valve SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 89 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-28 AIR CONDITIONING (OPTIONAL)

Removing Manifold Gauge Set

When A/C system has been charged with a specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set. (The

high pressure side valve is closed continuously during the

process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service valves.

This operation must be performed rapidly.

5) Put caps on service valves.

Leak Test

Whenever a refrigerant leak is suspected in the system or any

service operation has been performed which may result in dis-

turbing lines or connections, it is advisable to test for leaks.

Common sense should be used in performing any refrigerant leak

test, since the need and extent of any such test will, in general,

depend upon the nature of a complaint and the type of a service

performed on the system.

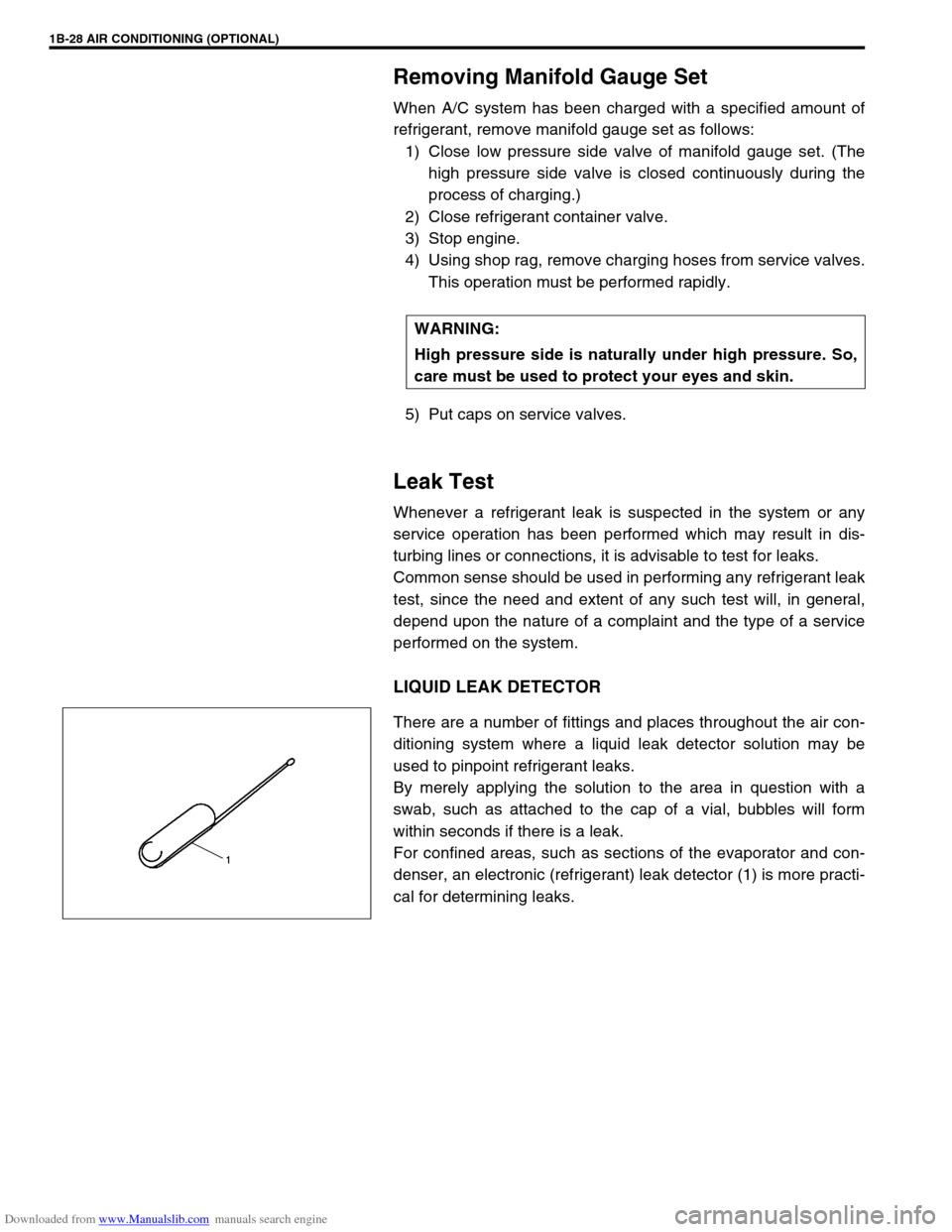

LIQUID LEAK DETECTOR

There are a number of fittings and places throughout the air con-

ditioning system where a liquid leak detector solution may be

used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question with a

swab, such as attached to the cap of a vial, bubbles will form

within seconds if there is a leak.

For confined areas, such as sections of the evaporator and con-

denser, an electronic (refrigerant) leak detector (1) is more practi-

cal for determining leaks.WARNING:

High pressure side is naturally under high pressure. So,

care must be used to protect your eyes and skin.

Page 90 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-29

On-Vehicle Service

Service Precaution

When servicing air conditioning system, note the following instructions.

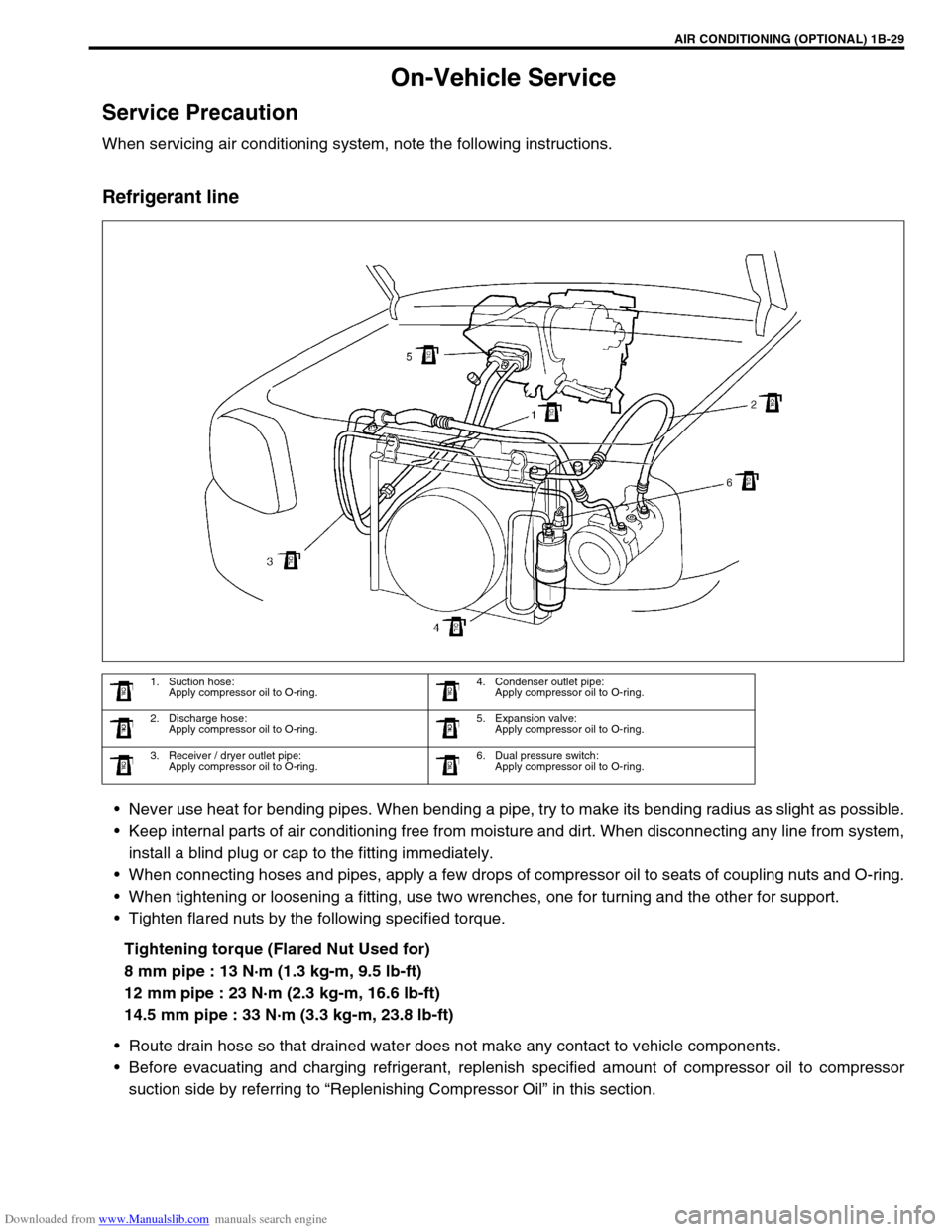

Refrigerant line

Never use heat for bending pipes. When bending a pipe, try to make its bending radius as slight as possible.

Keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system,

install a blind plug or cap to the fitting immediately.

When connecting hoses and pipes, apply a few drops of compressor oil to seats of coupling nuts and O-ring.

When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

Tighten flared nuts by the following specified torque.

Tightening torque (Flared Nut Used for)

8 mm pipe : 13 N·m (1.3 kg-m, 9.5 lb-ft)

12 mm pipe : 23 N·m (2.3 kg-m, 16.6 lb-ft)

14.5 mm pipe : 33 N·m (3.3 kg-m, 23.8 lb-ft)

Route drain hose so that drained water does not make any contact to vehicle components.

Before evacuating and charging refrigerant, replenish specified amount of compressor oil to compressor

suction side by referring to “Replenishing Compressor Oil” in this section.

1. Suction hose:

Apply compressor oil to O-ring.4. Condenser outlet pipe:

Apply compressor oil to O-ring.

2. Discharge hose:

Apply compressor oil to O-ring.5. Expansion valve:

Apply compressor oil to O-ring.

3. Receiver / dryer outlet pipe:

Apply compressor oil to O-ring.6. Dual pressure switch:

Apply compressor oil to O-ring.

Page 95 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-34 AIR CONDITIONING (OPTIONAL)

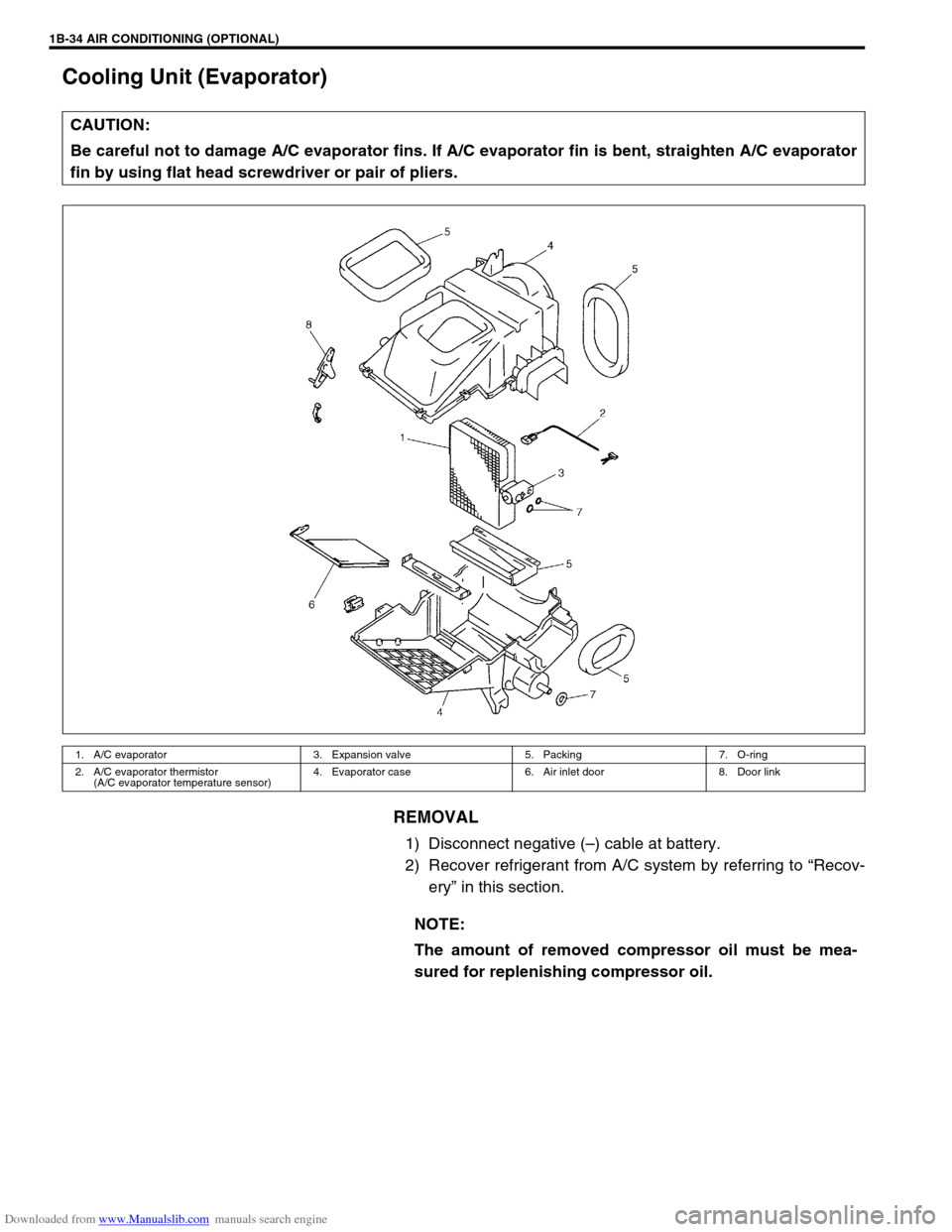

Cooling Unit (Evaporator)

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Recover refrigerant from A/C system by referring to “Recov-

ery” in this section. CAUTION:

Be careful not to damage A/C evaporator fins. If A/C evaporator fin is bent, straighten A/C evaporator

fin by using flat head screwdriver or pair of pliers.

1. A/C evaporator 3. Expansion valve 5. Packing 7. O-ring

2. A/C evaporator thermistor

(A/C evaporator temperature sensor)4. Evaporator case 6. Air inlet door 8. Door link

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 96 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-35

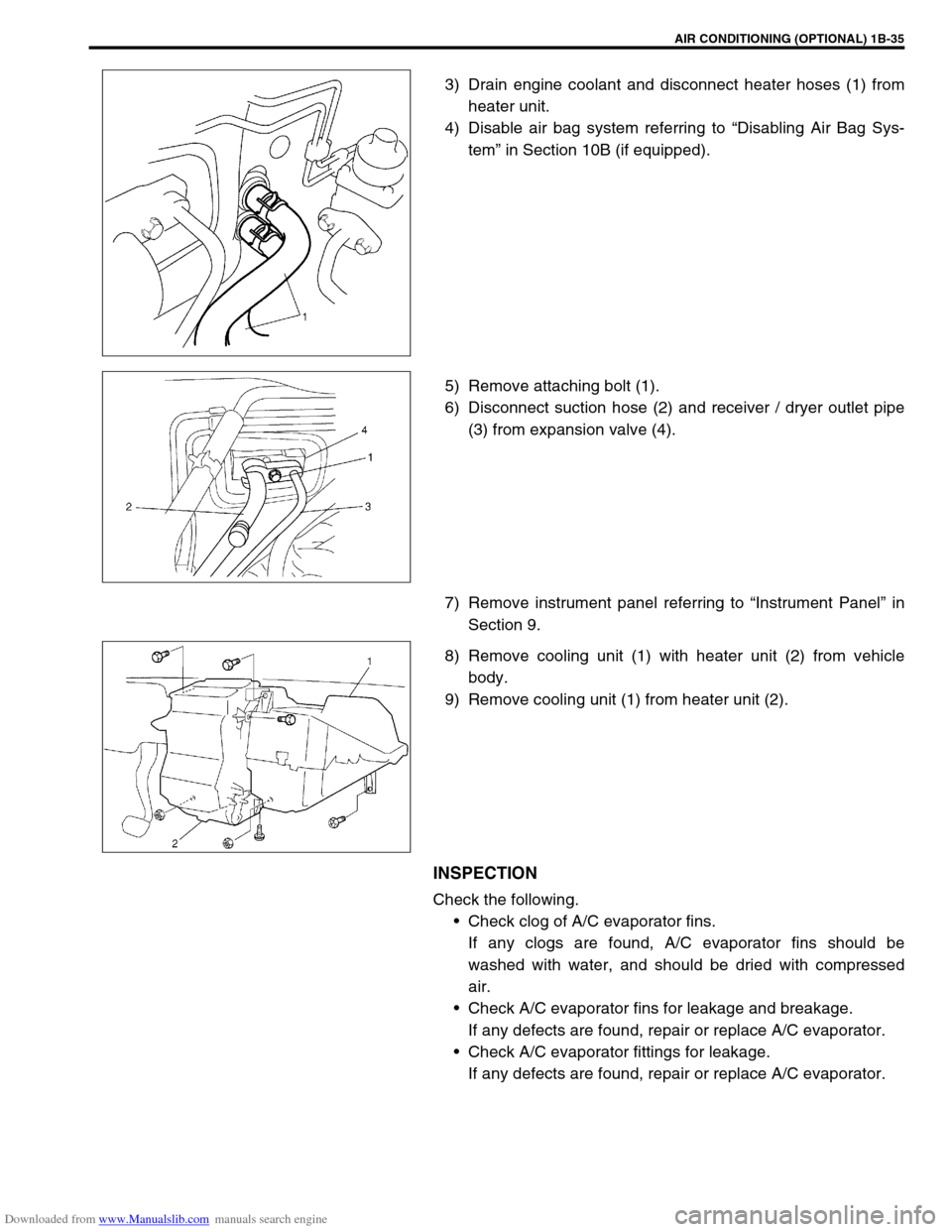

3) Drain engine coolant and disconnect heater hoses (1) from

heater unit.

4) Disable air bag system referring to “Disabling Air Bag Sys-

tem” in Section 10B (if equipped).

5) Remove attaching bolt (1).

6) Disconnect suction hose (2) and receiver / dryer outlet pipe

(3) from expansion valve (4).

7) Remove instrument panel referring to “Instrument Panel” in

Section 9.

8) Remove cooling unit (1) with heater unit (2) from vehicle

body.

9) Remove cooling unit (1) from heater unit (2).

INSPECTION

Check the following.

Check clog of A/C evaporator fins.

If any clogs are found, A/C evaporator fins should be

washed with water, and should be dried with compressed

air.

Check A/C evaporator fins for leakage and breakage.

If any defects are found, repair or replace A/C evaporator.

Check A/C evaporator fittings for leakage.

If any defects are found, repair or replace A/C evaporator.

Page 98 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-37

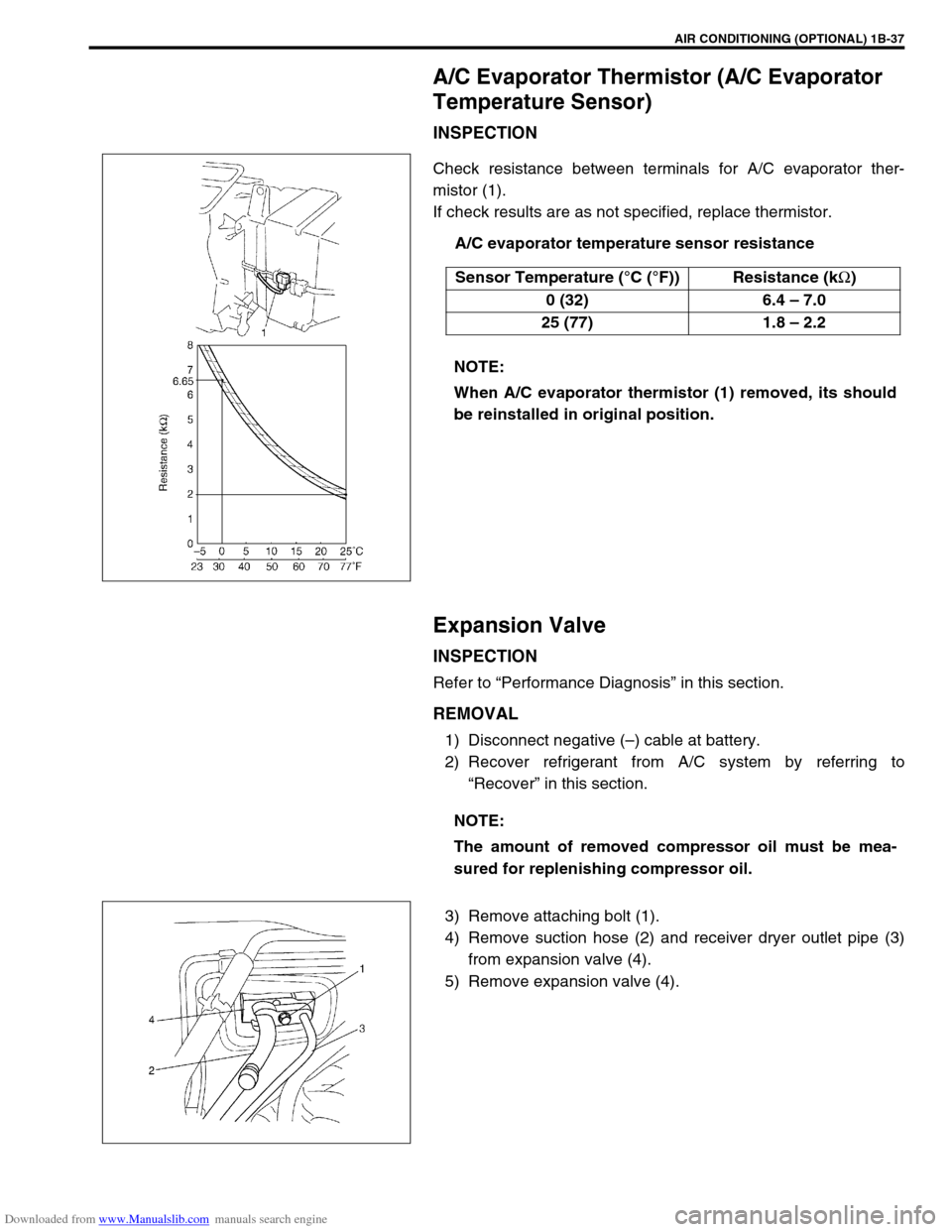

A/C Evaporator Thermistor (A/C Evaporator

Temperature Sensor)

INSPECTION

Check resistance between terminals for A/C evaporator ther-

mistor (1).

If check results are as not specified, replace thermistor.

A/C evaporator temperature sensor resistance

Expansion Valve

INSPECTION

Refer to “Performance Diagnosis” in this section.

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Recover refrigerant from A/C system by referring to

“Recover” in this section.

3) Remove attaching bolt (1).

4) Remove suction hose (2) and receiver dryer outlet pipe (3)

from expansion valve (4).

5) Remove expansion valve (4).Sensor Temperature (°C (°F)) Resistance (k

Ω)

0 (32) 6.4 – 7.0

25 (77) 1.8 – 2.2

NOTE:

When A/C evaporator thermistor (1) removed, its should

be reinstalled in original position.

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 133 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-2 POWER STEERING (P/S) SYSTEM (If equipped)

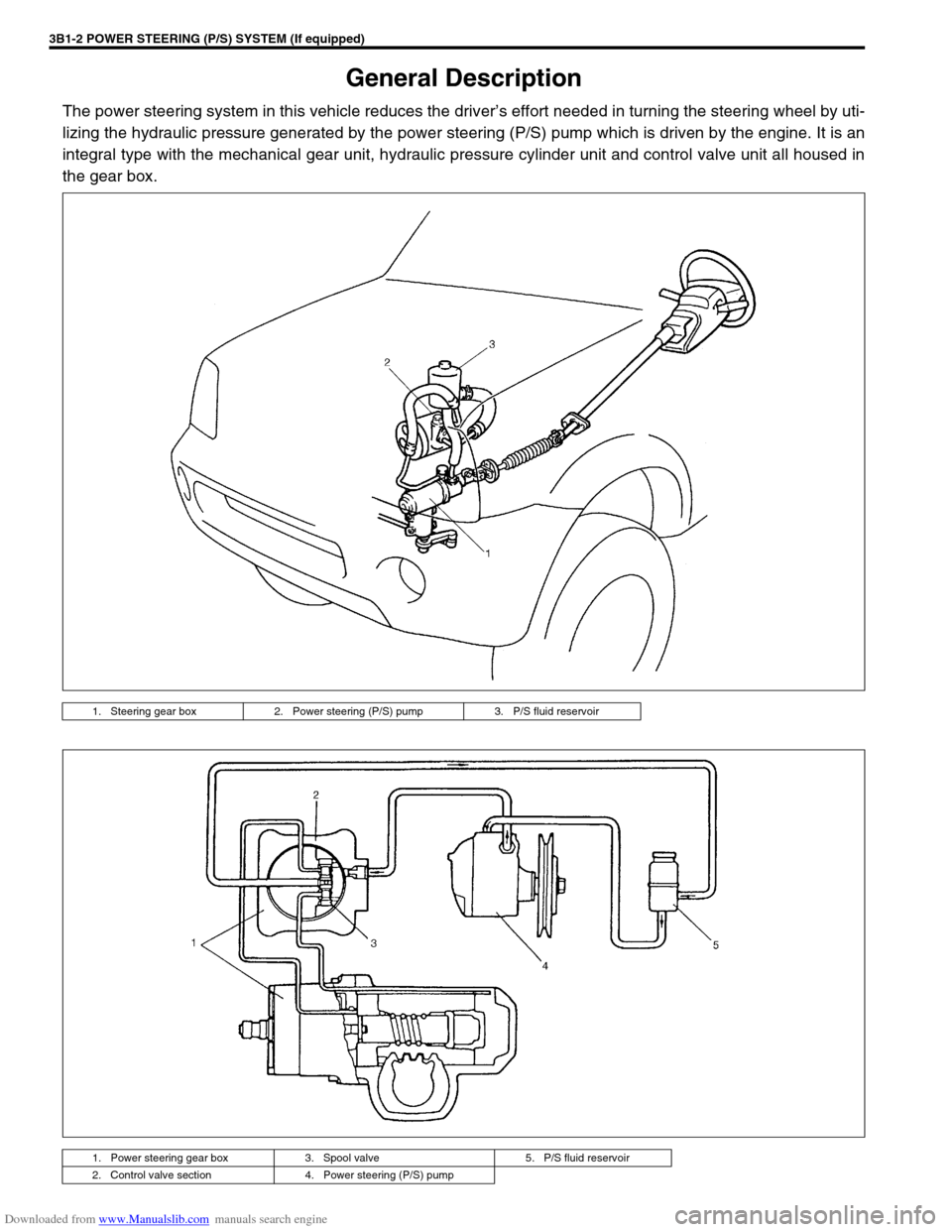

General Description

The power steering system in this vehicle reduces the driver’s effort needed in turning the steering wheel by uti-

lizing the hydraulic pressure generated by the power steering (P/S) pump which is driven by the engine. It is an

integral type with the mechanical gear unit, hydraulic pressure cylinder unit and control valve unit all housed in

the gear box.

1. Steering gear box 2. Power steering (P/S) pump 3. P/S fluid reservoir

1. Power steering gear box 3. Spool valve 5. P/S fluid reservoir

2. Control valve section 4. Power steering (P/S) pump

Page 134 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-3

Diagnosis

Diagnosis Table

Condition Possible Cause Correction

Steering wheel feels

heavy

(at low speed)Fluid deteriorated, low viscosity, different type of

fluid mixedChange fluid.

Pipes or hoses deformed, air entering through

jointCorrect or replace.

Insufficient air bleeding from piping Bleed air.

Belt worn, lacking in tension Adjust belt tension or replace belt

as necessary.

Tire inflation pressure too low Inflate tire.

Wheel alignment out of adjustment Adjust front wheel alignment.

Steering wheel installed improperly (twisted) Install steering wheel correctly.

Hydraulic pressure failing to rise (See NOTE

“A”.)Replace P/S pump.

Slow hydraulic pressure rise (See NOTE “A”.)

Steering wheel feels

heavy momentarily

when turning it to the

left or right.Air drawn in due to insufficient amount of fluid Add fluid and bleed air.

Slipping belt Adjust belt tension or replace belt

as necessary.

No idle-up (See NOTE

“B”.)Defective pressure switch Replace pressure switch

(terminal set).

NOTE:

“A” : Be sure to warm up engine fully before performing this check. Pump vanes are sometimes

hard to come out where temperature is low.

“B” : Acceptable if idling speed does not drop.

Condition Possible Cause Correction

Steering wheel returns

slowly from turns.

(See NOTE “C”.)Dust or foreign object mixed in fluid Change fluid.

Deformed pipes or hoses Correct or replace.

Steering column installed improperly Install correctly.

Wheel alignment maladjusted Adjust.

Linkage or joints not operating smoothly Correct.

Vehicle pulls to one

side during straight

driving.Low or uneven tire inflation pressure Inflate tire (s) as necessary.

Wheel alignment maladjusted Adjust.

Defective spool valve Replace gear box assembly.

Steering wheel play is

large and vehicle wan-

ders.Loose steering shaft nut Retighten.

Loose linkage or joint Retighten.

Loose gear box fixing bolt Retighten.

Front wheel bearing worn Replace.

Fluid leakage

Loose joints of hydraulic pressure pipes and

hosesRetighten.

Deformed or damaged pipes or hoses Correct or replace.

Gear box Replace gear box assembly.

Page 135 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-4 POWER STEERING (P/S) SYSTEM (If equipped)

Abnormal noise

(See NOTE “D”.)Air drawn in due to insufficient fluid Replenish fluid.

Air drawn in through pipe or hose joints Retighten or replace.

Belt slipping (loose) Adjust.

Worn belt Replace.

Loose steering linkage Retighten.

Loose gear box fixing bolt Retighten.

Loose pitman arm Retighten.

Pipes or hoses in contact with chassis Correct.

Defective pump vane Replace pump assembly.

Malfunction of flow control valve Replace gear box assembly.

Defective pump shaft bearing Replace pump assembly. Condition Possible Cause Correction

NOTE:

“C” : Turn steering wheel 90° at 35 km/h (22 mile/h) and let it free. If it returns more than 60° then, it

is normal.

“D” : Some hissing noise may be heard through steering column when turning steering wheel with

vehicle halted. It is from operation of the valve in the gear box and indicates nothing abnormal.

Page 141 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-10 POWER STEERING (P/S) SYSTEM (If equipped)

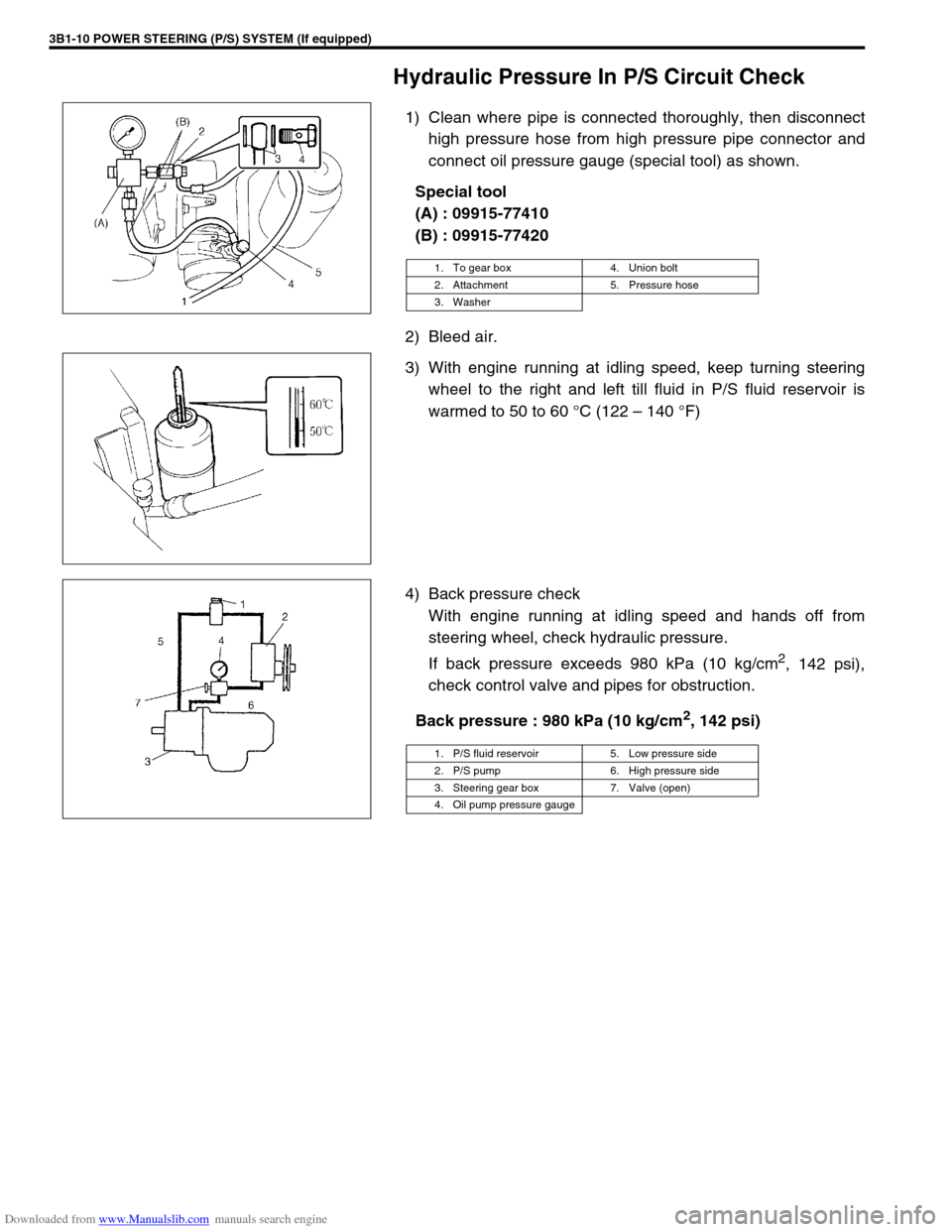

Hydraulic Pressure In P/S Circuit Check

1) Clean where pipe is connected thoroughly, then disconnect

high pressure hose from high pressure pipe connector and

connect oil pressure gauge (special tool) as shown.

Special tool

(A) : 09915-77410

(B) : 09915-77420

2) Bleed air.

3) With engine running at idling speed, keep turning steering

wheel to the right and left till fluid in P/S fluid reservoir is

warmed to 50 to 60 °C (122 – 140 °F)

4) Back pressure check

With engine running at idling speed and hands off from

steering wheel, check hydraulic pressure.

If back pressure exceeds 980 kPa (10 kg/cm

2, 142 psi),

check control valve and pipes for obstruction.

Back pressure : 980 kPa (10 kg/cm

2, 142 psi)

1. To gear box 4. Union bolt

2. Attachment 5. Pressure hose

3. Washer

1. P/S fluid reservoir 5. Low pressure side

2. P/S pump 6. High pressure side

3. Steering gear box 7. Valve (open)

4. Oil pump pressure gauge

Page 142 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-11

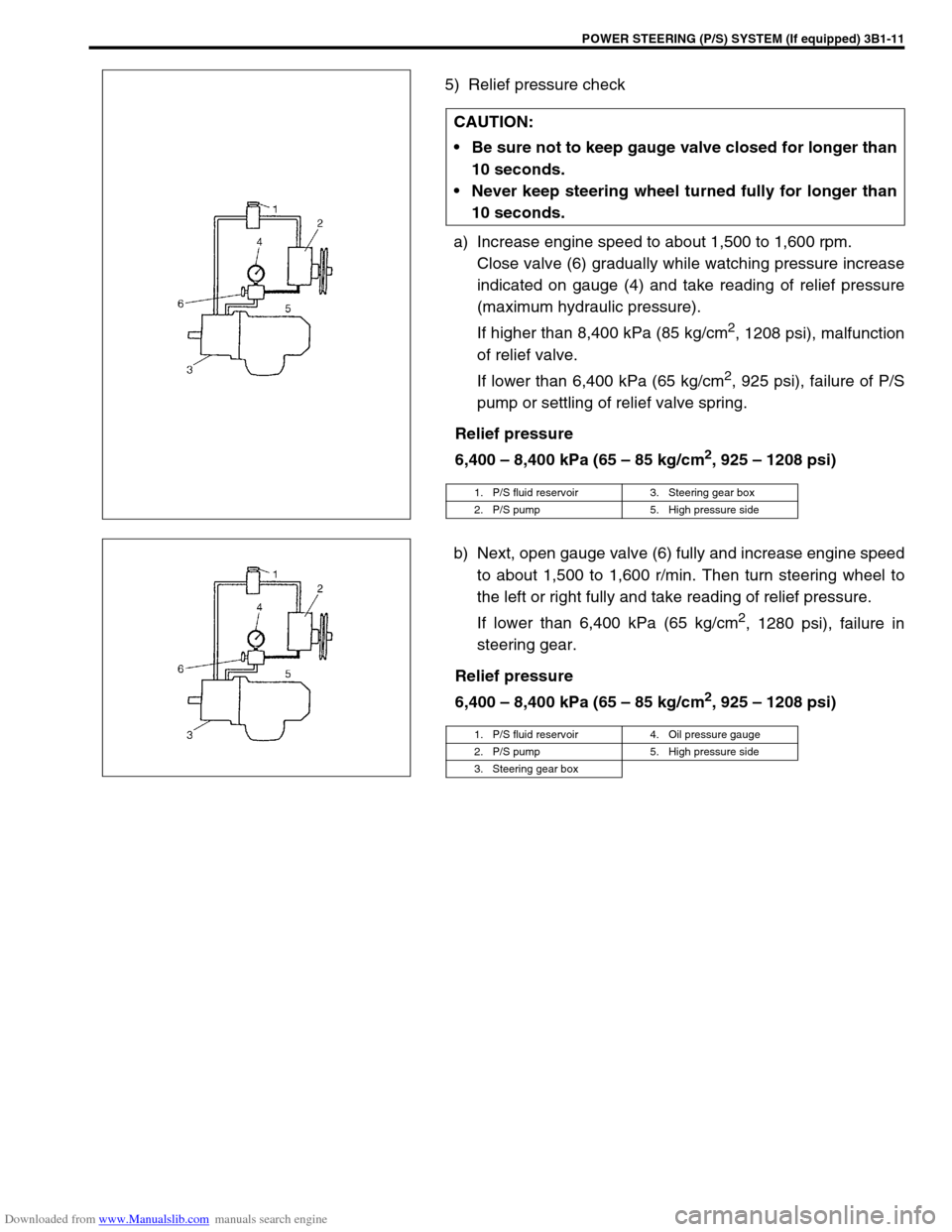

5) Relief pressure check

a) Increase engine speed to about 1,500 to 1,600 rpm.

Close valve (6) gradually while watching pressure increase

indicated on gauge (4) and take reading of relief pressure

(maximum hydraulic pressure).

If higher than 8,400 kPa (85 kg/cm

2, 1208 psi), malfunction

of relief valve.

If lower than 6,400 kPa (65 kg/cm

2, 925 psi), failure of P/S

pump or settling of relief valve spring.

Relief pressure

6,400 – 8,400 kPa (65 – 85 kg/cm

2, 925 – 1208 psi)

b) Next, open gauge valve (6) fully and increase engine speed

to about 1,500 to 1,600 r/min. Then turn steering wheel to

the left or right fully and take reading of relief pressure.

If lower than 6,400 kPa (65 kg/cm

2, 1280 psi), failure in

steering gear.

Relief pressure

6,400 – 8,400 kPa (65 – 85 kg/cm

2, 925 – 1208 psi) CAUTION:

Be sure not to keep gauge valve closed for longer than

10 seconds.

Never keep steering wheel turned fully for longer than

10 seconds.

1. P/S fluid reservoir 3. Steering gear box

2. P/S pump 5. High pressure side

1. P/S fluid reservoir 4. Oil pressure gauge

2. P/S pump 5. High pressure side

3. Steering gear box