length SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 210 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-37

INSTALLATION

1) Install bushings (1) by using hydraulic press and special

tools, noting the following point.

Install bushings (1) so that either face of bushing are aligned

with housing edge of leading arm (2), also the length

between the aligned side end of bushing and leading arm (2)

are within specification below.

Special tool

(A) : 09913-85210

(B) : 09951-26010

Specification for leading arm bushing protrusion

“a” : 8.5 – 10.5 mm (0.33 – 0.41 in.)

“b” : 6.0 – 9.0 mm (0.24 – 0.35 in.)

2) Install leading arm (1) to vehicle body and axle housing,

referring to figure for proper installing direction of bolts.

Nuts should not be tightened.

3) Install shock absorber lower mounting bolt, refer to “Front

Shock Absorber” in this section.

4) Install air locking hub vacuum pipe clamp bolts and tighten

them to specified torque (for 4WD).

Tightening torque

Vacuum pipe clamp bolts

(b) : 5.5 N·m (0.55 kg-m, 4.0 lb-ft)

5) Lower hoist and with vehicle in non-loaded condition, tighten

nuts of leading arm to specified torque.

Tightening torque

Leading arm nuts

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

2. Vacuum hose

3. Body outside

[A] : Front

[B] : Rear

Page 231 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-12 REAR SUSPENSION

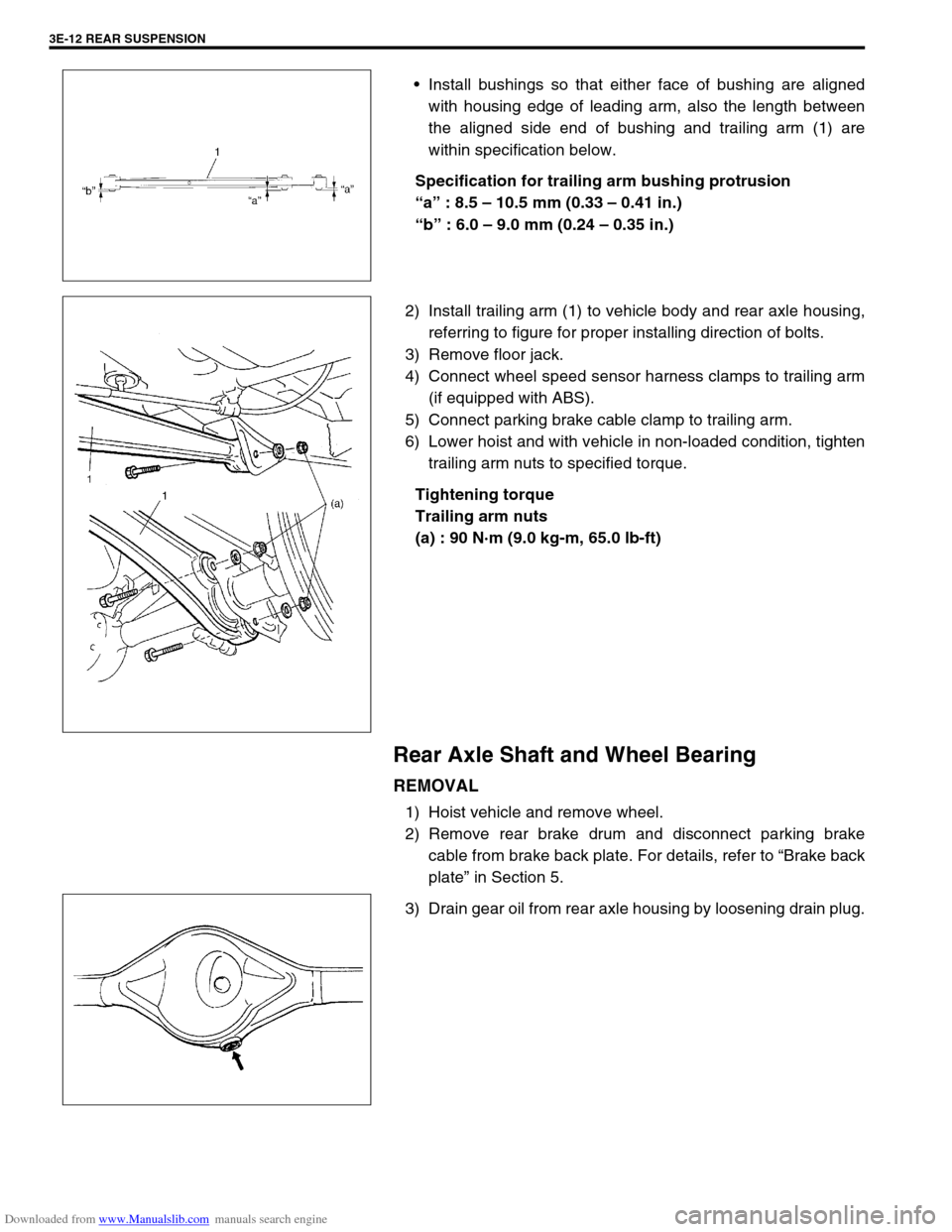

Install bushings so that either face of bushing are aligned

with housing edge of leading arm, also the length between

the aligned side end of bushing and trailing arm (1) are

within specification below.

Specification for trailing arm bushing protrusion

“a” : 8.5 – 10.5 mm (0.33 – 0.41 in.)

“b” : 6.0 – 9.0 mm (0.24 – 0.35 in.)

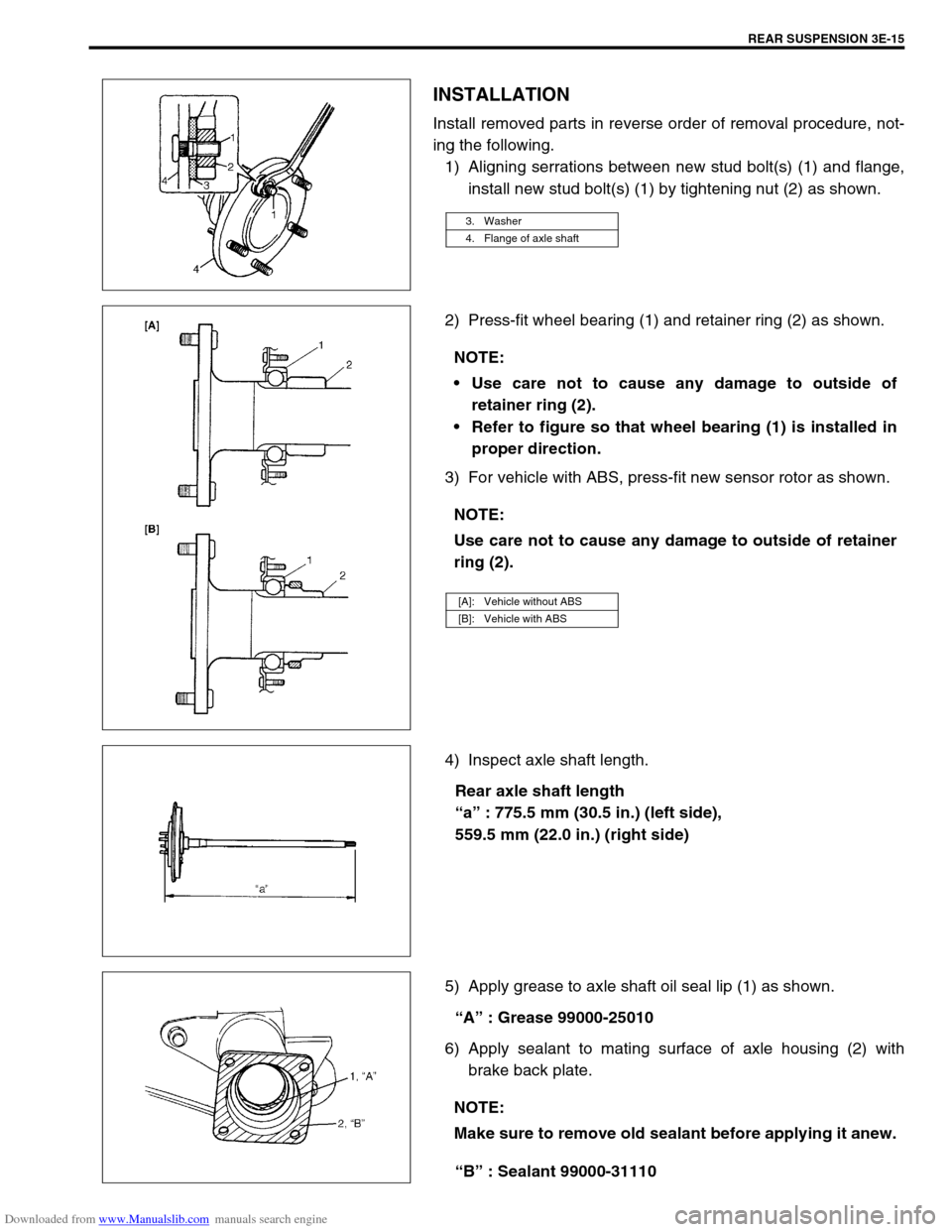

2) Install trailing arm (1) to vehicle body and rear axle housing,

referring to figure for proper installing direction of bolts.

3) Remove floor jack.

4) Connect wheel speed sensor harness clamps to trailing arm

(if equipped with ABS).

5) Connect parking brake cable clamp to trailing arm.

6) Lower hoist and with vehicle in non-loaded condition, tighten

trailing arm nuts to specified torque.

Tightening torque

Trailing arm nuts

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

Rear Axle Shaft and Wheel Bearing

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove rear brake drum and disconnect parking brake

cable from brake back plate. For details, refer to “Brake back

plate” in Section 5.

3) Drain gear oil from rear axle housing by loosening drain plug.

Page 234 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-15

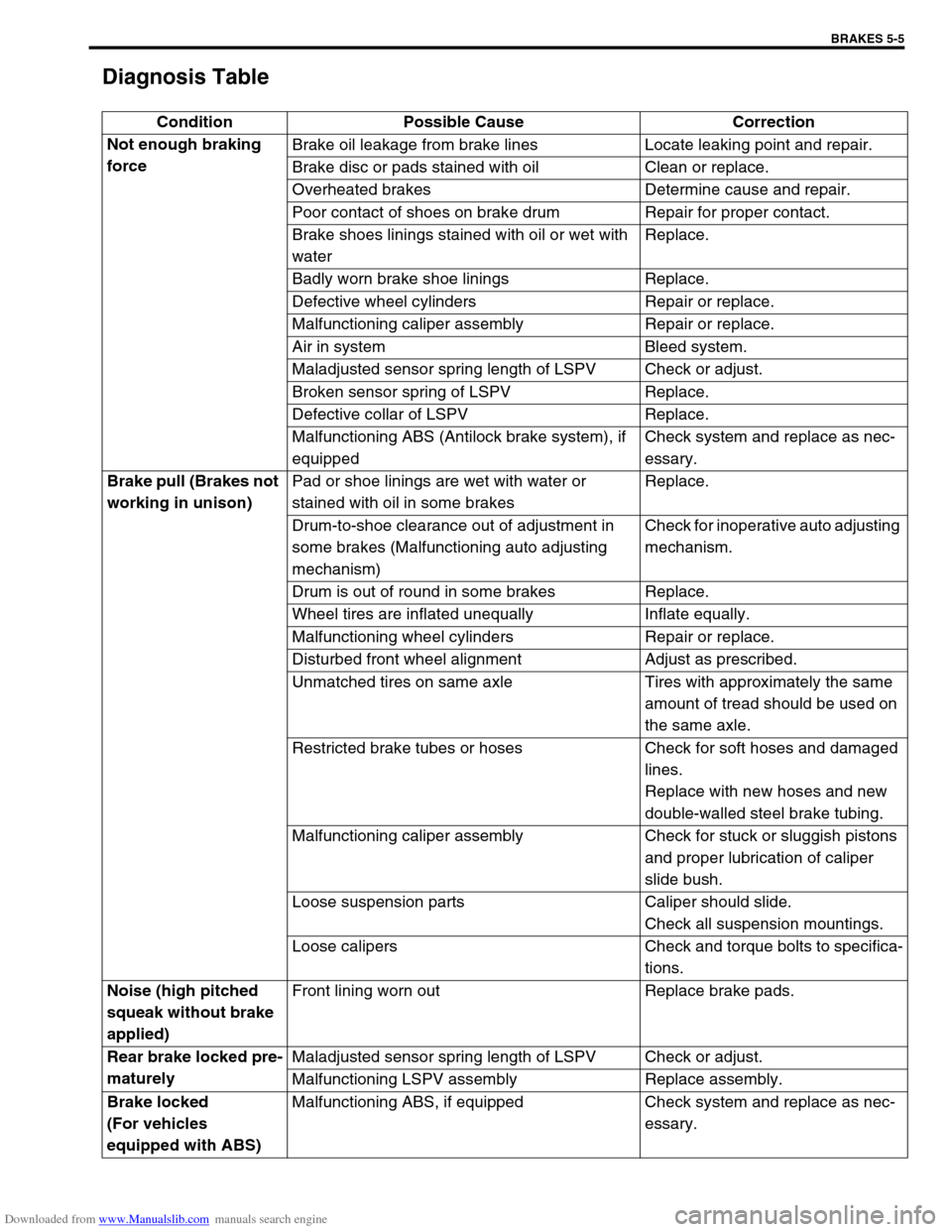

INSTALLATION

Install removed parts in reverse order of removal procedure, not-

ing the following.

1) Aligning serrations between new stud bolt(s) (1) and flange,

install new stud bolt(s) (1) by tightening nut (2) as shown.

2) Press-fit wheel bearing (1) and retainer ring (2) as shown.

3) For vehicle with ABS, press-fit new sensor rotor as shown.

4) Inspect axle shaft length.

Rear axle shaft length

“a” : 775.5 mm (30.5 in.) (left side),

559.5 mm (22.0 in.) (right side)

5) Apply grease to axle shaft oil seal lip (1) as shown.

“A” : Grease 99000-25010

6) Apply sealant to mating surface of axle housing (2) with

brake back plate.

“B” : Sealant 99000-31110

3. Washer

4. Flange of axle shaft

NOTE:

Use care not to cause any damage to outside of

retainer ring (2).

Refer to figure so that wheel bearing (1) is installed in

proper direction.

NOTE:

Use care not to cause any damage to outside of retainer

ring (2).

[A]: Vehicle without ABS

[B]: Vehicle with ABS

NOTE:

Make sure to remove old sealant before applying it anew.

Page 266 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-5

Diagnosis Table

Condition Possible Cause Correction

Not enough braking

forceBrake oil leakage from brake lines Locate leaking point and repair.

Brake disc or pads stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Poor contact of shoes on brake drum Repair for proper contact.

Brake shoes linings stained with oil or wet with

waterReplace.

Badly worn brake shoe linings Replace.

Defective wheel cylinders Repair or replace.

Malfunctioning caliper assembly Repair or replace.

Air in system Bleed system.

Maladjusted sensor spring length of LSPV Check or adjust.

Broken sensor spring of LSPV Replace.

Defective collar of LSPV Replace.

Malfunctioning ABS (Antilock brake system), if

equippedCheck system and replace as nec-

essary.

Brake pull (Brakes not

working in unison)Pad or shoe linings are wet with water or

stained with oil in some brakesReplace.

Drum-to-shoe clearance out of adjustment in

some brakes (Malfunctioning auto adjusting

mechanism)Check for inoperative auto adjusting

mechanism.

Drum is out of round in some brakes Replace.

Wheel tires are inflated unequally Inflate equally.

Malfunctioning wheel cylinders Repair or replace.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same

amount of tread should be used on

the same axle.

Restricted brake tubes or hoses Check for soft hoses and damaged

lines.

Replace with new hoses and new

double-walled steel brake tubing.

Malfunctioning caliper assembly Check for stuck or sluggish pistons

and proper lubrication of caliper

slide bush.

Loose suspension parts Caliper should slide.

Check all suspension mountings.

Loose calipers Check and torque bolts to specifica-

tions.

Noise (high pitched

squeak without brake

applied)Front lining worn out Replace brake pads.

Rear brake locked pre-

maturelyMaladjusted sensor spring length of LSPV Check or adjust.

Malfunctioning LSPV assembly Replace assembly.

Brake locked

(For vehicles

equipped with ABS)Malfunctioning ABS, if equipped Check system and replace as nec-

essary.

Page 270 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-9

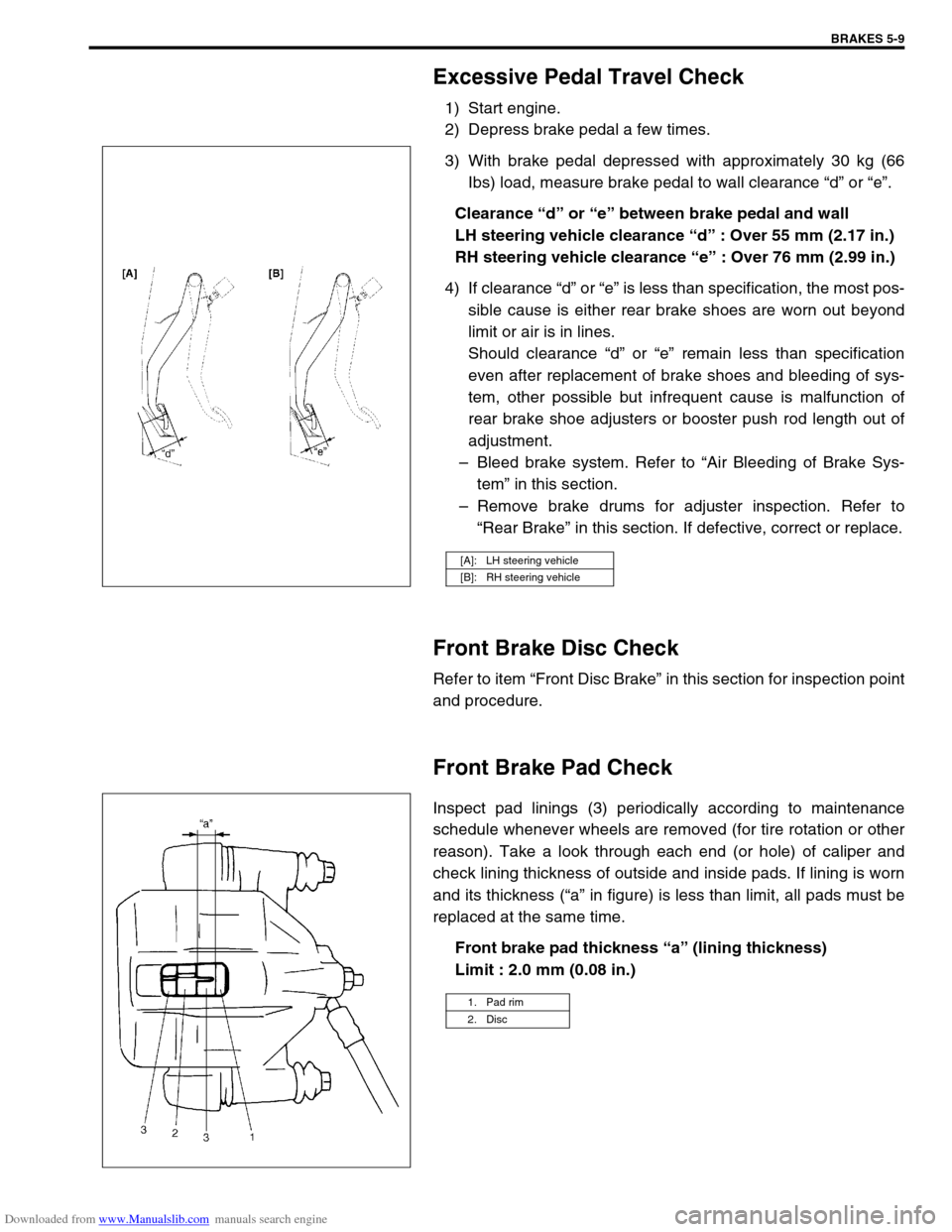

Excessive Pedal Travel Check

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 30 kg (66

Ibs) load, measure brake pedal to wall clearance “d” or “e”.

Clearance “d” or “e” between brake pedal and wall

LH steering vehicle clearance “d” : Over 55 mm (2.17 in.)

RH steering vehicle clearance “e” : Over 76 mm (2.99 in.)

4) If clearance “d” or “e” is less than specification, the most pos-

sible cause is either rear brake shoes are worn out beyond

limit or air is in lines.

Should clearance “d” or “e” remain less than specification

even after replacement of brake shoes and bleeding of sys-

tem, other possible but infrequent cause is malfunction of

rear brake shoe adjusters or booster push rod length out of

adjustment.

–Bleed brake system. Refer to “Air Bleeding of Brake Sys-

tem” in this section.

–Remove brake drums for adjuster inspection. Refer to

“Rear Brake” in this section. If defective, correct or replace.

Front Brake Disc Check

Refer to item “Front Disc Brake” in this section for inspection point

and procedure.

Front Brake Pad Check

Inspect pad linings (3) periodically according to maintenance

schedule whenever wheels are removed (for tire rotation or other

reason). Take a look through each end (or hole) of caliper and

check lining thickness of outside and inside pads. If lining is worn

and its thickness (“a” in figure) is less than limit, all pads must be

replaced at the same time.

Front brake pad thickness “a” (lining thickness)

Limit : 2.0 mm (0.08 in.)

[A]: LH steering vehicle

[B]: RH steering vehicle

1. Pad rim

2. Disc

Page 298 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-37

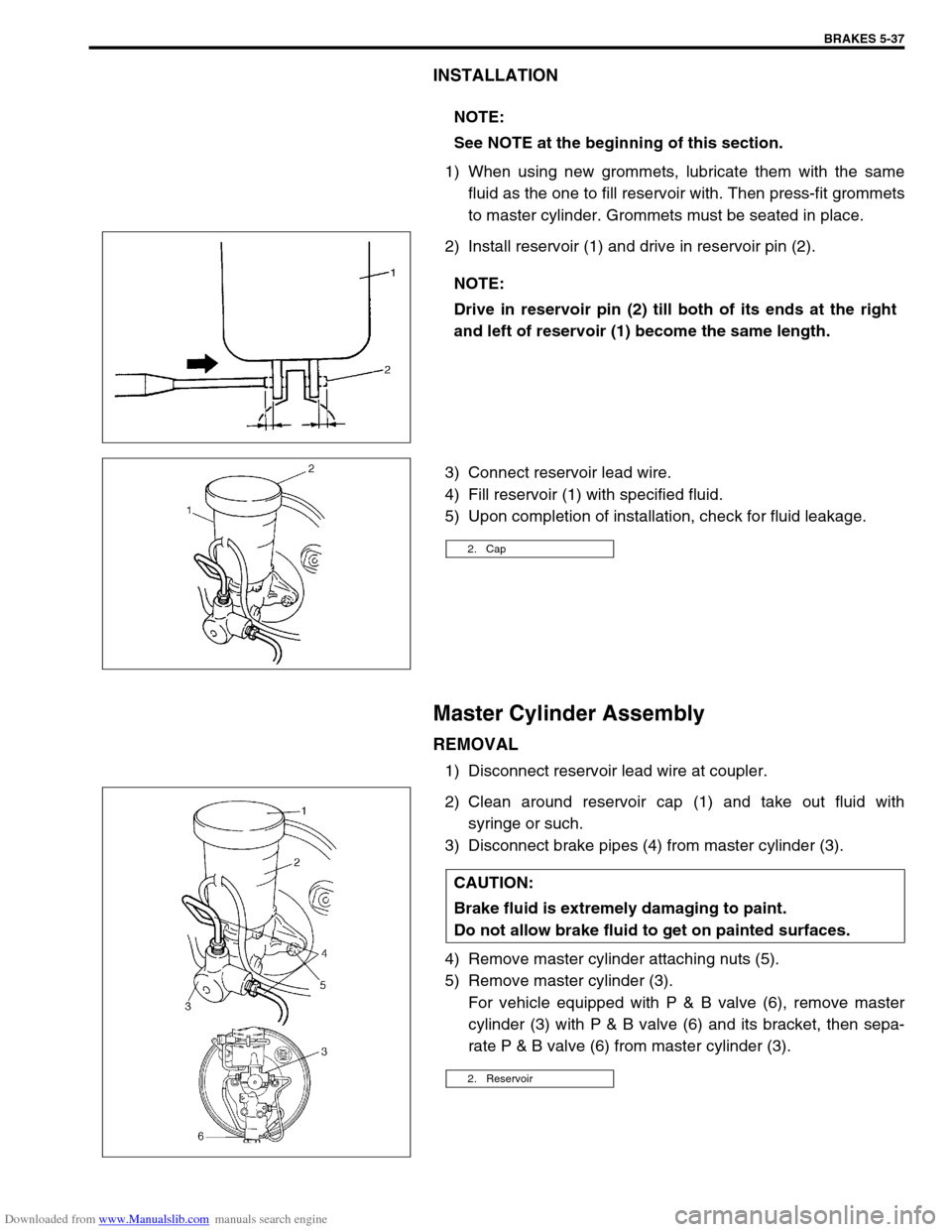

INSTALLATION

1) When using new grommets, lubricate them with the same

fluid as the one to fill reservoir with. Then press-fit grommets

to master cylinder. Grommets must be seated in place.

2) Install reservoir (1) and drive in reservoir pin (2).

3) Connect reservoir lead wire.

4) Fill reservoir (1) with specified fluid.

5) Upon completion of installation, check for fluid leakage.

Master Cylinder Assembly

REMOVAL

1) Disconnect reservoir lead wire at coupler.

2) Clean around reservoir cap (1) and take out fluid with

syringe or such.

3) Disconnect brake pipes (4) from master cylinder (3).

4) Remove master cylinder attaching nuts (5).

5) Remove master cylinder (3).

For vehicle equipped with P & B valve (6), remove master

cylinder (3) with P & B valve (6) and its bracket, then sepa-

rate P & B valve (6) from master cylinder (3). NOTE:

See NOTE at the beginning of this section.

NOTE:

Drive in reservoir pin (2) till both of its ends at the right

and left of reservoir (1) become the same length.

2. Cap

CAUTION:

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted surfaces.

2. Reservoir

Page 304 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-43

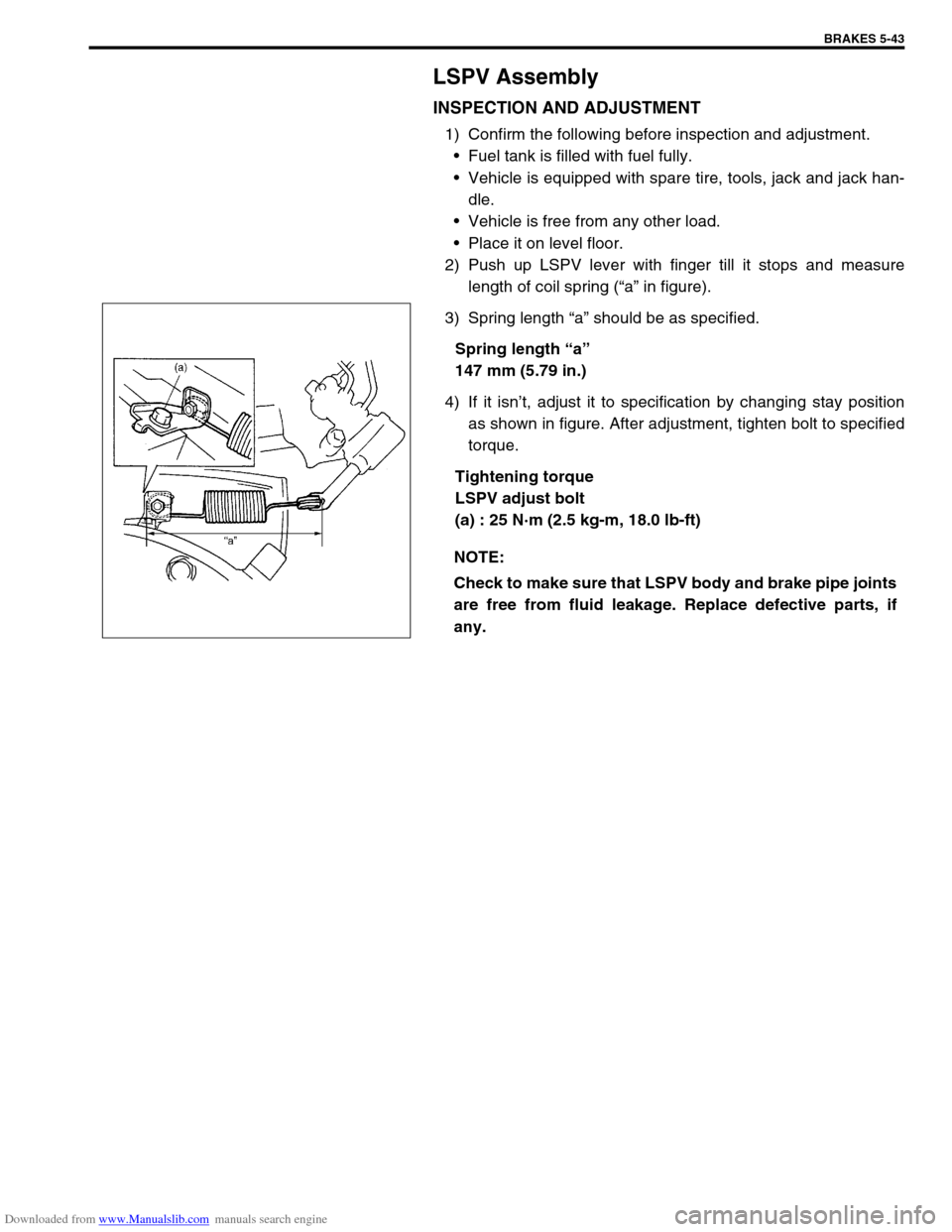

LSPV Assembly

INSPECTION AND ADJUSTMENT

1) Confirm the following before inspection and adjustment.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

Vehicle is free from any other load.

Place it on level floor.

2) Push up LSPV lever with finger till it stops and measure

length of coil spring (“a” in figure).

3) Spring length “a” should be as specified.

Spring length “a”

147 mm (5.79 in.)

4) If it isn’t, adjust it to specification by changing stay position

as shown in figure. After adjustment, tighten bolt to specified

torque.

Tightening torque

LSPV adjust bolt

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

NOTE:

Check to make sure that LSPV body and brake pipe joints

are free from fluid leakage. Replace defective parts, if

any.

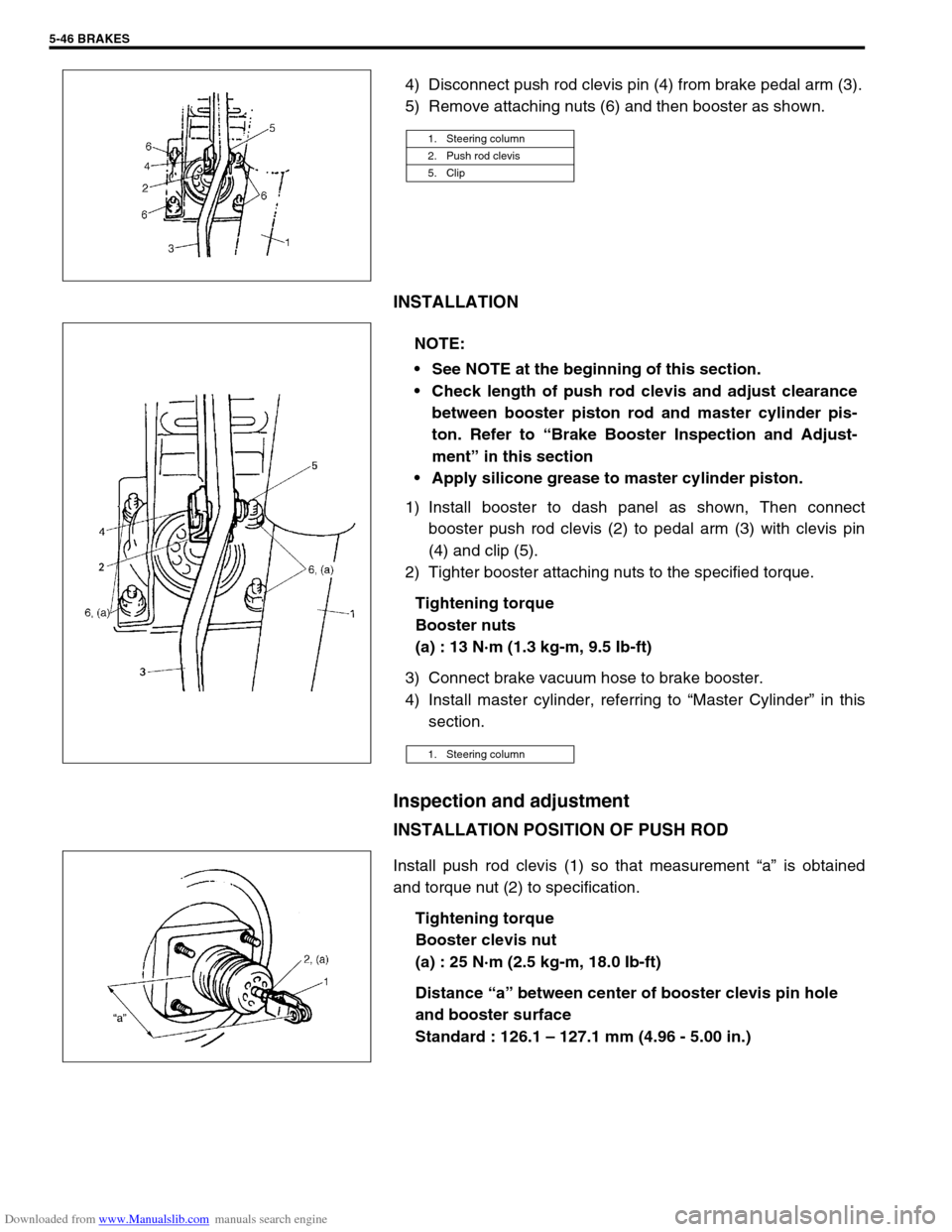

Page 307 of 687

Downloaded from www.Manualslib.com manuals search engine 5-46 BRAKES

4) Disconnect push rod clevis pin (4) from brake pedal arm (3).

5) Remove attaching nuts (6) and then booster as shown.

INSTALLATION

1) Install booster to dash panel as shown, Then connect

booster push rod clevis (2) to pedal arm (3) with clevis pin

(4) and clip (5).

2) Tighter booster attaching nuts to the specified torque.

Tightening torque

Booster nuts

(a) : 13 N·m (1.3 kg-m, 9.5 Ib-ft)

3) Connect brake vacuum hose to brake booster.

4) Install master cylinder, referring to “Master Cylinder” in this

section.

Inspection and adjustment

INSTALLATION POSITION OF PUSH ROD

Install push rod clevis (1) so that measurement “a” is obtained

and torque nut (2) to specification.

Tightening torque

Booster clevis nut

(a) : 25 N·m (2.5 kg-m, 18.0 Ib-ft)

Distance “a” between center of booster clevis pin hole

and booster surface

Standard : 126.1 – 127.1 mm (4.96 - 5.00 in.)

1. Steering column

2. Push rod clevis

5. Clip

NOTE:

See NOTE at the beginning of this section.

Check length of push rod clevis and adjust clearance

between booster piston rod and master cylinder pis-

ton. Refer to “Brake Booster Inspection and Adjust-

ment” in this section

Apply silicone grease to master cylinder piston.

1. Steering column

Page 308 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-47

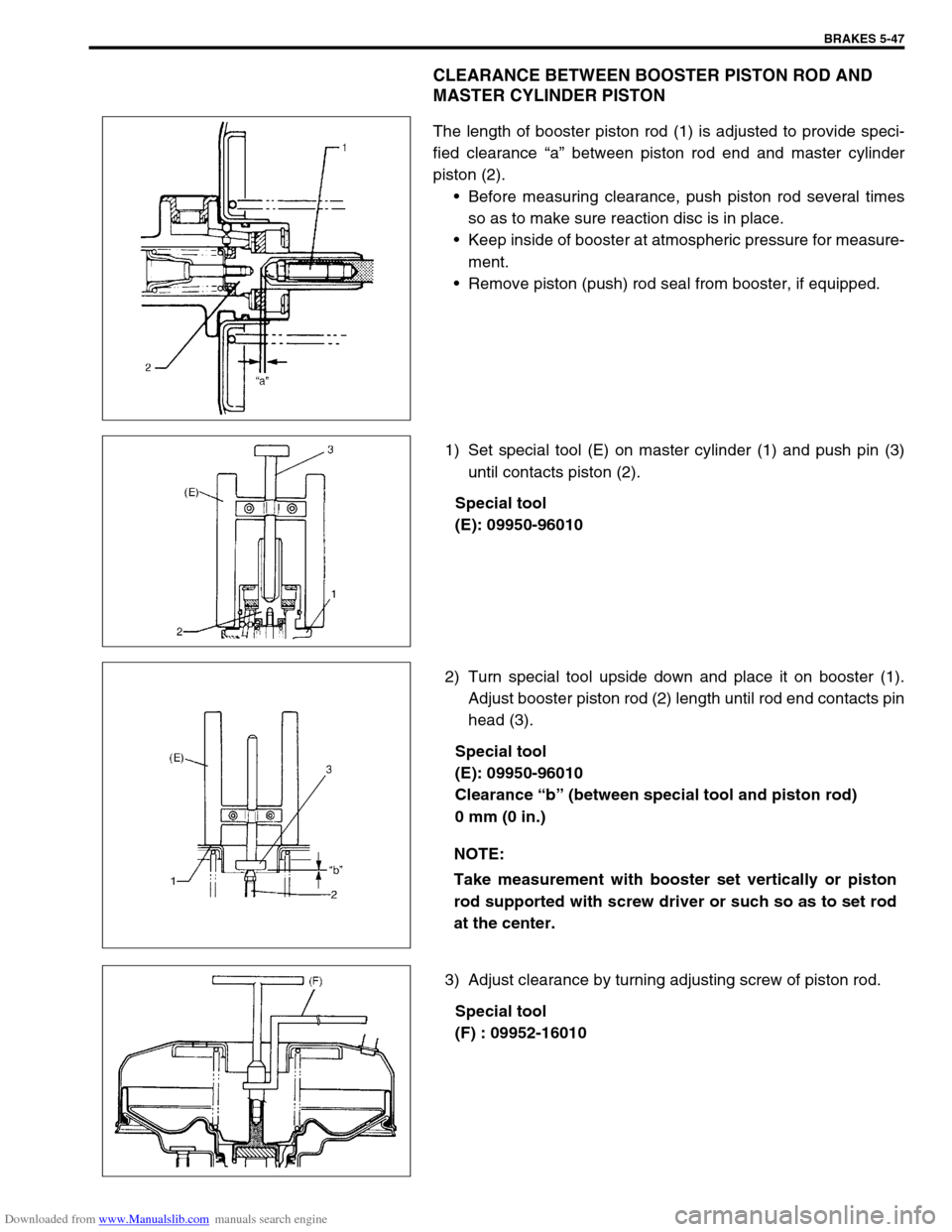

CLEARANCE BETWEEN BOOSTER PISTON ROD AND

MASTER CYLINDER PISTON

The length of booster piston rod (1) is adjusted to provide speci-

fied clearance “a” between piston rod end and master cylinder

piston (2).

Before measuring clearance, push piston rod several times

so as to make sure reaction disc is in place.

Keep inside of booster at atmospheric pressure for measure-

ment.

Remove piston (push) rod seal from booster, if equipped.

1) Set special tool (E) on master cylinder (1) and push pin (3)

until contacts piston (2).

Special tool

(E): 09950-96010

2) Turn special tool upside down and place it on booster (1).

Adjust booster piston rod (2) length until rod end contacts pin

head (3).

Special tool

(E): 09950-96010

Clearance “b” (between special tool and piston rod)

0 mm (0 in.)

3) Adjust clearance by turning adjusting screw of piston rod.

Special tool

(F) : 09952-16010

NOTE:

Take measurement with booster set vertically or piston

rod supported with screw driver or such so as to set rod

at the center.

Page 511 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-30 ENGINE MECHANICAL (M13 ENGINE)

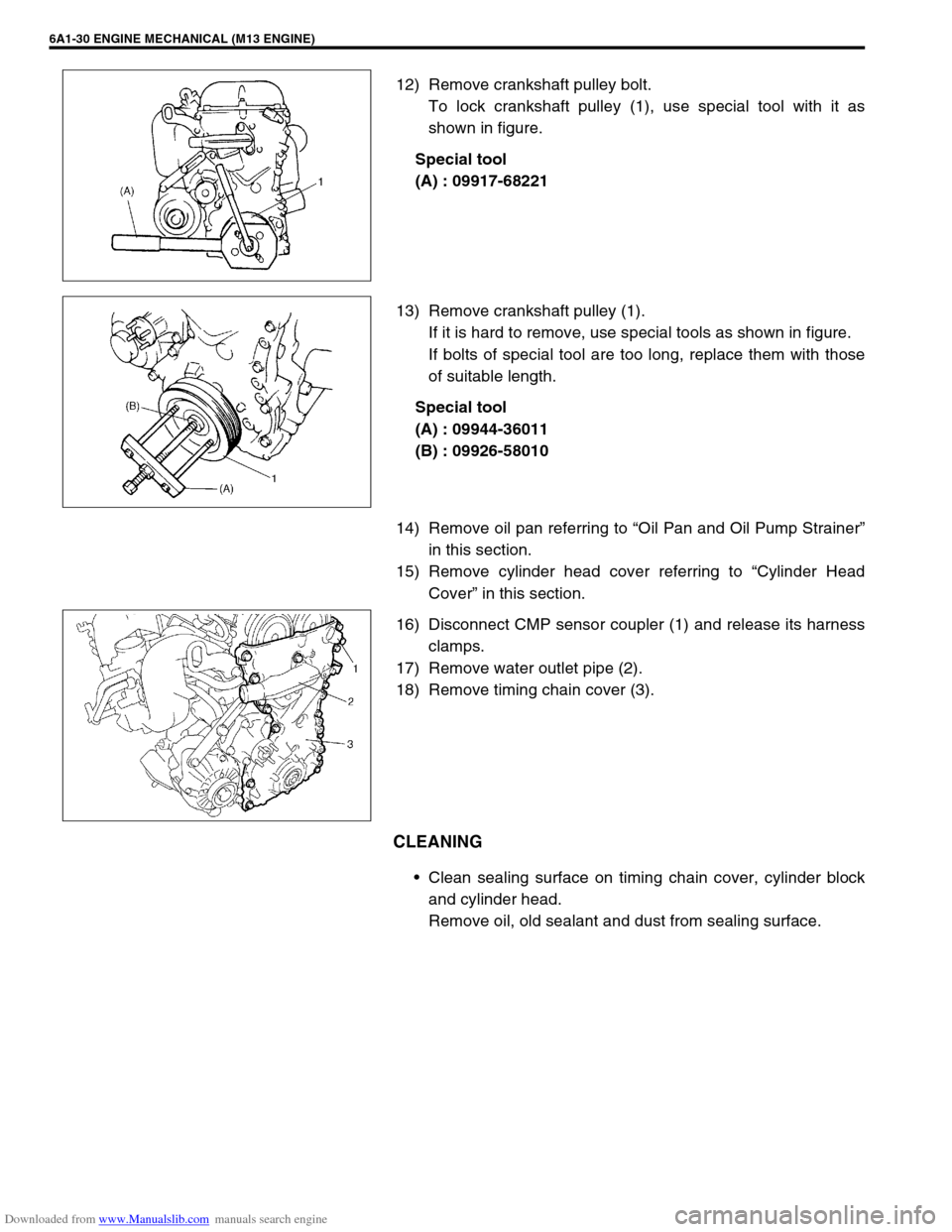

12) Remove crankshaft pulley bolt.

To lock crankshaft pulley (1), use special tool with it as

shown in figure.

Special tool

(A) : 09917-68221

13) Remove crankshaft pulley (1).

If it is hard to remove, use special tools as shown in figure.

If bolts of special tool are too long, replace them with those

of suitable length.

Special tool

(A) : 09944-36011

(B) : 09926-58010

14) Remove oil pan referring to “Oil Pan and Oil Pump Strainer”

in this section.

15) Remove cylinder head cover referring to “Cylinder Head

Cover” in this section.

16) Disconnect CMP sensor coupler (1) and release its harness

clamps.

17) Remove water outlet pipe (2).

18) Remove timing chain cover (3).

CLEANING

Clean sealing surface on timing chain cover, cylinder block

and cylinder head.

Remove oil, old sealant and dust from sealing surface.