its circuit check :

1) With engine running, check voltage from

“C51-3-3” terminal of ECM connector to

body ground. See Fig.

Is voltage about 0.90 – 3.98 V?Knock sensor and its cir-

cuit are in good condition.

Intermittent trouble or

faulty ECM.

Recheck, referring to

“INTERMITTENT TROU-

BLE” in Section 0A.Go to Step 3.

3 Knock sensor power source circuit check :

1) Stop engine.

2) With ignition switch at OFF position, discon-

nect knock sensor connector.

3) With ignition switch at ON position, check

voltage from “WHT” to body ground terminal

of knock sensor connector. See Fig.

Is it 4 – 5 V?Substitute a known-good

knock sensor and

recheck.“WHT” wire open, shorted

to ground circuit or poor

“C51-3-3” connection.

If wire and connection are

OK, substitute a known-

good substitute a known-

good ECM and recheck.

1. Knock sensor

2. Knock sensor connector

Page 248 of 656

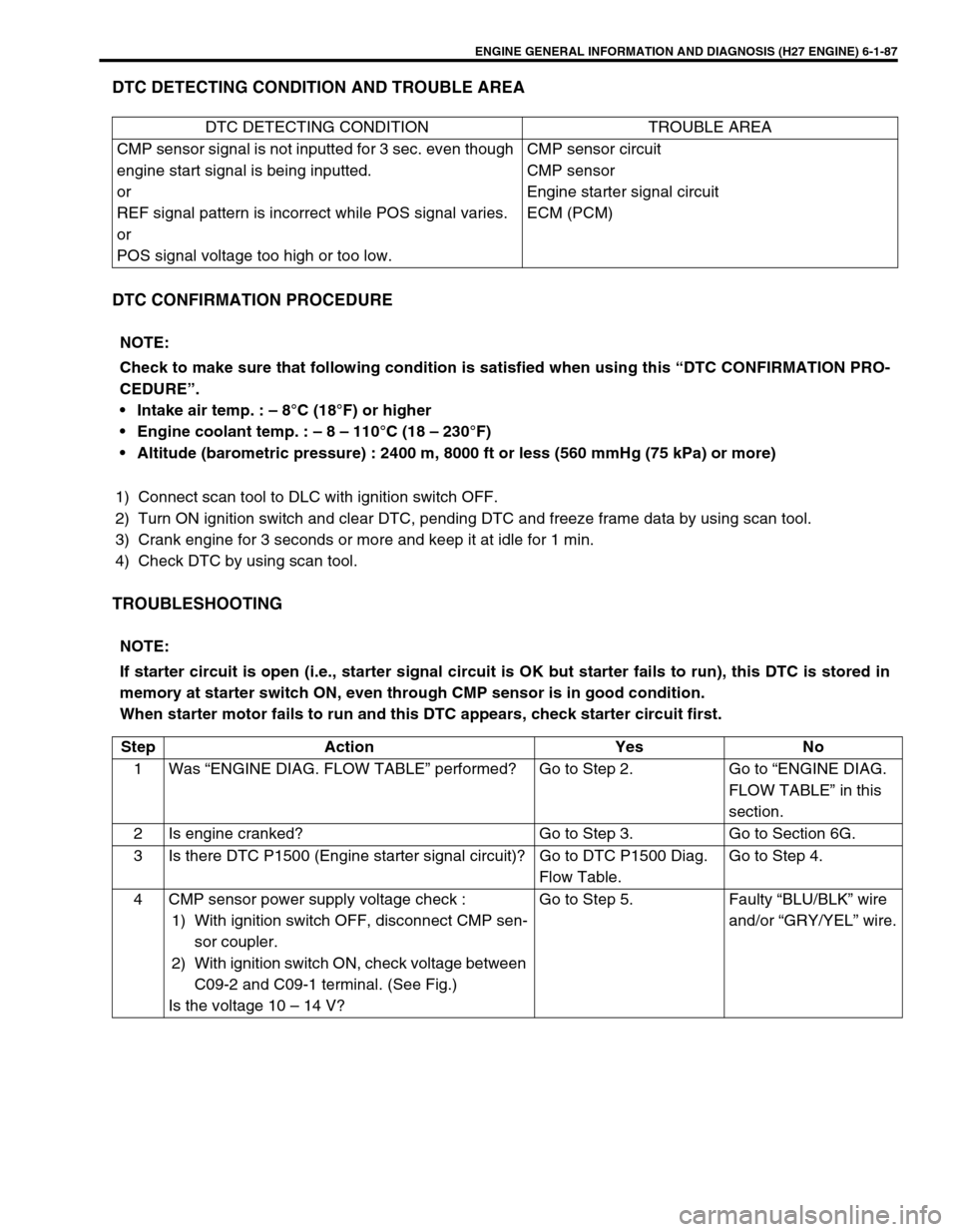

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-87

DTC DETECTING CONDITION AND TROUBLE AREA

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool.

3) Crank engine for 3 seconds or more and keep it at idle for 1 min.

4) Check DTC by using scan tool.

TROUBLESHOOTING

DTC DETECTING CONDITION TROUBLE AREA

CMP sensor signal is not inputted for 3 sec. even though

engine start signal is being inputted.

or

REF signal pattern is incorrect while POS signal varies.

or

POS signal voltage too high or too low.CMP sensor circuit

CMP sensor

Engine starter signal circuit

ECM (PCM)

NOTE:

Check to make sure that following condition is satisfied when using this “DTC CONFIRMATION PRO-

CEDURE”.

Intake air temp. : – 8°C (18°F) or higher

Engine coolant temp. : – 8 – 110°C (18 – 230°F)

Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

NOTE:

If starter circuit is open (i.e., starter signal circuit is OK but starter fails to run), this DTC is stored in

memory at starter switch ON, even through CMP sensor is in good condition.

When starter motor fails to run and this DTC appears, check starter circuit first.

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Is engine cranked? Go to Step 3. Go to Section 6G.

3 Is there DTC P1500 (Engine starter signal circuit)? Go to DTC P1500 Diag.

Flow Table.Go to Step 4.

4 CMP sensor power supply voltage check :

1) With ignition switch OFF, disconnect CMP sen-

sor coupler.

2) With ignition switch ON, check voltage between

C09-2 and C09-1 terminal. (See Fig.)

Is the voltage 10 – 14 V?Go to Step 5. Faulty “BLU/BLK” wire

and/or “GRY/YEL” wire.

Page 252 of 656

ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-91

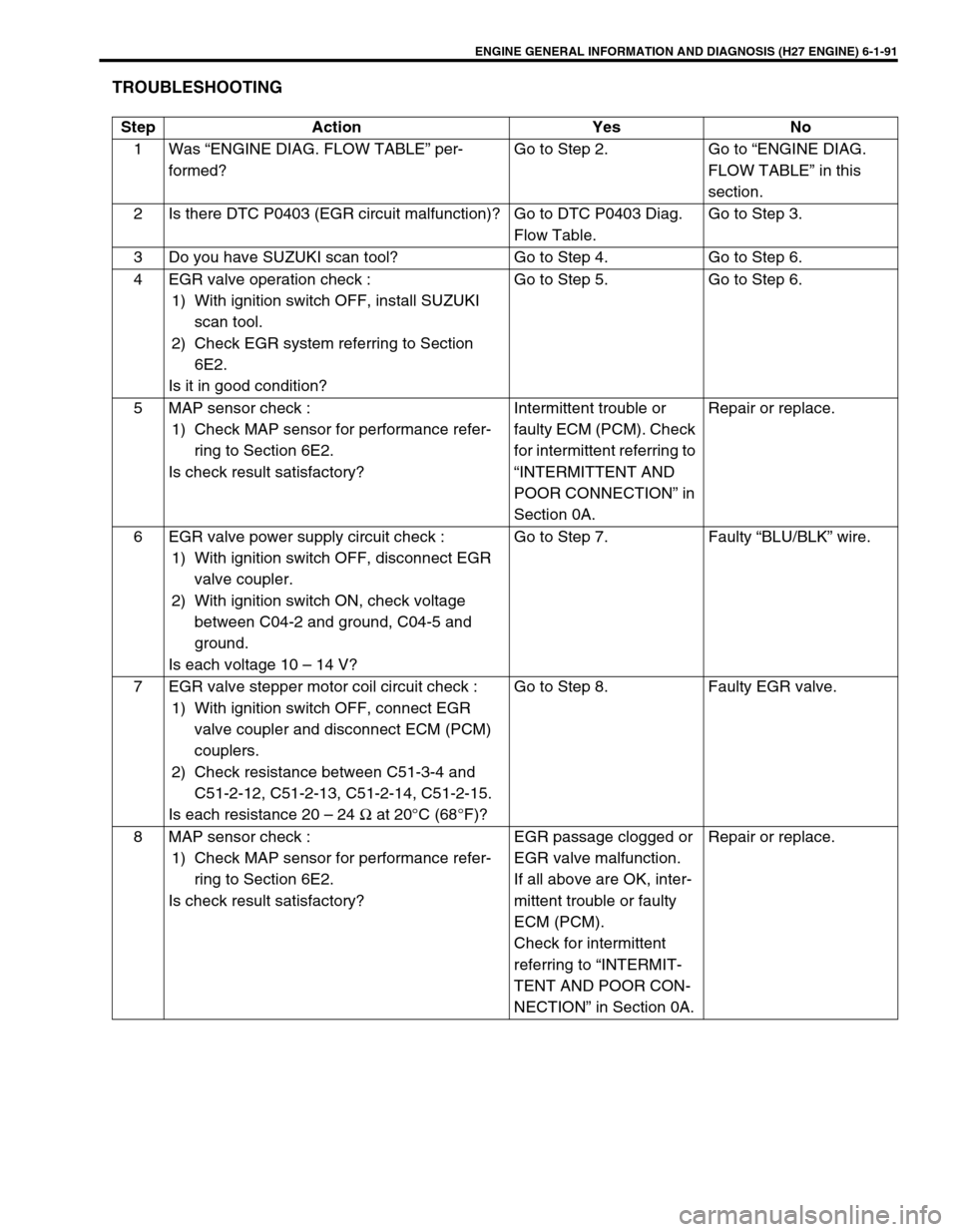

TROUBLESHOOTING

Step Action Yes No

1 Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Is there DTC P0403 (EGR circuit malfunction)? Go to DTC P0403 Diag.

Flow Table.Go to Step 3.

3 Do you have SUZUKI scan tool? Go to Step 4. Go to Step 6.

4 EGR valve operation check :

1) With ignition switch OFF, install SUZUKI

scan tool.

2) Check EGR system referring to Section

6E2.

Is it in good condition?Go to Step 5. Go to Step 6.

5 MAP sensor check :

1) Check MAP sensor for performance refer-

ring to Section 6E2.

Is check result satisfactory?Intermittent trouble or

faulty ECM (PCM). Check

for intermittent referring to

“INTERMITTENT AND

POOR CONNECTION” in

Section 0A.Repair or replace.

6 EGR valve power supply circuit check :

1) With ignition switch OFF, disconnect EGR

valve coupler.

2) With ignition switch ON, check voltage

between C04-2 and ground, C04-5 and

ground.

Is each voltage 10 – 14 V?Go to Step 7. Faulty “BLU/BLK” wire.

7 EGR valve stepper motor coil circuit check :

1) With ignition switch OFF, connect EGR

valve coupler and disconnect ECM (PCM)

couplers.

2) Check resistance between C51-3-4 and

C51-2-12, C51-2-13, C51-2-14, C51-2-15.

Is each resistance 20 – 24 Ω at 20°C (68°F)?Go to Step 8. Faulty EGR valve.

8 MAP sensor check :

1) Check MAP sensor for performance refer-

ring to Section 6E2.

Is check result satisfactory?EGR passage clogged or

EGR valve malfunction.

If all above are OK, inter-

mittent trouble or faulty

ECM (PCM).

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.Repair or replace.