Engine fuel SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 362 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-5

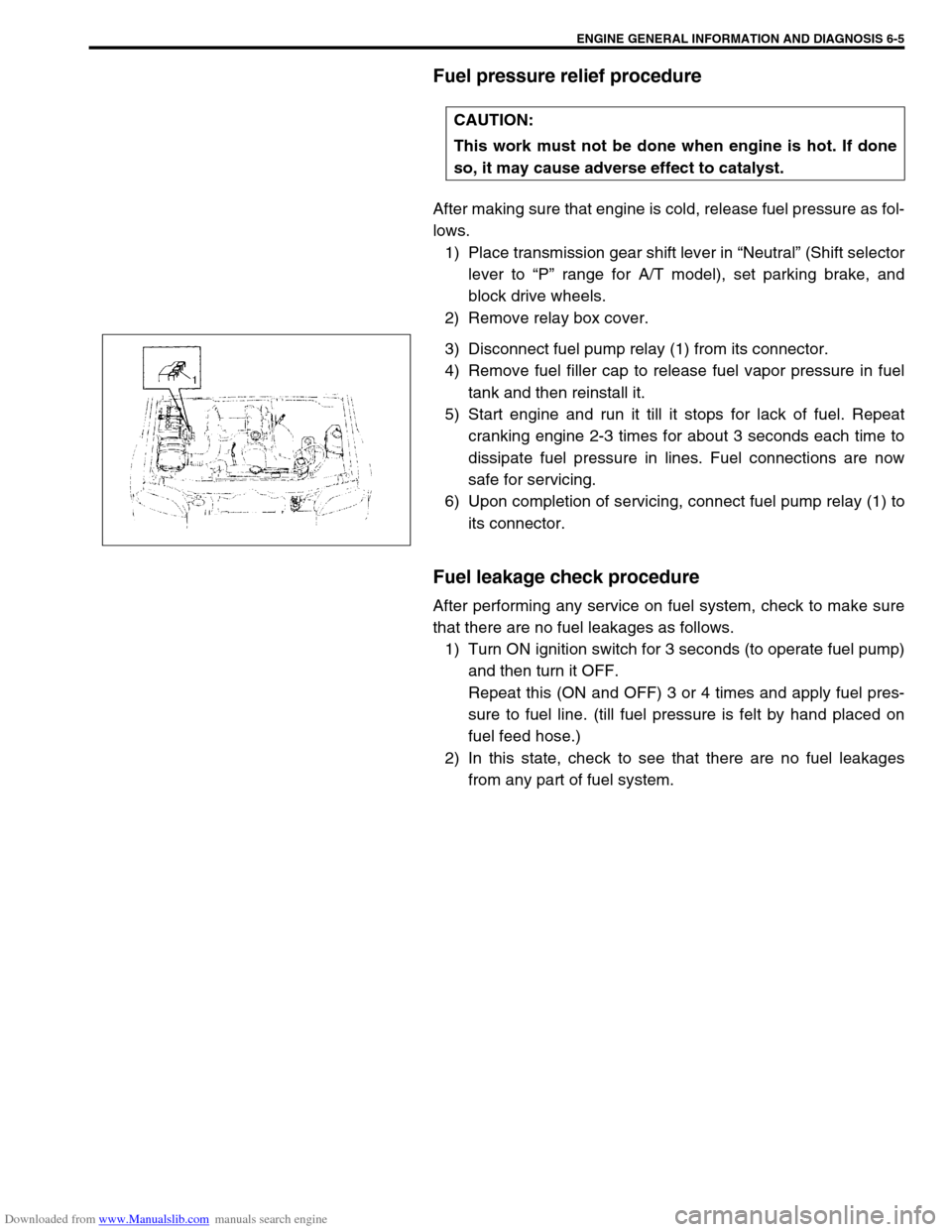

Fuel pressure relief procedure

After making sure that engine is cold, release fuel pressure as fol-

lows.

1) Place transmission gear shift lever in “Neutral” (Shift selector

lever to “P” range for A/T model), set parking brake, and

block drive wheels.

2) Remove relay box cover.

3) Disconnect fuel pump relay (1) from its connector.

4) Remove fuel filler cap to release fuel vapor pressure in fuel

tank and then reinstall it.

5) Start engine and run it till it stops for lack of fuel. Repeat

cranking engine 2-3 times for about 3 seconds each time to

dissipate fuel pressure in lines. Fuel connections are now

safe for servicing.

6) Upon completion of servicing, connect fuel pump relay (1) to

its connector.

Fuel leakage check procedure

After performing any service on fuel system, check to make sure

that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump)

and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply fuel pres-

sure to fuel line. (till fuel pressure is felt by hand placed on

fuel feed hose.)

2) In this state, check to see that there are no fuel leakages

from any part of fuel system. CAUTION:

This work must not be done when engine is hot. If done

so, it may cause adverse effect to catalyst.

Page 364 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-7

DRIVING CYCLE

A “Driving Cycle” consists of engine startup and engine shutoff.

2 DRIVING CYCLES DETECTION LOGIC

The malfunction detected in the first driving cycle is stored in

ECM memory (in the form of pending DTC and freeze frame data)

but the malfunction indicator lamp does not light at this time. It

lights up at the second detection of same malfunction also in the

next driving cycle.

PENDING DTC

Pending DTC means a DTC detected and stored temporarily at 1

driving cycle of the DTC which is detected in the 2 driving cycle

detection logic.

FREEZE FRAME DATA

ECM stores the engine and driving conditions (in the from of data

as shown in the figure) at the moment of the detection of a mal-

function in its memory. This data is called “Freeze frame data”.

Therefore, it is possible to know engine and driving conditions

(e.g., whether the engine was warm or not, where the vehicle was

running or stopped, where air / fuel mixture was lean or rich)

when a malfunction was detected by checking the freeze frame

data. Also, ECM has a function to store each freeze frame data

for three different malfunctions in the order as the malfunction is

detected. Utilizing this function, it is possible to know the order of

malfunctions that have been detected. Its use is helpful when

rechecking or diagnosing a trouble.

Priority of freeze frame data :

ECM has 4 frames where the freeze frame data can be stored.

The first frame stores the freeze frame data of the malfunction

which was detected first. However, the freeze frame data stored

in this frame is updated according to the priority described below.

(If malfunction as described in the upper square “1” below is

detected while the freeze frame data in the lower square “2” has

been stored, the freeze frame data “2” will be updated by the

freeze frame data “1”.)

[A] : An Example of Freeze Frame Data

[B] : 1st, 2nd or 3rd in parentheses here represents which position in the order

the malfunction is detected.

PRIORITY FREEZE FRAME DATA IN FRAME 1

1Freeze frame data at initial detection of mal-

function among misfire detected (P0300 –

P0304), fuel system too lean (P0171) and fuel

system too rich (P0172)

2Freeze frame data when a malfunction other

than those in “1” above is detected

Page 365 of 687

Downloaded from www.Manualslib.com manuals search engine 6-8 ENGINE GENERAL INFORMATION AND DIAGNOSIS

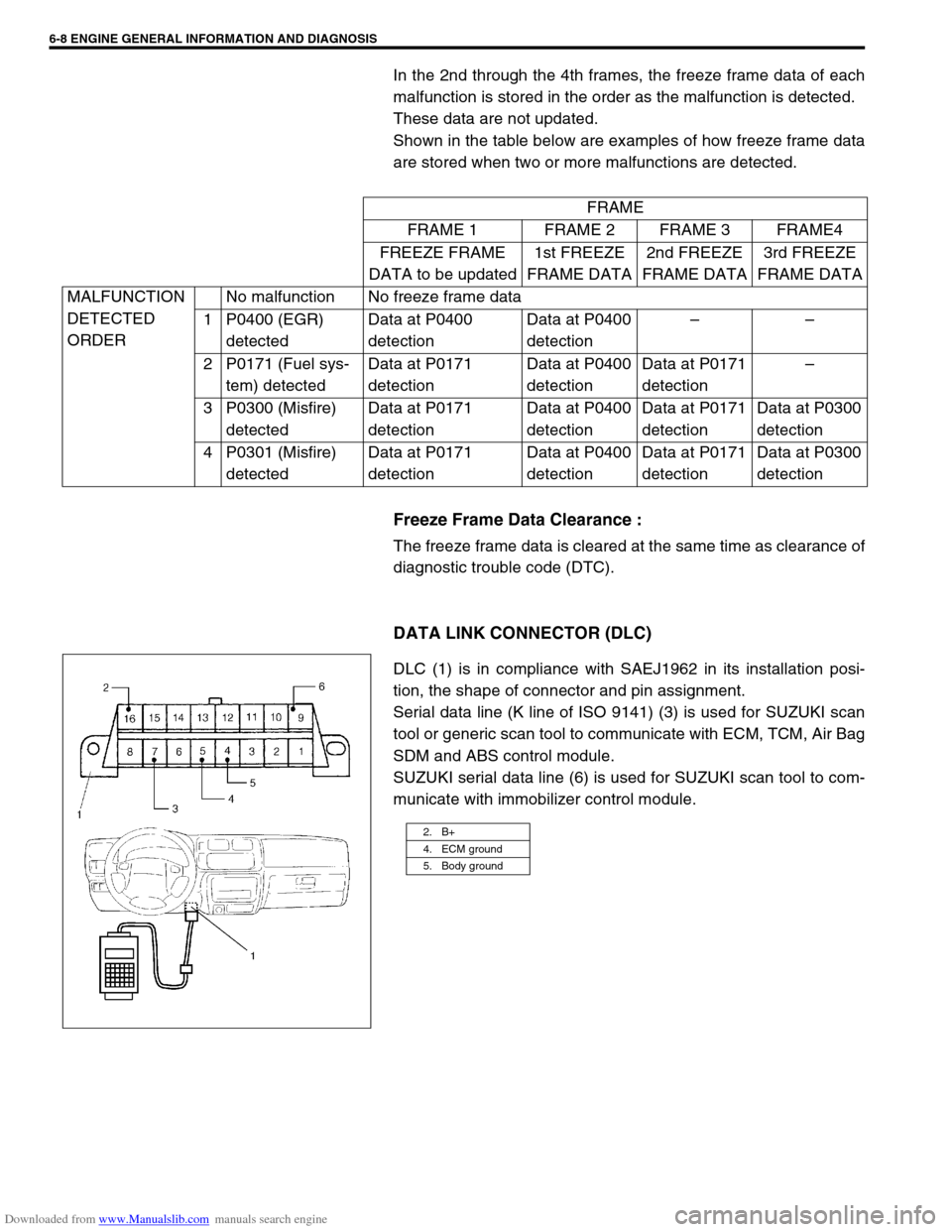

In the 2nd through the 4th frames, the freeze frame data of each

malfunction is stored in the order as the malfunction is detected.

These data are not updated.

Shown in the table below are examples of how freeze frame data

are stored when two or more malfunctions are detected.

Freeze Frame Data Clearance :

The freeze frame data is cleared at the same time as clearance of

diagnostic trouble code (DTC).

DATA LINK CONNECTOR (DLC)

DLC (1) is in compliance with SAEJ1962 in its installation posi-

tion, the shape of connector and pin assignment.

Serial data line (K line of ISO 9141) (3) is used for SUZUKI scan

tool or generic scan tool to communicate with ECM, TCM, Air Bag

SDM and ABS control module.

SUZUKI serial data line (6) is used for SUZUKI scan tool to com-

municate with immobilizer control module.FRAME

FRAME 1 FRAME 2 FRAME 3 FRAME4

FREEZE FRAME

DATA to be updated1st FREEZE

FRAME DATA2nd FREEZE

FRAME DATA3rd FREEZE

FRAME DATA

MALFUNCTION

DETECTED

ORDERNo malfunction No freeze frame data

1 P0400 (EGR)

detectedData at P0400

detectionData at P0400

detection––

2 P0171 (Fuel sys-

tem) detectedData at P0171

detectionData at P0400

detectionData at P0171

detection–

3 P0300 (Misfire)

detectedData at P0171

detectionData at P0400

detectionData at P0171

detectionData at P0300

detection

4 P0301 (Misfire)

detectedData at P0171

detectionData at P0400

detectionData at P0171

detectionData at P0300

detection

2. B+

4. ECM ground

5. Body ground

Page 367 of 687

Downloaded from www.Manualslib.com manuals search engine 6-10 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Precaution in Diagnosing Trouble

Don’t disconnect couplers from ECM, battery cable at battery, ECM ground wire harness from engine or

main fuse before confirming diagnostic information (DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information in ECM memory.

Diagnostic information stored in ECM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available and how to use it.

Priorities for diagnosing troubles (Vehicle with Immobilizer indicator lamp).

If multiple diagnostic trouble codes (DTCs) are stored, proceed to the flow table of the DTC which has

detected earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/P0172 (Fuel system too lean / too rich), DTC

P0300/P0301/P0302/P0303/P0304 (Misfire detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172 (Fuel system too lean / too rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304 (Misfire detected)

Be sure to read “Precautions for Electrical Circuit Service” in Section 0A before inspection and observe what

is written there.

ECM Replacement

When substituting a known-good ECM, check for following conditions. Neglecting this check may cause

damage to a known-good ECM.

–Resistance value of all relays, actuators is as specified respectively.

–MAP sensor and TP sensor are in good condition and none of power circuits of these sensors is shorted

to ground.AMBIENT TEMPERATURE TIME TO CUT POWER TO

ECM

Over 0 °C (32 °F) 60 sec. or longer

Under 0 °C (32 °F)Not specifiable.

Select a place with higher than

0 °C (32 °F) temperature.

Page 373 of 687

Downloaded from www.Manualslib.com manuals search engine 6-16 ENGINE GENERAL INFORMATION AND DIAGNOSIS

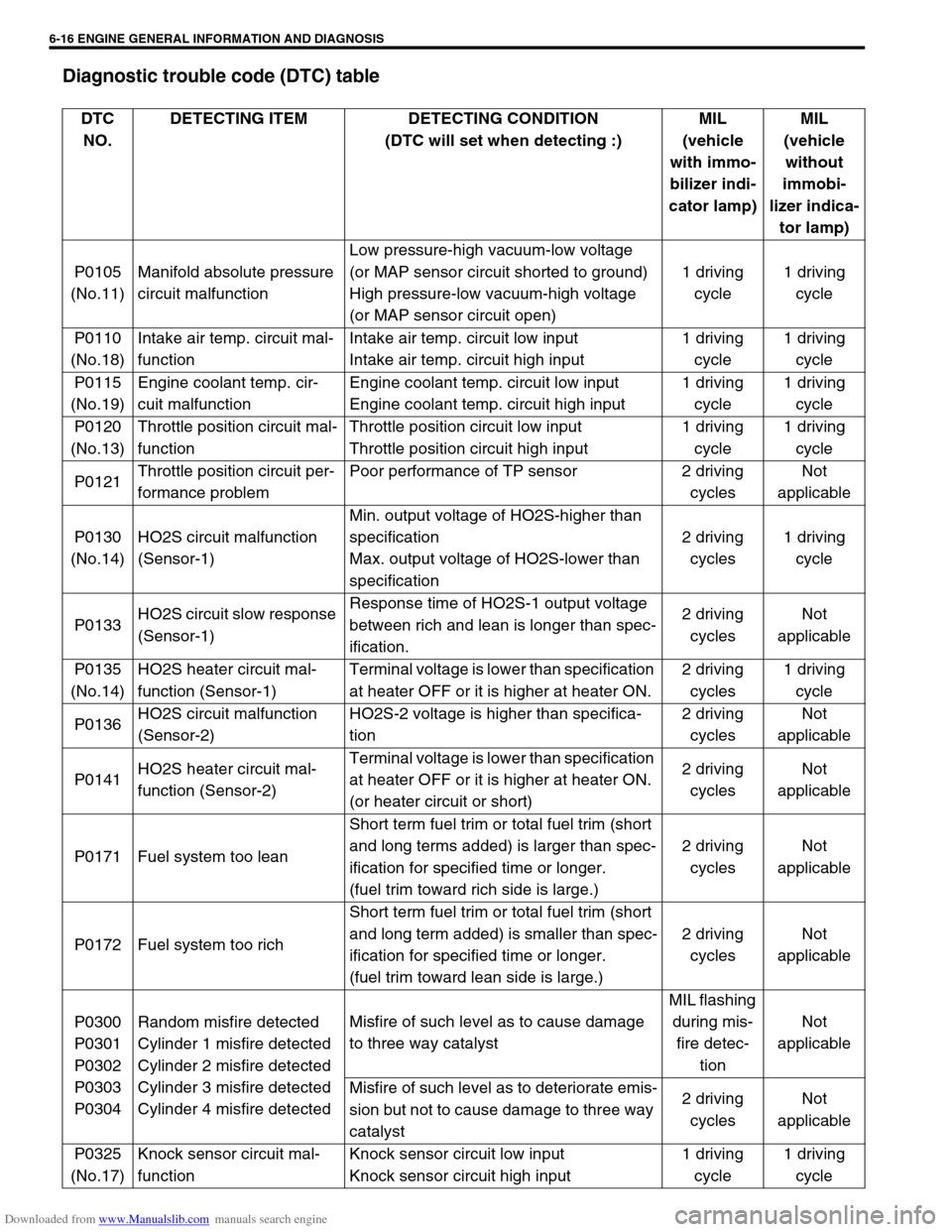

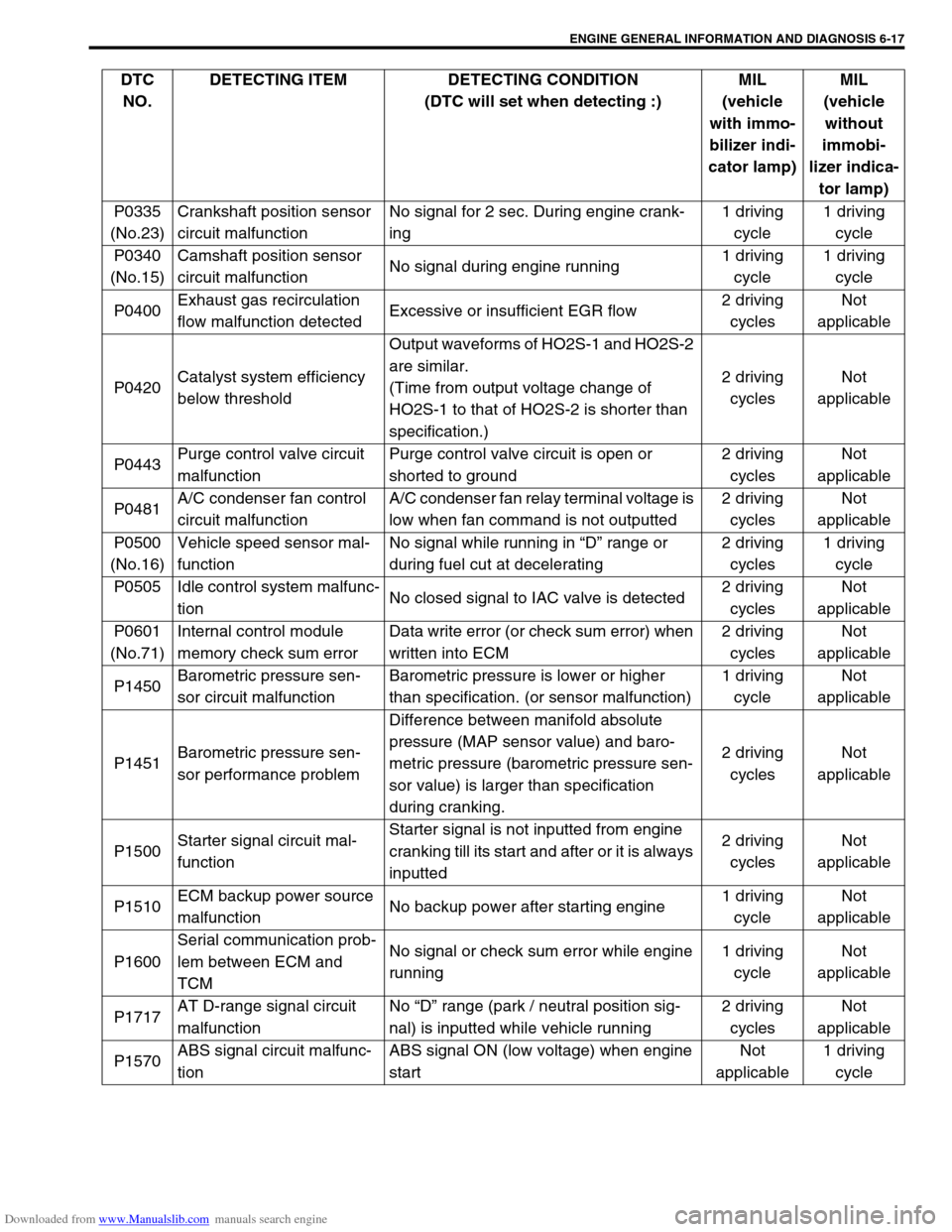

Diagnostic trouble code (DTC) table

DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

P0105

(No.11)Manifold absolute pressure

circuit malfunctionLow pressure-high vacuum-low voltage

(or MAP sensor circuit shorted to ground)

High pressure-low vacuum-high voltage

(or MAP sensor circuit open)1 driving

cycle1 driving

cycle

P0110

(No.18)Intake air temp. circuit mal-

functionIntake air temp. circuit low input

Intake air temp. circuit high input1 driving

cycle1 driving

cycle

P0115

(No.19)Engine coolant temp. cir-

cuit malfunctionEngine coolant temp. circuit low input

Engine coolant temp. circuit high input1 driving

cycle1 driving

cycle

P0120

(No.13)Throttle position circuit mal-

functionThrottle position circuit low input

Throttle position circuit high input1 driving

cycle1 driving

cycle

P0121Throttle position circuit per-

formance problemPoor performance of TP sensor 2 driving

cyclesNot

applicable

P0130

(No.14)HO2S circuit malfunction

(Sensor-1)Min. output voltage of HO2S-higher than

specification

Max. output voltage of HO2S-lower than

specification2 driving

cycles1 driving

cycle

P0133HO2S circuit slow response

(Sensor-1)Response time of HO2S-1 output voltage

between rich and lean is longer than spec-

ification.2 driving

cyclesNot

applicable

P0135

(No.14)HO2S heater circuit mal-

function (Sensor-1)Terminal voltage is lower than specification

at heater OFF or it is higher at heater ON.2 driving

cycles1 driving

cycle

P0136HO2S circuit malfunction

(Sensor-2)HO2S-2 voltage is higher than specifica-

tion2 driving

cyclesNot

applicable

P0141HO2S heater circuit mal-

function (Sensor-2)Terminal voltage is lower than specification

at heater OFF or it is higher at heater ON.

(or heater circuit or short)2 driving

cyclesNot

applicable

P0171 Fuel system too leanShort term fuel trim or total fuel trim (short

and long terms added) is larger than spec-

ification for specified time or longer.

(fuel trim toward rich side is large.)2 driving

cyclesNot

applicable

P0172 Fuel system too richShort term fuel trim or total fuel trim (short

and long term added) is smaller than spec-

ification for specified time or longer.

(fuel trim toward lean side is large.)2 driving

cyclesNot

applicable

P0300

P0301

P0302

P0303

P0304Random misfire detected

Cylinder 1 misfire detected

Cylinder 2 misfire detected

Cylinder 3 misfire detected

Cylinder 4 misfire detectedMisfire of such level as to cause damage

to three way catalystMIL flashing

during mis-

fire detec-

tionNot

applicable

Misfire of such level as to deteriorate emis-

sion but not to cause damage to three way

catalyst2 driving

cyclesNot

applicable

P0325

(No.17)Knock sensor circuit mal-

functionKnock sensor circuit low input

Knock sensor circuit high input1 driving

cycle1 driving

cycle

Page 374 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-17

P0335

(No.23)Crankshaft position sensor

circuit malfunctionNo signal for 2 sec. During engine crank-

ing1 driving

cycle1 driving

cycle

P0340

(No.15)Camshaft position sensor

circuit malfunctionNo signal during engine running1 driving

cycle1 driving

cycle

P0400Exhaust gas recirculation

flow malfunction detectedExcessive or insufficient EGR flow2 driving

cyclesNot

applicable

P0420Catalyst system efficiency

below thresholdOutput waveforms of HO2S-1 and HO2S-2

are similar.

(Time from output voltage change of

HO2S-1 to that of HO2S-2 is shorter than

specification.)2 driving

cyclesNot

applicable

P0443Purge control valve circuit

malfunctionPurge control valve circuit is open or

shorted to ground2 driving

cyclesNot

applicable

P0481A/C condenser fan control

circuit malfunctionA/C condenser fan relay terminal voltage is

low when fan command is not outputted2 driving

cyclesNot

applicable

P0500

(No.16)Vehicle speed sensor mal-

functionNo signal while running in “D” range or

during fuel cut at decelerating2 driving

cycles1 driving

cycle

P0505 Idle control system malfunc-

tionNo closed signal to IAC valve is detected2 driving

cyclesNot

applicable

P0601

(No.71)Internal control module

memory check sum errorData write error (or check sum error) when

written into ECM2 driving

cyclesNot

applicable

P1450 Barometric pressure sen-

sor circuit malfunctionBarometric pressure is lower or higher

than specification. (or sensor malfunction)1 driving

cycleNot

applicable

P1451Barometric pressure sen-

sor performance problemDifference between manifold absolute

pressure (MAP sensor value) and baro-

metric pressure (barometric pressure sen-

sor value) is larger than specification

during cranking.2 driving

cyclesNot

applicable

P1500Starter signal circuit mal-

functionStarter signal is not inputted from engine

cranking till its start and after or it is always

inputted2 driving

cyclesNot

applicable

P1510ECM backup power source

malfunctionNo backup power after starting engine1 driving

cycleNot

applicable

P1600Serial communication prob-

lem between ECM and

TCMNo signal or check sum error while engine

running1 driving

cycleNot

applicable

P1717AT D-range signal circuit

malfunctionNo “D” range (park / neutral position sig-

nal) is inputted while vehicle running2 driving

cyclesNot

applicable

P1570ABS signal circuit malfunc-

tionABS signal ON (low voltage) when engine

startNot

applicable1 driving

cycle DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

Page 377 of 687

Downloaded from www.Manualslib.com manuals search engine 6-20 ENGINE GENERAL INFORMATION AND DIAGNOSIS

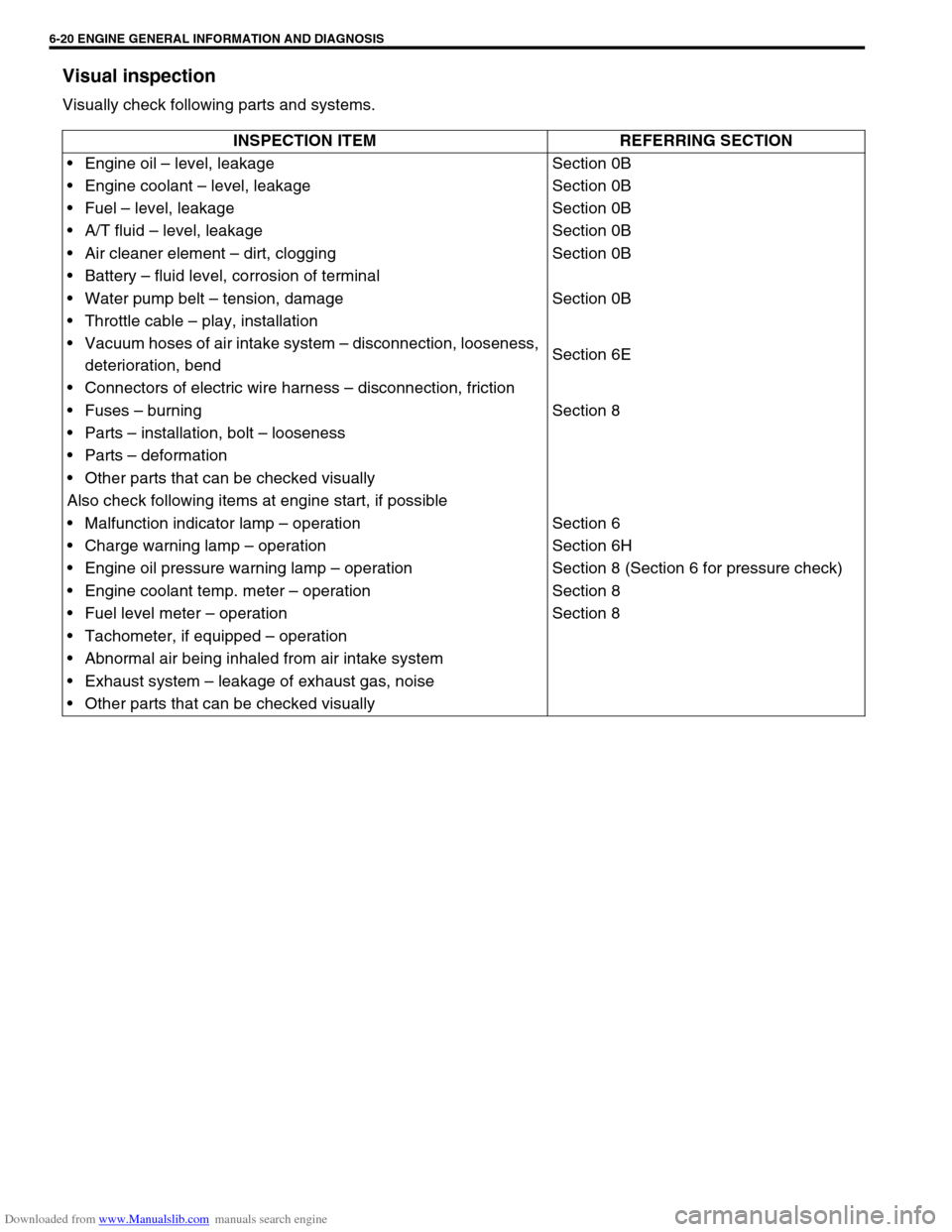

Visual inspection

Visually check following parts and systems.

INSPECTION ITEM REFERRING SECTION

Engine oil – level, leakage Section 0B

Engine coolant – level, leakage Section 0B

Fuel – level, leakage Section 0B

A/T fluid – level, leakage Section 0B

Air cleaner element – dirt, clogging Section 0B

Battery – fluid level, corrosion of terminal

Water pump belt – tension, damage Section 0B

Throttle cable – play, installation

Section 6E Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend

Connectors of electric wire harness – disconnection, friction

Fuses – burning Section 8

Parts – installation, bolt – looseness

Parts – deformation

Other parts that can be checked visually

Also check following items at engine start, if possible

Malfunction indicator lamp – operation Section 6

Charge warning lamp – operation Section 6H

Engine oil pressure warning lamp – operation Section 8 (Section 6 for pressure check)

Engine coolant temp. meter – operation Section 8

Fuel level meter – operation Section 8

Tachometer, if equipped – operation

Abnormal air being inhaled from air intake system

Exhaust system – leakage of exhaust gas, noise

Other parts that can be checked visually

Page 379 of 687

![SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 6-22 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 7 / [C] Fig. 3 for Step 810 Check fuel supply as foll SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 6-22 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 7 / [C] Fig. 3 for Step 810 Check fuel supply as foll](/img/20/7588/w960_7588-378.png)

Downloaded from www.Manualslib.com manuals search engine 6-22 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[A] Fig. 1 for Step 5 / [B] Fig. 2 for Step 7 / [C] Fig. 3 for Step 810 Check fuel supply as follows :

1) Check to make sure that enough fuel is filled

in fuel tank.

2) Turn ON ignition switch for 2 seconds and

then OFF. See Fig. 5.

Is fuel return pressure (returning sounds) felt

from fuel feed hose (1) when ignition switch is

turned ON?Go to Step 12. Go to Step 11.

11 Check fuel pump for operating.

1) Was fuel pump operating sound heard from

fuel filler for about 2 seconds after ignition

switch ON and stop?Go to “Diag. Flow Table

B-3”.Go to “Diag. Flow Table

B-2”.

12 Check ignition spark as follows :

1) Disconnect injector couplers.

2) Remove spark plugs and connect them to

high tension cords.

3) Ground spark plugs.

4) Crank engine and check if each spark plug

sparks.

Is it in good condition?Go to Step 13. Go to “Ignition Spark Test”

in Section 6F.

13 Check fuel injector for operation as follows :

1) Install spark plugs and connect injector con-

nectors.

2) Using sound scope (2), check operating

sound of each injector (3) when cranking

engine. See Fig. 6.

Was injector operating sound heard from all

injectors?Go to “Engine Diagnosis

Table”.Go to “Diag. Flow Table

B-1”. Step Action Yes No

[B] : When not using SUZUKI scan tool :

[C] : When using SUZUKI scan tool

Page 380 of 687

![SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab](/img/20/7588/w960_7588-379.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

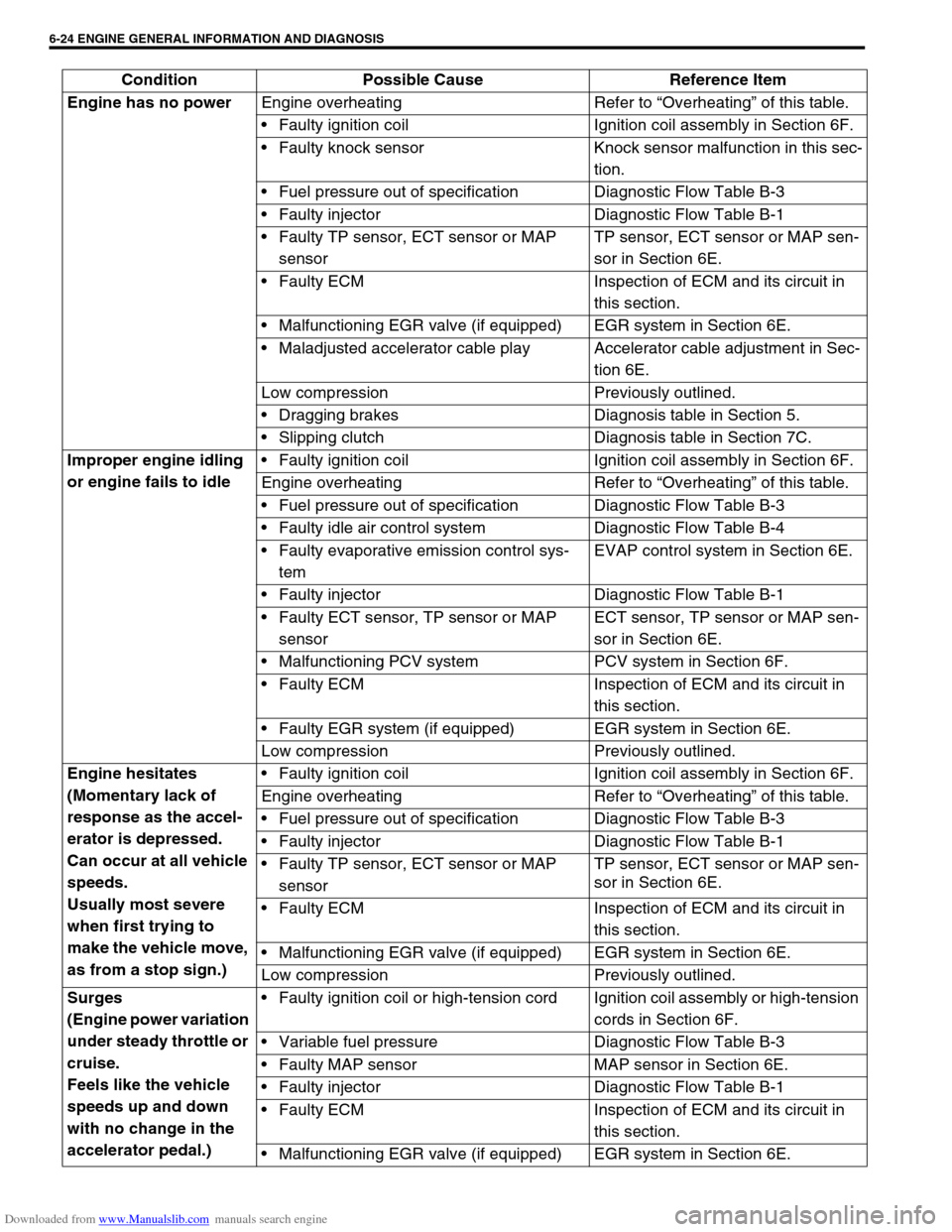

Engine diagnosis table

Perform troubleshooting referring to following table when ECM has no DTC and no abnormality found in visual

inspection and engine basic inspection previously.

Condition Possible Cause Reference Item

Hard Starting

(Engine cranks OK)Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty CMP sensing rotor or CKP sensing

rotorCMP sensing rotor or CKP sensing

rotor inspection in Section 6E.

Faulty idle air control system Diagnostic Flow Table B-4

Faulty ECT sensor, TP sensor, CKP sen-

sor, CMP sensor or MAP sensorECT sensor, TP sensor, CKP sensor,

CMP sensor or MAP sensor in Sec-

tion 6E.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty fuel injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning PCV system PCV system in Section 6E.

Low compression Compression check in Section 6A1.

Improper valve lash Valve lash in Section 6A1.

Improper valve timing Timing chain and chain tensioner in

Section 6A1.

Compression leak from valve seat Valves and cylinder head in Section

6A1.

Sticky valve stem Valves and cylinder head in Section

6A1.

Weak or damaged valve springs Valves and cylinder head in Section

6A1.

Compression leak at cylinder head gasket Valves and cylinder head in Section

6A1.

Sticking or damaged piston ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston, ring or cylinder Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Page 381 of 687

Downloaded from www.Manualslib.com manuals search engine 6-24 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Engine has no power

Engine overheating Refer to “Overheating” of this table.

Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Maladjusted accelerator cable play Accelerator cable adjustment in Sec-

tion 6E.

Low compression Previously outlined.

Dragging brakes Diagnosis table in Section 5.

Slipping clutch Diagnosis table in Section 7C.

Improper engine idling

or engine fails to idleFaulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty idle air control system Diagnostic Flow Table B-4

Faulty evaporative emission control sys-

temEVAP control system in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECT sensor, TP sensor or MAP

sensorECT sensor, TP sensor or MAP sen-

sor in Section 6E.

Malfunctioning PCV system PCV system in Section 6F.

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Engine hesitates

(Momentary lack of

response as the accel-

erator is depressed.

Can occur at all vehicle

speeds.

Usually most severe

when first trying to

make the vehicle move,

as from a stop sign.)Faulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Surges

(Engine power variation

under steady throttle or

cruise.

Feels like the vehicle

speeds up and down

with no change in the

accelerator pedal.)Faulty ignition coil or high-tension cord Ignition coil assembly or high-tension

cords in Section 6F.

Variable fuel pressure Diagnostic Flow Table B-3

Faulty MAP sensor MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E. Condition Possible Cause Reference Item