oxygen sensor SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 416 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-59

DTC P0130 (DTC No.14) Heated Oxygen Sensor (HO2S) Circuit Malfunction

(Sensor-1)

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF. Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

2) Warm up engine to normal operating temperature.

3) Drive vehicle at 30 – 40 mph, 50 – 60 km/h for 2 min.

4) Stop vehicle and run engine at idle for 2 min.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

1. Heated oxygen sensor-1 (HO2S-1)

DTC DETECTING CONDITION POSSIBLE CAUSE

When running at idle speed after engine warmed up and

running at specified vehicle speed, HO2S-1 output volt-

age does not go below 0.3 V or over 0.6 V.

✱2 driving cycle detection logic, Monitoring once / 1 driving.Heated oxygen sensor-1 malfunction

“B/Bl” or “R” circuit open (poor connection) or

short

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 418 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-61

DTC P0133 Heated Oxygen Sensor (HO2S) Circuit Slow Response (Sensor-1)

WIRING DIAGRAM

Refer to DTC P0130 section.

CIRCUIT DESCRIPTION

Fig. 1

DTC CONFIRMATION PROCEDURE

Refer to DTC P0130 section.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

When running at specified idle speed after engine warmed up and

running at specified vehicle speed, response time (time to change

from lean to rich or from rich to lean) of HO2S-1 output voltage is

about 1 sec. at minimum or average time of 1 cycle is 5 sec. at

minimum. See. Fig. 1

✱

✱✱ ✱2 driving cycle detection logic, Monitoring once / 1 driving.Heated oxygen sensor-1 malfunction

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Is there DTC(s) other than HO2S-1 (DTC

P0133)?Go to applicable DTC

Diag. Flow Table.Replace HO2S-1.

Page 419 of 687

Downloaded from www.Manualslib.com manuals search engine 6-62 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0135 (DTC No.14) Heated Oxygen Sensor (HO2S) Heater Circuit Mal-

function (Sensor-1)

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON, start engine and keep it at idle for 1 min.

3) Start vehicle and depress accelerator pedal fully for 5 sec. or longer.

4) Stop vehicle.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

1. Heated oxygen sensor-1 (HO2S-1) heater

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when A or B condition is met.

A :

Low voltage at terminal E19-7 when engine is running

at high load.

B :

High voltage at terminal E19-7 when engine is running

under condition other than above.

✱

✱✱ ✱2 driving cycle detection logic, Continuous monitoring.HO2S-1 heater circuit open or shorted to ground

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 421 of 687

Downloaded from www.Manualslib.com manuals search engine 6-64 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0136 Heated Oxygen Sensor (HO2S) Circuit Malfunction (Sensor-2)

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–No exhaust gas leakage and loose connection

2) Warm up engine to normal operating temperature.

3) Drive vehicle under usual driving condition for 5 min. and check HO2S-2 output voltage and “short term fuel

trim” with “Data List” mode on scan tool, and write it down.

4) Stop vehicle (don’t turn ignition switch OFF).

5) Increase vehicle speed to higher than 20 mph, 32 km/h and then stop vehicle.

1. Heated oxygen sensor-2 (HO2S-2) [A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine is warmed up and HO2S-2 voltage is 4.5 V or more.

(circuit open)

✱

✱✱ ✱2 driving cycle detection logic, monitoring once / 1 driving.Exhaust gas leakage

“W” or “B/Bl” circuit open or short

Heated oxygen sensor-2 malfunction

Fuel system malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 422 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-65

6) Repeat above steps 5) 4 times.

7) Increase vehicle speed to about 50 mph (80 km/h) in 3rd gear or 2 range.

8) Release accelerator pedal and with engine brake applied, keep vehicle coasting (fuel cut condition) for

10sec. or more.

9) Stop vehicle (don’t turn ignition switch OFF) and run engine at idle for 2 min. After this step 9), if “Oxygen

Sensor Monitoring TEST COMPLETED” is displayed in “READINESS TESTS” mode and DTC is not dis-

played in “DTC” mode, confirmation test is completed.

If “TEST NOT COMPLTD” is still being displayed, proceed to next step 10).

10) Drive vehicle under usual driving condition for 10 min. (or vehicle is at a stop and run engine at idle for 10

min. or longer)

11) Stop vehicle (don’t turn ignition switch OFF). Confirm test results according to “Test Result Confirmation

Flow Table” in “DTC CONFIRMATION PROCEDURE” of DTC P0420.

INSPECTION

*Usual driving : Driving at 30 – 40 mph, 50 – 60 km/h including short stop according to traffic signal. (under driving condition other than high-load, high-engine

speed, rapid accelerating and decelerating)

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check exhaust system for leakage, loose con-

nection and damage.

Is it good condition?Go to Step 3. Repair or replace.

3 Check HO2S-2 and Its Circuit.

Was HO2S-2 output voltage indicated on scan

tool in step 3) of DTC confirmation test less

than 1.275 V?Go to Step 4.“B/Bl” or “W” circuit open

or HO2S-2 malfunction.

4 Check Short Term Fuel Trim.

Did short term fuel trim very within –20 – + 20%

range in step 3) of DTC confirmation test?Check “W” and “B/Bl” wire

for open and short, and

connection for poor con-

nection. If wire and con-

nection are OK, replace

HO2S-2.Check fuel system. Go to

DTC P0171 / P0172 Diag.

Flow Table.

Page 423 of 687

Downloaded from www.Manualslib.com manuals search engine 6-66 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0141 Heated Oxygen Sensor (HO2S) Heater Circuit Malfunction (Sen-

sor-2)

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF once and then ON.

2) Clear DTC, start engine and warm up engine to normal operating temperature.

3) Keep it at 2000 r/min for 2 min.

4) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when A or B condition it met.

1) Low voltage at terminal E18-4 for specified time after

engine start or while engine running at high load.

2) High voltage at terminal E18-4 while engine running

under other than above condition.

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.HO2S-2 heater circuit open or shorted to ground

ECM malfunction

Page 425 of 687

![SUZUKI JIMNY 2005 3.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 Fuel System Too Lean

DTC P0172 Fuel System Too Rich

CIRCUIT DESCRIPTION

[a] : Signal to SUZUKI JIMNY 2005 3.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 Fuel System Too Lean

DTC P0172 Fuel System Too Rich

CIRCUIT DESCRIPTION

[a] : Signal to](/img/20/7588/w960_7588-424.png)

Downloaded from www.Manualslib.com manuals search engine 6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 Fuel System Too Lean

DTC P0172 Fuel System Too Rich

CIRCUIT DESCRIPTION

[a] : Signal to decrease amount of fuel injection [d] : A/F mixture becomes richer

(Oxygen concentration decreases)1. Injector

[b] : Signal to increase amount of fuel injection [e] : High voltage 2. Heated oxygen sensor-1 (HO2S-1)

[c] : A/F mixture becomes leaner

(Oxygen concentration increases)[f] : Low voltage

DTC DETECTING CONDITION POSSIBLE CAUSE

When following condition occurs while engine running

under closed loop condition.

–Air / fuel ratio too lean

(Total fuel trim (short and long terms added) is more

than 30%)

or

–Air / fuel ratio too rich

(Total fuel trim is less than –30%)

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.Vacuum leaks (air drawn in).

Exhaust gas leakage.

Heated oxygen sensor-1 circuit malfunction.

Fuel pressure out of specification.

Fuel injector malfunction (clogged or leakage).

MAP sensor poor performance.

ECT sensor poor performance.

IAT sensor poor performance.

TP sensor poor performance.

EVAP control system malfunction.

PCV valve malfunction.

Page 445 of 687

Downloaded from www.Manualslib.com manuals search engine 6-88 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0420 Catalyst System Efficiency below Threshold

CIRCUIT DESCRIPTION

ECM monitors oxygen concentration in the exhaust gas which has passed the three way catalytic converter by

HO2S-2.

When the catalyst is functioning properly, the variation cycle of HO2S-2 output voltage (oxygen concentration) is

slower than that of HO2S-1 output voltage because of the amount of oxygen in the exhaust gas which has been

stored in the catalyst.

REFERENCE

1. Heated oxygen sensor-1 3. Three way catalytic converter 5. To the sensor [B] : Case of TYPE B is shown

(See NOTE)

2. Warm up three way catalytic

converter4. Heated oxygen sensor-2 [A] : Case of TYPE A is shown

(See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

1. Engine running at closed loop

condition2. Fuel cut 3. Idle after fuel cut [A] : Oscilloscope waveforms

Page 502 of 687

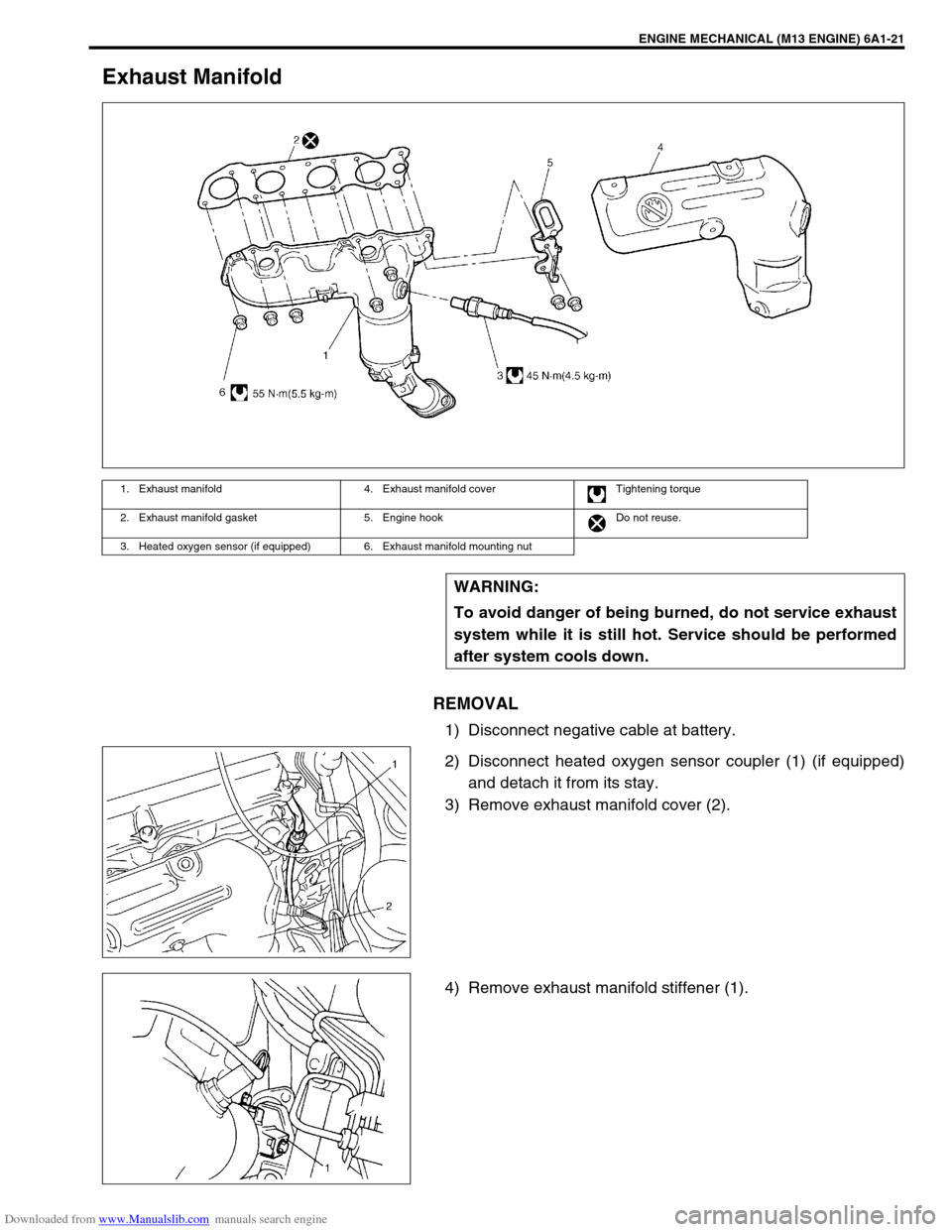

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-21

Exhaust Manifold

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect heated oxygen sensor coupler (1) (if equipped)

and detach it from its stay.

3) Remove exhaust manifold cover (2).

4) Remove exhaust manifold stiffener (1).

1. Exhaust manifold 4. Exhaust manifold cover Tightening torque

2. Exhaust manifold gasket 5. Engine hook Do not reuse.

3. Heated oxygen sensor (if equipped) 6. Exhaust manifold mounting nut

WARNING:

To avoid danger of being burned, do not service exhaust

system while it is still hot. Service should be performed

after system cools down.

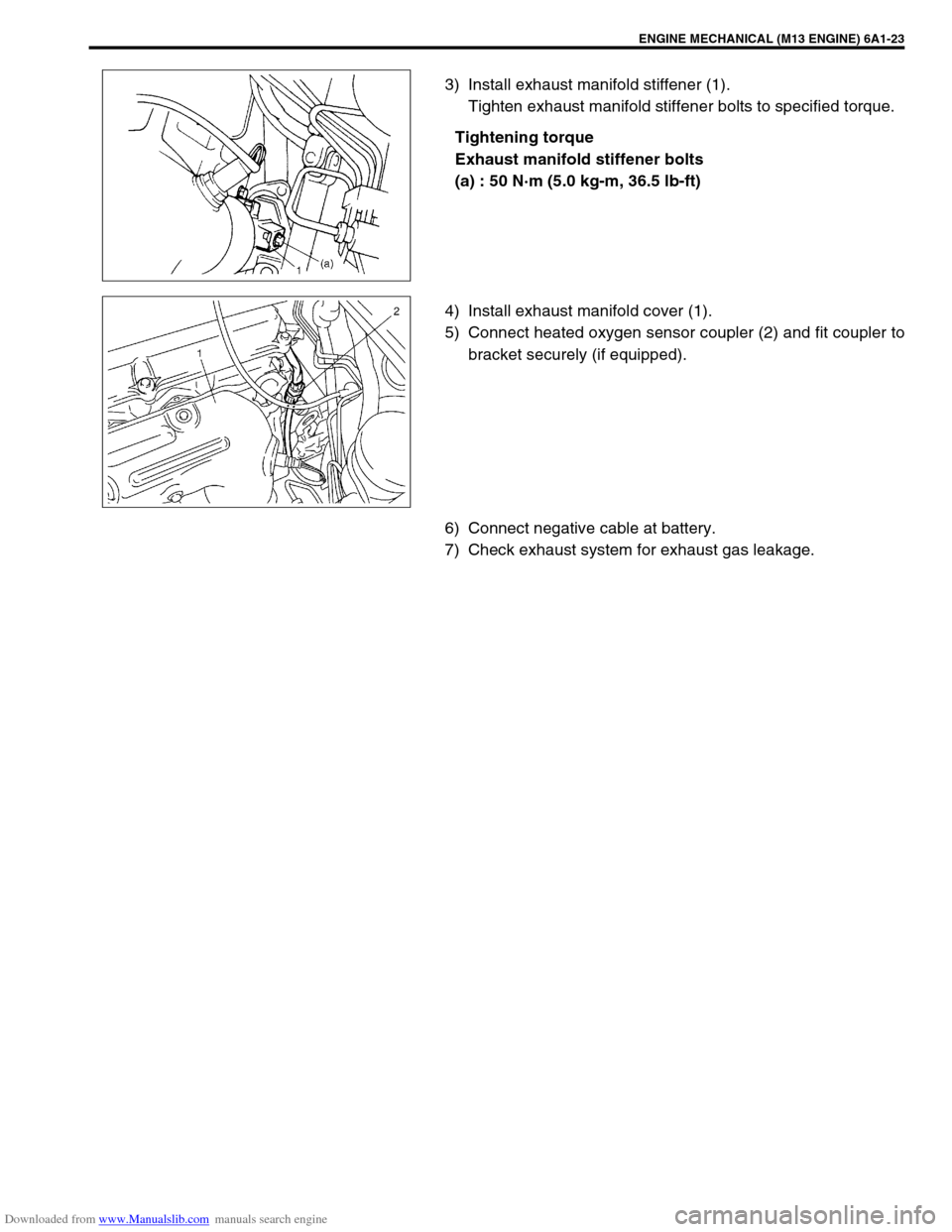

Page 504 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-23

3) Install exhaust manifold stiffener (1).

Tighten exhaust manifold stiffener bolts to specified torque.

Tightening torque

Exhaust manifold stiffener bolts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

4) Install exhaust manifold cover (1).

5) Connect heated oxygen sensor coupler (2) and fit coupler to

bracket securely (if equipped).

6) Connect negative cable at battery.

7) Check exhaust system for exhaust gas leakage.