service SUZUKI JIMNY 2005 3.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 411 of 687

![SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 6-54 ENGINE GENERAL INFORMATION AND DIAGNOSIS

INSPECTION

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 5 / [C] Fig. 3 for Step 6Step Action Yes N SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 6-54 ENGINE GENERAL INFORMATION AND DIAGNOSIS

INSPECTION

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 5 / [C] Fig. 3 for Step 6Step Action Yes N](/img/20/7588/w960_7588-410.png)

Downloaded from www.Manualslib.com manuals search engine 6-54 ENGINE GENERAL INFORMATION AND DIAGNOSIS

INSPECTION

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 5 / [C] Fig. 3 for Step 6Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check ECT Sensor and Its Circuit.

1) Connect scan tool with ignition switch OFF.

See Fig. 1.

2) Turn ignition switch ON.

3) Check engine coolant temp. displayed on

scan tool.

Is –40 °C (–40 °F) or 119 °C (246 °F) indicated?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.

3 Check Wire Harness.

1) Disconnect ECT sensor connector.

2) Check engine coolant temp. displayed on

scan tool.

Is –40 °C (–40 °F) indicated?Replace ECT sensor.“G/B” wire shorted to

ground.

If wire is OK, substitute a

known-good ECM and

recheck.

4 Does scan tool indicate –40 °C (–40 °F) at Step

2.Go to Step 6. Go to Step 5.

5 Check Wire Harness.

1) Disconnect ECT sensor connector with igni-

tion switch OFF.

2) Check for proper connection to ECT sensor

at “B/Bl” and “G/B” wire terminals.

See Fig. 2.

3) If OK, then with ignition switch ON.

Is voltage applied to “B/Bl” wire terminal about

4 – 6 V?Go to Step 4.“G/B” wire open or

shorted to power, or poor

E19-14 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

6 Check Wire Harness.

1) Using service wire, connect ECT sensor

connector terminals. See Fig. 3.

2) Turn ignition switch ON and check engine

coolant temp. displayed on scan tool.

Is 119 °C (246 °F) indicated?Replace ECT sensor.“B/Bl” wire open or poor

E19-10 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

Page 467 of 687

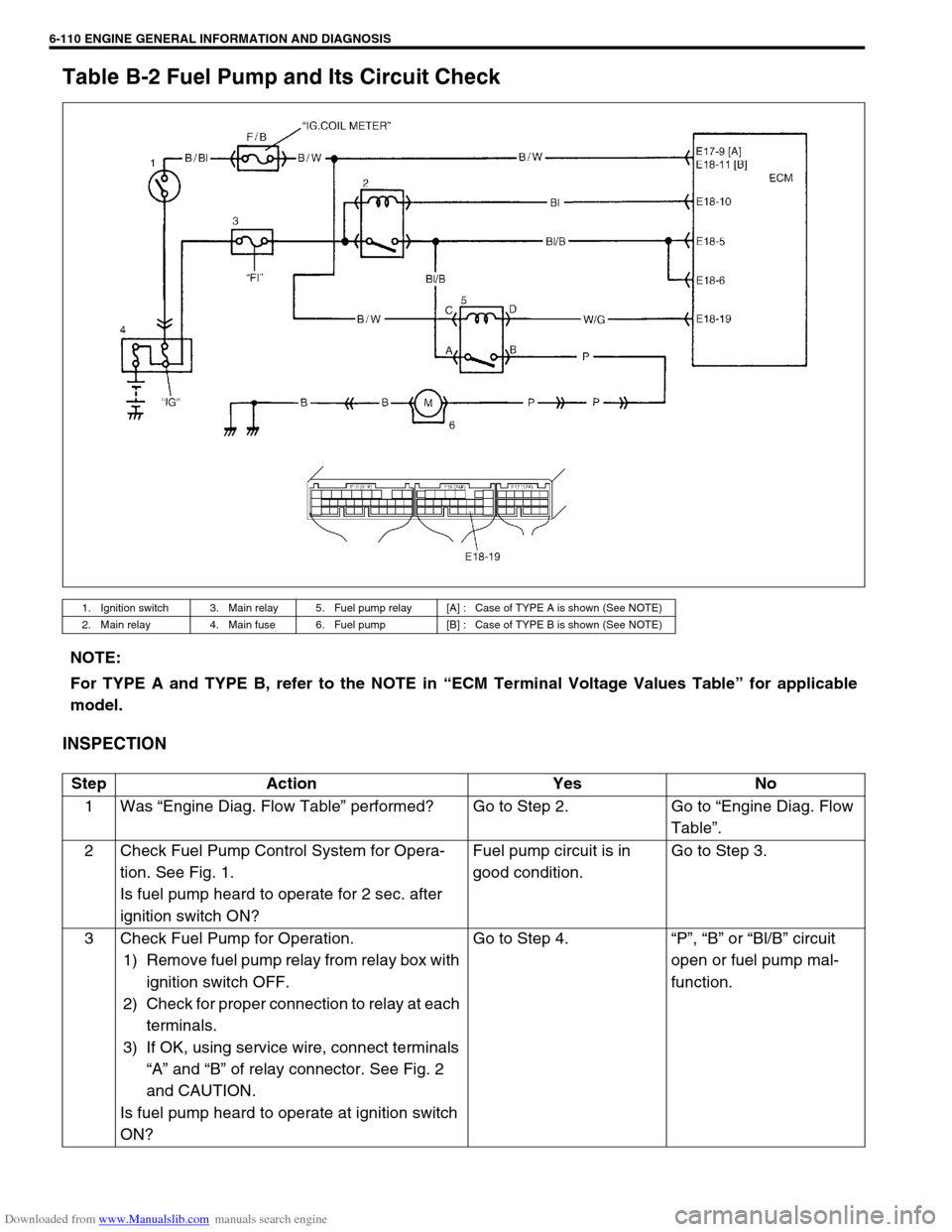

Downloaded from www.Manualslib.com manuals search engine 6-110 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Table B-2 Fuel Pump and Its Circuit Check

INSPECTION

1. Ignition switch 3. Main relay 5. Fuel pump relay [A] : Case of TYPE A is shown (See NOTE)

2. Main relay 4. Main fuse 6. Fuel pump [B] : Case of TYPE B is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check Fuel Pump Control System for Opera-

tion. See Fig. 1.

Is fuel pump heard to operate for 2 sec. after

ignition switch ON?Fuel pump circuit is in

good condition.Go to Step 3.

3 Check Fuel Pump for Operation.

1) Remove fuel pump relay from relay box with

ignition switch OFF.

2) Check for proper connection to relay at each

terminals.

3) If OK, using service wire, connect terminals

“A” and “B” of relay connector. See Fig. 2

and CAUTION.

Is fuel pump heard to operate at ignition switch

ON?Go to Step 4.“P”, “B” or “Bl/B” circuit

open or fuel pump mal-

function.

Page 482 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-1

6F1

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8C

6A1

8E

9

9

10B

SECTION 6A1

ENGINE MECHANICAL (M13 ENGINE)

CONTENTS

General Description ......................................6A1-2

Engine ......................................................... 6A1-2

Engine Lubrication ...................................... 6A1-3

Diagnosis .......................................................6A1-4

Diagnosis Table .......................................... 6A1-4

Compression Check .................................... 6A1-4

Engine Vacuum Check ................................ 6A1-6

Oil Pressure Check ..................................... 6A1-7

Valve Lash (Clearance) ............................... 6A1-9

On-Vehicle Service......................................6A1-13

Air Cleaner Element .................................. 6A1-13

Air Cleaner Assembly ................................ 6A1-14

Knock Sensor ............................................ 6A1-14

Cylinder Head Cover ................................. 6A1-15

Throttle Body and Intake Manifold ............ 6A1-18

Exhaust Manifold ....................................... 6A1-21Oil Pan and Oil Pump Strainer .................. 6A1-24

Timing Chain Cover .................................. 6A1-28

Oil Pump ................................................... 6A1-33

Timing Chain and Chain Tensioner .......... 6A1-37

Camshaft, Tappet and Shim ..................... 6A1-42

Valves and Cylinder Head ........................ 6A1-48

Pistons, Piston Rings, Connecting

Rods and Cylinders................................... 6A1-62

Engine Mountings ..................................... 6A1-72

Unit Repair Overhaul .................................. 6A1-73

Engine Assembly ...................................... 6A1-73

Main Bearings, Crankshaft and Cylinder

Block ......................................................... 6A1-79

Required Service Material .......................... 6A1-93

Tightening Torque Specification ............... 6A1-93

Special Tool ................................................. 6A1-94

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 494 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-13

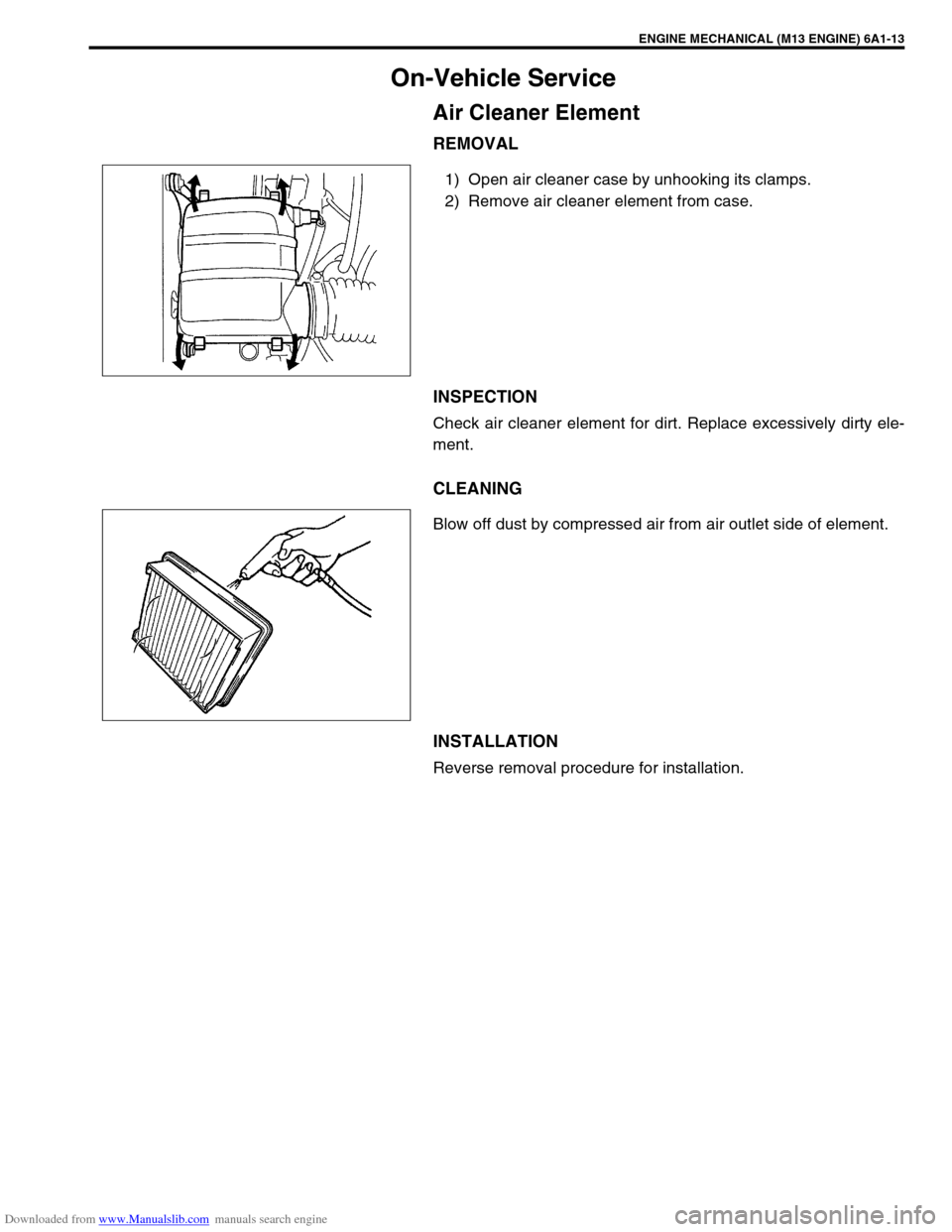

On-Vehicle Service

Air Cleaner Element

REMOVAL

1) Open air cleaner case by unhooking its clamps.

2) Remove air cleaner element from case.

INSPECTION

Check air cleaner element for dirt. Replace excessively dirty ele-

ment.

CLEANING

Blow off dust by compressed air from air outlet side of element.

INSTALLATION

Reverse removal procedure for installation.

Page 502 of 687

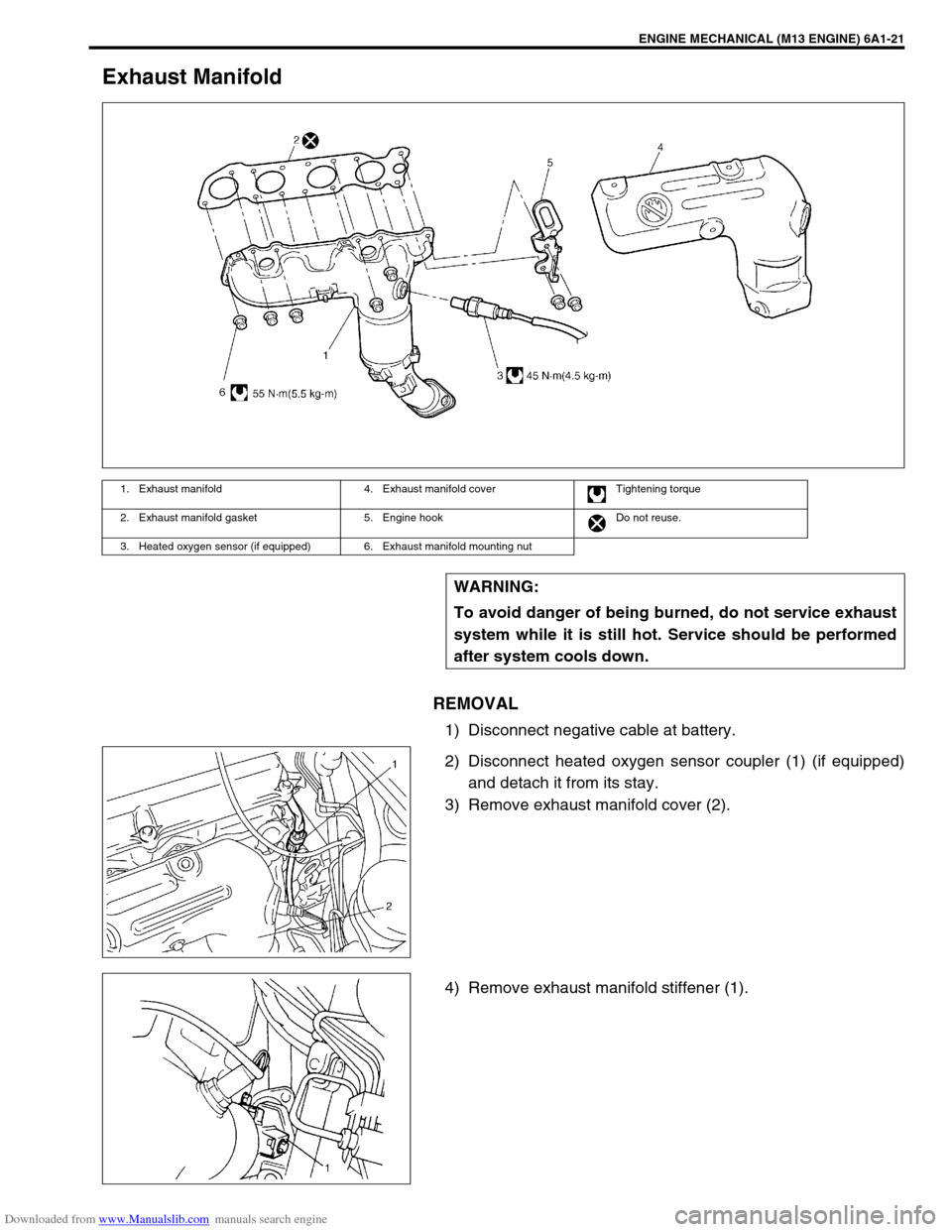

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-21

Exhaust Manifold

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect heated oxygen sensor coupler (1) (if equipped)

and detach it from its stay.

3) Remove exhaust manifold cover (2).

4) Remove exhaust manifold stiffener (1).

1. Exhaust manifold 4. Exhaust manifold cover Tightening torque

2. Exhaust manifold gasket 5. Engine hook Do not reuse.

3. Heated oxygen sensor (if equipped) 6. Exhaust manifold mounting nut

WARNING:

To avoid danger of being burned, do not service exhaust

system while it is still hot. Service should be performed

after system cools down.

Page 563 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-82 ENGINE MECHANICAL (M13 ENGINE)

Tighten bearing cap No.1 bolts (1) – (10) and No.2 bolts (11) –

(20) gradually as follows.

1) Tighten bolts (1) – (10) to 30 N·m (3.0 kg-m, 22.0 lb-ft)

according to numerical order in figure.

2) In the same manner as in Step 1), tighten them to 50 N·m

(5.0 kg-m, 36.5 lb-ft).

3) In the same manner as in step 1), retighten them to 60°.

4) Tighten bolts (11) – (20) to 22 N·m (2.2 kg-m, 16.0 lb-ft)

according to numerical order in figure.

Tightening torque

Crankshaft bearing cap No.1 bolts (1) – (10) :

50 N·m (5.0 kg-m, 36.5 lb-ft) and extra tightening 60°

Crankshaft bearing cap No.2 bolts (11) – (20) :

22 N·m (2.2 kg-m, 16.0 lb-ft)

Use a dial gauge to read displacement in axial (thrust) direction of

crankshaft.

If its limit is exceeded, replace thrust bearing with new standard

one or oversize one to obtain standard thrust play.

Crankshaft thrust play

Standard : 0.11 – 0.31 mm (0.0043 – 0.0122 in.)

Limit : 0.35 mm (0.0138 in.)

Out-of-round and taper of journals

An unevenly worn crankshaft journal shows up as a difference in

diameter at a cross section or along its length (or both). This dif-

ference, if any, is determined by taking micrometer readings. If

any one of journals is badly damaged or if amount of uneven

wear in the sense explained above exceeds its limit, regrind or

replace crankshaft.

Crankshaft out-of-round and taper

Limit : 0.01 mm (0.0004 in.)

Out-of-round : A – B

Taper : a – b

Main Bearings

General information

Service main bearings are available in standard size and

0.25 mm (0.0098 in.) undersize, and each of them has 5

kinds of bearings differing in tolerance.

NOTE:

After checking the thrust play, check for thread deforma-

tion of each bearing cap No.1 bolt according to previous

mentioned “Main Bearing Cap No.1 Bolt” once again.

Page 574 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-93

Required Service Material

Tightening Torque Specification

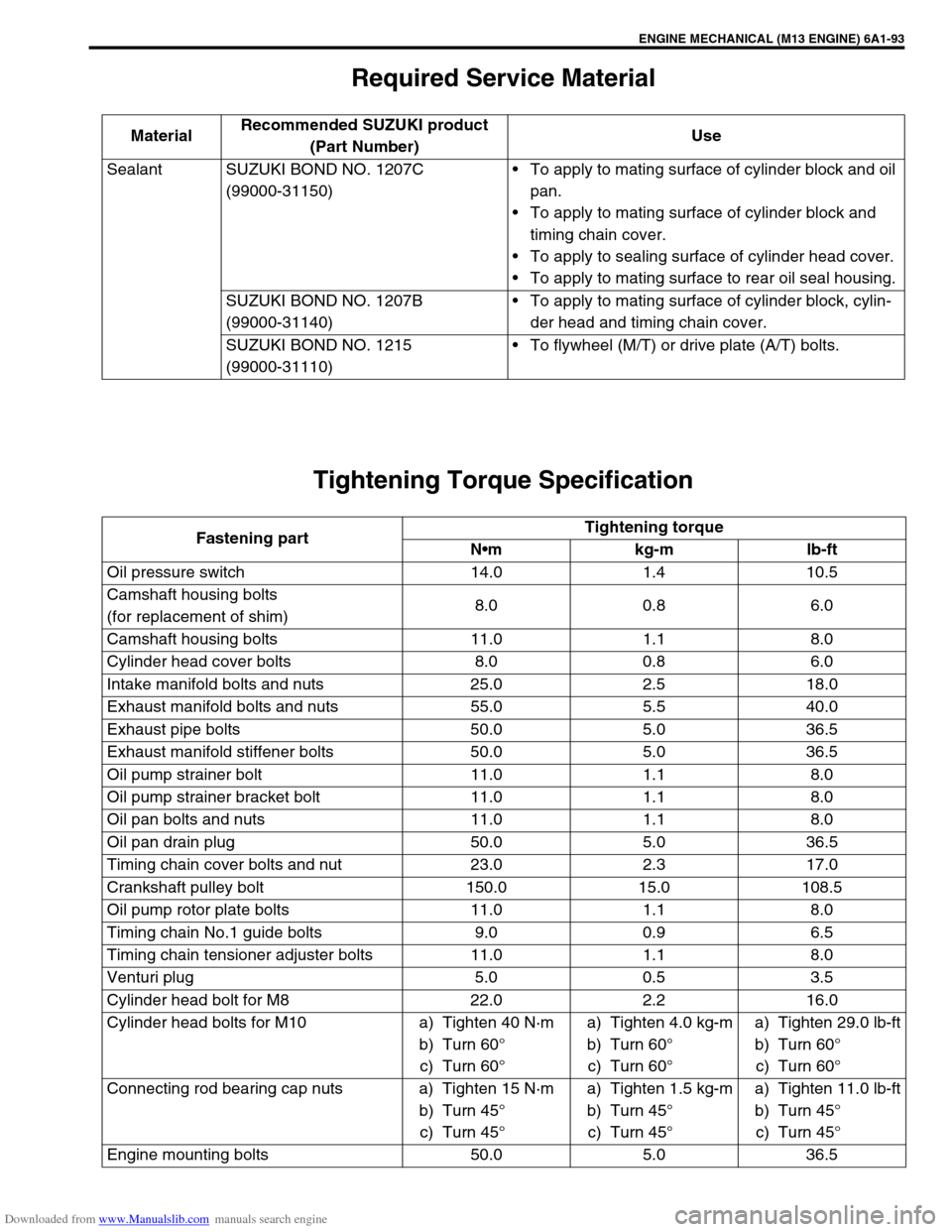

MaterialRecommended SUZUKI product

(Part Number)Use

Sealant SUZUKI BOND NO. 1207C

(99000-31150)To apply to mating surface of cylinder block and oil

pan.

To apply to mating surface of cylinder block and

timing chain cover.

To apply to sealing surface of cylinder head cover.

To apply to mating surface to rear oil seal housing.

SUZUKI BOND NO. 1207B

(99000-31140)To apply to mating surface of cylinder block, cylin-

der head and timing chain cover.

SUZUKI BOND NO. 1215

(99000-31110)To flywheel (M/T) or drive plate (A/T) bolts.

Fastening partTightening torque

Nm kg-m lb-ft

Oil pressure switch 14.0 1.4 10.5

Camshaft housing bolts

(for replacement of shim)8.0 0.8 6.0

Camshaft housing bolts 11.0 1.1 8.0

Cylinder head cover bolts 8.0 0.8 6.0

Intake manifold bolts and nuts 25.0 2.5 18.0

Exhaust manifold bolts and nuts 55.0 5.5 40.0

Exhaust pipe bolts 50.0 5.0 36.5

Exhaust manifold stiffener bolts 50.0 5.0 36.5

Oil pump strainer bolt 11.0 1.1 8.0

Oil pump strainer bracket bolt 11.0 1.1 8.0

Oil pan bolts and nuts 11.0 1.1 8.0

Oil pan drain plug 50.0 5.0 36.5

Timing chain cover bolts and nut 23.0 2.3 17.0

Crankshaft pulley bolt 150.0 15.0 108.5

Oil pump rotor plate bolts 11.0 1.1 8.0

Timing chain No.1 guide bolts 9.0 0.9 6.5

Timing chain tensioner adjuster bolts 11.0 1.1 8.0

Venturi plug 5.0 0.5 3.5

Cylinder head bolt for M8 22.0 2.2 16.0

Cylinder head bolts for M10 a) Tighten 40 N·m

b) Turn 60°

c) Turn 60°a) Tighten 4.0 kg-m

b) Turn 60°

c) Turn 60°a) Tighten 29.0 lb-ft

b) Turn 60°

c) Turn 60°

Connecting rod bearing cap nuts a) Tighten 15 N·m

b) Turn 45°

c) Turn 45°a) Tighten 1.5 kg-m

b) Turn 45°

c) Turn 45°a) Tighten 11.0 lb-ft

b) Turn 45°

c) Turn 45°

Engine mounting bolts 50.0 5.0 36.5

Page 578 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-1

6B

SECTION 6B

ENGINE COOLING

CONTENTS

General Description ........................................6B-2

Cooling System Circulation ........................... 6B-2

Radiator Cap ................................................. 6B-3

Coolant Reservoir ......................................... 6B-3

Water Pump .................................................. 6B-4

Thermostat .................................................... 6B-4

Cooling Fan Clutch ........................................ 6B-4

Coolant (Water) Temperature Gauge............ 6B-4

Diagnosis .........................................................6B-5

Maintenance ....................................................6B-6

Coolant .......................................................... 6B-6

Coolant Level ................................................ 6B-7

Cooling System Service ................................ 6B-7Cooling System Flush and Refill ................... 6B-8

Water Pump Belt Tension ............................. 6B-9

On-Vehicle Service ....................................... 6B-10

Cooling System Component ....................... 6B-10

Coolant Draining ......................................... 6B-11

Cooling Water Pipes or Hoses .................... 6B-11

Thermostat .................................................. 6B-11

Water Pump Belt and Cooling Fan ............. 6B-13

Radiator ...................................................... 6B-14

Water Pump ................................................ 6B-15

Required Service Material ............................ 6B-17

Tightening Torque Specification ................. 6B-17

Page 584 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-7

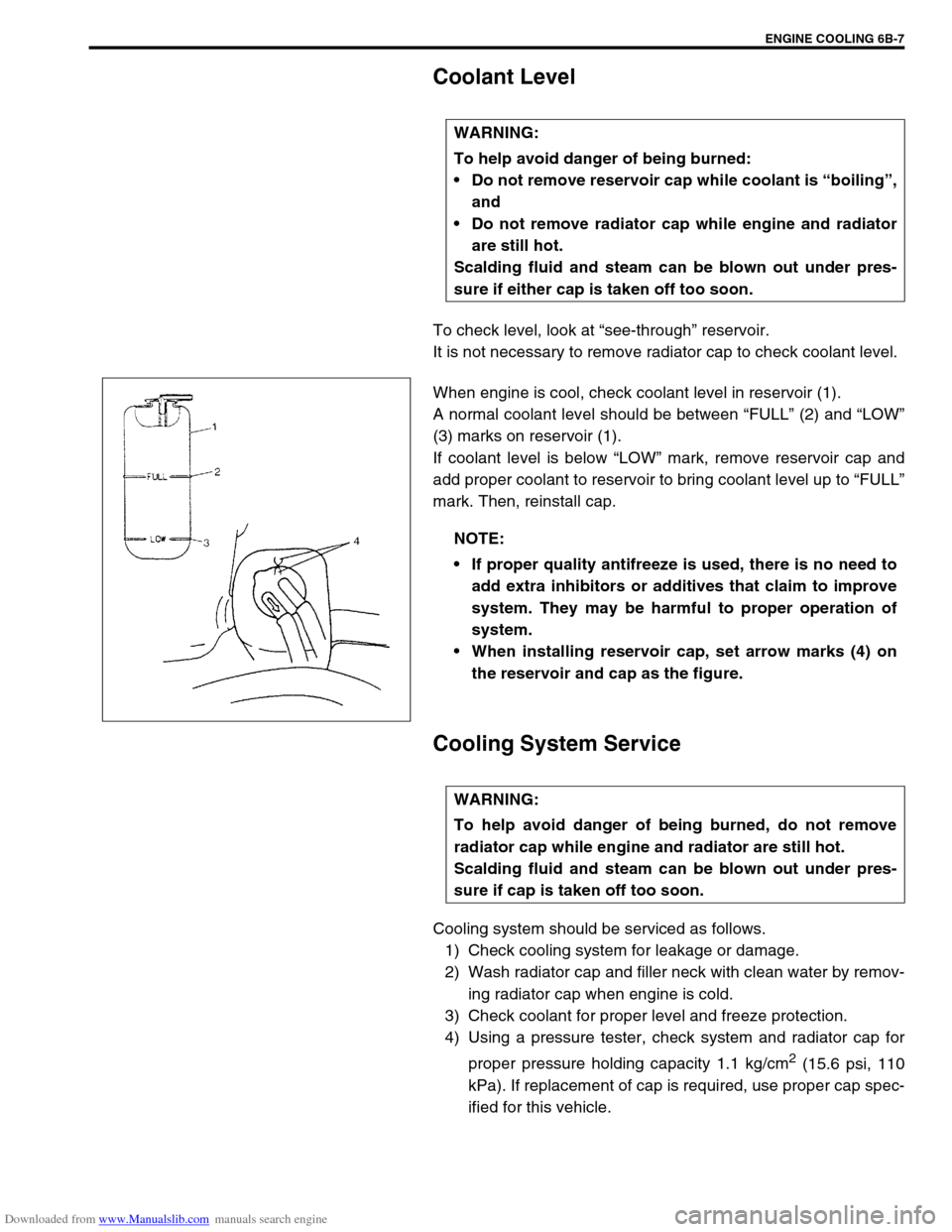

Coolant Level

To check level, look at “see-through” reservoir.

It is not necessary to remove radiator cap to check coolant level.

When engine is cool, check coolant level in reservoir (1).

A normal coolant level should be between “FULL” (2) and “LOW”

(3) marks on reservoir (1).

If coolant level is below “LOW” mark, remove reservoir cap and

add proper coolant to reservoir to bring coolant level up to “FULL”

mark. Then, reinstall cap.

Cooling System Service

Cooling system should be serviced as follows.

1) Check cooling system for leakage or damage.

2) Wash radiator cap and filler neck with clean water by remov-

ing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

4) Using a pressure tester, check system and radiator cap for

proper pressure holding capacity 1.1 kg/cm

2 (15.6 psi, 110

kPa). If replacement of cap is required, use proper cap spec-

ified for this vehicle. WARNING:

To help avoid danger of being burned:

Do not remove reservoir cap while coolant is “boiling”,

and

Do not remove radiator cap while engine and radiator

are still hot.

Scalding fluid and steam can be blown out under pres-

sure if either cap is taken off too soon.

NOTE:

If proper quality antifreeze is used, there is no need to

add extra inhibitors or additives that claim to improve

system. They may be harmful to proper operation of

system.

When installing reservoir cap, set arrow marks (4) on

the reservoir and cap as the figure.

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.

Page 587 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-10 ENGINE COOLING

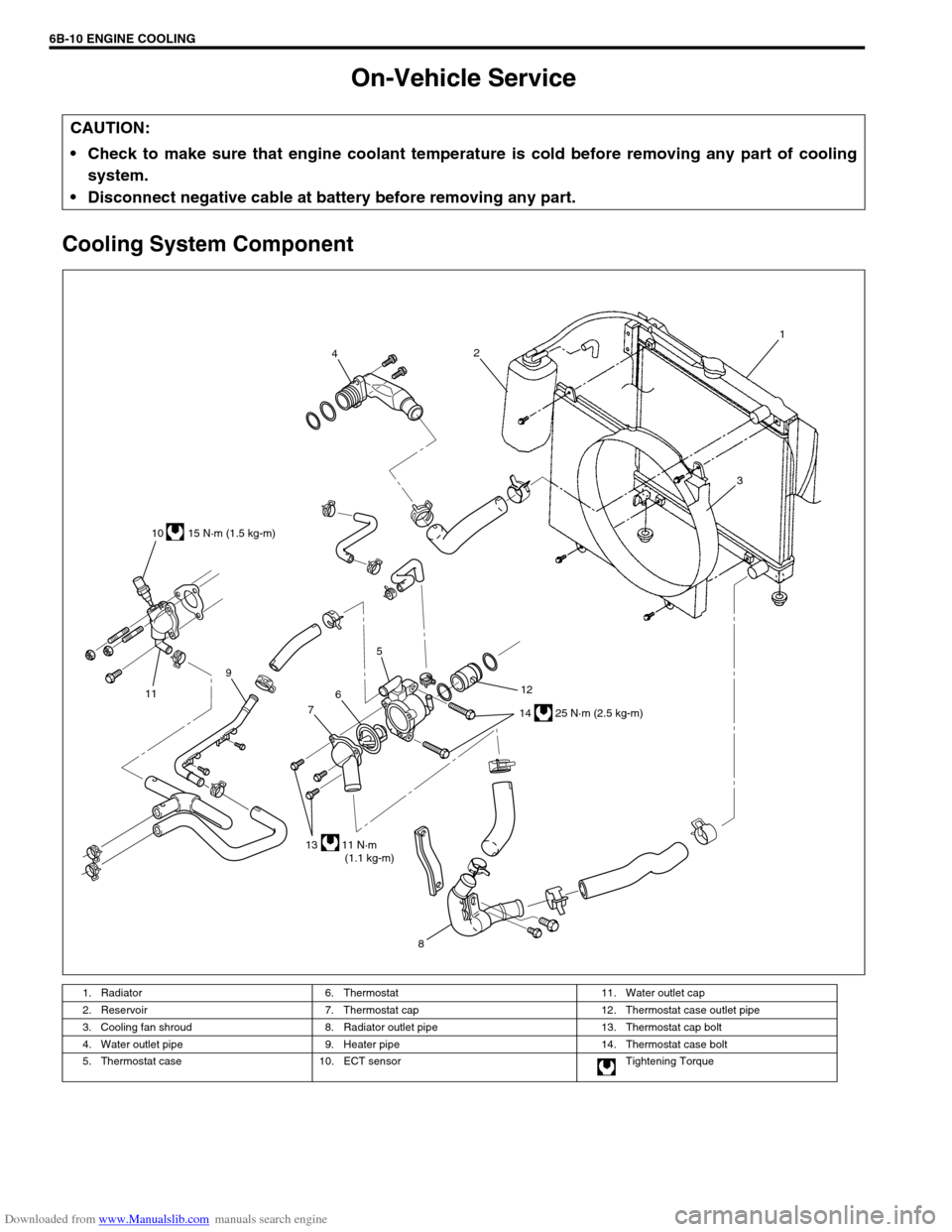

On-Vehicle Service

Cooling System Component

CAUTION:

Check to make sure that engine coolant temperature is cold before removing any part of cooling

system.

Disconnect negative cable at battery before removing any part.

1. Radiator 6. Thermostat 11. Water outlet cap

2. Reservoir 7. Thermostat cap 12. Thermostat case outlet pipe

3. Cooling fan shroud 8. Radiator outlet pipe 13. Thermostat cap bolt

4. Water outlet pipe 9. Heater pipe 14. Thermostat case bolt

5. Thermostat case 10. ECT sensor Tightening Torque

814 25 N·m (2.5 kg-m) 10 15 N·m (1.5 kg-m)

12 5

6

7

13 11 N·m

(1.1 kg-m) 119421

3