engine SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 221 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-2 REAR SUSPENSION

General Description

1. Rear axle housing 4. Bearing oil seal 7. Brake drum 10. Bump stopper

2. Rear wheel bearing 5. Oil seal protector 8. Rear axle shaft 11. Coil spring

3. Bearing retainer ring 6. Lateral rod 9. Shock absorber 12. Trailing arm

Page 222 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-3

Diagnosis

Diagnosis Table

Refer to “Diagnosis Table” in Section 3.

Rear Shock Absorber Check

Inspect for deformation or damage.

Inspect bushings for wear or damage.

Inspect for evidence of oil leakage.

Replace any defective part.

Trailing Arm, Lateral Rod, Axle Housing and

Coil Spring Check

Inspect for cracks, deformation or damage.

Replace any defective part.

Trailing Arm and Lateral Rod Bush Check

Inspect for wear and breakage. If found defective, replace.WARNING:

When handling rear shock absorber in which high-pres-

sure gas is sealed, make sure to observe the following

precautions.

Don’t disassemble it.

Don’t put it into the fire.

Don’t store it where it gets hot.

Before disposing it, be sure to drill a hole in it where

shown by an arrow in the figure and let gas and oil out.

Lay it down sideways for this work.

The gas itself is harmless but it may issue out of the

hole together with chips generated by the drill. There-

fore, be sure to wear goggle.

A : Drill hole with approximately 3 mm (0.12 in.) diameter.

Page 223 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-4 REAR SUSPENSION

Rear Suspension Fasteners

Check each bolt and nut fastening suspension parts for tightness.

Tighten loose one, if any, to specified torque, referring to “Tighten-

ing Torque Specifications” of this section.

Bearing Retainer and Axle Shaft Oil Seal

Check

When brake drum has been removed, check inside of brake

drum for gear oil leakage.

Also, check backside of brake back plate for oil leakage.If oil

leakage is found, replace defective oil seal.

Whenever it is possible to check oil seal during disassembly,

check its lip for wear.

If oil leakage or worn lip is found, replace defective oil seal.

Bump Stopper and Spring Rubber Seat Check

Inspect for wear and breakage. If found defective, replace.

Wheel Disc, Nut and Bearing Check

Inspect each wheel disc for dents, distortion and cracks. A

disc in badly damaged condition must be replaced.

Check wheel hub nuts for tightness and, as necessary,

retighten to specification.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

Page 224 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-5

Check wheel bearings for wear. When measuring thrust

play, apply a dial gauge to axle shaft center after removing

wheel center cap from wheel disc.

When measurement exceeds limit, replace bearing.

Rear wheel bearing thrust play limit

: 0.8 mm (0.03 in.)

By rotating wheel actually, check wheel bearing for noise and

smooth rotation. If it is defective, replace bearing.

On-Vehicle Service

Rear Shock Absorber

The shock absorber is non-adjustable, non-refillable, and cannot be disassembled. The only service the shock

absorber requires is replacement when it has lost its resistance, is damaged, or leaking fluid.

REMOVAL

1) Hoist vehicle.

2) Support rear axle housing (1) by using floor jack (2) to pre-

vent it from lowering.

WARNING:

When discarding shock absorber, be sure to refer to instructions in “Rear Shock Absorber Check” in

this section for proper procedure as it is gas sealed type.

Page 225 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-6 REAR SUSPENSION

3) Remove upper mounting bolt (2).

4) Remove lower mounting bolt (3).

5) Remove shock absorber (1).

INSTALLATION

1) Install shock absorber (1), refer to figure for proper installing

direction of bush and washer (2).

Tighten bolts (3) temporarily by hand.

2) Remove floor jack.

3) Lower hoist.

4) Tighten shock absorber bolts (3) to specified torque.

Tightening torque

Shock absorber upper and lower bolts

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

Coil Spring

REMOVAL

1) Hoist vehicle and remove wheel.

2) Support rear axle housing (1) by using floor jack (2).

3) Remove brake flexible hose E-ring (2).

NOTE:

Tighten lower bolt with vehicle off hoist and in non-

loaded condition.

1. Brake flexible hose

Page 226 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-7

4) Remove shock absorber lower mounting bolt (2).

5) Lower rear axle housing (2) gradually as far down as where

coil spring (1) can be removed.

6) Remove coil spring (1).

7) Remove spring rubber seat (1).

1. Shock absorber

Page 227 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-8 REAR SUSPENSION

INSTALLATION

1) Install spring rubber seat (1).

2) Install coil spring (2) on spring seat (1) of axle housing and

then raise axle housing.

3) Install shock absorber lower mounting bolt.

Tighten bolt temporarily by hand.

4) Install brake flexible hose E-ring.

5) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

6) Lower hoist and tighten absorber lower bolt (2) to specified

torque.

Tightening torque

Shock absorber lower bolt

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft) NOTE:

Before installing spring rubber seat (1), apply soap water

on it.

NOTE:

Upper and lower diameters of coil spring (2) are differ-

ent.

Bring larger diameter end at bottom and set its open

end in place on spring seat (1).

When seating coil spring (2), mate spring end with

stepped part (3) of rear axle spring seat (1) as shown.

A : Upper side (small dia.)

B : Lower side (large dia.)

NOTE:

For tightening of lower bolt (2), refer to NOTE given under

“Shock Absorber” in this section.

Page 228 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-9

Bump Stopper

REMOVAL

1) Hoist vehicle.

2) Remove wheel.

3) Remove bump stopper (1) by using special tool.

Special tool

(A) : 09941-66010

INSTALLATION

1) Tighten bump stopper (1) to specified torque by using spe-

cial tool.

Special tool

(A) : 09941-66010

Tightening torque

Bump stopper

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

2) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

3) Lower hoist.

Lateral Rod

REMOVAL

1) Hoist vehicle.

2) Remove lateral rod mounting bolt (2) and nut (3).

3) Remove lateral rod (1).

Page 229 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-10 REAR SUSPENSION

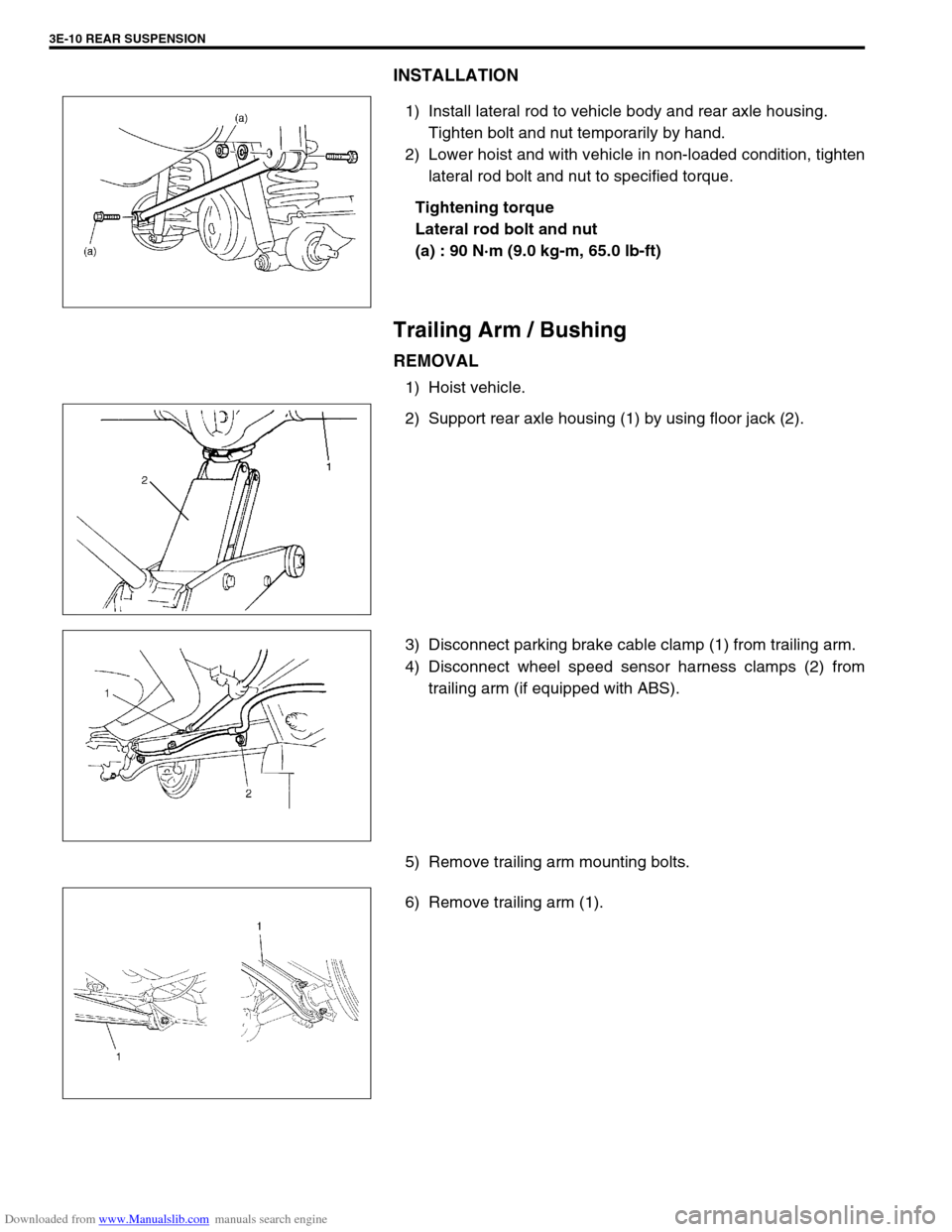

INSTALLATION

1) Install lateral rod to vehicle body and rear axle housing.

Tighten bolt and nut temporarily by hand.

2) Lower hoist and with vehicle in non-loaded condition, tighten

lateral rod bolt and nut to specified torque.

Tightening torque

Lateral rod bolt and nut

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

Trailing Arm / Bushing

REMOVAL

1) Hoist vehicle.

2) Support rear axle housing (1) by using floor jack (2).

3) Disconnect parking brake cable clamp (1) from trailing arm.

4) Disconnect wheel speed sensor harness clamps (2) from

trailing arm (if equipped with ABS).

5) Remove trailing arm mounting bolts.

6) Remove trailing arm (1).

Page 230 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-11

7) Remove bushings (1) by using hydraulic press and special

tools.

Special tool

(A) : 09924-74510

(B) : 09951-16030

(C) : 09951-26010

INSTALLATION

1) Install bushings (1) by using hydraulic press and special

tools, noting the following points.

Special tool

(A) : 09913-85210

(B) : 09951-26010

For axle side bushings (1), install them so that center line

and slit lines of them are parallel as shown figure.

2. Slit

3. Center line of bushings

4. Slit line of bushings