Map sensor SUZUKI JIMNY 2005 3.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 634 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-29

Electronic Control System

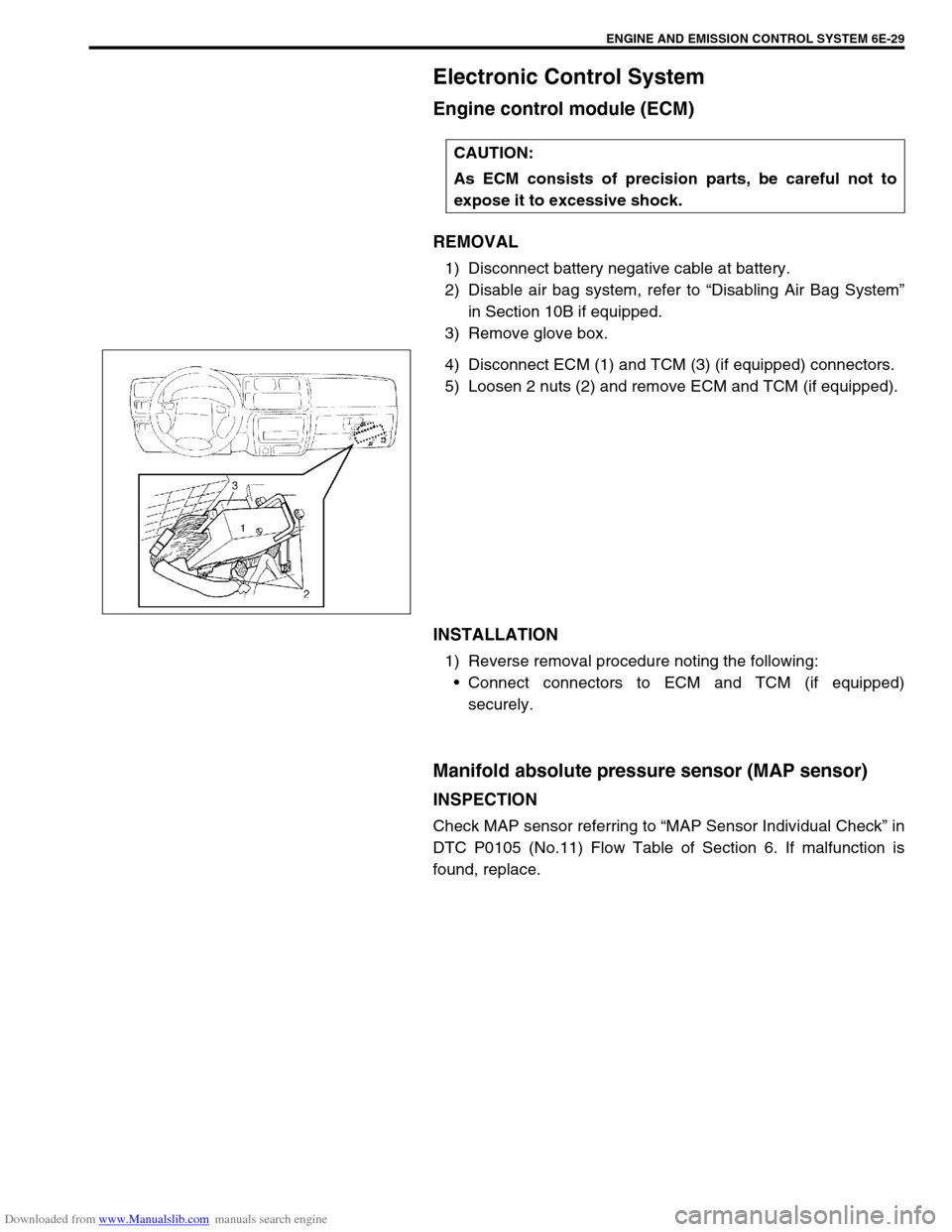

Engine control module (ECM)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Disable air bag system, refer to “Disabling Air Bag System”

in Section 10B if equipped.

3) Remove glove box.

4) Disconnect ECM (1) and TCM (3) (if equipped) connectors.

5) Loosen 2 nuts (2) and remove ECM and TCM (if equipped).

INSTALLATION

1) Reverse removal procedure noting the following:

Connect connectors to ECM and TCM (if equipped)

securely.

Manifold absolute pressure sensor (MAP sensor)

INSPECTION

Check MAP sensor referring to “MAP Sensor Individual Check” in

DTC P0105 (No.11) Flow Table of Section 6. If malfunction is

found, replace.CAUTION:

As ECM consists of precision parts, be careful not to

expose it to excessive shock.

Page 651 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-2 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

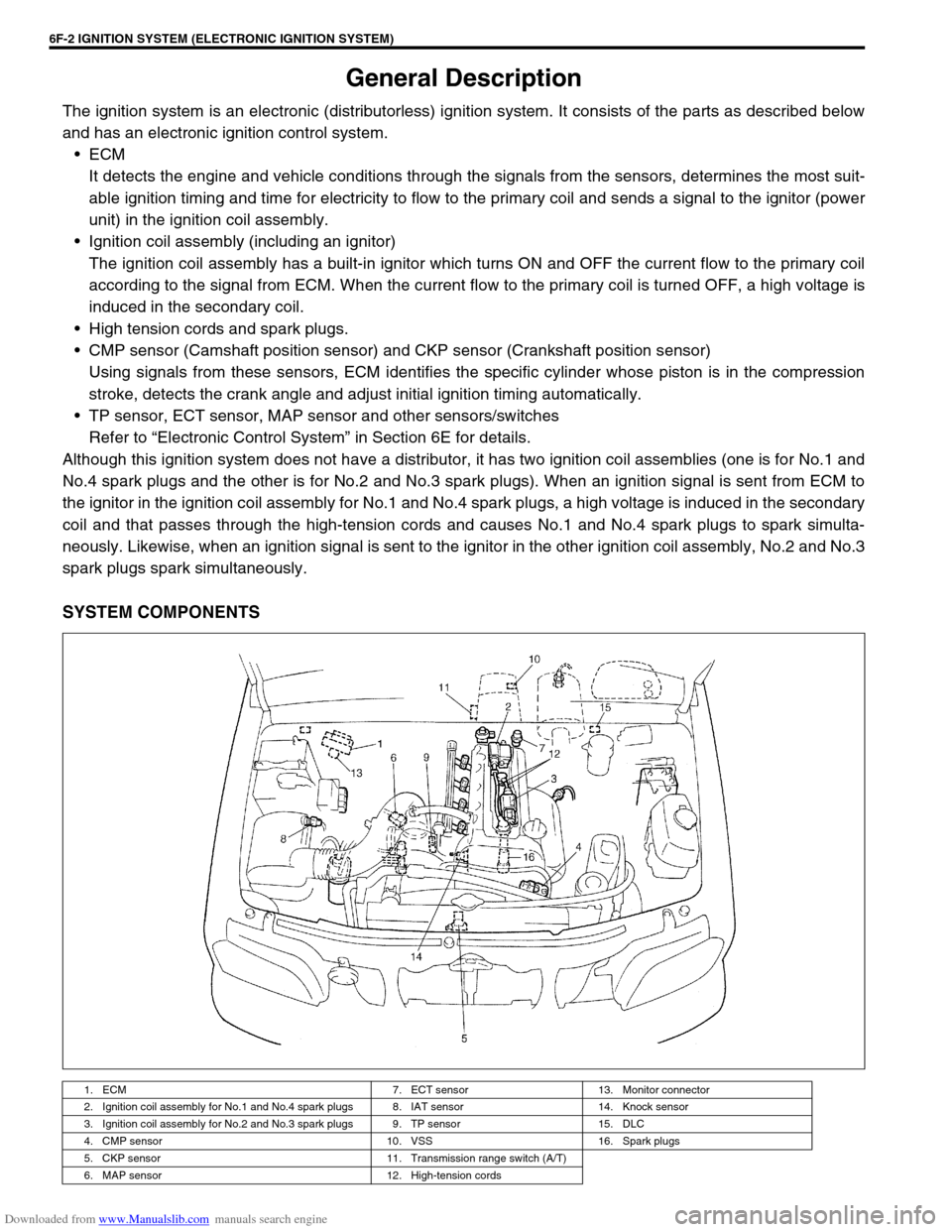

General Description

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below

and has an electronic ignition control system.

ECM

It detects the engine and vehicle conditions through the signals from the sensors, determines the most suit-

able ignition timing and time for electricity to flow to the primary coil and sends a signal to the ignitor (power

unit) in the ignition coil assembly.

Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built-in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is

induced in the secondary coil.

High tension cords and spark plugs.

CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression

stroke, detects the crank angle and adjust initial ignition timing automatically.

TP sensor, ECT sensor, MAP sensor and other sensors/switches

Refer to “Electronic Control System” in Section 6E for details.

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and

No.4 spark plugs and the other is for No.2 and No.3 spark plugs). When an ignition signal is sent from ECM to

the ignitor in the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary

coil and that passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simulta-

neously. Likewise, when an ignition signal is sent to the ignitor in the other ignition coil assembly, No.2 and No.3

spark plugs spark simultaneously.

SYSTEM COMPONENTS

1. ECM 7. ECT sensor 13. Monitor connector

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. IAT sensor 14. Knock sensor

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. TP sensor 15. DLC

4. CMP sensor 10. VSS 16. Spark plugs

5. CKP sensor 11. Transmission range switch (A/T)

6. MAP sensor 12. High-tension cords

Page 652 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-3

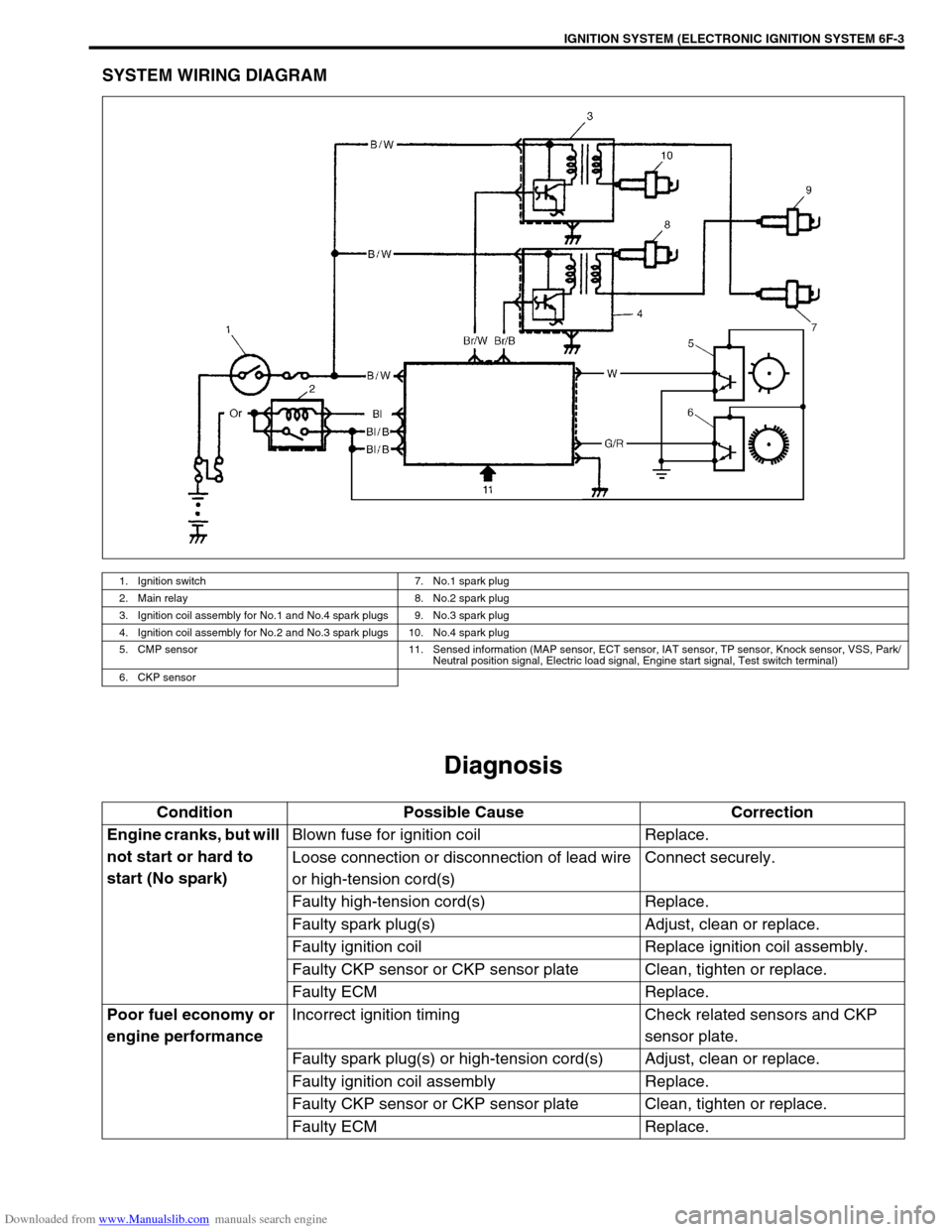

SYSTEM WIRING DIAGRAM

Diagnosis

1. Ignition switch 7. No.1 spark plug

2. Main relay 8. No.2 spark plug

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, IAT sensor, TP sensor, Knock sensor, VSS, Park/

Neutral position signal, Electric load signal, Engine start signal, Test switch terminal)

6. CKP sensor

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to

start (No spark)Blown fuse for ignition coil Replace.

Loose connection or disconnection of lead wire

or high-tension cord(s)Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Adjust, clean or replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performanceIncorrect ignition timing Check related sensors and CKP

sensor plate.

Faulty spark plug(s) or high-tension cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.