relay SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 403 of 687

Downloaded from www.Manualslib.com manuals search engine 6-46 ENGINE GENERAL INFORMATION AND DIAGNOSIS

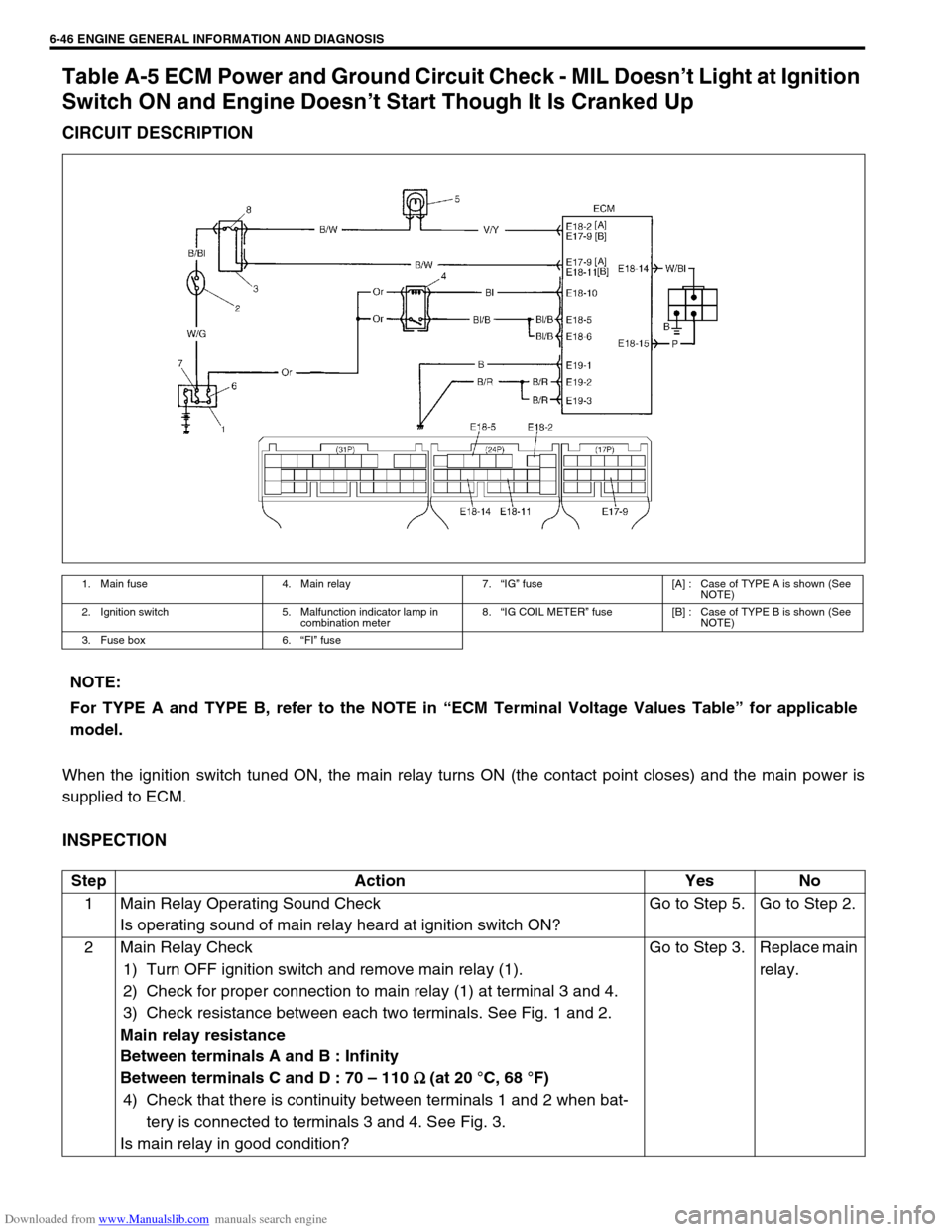

Table A-5 ECM Power and Ground Circuit Check - MIL Doesn’t Light at Ignition

Switch ON and Engine Doesn’t Start Though It Is Cranked Up

CIRCUIT DESCRIPTION

When the ignition switch tuned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

INSPECTION

1. Main fuse 4. Main relay 7.“IG” fuse [A] : Case of TYPE A is shown (See

NOTE)

2. Ignition switch 5. Malfunction indicator lamp in

combination meter8.“IG COIL METER” fuse [B] : Case of TYPE B is shown (See

NOTE)

3. Fuse box 6.“FI” fuse

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1 Main Relay Operating Sound Check

Is operating sound of main relay heard at ignition switch ON?Go to Step 5. Go to Step 2.

2 Main Relay Check

1) Turn OFF ignition switch and remove main relay (1).

2) Check for proper connection to main relay (1) at terminal 3 and 4.

3) Check resistance between each two terminals. See Fig. 1 and 2.

Main relay resistance

Between terminals A and B : Infinity

Between terminals C and D : 70 – 110

Ω

Ω Ω Ω (at 20 °C, 68 °F)

4) Check that there is continuity between terminals 1 and 2 when bat-

tery is connected to terminals 3 and 4. See Fig. 3.

Is main relay in good condition?Go to Step 3. Replace main

relay.

Page 404 of 687

![SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-47

[A] Fig. 1 for Step 2 and 3 / [B] Fig. 2 for Step 2 / [C] Fig. 3 for Step 23 Fuse Check

Is main � SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-47

[A] Fig. 1 for Step 2 and 3 / [B] Fig. 2 for Step 2 / [C] Fig. 3 for Step 23 Fuse Check

Is main �](/img/20/7588/w960_7588-403.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-47

[A] Fig. 1 for Step 2 and 3 / [B] Fig. 2 for Step 2 / [C] Fig. 3 for Step 23 Fuse Check

Is main “FI” fuse in good condition? See Fig. 1.Go to Step 4. Check for

short in cir-

cuits con-

nected to this

fuse.

4 ECM Power Circuit Check

1) Turn OFF ignition switch, disconnect connectors from ECM and

install main relay.

2) Check for proper connection to ECM at terminals E17-9 (Case of

TYPE A) (See NOTE) or E18-11 (Case of TYPE B) (See NOTE),

E18-10, E18-5 and E18-6.

3) If OK, then measure voltage between terminal E18-10 and ground,

E17-9 (Case of TYPE A) (See NOTE) or E18-11 (Case of TYPE B)

(See NOTE) and ground with ignition switch ON.

Is each voltage 10 – 14 V?Go to Step 5.“B/W”, “Or” or

“Bl/B” circuit

open.

5 ECM Power Circuit Check

1) Using service wire, ground terminal E18-10 and measure voltage

between terminal E18-5 and ground at ignition switch ON.

Is it 10 – 14 V?Check

ground cir-

cuits “B” and

“B/R” for

open.

If OK, then

substitute a

known-good

ECM and

recheck.Go to Step 6.

6 Is operating sound of main relay heard in Step 1? Go to Step 7.“Bl/B” or “B/

R” wire open.

7 Main Relay Check

1) Check main relay according to procedure in Step 2.

Is main relay in good condition?“Or” or “Bl/B”

wire open.Replace main

relay. Step Action Yes No

2.“F1” fuse

Page 449 of 687

Downloaded from www.Manualslib.com manuals search engine 6-92 ENGINE GENERAL INFORMATION AND DIAGNOSIS

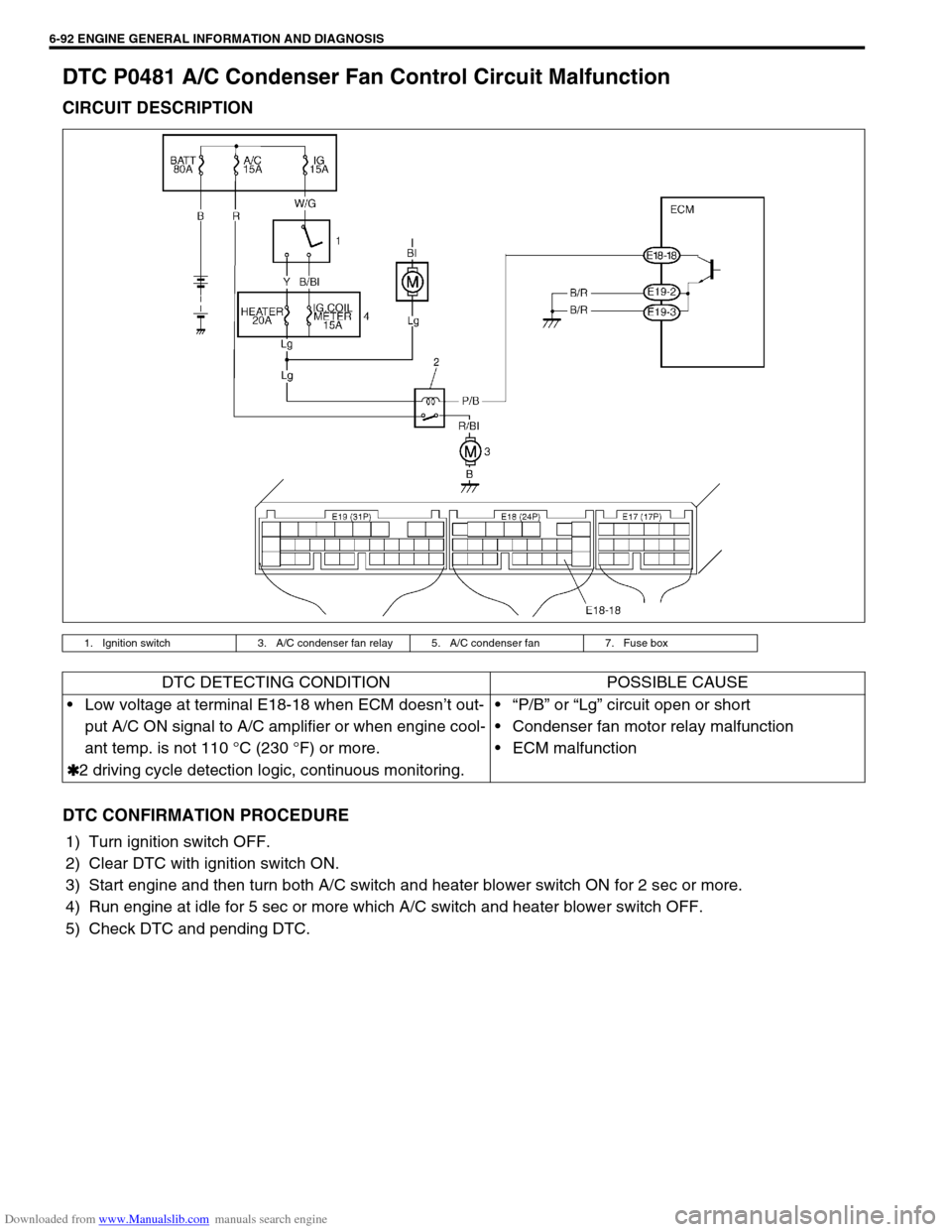

DTC P0481 A/C Condenser Fan Control Circuit Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Start engine and then turn both A/C switch and heater blower switch ON for 2 sec or more.

4) Run engine at idle for 5 sec or more which A/C switch and heater blower switch OFF.

5) Check DTC and pending DTC.

1. Ignition switch 3. A/C condenser fan relay 5. A/C condenser fan 7. Fuse box

DTC DETECTING CONDITION POSSIBLE CAUSE

Low voltage at terminal E18-18 when ECM doesn’t out-

put A/C ON signal to A/C amplifier or when engine cool-

ant temp. is not 110 °C (230 °F) or more.

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.“P/B” or “Lg” circuit open or short

Condenser fan motor relay malfunction

ECM malfunction

Page 450 of 687

![SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-93

INSPECTION

[A] Fig. 1 for Step 3 / [B] Fig. 2 for Step 3Step Action Yes No

1Was “Engine Diag. F SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-93

INSPECTION

[A] Fig. 1 for Step 3 / [B] Fig. 2 for Step 3Step Action Yes No

1Was “Engine Diag. F](/img/20/7588/w960_7588-449.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-93

INSPECTION

[A] Fig. 1 for Step 3 / [B] Fig. 2 for Step 3Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag.

Flow Table”.

2 Check A/C Condenser Fan Control Relay and its

Circuit.

1) Turn ignition switch ON.

2) Check for voltage at terminal E18-18 of ECM

connector connected, under following condition.

When A/C switch turns OFF : 10 – 14 V

Is voltage as specified?Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Go to Step 3.

3 Check A/C Condenser Fan Control Relay.

1) Turn ignition switch OFF and remove A/C con-

denser fan control relay (1). See Fig.1.

2) Check for proper connection to the relay at “P/B”

and “Lg” wire terminals.

3) If OK, then measure resistance between termi-

nals C and D. See Fig.2.

Is it 70 - 110Ω?“Lg” or “P/B” circuit open

or short.

If wires and connections

are OK, substitute a

known-good ECM and

recheck.Replace A/C con-

denser fan control

relay.

Page 453 of 687

Downloaded from www.Manualslib.com manuals search engine 6-96 ENGINE GENERAL INFORMATION AND DIAGNOSIS

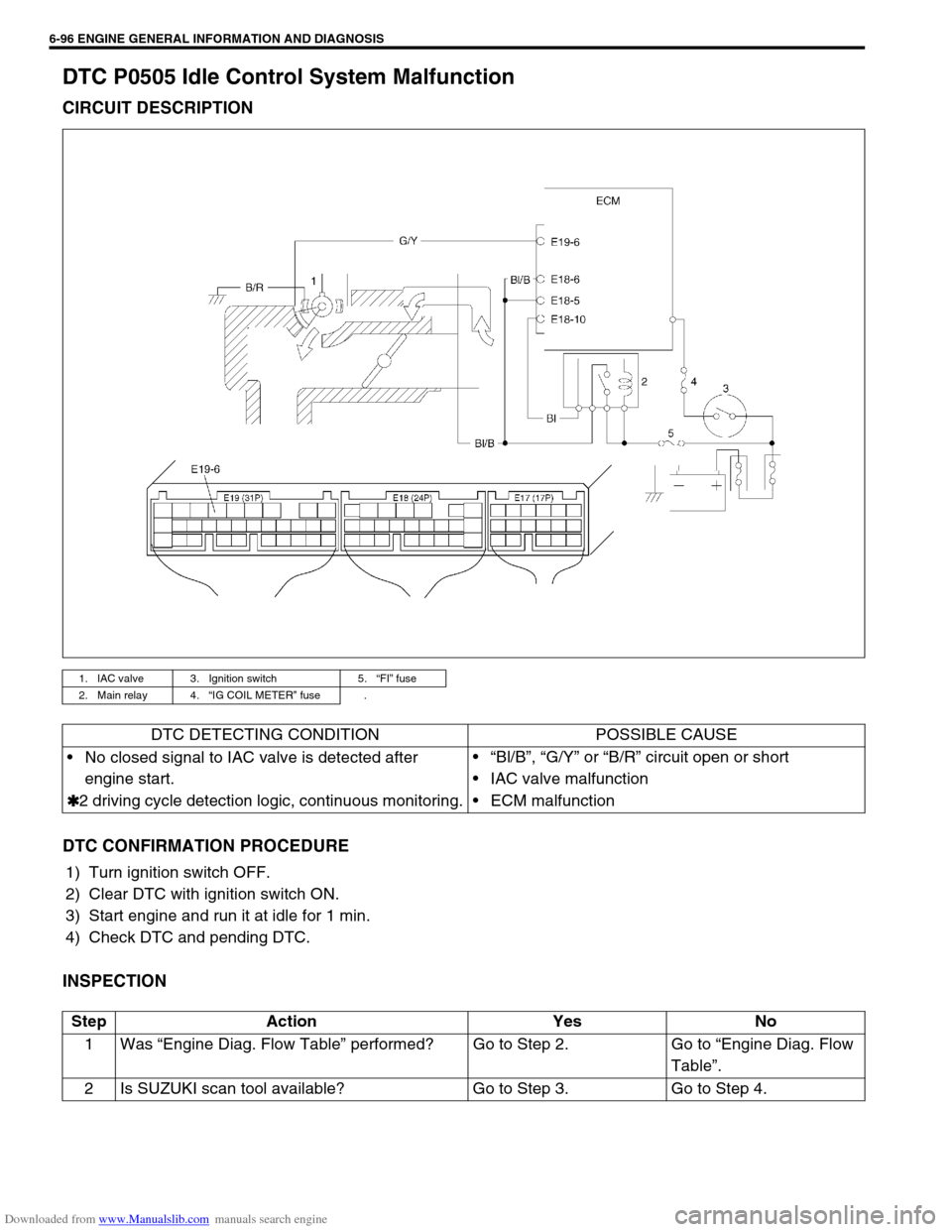

DTC P0505 Idle Control System Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Start engine and run it at idle for 1 min.

4) Check DTC and pending DTC.

INSPECTION

1. IAC valve 3. Ignition switch 5.“FI” fuse

2. Main relay 4.“IG COIL METER” fuse .

DTC DETECTING CONDITION POSSIBLE CAUSE

No closed signal to IAC valve is detected after

engine start.

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.“Bl/B”, “G/Y” or “B/R” circuit open or short

IAC valve malfunction

ECM malfunction

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Is SUZUKI scan tool available? Go to Step 3. Go to Step 4.

Page 467 of 687

Downloaded from www.Manualslib.com manuals search engine 6-110 ENGINE GENERAL INFORMATION AND DIAGNOSIS

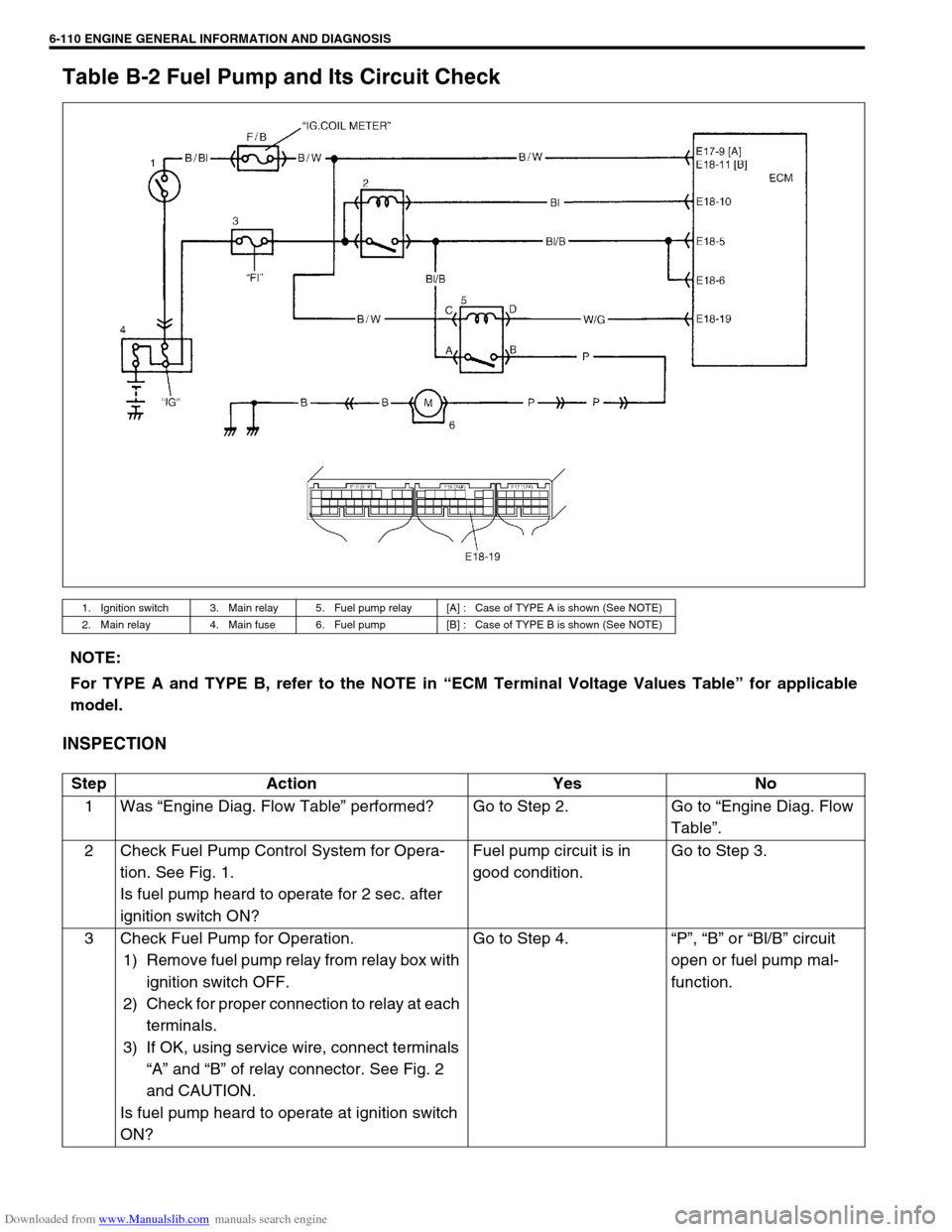

Table B-2 Fuel Pump and Its Circuit Check

INSPECTION

1. Ignition switch 3. Main relay 5. Fuel pump relay [A] : Case of TYPE A is shown (See NOTE)

2. Main relay 4. Main fuse 6. Fuel pump [B] : Case of TYPE B is shown (See NOTE)

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check Fuel Pump Control System for Opera-

tion. See Fig. 1.

Is fuel pump heard to operate for 2 sec. after

ignition switch ON?Fuel pump circuit is in

good condition.Go to Step 3.

3 Check Fuel Pump for Operation.

1) Remove fuel pump relay from relay box with

ignition switch OFF.

2) Check for proper connection to relay at each

terminals.

3) If OK, using service wire, connect terminals

“A” and “B” of relay connector. See Fig. 2

and CAUTION.

Is fuel pump heard to operate at ignition switch

ON?Go to Step 4.“P”, “B” or “Bl/B” circuit

open or fuel pump mal-

function.

Page 468 of 687

![SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for SUZUKI JIMNY 2005 3.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for](/img/20/7588/w960_7588-467.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-111

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3 / [C] Fig. 3 for Step 44 Check Fuel Pump Relay for Operation.

1) Check resistance between each two termi-

nals of fuel pump relay. See Fig.3.

Fuel pump relay resistance

Between terminals “A” and “B” : Infinity

Between terminals “C” and “D”: 100 – 150

Ω

ΩΩ Ω

2) Check that there is continuity between ter-

minals “A” and “B” when battery is con-

nected to terminals “C” and “D”. See Fig. 3.

Is fuel pump relay in good condition?“W/G” circuit open or poor

E18-19 connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.Replace fuel pump

relay. Step Action Yes No

CAUTION:

Check to make sure that connection is made between correct terminals. Wrong connection can cause

damage to ECM, wire harness, etc.

Page 471 of 687

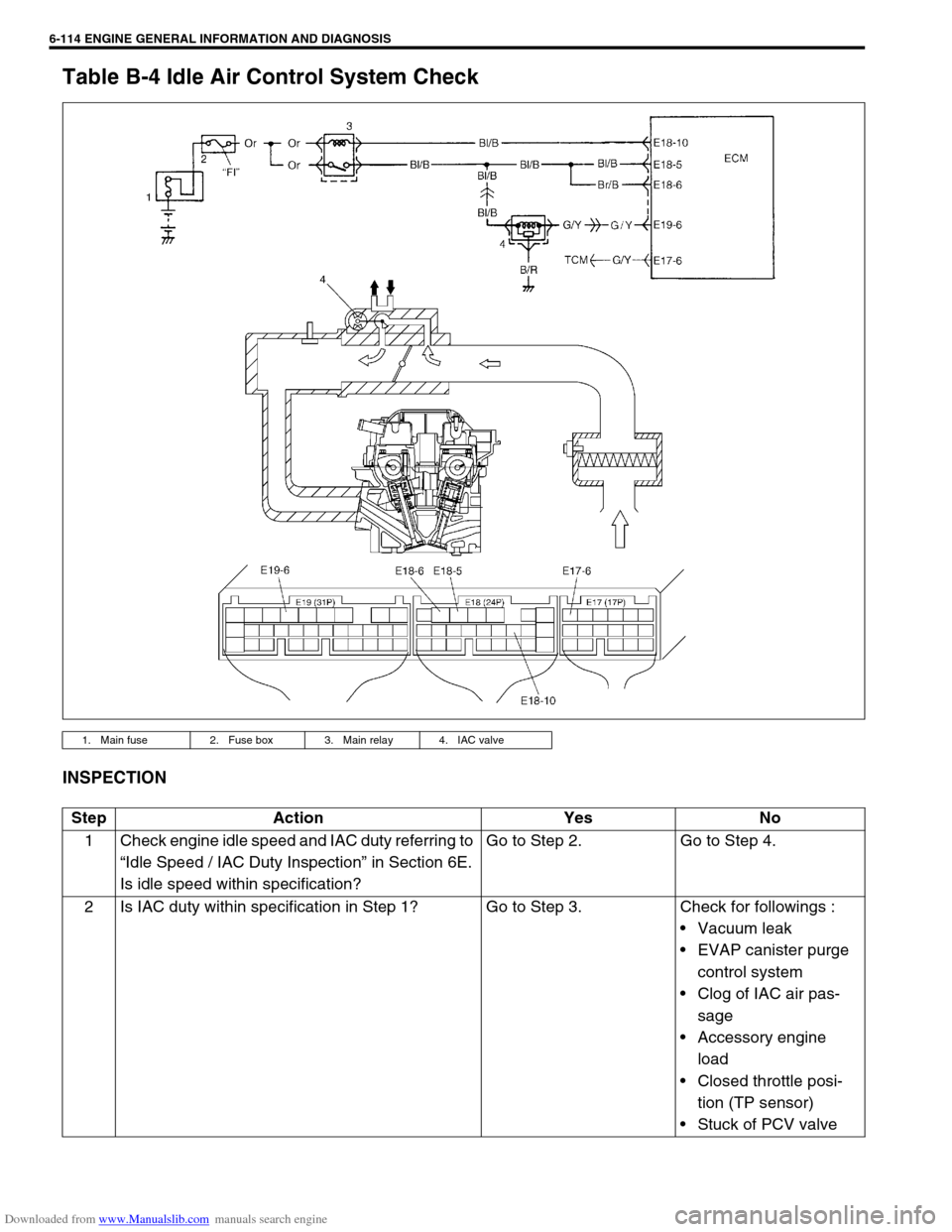

Downloaded from www.Manualslib.com manuals search engine 6-114 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Table B-4 Idle Air Control System Check

INSPECTION

1. Main fuse 2. Fuse box 3. Main relay 4. IAC valve

Step Action Yes No

1 Check engine idle speed and IAC duty referring to

“Idle Speed / IAC Duty Inspection” in Section 6E.

Is idle speed within specification?Go to Step 2. Go to Step 4.

2 Is IAC duty within specification in Step 1? Go to Step 3. Check for followings :

Vacuum leak

EVAP canister purge

control system

Clog of IAC air pas-

sage

Accessory engine

load

Closed throttle posi-

tion (TP sensor)

Stuck of PCV valve

Page 478 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-121

TAble B-7 A/C Condenser Fan Control System Check

INSPECTION

Step Action Yes No

1 Check Fan Control System.

1) Connect scan tool to DLC with ignition switch OFF. See

Fig. 1.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 110 °C, 230 °F or

higher and A/C switch turn OFF. (If engine coolant temp.

does not rise, check engine cooling system or ECT sen-

sor.)

Is A/C condenser fan started when engine coolant temp.

reached above temp.?A/C condenser fan con-

trol system is in good

condition.Go to Step 2.

2 Check A/C Condenser Fan Relay and Its Circuit.

1) Check DTC and pending DTC with scan tool.

Is DTC P0481 displayed?Go to DTC P0481 Diag.

Flow Table.Go to Step 3.

3 Check A/C Condenser Fan Relay (1).

1) Turn ignition switch OFF and remove A/C condenser fan

relay.

2) Check for proper connection to relay at terminals “A”

and “B”.

3) If OK, check that there is continuity between “A” and “B”

when battery is connected to terminals “C” and “D”. See

Fig. 2.

Is check result satisfactory?Go to Step 4. Replace A/C

condenser fan

relay.

Page 606 of 687

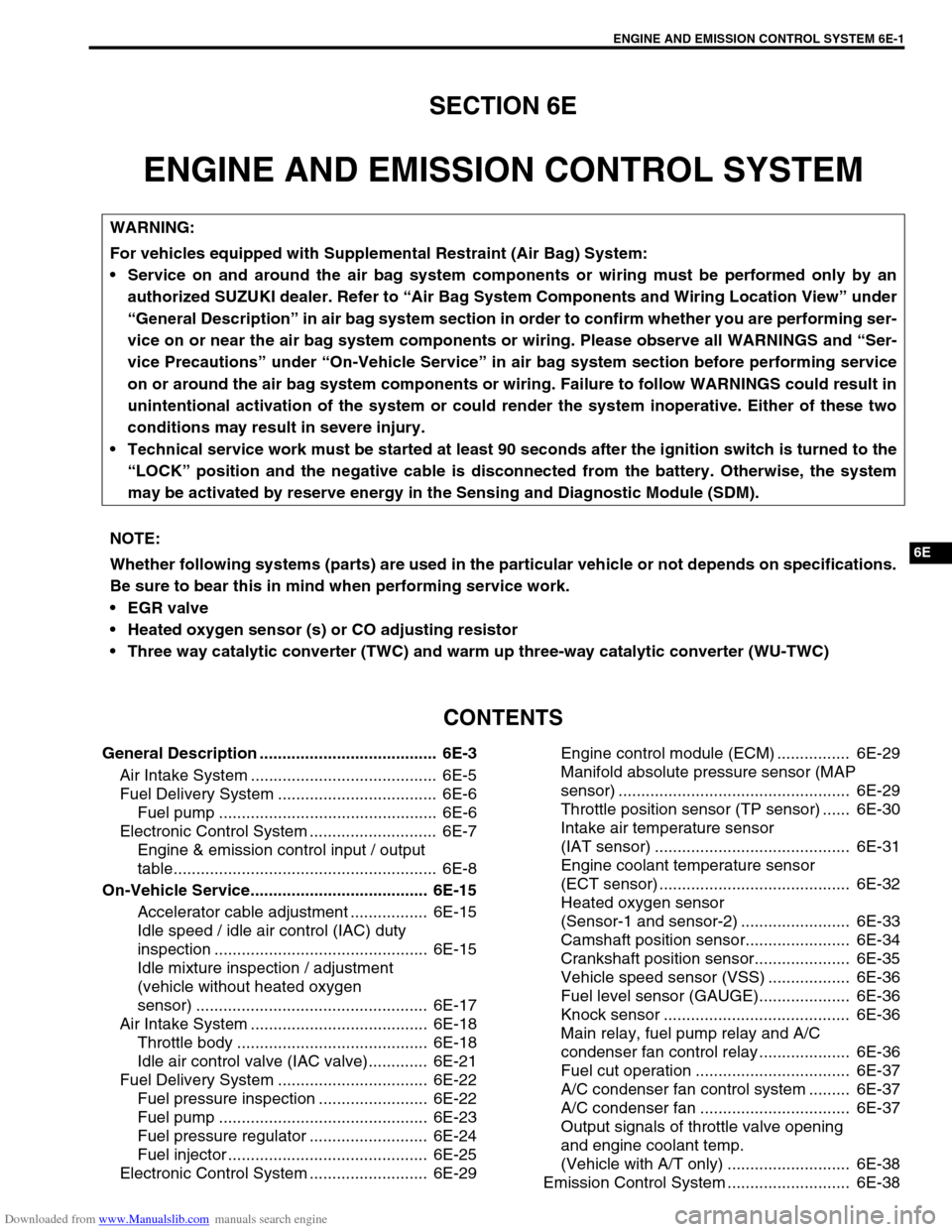

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-1

6F1

6F2

6G

7C1

7D

7E

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

6H

6E

10

10A

10B

SECTION 6E

ENGINE AND EMISSION CONTROL SYSTEM

CONTENTS

General Description ....................................... 6E-3

Air Intake System ......................................... 6E-5

Fuel Delivery System ................................... 6E-6

Fuel pump ................................................ 6E-6

Electronic Control System ............................ 6E-7

Engine & emission control input / output

table.......................................................... 6E-8

On-Vehicle Service....................................... 6E-15

Accelerator cable adjustment ................. 6E-15

Idle speed / idle air control (IAC) duty

inspection ............................................... 6E-15

Idle mixture inspection / adjustment

(vehicle without heated oxygen

sensor) ................................................... 6E-17

Air Intake System ....................................... 6E-18

Throttle body .......................................... 6E-18

Idle air control valve (IAC valve)............. 6E-21

Fuel Delivery System ................................. 6E-22

Fuel pressure inspection ........................ 6E-22

Fuel pump .............................................. 6E-23

Fuel pressure regulator .......................... 6E-24

Fuel injector ............................................ 6E-25

Electronic Control System .......................... 6E-29Engine control module (ECM) ................ 6E-29

Manifold absolute pressure sensor (MAP

sensor) ................................................... 6E-29

Throttle position sensor (TP sensor) ...... 6E-30

Intake air temperature sensor

(IAT sensor) ........................................... 6E-31

Engine coolant temperature sensor

(ECT sensor) .......................................... 6E-32

Heated oxygen sensor

(Sensor-1 and sensor-2) ........................ 6E-33

Camshaft position sensor....................... 6E-34

Crankshaft position sensor..................... 6E-35

Vehicle speed sensor (VSS) .................. 6E-36

Fuel level sensor (GAUGE).................... 6E-36

Knock sensor ......................................... 6E-36

Main relay, fuel pump relay and A/C

condenser fan control relay .................... 6E-36

Fuel cut operation .................................. 6E-37

A/C condenser fan control system ......... 6E-37

A/C condenser fan ................................. 6E-37

Output signals of throttle valve opening

and engine coolant temp.

(Vehicle with A/T only) ........................... 6E-38

Emission Control System ........................... 6E-38 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether following systems (parts) are used in the particular vehicle or not depends on specifications.

Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor (s) or CO adjusting resistor

Three way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)