Ps sensor SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 232 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-13

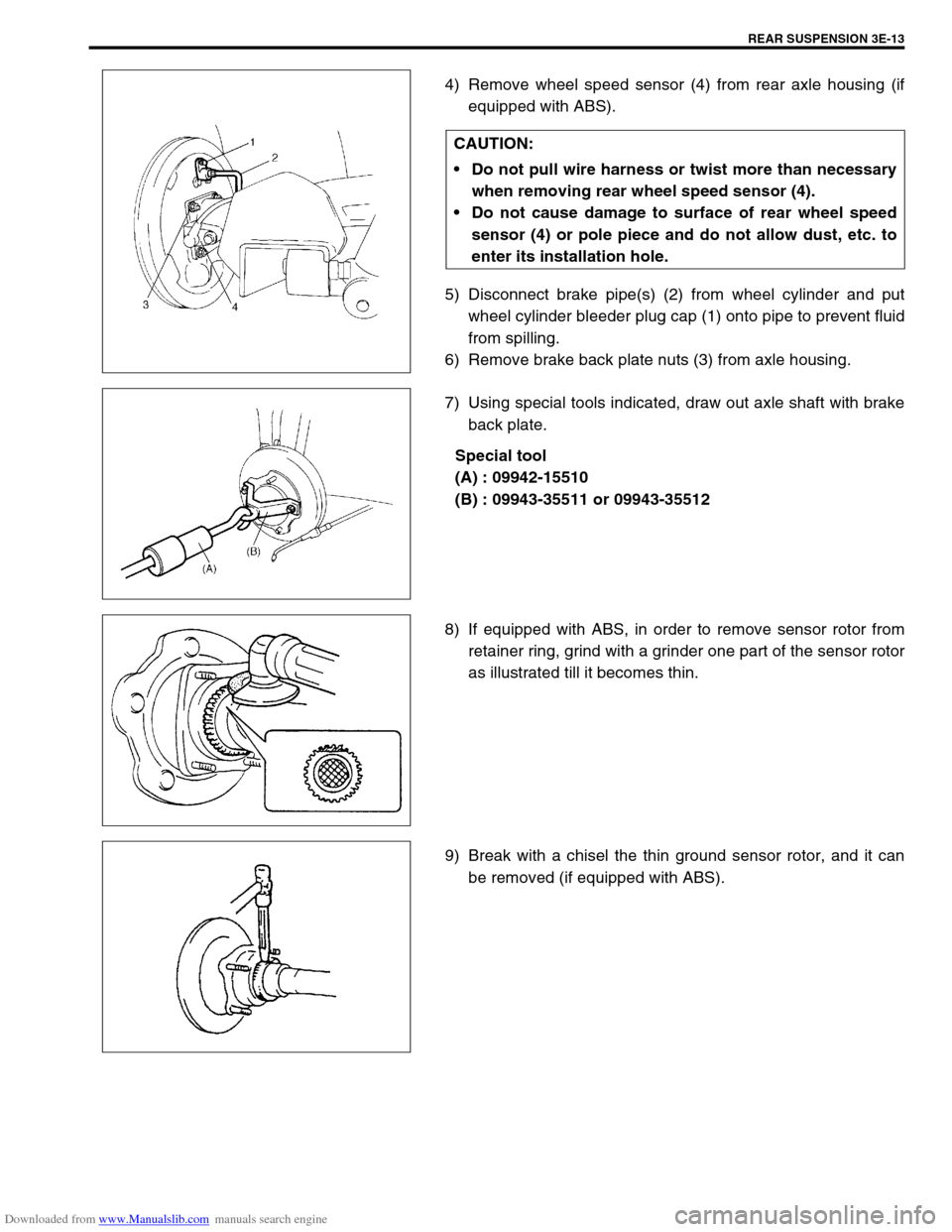

4) Remove wheel speed sensor (4) from rear axle housing (if

equipped with ABS).

5) Disconnect brake pipe(s) (2) from wheel cylinder and put

wheel cylinder bleeder plug cap (1) onto pipe to prevent fluid

from spilling.

6) Remove brake back plate nuts (3) from axle housing.

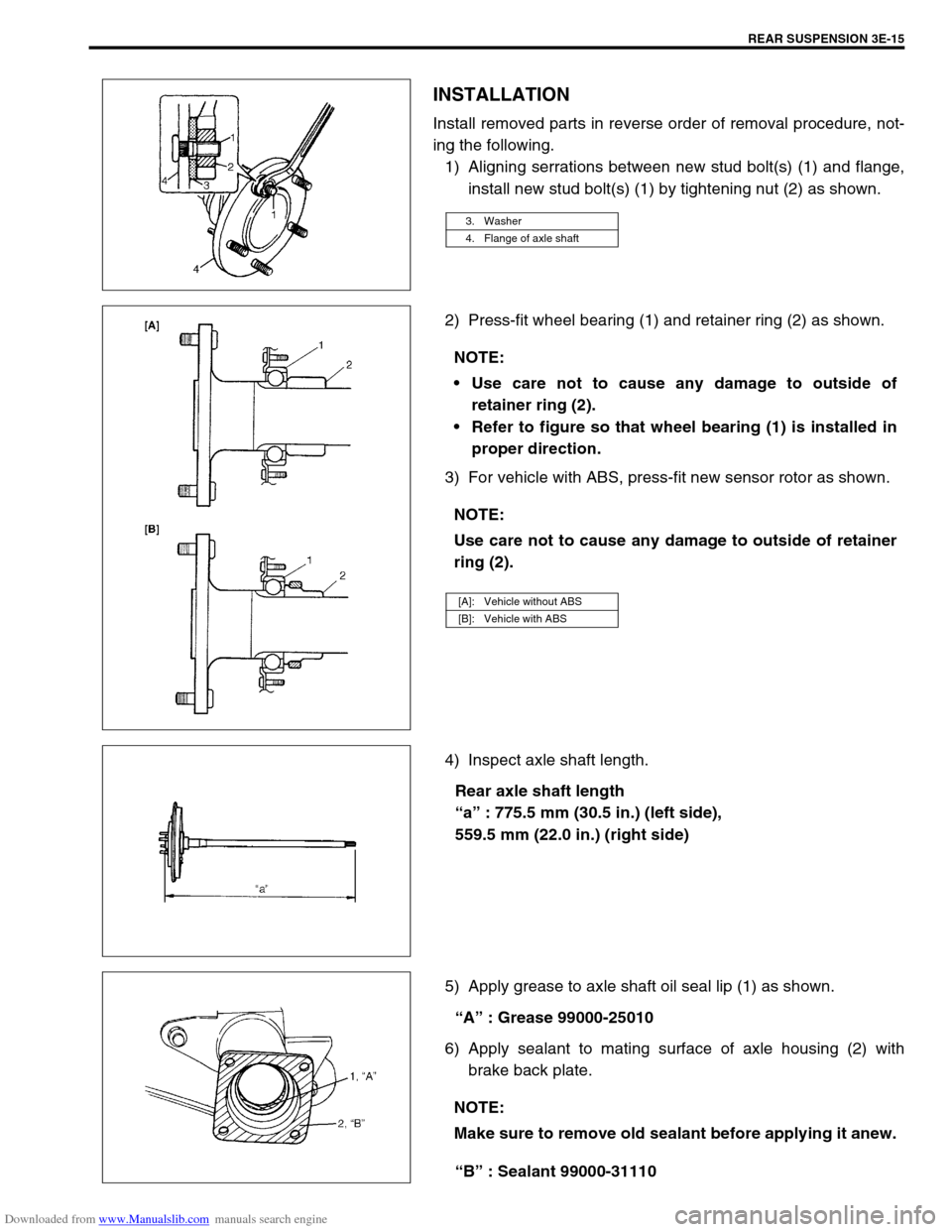

7) Using special tools indicated, draw out axle shaft with brake

back plate.

Special tool

(A) : 09942-15510

(B) : 09943-35511 or 09943-35512

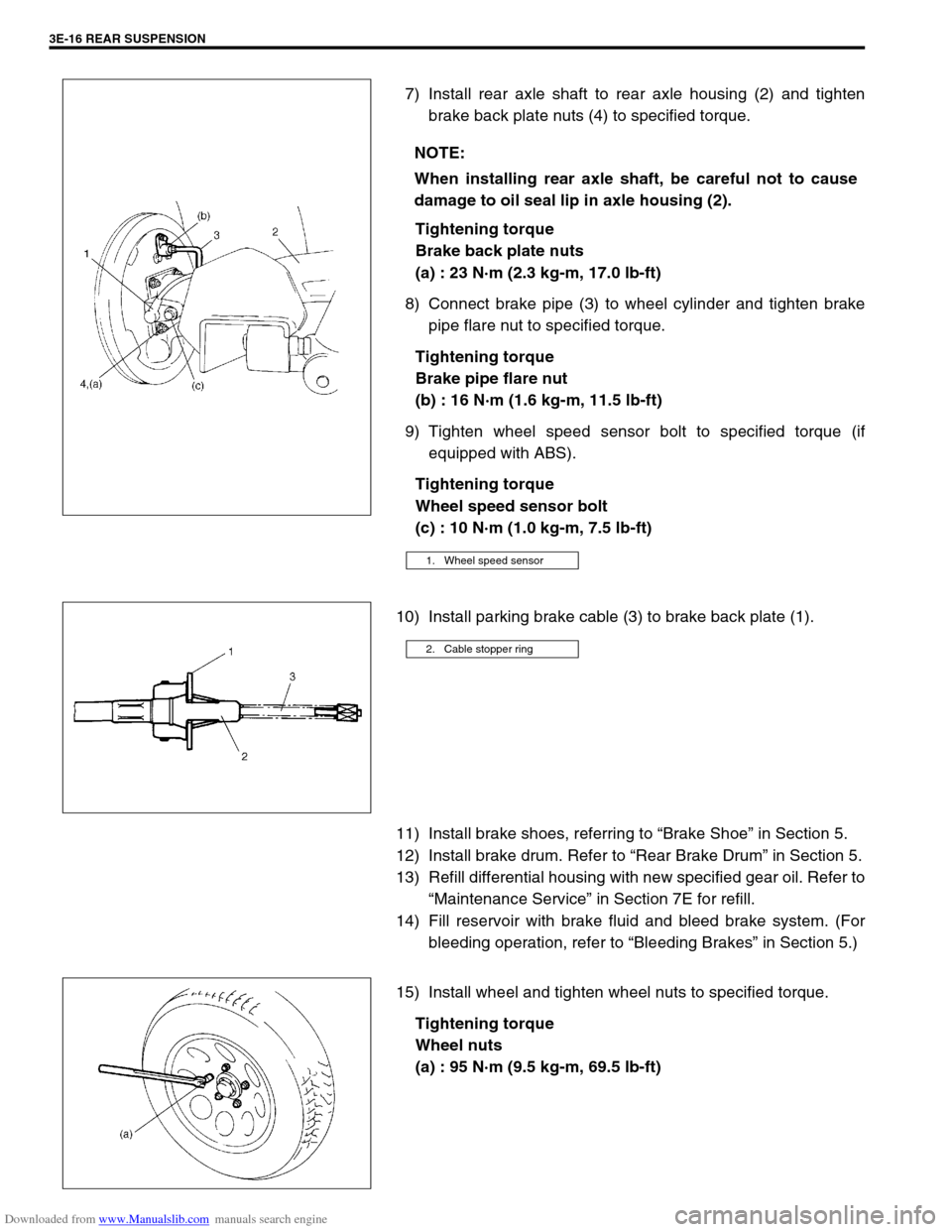

8) If equipped with ABS, in order to remove sensor rotor from

retainer ring, grind with a grinder one part of the sensor rotor

as illustrated till it becomes thin.

9) Break with a chisel the thin ground sensor rotor, and it can

be removed (if equipped with ABS). CAUTION:

Do not pull wire harness or twist more than necessary

when removing rear wheel speed sensor (4).

Do not cause damage to surface of rear wheel speed

sensor (4) or pole piece and do not allow dust, etc. to

enter its installation hole.

Page 234 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-15

INSTALLATION

Install removed parts in reverse order of removal procedure, not-

ing the following.

1) Aligning serrations between new stud bolt(s) (1) and flange,

install new stud bolt(s) (1) by tightening nut (2) as shown.

2) Press-fit wheel bearing (1) and retainer ring (2) as shown.

3) For vehicle with ABS, press-fit new sensor rotor as shown.

4) Inspect axle shaft length.

Rear axle shaft length

“a” : 775.5 mm (30.5 in.) (left side),

559.5 mm (22.0 in.) (right side)

5) Apply grease to axle shaft oil seal lip (1) as shown.

“A” : Grease 99000-25010

6) Apply sealant to mating surface of axle housing (2) with

brake back plate.

“B” : Sealant 99000-31110

3. Washer

4. Flange of axle shaft

NOTE:

Use care not to cause any damage to outside of

retainer ring (2).

Refer to figure so that wheel bearing (1) is installed in

proper direction.

NOTE:

Use care not to cause any damage to outside of retainer

ring (2).

[A]: Vehicle without ABS

[B]: Vehicle with ABS

NOTE:

Make sure to remove old sealant before applying it anew.

Page 235 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-16 REAR SUSPENSION

7) Install rear axle shaft to rear axle housing (2) and tighten

brake back plate nuts (4) to specified torque.

Tightening torque

Brake back plate nuts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

8) Connect brake pipe (3) to wheel cylinder and tighten brake

pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut

(b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

9) Tighten wheel speed sensor bolt to specified torque (if

equipped with ABS).

Tightening torque

Wheel speed sensor bolt

(c) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

10) Install parking brake cable (3) to brake back plate (1).

11) Install brake shoes, referring to “Brake Shoe” in Section 5.

12) Install brake drum. Refer to “Rear Brake Drum” in Section 5.

13) Refill differential housing with new specified gear oil. Refer to

“Maintenance Service” in Section 7E for refill.

14) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, refer to “Bleeding Brakes” in Section 5.)

15) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.5 lb-ft) NOTE:

When installing rear axle shaft, be careful not to cause

damage to oil seal lip in axle housing (2).

1. Wheel speed sensor

2. Cable stopper ring

Page 241 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-22 REAR SUSPENSION

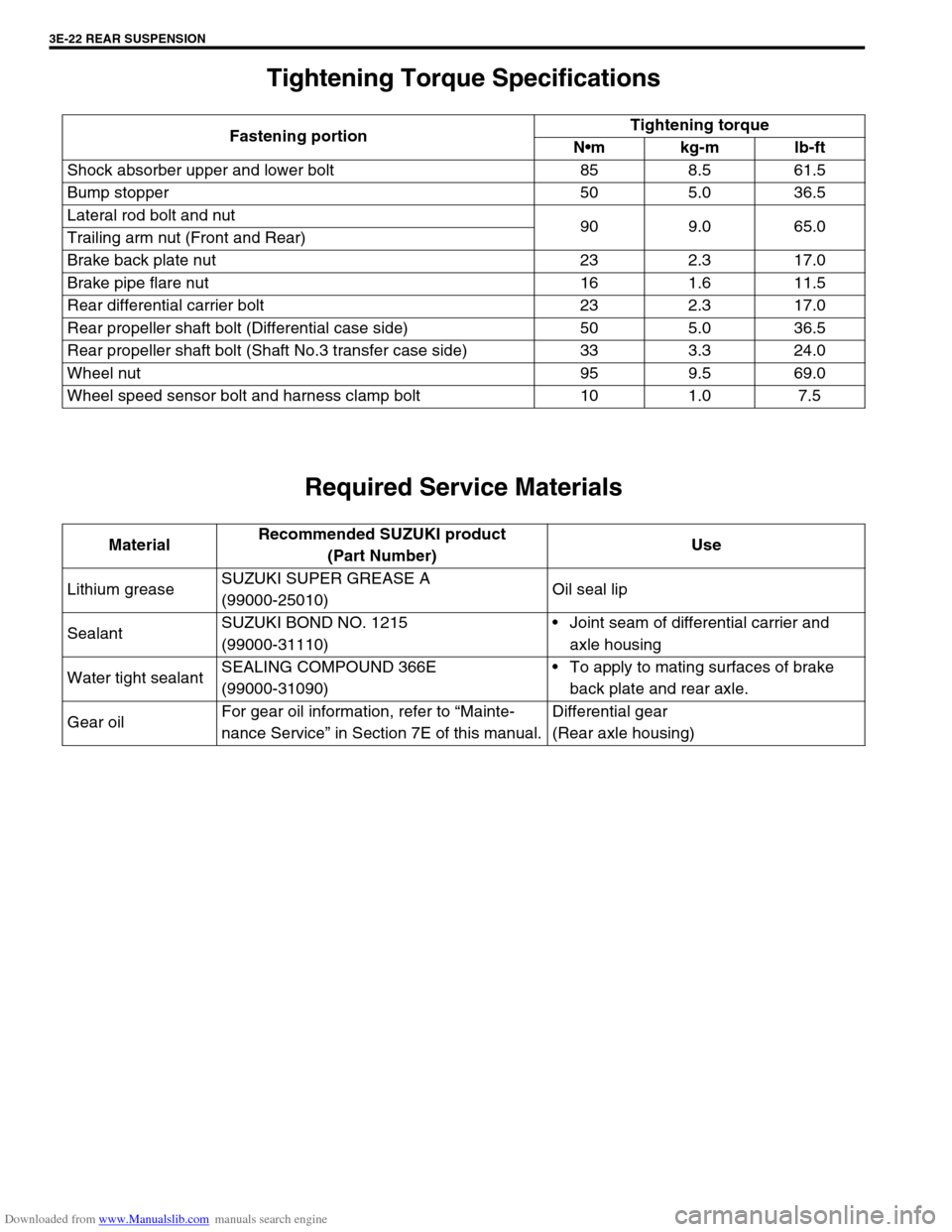

Tightening Torque Specifications

Required Service Materials

Fastening portionTightening torque

Nm kg-m lb-ft

Shock absorber upper and lower bolt 85 8.5 61.5

Bump stopper 50 5.0 36.5

Lateral rod bolt and nut

90 9.0 65.0

Trailing arm nut (Front and Rear)

Brake back plate nut 23 2.3 17.0

Brake pipe flare nut 16 1.6 11.5

Rear differential carrier bolt 23 2.3 17.0

Rear propeller shaft bolt (Differential case side) 50 5.0 36.5

Rear propeller shaft bolt (Shaft No.3 transfer case side) 33 3.3 24.0

Wheel nut 95 9.5 69.0

Wheel speed sensor bolt and harness clamp bolt 10 1.0 7.5

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium greaseSUZUKI SUPER GREASE A

(99000-25010)Oil seal lip

SealantSUZUKI BOND NO. 1215

(99000-31110)Joint seam of differential carrier and

axle housing

Water tight sealantSEALING COMPOUND 366E

(99000-31090)To apply to mating surfaces of brake

back plate and rear axle.

Gear oilFor gear oil information, refer to “Mainte-

nance Service” in Section 7E of this manual.Differential gear

(Rear axle housing)

Page 266 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-5

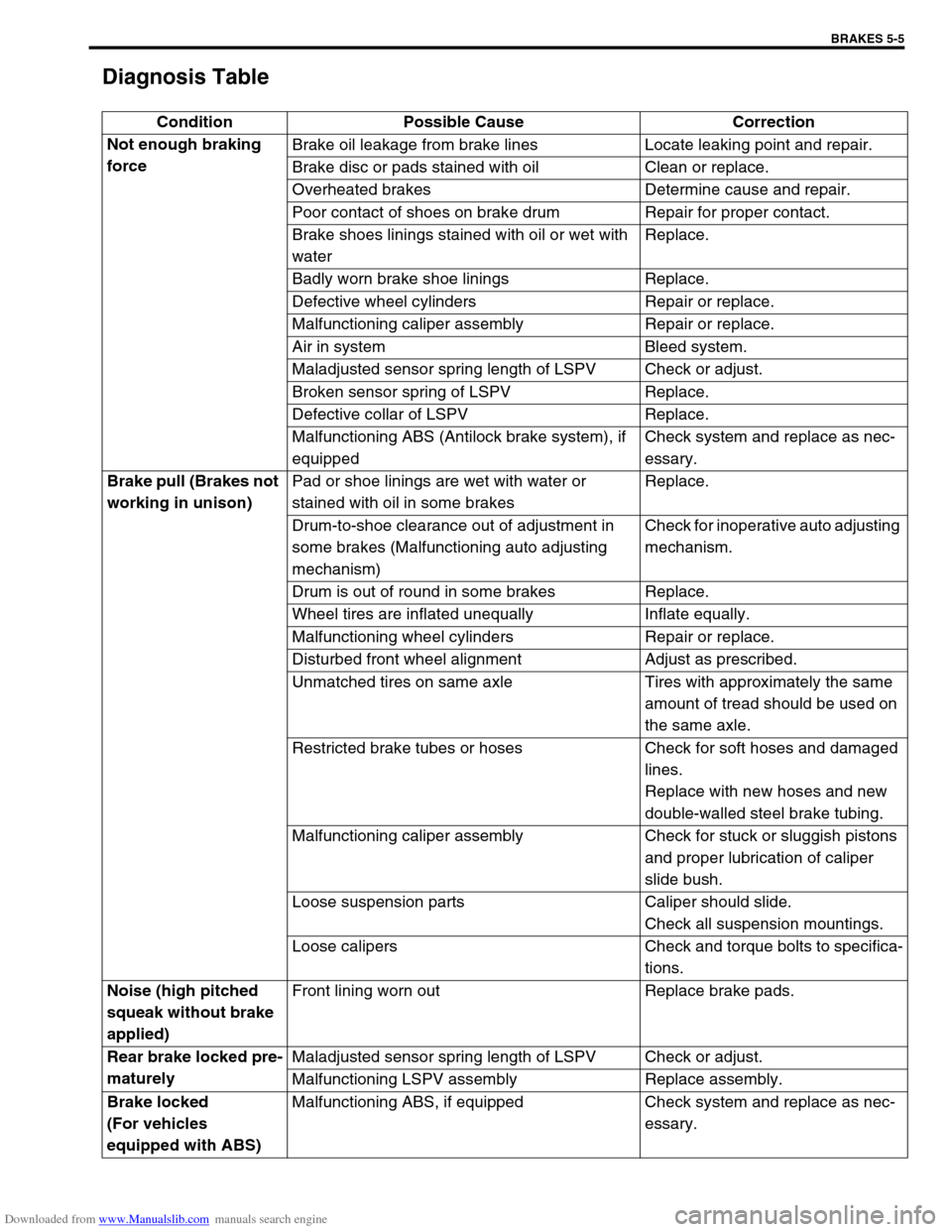

Diagnosis Table

Condition Possible Cause Correction

Not enough braking

forceBrake oil leakage from brake lines Locate leaking point and repair.

Brake disc or pads stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Poor contact of shoes on brake drum Repair for proper contact.

Brake shoes linings stained with oil or wet with

waterReplace.

Badly worn brake shoe linings Replace.

Defective wheel cylinders Repair or replace.

Malfunctioning caliper assembly Repair or replace.

Air in system Bleed system.

Maladjusted sensor spring length of LSPV Check or adjust.

Broken sensor spring of LSPV Replace.

Defective collar of LSPV Replace.

Malfunctioning ABS (Antilock brake system), if

equippedCheck system and replace as nec-

essary.

Brake pull (Brakes not

working in unison)Pad or shoe linings are wet with water or

stained with oil in some brakesReplace.

Drum-to-shoe clearance out of adjustment in

some brakes (Malfunctioning auto adjusting

mechanism)Check for inoperative auto adjusting

mechanism.

Drum is out of round in some brakes Replace.

Wheel tires are inflated unequally Inflate equally.

Malfunctioning wheel cylinders Repair or replace.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same

amount of tread should be used on

the same axle.

Restricted brake tubes or hoses Check for soft hoses and damaged

lines.

Replace with new hoses and new

double-walled steel brake tubing.

Malfunctioning caliper assembly Check for stuck or sluggish pistons

and proper lubrication of caliper

slide bush.

Loose suspension parts Caliper should slide.

Check all suspension mountings.

Loose calipers Check and torque bolts to specifica-

tions.

Noise (high pitched

squeak without brake

applied)Front lining worn out Replace brake pads.

Rear brake locked pre-

maturelyMaladjusted sensor spring length of LSPV Check or adjust.

Malfunctioning LSPV assembly Replace assembly.

Brake locked

(For vehicles

equipped with ABS)Malfunctioning ABS, if equipped Check system and replace as nec-

essary.

Page 296 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-35

7) Using special tools, draw out rear axle shaft with brake back

plate.

Special tool

(A) : 09943-35511

(B) : 09942-15510

8) Remove wheel bearing retainer and wheel sensor ring (if

equipped with ABS), refer to “Rear Axle Shaft and Wheel

Bearing” in Section 3E.

9) Remove brake back plate from axle shaft.

INSTALLATION

1) Install wheel cylinder, and tighten wheel cylinder bolts to

specified torque. Refer to “Wheel Cylinder” in this section.

2) Install brake back plate (2) to axle shaft (1).

3) For installation procedure here after perform “Rear Axle

Shaft and Wheel Bearing” in Section 3E.

3. Wheel bearing

4. Retainer ring

Page 318 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8E

5E

9

10

10A

10B

10

10A

10B

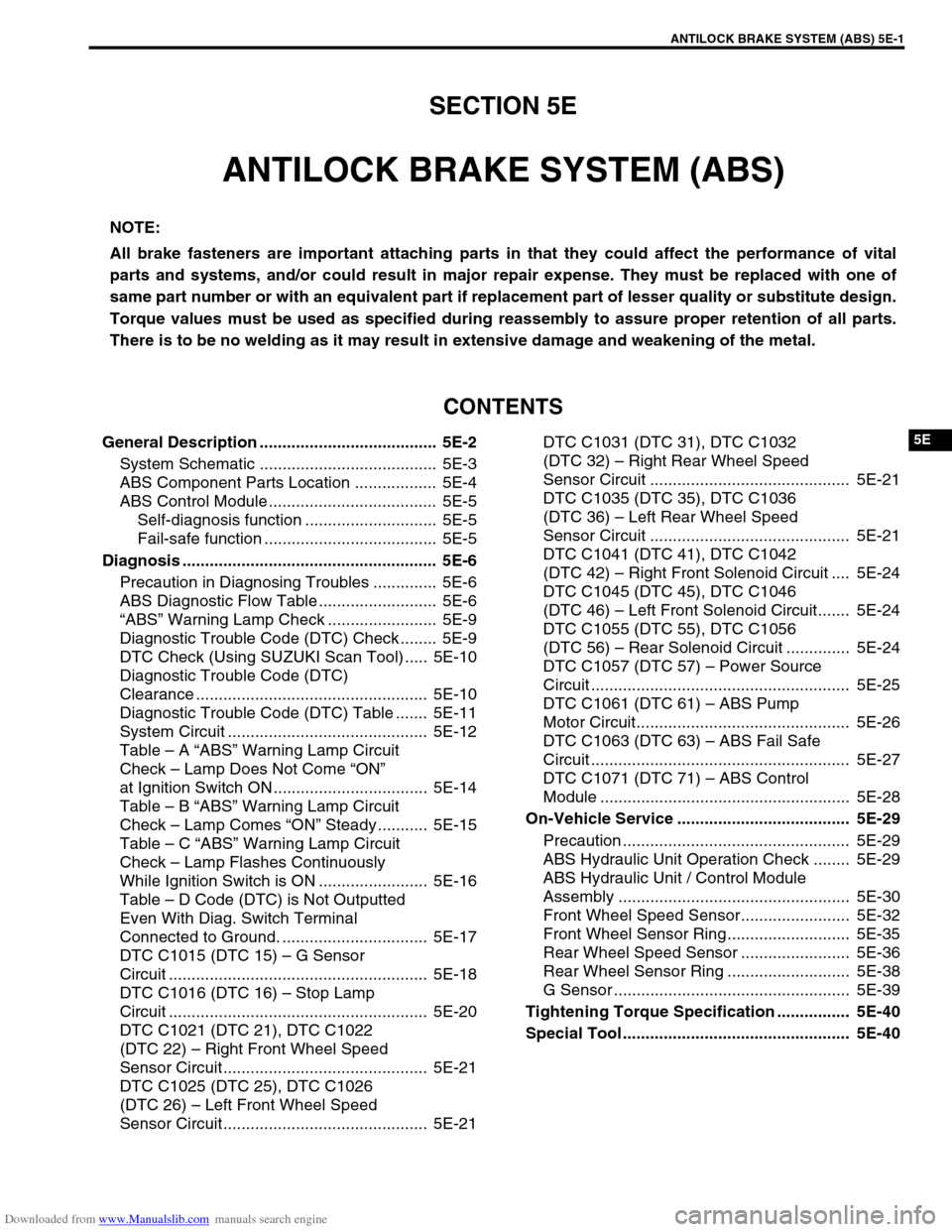

SECTION 5E

ANTILOCK BRAKE SYSTEM (ABS)

CONTENTS

General Description ....................................... 5E-2

System Schematic ....................................... 5E-3

ABS Component Parts Location .................. 5E-4

ABS Control Module ..................................... 5E-5

Self-diagnosis function ............................. 5E-5

Fail-safe function ...................................... 5E-5

Diagnosis ........................................................ 5E-6

Precaution in Diagnosing Troubles .............. 5E-6

ABS Diagnostic Flow Table .......................... 5E-6

“ABS” Warning Lamp Check ........................ 5E-9

Diagnostic Trouble Code (DTC) Check ........ 5E-9

DTC Check (Using SUZUKI Scan Tool) ..... 5E-10

Diagnostic Trouble Code (DTC)

Clearance ................................................... 5E-10

Diagnostic Trouble Code (DTC) Table ....... 5E-11

System Circuit ............................................ 5E-12

Table – A “ABS” Warning Lamp Circuit

Check – Lamp Does Not Come “ON”

at Ignition Switch ON .................................. 5E-14

Table – B “ABS” Warning Lamp Circuit

Check – Lamp Comes “ON” Steady ........... 5E-15

Table – C “ABS” Warning Lamp Circuit

Check – Lamp Flashes Continuously

While Ignition Switch is ON ........................ 5E-16

Table – D Code (DTC) is Not Outputted

Even With Diag. Switch Terminal

Connected to Ground. ................................ 5E-17

DTC C1015 (DTC 15) – G Sensor

Circuit ......................................................... 5E-18

DTC C1016 (DTC 16) – Stop Lamp

Circuit ......................................................... 5E-20

DTC C1021 (DTC 21), DTC C1022

(DTC 22) – Right Front Wheel Speed

Sensor Circuit ............................................. 5E-21

DTC C1025 (DTC 25), DTC C1026

(DTC 26) – Left Front Wheel Speed

Sensor Circuit ............................................. 5E-21DTC C1031 (DTC 31), DTC C1032

(DTC 32) – Right Rear Wheel Speed

Sensor Circuit ............................................ 5E-21

DTC C1035 (DTC 35), DTC C1036

(DTC 36) – Left Rear Wheel Speed

Sensor Circuit ............................................ 5E-21

DTC C1041 (DTC 41), DTC C1042

(DTC 42) – Right Front Solenoid Circuit .... 5E-24

DTC C1045 (DTC 45), DTC C1046

(DTC 46) – Left Front Solenoid Circuit....... 5E-24

DTC C1055 (DTC 55), DTC C1056

(DTC 56) – Rear Solenoid Circuit .............. 5E-24

DTC C1057 (DTC 57) – Power Source

Circuit ......................................................... 5E-25

DTC C1061 (DTC 61) – ABS Pump

Motor Circuit............................................... 5E-26

DTC C1063 (DTC 63) – ABS Fail Safe

Circuit ......................................................... 5E-27

DTC C1071 (DTC 71) – ABS Control

Module ....................................................... 5E-28

On-Vehicle Service ...................................... 5E-29

Precaution .................................................. 5E-29

ABS Hydraulic Unit Operation Check ........ 5E-29

ABS Hydraulic Unit / Control Module

Assembly ................................................... 5E-30

Front Wheel Speed Sensor........................ 5E-32

Front Wheel Sensor Ring........................... 5E-35

Rear Wheel Speed Sensor ........................ 5E-36

Rear Wheel Sensor Ring ........................... 5E-38

G Sensor .................................................... 5E-39

Tightening Torque Specification ................ 5E-40

Special Tool .................................................. 5E-40 NOTE:

All brake fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of

same part number or with an equivalent part if replacement part of lesser quality or substitute design.

Torque values must be used as specified during reassembly to assure proper retention of all parts.

There is to be no welding as it may result in extensive damage and weakening of the metal.

Page 319 of 687

Downloaded from www.Manualslib.com manuals search engine 5E-2 ANTILOCK BRAKE SYSTEM (ABS)

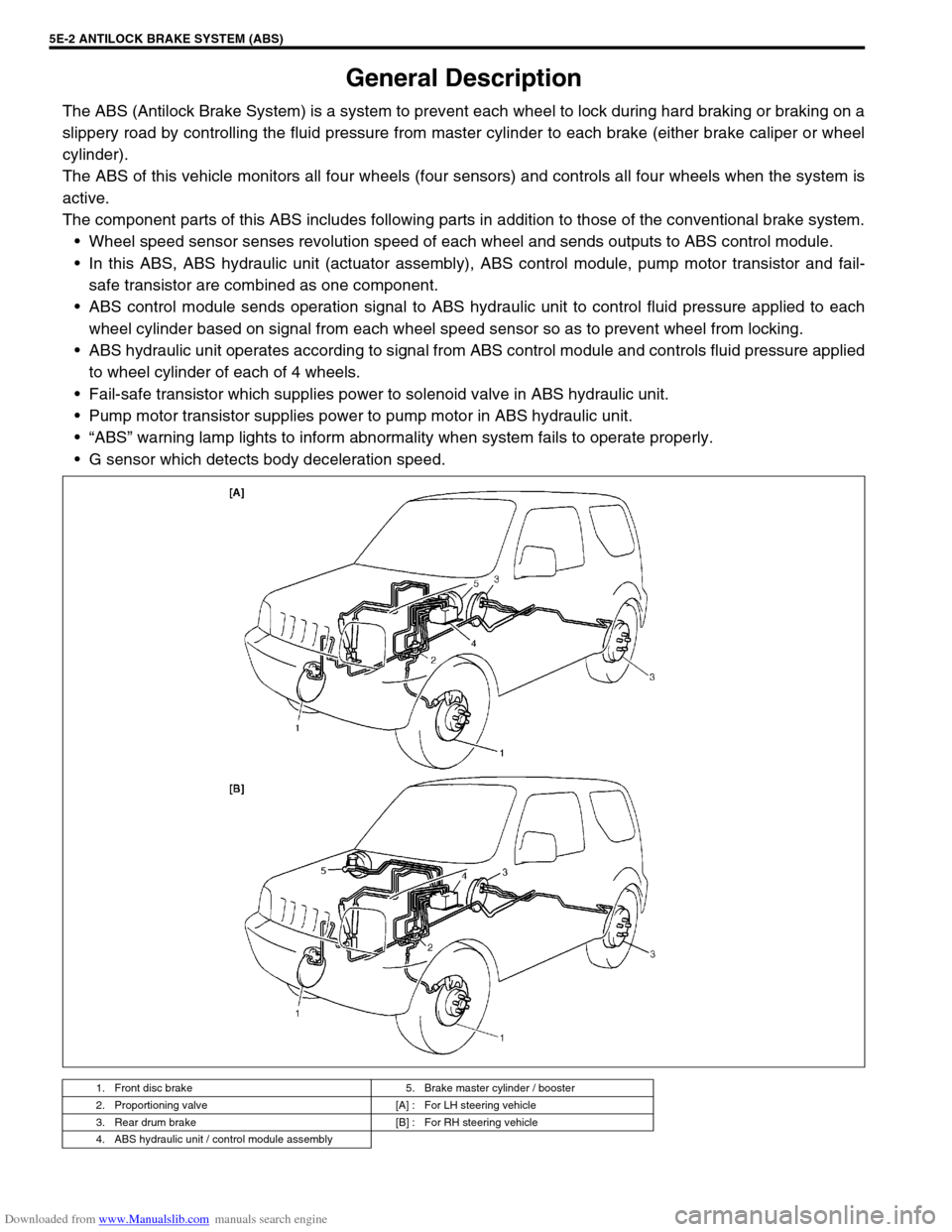

General Description

The ABS (Antilock Brake System) is a system to prevent each wheel to lock during hard braking or braking on a

slippery road by controlling the fluid pressure from master cylinder to each brake (either brake caliper or wheel

cylinder).

The ABS of this vehicle monitors all four wheels (four sensors) and controls all four wheels when the system is

active.

The component parts of this ABS includes following parts in addition to those of the conventional brake system.

Wheel speed sensor senses revolution speed of each wheel and sends outputs to ABS control module.

In this ABS, ABS hydraulic unit (actuator assembly), ABS control module, pump motor transistor and fail-

safe transistor are combined as one component.

ABS control module sends operation signal to ABS hydraulic unit to control fluid pressure applied to each

wheel cylinder based on signal from each wheel speed sensor so as to prevent wheel from locking.

ABS hydraulic unit operates according to signal from ABS control module and controls fluid pressure applied

to wheel cylinder of each of 4 wheels.

Fail-safe transistor which supplies power to solenoid valve in ABS hydraulic unit.

Pump motor transistor supplies power to pump motor in ABS hydraulic unit.

“ABS” warning lamp lights to inform abnormality when system fails to operate properly.

G sensor which detects body deceleration speed.

1. Front disc brake 5. Brake master cylinder / booster

2. Proportioning valve [A] : For LH steering vehicle

3. Rear drum brake [B] : For RH steering vehicle

4. ABS hydraulic unit / control module assembly

Page 320 of 687

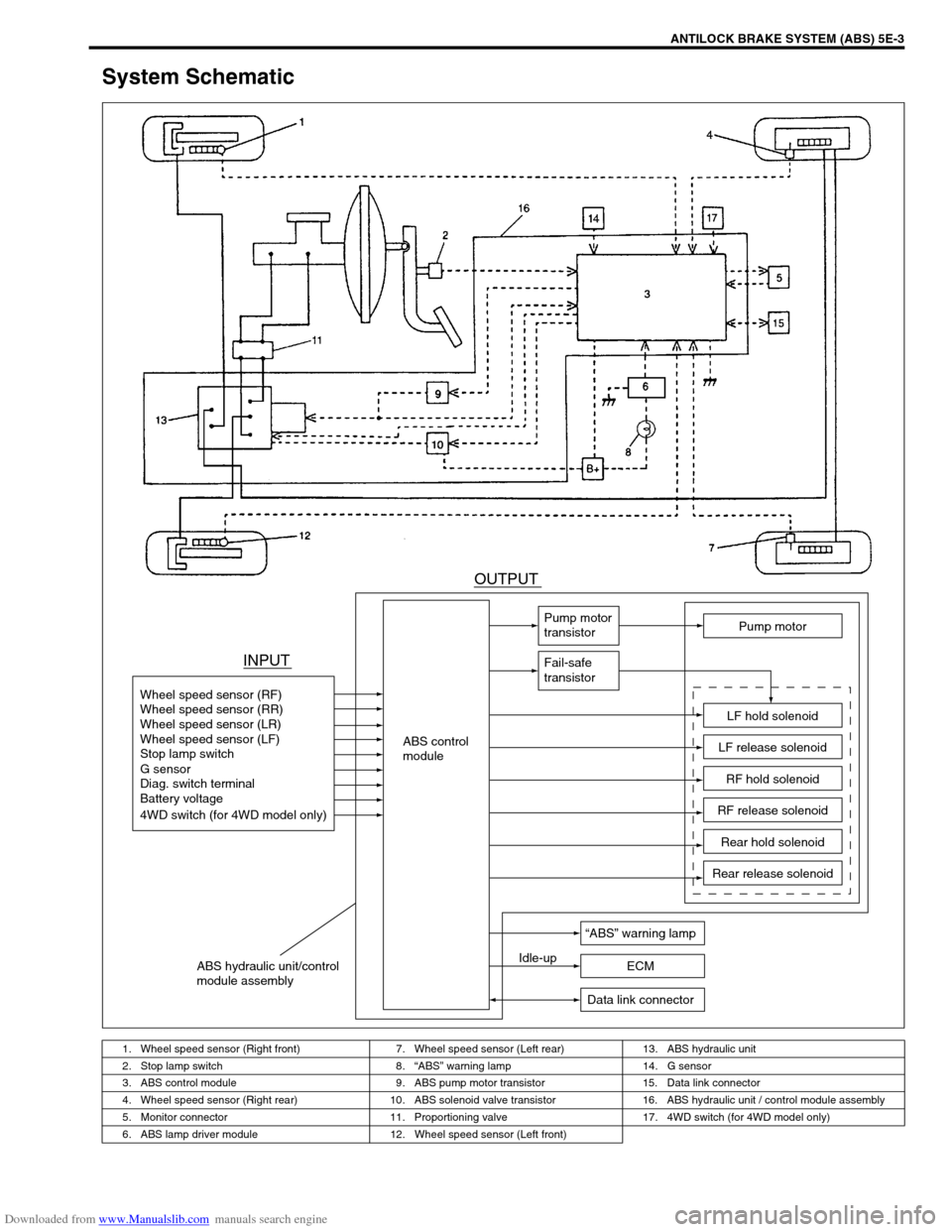

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-3

System Schematic

1. Wheel speed sensor (Right front) 7. Wheel speed sensor (Left rear) 13. ABS hydraulic unit

2. Stop lamp switch 8.“ABS” warning lamp 14. G sensor

3. ABS control module 9. ABS pump motor transistor 15. Data link connector

4. Wheel speed sensor (Right rear) 10. ABS solenoid valve transistor 16. ABS hydraulic unit / control module assembly

5. Monitor connector 11. Proportioning valve 17. 4WD switch (for 4WD model only)

6. ABS lamp driver module 12. Wheel speed sensor (Left front)

INPUTOUTPUT

ABS control

module Wheel speed sensor (RF)

Wheel speed sensor (RR)

Wheel speed sensor (LR)

Wheel speed sensor (LF)

Stop lamp switch

Diag. switch terminal

Battery voltage

4WD switch (for 4WD model only) G sensor

Pump motor

transistor

Fail-safe

transistor

Pump motor

LF hold solenoid

LF release solenoid

RF hold solenoid

RF release solenoid

Rear hold solenoid

Rear release solenoid

“ABS” warning lamp

Idle-up

ECM

Data link connector

ABS hydraulic unit/control

module assembly

Page 321 of 687

Downloaded from www.Manualslib.com manuals search engine 5E-4 ANTILOCK BRAKE SYSTEM (ABS)

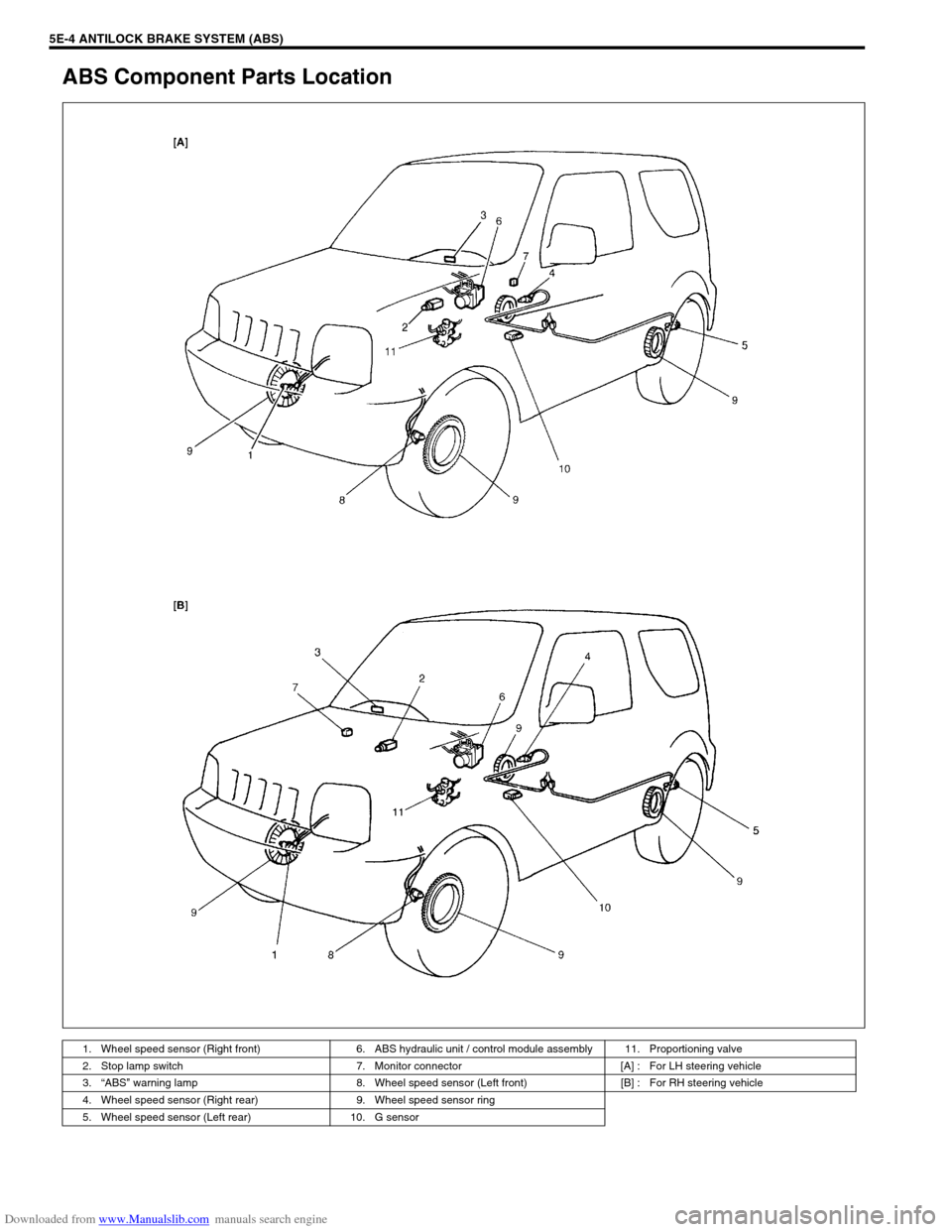

ABS Component Parts Location

1. Wheel speed sensor (Right front) 6. ABS hydraulic unit / control module assembly 11. Proportioning valve

2. Stop lamp switch 7. Monitor connector [A] : For LH steering vehicle

3.“ABS” warning lamp 8. Wheel speed sensor (Left front) [B] : For RH steering vehicle

4. Wheel speed sensor (Right rear) 9. Wheel speed sensor ring

5. Wheel speed sensor (Left rear) 10. G sensor