coolant temperature SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 410 of 687

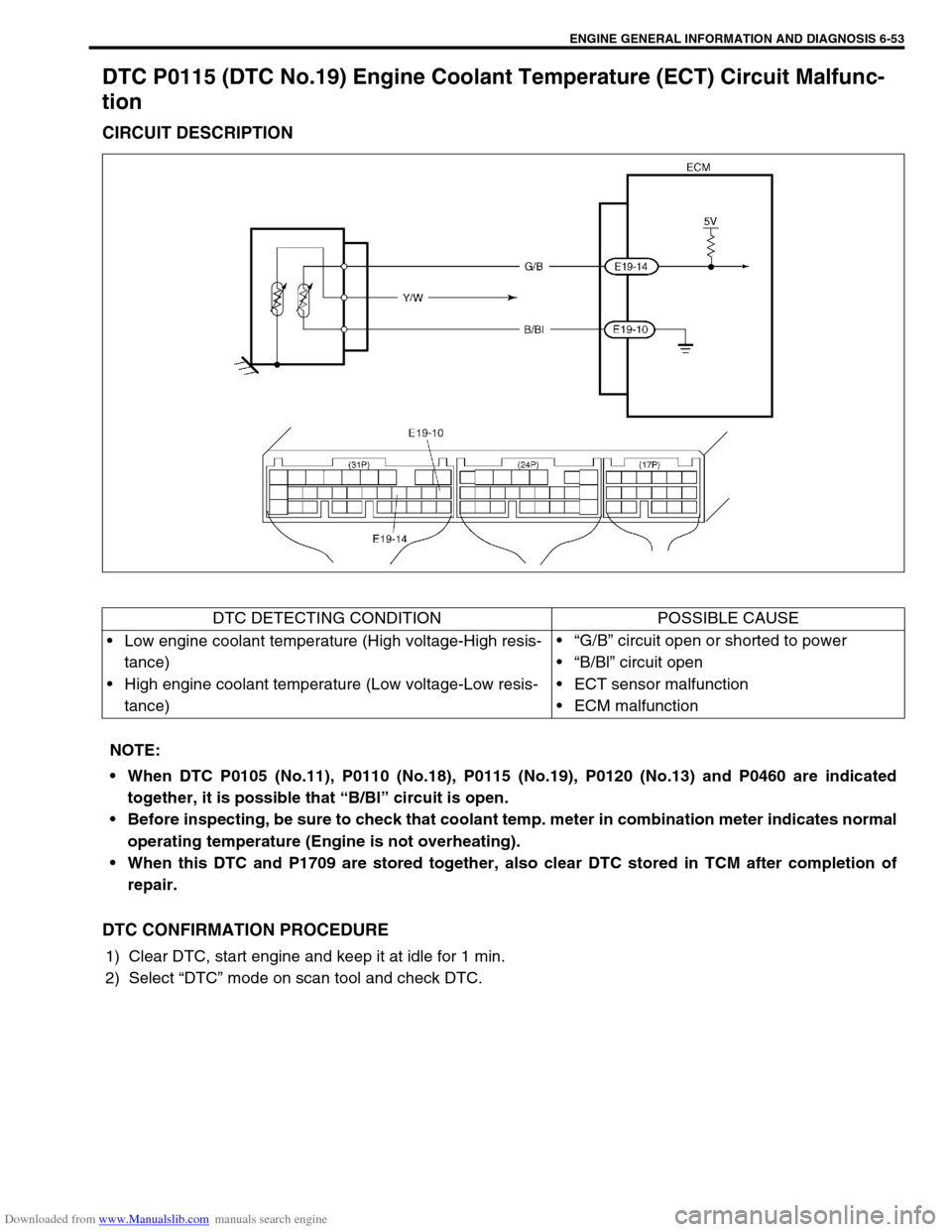

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-53

DTC P0115 (DTC No.19) Engine Coolant Temperature (ECT) Circuit Malfunc-

tion

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

DTC DETECTING CONDITION POSSIBLE CAUSE

Low engine coolant temperature (High voltage-High resis-

tance)

High engine coolant temperature (Low voltage-Low resis-

tance)“G/B” circuit open or shorted to power

“B/Bl” circuit open

ECT sensor malfunction

ECM malfunction

NOTE:

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19), P0120 (No.13) and P0460 are indicated

together, it is possible that “B/Bl” circuit is open.

Before inspecting, be sure to check that coolant temp. meter in combination meter indicates normal

operating temperature (Engine is not overheating).

When this DTC and P1709 are stored together, also clear DTC stored in TCM after completion of

repair.

Page 414 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-57

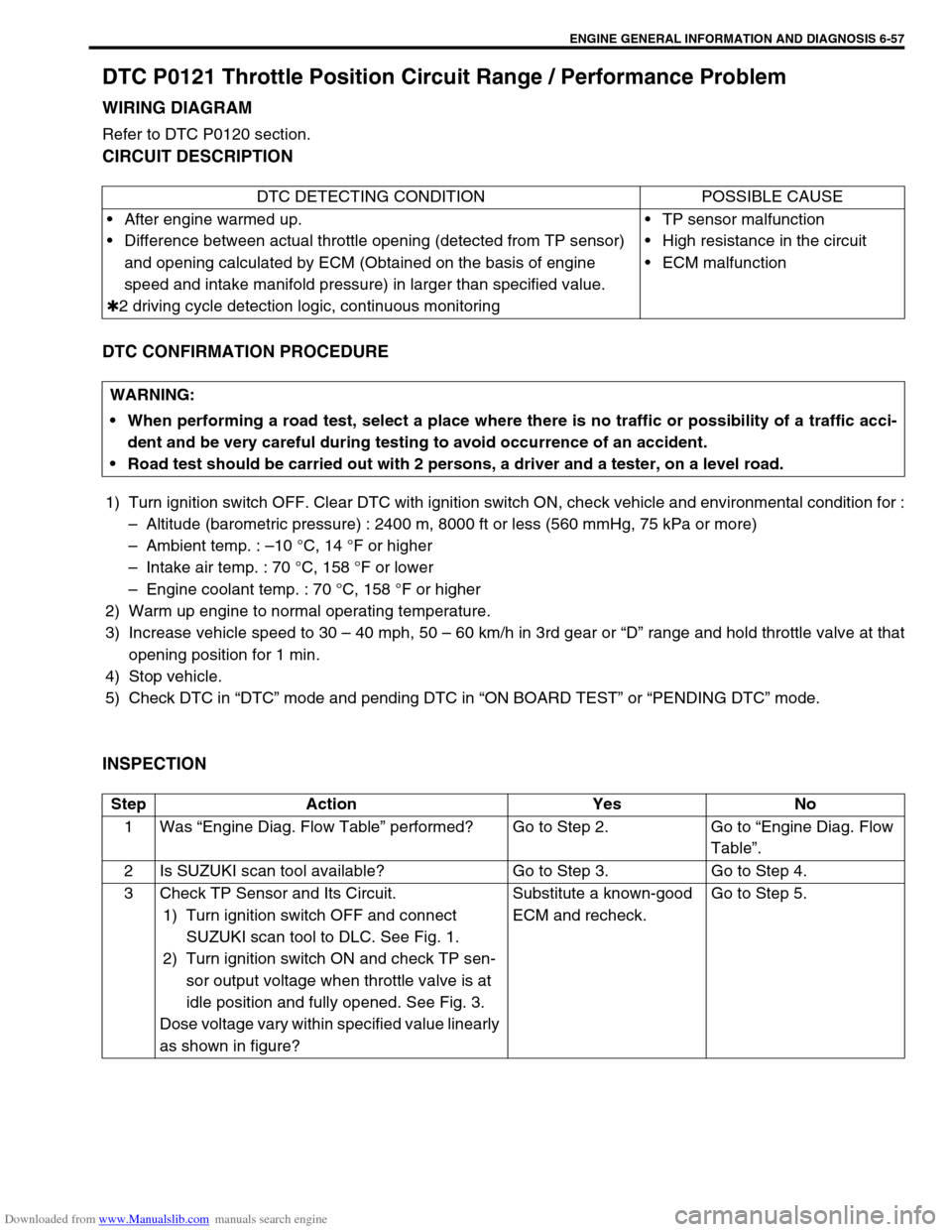

DTC P0121 Throttle Position Circuit Range / Performance Problem

WIRING DIAGRAM

Refer to DTC P0120 section.

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF. Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–Engine coolant temp. : 70 °C, 158 °F or higher

2) Warm up engine to normal operating temperature.

3) Increase vehicle speed to 30 – 40 mph, 50 – 60 km/h in 3rd gear or “D” range and hold throttle valve at that

opening position for 1 min.

4) Stop vehicle.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

After engine warmed up.

Difference between actual throttle opening (detected from TP sensor)

and opening calculated by ECM (Obtained on the basis of engine

speed and intake manifold pressure) in larger than specified value.

✱2 driving cycle detection logic, continuous monitoringTP sensor malfunction

High resistance in the circuit

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Is SUZUKI scan tool available? Go to Step 3. Go to Step 4.

3 Check TP Sensor and Its Circuit.

1) Turn ignition switch OFF and connect

SUZUKI scan tool to DLC. See Fig. 1.

2) Turn ignition switch ON and check TP sen-

sor output voltage when throttle valve is at

idle position and fully opened. See Fig. 3.

Dose voltage vary within specified value linearly

as shown in figure?Substitute a known-good

ECM and recheck.Go to Step 5.

Page 490 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-9

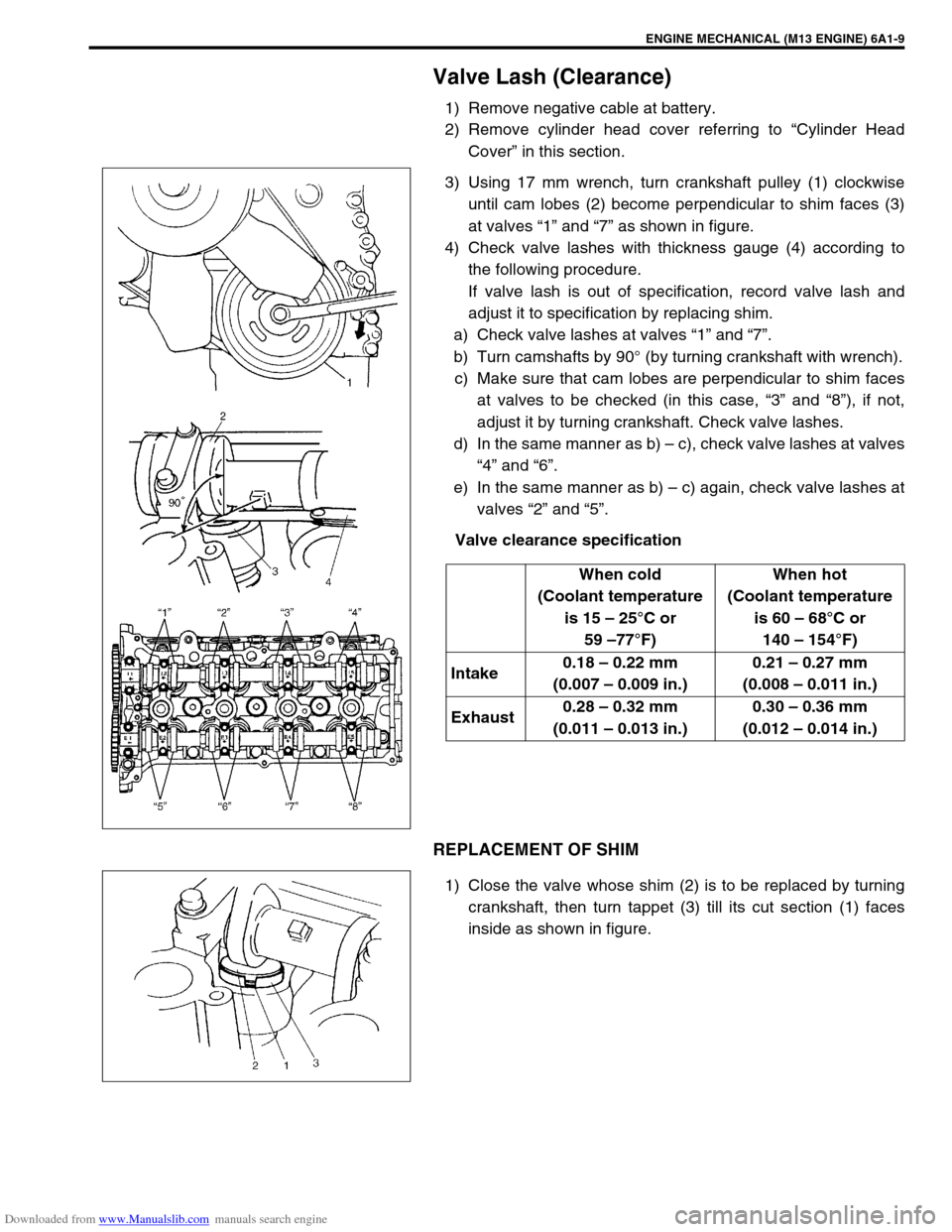

Valve Lash (Clearance)

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head

Cover” in this section.

3) Using 17 mm wrench, turn crankshaft pulley (1) clockwise

until cam lobes (2) become perpendicular to shim faces (3)

at valves “1” and “7” as shown in figure.

4) Check valve lashes with thickness gauge (4) according to

the following procedure.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90° (by turning crankshaft with wrench).

c) Make sure that cam lobes are perpendicular to shim faces

at valves to be checked (in this case, “3” and “8”), if not,

adjust it by turning crankshaft. Check valve lashes.

d) In the same manner as b) – c), check valve lashes at valves

“4” and “6”.

e) In the same manner as b) – c) again, check valve lashes at

valves “2” and “5”.

Valve clearance specification

REPLACEMENT OF SHIM

1) Close the valve whose shim (2) is to be replaced by turning

crankshaft, then turn tappet (3) till its cut section (1) faces

inside as shown in figure.When cold

(Coolant temperature

is 15 – 25°C or

59 –77°F)When hot

(Coolant temperature

is 60 – 68°C or

140 – 154°F)

Intake0.18 – 0.22 mm

(0.007 – 0.009 in.)0.21 – 0.27 mm

(0.008 – 0.011 in.)

Exhaust0.28 – 0.32 mm

(0.011 – 0.013 in.)0.30 – 0.36 mm

(0.012 – 0.014 in.)

Page 578 of 687

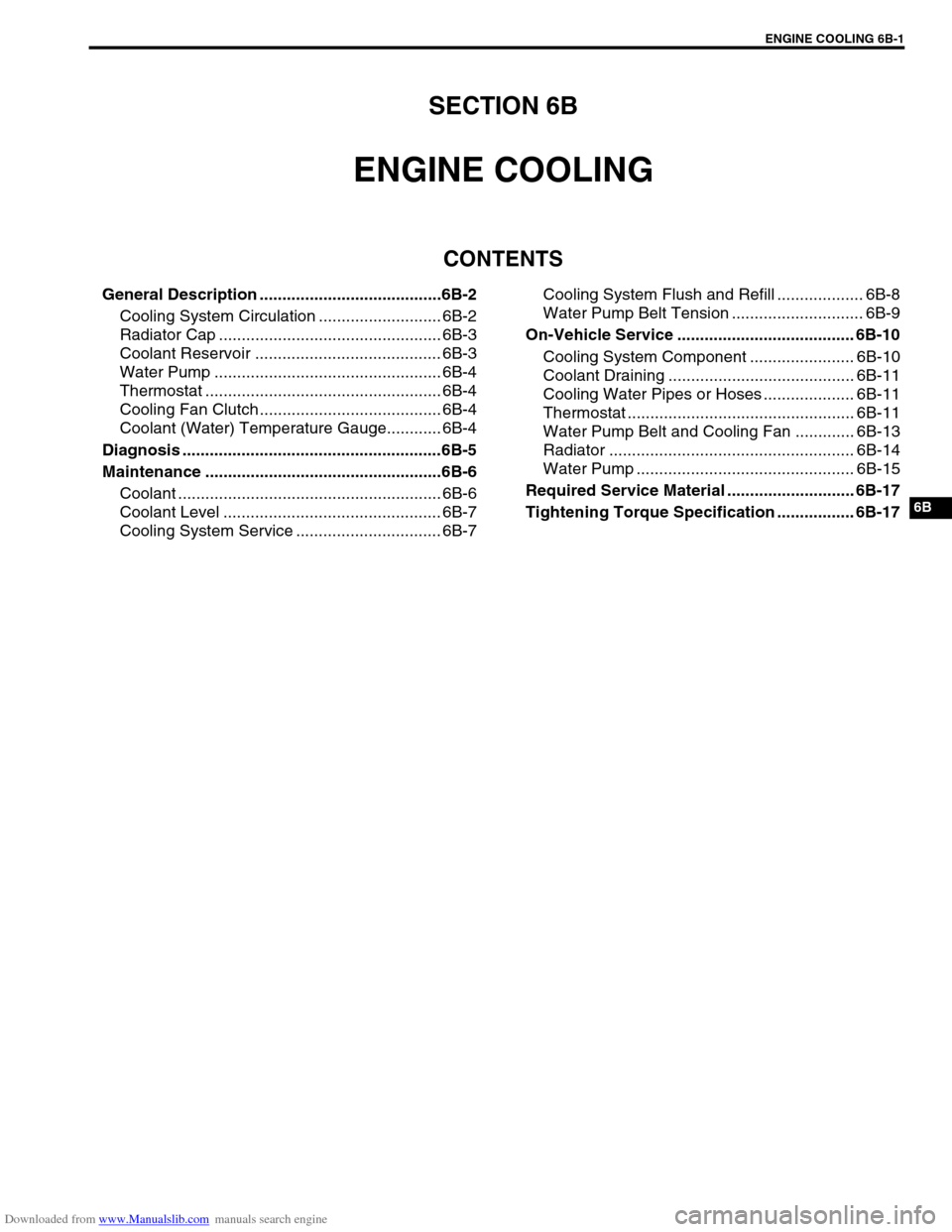

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-1

6B

SECTION 6B

ENGINE COOLING

CONTENTS

General Description ........................................6B-2

Cooling System Circulation ........................... 6B-2

Radiator Cap ................................................. 6B-3

Coolant Reservoir ......................................... 6B-3

Water Pump .................................................. 6B-4

Thermostat .................................................... 6B-4

Cooling Fan Clutch ........................................ 6B-4

Coolant (Water) Temperature Gauge............ 6B-4

Diagnosis .........................................................6B-5

Maintenance ....................................................6B-6

Coolant .......................................................... 6B-6

Coolant Level ................................................ 6B-7

Cooling System Service ................................ 6B-7Cooling System Flush and Refill ................... 6B-8

Water Pump Belt Tension ............................. 6B-9

On-Vehicle Service ....................................... 6B-10

Cooling System Component ....................... 6B-10

Coolant Draining ......................................... 6B-11

Cooling Water Pipes or Hoses .................... 6B-11

Thermostat .................................................. 6B-11

Water Pump Belt and Cooling Fan ............. 6B-13

Radiator ...................................................... 6B-14

Water Pump ................................................ 6B-15

Required Service Material ............................ 6B-17

Tightening Torque Specification ................. 6B-17

Page 580 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE COOLING 6B-3

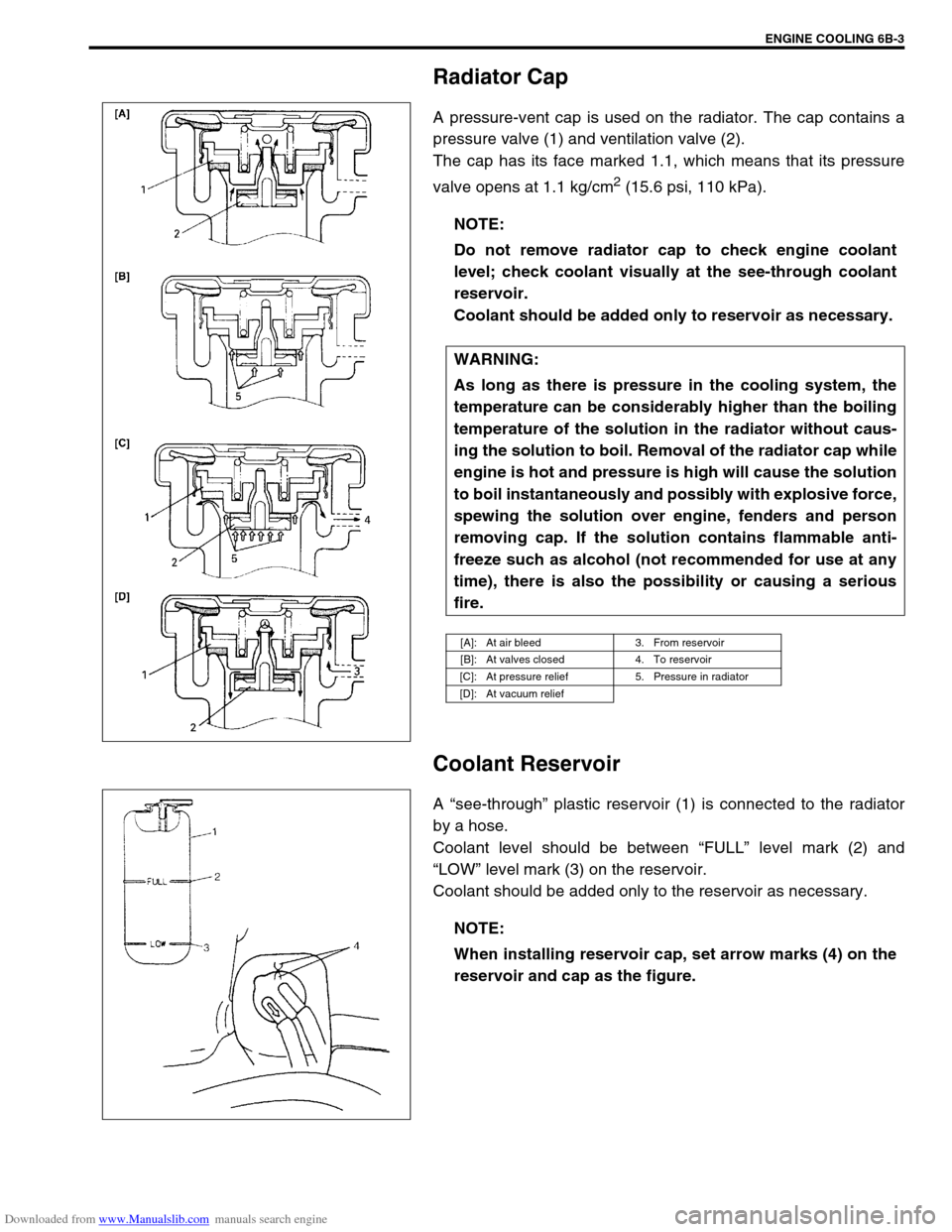

Radiator Cap

A pressure-vent cap is used on the radiator. The cap contains a

pressure valve (1) and ventilation valve (2).

The cap has its face marked 1.1, which means that its pressure

valve opens at 1.1 kg/cm

2 (15.6 psi, 110 kPa).

Coolant Reservoir

A “see-through” plastic reservoir (1) is connected to the radiator

by a hose.

Coolant level should be between “FULL” level mark (2) and

“LOW” level mark (3) on the reservoir.

Coolant should be added only to the reservoir as necessary.NOTE:

Do not remove radiator cap to check engine coolant

level; check coolant visually at the see-through coolant

reservoir.

Coolant should be added only to reservoir as necessary.

WARNING:

As long as there is pressure in the cooling system, the

temperature can be considerably higher than the boiling

temperature of the solution in the radiator without caus-

ing the solution to boil. Removal of the radiator cap while

engine is hot and pressure is high will cause the solution

to boil instantaneously and possibly with explosive force,

spewing the solution over engine, fenders and person

removing cap. If the solution contains flammable anti-

freeze such as alcohol (not recommended for use at any

time), there is also the possibility or causing a serious

fire.

[A]: At air bleed 3. From reservoir

[B]: At valves closed 4. To reservoir

[C]: At pressure relief 5. Pressure in radiator

[D]: At vacuum relief

NOTE:

When installing reservoir cap, set arrow marks (4) on the

reservoir and cap as the figure.

Page 581 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-4 ENGINE COOLING

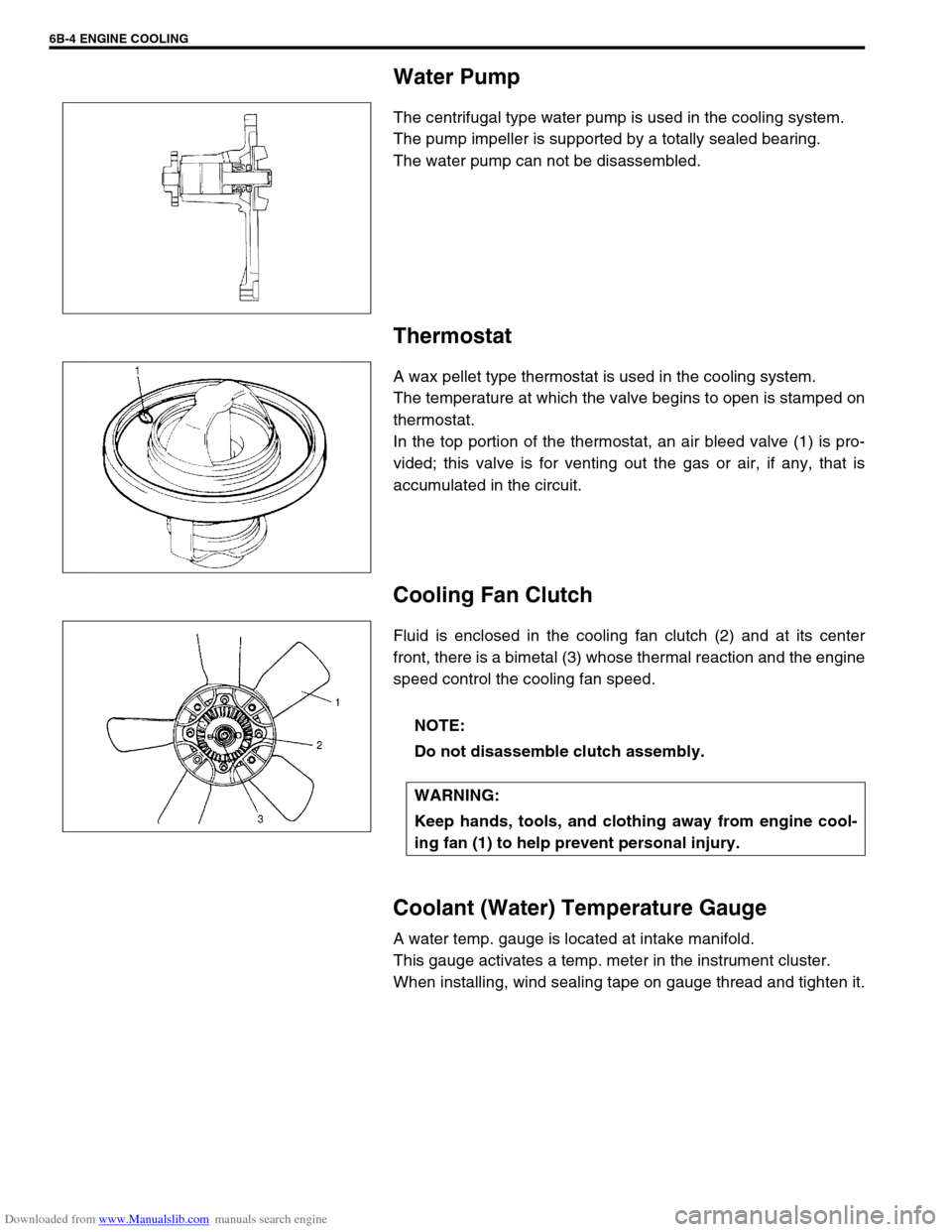

Water Pump

The centrifugal type water pump is used in the cooling system.

The pump impeller is supported by a totally sealed bearing.

The water pump can not be disassembled.

Thermostat

A wax pellet type thermostat is used in the cooling system.

The temperature at which the valve begins to open is stamped on

thermostat.

In the top portion of the thermostat, an air bleed valve (1) is pro-

vided; this valve is for venting out the gas or air, if any, that is

accumulated in the circuit.

Cooling Fan Clutch

Fluid is enclosed in the cooling fan clutch (2) and at its center

front, there is a bimetal (3) whose thermal reaction and the engine

speed control the cooling fan speed.

Coolant (Water) Temperature Gauge

A water temp. gauge is located at intake manifold.

This gauge activates a temp. meter in the instrument cluster.

When installing, wind sealing tape on gauge thread and tighten it.

NOTE:

Do not disassemble clutch assembly.

WARNING:

Keep hands, tools, and clothing away from engine cool-

ing fan (1) to help prevent personal injury.

Page 583 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-6 ENGINE COOLING

Maintenance

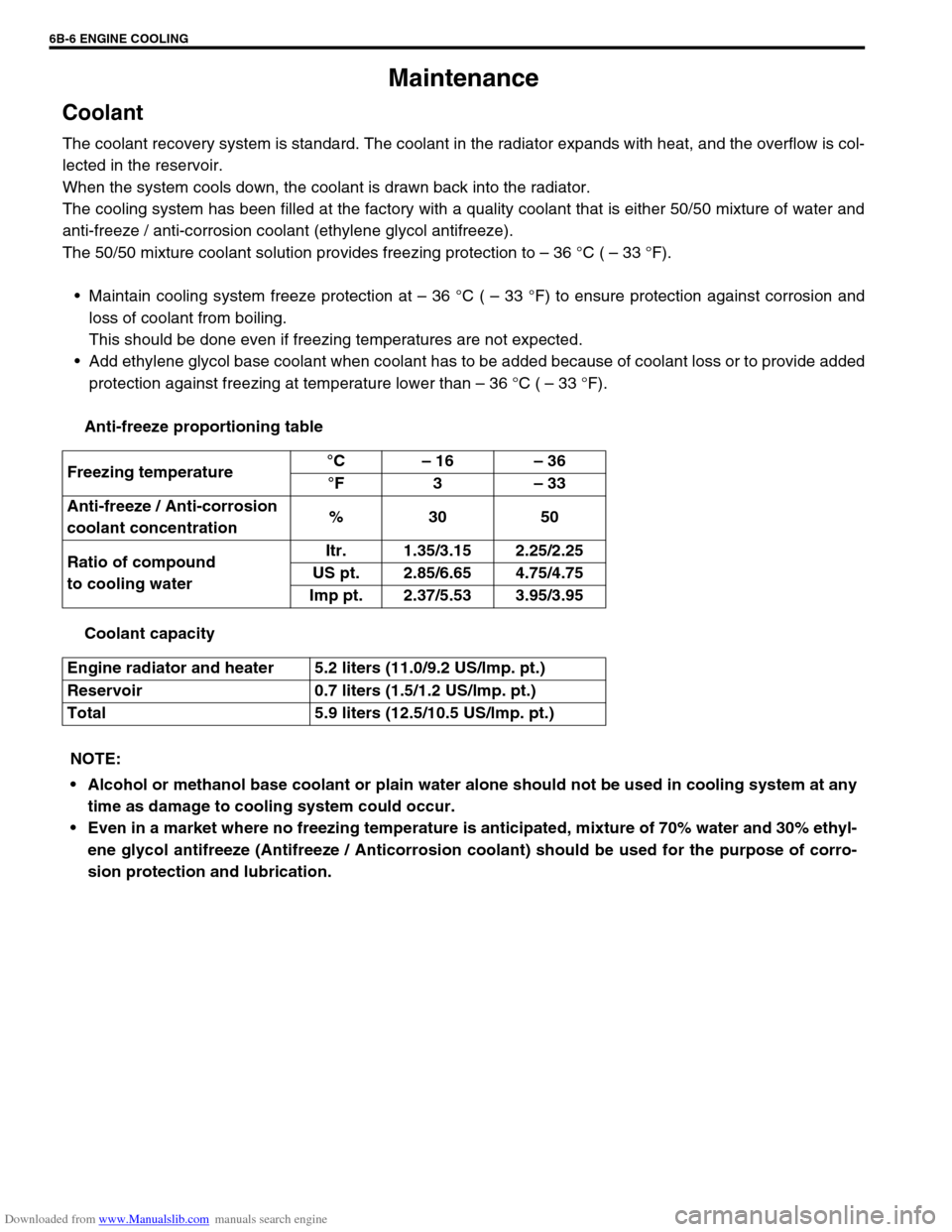

Coolant

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the overflow is col-

lected in the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has been filled at the factory with a quality coolant that is either 50/50 mixture of water and

anti-freeze / anti-corrosion coolant (ethylene glycol antifreeze).

The 50/50 mixture coolant solution provides freezing protection to – 36 °C ( – 33 °F).

Maintain cooling system freeze protection at – 36 °C ( – 33 °F) to ensure protection against corrosion and

loss of coolant from boiling.

This should be done even if freezing temperatures are not expected.

Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added

protection against freezing at temperature lower than – 36 °C ( – 33 °F).

Anti-freeze proportioning table

Coolant capacity Freezing temperature°C– 16– 36

°F3– 33

Anti-freeze / Anti-corrosion

coolant concentration%30 50

Ratio of compound

to cooling waterItr. 1.35/3.15 2.25/2.25

US pt. 2.85/6.65 4.75/4.75

Imp pt. 2.37/5.53 3.95/3.95

Engine radiator and heater 5.2 liters (11.0/9.2 US/lmp. pt.)

Reservoir 0.7 liters (1.5/1.2 US/lmp. pt.)

Total 5.9 liters (12.5/10.5 US/lmp. pt.)

NOTE:

Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

Even in a market where no freezing temperature is anticipated, mixture of 70% water and 30% ethyl-

ene glycol antifreeze (Antifreeze / Anticorrosion coolant) should be used for the purpose of corro-

sion protection and lubrication.

Page 587 of 687

Downloaded from www.Manualslib.com manuals search engine 6B-10 ENGINE COOLING

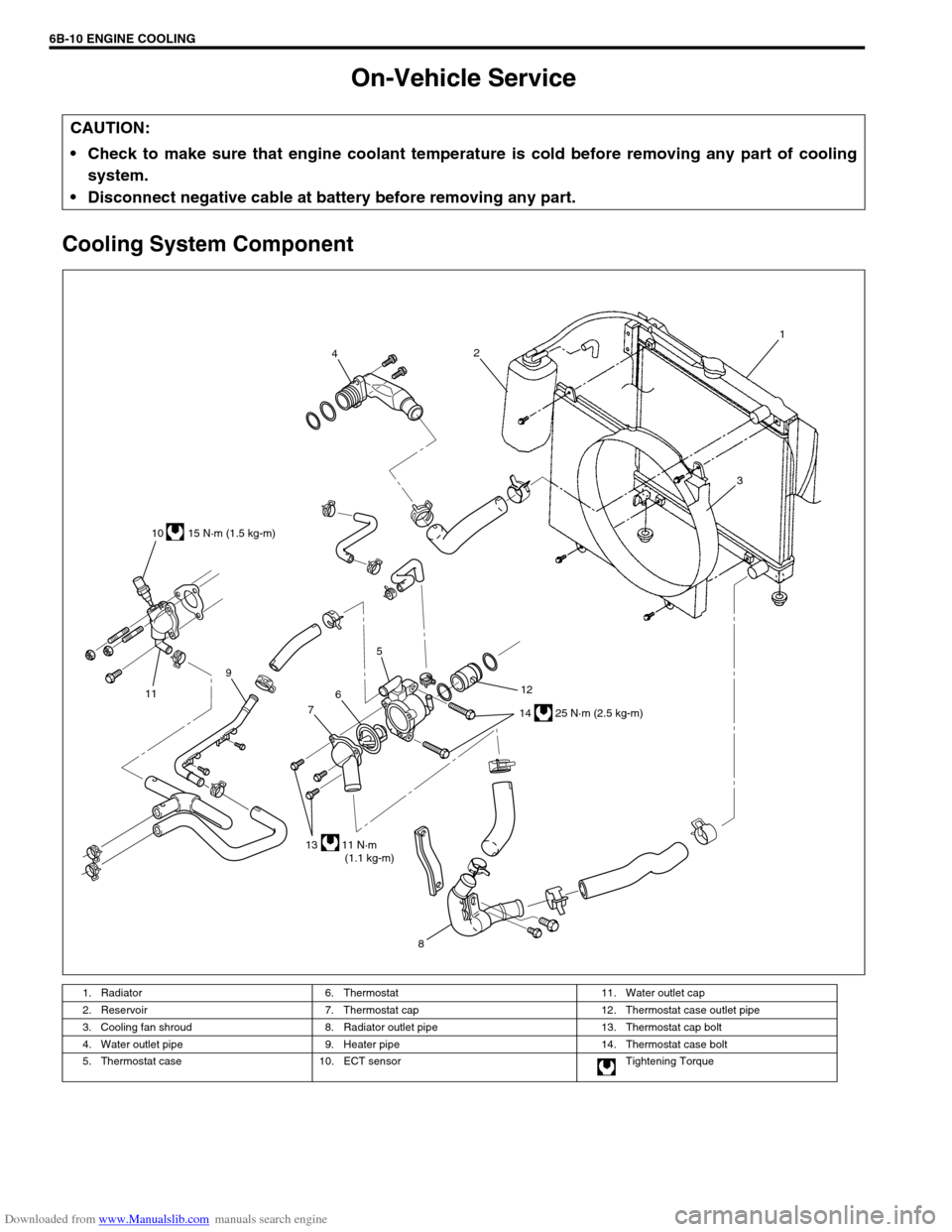

On-Vehicle Service

Cooling System Component

CAUTION:

Check to make sure that engine coolant temperature is cold before removing any part of cooling

system.

Disconnect negative cable at battery before removing any part.

1. Radiator 6. Thermostat 11. Water outlet cap

2. Reservoir 7. Thermostat cap 12. Thermostat case outlet pipe

3. Cooling fan shroud 8. Radiator outlet pipe 13. Thermostat cap bolt

4. Water outlet pipe 9. Heater pipe 14. Thermostat case bolt

5. Thermostat case 10. ECT sensor Tightening Torque

814 25 N·m (2.5 kg-m) 10 15 N·m (1.5 kg-m)

12 5

6

7

13 11 N·m

(1.1 kg-m) 119421

3

Page 606 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-1

6F1

6F2

6G

7C1

7D

7E

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

6H

6E

10

10A

10B

SECTION 6E

ENGINE AND EMISSION CONTROL SYSTEM

CONTENTS

General Description ....................................... 6E-3

Air Intake System ......................................... 6E-5

Fuel Delivery System ................................... 6E-6

Fuel pump ................................................ 6E-6

Electronic Control System ............................ 6E-7

Engine & emission control input / output

table.......................................................... 6E-8

On-Vehicle Service....................................... 6E-15

Accelerator cable adjustment ................. 6E-15

Idle speed / idle air control (IAC) duty

inspection ............................................... 6E-15

Idle mixture inspection / adjustment

(vehicle without heated oxygen

sensor) ................................................... 6E-17

Air Intake System ....................................... 6E-18

Throttle body .......................................... 6E-18

Idle air control valve (IAC valve)............. 6E-21

Fuel Delivery System ................................. 6E-22

Fuel pressure inspection ........................ 6E-22

Fuel pump .............................................. 6E-23

Fuel pressure regulator .......................... 6E-24

Fuel injector ............................................ 6E-25

Electronic Control System .......................... 6E-29Engine control module (ECM) ................ 6E-29

Manifold absolute pressure sensor (MAP

sensor) ................................................... 6E-29

Throttle position sensor (TP sensor) ...... 6E-30

Intake air temperature sensor

(IAT sensor) ........................................... 6E-31

Engine coolant temperature sensor

(ECT sensor) .......................................... 6E-32

Heated oxygen sensor

(Sensor-1 and sensor-2) ........................ 6E-33

Camshaft position sensor....................... 6E-34

Crankshaft position sensor..................... 6E-35

Vehicle speed sensor (VSS) .................. 6E-36

Fuel level sensor (GAUGE).................... 6E-36

Knock sensor ......................................... 6E-36

Main relay, fuel pump relay and A/C

condenser fan control relay .................... 6E-36

Fuel cut operation .................................. 6E-37

A/C condenser fan control system ......... 6E-37

A/C condenser fan ................................. 6E-37

Output signals of throttle valve opening

and engine coolant temp.

(Vehicle with A/T only) ........................... 6E-38

Emission Control System ........................... 6E-38 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether following systems (parts) are used in the particular vehicle or not depends on specifications.

Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor (s) or CO adjusting resistor

Three way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)

Page 637 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-32 ENGINE AND EMISSION CONTROL SYSTEM

Engine coolant temperature sensor (ECT sensor)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Drain coolant referring to Step 6) of “Cooling System Flush

and Refill” in Section 6B.

3) Disconnect connector from ECT sensor.

4) Remove ECT sensor (1) from water outlet cap.

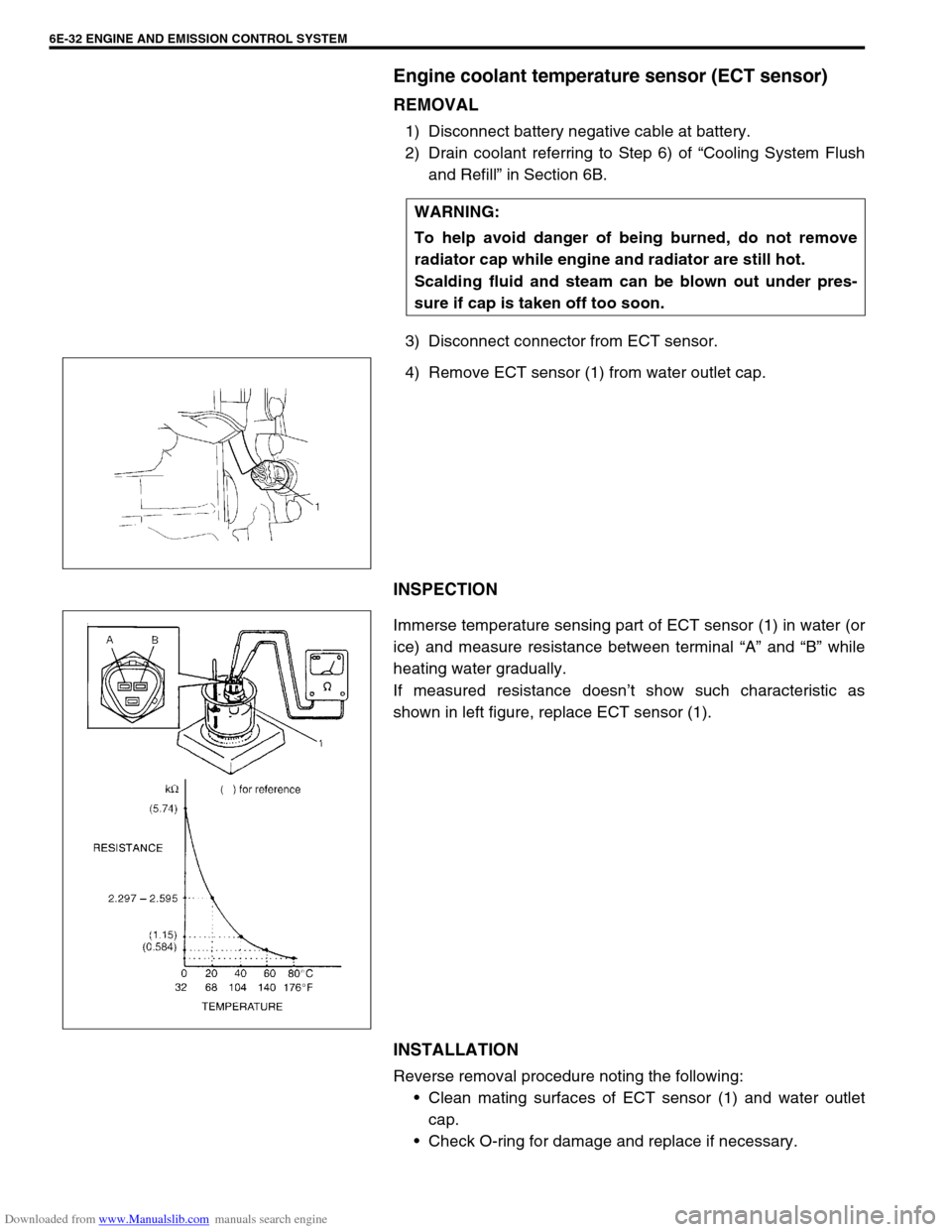

INSPECTION

Immerse temperature sensing part of ECT sensor (1) in water (or

ice) and measure resistance between terminal “A” and “B” while

heating water gradually.

If measured resistance doesn’t show such characteristic as

shown in left figure, replace ECT sensor (1).

INSTALLATION

Reverse removal procedure noting the following:

Clean mating surfaces of ECT sensor (1) and water outlet

cap.

Check O-ring for damage and replace if necessary. WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.