check engine SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 281 of 687

Downloaded from www.Manualslib.com manuals search engine 5-20 BRAKES

Brake pad

REMOVAL

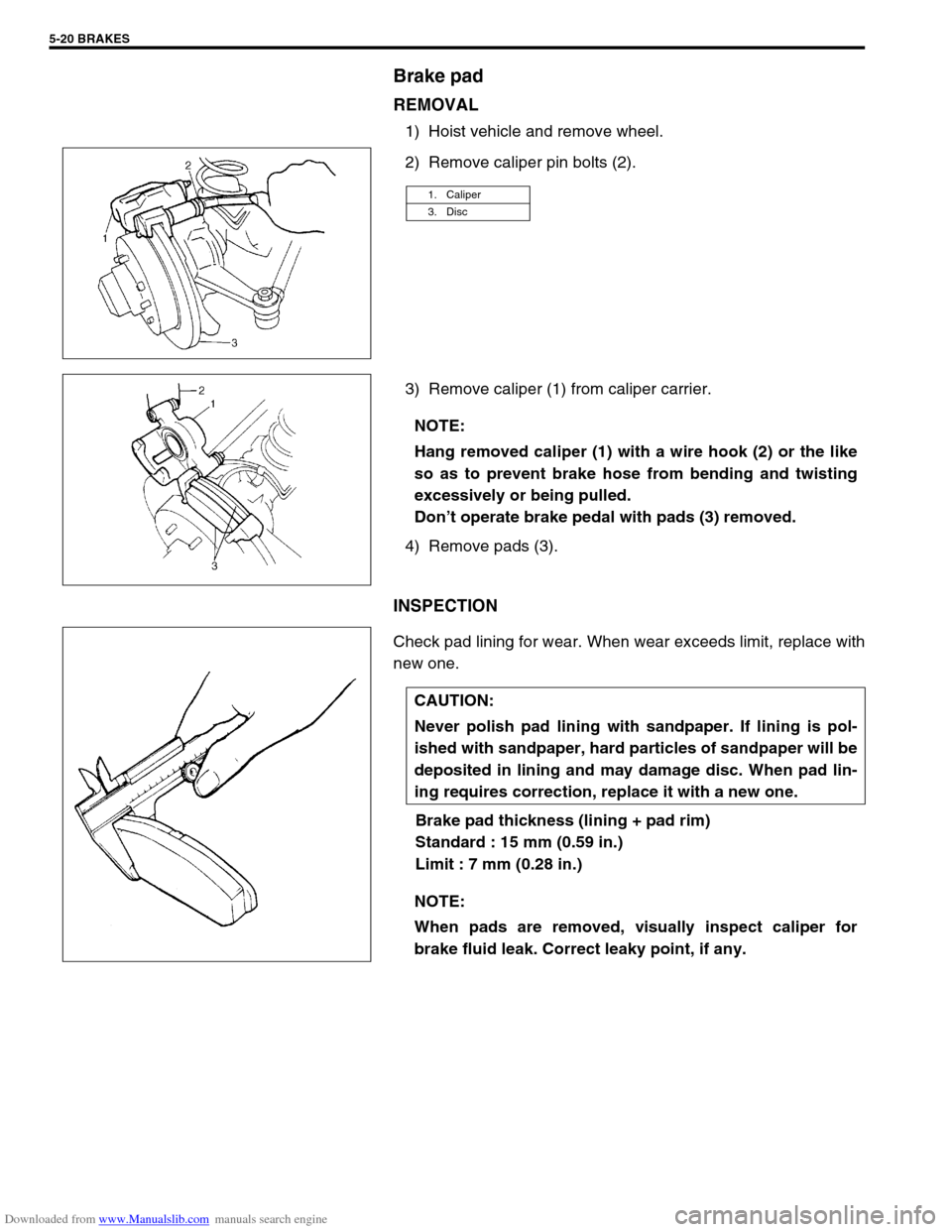

1) Hoist vehicle and remove wheel.

2) Remove caliper pin bolts (2).

3) Remove caliper (1) from caliper carrier.

4) Remove pads (3).

INSPECTION

Check pad lining for wear. When wear exceeds limit, replace with

new one.

Brake pad thickness (lining + pad rim)

Standard : 15 mm (0.59 in.)

Limit : 7 mm (0.28 in.)

1. Caliper

3. Disc

NOTE:

Hang removed caliper (1) with a wire hook (2) or the like

so as to prevent brake hose from bending and twisting

excessively or being pulled.

Don’t operate brake pedal with pads (3) removed.

CAUTION:

Never polish pad lining with sandpaper. If lining is pol-

ished with sandpaper, hard particles of sandpaper will be

deposited in lining and may damage disc. When pad lin-

ing requires correction, replace it with a new one.

NOTE:

When pads are removed, visually inspect caliper for

brake fluid leak. Correct leaky point, if any.

Page 284 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-23

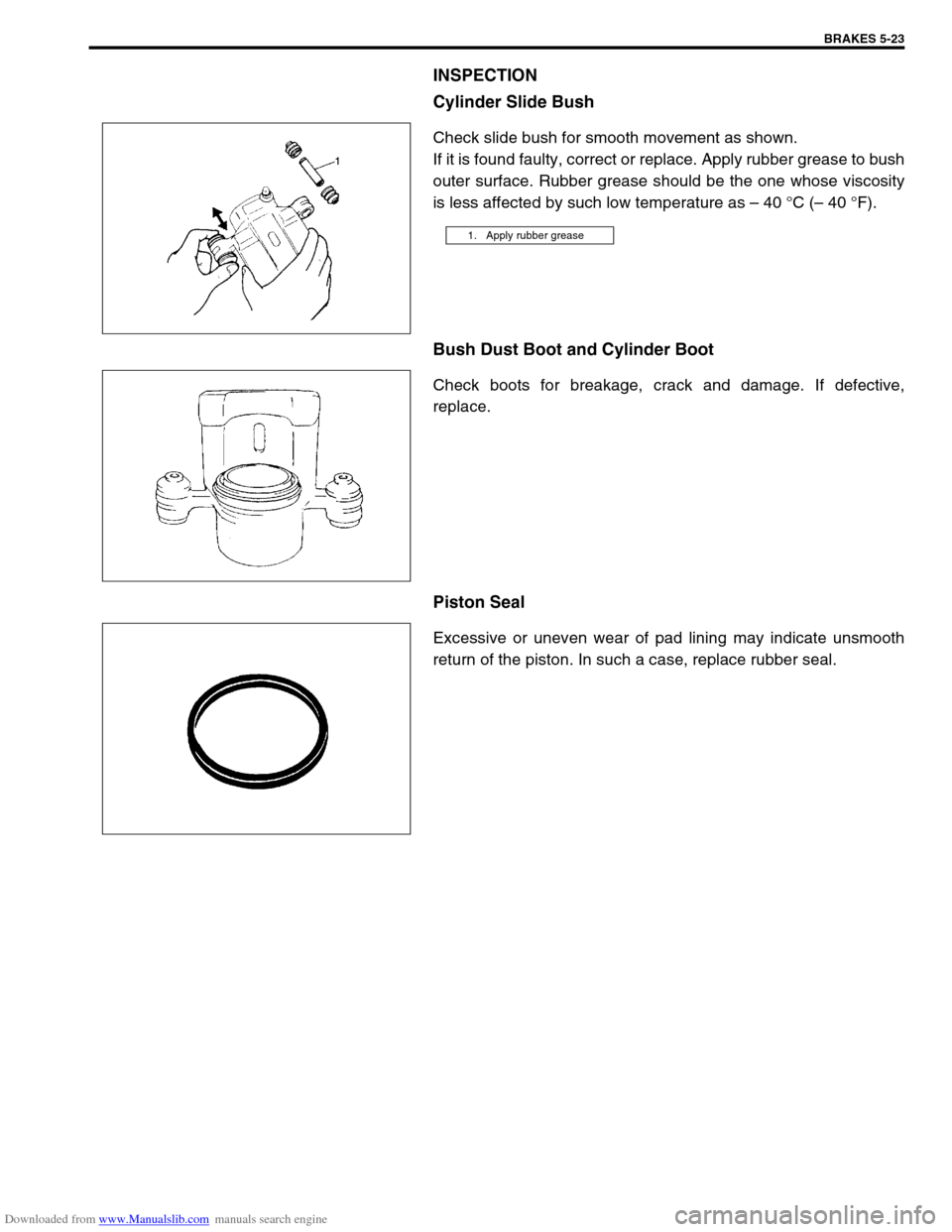

INSPECTION

Cylinder Slide Bush

Check slide bush for smooth movement as shown.

If it is found faulty, correct or replace. Apply rubber grease to bush

outer surface. Rubber grease should be the one whose viscosity

is less affected by such low temperature as – 40 °C (– 40 °F).

Bush Dust Boot and Cylinder Boot

Check boots for breakage, crack and damage. If defective,

replace.

Piston Seal

Excessive or uneven wear of pad lining may indicate unsmooth

return of the piston. In such a case, replace rubber seal.

1. Apply rubber grease

Page 285 of 687

Downloaded from www.Manualslib.com manuals search engine 5-24 BRAKES

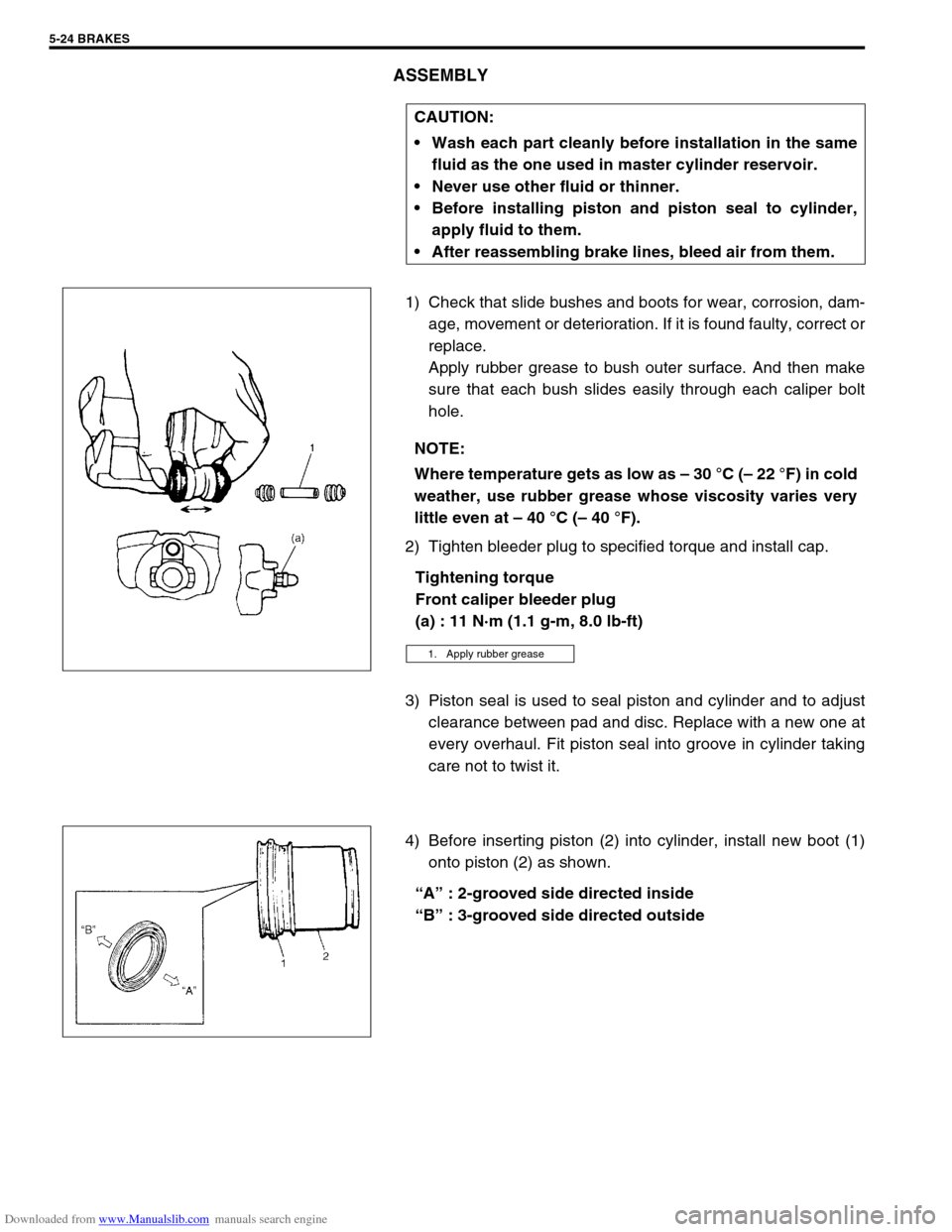

ASSEMBLY

1) Check that slide bushes and boots for wear, corrosion, dam-

age, movement or deterioration. If it is found faulty, correct or

replace.

Apply rubber grease to bush outer surface. And then make

sure that each bush slides easily through each caliper bolt

hole.

2) Tighten bleeder plug to specified torque and install cap.

Tightening torque

Front caliper bleeder plug

(a) : 11 N·m (1.1 g-m, 8.0 lb-ft)

3) Piston seal is used to seal piston and cylinder and to adjust

clearance between pad and disc. Replace with a new one at

every overhaul. Fit piston seal into groove in cylinder taking

care not to twist it.

4) Before inserting piston (2) into cylinder, install new boot (1)

onto piston (2) as shown.

“A” : 2-grooved side directed inside

“B” : 3-grooved side directed outside CAUTION:

Wash each part cleanly before installation in the same

fluid as the one used in master cylinder reservoir.

Never use other fluid or thinner.

Before installing piston and piston seal to cylinder,

apply fluid to them.

After reassembling brake lines, bleed air from them.

NOTE:

Where temperature gets as low as – 30 °C (– 22 °F) in cold

weather, use rubber grease whose viscosity varies very

little even at – 40 °C (– 40 °F).

1. Apply rubber grease

Page 287 of 687

Downloaded from www.Manualslib.com manuals search engine 5-26 BRAKES

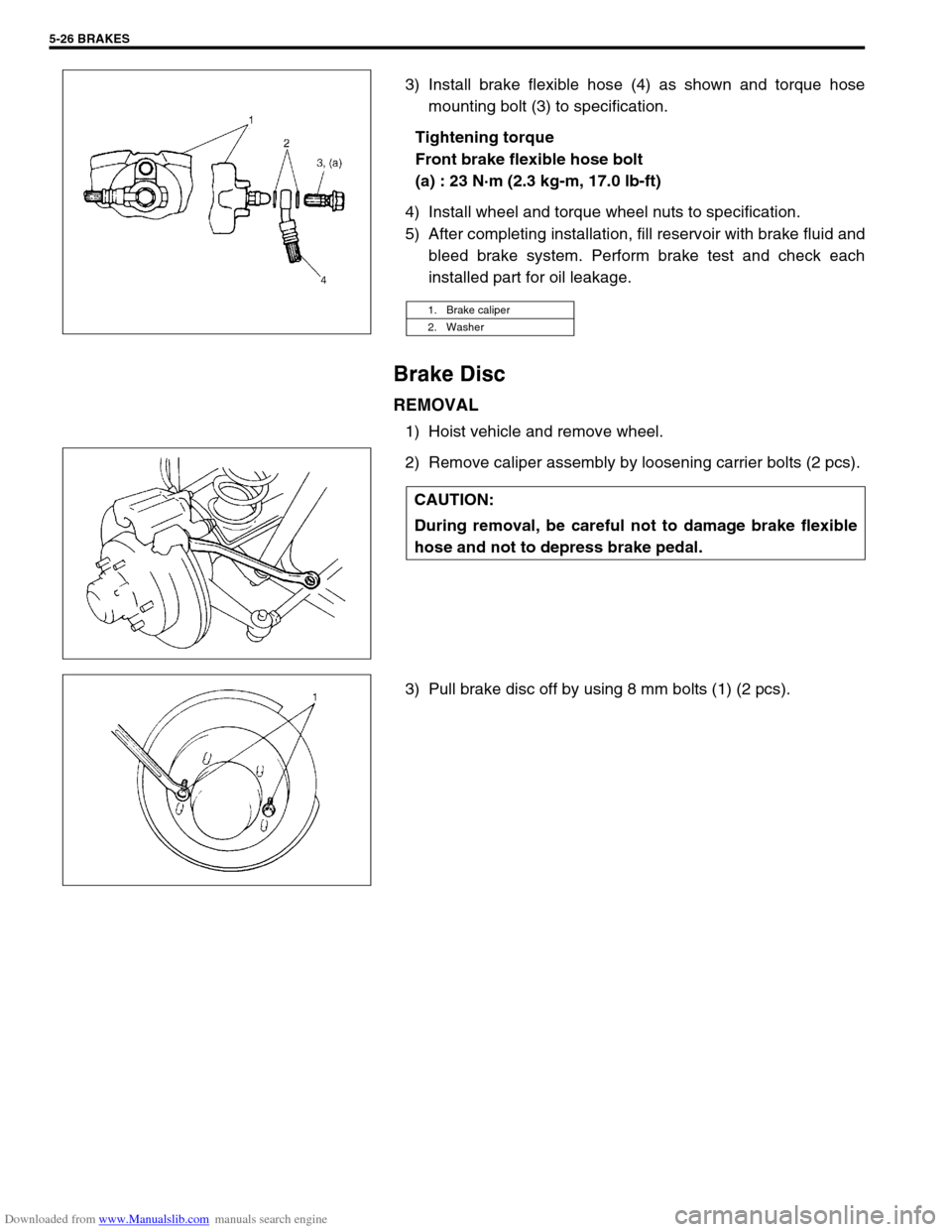

3) Install brake flexible hose (4) as shown and torque hose

mounting bolt (3) to specification.

Tightening torque

Front brake flexible hose bolt

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

4) Install wheel and torque wheel nuts to specification.

5) After completing installation, fill reservoir with brake fluid and

bleed brake system. Perform brake test and check each

installed part for oil leakage.

Brake Disc

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by loosening carrier bolts (2 pcs).

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

1. Brake caliper

2. Washer

CAUTION:

During removal, be careful not to damage brake flexible

hose and not to depress brake pedal.

Page 288 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-27

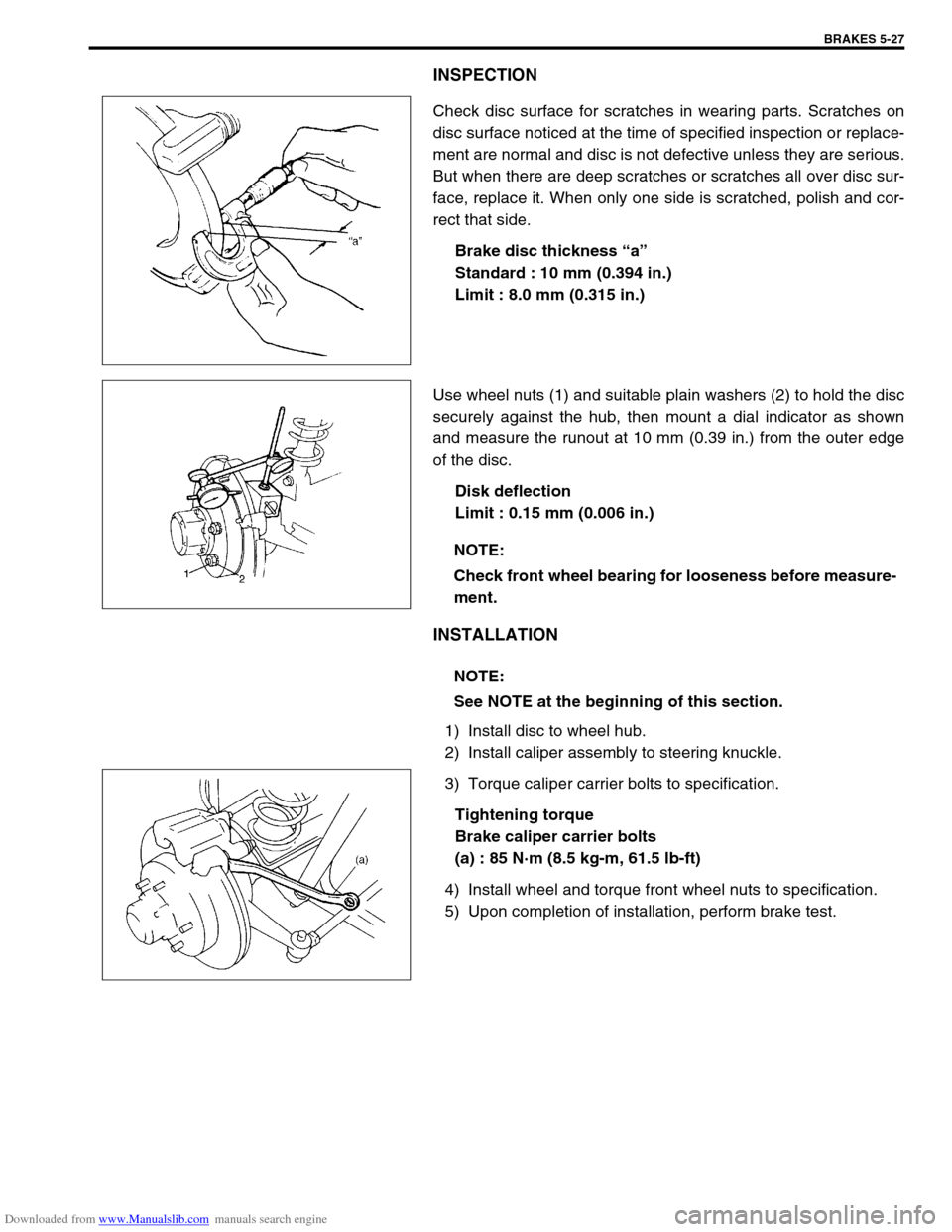

INSPECTION

Check disc surface for scratches in wearing parts. Scratches on

disc surface noticed at the time of specified inspection or replace-

ment are normal and disc is not defective unless they are serious.

But when there are deep scratches or scratches all over disc sur-

face, replace it. When only one side is scratched, polish and cor-

rect that side.

Brake disc thickness “a”

Standard : 10 mm (0.394 in.)

Limit : 8.0 mm (0.315 in.)

Use wheel nuts (1) and suitable plain washers (2) to hold the disc

securely against the hub, then mount a dial indicator as shown

and measure the runout at 10 mm (0.39 in.) from the outer edge

of the disc.

Disk deflection

Limit : 0.15 mm (0.006 in.)

INSTALLATION

1) Install disc to wheel hub.

2) Install caliper assembly to steering knuckle.

3) Torque caliper carrier bolts to specification.

Tightening torque

Brake caliper carrier bolts

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

4) Install wheel and torque front wheel nuts to specification.

5) Upon completion of installation, perform brake test.

NOTE:

Check front wheel bearing for looseness before measure-

ment.

NOTE:

See NOTE at the beginning of this section.

Page 289 of 687

Downloaded from www.Manualslib.com manuals search engine 5-28 BRAKES

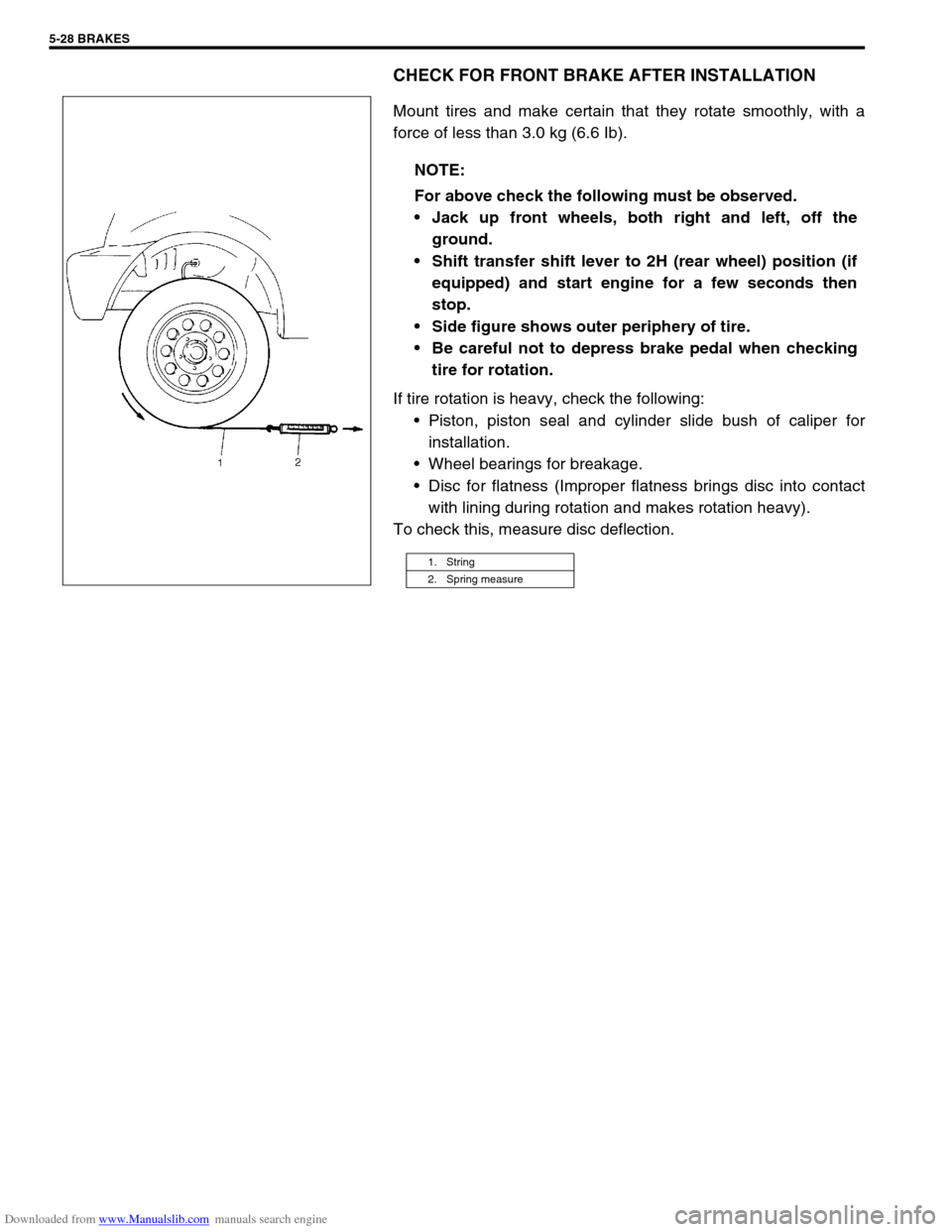

CHECK FOR FRONT BRAKE AFTER INSTALLATION

Mount tires and make certain that they rotate smoothly, with a

force of less than 3.0 kg (6.6 Ib).

If tire rotation is heavy, check the following:

Piston, piston seal and cylinder slide bush of caliper for

installation.

Wheel bearings for breakage.

Disc for flatness (Improper flatness brings disc into contact

with lining during rotation and makes rotation heavy).

To check this, measure disc deflection.NOTE:

For above check the following must be observed.

Jack up front wheels, both right and left, off the

ground.

Shift transfer shift lever to 2H (rear wheel) position (if

equipped) and start engine for a few seconds then

stop.

Side figure shows outer periphery of tire.

Be careful not to depress brake pedal when checking

tire for rotation.

1. String

2. Spring measure

Page 291 of 687

Downloaded from www.Manualslib.com manuals search engine 5-30 BRAKES

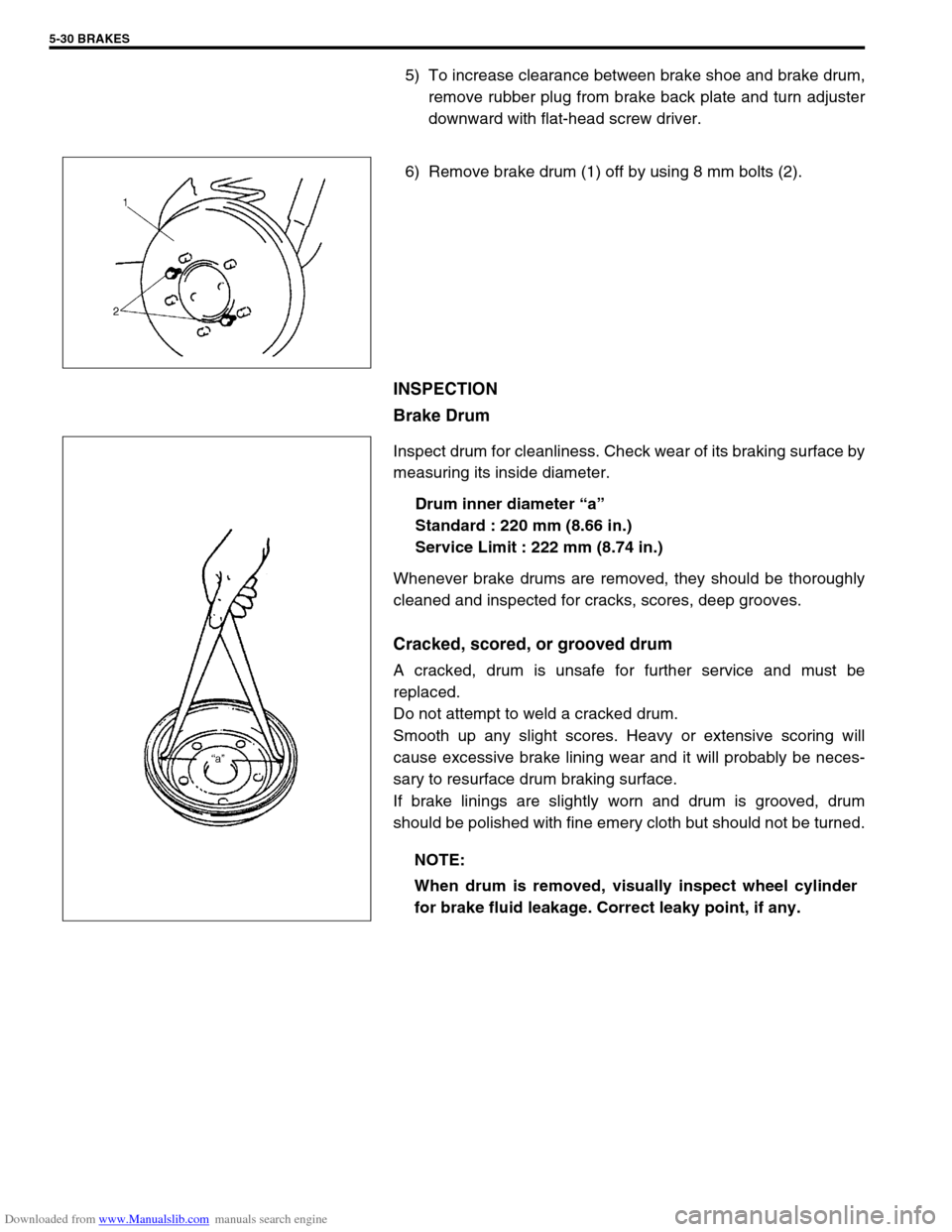

5) To increase clearance between brake shoe and brake drum,

remove rubber plug from brake back plate and turn adjuster

downward with flat-head screw driver.

6) Remove brake drum (1) off by using 8 mm bolts (2).

INSPECTION

Brake Drum

Inspect drum for cleanliness. Check wear of its braking surface by

measuring its inside diameter.

Drum inner diameter “a”

Standard : 220 mm (8.66 in.)

Service Limit : 222 mm (8.74 in.)

Whenever brake drums are removed, they should be thoroughly

cleaned and inspected for cracks, scores, deep grooves.

Cracked, scored, or grooved drum

A cracked, drum is unsafe for further service and must be

replaced.

Do not attempt to weld a cracked drum.

Smooth up any slight scores. Heavy or extensive scoring will

cause excessive brake lining wear and it will probably be neces-

sary to resurface drum braking surface.

If brake linings are slightly worn and drum is grooved, drum

should be polished with fine emery cloth but should not be turned.

NOTE:

When drum is removed, visually inspect wheel cylinder

for brake fluid leakage. Correct leaky point, if any.

Page 292 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-31

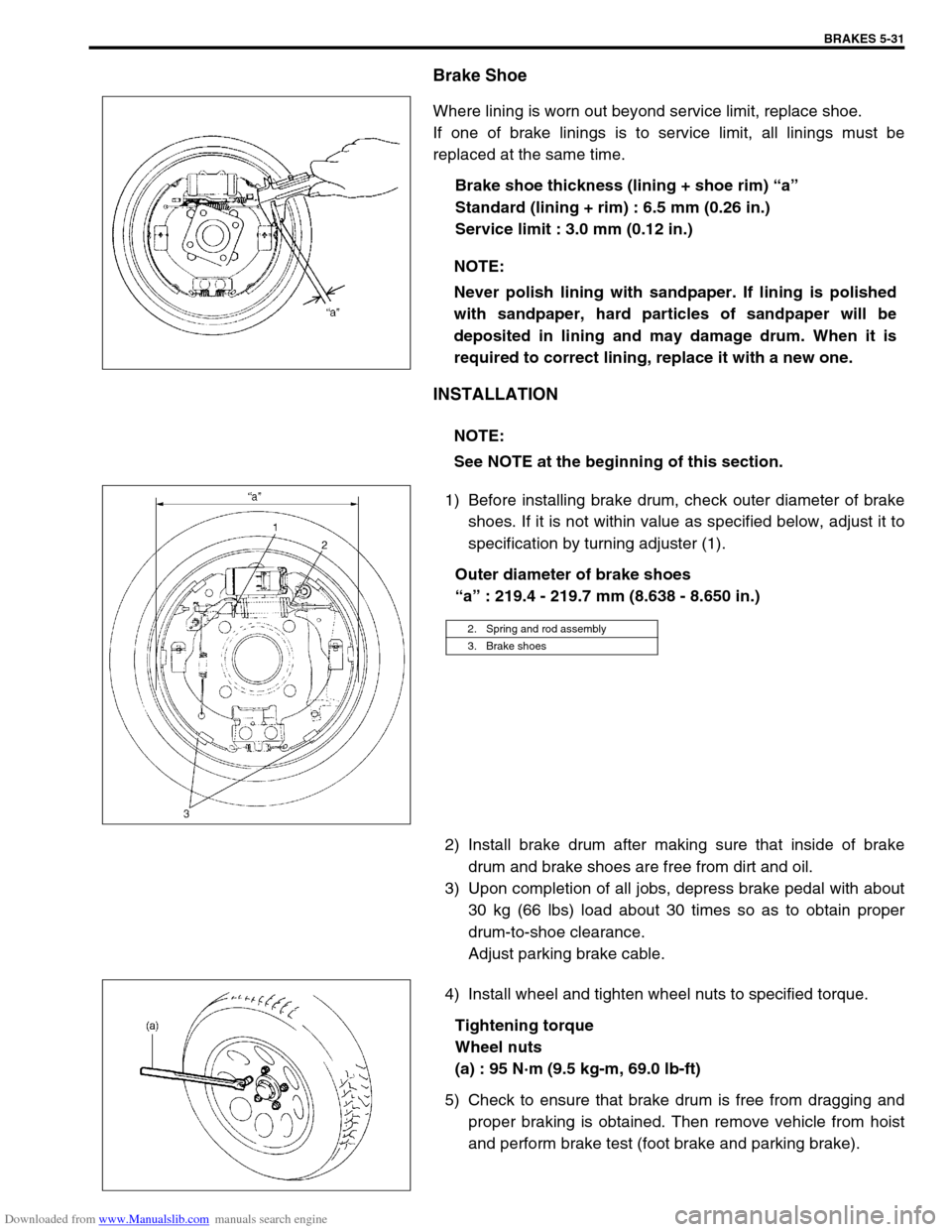

Brake Shoe

Where lining is worn out beyond service limit, replace shoe.

If one of brake linings is to service limit, all linings must be

replaced at the same time.

Brake shoe thickness (lining + shoe rim) “a”

Standard (lining + rim) : 6.5 mm (0.26 in.)

Service limit : 3.0 mm (0.12 in.)

INSTALLATION

1) Before installing brake drum, check outer diameter of brake

shoes. If it is not within value as specified below, adjust it to

specification by turning adjuster (1).

Outer diameter of brake shoes

“a” : 219.4 - 219.7 mm (8.638 - 8.650 in.)

2) Install brake drum after making sure that inside of brake

drum and brake shoes are free from dirt and oil.

3) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load about 30 times so as to obtain proper

drum-to-shoe clearance.

Adjust parking brake cable.

4) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

5) Check to ensure that brake drum is free from dragging and

proper braking is obtained. Then remove vehicle from hoist

and perform brake test (foot brake and parking brake). NOTE:

Never polish lining with sandpaper. If lining is polished

with sandpaper, hard particles of sandpaper will be

deposited in lining and may damage drum. When it is

required to correct lining, replace it with a new one.

NOTE:

See NOTE at the beginning of this section.

2. Spring and rod assembly

3. Brake shoes

Page 298 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-37

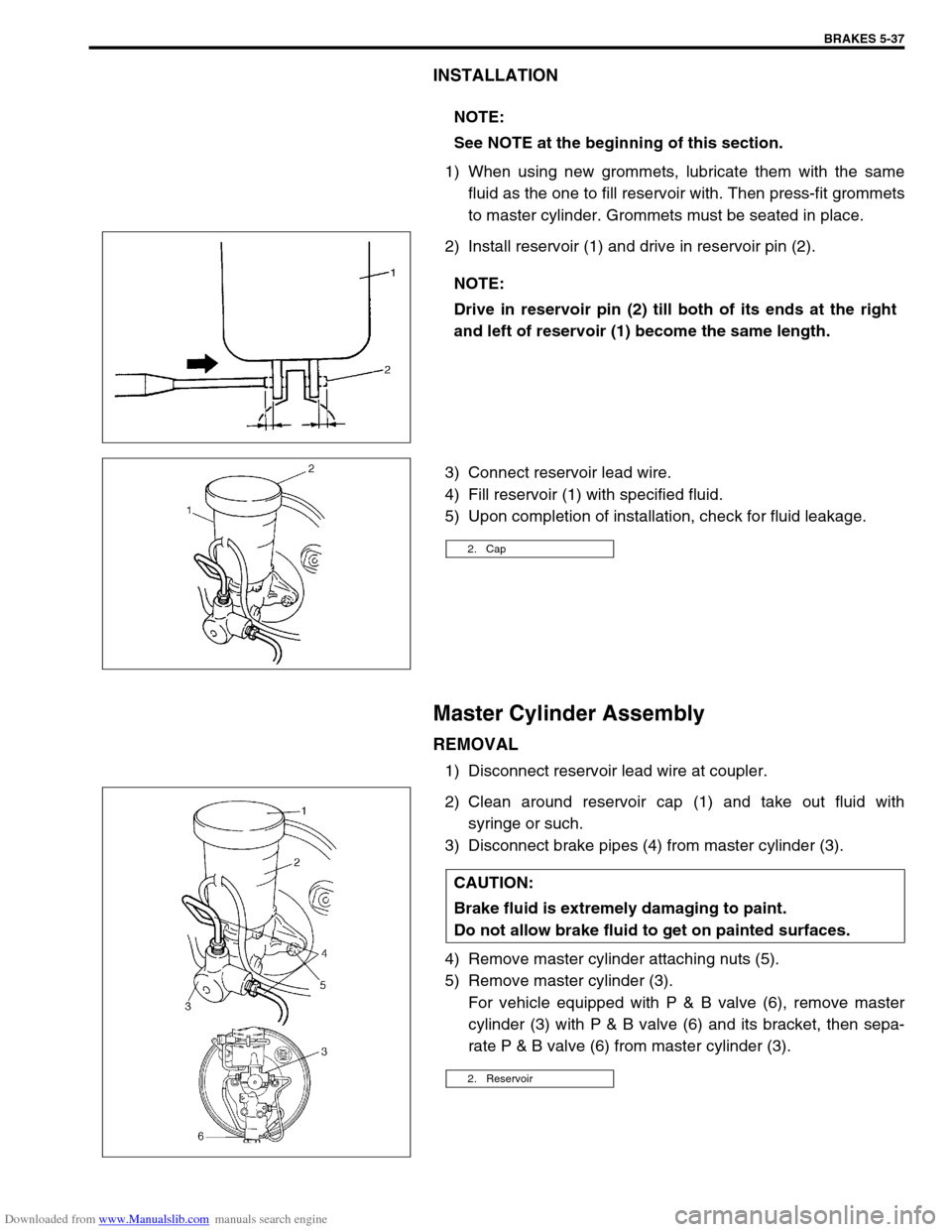

INSTALLATION

1) When using new grommets, lubricate them with the same

fluid as the one to fill reservoir with. Then press-fit grommets

to master cylinder. Grommets must be seated in place.

2) Install reservoir (1) and drive in reservoir pin (2).

3) Connect reservoir lead wire.

4) Fill reservoir (1) with specified fluid.

5) Upon completion of installation, check for fluid leakage.

Master Cylinder Assembly

REMOVAL

1) Disconnect reservoir lead wire at coupler.

2) Clean around reservoir cap (1) and take out fluid with

syringe or such.

3) Disconnect brake pipes (4) from master cylinder (3).

4) Remove master cylinder attaching nuts (5).

5) Remove master cylinder (3).

For vehicle equipped with P & B valve (6), remove master

cylinder (3) with P & B valve (6) and its bracket, then sepa-

rate P & B valve (6) from master cylinder (3). NOTE:

See NOTE at the beginning of this section.

NOTE:

Drive in reservoir pin (2) till both of its ends at the right

and left of reservoir (1) become the same length.

2. Cap

CAUTION:

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted surfaces.

2. Reservoir

Page 299 of 687

Downloaded from www.Manualslib.com manuals search engine 5-38 BRAKES

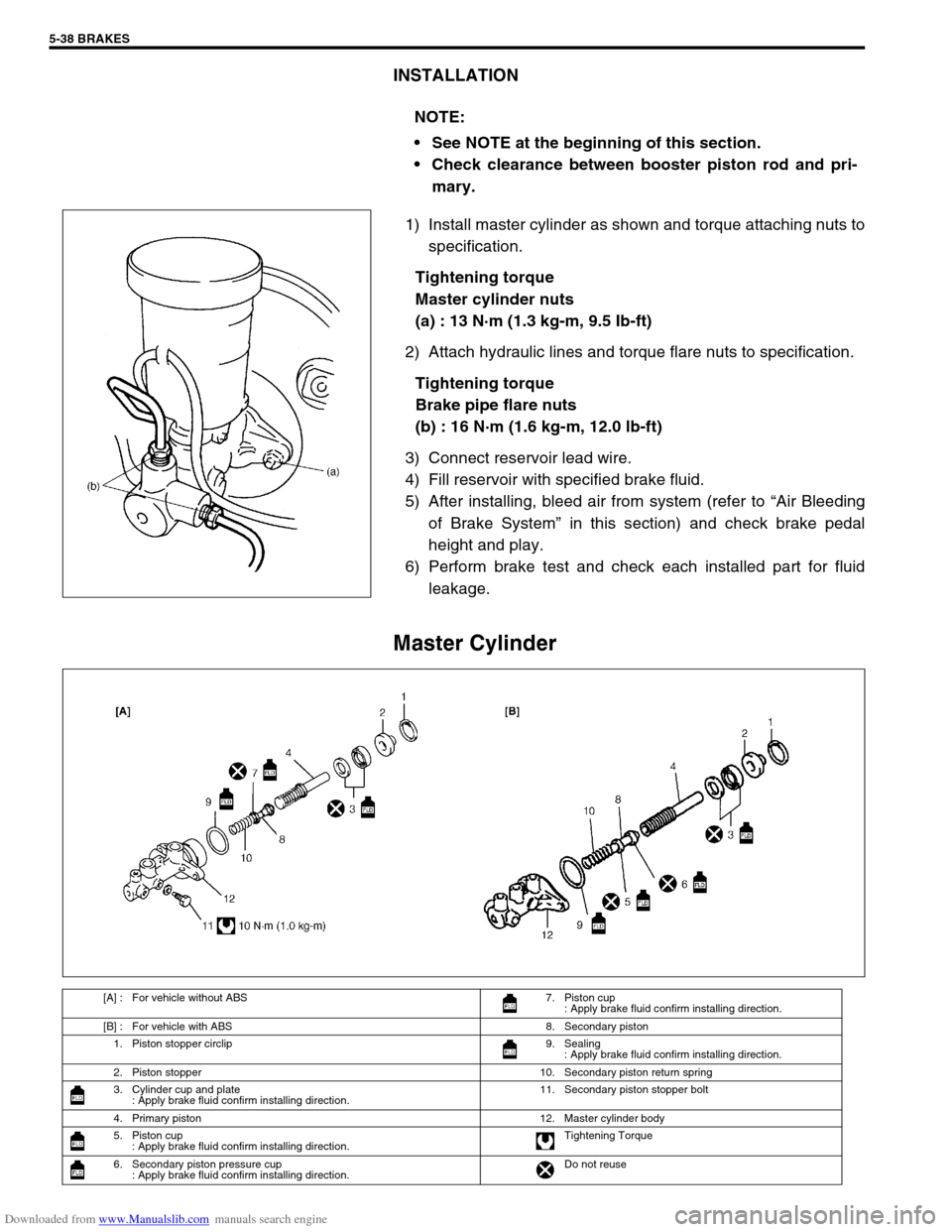

INSTALLATION

1) Install master cylinder as shown and torque attaching nuts to

specification.

Tightening torque

Master cylinder nuts

(a) : 13 N·m (1.3 kg-m, 9.5 Ib-ft)

2) Attach hydraulic lines and torque flare nuts to specification.

Tightening torque

Brake pipe flare nuts

(b) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

3) Connect reservoir lead wire.

4) Fill reservoir with specified brake fluid.

5) After installing, bleed air from system (refer to “Air Bleeding

of Brake System” in this section) and check brake pedal

height and play.

6) Perform brake test and check each installed part for fluid

leakage.

Master Cylinder

NOTE:

See NOTE at the beginning of this section.

Check clearance between booster piston rod and pri-

mary.

[A] : For vehicle without ABS 7. Piston cup

: Apply brake fluid confirm installing direction.

[B] : For vehicle with ABS 8. Secondary piston

1. Piston stopper circlip 9. Sealing

: Apply brake fluid confirm installing direction.

2. Piston stopper 10. Secondary piston return spring

3. Cylinder cup and plate

: Apply brake fluid confirm installing direction.11. Secondary piston stopper bolt

4. Primary piston 12. Master cylinder body

5. Piston cup

: Apply brake fluid confirm installing direction.Tightening Torque

6. Secondary piston pressure cup

: Apply brake fluid confirm installing direction.Do not reuse