tire SUZUKI GRAND VITARA 2017 Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 2017Pages: 482, PDF Size: 21 MB

Page 401 of 482

8-1

EMERGENCY SERVICE

54P00-01E

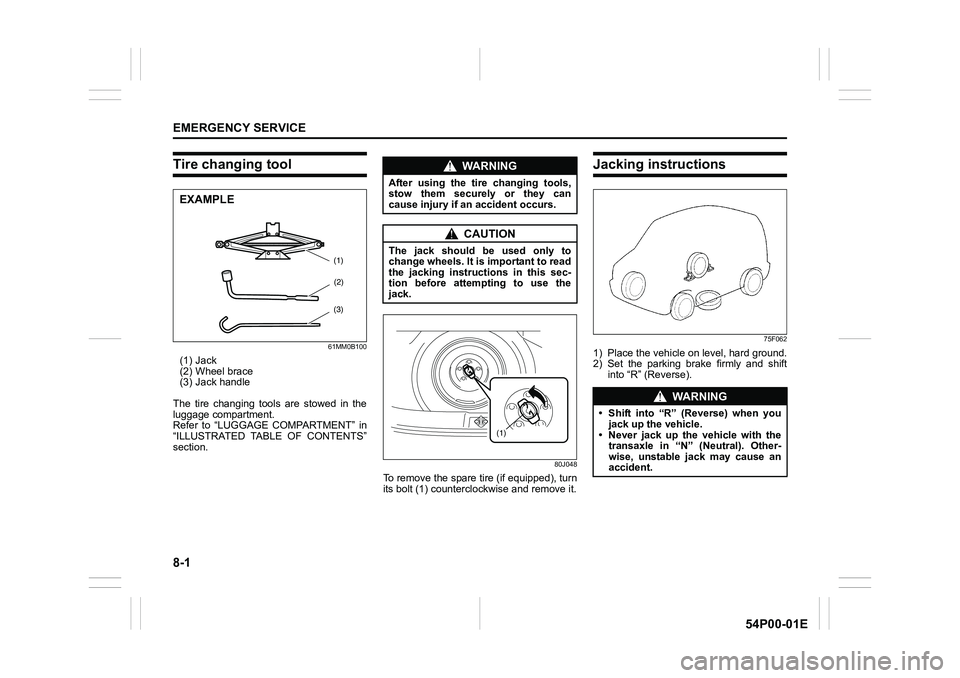

Tire changing tool

61MM0B100

(1) Jack

(2) Wheel brace

(3) Jack handle

The tire changing tools are stowed in the

luggage compartment.

Refer to “LUGGAGE COMPARTMENT” in

“ILLUSTRATED TABLE OF CONTENTS”

section.

80J048

To remove the spare tire (if equipped), turn

its bolt (1) counterclockwise and remove it.

Jacking instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).

EXAMPLE

(3)

(2)

(1)

WA R N I N G

After using the tire changing tools,

stow them securely or they can

cause injury if an accident occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

(1)

WA R N I N G

• Shift into “R” (Reverse) when you

jack up the vehicle.

• Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

Page 402 of 482

8-2

EMERGENCY SERVICE

54P00-01E

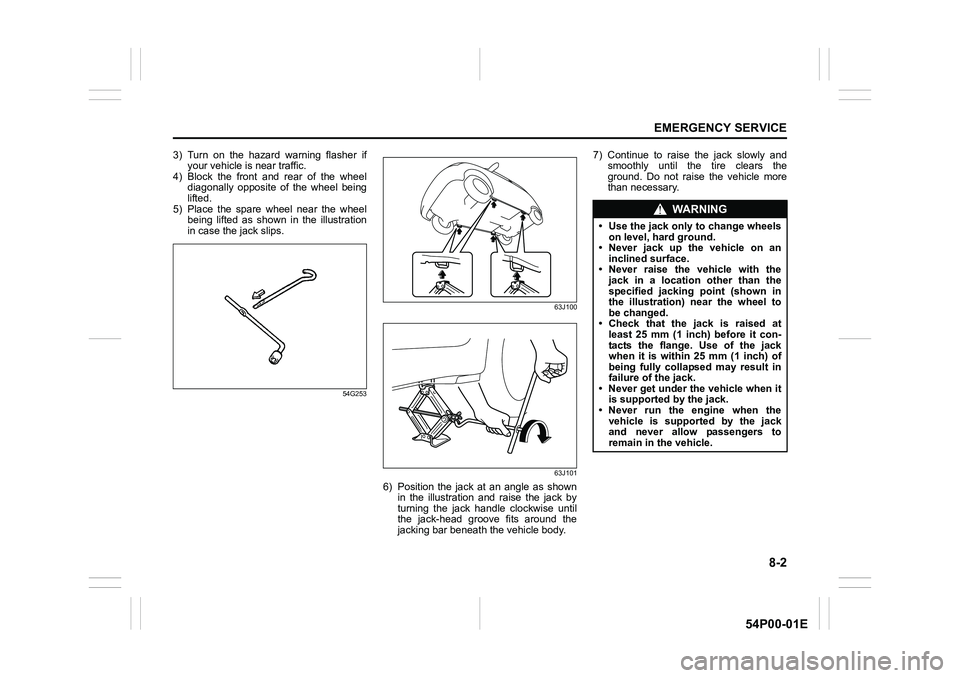

3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case the jack slips.

54G25363J100

63J101

6) Position the jack at an angle as shown

in the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.7) Continue to raise the jack slowly and

smoothly until the tire clears the

ground. Do not raise the vehicle more

than necessary.

WA R N I N G

• Use the jack only to change wheels

on level, hard ground.

• Never jack up the vehicle on an

inclined surface.

• Never raise the vehicle with the

jack in a location other than the

specified jacking point (shown in

the illustration) near the wheel to

be changed.

• Check that the jack is raised at

least 25 mm (1 inch) before it con-

tacts the flange. Use of the jack

when it is within 25 mm (1 inch) of

being fully collapsed may result in

failure of the jack.

• Never get under the vehicle when it

is supported by the jack.

• Never run the engine when the

vehicle is supported by the jack

and never allow passengers to

remain in the vehicle.

Page 405 of 482

8-5

EMERGENCY SERVICE

54P00-01E

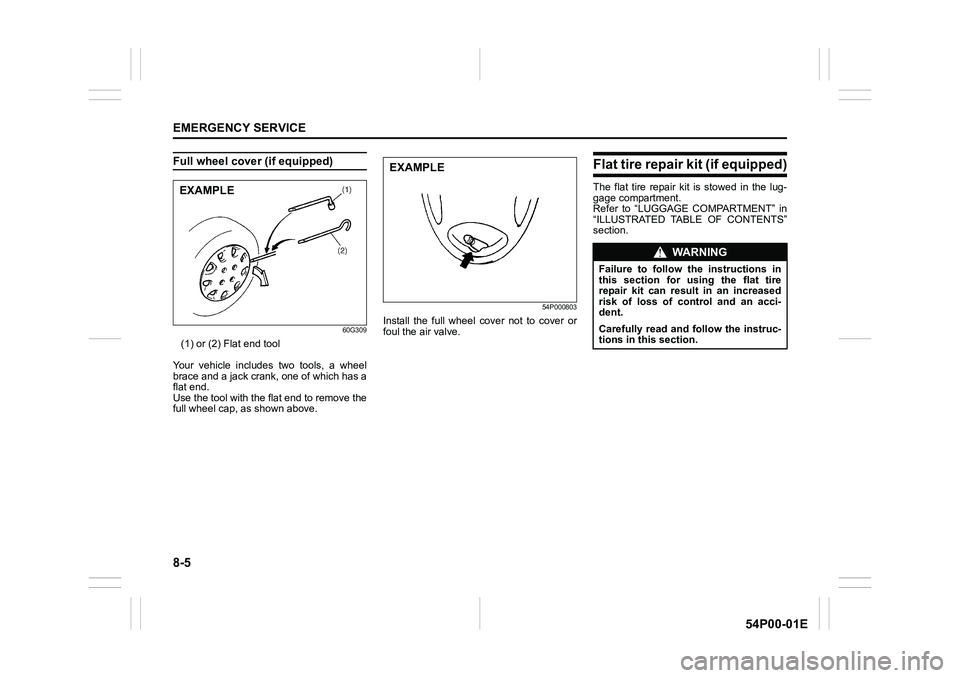

Full wheel cover (if equipped)

60G309

(1) or (2) Flat end tool

Your vehicle includes two tools, a wheel

brace and a jack crank, one of which has a

flat end.

Use the tool with the flat end to remove the

full wheel cap, as shown above.

54P000803

Install the full wheel cover not to cover or

foul the air valve.

Flat tire repair kit (if equipped)

The flat tire repair kit is stowed in the lug-

gage compartment.

Refer to “LUGGAGE COMPARTMENT” in

“ILLUSTRATED TABLE OF CONTENTS”

section.EXAMPLE

EXAMPLE

WA R N I N G

Failure to follow the instructions in

this section for using the flat tire

repair kit can result in an increased

risk of loss of control and an acci-

dent.

Carefully read and follow the instruc-

tions in this section.

Page 406 of 482

8-6

EMERGENCY SERVICE

54P00-01E

IMPORTANT

The flat tire repair kit cannot be used in

the following cases. Consult a SUZUKI

dealer or a roadside assistance service.

• Cuts or piercing in the tire tread

larger than approx. 4 mm.

• Cuts in the tire side wall.

• Tire damage caused by driving with

considerably reduced tire pressure or

even with deflated tire.

• The tire bead completely unseated

outside of the rim.

• The rim damaged.

Small punctures in the tire tread,

caused by a nail or a screw, can be

sealed with the flat tire repair kit.

Do not remove nails or screws from the

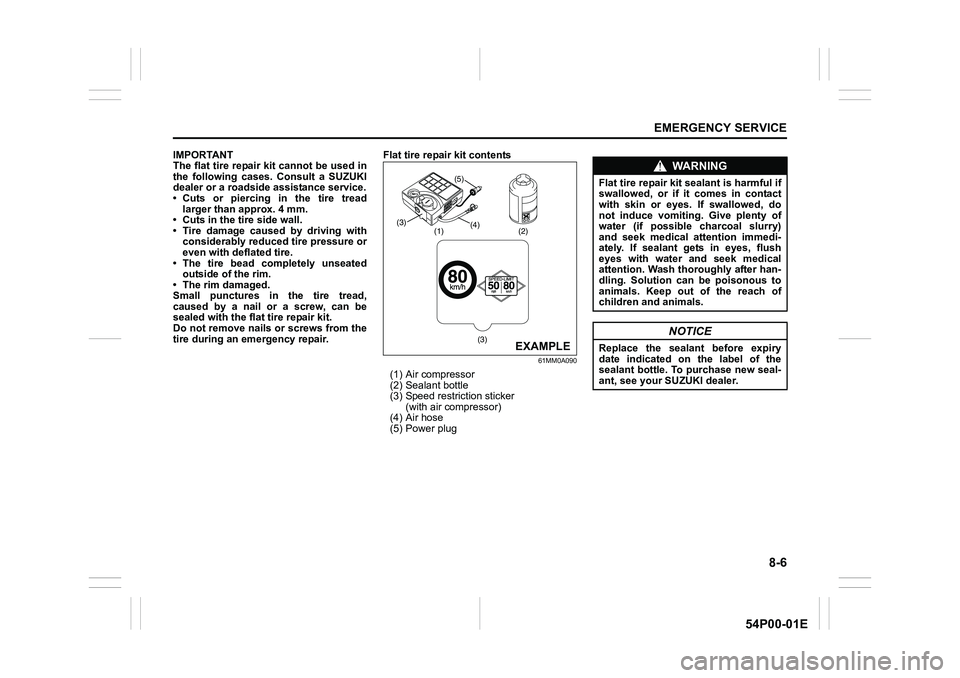

tire during an emergency repair.Flat tire repair kit contents

61MM0A090

(1) Air compressor

(2) Sealant bottle

(3) Speed restriction sticker

(with air compressor)

(4) Air hose

(5) Power plug

(1)(4) (5)

(3)(2)(3)

EXAMPLE

WA R N I N G

Flat tire repair kit sealant is harmful if

swallowed, or if it comes in contact

with skin or eyes. If swallowed, do

not induce vomiting. Give plenty of

water (if possible charcoal slurry)

and seek medical attention immedi-

ately. If sealant gets in eyes, flush

eyes with water and seek medical

attention. Wash thoroughly after han-

dling. Solution can be poisonous to

animals. Keep out of the reach of

children and animals.

NOTICE

Replace the sealant before expiry

date indicated on the label of the

sealant bottle. To purchase new seal-

ant, see your SUZUKI dealer.

Page 407 of 482

8-7

EMERGENCY SERVICE

54P00-01E

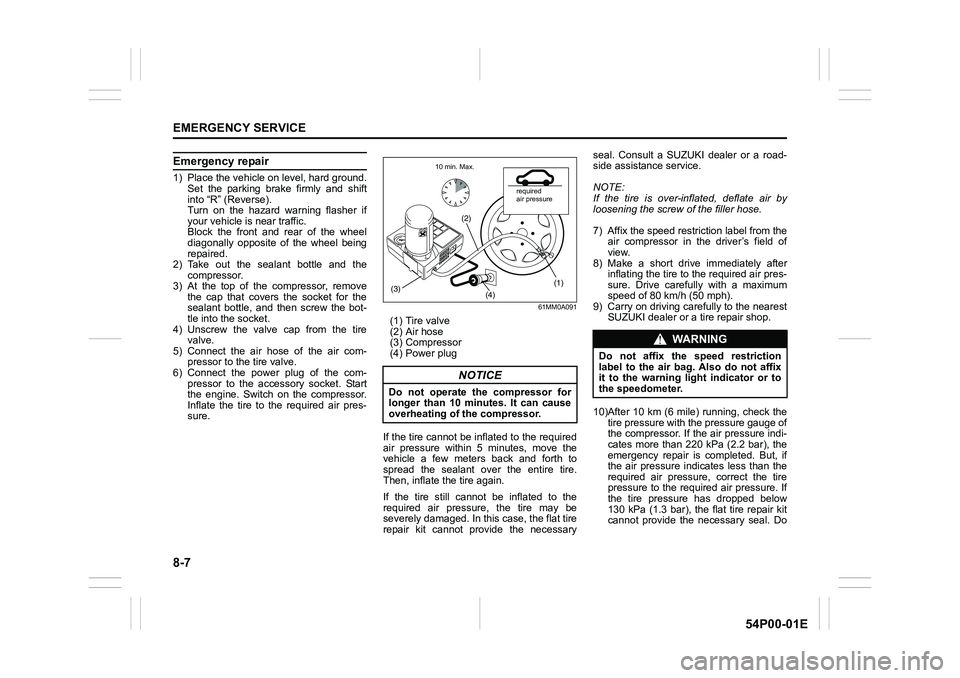

Emergency repair

1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “R” (Reverse).

Turn on the hazard warning flasher if

your vehicle is near traffic.

Block the front and rear of the wheel

diagonally opposite of the wheel being

repaired.

2) Take out the sealant bottle and the

compressor.

3) At the top of the compressor, remove

the cap that covers the socket for the

sealant bottle, and then screw the bot-

tle into the socket.

4) Unscrew the valve cap from the tire

valve.

5) Connect the air hose of the air com-

pressor to the tire valve.

6) Connect the power plug of the com-

pressor to the accessory socket. Start

the engine. Switch on the compressor.

Inflate the tire to the required air pres-

sure.

61MM0A091

(1) Tire valve

(2) Air hose

(3) Compressor

(4) Power plug

If the tire cannot be inflated to the required

air pressure within 5 minutes, move the

vehicle a few meters back and forth to

spread the sealant over the entire tire.

Then, inflate the tire again.

If the tire still cannot be inflated to the

required air pressure, the tire may be

severely damaged. In this case, the flat tire

repair kit cannot provide the necessaryseal. Consult a SUZUKI dealer or a road-

side assistance service.

NOTE:

If the tire is over-inflated, deflate air by

loosening the screw of the filler hose.

7) Affix the speed restriction label from the

air compressor in the driver’s field of

view.

8) Make a short drive immediately after

inflating the tire to the required air pres-

sure. Drive carefully with a maximum

speed of 80 km/h (50 mph).

9) Carry on driving carefully to the nearest

SUZUKI dealer or a tire repair shop.

10)After 10 km (6 mile) running, check the

tire pressure with the pressure gauge of

the compressor. If the air pressure indi-

cates more than 220 kPa (2.2 bar), the

emergency repair is completed. But, if

the air pressure indicates less than the

required air pressure, correct the tire

pressure to the required air pressure. If

the tire pressure has dropped below

130 kPa (1.3 bar), the flat tire repair kit

cannot provide the necessary seal. Do

NOTICE

Do not operate the compressor for

longer than 10 minutes. It can cause

overheating of the compressor.

(1)

(4)

(2)

(3)

required

air pressure 10 min. Max.

WA R N I N G

Do not affix the speed restriction

label to the air bag. Also do not affix

it to the warning light indicator or to

the speedometer.

Page 408 of 482

8-8

EMERGENCY SERVICE

54P00-01E

not use the tire and consult a SUZUKI

dealer or a roadside assistance service.Using compressor to inflate a tire

1) Place the vehicle on level, hard ground.

Set the parking brake firmly and shift

into “R” (Reverse).

2) Take out the compressor.

3) Unscrew the valve cap from the tire

valve.

4) Connect the air hose of the compressor

to the tire valve.

5) Connect the power plug of the com-

pressor to the accessory socket. Start

the engine. Switch on the compressor.

Inflate the tire to the required air pres-

sure.

Jump-starting instructions

WA R N I N G

Check the tire pressure and confirm

the completion of the emergency

repair after 10 km (6 mile) of running.

NOTICE

Have the tire renewed at the nearest

SUZUKI dealer. When reusing the

sealed tire, consult a tire repair shop.

The wheel can be reused after wiping

sealant off completely with cloth in

order to prevent rust, but the tire

valve and tire pressure monitoring

system (TPMS) sensor must be

renewed.

Dispose of the sealant bottle at a

SUZUKI dealer or in accordance with

your regional codes and practices.

After using the sealant bottle, replace

it with a new bottle from your SUZUKI

dealer.

NOTICE

Do not operate the compressor for

longer than 10 minutes. It can cause

overheating of the compressor.

WA R N I N G

• Never attempt to jump-start your

vehicle if the battery appears to be

frozen. Batteries in this condition

may explode.

• When making jump lead connec-

tions, check that your hands and

the jump leads remain clear from

pulleys, belts or fans.

• Batteries produce flammable

hydrogen gas. Keep flames and

sparks away from the battery or an

explosion may occur. Never smoke

when working near the battery.

• If the booster battery you use for

jump-starting is installed in another

vehicle, check that the two vehicles

are not touching each other.

• If your battery discharges repeat-

edly, for no apparent reason, have

your vehicle inspected by an

authorized SUZUKI dealer.

• To avoid harm to yourself or dam-

age to your vehicle or battery, fol-

low the jump-starting instructions

below.

If you are in doubt, call for qualified

road service.

Page 418 of 482

9-4

APPEARANCE CARE

54P00-01E

Washing

60B212S

When washing the vehicle, park it in the

place where direct sunlight does not fall on

it and follow the instructions below:

1) Flush the underside of body and wheel

housings with pressurized water to

remove mud and debris. Use plenty of

water.2) Rinse the body to loosen the dirt.

Remove dirt and mud from the body

exterior with running water. You may

use a soft sponge or brush. Do not use

hard materials which can scratch the

paint or plastic. Remember that the

headlight covers or lenses are made of

plastic in many cases.

3) Wash the entire exterior with a mild

detergent or car wash soap using a

sponge or soft cloth. The sponge or

cloth should be frequently soaked in the

soap solution.

4) Once the dirt has been completely

removed, rinse off the detergent with

running water.

5) Wipe off the vehicle body with a wet

chamois or cloth and allow it to dry in

the shade.

WA R N I N G

• Never attempt to wash and wax

your vehicle with the engine run-

ning.

• When cleaning the underside of the

body and fender, where there may

be sharp-edged parts, wear gloves

and a long-sleeved shirt to protect

your hands and arms from being

cut.

• After washing your vehicle, care-

fully test the brakes before driving

to check that they have maintained

their normal effectiveness.

CAUTION

If your vehicle is equipped with an

rain-sensing wiper system, place the

wiper control lever in “OFF” position.

If the lever is left in “AUTO” position,

the wipers could unexpectedly oper-

ate and cause an injury, and could

also be damaged.

NOTICE

When washing the vehicle:

• Avoid directing steam or hot water

of more than 80°C (176°F) on plas-

tic parts.

• To avoid damaging engine compo-

nents, do not use pressurized

water in the engine compartment.

NOTICE

To avoid damage to the paint or plas-

tic surface, do not wipe the dirt off

without ample water. Follow the

above procedure.

NOTICE

When using a commercial car wash

product, observe the cautions speci-

fied by the manufacturer. Never use

strong household detergents or

soaps.

Page 427 of 482

11-4

SPECIFICATIONS

54P00-01E

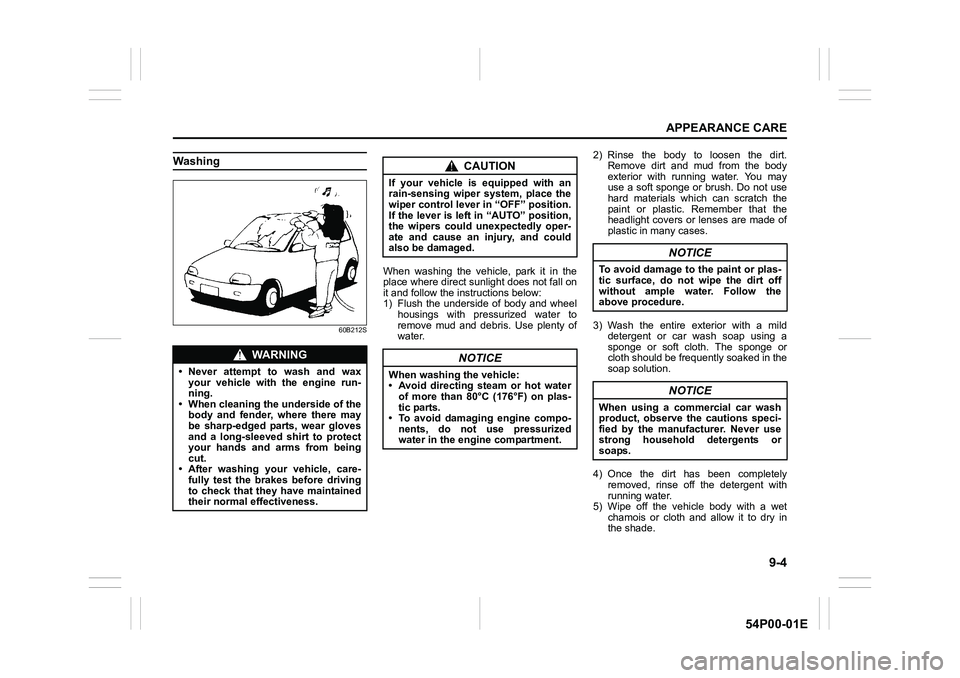

NOTE:

1) If loading over 4 people, follow the specified tire pressure listed on the tire information label.

*1 If you cannot prepare tires with the specified load index rate and speed symbol, prepare tires with higher load index rate and speed

symbol.

*2 If you prepare snow tires;

• Check that they are tires of the same size, structure and load capacity as the originally installed tires.

• Mount the snow tires on all four wheels.

• Understand that the maximum permissible speed of snow tires is generally less than the originally installed tires.

Consult your SUZUKI dealer or supplier for further information. ITEM: Wheels and tires

Tire size, front and rear

215/60R16 95H*1, 215/55R17 94V*1

Rim size 215/60R16 tire: 16X6 1/2J

215/55R17 tire: 17X6 1/2J

Tire pressures For the specified tire pressure, see the tire information label located

on the driver’s door lock pillar.

When loading 4 people or less, eco tire pressure as listed below is

recommended to achieve the smallest amount of fuel consumption.

1)

Front 280 kPa (2.80 kg/cm2, 41 psi)

Rear 260 kPa (2.60 kg/cm2, 38 psi)

Recommended snow chain (for Europe) Radial thickness: 10 mm, axial thickness: 10 mm

Recommended snow tire 215/60R16

*2 or 215/55R17*2

Page 431 of 482

12-1

SUPPLEMENT

54P00-01E

For Australia

Built date

Built date is located on vehicle identifica-

tion plate.

“Built Date” means – the calendar month

and the year in which the body shell and

power train sub-assemblies are conjoined

and the vehicle is driven or moved from the

production line.

Temporary-use spare tire (compact spare tire)

Temporary spare tires fitted to this vehicle

must have a maximum load rating of not

less than 850 kg, or a load index of “102”

and a speed category symbol of not less

than “M” (130 km/h).

Drive with caution when the temporary-use

spare unit is fitted. Reinstall standard unit

as soon as possible.

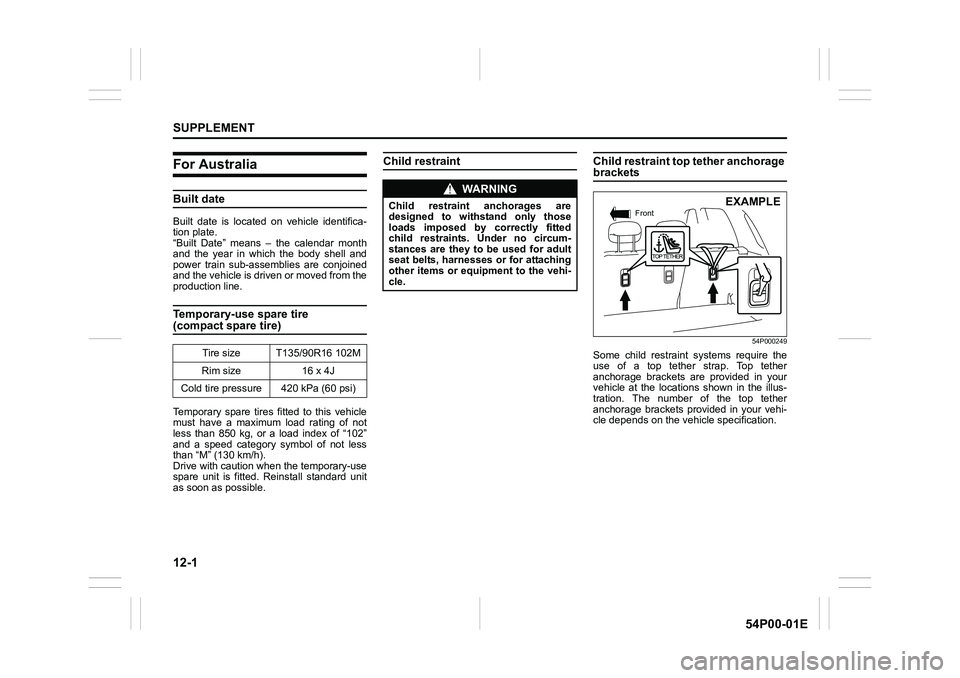

Child restraintChild restraint top tether anchorage brackets

54P000249

Some child restraint systems require the

use of a top tether strap. Top tether

anchorage brackets are provided in your

vehicle at the locations shown in the illus-

tration. The number of the top tether

anchorage brackets provided in your vehi-

cle depends on the vehicle specification. Tire size T135/90R16 102M

Rim size 16 x 4J

Cold tire pressure 420 kPa (60 psi)

WA R N I N G

Child restraint anchorages are

designed to withstand only those

loads imposed by correctly fitted

child restraints. Under no circum-

stances are they to be used for adult

seat belts, harnesses or for attaching

other items or equipment to the vehi-

cle.EXAMPLEFront

Page 433 of 482

12-3

SUPPLEMENT

54P00-01E

Seat belt warning

Follow this warning as well as the instruc-

tion for seat belt in this book.

In the case where a “Seat Belt Assembly”

incorporates an “Automatic Length Adjust-

ing and Locking Retractor” or an “Emer-

gency Locking Retractor”.

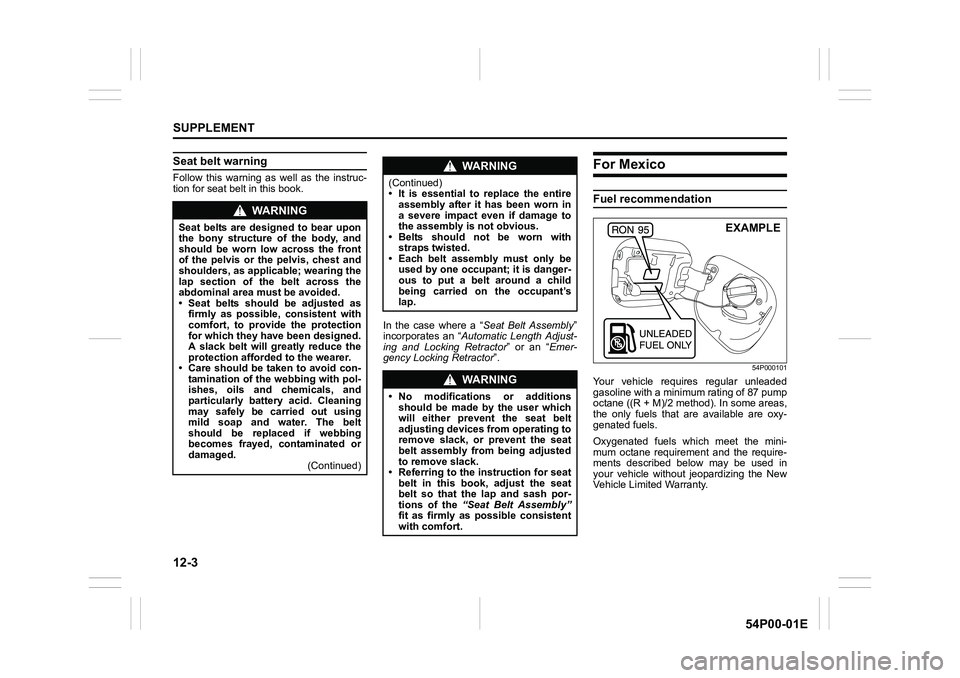

For Mexico

Fuel recommendation

54P000101

Your vehicle requires regular unleaded

gasoline with a minimum rating of 87 pump

octane ((R + M)/2 method). In some areas,

the only fuels that are available are oxy-

genated fuels.

Oxygenated fuels which meet the mini-

mum octane requirement and the require-

ments described below may be used in

your vehicle without jeopardizing the New

Vehicle Limited Warranty.

WA R N I N G

Seat belts are designed to bear upon

the bony structure of the body, and

should be worn low across the front

of the pelvis or the pelvis, chest and

shoulders, as applicable; wearing the

lap section of the belt across the

abdominal area must be avoided.

• Seat belts should be adjusted as

firmly as possible, consistent with

comfort, to provide the protection

for which they have been designed.

A slack belt will greatly reduce the

protection afforded to the wearer.

• Care should be taken to avoid con-

tamination of the webbing with pol-

ishes, oils and chemicals, and

particularly battery acid. Cleaning

may safely be carried out using

mild soap and water. The belt

should be replaced if webbing

becomes frayed, contaminated or

damaged.

(Continued)

WA R N I N G

(Continued)

• It is essential to replace the entire

assembly after it has been worn in

a severe impact even if damage to

the assembly is not obvious.

• Belts should not be worn with

straps twisted.

• Each belt assembly must only be

used by one occupant; it is danger-

ous to put a belt around a child

being carried on the occupant’s

lap.

WA R N I N G

• No modifications or additions

should be made by the user which

will either prevent the seat belt

adjusting devices from operating to

remove slack, or prevent the seat

belt assembly from being adjusted

to remove slack.

• Referring to the instruction for seat

belt in this book, adjust the seat

belt so that the lap and sash por-

tions of the “Seat Belt Assembly”

fit as firmly as possible consistent

with comfort.

EXAMPLE