Ps sensor SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 436 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-79

DTC P0335 (DTC No.23) Crankshaft Position (CKP) Sensor Circuit Malfunction

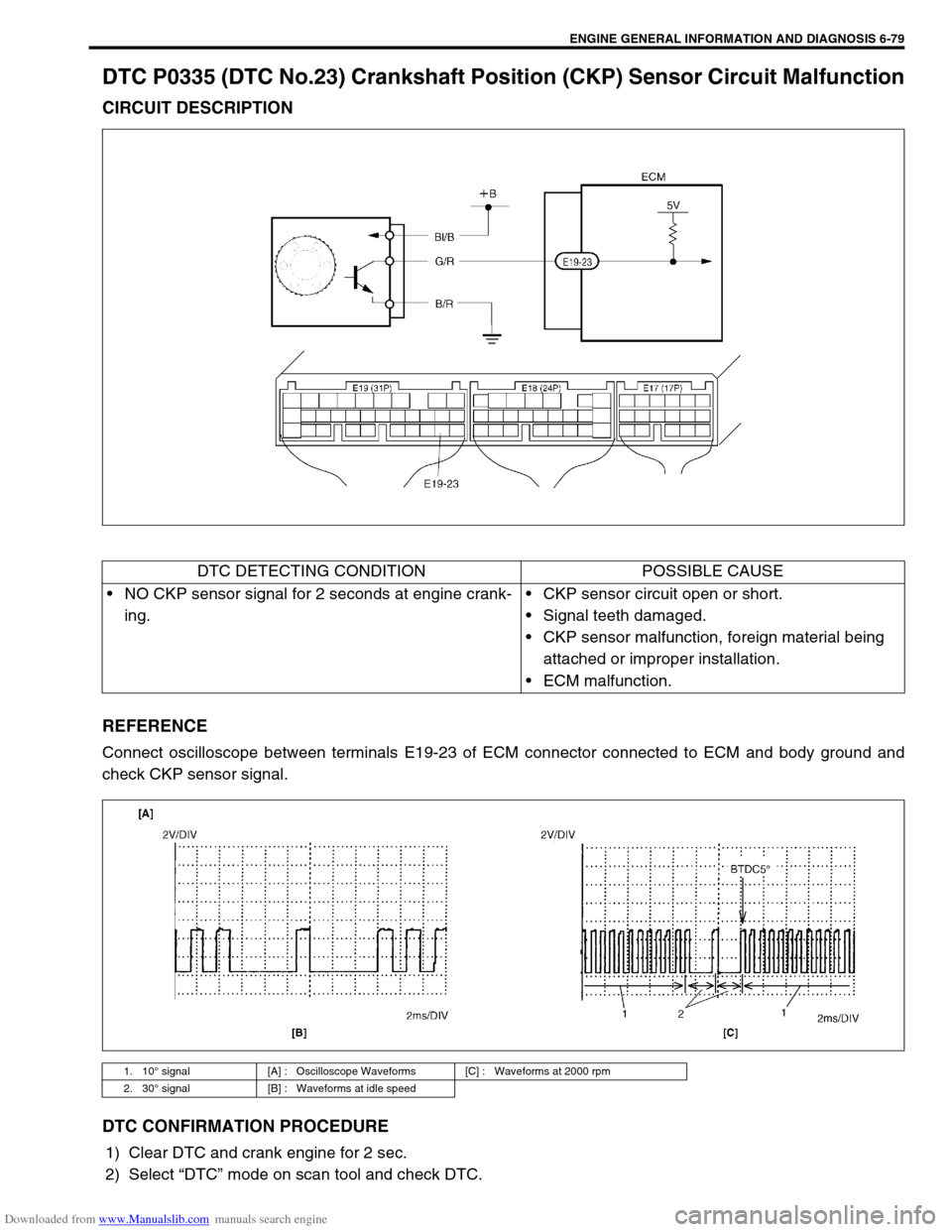

CIRCUIT DESCRIPTION

REFERENCE

Connect oscilloscope between terminals E19-23 of ECM connector connected to ECM and body ground and

check CKP sensor signal.

DTC CONFIRMATION PROCEDURE

1) Clear DTC and crank engine for 2 sec.

2) Select “DTC” mode on scan tool and check DTC.

DTC DETECTING CONDITION POSSIBLE CAUSE

NO CKP sensor signal for 2 seconds at engine crank-

ing.CKP sensor circuit open or short.

Signal teeth damaged.

CKP sensor malfunction, foreign material being

attached or improper installation.

ECM malfunction.

1. 10° signal [A] : Oscilloscope Waveforms [C] : Waveforms at 2000 rpm

2. 30° signal [B] : Waveforms at idle speed

Page 437 of 687

Downloaded from www.Manualslib.com manuals search engine 6-80 ENGINE GENERAL INFORMATION AND DIAGNOSIS

INSPECTION

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag.

Flow Table”.

2 Check CKP Sensor and connector for proper

installation.

Is CKP sensor installed properly and connector

connected securely?Go to Step 3. Correct.

3 Check Wire Harness and Connection.

1) Disconnect connector from CKP sensor.

2) Check for proper connection to CKP sensor at

each terminal.

3) If OK, turn ignition switch ON and check for

voltage at each terminal of sensor connector

disconnected. See Fig. 1.

Terminal “B+” : 10 – 14 V

Terminal “Vout” : 4 – 5 V

Terminal “GND” : 0 V

Is check result satisfactory?Go to Step 5. Go to Step 4.

4 Was terminal “Vout” voltage out of specification in

Step 3 check?“G/R” wire open, short or

poor connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.“Bl/B” or “B/R” wire

open, short or poor

connection.

5 Check Ground Circuit for Open.

1) Turn ignition switch OFF.

2) Check for continuity between “GND” terminal

of CKP sensor connector and engine ground.

Is continuity indicated?Go to Step 6.“B/R” wire open or

poor ground connec-

tion.

6 Check CKP Sensor for Operation.

1) Remove CKP sensor from sensor case.

2) Remove metal particles on end face of CKP

sensor, if any.

3) Connect each connector to ECM and CKP

sensor.

4) Turn ignition switch ON.

5) Check for voltage at terminal E19-23 of con-

nector connected to ECM by passing magnetic

substance (iron) (1) while keeping approxi-

mately 1 mm (0.03 in.) gap with respect to end

face of CKP sensor. See Fig. 2 and 3.

Does voltage vary from low (0 – 1 V) to high (4 – 5

V) or from high to low?Go to Step 7. Replace CKP sensor.

7 Check signal rotor for the following. See Fig. 4.

Damage

No foreign material attached

Is it in good condition?Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Clean rotor teeth or

replace CKP sensor.

Page 439 of 687

Downloaded from www.Manualslib.com manuals search engine 6-82 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0340 (DTC No.15) Camshaft Position (CMP) Sensor Circuit Malfunction

CIRCUIT DESCRIPTION

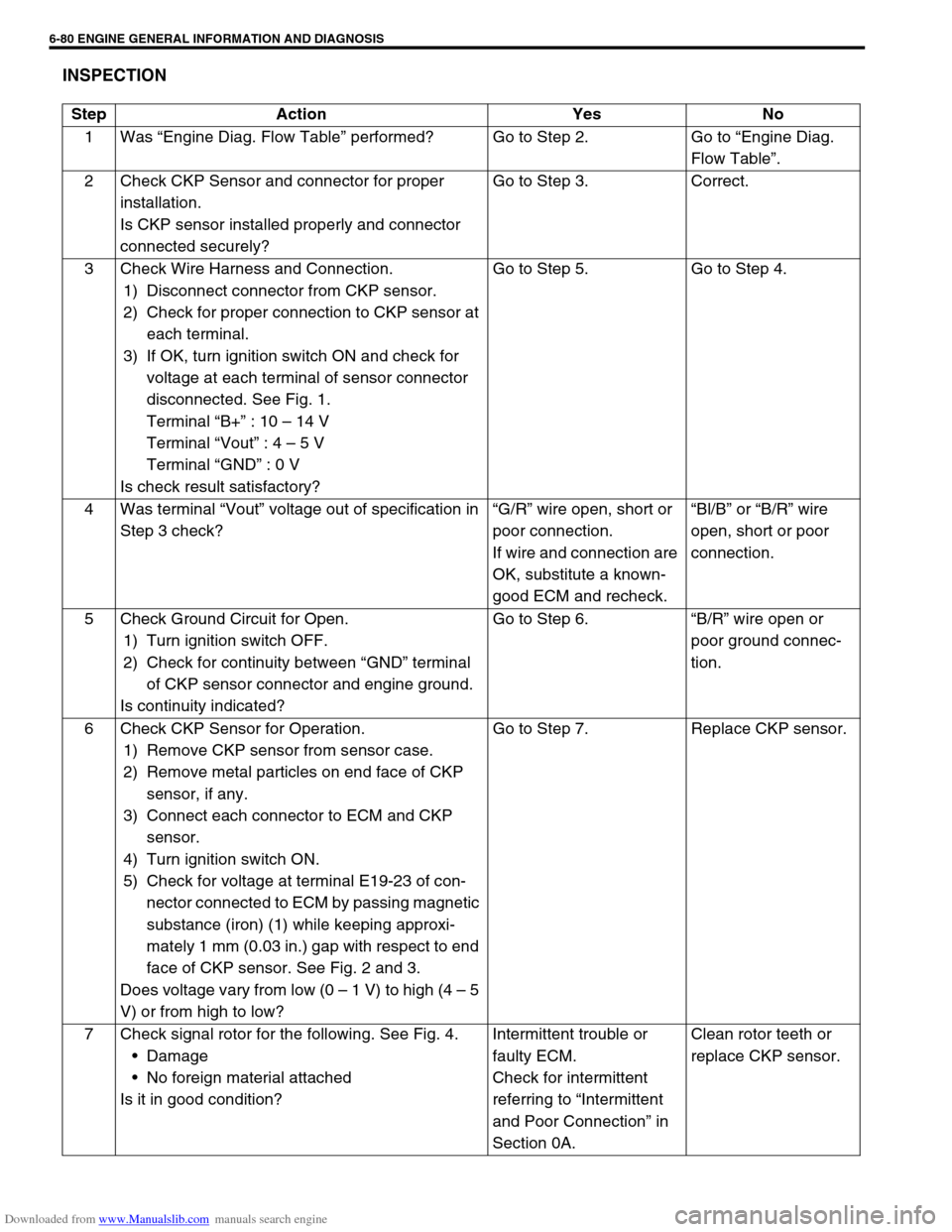

REFERENCE

Connect oscilloscope between terminals E19-11 of ECM connector connected to ECM and body ground and

check CMP sensor signal.

DTC CONFIRMATION PROCEDURE

1) Clear DTC.

2) Start engine and keep it at idle for 1 min.

3) Select “DTC” mode on scan tool and check DTC.

DTC DETECTING CONDITION POSSIBLE CAUSE

The number of CMP sensor signal pulses is incor-

rect during 8 revolution of crankshaft.CMP sensor circuit open or short.

Signal rotor teeth damaged.

CMP sensor malfunction, foreign material being

attached or improper installation.

ECM malfunction.

CMP sensor phase lag.

1. No.1 cylinder 3. No.3 cylinder [A] : Oscilloscope Waveforms [C] : CKP sensor waveform

2. No.2 cylinder 4. No.4 cylinder [B] : Waveforms at specified idle speed [D] : CMP sensor waveform

Page 440 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-83

INSPECTION

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag.

Flow Table”.

2 Check CMP Sensor and connector for proper installa-

tion.

Is CMP sensor installed properly and connector con-

nected securely?Go to Step 3. Correct.

3 Check Wire Harness and Connection.

1) Disconnect connector from CMP sensor.

2) Check for proper connection to CMP sensor at

each terminal.

3) If OK, turn ignition switch ON and check for volt-

age at each terminal of sensor connector discon-

nected. See Fig. 1.

Terminal “B+” : 10 – 14 V

Terminal “Vout” : 4 – 5 V

Terminal “GND” : 0 V

Is check result satisfactory?Go to Step 5. Go to Step 4.

4 Was terminal “Vout” voltage out of specification in

Step 3 check?“W” wire open, short or

poor connection.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.“Bl/B” or “B/R” wire

open, short or poor

connection.

5 Check Ground Circuit for Open.

1) Turn ignition switch OFF.

2) Check for continuity between “GND” terminal of

CMP sensor connector and engine ground.

Is continuity indicated?Go to Step 6.“B/R” wire open or

poor ground connec-

tion.

6 Check CMP Sensor for Operation.

1) Remove CMP sensor from sensor case.

2) Remove metal particles on end face of CMP sen-

sor, if any.

3) Connect each connector to ECM and CMP sensor.

4) Turn ignition switch ON.

5) Check for voltage at terminal E19-11 of connector

connected to ECM by passing magnetic sub-

stance (iron) (1) while keeping approximately 1

mm (0.03 in.) gap with respect to end face of CMP

sensor. See Fig. 2 and 3.

Does voltage vary from low (0 – 1 V) to high (4 – 5 V)

or from high to low?Go to Step 7. Replace CMP sen-

sor.

7 Check signal rotor for the following.

See Fig. 4.

Damage

No foreign material attached

Is it in good condition?Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Clean rotor teeth or

replace CMP sensor.

Page 445 of 687

Downloaded from www.Manualslib.com manuals search engine 6-88 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0420 Catalyst System Efficiency below Threshold

CIRCUIT DESCRIPTION

ECM monitors oxygen concentration in the exhaust gas which has passed the three way catalytic converter by

HO2S-2.

When the catalyst is functioning properly, the variation cycle of HO2S-2 output voltage (oxygen concentration) is

slower than that of HO2S-1 output voltage because of the amount of oxygen in the exhaust gas which has been

stored in the catalyst.

REFERENCE

1. Heated oxygen sensor-1 3. Three way catalytic converter 5. To the sensor [B] : Case of TYPE B is shown

(See NOTE)

2. Warm up three way catalytic

converter4. Heated oxygen sensor-2 [A] : Case of TYPE A is shown

(See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

1. Engine running at closed loop

condition2. Fuel cut 3. Idle after fuel cut [A] : Oscilloscope waveforms

Page 451 of 687

Downloaded from www.Manualslib.com manuals search engine 6-94 ENGINE GENERAL INFORMATION AND DIAGNOSIS

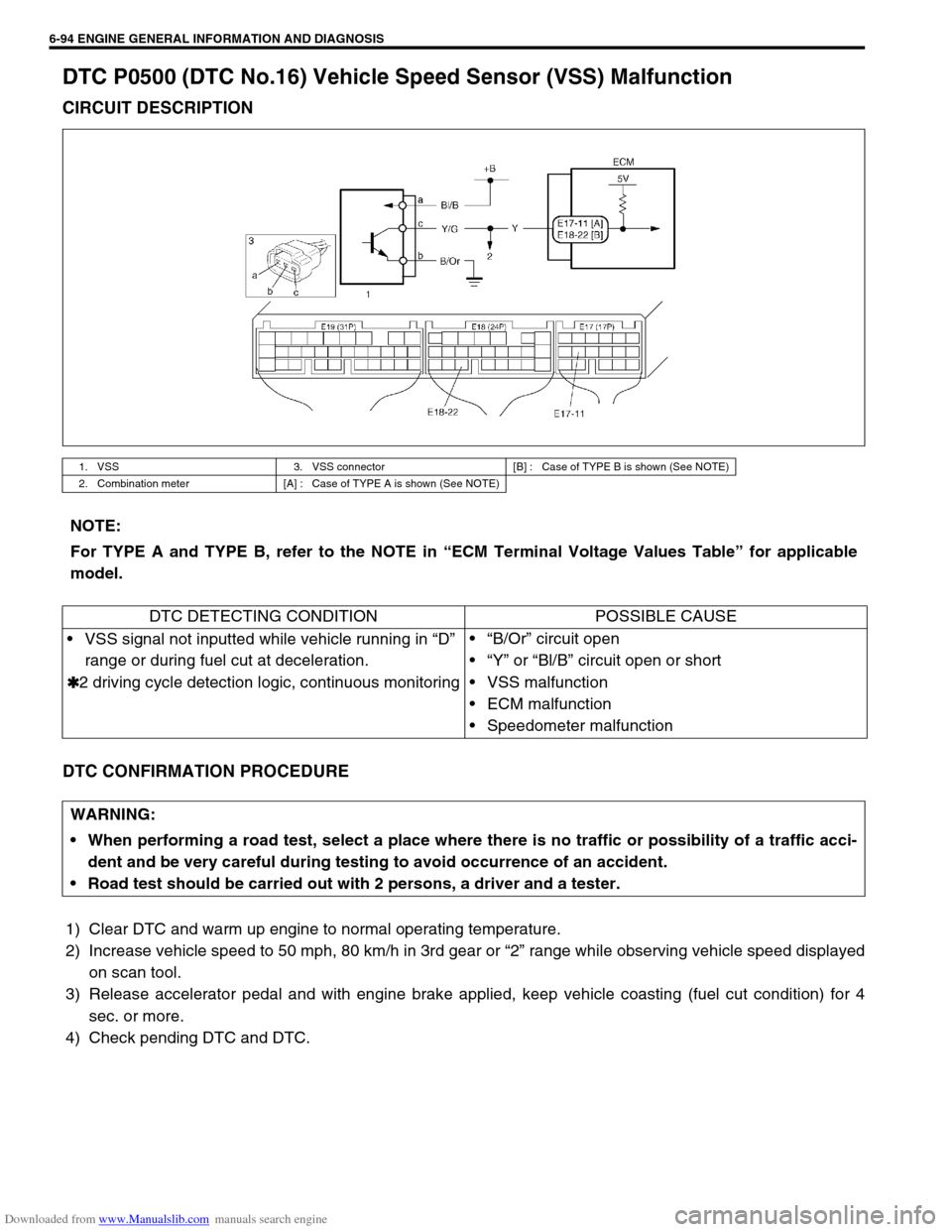

DTC P0500 (DTC No.16) Vehicle Speed Sensor (VSS) Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC and warm up engine to normal operating temperature.

2) Increase vehicle speed to 50 mph, 80 km/h in 3rd gear or “2” range while observing vehicle speed displayed

on scan tool.

3) Release accelerator pedal and with engine brake applied, keep vehicle coasting (fuel cut condition) for 4

sec. or more.

4) Check pending DTC and DTC.

1. VSS 3. VSS connector [B] : Case of TYPE B is shown (See NOTE)

2. Combination meter [A] : Case of TYPE A is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

DTC DETECTING CONDITION POSSIBLE CAUSE

VSS signal not inputted while vehicle running in “D”

range or during fuel cut at deceleration.

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring“B/Or” circuit open

“Y” or “Bl/B” circuit open or short

VSS malfunction

ECM malfunction

Speedometer malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 452 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-95

INSPECTION

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 4 and Step 6Step Action Yes No

1Was “Eng SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-95

INSPECTION

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 4 and Step 6Step Action Yes No

1Was “Eng](/img/20/7588/w960_7588-451.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-95

INSPECTION

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 4 and Step 6Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Does speedometer indicate vehicle speed? Go to Step 3. Go to Step 5.

3 Check Vehicle Speed Signal.

Is vehicle speed displayed on scan tool in step

2) and 3) of DTC confirmation procedure?Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Go to Step 4.

4 1) Turn ignition switch to OFF position.

2) Disconnect combination meter connec-

tors.Refer to Section 8.

3) Turn ignition switch to ON position, without

running engine.

4) Measure voltage from terminal “c” of VSS

connector to ground. See Fig.2.

Is voltage within 4 – 5 V?Faulty speedometer.“Y” or “Y/G” wire open or

short.

Poor connection of ECM

connector terminal.

If OK, substitute a known-

good ECM and recheck.

5 1) With ignition switch at OFF position, discon-

nect VSS connector.

2) Turn ignition switch to ON position, without

running engine.

3) Measure voltage from terminal “a” to “b” of

VSS connector. See Fig.1.

Is voltage within 10 – 14 V?Go to Step 6.“Bl/B” or “B/Or” wire open

or short.

6 1) Measure voltage from terminal “c” of VSS

connector to ground. See Fig.2.

Is voltage more than 4 V?Go to Step 7.“Y” or “Y/G” wire open or

short.

Poor connection of ECM

connector terminal.

If OK, substitute a known-

good ECM and recheck.

7 1) Remove VSS.

2) Visually inspect VSS sensor signal rotor for

damage.

Was any damage found?Faulty VSS signal rotor. Poor connection of VSS

connector terminal.

If OK, substitute a known-

good VSS and recheck.

Page 456 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-99

DTC P1450 Barometric Pressure Sensor Low / High Input

DTC P1451 Barometric Pressure Sensor Performance Problem

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Barometric pressure sensor is installed in ECM.

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Turn ignition switch ON for 2 sec., crank engine for 2 sec. and run it at idle for 1 min.

4) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

INSPECTION

DTC P1450 :

Substitute a known-good ECM and recheck.

DTC P1451 :

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC P1450 :

Barometric pressure sensor voltage is 4.7 V or higher, or

1.6 V or lowerECM (barometric pressure sensor) malfunc-

tion

DTC P1451 :

Vehicle stopped

Engine cranking

Difference between barometric pressure and intake mani-

fold absolute pressure is 26 kPa, 200 mmHg or more.

Difference between intake manifold absolute pressure at

engine start and pressure after engine start is less than 1.3

kPa, 10 mmHg.

✱

✱✱ ✱2 driving cycle detection logic, monitoring once / 1 driving.ECM (barometric pressure sensor) malfunc-

tion

NOTE:

Note that atmospheric pressure varies depending on weather conditions as well as altitude.

Take that into consideration when performing these check.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 1) Connect scan tool to DLC with ignition

switch OFF. See Fig.1.

2) Turn ignition switch ON and select “DATA

LIST” mode on scan tool.

3) Check manifold absolute pressure.

Is it barometric pressure (approx. 100 kPa, 760

mmHg) at sea level?Substitute a known-good

ECM and recheck.Go to Step 3.

Page 457 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-100 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3

Table 13 Check MAP Sensor

1) Remove MAP sensor fro SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-100 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3

Table 13 Check MAP Sensor

1) Remove MAP sensor fro](/img/20/7588/w960_7588-456.png)

Downloaded from www.Manualslib.com manuals search engine 6-100 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3

Table 13 Check MAP Sensor

1) Remove MAP sensor from intake manifold

and connect vacuum pump gauge to MAP

sensor. See Fig. 2.

2) Connect scan tool to DLC and turn ignition

switch ON.

3) Check intake manifold absolute pressure

displayed on scan tool for specified value.

See Table 1.

Is check result satisfactory?Check air intake system

for air being drawn in and

engine compression.

If OK, then substitute a

known-good ECM and

recheck.Replace MAP sensor. Step Action Yes No

Applying Vacuum Displayed Value on Scan Tool

0 Barometric pressure

(Approx. 100 kPa, 760 mmHg)

027 kPa

200 mmHgBarometric pressure – 27 kPa

(Approx. 73 kPa, 560 mmHg)

67 kPa

500 mmHgBarometric pressure – 67 kPa

(Approx. 33 kPa, 260 mmHg)

Page 458 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-101

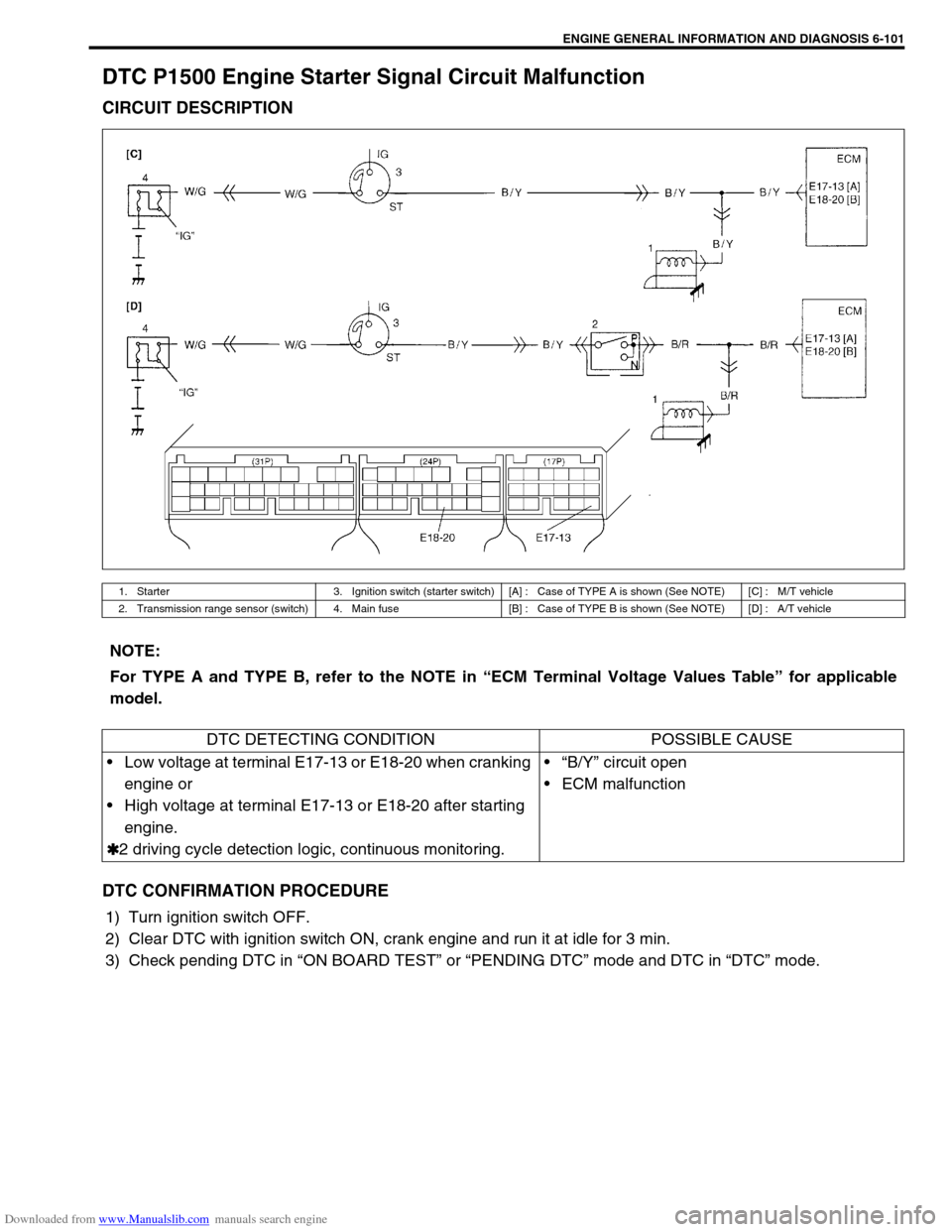

DTC P1500 Engine Starter Signal Circuit Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON, crank engine and run it at idle for 3 min.

3) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

1. Starter 3. Ignition switch (starter switch) [A] : Case of TYPE A is shown (See NOTE) [C] : M/T vehicle

2. Transmission range sensor (switch) 4. Main fuse [B] : Case of TYPE B is shown (See NOTE) [D] : A/T vehicle

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

DTC DETECTING CONDITION POSSIBLE CAUSE

Low voltage at terminal E17-13 or E18-20 when cranking

engine or

High voltage at terminal E17-13 or E18-20 after starting

engine.

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.“B/Y” circuit open

ECM malfunction