service SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 658 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-9

5) Fix ignition timing to initial one as follows.

a) When using SUZUKI scan tool:

Select “MISC” mode on SUZUKI scan tool and fix ignition

timing to initial one.

b) Without using SUZUKI scan tool: (vehicle without immobi-

lizer indicator lamp)

Disconnect scan tool from DLC, and connect D and E ter-

minals of monitor connector (1) or E to body ground by

using service wire so that ignition timing is fixed on initial

one.

6) Using timing light (1), check that ignition timing is within

specification.

Initial ignition timing (test switch terminal grounded or

fixed with SUZUKI scan tool)

5

± 3° BTDC at idle speed

Ignition order

1-3-4-2

7) If ignition timing is out of specification, check the followings:

CKP sensor

CKP sensor plate

TP sensor

Test switch signal circuit

VSS

Timing chain cover installation

8) After checking Initial Ignition Timing, release ignition timing

fixation by using SUZUKI scan tool or disconnect service

wire from monitor connector.

9) With engine idling (test switch terminal ungrounded, throttle

opening at closed position and car stopped), check that igni-

tion timing is about 7°–17° BTDC. (Constant variation within

a few degrees from 7°–17° indicates no abnormality but

proves operation of electronic timing control system.) Also,

check that increasing engine speed advances ignition timing.

If above check results are not satisfactory, check CKP sen-

sor, test switch terminal circuit and ECM.

Page 660 of 687

Downloaded from www.Manualslib.com manuals search engine CRANKING SYSTEM 6G-1

6F1

6F2

6H

7C1

7D

7E

7C1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

6G

7A1

10A

10B

SECTION 6G

CRANKING SYSTEM

CONTENTS

General Description ....................................... 6G-2

Cranking Circuit ............................................ 6G-2

Diagnosis ........................................................ 6G-2

Diagnosis Table ........................................... 6G-2Performance Test .........................................6G-4

On-Vehicle Service .........................................6G-5

Starting Motor ...............................................6G-5

Specifications..................................................6G-7

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Starting motor varies depending on specifications, etc. Therefore, be sure to check model and speci-

fication of vehicle being serviced before replacing parts.

Page 664 of 687

Downloaded from www.Manualslib.com manuals search engine CRANKING SYSTEM 6G-5

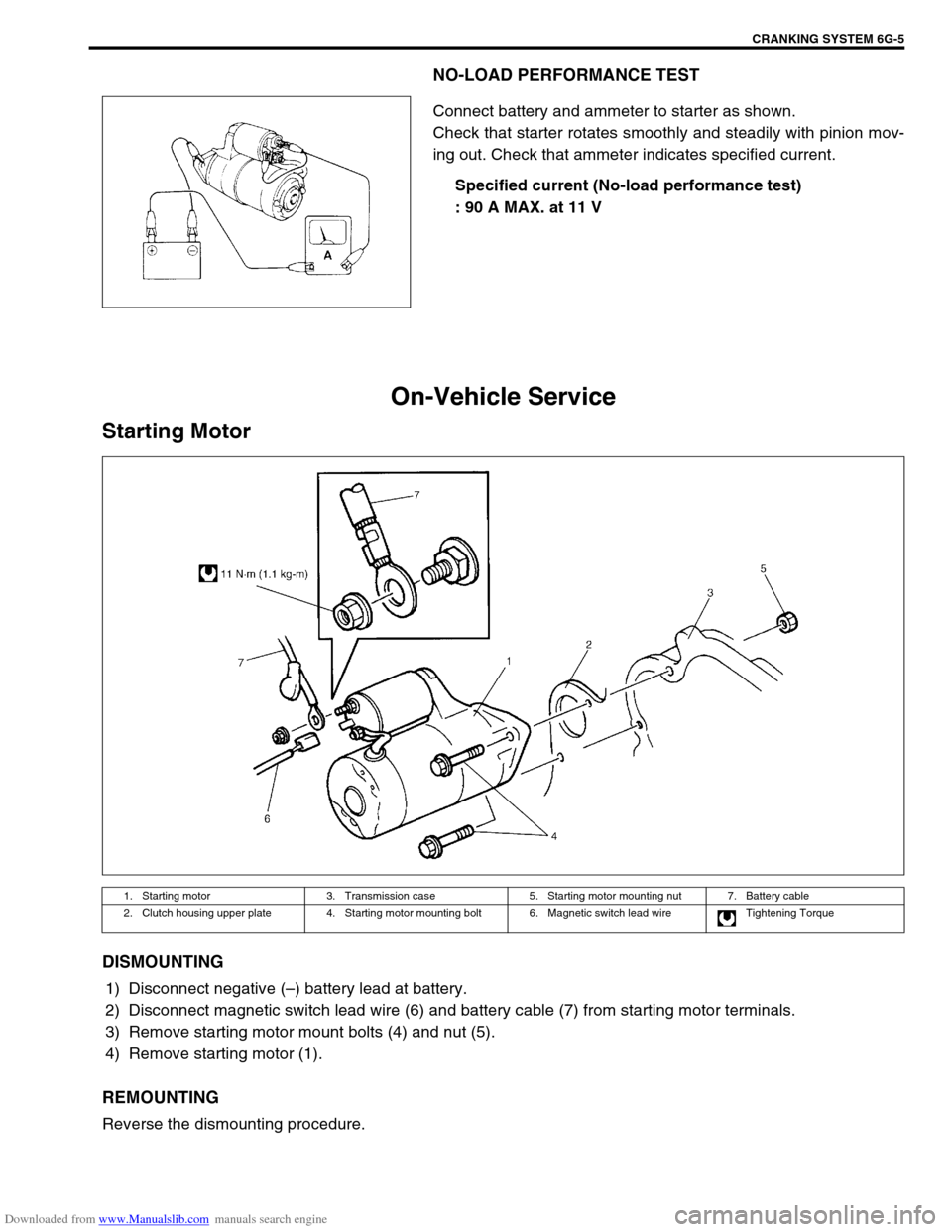

NO-LOAD PERFORMANCE TEST

Connect battery and ammeter to starter as shown.

Check that starter rotates smoothly and steadily with pinion mov-

ing out. Check that ammeter indicates specified current.

Specified current (No-load performance test)

: 90 A MAX. at 11 V

On-Vehicle Service

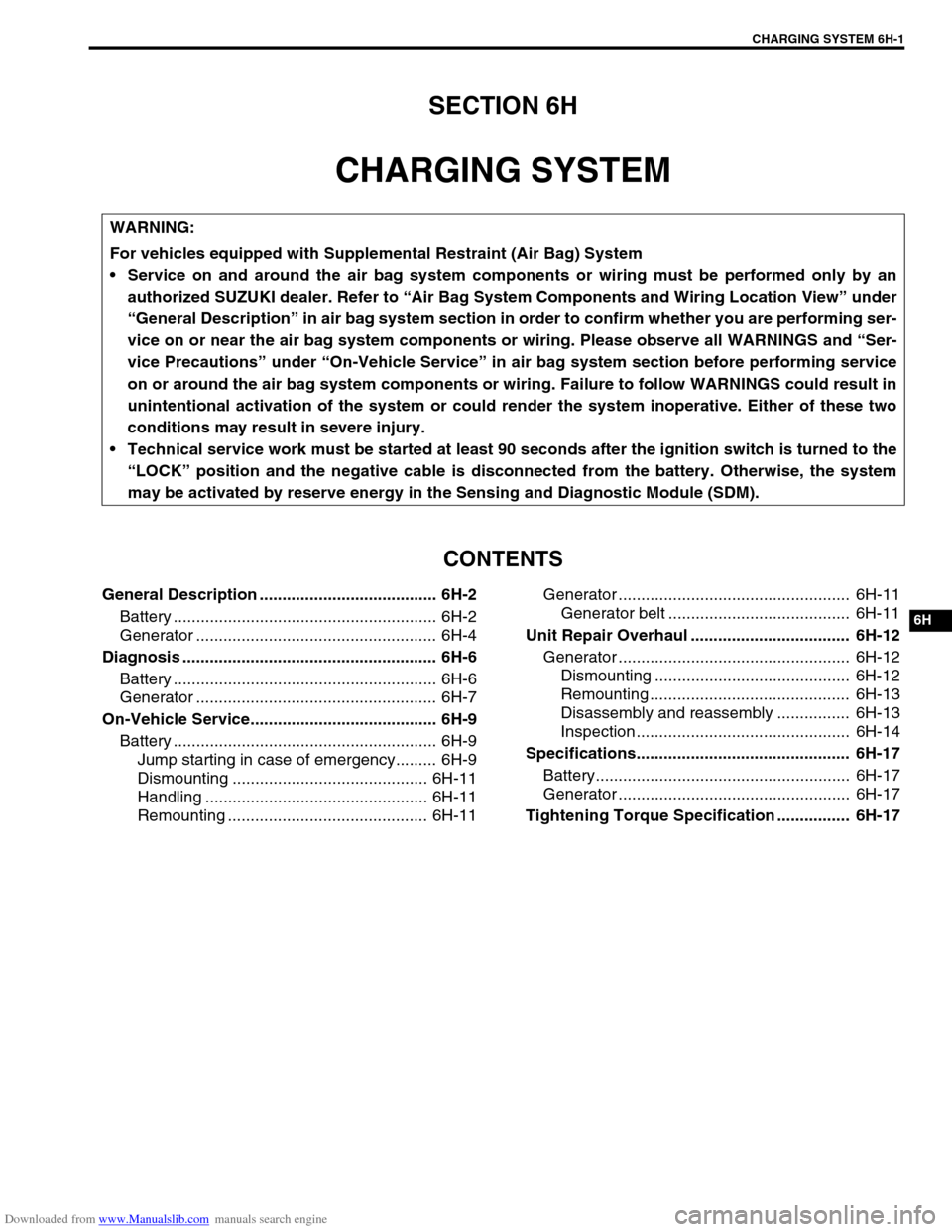

Starting Motor

DISMOUNTING

1) Disconnect negative (–) battery lead at battery.

2) Disconnect magnetic switch lead wire (6) and battery cable (7) from starting motor terminals.

3) Remove starting motor mount bolts (4) and nut (5).

4) Remove starting motor (1).

REMOUNTING

Reverse the dismounting procedure.

1. Starting motor 3. Transmission case 5. Starting motor mounting nut 7. Battery cable

2. Clutch housing upper plate 4. Starting motor mounting bolt 6. Magnetic switch lead wire Tightening Torque

Page 668 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-1

6F1

6F2

6G

6K

7D

7E

7F

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

7A

6H

7B1

10B

SECTION 6H

CHARGING SYSTEM

CONTENTS

General Description ....................................... 6H-2

Battery .......................................................... 6H-2

Generator ..................................................... 6H-4

Diagnosis ........................................................ 6H-6

Battery .......................................................... 6H-6

Generator ..................................................... 6H-7

On-Vehicle Service......................................... 6H-9

Battery .......................................................... 6H-9

Jump starting in case of emergency......... 6H-9

Dismounting ........................................... 6H-11

Handling ................................................. 6H-11

Remounting ............................................ 6H-11Generator ................................................... 6H-11

Generator belt ........................................ 6H-11

Unit Repair Overhaul ................................... 6H-12

Generator ................................................... 6H-12

Dismounting ........................................... 6H-12

Remounting ............................................ 6H-13

Disassembly and reassembly ................ 6H-13

Inspection ............................................... 6H-14

Specifications............................................... 6H-17

Battery........................................................ 6H-17

Generator ................................................... 6H-17

Tightening Torque Specification ................ 6H-17

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 671 of 687

Downloaded from www.Manualslib.com manuals search engine 6H-4 CHARGING SYSTEM

When keeping battery on vehicle over a long period of time, follow

instructions given below.

Weekly, start the engine and run it until it reaches normal

operating temperature with engine speed of 2,000 to 3,000

rpm. Make sure all electric switches are off before storing the

vehicle.

Recharge the battery twice a month to prevent it from dis-

charging excessively. This is especially important when

ambient temperature is low.

The battery discharges even when it is not used, while vehi-

cles are being stored. Battery electrolyte can freeze and bat-

tery case can crack at cold ambient condition if battery is not

properly charged.

2) Keep the battery cable connections clean.

The cable connections, particularly at the positive (+) termi-

nal post, tend to become corroded. The product of corrosion,

or rust, on the mating faces of conductors resists the flow of

current.

Clean the terminals and fittings periodically to ensure good

metal-to-metal contact, and grease the connections after

each cleaning to protect them against rusting.

3) Be always in the know as to the state of charge of the bat-

tery. The simplest way to tell the state of charge is to carry

out a hydrometer test. The hydrometer is an instrument for

measuring the specific gravity (S.G.) of the battery electro-

lyte. The S.G. of the electrolyte is indicative of the state of

charge. Refer to “HYDROMETER TEST” in this section.

Generator

The generator is a small and high performance type with an IC regulator incorporated.

The internal components are connected electrically as shown below figure.

The generator features are as follows:

Solid state regulator is mounted inside the generator.

All regulator components are enclosed into a solid mold.

This unit along with the brush holder assembly is attached to the rear housing.

The IC regulator uses integrated circuits and controls the voltage produced by the generator, and the volt-

age setting cannot be adjusted.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication. Two

brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal con-

ditions will provide long period of attention-free service.

The stator windings are assembled on the inside of a laminated core that forms part of the generator frame.

A condenser mounted in the rear housing suppresses radio noise.

Page 673 of 687

Downloaded from www.Manualslib.com manuals search engine 6H-6 CHARGING SYSTEM

Diagnosis

Battery

COMMON CAUSES OF FAILURE

A battery is not designed to last indefinitely; however, with proper

care, it will provide many years of service. If the battery performs

satisfactorily during test but fails to operate properly for no appar-

ent reason, the followings are some factors that may point to the

cause of trouble:

Accessories left on overnight or for an extended period with-

out the generator operating.

Slow average driving speeds for short periods.

Electrical load exceeding generator output particularly with

addition of after market equipment.

Defects in charging system such as high resistance, slipping

drive belt, loose generator output terminal, faulty generator

or voltage regulator. Refer to “Generator” in this “Diagnosis”

section.

Battery abuse, including failure to keep battery cable termi-

nals clean and tight or loose battery hold down.

Mechanical problems in electrical system such as shorted or

pinched wires.

VISUAL INSPECTION

Check for obvious damage, such as cracked or broken case or

cover, that could permit loss of electrolyte. If obvious damage is

noted, replace battery. Determine cause of damage and correct

as needed.

HYDROMETER TEST

The direct method of checking the battery for state of charge is to

carry out a high rate discharge test, which involves a special pre-

cise voltmeter and an expensive instrument used in the service

shops, but not recommendable to the user of the vehicle.

At 20 °C of battery temperature (electrolyte temperature):

The battery is in FULLY CHARGED STATE if the electrolyte

S.G. is 1.280.

The battery is in HALF CHARGED STATE if the S.G. is

1.220.

The battery is in NEARLY DISCHARGED STATE if the S.G.

is 1.150 and is in danger of freezing.

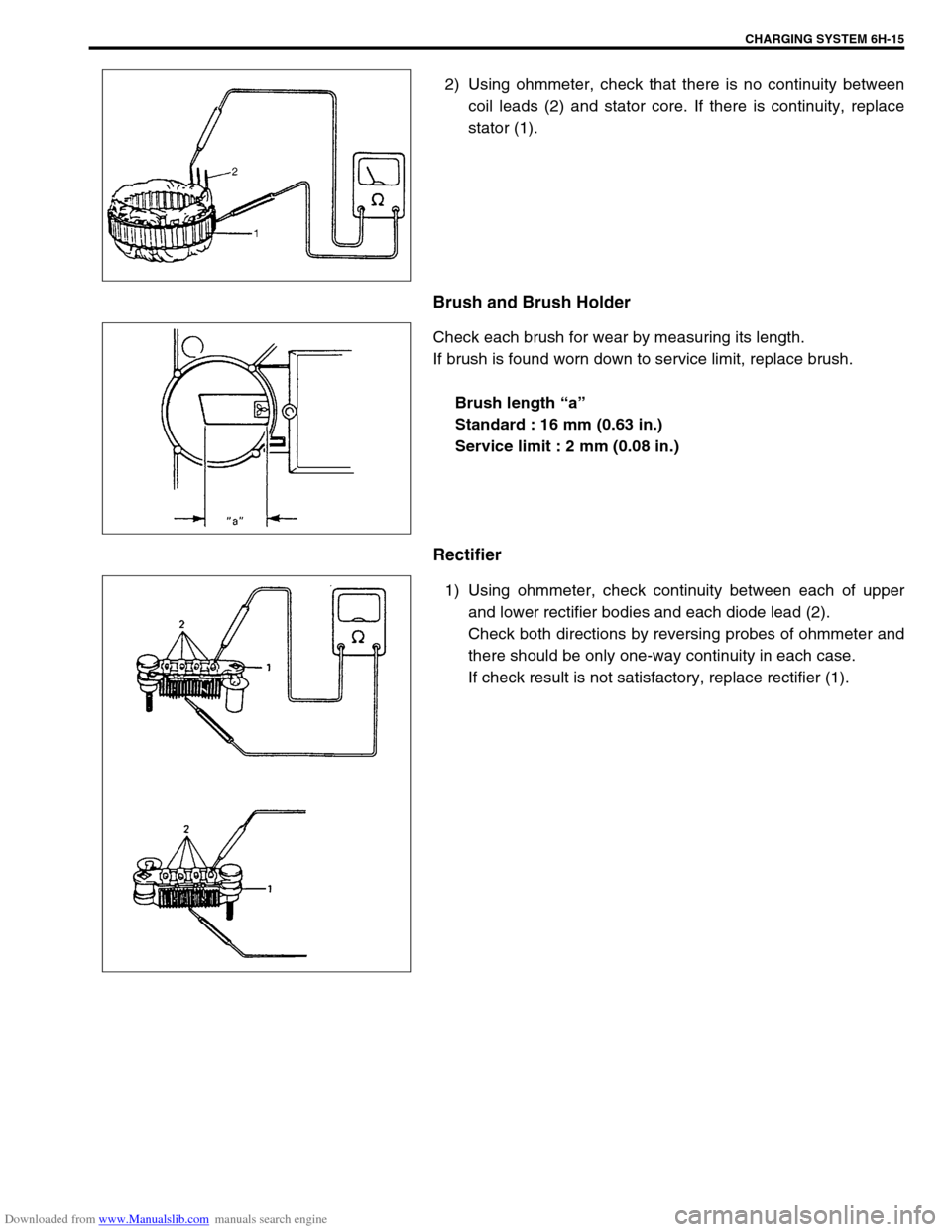

As the S.G. varies with the temperature, if battery temperature is

not at 20 °C (68 °F), you have to correct your S.G. reading (taken

with your hydrometer) to the value at 20 °C (68 °F) and apply the

corrected S.G. value to the three-point guide stated value. For the

manner of correction, refer to the graph showing the relation

between S.G. value and temperature.

Page 676 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-9

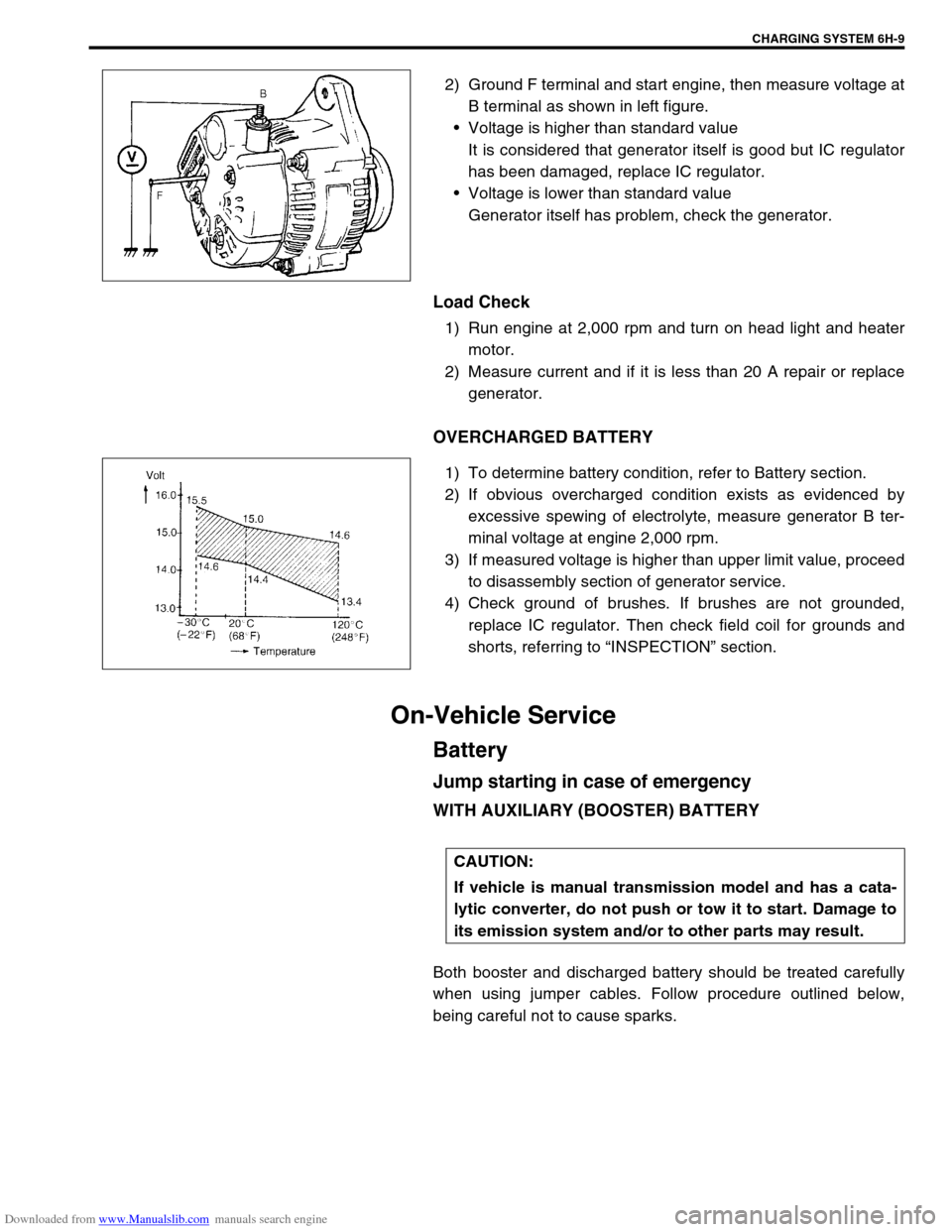

2) Ground F terminal and start engine, then measure voltage at

B terminal as shown in left figure.

Voltage is higher than standard value

It is considered that generator itself is good but IC regulator

has been damaged, replace IC regulator.

Voltage is lower than standard value

Generator itself has problem, check the generator.

Load Check

1) Run engine at 2,000 rpm and turn on head light and heater

motor.

2) Measure current and if it is less than 20 A repair or replace

generator.

OVERCHARGED BATTERY

1) To determine battery condition, refer to Battery section.

2) If obvious overcharged condition exists as evidenced by

excessive spewing of electrolyte, measure generator B ter-

minal voltage at engine 2,000 rpm.

3) If measured voltage is higher than upper limit value, proceed

to disassembly section of generator service.

4) Check ground of brushes. If brushes are not grounded,

replace IC regulator. Then check field coil for grounds and

shorts, referring to “INSPECTION” section.

On-Vehicle Service

Battery

Jump starting in case of emergency

WITH AUXILIARY (BOOSTER) BATTERY

Both booster and discharged battery should be treated carefully

when using jumper cables. Follow procedure outlined below,

being careful not to cause sparks.

CAUTION:

If vehicle is manual transmission model and has a cata-

lytic converter, do not push or tow it to start. Damage to

its emission system and/or to other parts may result.

Page 682 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-15

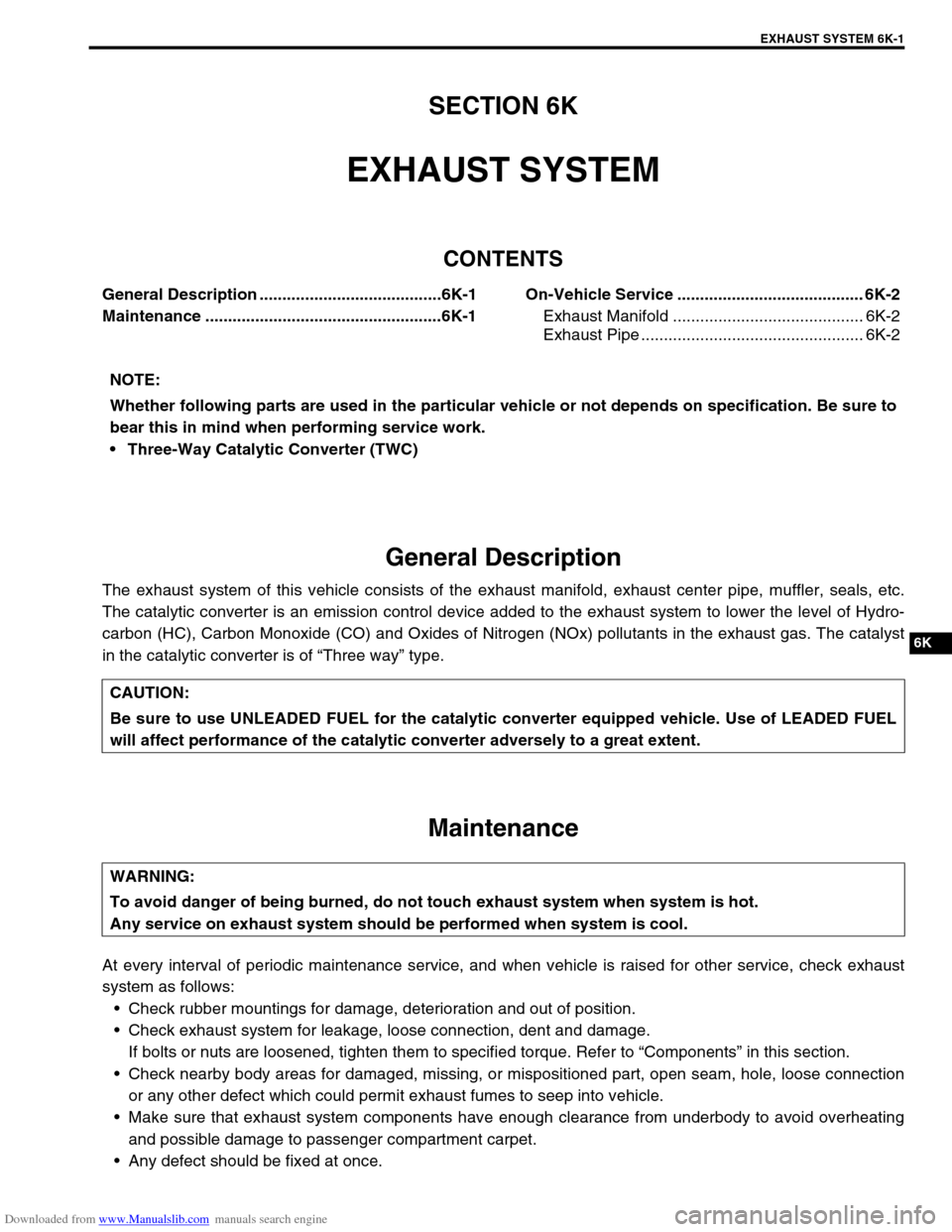

2) Using ohmmeter, check that there is no continuity between

coil leads (2) and stator core. If there is continuity, replace

stator (1).

Brush and Brush Holder

Check each brush for wear by measuring its length.

If brush is found worn down to service limit, replace brush.

Brush length “a”

Standard : 16 mm (0.63 in.)

Service limit : 2 mm (0.08 in.)

Rectifier

1) Using ohmmeter, check continuity between each of upper

and lower rectifier bodies and each diode lead (2).

Check both directions by reversing probes of ohmmeter and

there should be only one-way continuity in each case.

If check result is not satisfactory, replace rectifier (1).

Page 686 of 687

Downloaded from www.Manualslib.com manuals search engine EXHAUST SYSTEM 6K-1

6F1

6F2

6G

6H

7D

7E

7F

7D

7E

7F

8A

8B

8C

8D

8E

9

7A1

6K

7C1

SECTION 6K

EXHAUST SYSTEM

CONTENTS

General Description ........................................6K-1

Maintenance ....................................................6K-1On-Vehicle Service ......................................... 6K-2

Exhaust Manifold .......................................... 6K-2

Exhaust Pipe ................................................. 6K-2

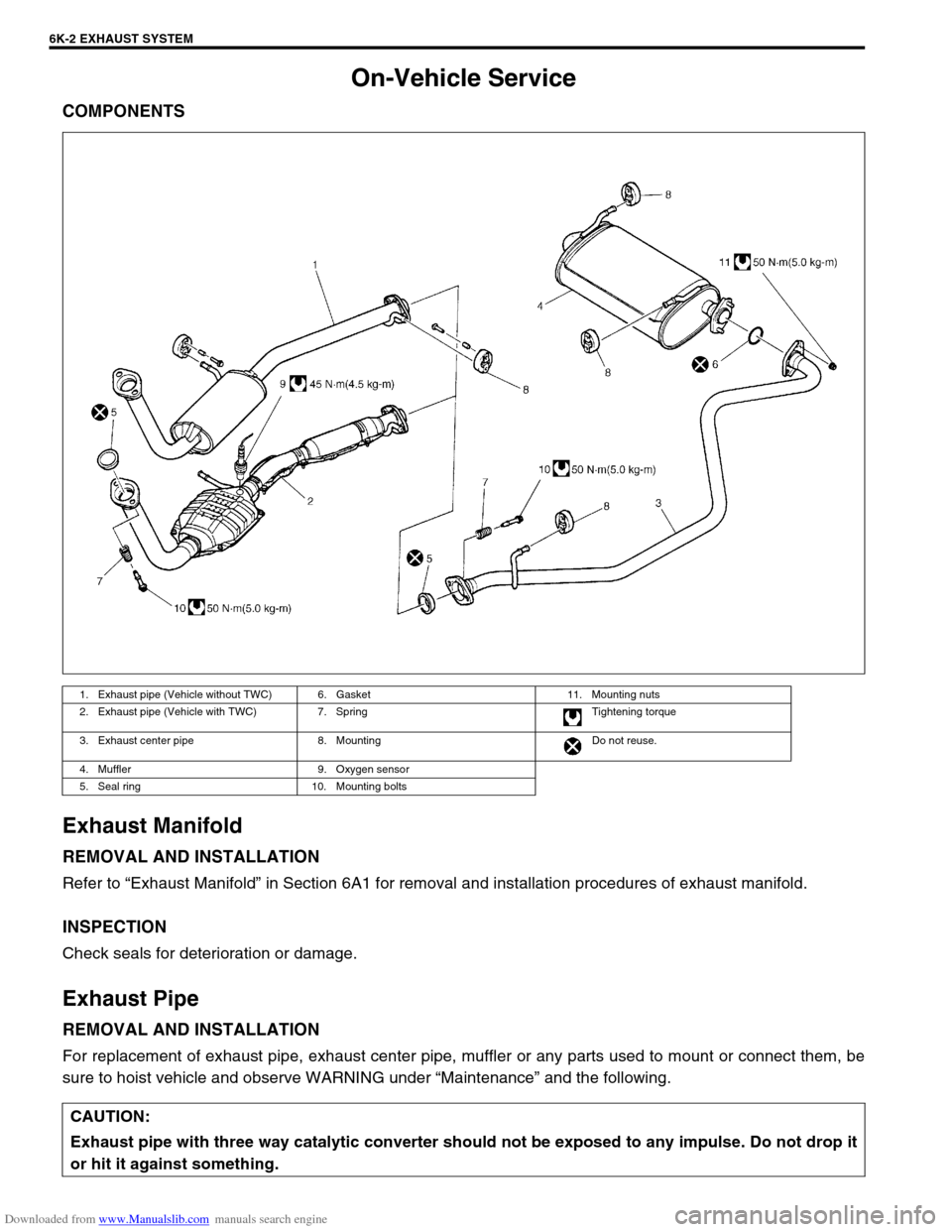

General Description

The exhaust system of this vehicle consists of the exhaust manifold, exhaust center pipe, muffler, seals, etc.

The catalytic converter is an emission control device added to the exhaust system to lower the level of Hydro-

carbon (HC), Carbon Monoxide (CO) and Oxides of Nitrogen (NOx) pollutants in the exhaust gas. The catalyst

in the catalytic converter is of “Three way” type.

Maintenance

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust

system as follows:

Check rubber mountings for damage, deterioration and out of position.

Check exhaust system for leakage, loose connection, dent and damage.

If bolts or nuts are loosened, tighten them to specified torque. Refer to “Components” in this section.

Check nearby body areas for damaged, missing, or mispositioned part, open seam, hole, loose connection

or any other defect which could permit exhaust fumes to seep into vehicle.

Make sure that exhaust system components have enough clearance from underbody to avoid overheating

and possible damage to passenger compartment carpet.

Any defect should be fixed at once. NOTE:

Whether following parts are used in the particular vehicle or not depends on specification. Be sure to

bear this in mind when performing service work.

Three-Way Catalytic Converter (TWC)

CAUTION:

Be sure to use UNLEADED FUEL for the catalytic converter equipped vehicle. Use of LEADED FUEL

will affect performance of the catalytic converter adversely to a great extent.

WARNING:

To avoid danger of being burned, do not touch exhaust system when system is hot.

Any service on exhaust system should be performed when system is cool.

Page 687 of 687

Downloaded from www.Manualslib.com manuals search engine 6K-2 EXHAUST SYSTEM

On-Vehicle Service

COMPONENTS

Exhaust Manifold

REMOVAL AND INSTALLATION

Refer to “Exhaust Manifold” in Section 6A1 for removal and installation procedures of exhaust manifold.

INSPECTION

Check seals for deterioration or damage.

Exhaust Pipe

REMOVAL AND INSTALLATION

For replacement of exhaust pipe, exhaust center pipe, muffler or any parts used to mount or connect them, be

sure to hoist vehicle and observe WARNING under “Maintenance” and the following.

1. Exhaust pipe (Vehicle without TWC) 6. Gasket 11. Mounting nuts

2. Exhaust pipe (Vehicle with TWC) 7. Spring Tightening torque

3. Exhaust center pipe 8. Mounting Do not reuse.

4. Muffler 9. Oxygen sensor

5. Seal ring 10. Mounting bolts

CAUTION:

Exhaust pipe with three way catalytic converter should not be exposed to any impulse. Do not drop it

or hit it against something.