engine SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 241 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-22 REAR SUSPENSION

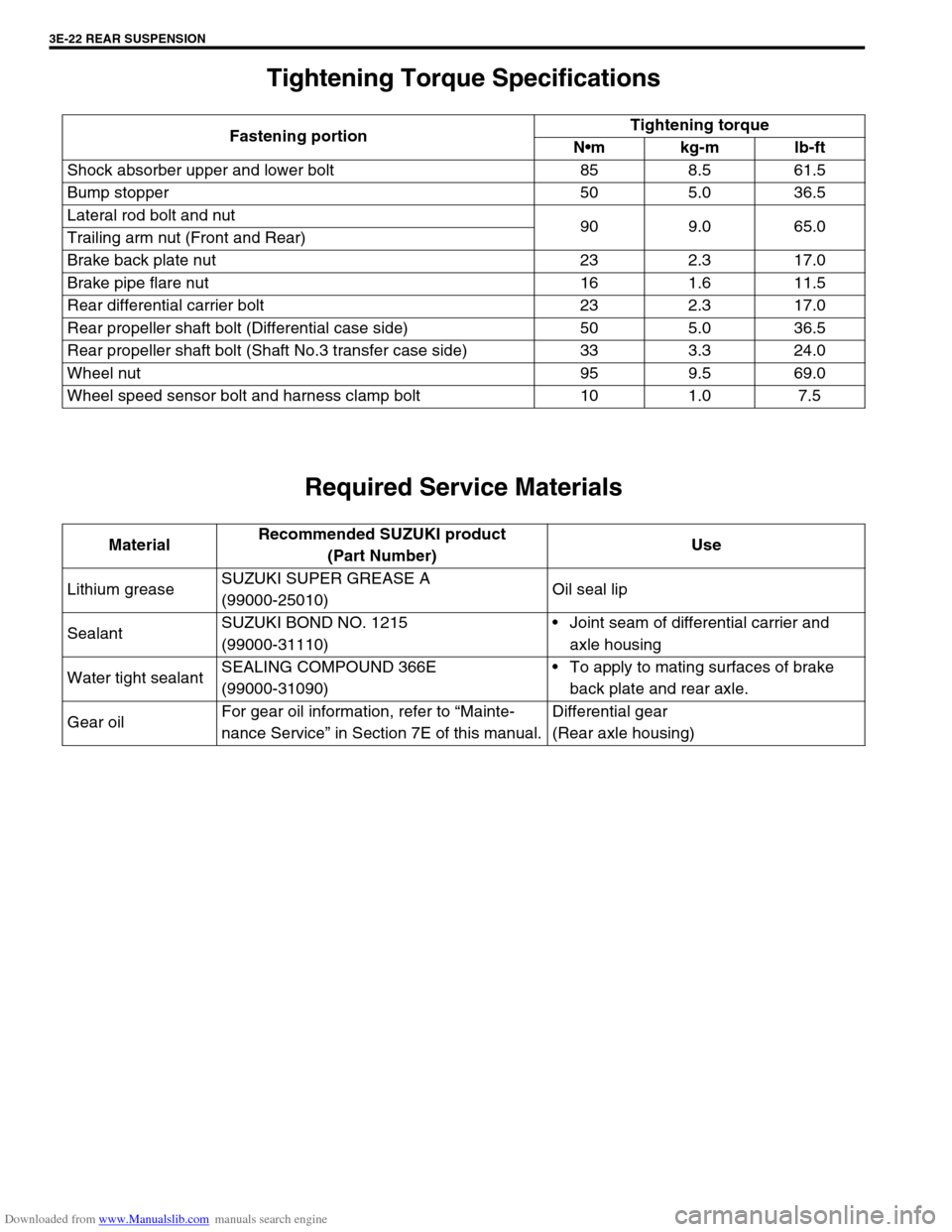

Tightening Torque Specifications

Required Service Materials

Fastening portionTightening torque

Nm kg-m lb-ft

Shock absorber upper and lower bolt 85 8.5 61.5

Bump stopper 50 5.0 36.5

Lateral rod bolt and nut

90 9.0 65.0

Trailing arm nut (Front and Rear)

Brake back plate nut 23 2.3 17.0

Brake pipe flare nut 16 1.6 11.5

Rear differential carrier bolt 23 2.3 17.0

Rear propeller shaft bolt (Differential case side) 50 5.0 36.5

Rear propeller shaft bolt (Shaft No.3 transfer case side) 33 3.3 24.0

Wheel nut 95 9.5 69.0

Wheel speed sensor bolt and harness clamp bolt 10 1.0 7.5

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium greaseSUZUKI SUPER GREASE A

(99000-25010)Oil seal lip

SealantSUZUKI BOND NO. 1215

(99000-31110)Joint seam of differential carrier and

axle housing

Water tight sealantSEALING COMPOUND 366E

(99000-31090)To apply to mating surfaces of brake

back plate and rear axle.

Gear oilFor gear oil information, refer to “Mainte-

nance Service” in Section 7E of this manual.Differential gear

(Rear axle housing)

Page 242 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-23

Special Tools

09913-75520 09913-85210 09924-74510 1) 09927-18411

Universal puller

Bearing installer Oil seal installer Bearing installer handle 2) 09921-57810

Bearing remover

09941-66010 09942-15510 09943-35511 or

09943-3551209944-96010

Bearing outer race

remover

Bump stopper wrench Sliding hammer Brake drum remover 09921-26010

Bearing outer race

remover collar

09951-16030 09951-26010

Bush remover Bush remover plate

Page 243 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-24 REAR SUSPENSION

Page 244 of 687

Downloaded from www.Manualslib.com manuals search engine WHEELS AND TIRES 3F-1

6F1

6F2

6G

3F

8A

8B

8C

8B

8C

8D

8E

9

10

10A

10B

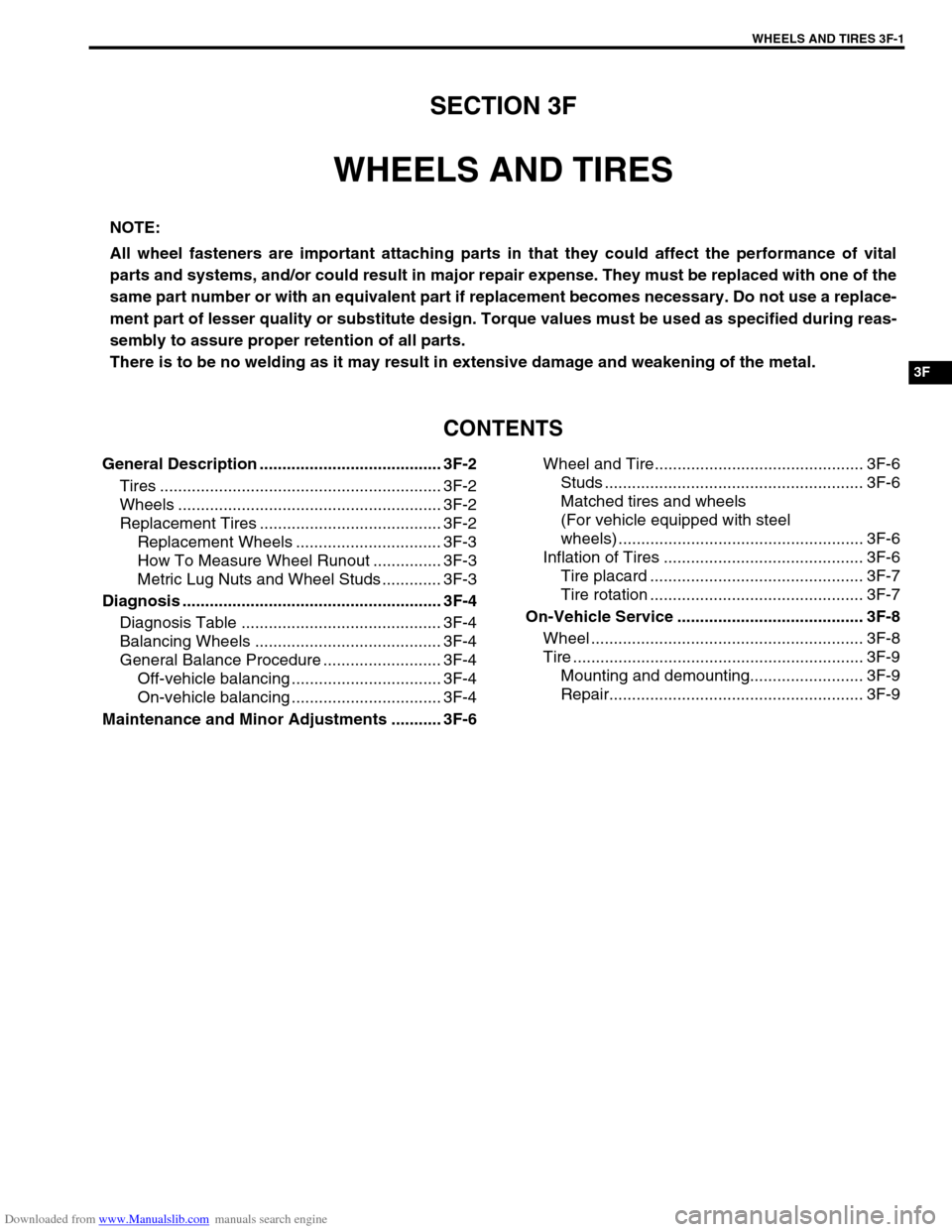

SECTION 3F

WHEELS AND TIRES

CONTENTS

General Description ........................................ 3F-2

Tires .............................................................. 3F-2

Wheels .......................................................... 3F-2

Replacement Tires ........................................ 3F-2

Replacement Wheels ................................ 3F-3

How To Measure Wheel Runout ............... 3F-3

Metric Lug Nuts and Wheel Studs ............. 3F-3

Diagnosis ......................................................... 3F-4

Diagnosis Table ............................................ 3F-4

Balancing Wheels ......................................... 3F-4

General Balance Procedure .......................... 3F-4

Off-vehicle balancing ................................. 3F-4

On-vehicle balancing ................................. 3F-4

Maintenance and Minor Adjustments ........... 3F-6Wheel and Tire.............................................. 3F-6

Studs ......................................................... 3F-6

Matched tires and wheels

(For vehicle equipped with steel

wheels) ...................................................... 3F-6

Inflation of Tires ............................................ 3F-6

Tire placard ............................................... 3F-7

Tire rotation ............................................... 3F-7

On-Vehicle Service ......................................... 3F-8

Wheel ............................................................ 3F-8

Tire ................................................................ 3F-9

Mounting and demounting......................... 3F-9

Repair........................................................ 3F-9

NOTE:

All wheel fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of the

same part number or with an equivalent part if replacement becomes necessary. Do not use a replace-

ment part of lesser quality or substitute design. Torque values must be used as specified during reas-

sembly to assure proper retention of all parts.

There is to be no welding as it may result in extensive damage and weakening of the metal.

Page 245 of 687

Downloaded from www.Manualslib.com manuals search engine 3F-2 WHEELS AND TIRES

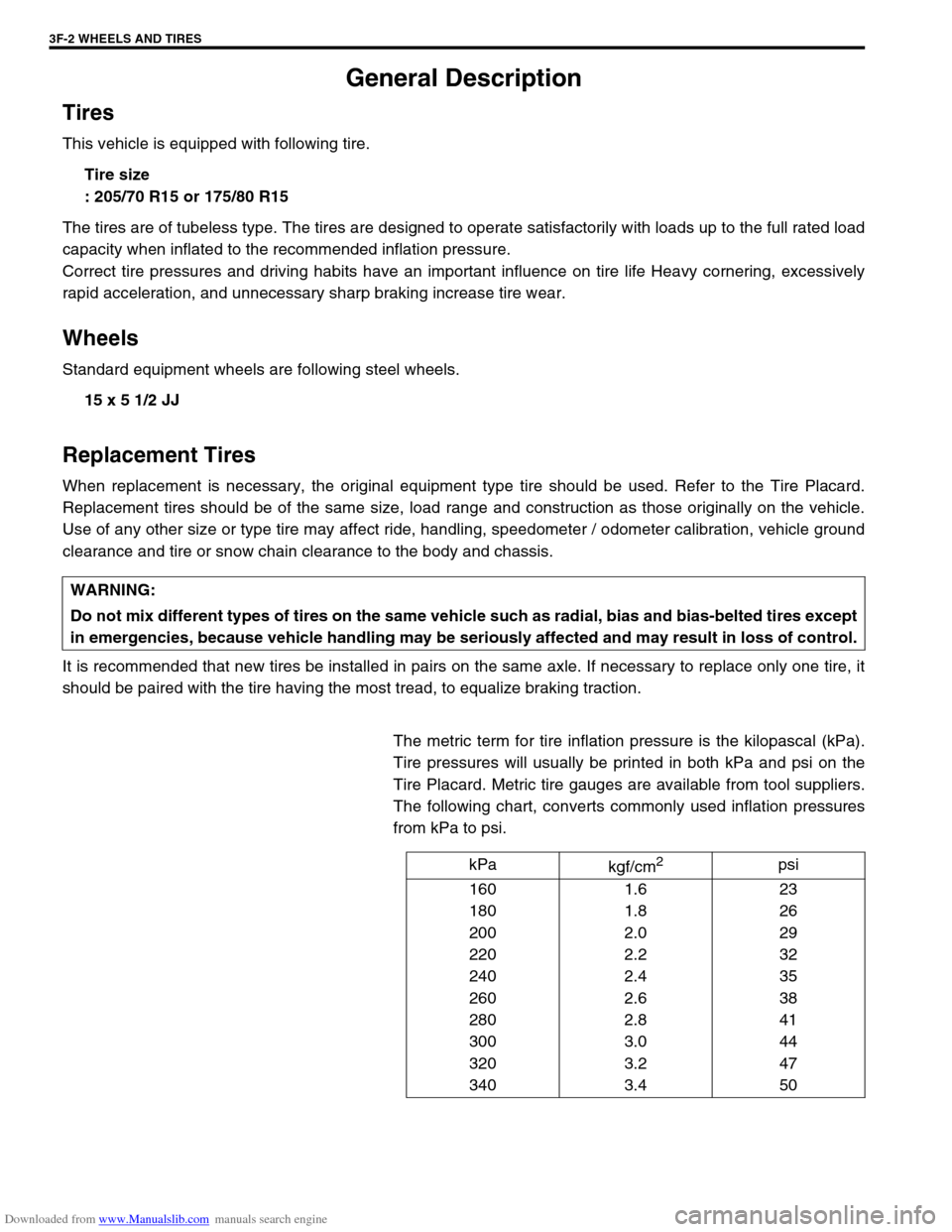

General Description

Tires

This vehicle is equipped with following tire.

Tire size

: 205/70 R15 or 175/80 R15

The tires are of tubeless type. The tires are designed to operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation pressure.

Correct tire pressures and driving habits have an important influence on tire life Heavy cornering, excessively

rapid acceleration, and unnecessary sharp braking increase tire wear.

Wheels

Standard equipment wheels are following steel wheels.

15 x 5 1/2 JJ

Replacement Tires

When replacement is necessary, the original equipment type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride, handling, speedometer / odometer calibration, vehicle ground

clearance and tire or snow chain clearance to the body and chassis.

It is recommended that new tires be installed in pairs on the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to equalize braking traction.

The metric term for tire inflation pressure is the kilopascal (kPa).

Tire pressures will usually be printed in both kPa and psi on the

Tire Placard. Metric tire gauges are available from tool suppliers.

The following chart, converts commonly used inflation pressures

from kPa to psi. WARNING:

Do not mix different types of tires on the same vehicle such as radial, bias and bias-belted tires except

in emergencies, because vehicle handling may be seriously affected and may result in loss of control.

kPa

kgf/cm2psi

160

180

200

220

240

260

280

300

320

3401.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.423

26

29

32

35

38

41

44

47

50

Page 246 of 687

Downloaded from www.Manualslib.com manuals search engine WHEELS AND TIRES 3F-3

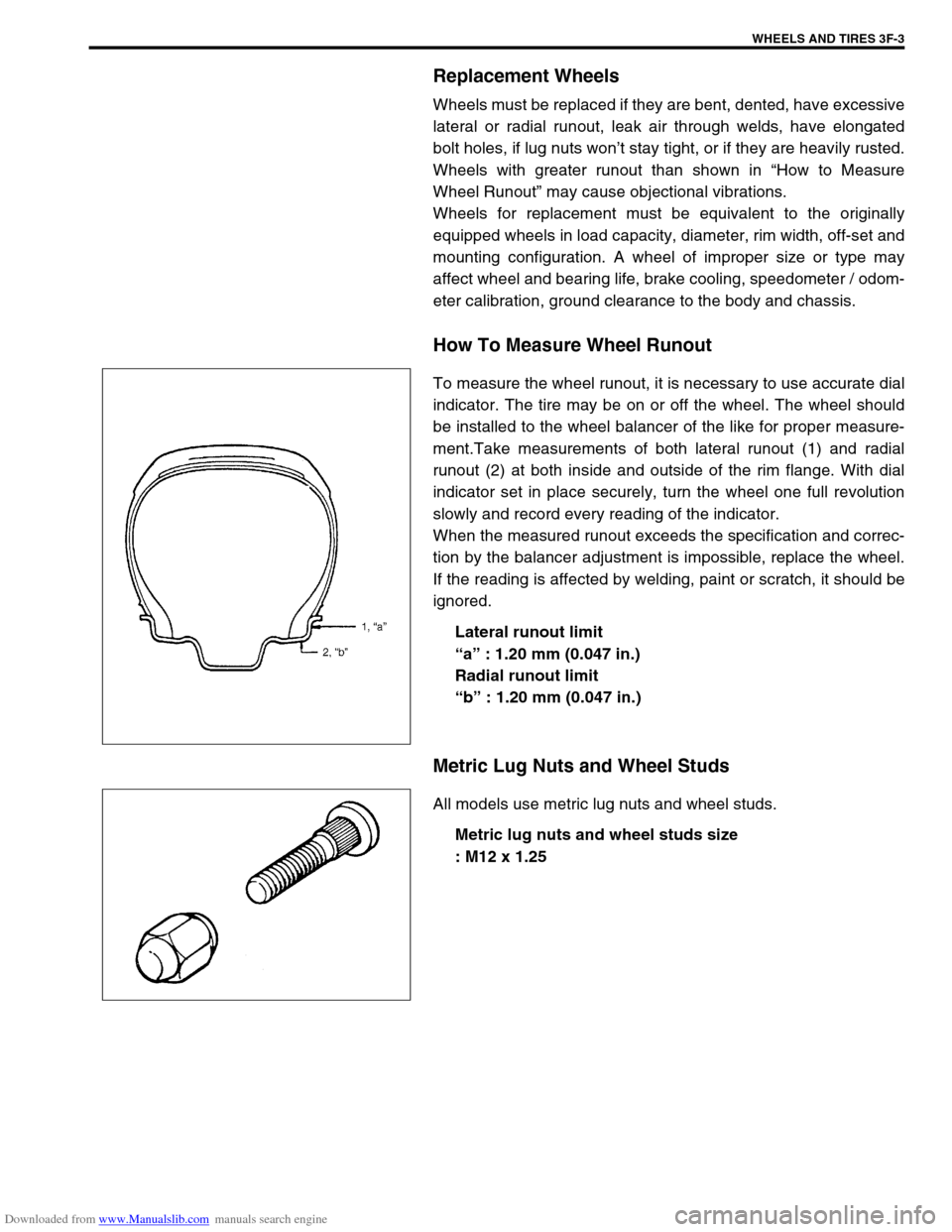

Replacement Wheels

Wheels must be replaced if they are bent, dented, have excessive

lateral or radial runout, leak air through welds, have elongated

bolt holes, if lug nuts won’t stay tight, or if they are heavily rusted.

Wheels with greater runout than shown in “How to Measure

Wheel Runout” may cause objectional vibrations.

Wheels for replacement must be equivalent to the originally

equipped wheels in load capacity, diameter, rim width, off-set and

mounting configuration. A wheel of improper size or type may

affect wheel and bearing life, brake cooling, speedometer / odom-

eter calibration, ground clearance to the body and chassis.

How To Measure Wheel Runout

To measure the wheel runout, it is necessary to use accurate dial

indicator. The tire may be on or off the wheel. The wheel should

be installed to the wheel balancer of the like for proper measure-

ment.Take measurements of both lateral runout (1) and radial

runout (2) at both inside and outside of the rim flange. With dial

indicator set in place securely, turn the wheel one full revolution

slowly and record every reading of the indicator.

When the measured runout exceeds the specification and correc-

tion by the balancer adjustment is impossible, replace the wheel.

If the reading is affected by welding, paint or scratch, it should be

ignored.

Lateral runout limit

“a” : 1.20 mm (0.047 in.)

Radial runout limit

“b” : 1.20 mm (0.047 in.)

Metric Lug Nuts and Wheel Studs

All models use metric lug nuts and wheel studs.

Metric lug nuts and wheel studs size

: M12 x 1.25

Page 247 of 687

Downloaded from www.Manualslib.com manuals search engine 3F-4 WHEELS AND TIRES

Diagnosis

Diagnosis Table

Refer to “Diagnosis Table” in Section 3.

Balancing Wheels

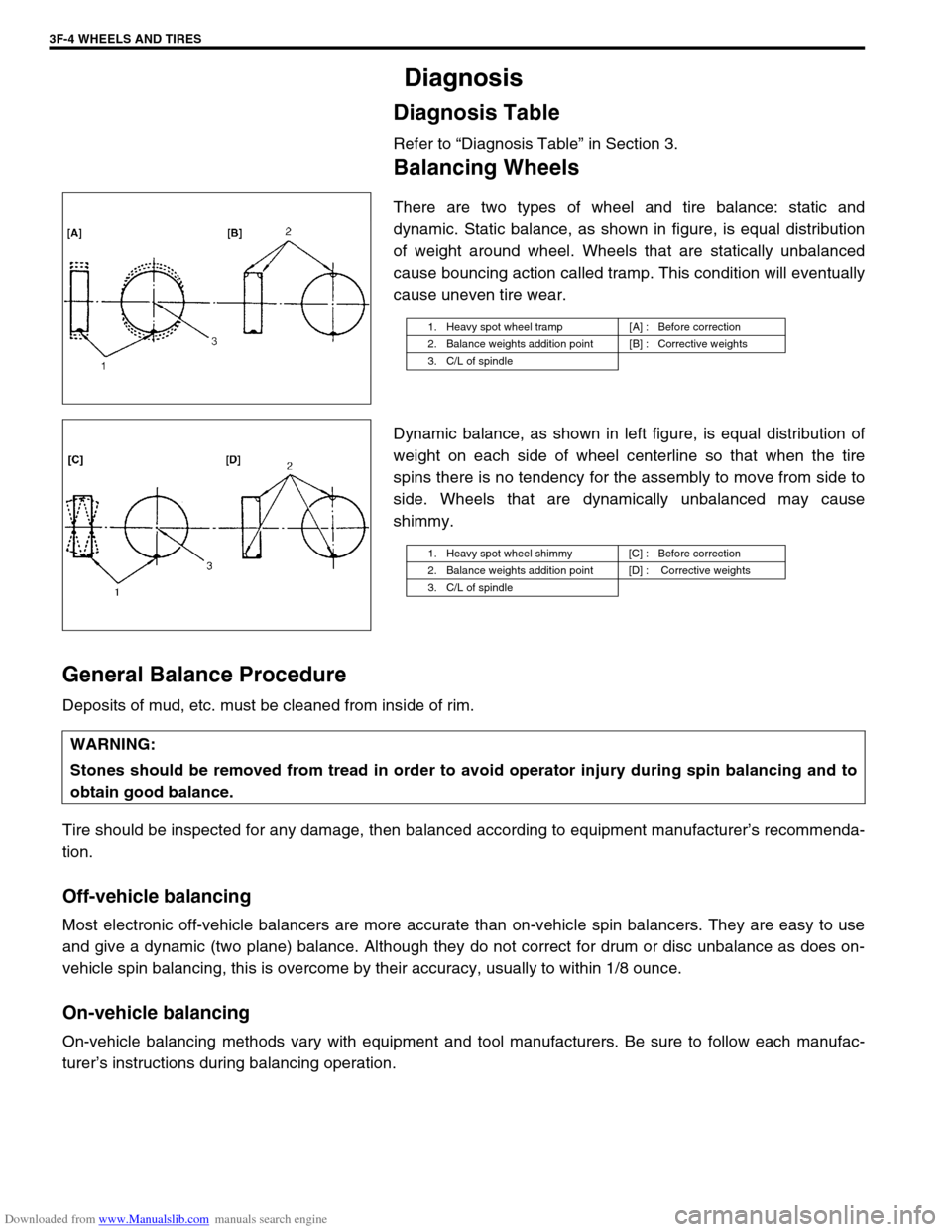

There are two types of wheel and tire balance: static and

dynamic. Static balance, as shown in figure, is equal distribution

of weight around wheel. Wheels that are statically unbalanced

cause bouncing action called tramp. This condition will eventually

cause uneven tire wear.

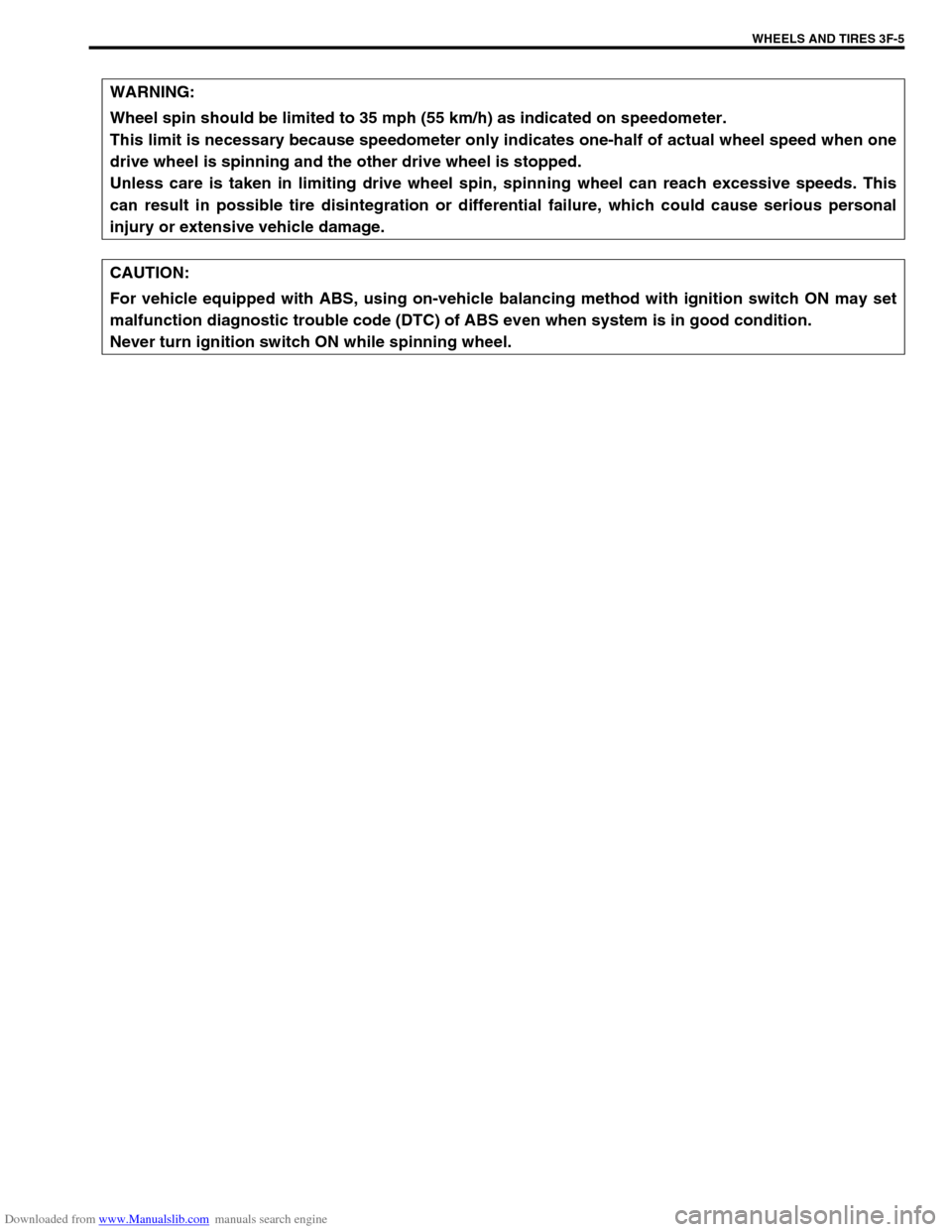

Dynamic balance, as shown in left figure, is equal distribution of

weight on each side of wheel centerline so that when the tire

spins there is no tendency for the assembly to move from side to

side. Wheels that are dynamically unbalanced may cause

shimmy.

General Balance Procedure

Deposits of mud, etc. must be cleaned from inside of rim.

Tire should be inspected for any damage, then balanced according to equipment manufacturer’s recommenda-

tion.

Off-vehicle balancing

Most electronic off-vehicle balancers are more accurate than on-vehicle spin balancers. They are easy to use

and give a dynamic (two plane) balance. Although they do not correct for drum or disc unbalance as does on-

vehicle spin balancing, this is overcome by their accuracy, usually to within 1/8 ounce.

On-vehicle balancing

On-vehicle balancing methods vary with equipment and tool manufacturers. Be sure to follow each manufac-

turer’s instructions during balancing operation.

1. Heavy spot wheel tramp [A] : Before correction

2. Balance weights addition point [B] : Corrective weights

3. C/L of spindle

1. Heavy spot wheel shimmy [C] : Before correction

2. Balance weights addition point [D] : Corrective weights

3. C/L of spindle

WARNING:

Stones should be removed from tread in order to avoid operator injury during spin balancing and to

obtain good balance.

Page 248 of 687

Downloaded from www.Manualslib.com manuals search engine WHEELS AND TIRES 3F-5

WARNING:

Wheel spin should be limited to 35 mph (55 km/h) as indicated on speedometer.

This limit is necessary because speedometer only indicates one-half of actual wheel speed when one

drive wheel is spinning and the other drive wheel is stopped.

Unless care is taken in limiting drive wheel spin, spinning wheel can reach excessive speeds. This

can result in possible tire disintegration or differential failure, which could cause serious personal

injury or extensive vehicle damage.

CAUTION:

For vehicle equipped with ABS, using on-vehicle balancing method with ignition switch ON may set

malfunction diagnostic trouble code (DTC) of ABS even when system is in good condition.

Never turn ignition switch ON while spinning wheel.

Page 249 of 687

Downloaded from www.Manualslib.com manuals search engine 3F-6 WHEELS AND TIRES

Maintenance and Minor Adjustments

Wheel and Tire

Wheel repairs that use welding, heating, or peening are not approved. All damaged wheels should be replaced.

Studs

If a broken stud is found, see Section 3E (rear) or Section 3D (front) for Note and Replacement procedure.

Matched tires and wheels

(For vehicle equipped with steel wheels)

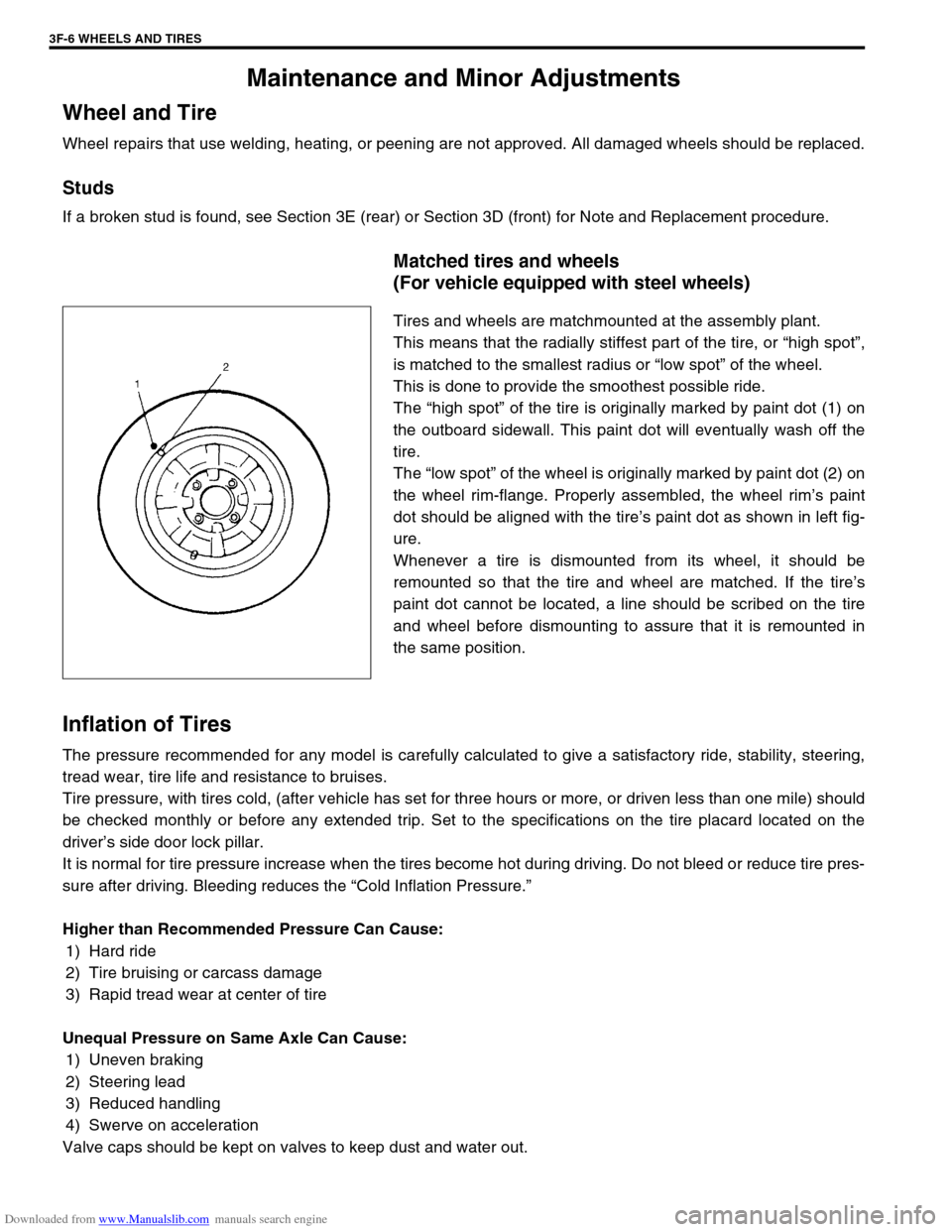

Tires and wheels are matchmounted at the assembly plant.

This means that the radially stiffest part of the tire, or “high spot”,

is matched to the smallest radius or “low spot” of the wheel.

This is done to provide the smoothest possible ride.

The “high spot” of the tire is originally marked by paint dot (1) on

the outboard sidewall. This paint dot will eventually wash off the

tire.

The “low spot” of the wheel is originally marked by paint dot (2) on

the wheel rim-flange. Properly assembled, the wheel rim’s paint

dot should be aligned with the tire’s paint dot as shown in left fig-

ure.

Whenever a tire is dismounted from its wheel, it should be

remounted so that the tire and wheel are matched. If the tire’s

paint dot cannot be located, a line should be scribed on the tire

and wheel before dismounting to assure that it is remounted in

the same position.

Inflation of Tires

The pressure recommended for any model is carefully calculated to give a satisfactory ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for three hours or more, or driven less than one mile) should

be checked monthly or before any extended trip. Set to the specifications on the tire placard located on the

driver’s side door lock pillar.

It is normal for tire pressure increase when the tires become hot during driving. Do not bleed or reduce tire pres-

sure after driving. Bleeding reduces the “Cold Inflation Pressure.”

Higher than Recommended Pressure Can Cause:

1) Hard ride

2) Tire bruising or carcass damage

3) Rapid tread wear at center of tire

Unequal Pressure on Same Axle Can Cause:

1) Uneven braking

2) Steering lead

3) Reduced handling

4) Swerve on acceleration

Valve caps should be kept on valves to keep dust and water out.

Page 250 of 687

Downloaded from www.Manualslib.com manuals search engine WHEELS AND TIRES 3F-7

Lower than Recommended Pressure Can Cause:

1) Tire squeal on turns

2) Hard steering

3) Rapid and uneven wear on the edges of the tread

4) Tire rim bruises and rupture

5) Tire cord breakage

6) High tire temperatures

7) Reduced handling

8) High fuel consumption

Tire placard

The tire placard is located on the driver’s side door lock pillar and should be referred to for tire information. The

placard lists the maximum load, tire size and cold tire pressure where applicable.

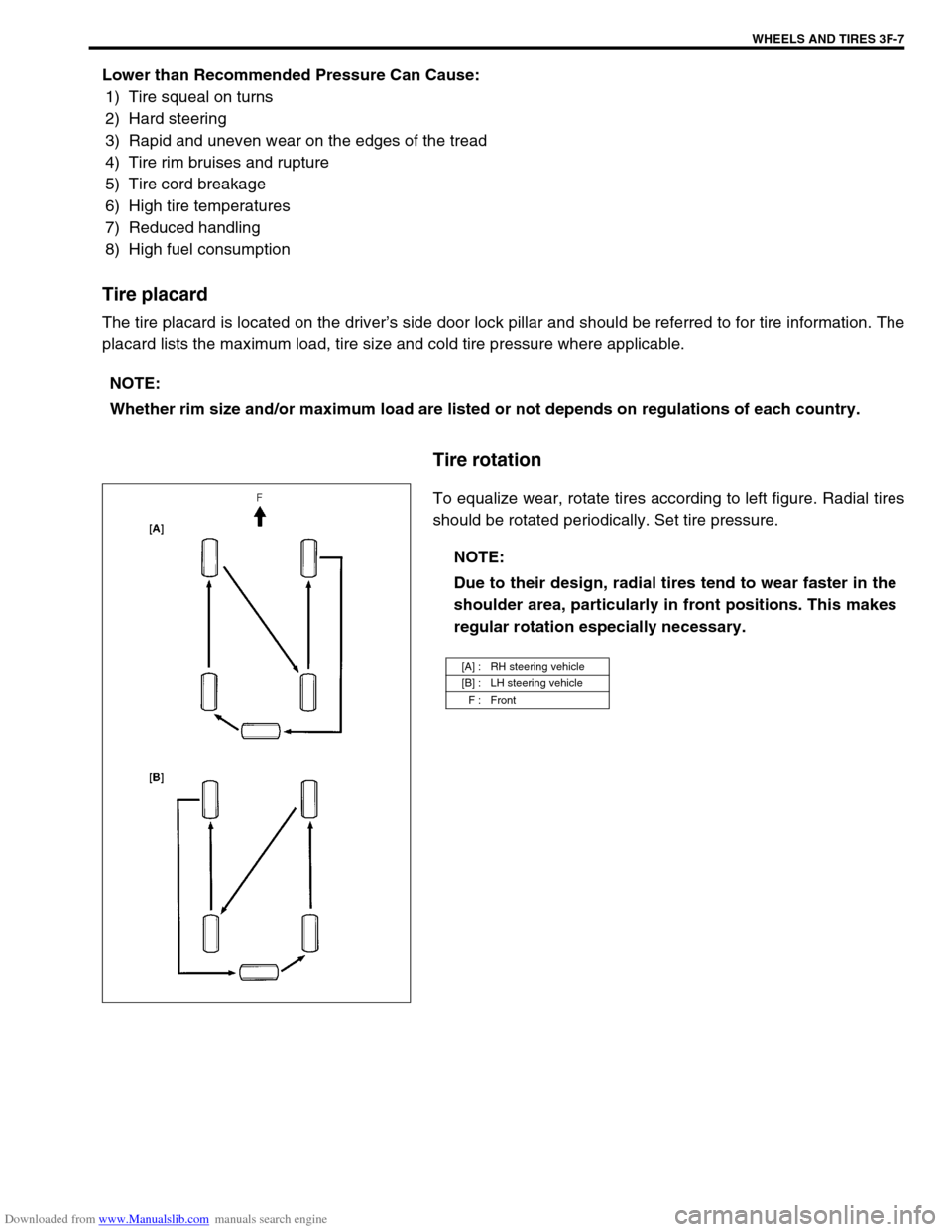

Tire rotation

To equalize wear, rotate tires according to left figure. Radial tires

should be rotated periodically. Set tire pressure. NOTE:

Whether rim size and/or maximum load are listed or not depends on regulations of each country.

NOTE:

Due to their design, radial tires tend to wear faster in the

shoulder area, particularly in front positions. This makes

regular rotation especially necessary.

[A] : RH steering vehicle

[B] : LH steering vehicle

F : Front