engine SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 301 of 687

Downloaded from www.Manualslib.com manuals search engine 5-40 BRAKES

Rinse cylinder in clean brake fluid. Shake excess rinsing

fluid from cylinder. Do not use a cloth to dry cylinder, as lint

from cloth cannot be kept from cylinder bore surfaces.

ASSEMBLY

1) Install secondary piston assembly into cylinder.

2) Install primary piston in cylinder.

3) Depress, and install circlip (2).

4) Install piston stopper bolt with pistons pushed in all the way

and tighten it to specified torque (For vehicle without ABS).

Tightening torque

Piston stopper bolt

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

Fill Reservoir

NOTE:

See NOTE at the beginning of this section.

Before assembling, wash each part in fluid recom-

mended to use for that vehicle.

1. Rod

CAUTION:

Do not use shock absorber fluid or any other fluid which

contains mineral oil. Do not use container which has

been used for mineral oil or which is wet from water. Min-

eral oil will cause swelling and distortion of rubber parts

in hydraulic brake system and water will mix with brake

fluid, lowering fluid boiling point. Keep all fluid contain-

ers capped to prevent contamination.

Page 302 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-41

Fluid to fill reservoir with is indicated on reservoir cap of that vehi-

cle with embossed letters or in owner’s manual supplied with it.

Add fluid up to MAX line.

Page 303 of 687

Downloaded from www.Manualslib.com manuals search engine 5-42 BRAKES

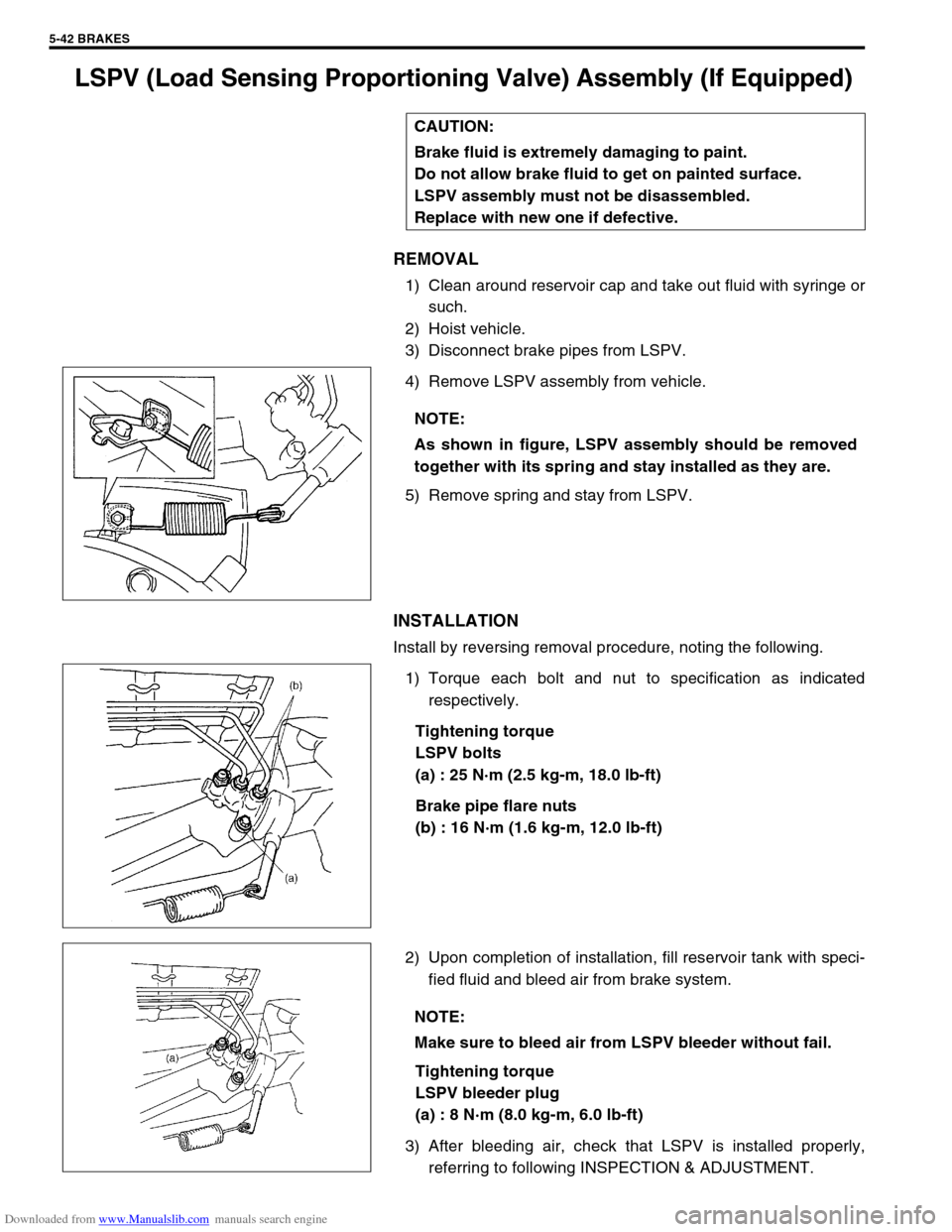

LSPV (Load Sensing Proportioning Valve) Assembly (If Equipped)

REMOVAL

1) Clean around reservoir cap and take out fluid with syringe or

such.

2) Hoist vehicle.

3) Disconnect brake pipes from LSPV.

4) Remove LSPV assembly from vehicle.

5) Remove spring and stay from LSPV.

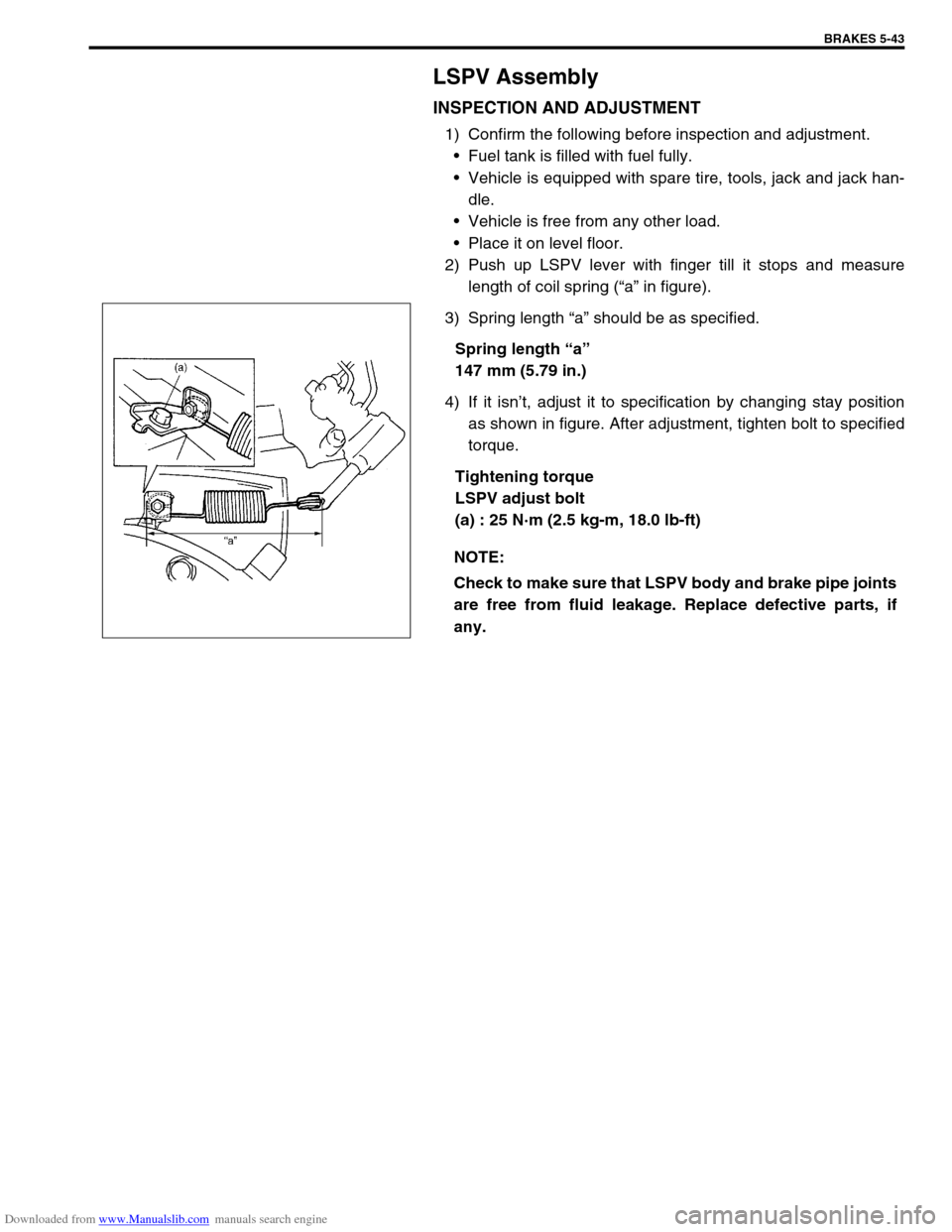

INSTALLATION

Install by reversing removal procedure, noting the following.

1) Torque each bolt and nut to specification as indicated

respectively.

Tightening torque

LSPV bolts

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

Brake pipe flare nuts

(b) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

2) Upon completion of installation, fill reservoir tank with speci-

fied fluid and bleed air from brake system.

Tightening torque

LSPV bleeder plug

(a) : 8 N·m (8.0 kg-m, 6.0 lb-ft)

3) After bleeding air, check that LSPV is installed properly,

referring to following INSPECTION & ADJUSTMENT. CAUTION:

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted surface.

LSPV assembly must not be disassembled.

Replace with new one if defective.

NOTE:

As shown in figure, LSPV assembly should be removed

together with its spring and stay installed as they are.

NOTE:

Make sure to bleed air from LSPV bleeder without fail.

Page 304 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-43

LSPV Assembly

INSPECTION AND ADJUSTMENT

1) Confirm the following before inspection and adjustment.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

Vehicle is free from any other load.

Place it on level floor.

2) Push up LSPV lever with finger till it stops and measure

length of coil spring (“a” in figure).

3) Spring length “a” should be as specified.

Spring length “a”

147 mm (5.79 in.)

4) If it isn’t, adjust it to specification by changing stay position

as shown in figure. After adjustment, tighten bolt to specified

torque.

Tightening torque

LSPV adjust bolt

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

NOTE:

Check to make sure that LSPV body and brake pipe joints

are free from fluid leakage. Replace defective parts, if

any.

Page 305 of 687

Downloaded from www.Manualslib.com manuals search engine 5-44 BRAKES

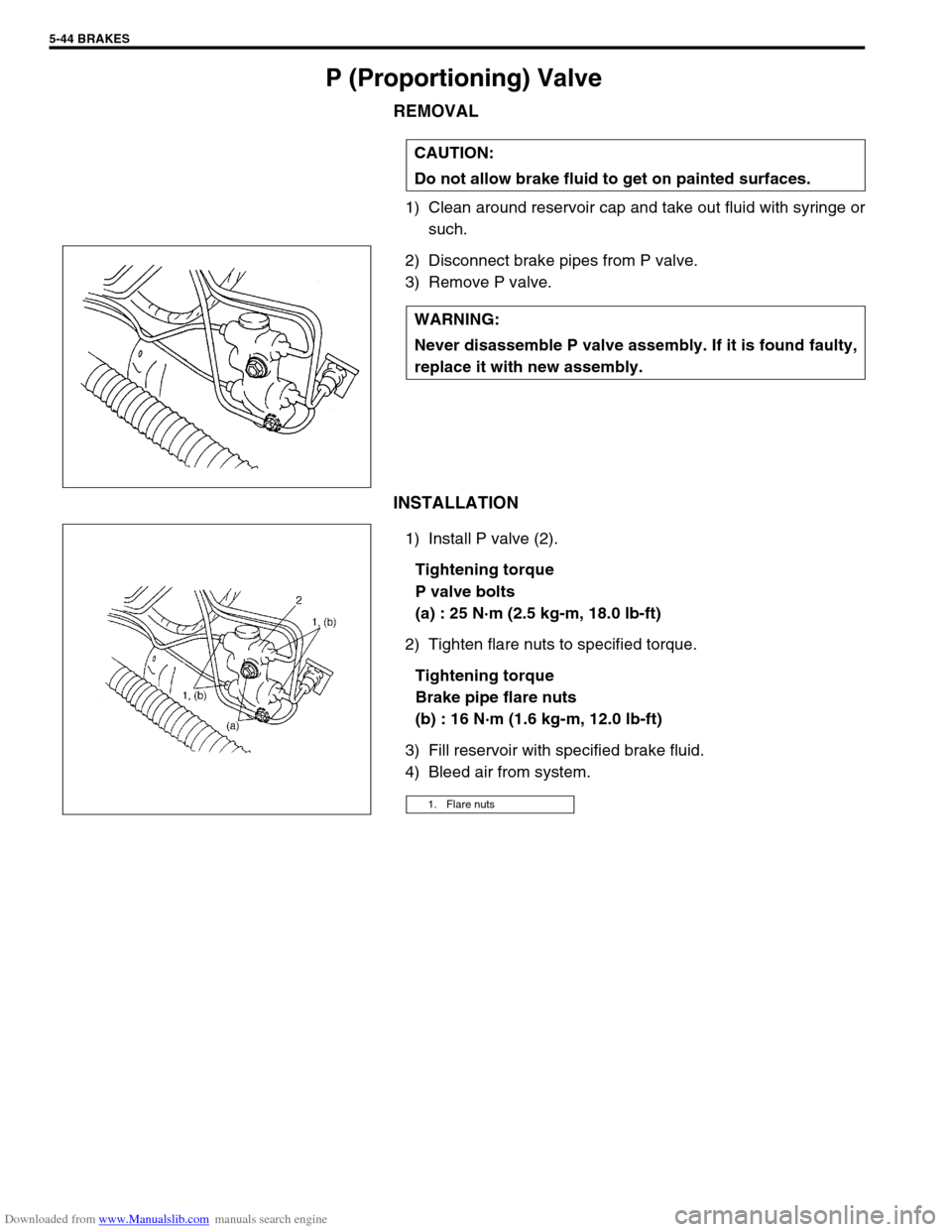

P (Proportioning) Valve

REMOVAL

1) Clean around reservoir cap and take out fluid with syringe or

such.

2) Disconnect brake pipes from P valve.

3) Remove P valve.

INSTALLATION

1) Install P valve (2).

Tightening torque

P valve bolts

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

2) Tighten flare nuts to specified torque.

Tightening torque

Brake pipe flare nuts

(b) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

3) Fill reservoir with specified brake fluid.

4) Bleed air from system.CAUTION:

Do not allow brake fluid to get on painted surfaces.

WARNING:

Never disassemble P valve assembly. If it is found faulty,

replace it with new assembly.

1. Flare nuts

Page 306 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-45

Brake Booster

REMOVAL

1) Remove master cylinder assembly, referring to “Maser Cylin-

der” in the section.

2) Disconnect brake vacuum hose (2) from booster (1).

3) Remove brake pipes (3).

1. Brake master cylinder assembly 5. Nut 9. Brake vacuum hose

2. Brake booster assembly 6. Clevis pin Tightening torque

3. Gasket 7. Clip

4. Push rod clevis 8. Nut

CAUTION:

Never disassemble brake booster. Disassembly will spoil

its original function. If faulty condition is found, replace it

with new one.

Page 307 of 687

Downloaded from www.Manualslib.com manuals search engine 5-46 BRAKES

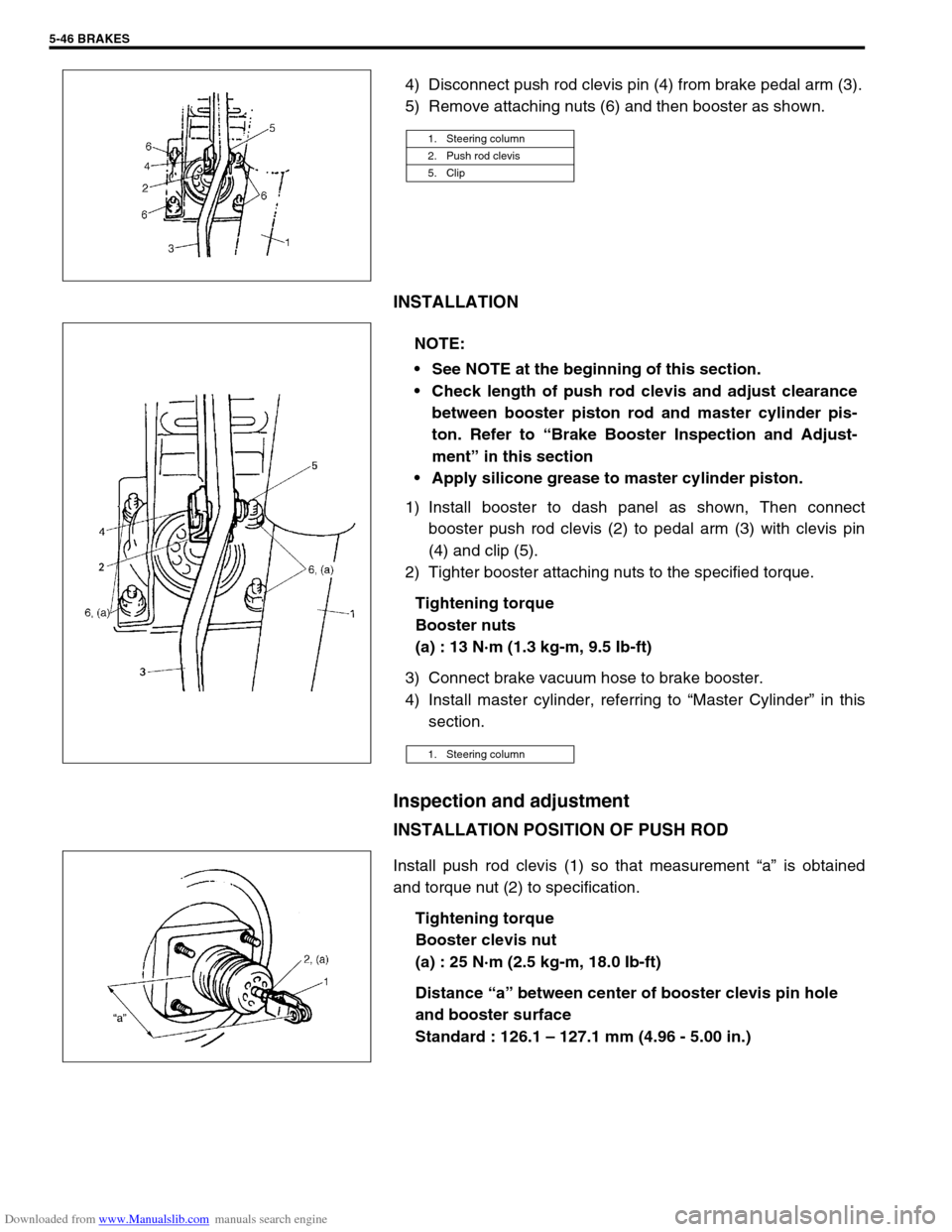

4) Disconnect push rod clevis pin (4) from brake pedal arm (3).

5) Remove attaching nuts (6) and then booster as shown.

INSTALLATION

1) Install booster to dash panel as shown, Then connect

booster push rod clevis (2) to pedal arm (3) with clevis pin

(4) and clip (5).

2) Tighter booster attaching nuts to the specified torque.

Tightening torque

Booster nuts

(a) : 13 N·m (1.3 kg-m, 9.5 Ib-ft)

3) Connect brake vacuum hose to brake booster.

4) Install master cylinder, referring to “Master Cylinder” in this

section.

Inspection and adjustment

INSTALLATION POSITION OF PUSH ROD

Install push rod clevis (1) so that measurement “a” is obtained

and torque nut (2) to specification.

Tightening torque

Booster clevis nut

(a) : 25 N·m (2.5 kg-m, 18.0 Ib-ft)

Distance “a” between center of booster clevis pin hole

and booster surface

Standard : 126.1 – 127.1 mm (4.96 - 5.00 in.)

1. Steering column

2. Push rod clevis

5. Clip

NOTE:

See NOTE at the beginning of this section.

Check length of push rod clevis and adjust clearance

between booster piston rod and master cylinder pis-

ton. Refer to “Brake Booster Inspection and Adjust-

ment” in this section

Apply silicone grease to master cylinder piston.

1. Steering column

Page 308 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-47

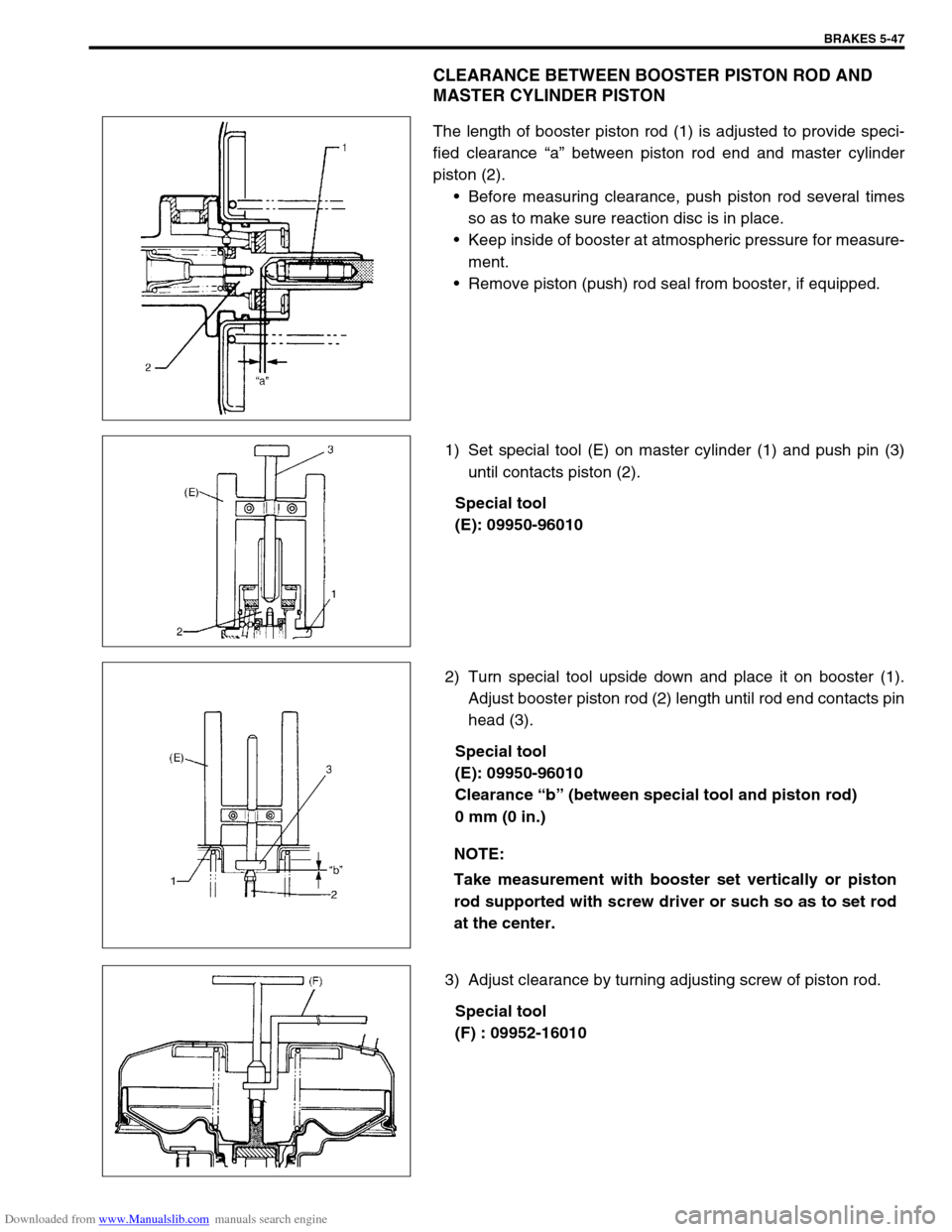

CLEARANCE BETWEEN BOOSTER PISTON ROD AND

MASTER CYLINDER PISTON

The length of booster piston rod (1) is adjusted to provide speci-

fied clearance “a” between piston rod end and master cylinder

piston (2).

Before measuring clearance, push piston rod several times

so as to make sure reaction disc is in place.

Keep inside of booster at atmospheric pressure for measure-

ment.

Remove piston (push) rod seal from booster, if equipped.

1) Set special tool (E) on master cylinder (1) and push pin (3)

until contacts piston (2).

Special tool

(E): 09950-96010

2) Turn special tool upside down and place it on booster (1).

Adjust booster piston rod (2) length until rod end contacts pin

head (3).

Special tool

(E): 09950-96010

Clearance “b” (between special tool and piston rod)

0 mm (0 in.)

3) Adjust clearance by turning adjusting screw of piston rod.

Special tool

(F) : 09952-16010

NOTE:

Take measurement with booster set vertically or piston

rod supported with screw driver or such so as to set rod

at the center.

Page 309 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 5-48 BRAKES

Brake Hose/Pipe

Front brake hose/pipe

For left-hand steering vehicle

[A] : For vehicle without ABS X : View X 5. Brake caliper 12. SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 5-48 BRAKES

Brake Hose/Pipe

Front brake hose/pipe

For left-hand steering vehicle

[A] : For vehicle without ABS X : View X 5. Brake caliper 12.](/img/20/7588/w960_7588-308.png)

Downloaded from www.Manualslib.com manuals search engine 5-48 BRAKES

Brake Hose/Pipe

Front brake hose/pipe

For left-hand steering vehicle

[A] : For vehicle without ABS X : View X 5. Brake caliper 12. To front left brake caliper

[B] : For vehicle with ABS Y : View Y 6. 4 way joint 13. To rear brake

F : Front side Z : View Z 7. 5 way joint a-d: Clamp

R : Right side 1. E-ring 8. ABS hydraulic unit/control mod-

ule assemblyTightening torque

T : Top side 2. Flexible hose 9. P valve

V : View V 3. Hose washer 10. Hose bracket

W : View W 4. Hose bolt 11. To front right brake caliper

Page 310 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine BRAKES 5-49

For right-hand steering vehicle

[A] : For vehicle without ABS X : View X 5. Brake caliper 12. To front left brake caliper

[B] : For SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine BRAKES 5-49

For right-hand steering vehicle

[A] : For vehicle without ABS X : View X 5. Brake caliper 12. To front left brake caliper

[B] : For](/img/20/7588/w960_7588-309.png)

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-49

For right-hand steering vehicle

[A] : For vehicle without ABS X : View X 5. Brake caliper 12. To front left brake caliper

[B] : For vehicle with ABS Y : View Y 6. 4 way joint 13. To rear brake

F : Front side Z : View Z 7. 5 way joint 14. Front brake master cylinder

R : Right side 1. E-ring 8. ABS hydraulic unit a-f: Clamp

T : Top side 2. Flexible hose 9. P valve Tightening torque

V : View V 3. Hose washer 10. Hose bracket

W : View W 4. Hose bolt 11. To front right brake caliper