valve SUZUKI JIMNY 2005 3.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 67 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-6 AIR CONDITIONING (OPTIONAL)

Cool air won’t come

out or insufficient

cooling (A/C system

normal operative)Insufficient or excessive charge of

refrigerantCheck charge of refrigerant and system for

leaks.

Condenser clogged Check condenser.

A/C evaporator clogged or frosted Check A/C evaporator and A/C evaporator

thermistor.

A/C evaporator thermistor faulty Check A/C evaporator thermistor.

Expansion valve faulty Check expansion valve.

Receiver / dryer clogged Check receiver / dryer.

Compressor drive belt loosen or broken Adjust or replace drive belt.

Magnetic clutch faulty Check magnetic clutch.

Compressor faulty Check compressor.

Air in A/C system Replace receiver / dryer, and perform

evacuation and charging.

Air leaking from cooling unit or air duct Repair as necessary.

Heater and ventilation system faulty Check air inlet box (cooling unit), heater

control lever assembly and heater unit

referring to Section 1A.

Blower fan motor faulty Check blower fan motor referring to Sec-

tion 1A.

Excessive compressor oil existing in

A/C systemPull out compressor oil in A/C system cir-

cuit, and replace compressor.

Cool air won’t come

out only intermittentlyWiring connection faulty Repair as necessary.

Expansion valve faulty Check expansion valve.

Excessive moisture in A/C system Replace receiver / dryer, and perform

evacuation and charging.

Magnetic clutch faulty Check magnetic clutch.

Excessive charge of refrigerant Check charge of refrigerant.

Thermal switch faulty Check thermal switch.

Cool air comes out

only at high speedCondenser clogged Check A/C condenser.

Insufficient charge of refrigerant Check charge of refrigerant.

Air in A/C system Replace receiver / dryer, and perform

evacuation and charging.

Compressor drive belt loosen or broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air won’t come

out only at high speedExcessive charge of refrigerant Check charge refrigerant.

A/C evaporator frosted Check A/C evaporator and A/C evaporator

thermistor.

Insufficient velocity of

cooled airA/C evaporator clogged or frosted Check A/C evaporator and A/C evaporator

thermistor.

Air leaking from cooling unit or air duct Repair as necessary.

Blower fan motor faulty Check blower fan motor referring to Sec-

tion 1A.

Wiring or grounding faulty Repair as necessary. Condition Possible Cause Correction

Page 69 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-8 AIR CONDITIONING (OPTIONAL)

Abnormal noise from crankshaft pulley

Abnormal noise from tension pulley

Abnormal noise from A/C evaporator

Abnormal noise from blower fan motor

Condition Possible Cause Correction

A large rattling noise

is heard at idle or sud-

den acceleration.Loosen crankshaft pulley bolt. Retighten bolt.

Condition Possible Cause Correction

Clattering noise is

heard from pulley.Worn or damaged bearing. Replace tension pulley.

Pulley cranks upon

contact.Cracked or loose bracket. Replace or retighten bracket.

Condition Possible Cause Correction

Whistling sound is

heard from A/C evapo-

rator.Depending on the combination of the interior /

exterior temperatures, engine rpm and refriger-

ant pressure, the refrigerant flowing out of the

expansion valve may, under certain conditions,

make a whistling sound.At times, slightly decreasing refrig-

erant volume may stop this noise.

Inspect expansion valve and

replace if faulty.

Condition Possible Cause Correction

Blower fan motor

emits a chirping

sound in proportion to

its speed of rotation.Worn or damaged motor brushes or commuta-

tor.Repair or replace blower fan motor.

Fluttering noise or

large droning noise is

heard from blower fan

motor.Leaves or other debris introduced from fresh air

inlet to blower fan motor.Remove debris and make sure that

the screen at fresh air inlet is intact.

Page 71 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-10 AIR CONDITIONING (OPTIONAL)

Performance Diagnosis

1) Confirm that vehicle and environmental conditions are as fol-

lows.

Vehicle is not exposed to direct sun.

Ambient temperature is within 15 – 35 °C (59 – 95 °F).

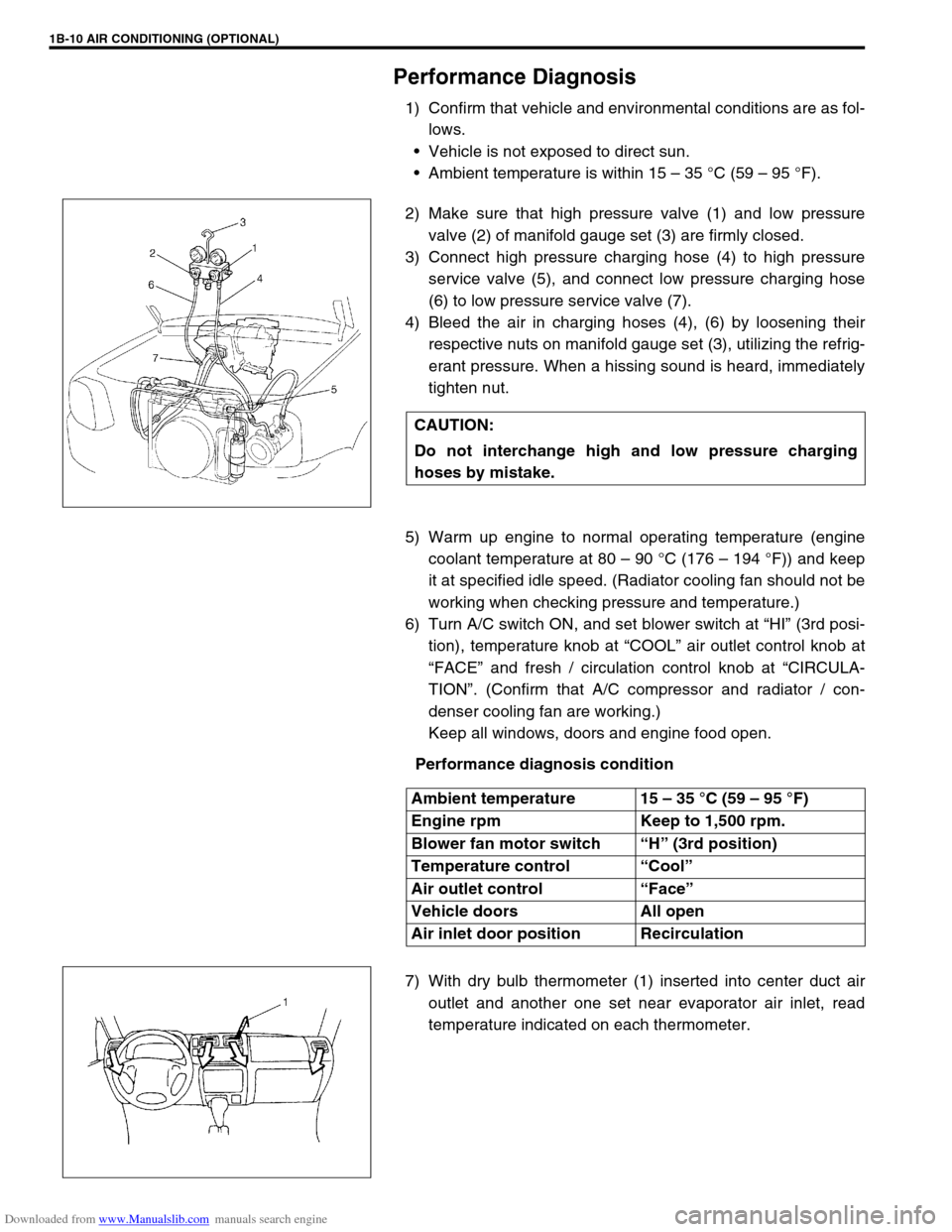

2) Make sure that high pressure valve (1) and low pressure

valve (2) of manifold gauge set (3) are firmly closed.

3) Connect high pressure charging hose (4) to high pressure

service valve (5), and connect low pressure charging hose

(6) to low pressure service valve (7).

4) Bleed the air in charging hoses (4), (6) by loosening their

respective nuts on manifold gauge set (3), utilizing the refrig-

erant pressure. When a hissing sound is heard, immediately

tighten nut.

5) Warm up engine to normal operating temperature (engine

coolant temperature at 80 – 90 °C (176 – 194 °F)) and keep

it at specified idle speed. (Radiator cooling fan should not be

working when checking pressure and temperature.)

6) Turn A/C switch ON, and set blower switch at “HI” (3rd posi-

tion), temperature knob at “COOL” air outlet control knob at

“FACE” and fresh / circulation control knob at “CIRCULA-

TION”. (Confirm that A/C compressor and radiator / con-

denser cooling fan are working.)

Keep all windows, doors and engine food open.

Performance diagnosis condition

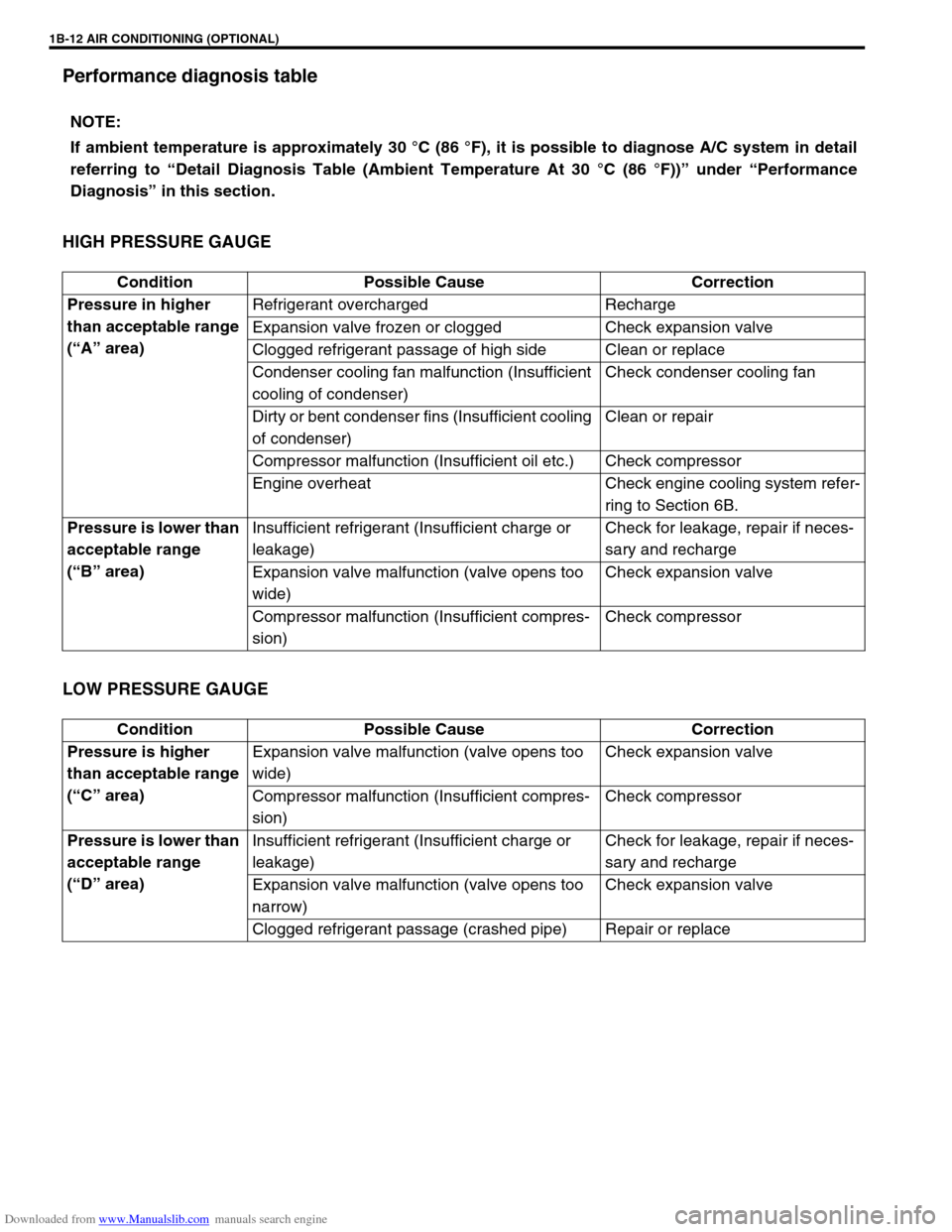

7) With dry bulb thermometer (1) inserted into center duct air

outlet and another one set near evaporator air inlet, read

temperature indicated on each thermometer. CAUTION:

Do not interchange high and low pressure charging

hoses by mistake.

Ambient temperature 15 – 35 °C (59 – 95 °F)

Engine rpm Keep to 1,500 rpm.

Blower fan motor switch “H” (3rd position)

Temperature control “Cool”

Air outlet control “Face”

Vehicle doors All open

Air inlet door position Recirculation

Page 73 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-12 AIR CONDITIONING (OPTIONAL)

Performance diagnosis table

HIGH PRESSURE GAUGE

LOW PRESSURE GAUGE

NOTE:

If ambient temperature is approximately 30 °C (86 °F), it is possible to diagnose A/C system in detail

referring to “Detail Diagnosis Table (Ambient Temperature At 30 °C (86 °F))” under “Performance

Diagnosis” in this section.

Condition Possible Cause Correction

Pressure in higher

than acceptable range

(“A” area)Refrigerant overcharged Recharge

Expansion valve frozen or clogged Check expansion valve

Clogged refrigerant passage of high side Clean or replace

Condenser cooling fan malfunction (Insufficient

cooling of condenser)Check condenser cooling fan

Dirty or bent condenser fins (Insufficient cooling

of condenser)Clean or repair

Compressor malfunction (Insufficient oil etc.) Check compressor

Engine overheat Check engine cooling system refer-

ring to Section 6B.

Pressure is lower than

acceptable range

(“B” area)Insufficient refrigerant (Insufficient charge or

leakage)Check for leakage, repair if neces-

sary and recharge

Expansion valve malfunction (valve opens too

wide)Check expansion valve

Compressor malfunction (Insufficient compres-

sion)Check compressor

Condition Possible Cause Correction

Pressure is higher

than acceptable range

(“C” area)Expansion valve malfunction (valve opens too

wide)Check expansion valve

Compressor malfunction (Insufficient compres-

sion)Check compressor

Pressure is lower than

acceptable range

(“D” area)Insufficient refrigerant (Insufficient charge or

leakage)Check for leakage, repair if neces-

sary and recharge

Expansion valve malfunction (valve opens too

narrow)Check expansion valve

Clogged refrigerant passage (crashed pipe) Repair or replace

Page 74 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-13

CROSSING POINT OF CENTER VENTILATION LOUVER TEMPERATURE AND RECIRCULATION AIR

INLET TEMPERATURE

Detail diagnosis table (Ambient temperature at 30°C (86°F))

Condition Possible Cause Correction

Crossing point is

higher than accept-

able range

(“E” area)Insufficient or excessive charge of refrigerant Check refrigerant pressure

Dirty or bent A/C evaporator fins Clean or repair

Air leakage from cooling (heater) unit or air duct Repair or replace

Malfunctioning, switch over function of door in

cooling (heater) unitRepair or replace

Compressor malfunction Check compressor

Crossing point is

lower than acceptable

range

(“F” area)Insufficient air volume from center duct (Heater

blower malfunction)Check blower motor and fan

Compressor malfunction Check compressor

Condition

Possible Cause Correction MANIFOLD

GAUGEMPa

(kg/cm

2)

(psi)Detail

Lo Hi

0.23 – 0.35

(2.3 – 3.5)

(33 – 50)1.4 – 1.75

(14 – 17.5)

(200 – 249)Normal condition

––

Negative

pressure0.5 – 0.6

(5 – 6)

(71.2 – 85.3)The low pressure side

reads a negative pres-

sure, and the high pres-

sure side reads an

extremely low pressure.

Presence of frost

around tubing to and

from receiver / dryer

and expansion valve.Dust particles or water

droplets are either stuck

or frozen inside expan-

sion valve, preventing the

refrigerant from flowing.Clean expansion valve.

Replace it if it cannot be

cleaned.

Replace receiver / dryer.

Evacuate the A/C sys-

tem and recharge with

fresh refrigerant.

Normal :

0.23 – 0.35

(2.3 – 3.5)

(33 – 50)

↑

↑ ↑ ↑ ↓

↓↓ ↓

Abnormal :

Negative

pressureNormal :

1.4 – 1.75

(14 – 17.5)

(200 – 249)

↑

↑ ↑ ↑ ↓

↓↓ ↓

Abnormal :

0.69 – 0.98

(7 – 10)

(100 – 142)During A/C operation,

the low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.Expansion valve is frozen

due to moisture in the

system, and temporarily

shuts off the refrigeration

cycle.Replace expansion valve.

Replace receiver / dryer.

Evacuate A/C system

and recharge with fresh

refrigerant.

Page 75 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-14 AIR CONDITIONING (OPTIONAL)

0.05 – 0.15

(0.5 – 1.5)

(4.2 – 21.3)

0.69 – 0.98

(7 – 10)

(100 – 142)Both low and high pres-

sure sides indicate low

readings.

Continuous air bub-

bles are visible through

sight glass.

Output air is slightly

cold.Insufficient refrigerant in

system.

(Refrigerant leaking)Using leak detector,

check for leaks and repair

as necessary.

Recharge refrigerant to a

specified amount.

If the pressure reading is

almost 0 when the mani-

fold gauges are attached,

check for any leaks,

repair them, and evacu-

ate the system.

0.4 – 0.6

(4 – 6)

(56.9 – 85.3)Pressure on low pres-

sure side is high.

Pressure on high pres-

sure side is low.

Both pressure becom-

ing equal right after A/C

is turned OFF.Internal leak in compres-

sor.Inspect compressor and

repair or replace as nec-

essary.

0.35 – 0.45

(3.5 – 4.5)

(50 – 64)

1.96 – 2.45

(20 – 25)

(285 – 355)Pressure on both low

and high pressure

sides is high.

Air bubbles are not visi-

ble even when engine

rpm is lowered.Overcharged A/C sys-

tem.Adjust refrigerant to

specified amount.

Faulty condenser cooling

operation.Clean condenser.

Faulty condenser cooling

fan operation.Inspect and repair con-

denser cooling fan.

Pressure on both low

and high pressure

sides is high.

Low pressure side tub-

ing is not cold when

touched.

Air bubbles are visible

through sight glass.Presence of air in A/C

system.

(Improperly evacuated)Replace receiver / dryer.

Inspect quantity of com-

pressor oil and presence

of contaminants in oil.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.55

(4.5 – 5.5)

(64 – 78)Pressure on both low

and high pressure

sides is high.

Large amount of frost

or dew on the low pres-

sure side tubing.Faulty expansion valve.

Refrigerant flow is not

regulated properly.Replace expansion valve. Condition

Possible Cause Correction MANIFOLD

GAUGEMPa

(kg/cm

2)

(psi)Detail

Lo Hi

Page 85 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-24 AIR CONDITIONING (OPTIONAL)

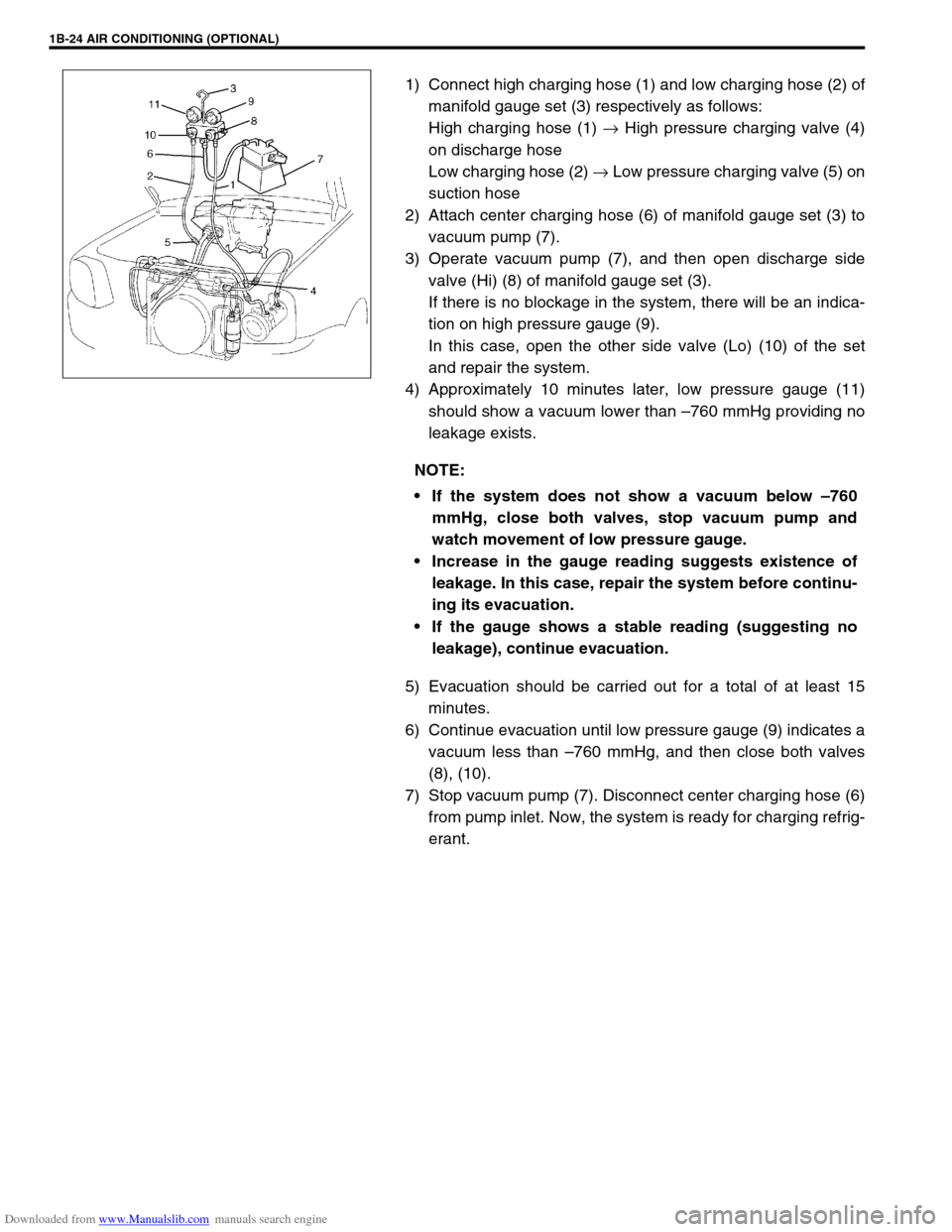

1) Connect high charging hose (1) and low charging hose (2) of

manifold gauge set (3) respectively as follows:

High charging hose (1) → High pressure charging valve (4)

on discharge hose

Low charging hose (2) → Low pressure charging valve (5) on

suction hose

2) Attach center charging hose (6) of manifold gauge set (3) to

vacuum pump (7).

3) Operate vacuum pump (7), and then open discharge side

valve (Hi) (8) of manifold gauge set (3).

If there is no blockage in the system, there will be an indica-

tion on high pressure gauge (9).

In this case, open the other side valve (Lo) (10) of the set

and repair the system.

4) Approximately 10 minutes later, low pressure gauge (11)

should show a vacuum lower than –760 mmHg providing no

leakage exists.

5) Evacuation should be carried out for a total of at least 15

minutes.

6) Continue evacuation until low pressure gauge (9) indicates a

vacuum less than –760 mmHg, and then close both valves

(8), (10).

7) Stop vacuum pump (7). Disconnect center charging hose (6)

from pump inlet. Now, the system is ready for charging refrig-

erant. NOTE:

If the system does not show a vacuum below –760

mmHg, close both valves, stop vacuum pump and

watch movement of low pressure gauge.

Increase in the gauge reading suggests existence of

leakage. In this case, repair the system before continu-

ing its evacuation.

If the gauge shows a stable reading (suggesting no

leakage), continue evacuation.

Page 86 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-25

Charging

Charging procedure

The initial charging of the A/C system is performed from the high

pressure side with the engine stopped.

And next, this method must be followed by charging from the low

pressure side with the engine running.

1) Check to make sure that hoses are routed properly after

evacuating the system. CAUTION:

Always charge through low pressure side of A/C sys-

tem at after the initial charging is performed from the

high pressure side with the engine stopped.

Never charge to high pressure side of A/C system with

engine running.

Do not charge while compressor is hot.

When installing tap valve to refrigerant container to

make a hole there through, carefully follow directions

given by manufacturer.

A pressure gauge should always be used before and

during charging.

The refrigerant container should be emptied of refrig-

erant when discarding it.

The refrigerant container should not be heated up to

40 °C (104 °F) or over.

Refrigerant container should not be reversed in direc-

tion during charging. Reversing in direction causes liq-

uid refrigerant to enter compressor, causing troubles,

such as compression of liquid refrigerant and the like.

NOTE:

The air conditioning system contains HFC-134a (R-134a).

Described here is a method to charge the air conditioning

system with refrigerant from the refrigerant service con-

tainer.

When charging refrigerant recovered by using the refrig-

erant and recycling equipment (when recycling refriger-

ant), follow the procedure described in the equipment

manufacturer’s instruction manual.

Page 87 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-26 AIR CONDITIONING (OPTIONAL)

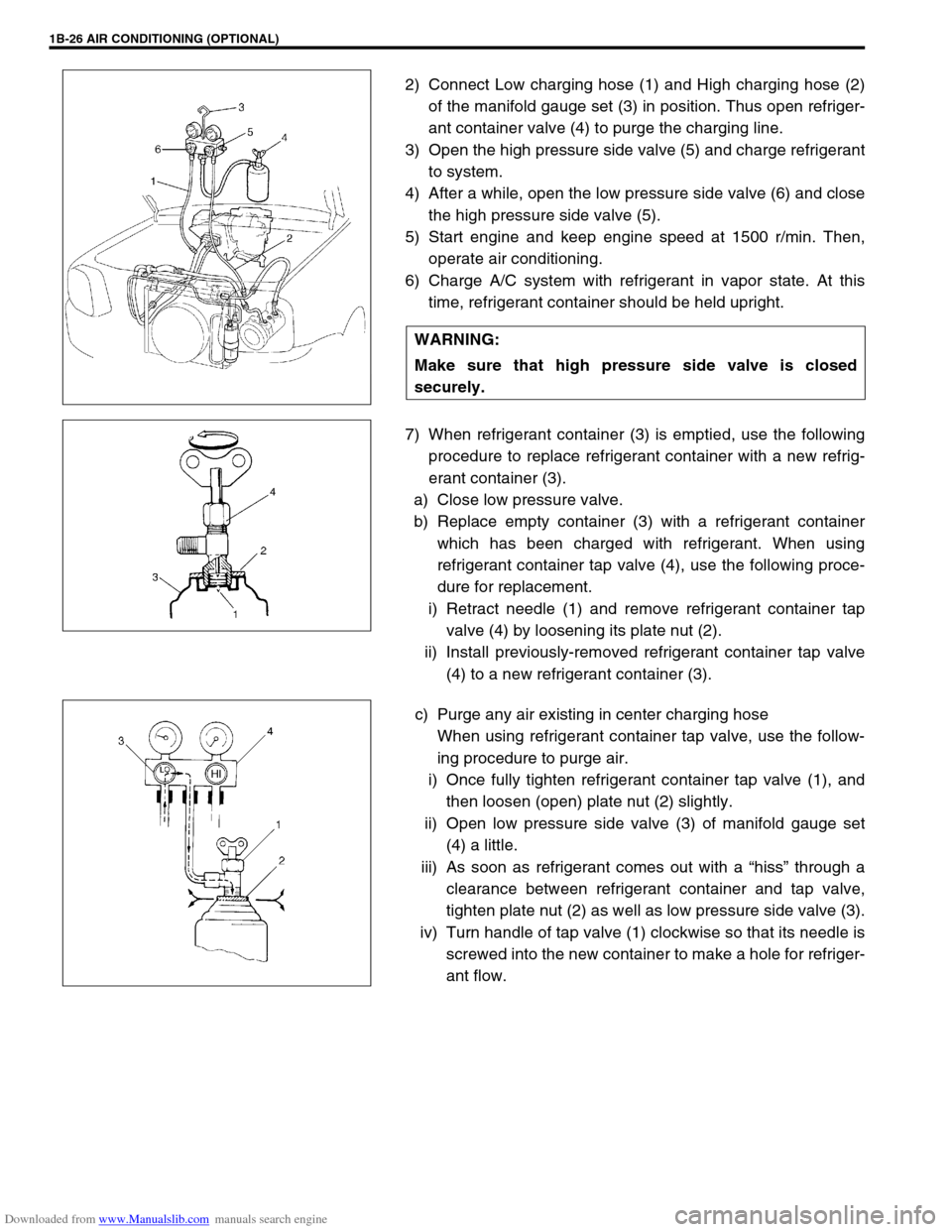

2) Connect Low charging hose (1) and High charging hose (2)

of the manifold gauge set (3) in position. Thus open refriger-

ant container valve (4) to purge the charging line.

3) Open the high pressure side valve (5) and charge refrigerant

to system.

4) After a while, open the low pressure side valve (6) and close

the high pressure side valve (5).

5) Start engine and keep engine speed at 1500 r/min. Then,

operate air conditioning.

6) Charge A/C system with refrigerant in vapor state. At this

time, refrigerant container should be held upright.

7) When refrigerant container (3) is emptied, use the following

procedure to replace refrigerant container with a new refrig-

erant container (3).

a) Close low pressure valve.

b) Replace empty container (3) with a refrigerant container

which has been charged with refrigerant. When using

refrigerant container tap valve (4), use the following proce-

dure for replacement.

i) Retract needle (1) and remove refrigerant container tap

valve (4) by loosening its plate nut (2).

ii) Install previously-removed refrigerant container tap valve

(4) to a new refrigerant container (3).

c) Purge any air existing in center charging hose

When using refrigerant container tap valve, use the follow-

ing procedure to purge air.

i) Once fully tighten refrigerant container tap valve (1), and

then loosen (open) plate nut (2) slightly.

ii) Open low pressure side valve (3) of manifold gauge set

(4) a little.

iii) As soon as refrigerant comes out with a “hiss” through a

clearance between refrigerant container and tap valve,

tighten plate nut (2) as well as low pressure side valve (3).

iv) Turn handle of tap valve (1) clockwise so that its needle is

screwed into the new container to make a hole for refriger-

ant flow. WARNING:

Make sure that high pressure side valve is closed

securely.

Page 88 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-27

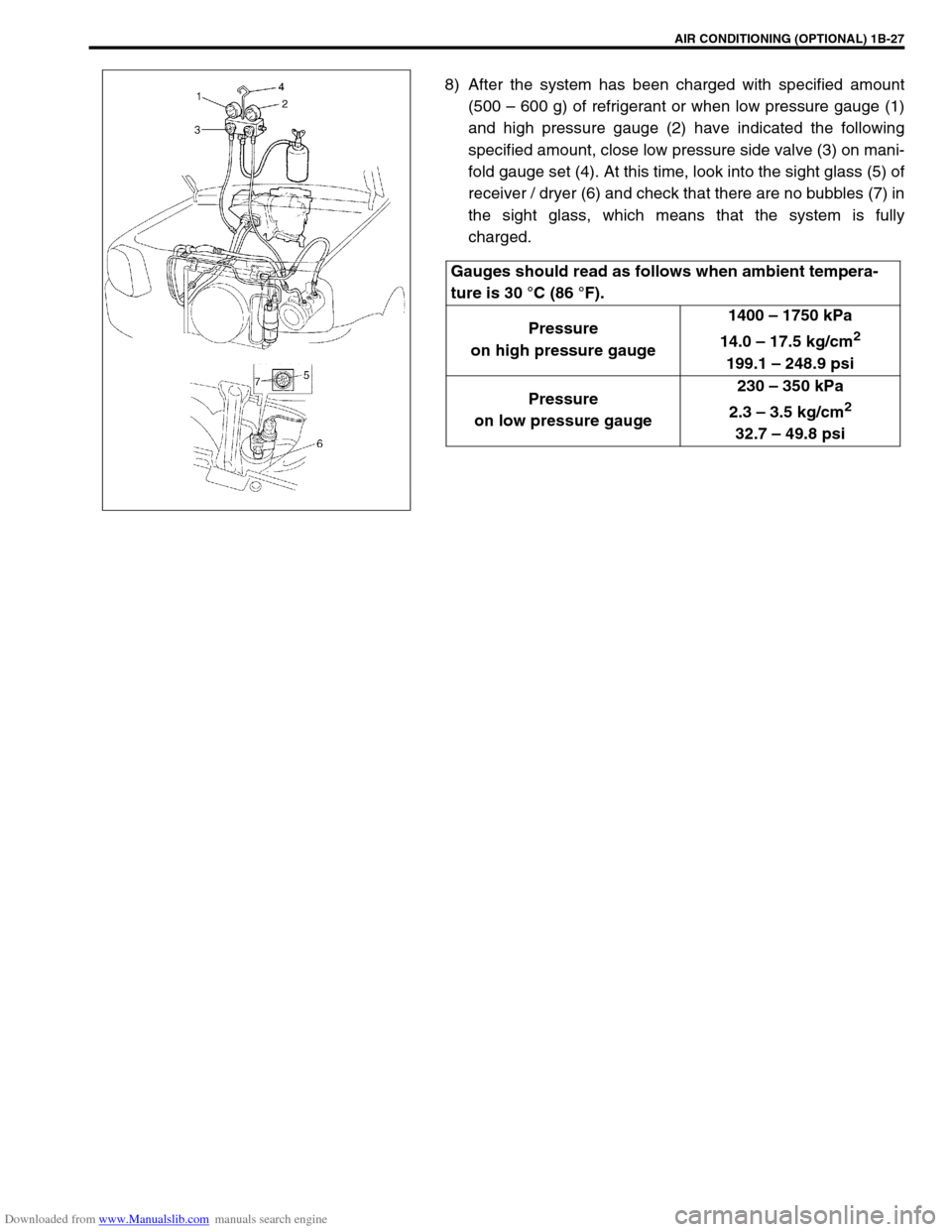

8) After the system has been charged with specified amount

(500 – 600 g) of refrigerant or when low pressure gauge (1)

and high pressure gauge (2) have indicated the following

specified amount, close low pressure side valve (3) on mani-

fold gauge set (4). At this time, look into the sight glass (5) of

receiver / dryer (6) and check that there are no bubbles (7) in

the sight glass, which means that the system is fully

charged.

Gauges should read as follows when ambient tempera-

ture is 30 °C (86 °F).

Pressure

on high pressure gauge1400 – 1750 kPa

14.0 – 17.5 kg/cm

2

199.1 – 248.9 psi

Pressure

on low pressure gauge230 – 350 kPa

2.3 – 3.5 kg/cm

2

32.7 – 49.8 psi