battery SUZUKI JIMNY 2005 3.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 262 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

5

9

10

10A

10B

9

10

10A

10B

SECTION 5

BRAKES

CONTENTS

General Description ......................................... 5-3

Diagnosis .......................................................... 5-4

Road Testing Brakes ...................................... 5-4

Brake Fluid Leaks .......................................... 5-4

Substandard or Contaminated Brake Fluid .... 5-4

Diagnosis Table ............................................. 5-5

Brake Pedal Free Height Adjustment ............. 5-8

Brake Pedal Play Check ................................ 5-8

Stop Light Switch Adjustment ........................ 5-8

Excessive Pedal Travel Check ....................... 5-9

Front Brake Disc Check ................................. 5-9

Front Brake Pad Check .................................. 5-9

Rear Brake Shoe Check .............................. 5-10

Master Cylinder and Brake Fluid Level

Check ........................................................... 5-10

Rear Drum Brake Shoe Adjustment ............. 5-11

Parking Brake Inspection and Adjustment ... 5-11

Booster Operation Check ............................. 5-12Fluid Pressure Test

(If Equipped with LSPV) ............................... 5-15

On-Vehicle Service ........................................ 5-17

Air Bleeding of Brake System ...................... 5-17

Brake Hose and Pipe Inspection.................. 5-18

Front Disc Brake .......................................... 5-19

Brake pad ................................................. 5-20

Caliper assembly...................................... 5-22

Brake Disc.................................................... 5-26

Rear Brake ................................................... 5-29

Brake drum............................................... 5-29

Brake shoe ............................................... 5-32

Wheel Cylinder............................................. 5-33

Brake back plate ...................................... 5-34

Master Cylinder .............................................. 5-36

Master Cylinder Reservoir ........................... 5-36

Master Cylinder Assembly ........................... 5-37 WARNING:

For lifting point of vehicle, refer to Section 0A.

WARNING:

For vehicles equipped with Supplement Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

When inspecting and servicing vehicle equipped with ABS, be sure to refer to section 5E first.

All brake fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of

same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of all parts. There is to be no welding as it may result

in extensive damage and weakening of the metal.

Page 313 of 687

Downloaded from www.Manualslib.com manuals search engine 5-52 BRAKES

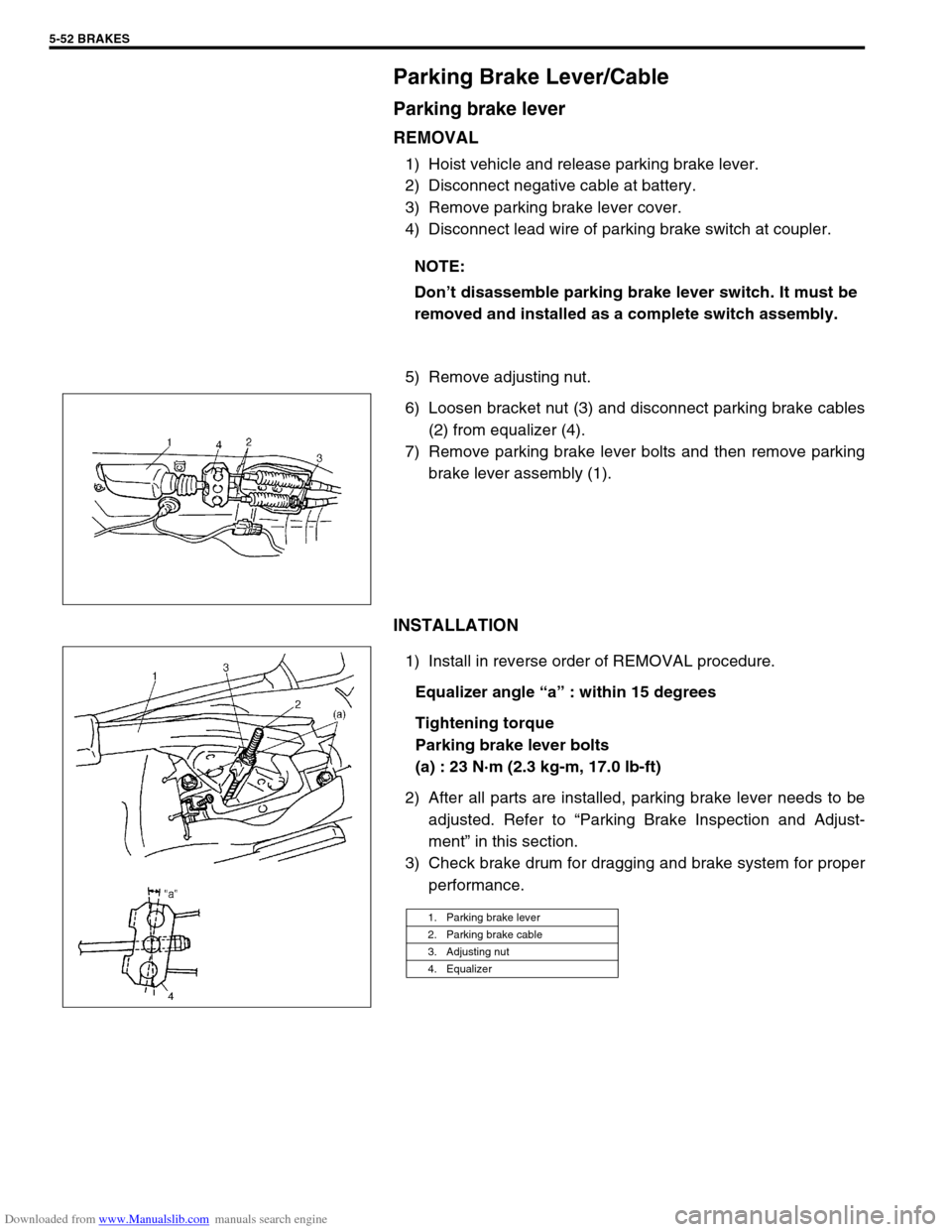

Parking Brake Lever/Cable

Parking brake lever

REMOVAL

1) Hoist vehicle and release parking brake lever.

2) Disconnect negative cable at battery.

3) Remove parking brake lever cover.

4) Disconnect lead wire of parking brake switch at coupler.

5) Remove adjusting nut.

6) Loosen bracket nut (3) and disconnect parking brake cables

(2) from equalizer (4).

7) Remove parking brake lever bolts and then remove parking

brake lever assembly (1).

INSTALLATION

1) Install in reverse order of REMOVAL procedure.

Equalizer angle “a” : within 15 degrees

Tightening torque

Parking brake lever bolts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

2) After all parts are installed, parking brake lever needs to be

adjusted. Refer to “Parking Brake Inspection and Adjust-

ment” in this section.

3) Check brake drum for dragging and brake system for proper

performance. NOTE:

Don’t disassemble parking brake lever switch. It must be

removed and installed as a complete switch assembly.

1. Parking brake lever

2. Parking brake cable

3. Adjusting nut

4. Equalizer

Page 320 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-3

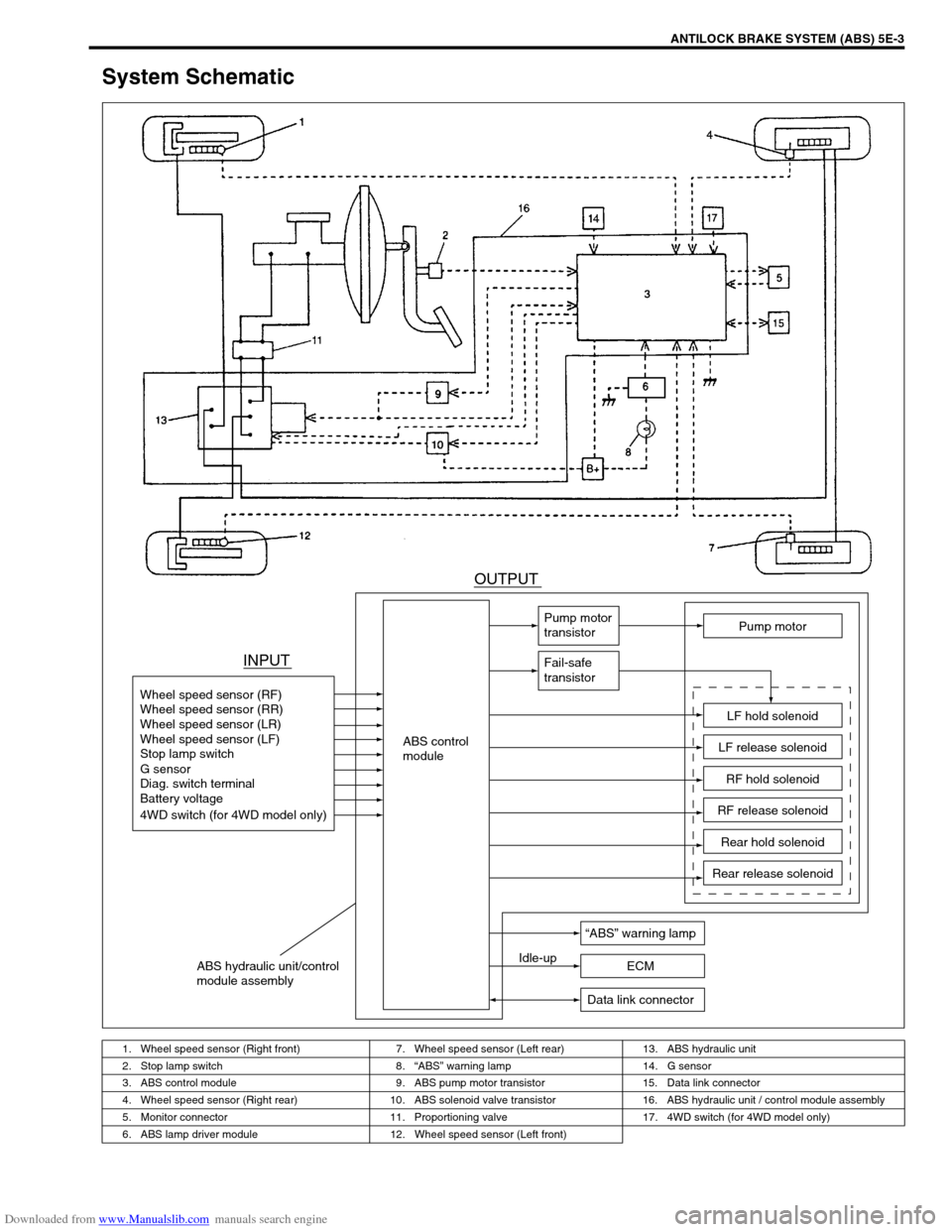

System Schematic

1. Wheel speed sensor (Right front) 7. Wheel speed sensor (Left rear) 13. ABS hydraulic unit

2. Stop lamp switch 8.“ABS” warning lamp 14. G sensor

3. ABS control module 9. ABS pump motor transistor 15. Data link connector

4. Wheel speed sensor (Right rear) 10. ABS solenoid valve transistor 16. ABS hydraulic unit / control module assembly

5. Monitor connector 11. Proportioning valve 17. 4WD switch (for 4WD model only)

6. ABS lamp driver module 12. Wheel speed sensor (Left front)

INPUTOUTPUT

ABS control

module Wheel speed sensor (RF)

Wheel speed sensor (RR)

Wheel speed sensor (LR)

Wheel speed sensor (LF)

Stop lamp switch

Diag. switch terminal

Battery voltage

4WD switch (for 4WD model only) G sensor

Pump motor

transistor

Fail-safe

transistor

Pump motor

LF hold solenoid

LF release solenoid

RF hold solenoid

RF release solenoid

Rear hold solenoid

Rear release solenoid

“ABS” warning lamp

Idle-up

ECM

Data link connector

ABS hydraulic unit/control

module assembly

Page 329 of 687

Downloaded from www.Manualslib.com manuals search engine 5E-12 ANTILOCK BRAKE SYSTEM (ABS)

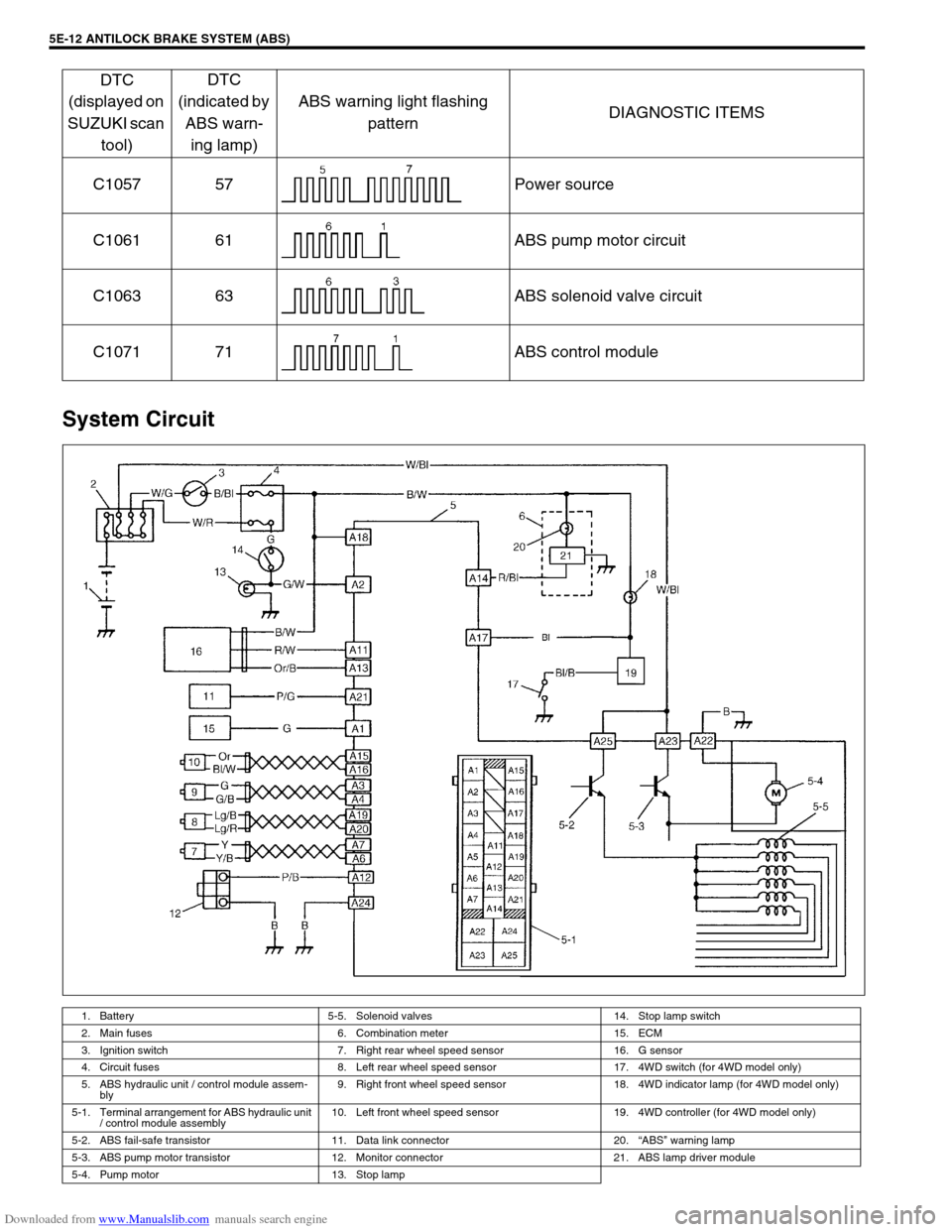

System Circuit

C1057 57 Power source

C1061 61 ABS pump motor circuit

C1063 63 ABS solenoid valve circuit

C1071 71 ABS control module

1. Battery 5-5. Solenoid valves 14. Stop lamp switch

2. Main fuses 6. Combination meter 15. ECM

3. Ignition switch 7. Right rear wheel speed sensor 16. G sensor

4. Circuit fuses 8. Left rear wheel speed sensor 17. 4WD switch (for 4WD model only)

5. ABS hydraulic unit / control module assem-

bly9. Right front wheel speed sensor 18. 4WD indicator lamp (for 4WD model only)

5-1. Terminal arrangement for ABS hydraulic unit

/ control module assembly10. Left front wheel speed sensor 19. 4WD controller (for 4WD model only)

5-2. ABS fail-safe transistor 11. Data link connector 20.“ABS” warning lamp

5-3. ABS pump motor transistor 12. Monitor connector 21. ABS lamp driver module

5-4. Pump motor 13. Stop lamp

DTC

(displayed on

SUZUKI scan

tool)DTC

(indicated by

ABS warn-

ing lamp)ABS warning light flashing

patternDIAGNOSTIC ITEMS

Page 342 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-25

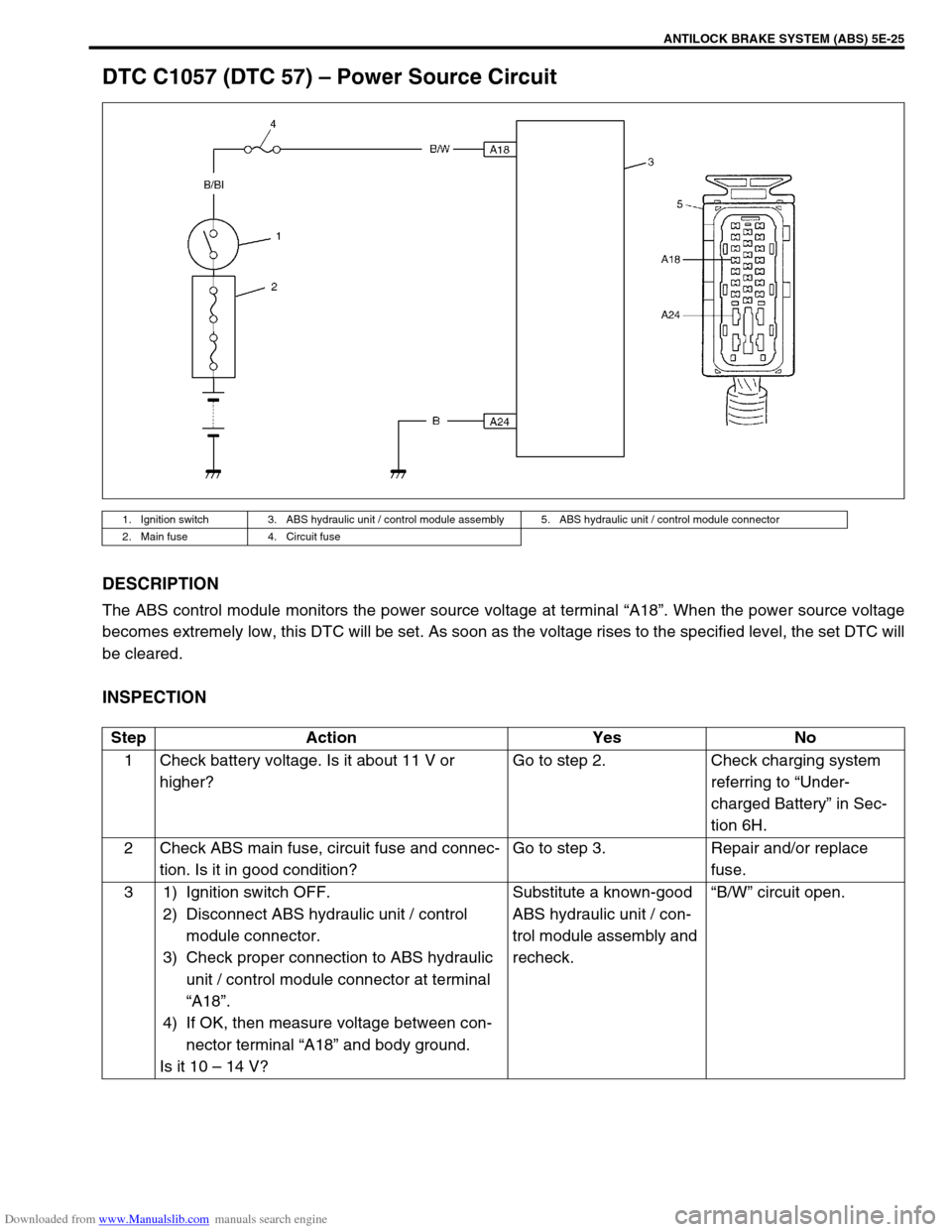

DTC C1057 (DTC 57) – Power Source Circuit

DESCRIPTION

The ABS control module monitors the power source voltage at terminal “A18”. When the power source voltage

becomes extremely low, this DTC will be set. As soon as the voltage rises to the specified level, the set DTC will

be cleared.

INSPECTION

1. Ignition switch 3. ABS hydraulic unit / control module assembly 5. ABS hydraulic unit / control module connector

2. Main fuse 4. Circuit fuse

Step Action Yes No

1 Check battery voltage. Is it about 11 V or

higher?Go to step 2. Check charging system

referring to “Under-

charged Battery” in Sec-

tion 6H.

2 Check ABS main fuse, circuit fuse and connec-

tion. Is it in good condition?Go to step 3. Repair and/or replace

fuse.

3 1) Ignition switch OFF.

2) Disconnect ABS hydraulic unit / control

module connector.

3) Check proper connection to ABS hydraulic

unit / control module connector at terminal

“A18”.

4) If OK, then measure voltage between con-

nector terminal “A18” and body ground.

Is it 10 – 14 V?Substitute a known-good

ABS hydraulic unit / con-

trol module assembly and

recheck.“B/W” circuit open.

Page 344 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-27

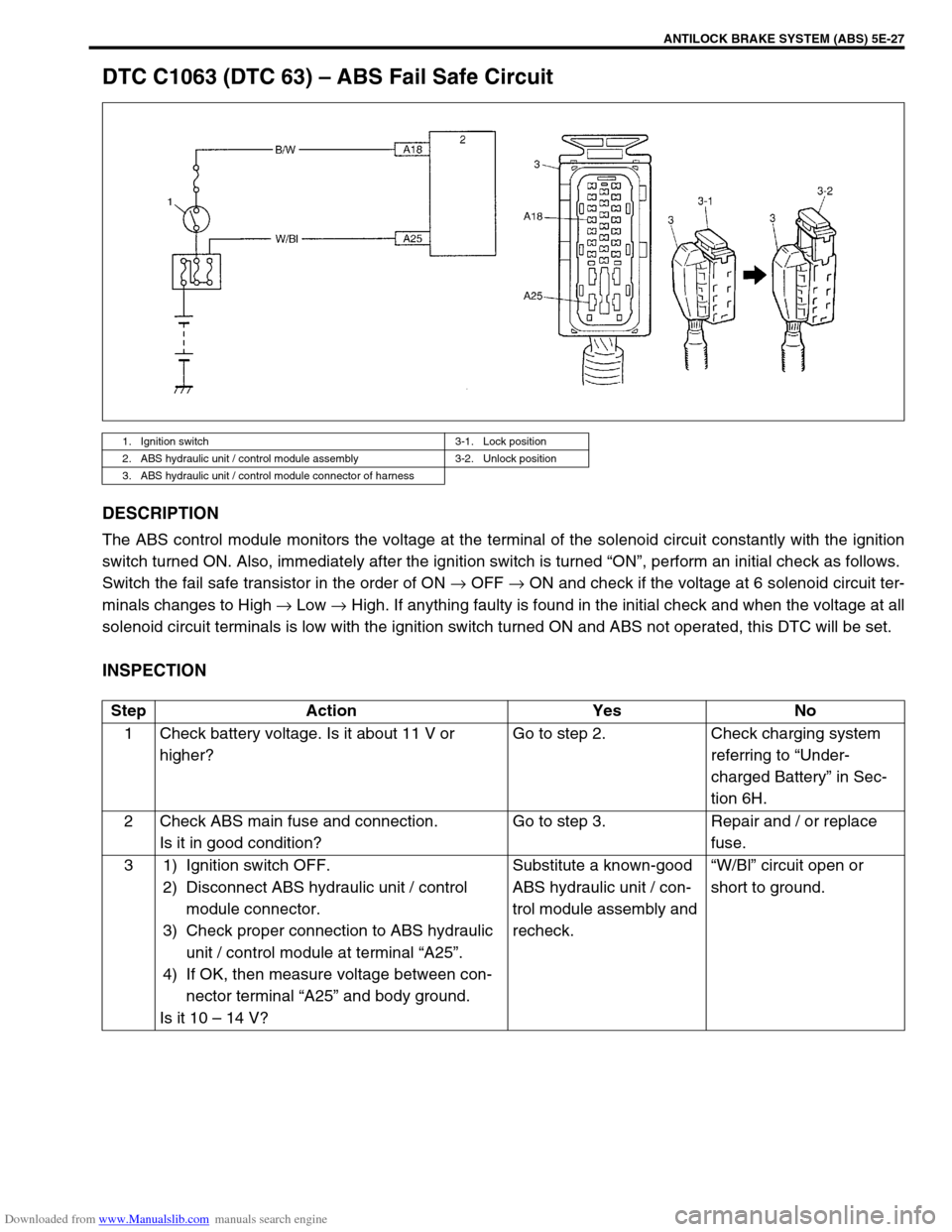

DTC C1063 (DTC 63) – ABS Fail Safe Circuit

DESCRIPTION

The ABS control module monitors the voltage at the terminal of the solenoid circuit constantly with the ignition

switch turned ON. Also, immediately after the ignition switch is turned “ON”, perform an initial check as follows.

Switch the fail safe transistor in the order of ON → OFF → ON and check if the voltage at 6 solenoid circuit ter-

minals changes to High → Low → High. If anything faulty is found in the initial check and when the voltage at all

solenoid circuit terminals is low with the ignition switch turned ON and ABS not operated, this DTC will be set.

INSPECTION

1. Ignition switch 3-1. Lock position

2. ABS hydraulic unit / control module assembly 3-2. Unlock position

3. ABS hydraulic unit / control module connector of harness

Step Action Yes No

1 Check battery voltage. Is it about 11 V or

higher?Go to step 2. Check charging system

referring to “Under-

charged Battery” in Sec-

tion 6H.

2 Check ABS main fuse and connection.

Is it in good condition?Go to step 3. Repair and / or replace

fuse.

3 1) Ignition switch OFF.

2) Disconnect ABS hydraulic unit / control

module connector.

3) Check proper connection to ABS hydraulic

unit / control module at terminal “A25”.

4) If OK, then measure voltage between con-

nector terminal “A25” and body ground.

Is it 10 – 14 V?Substitute a known-good

ABS hydraulic unit / con-

trol module assembly and

recheck.“W/Bl” circuit open or

short to ground.

Page 346 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-29

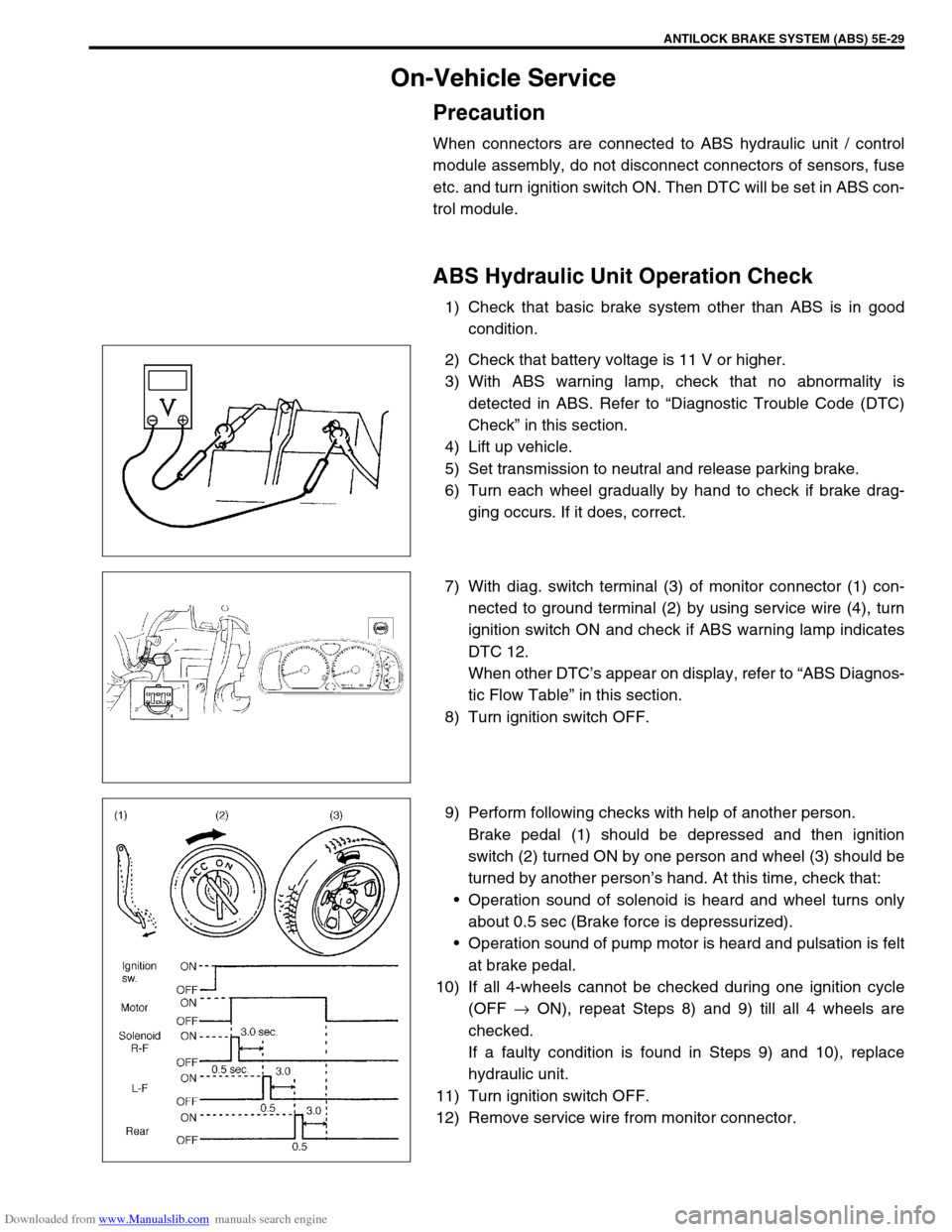

On-Vehicle Service

Precaution

When connectors are connected to ABS hydraulic unit / control

module assembly, do not disconnect connectors of sensors, fuse

etc. and turn ignition switch ON. Then DTC will be set in ABS con-

trol module.

ABS Hydraulic Unit Operation Check

1) Check that basic brake system other than ABS is in good

condition.

2) Check that battery voltage is 11 V or higher.

3) With ABS warning lamp, check that no abnormality is

detected in ABS. Refer to “Diagnostic Trouble Code (DTC)

Check” in this section.

4) Lift up vehicle.

5) Set transmission to neutral and release parking brake.

6) Turn each wheel gradually by hand to check if brake drag-

ging occurs. If it does, correct.

7) With diag. switch terminal (3) of monitor connector (1) con-

nected to ground terminal (2) by using service wire (4), turn

ignition switch ON and check if ABS warning lamp indicates

DTC 12.

When other DTC’s appear on display, refer to “ABS Diagnos-

tic Flow Table” in this section.

8) Turn ignition switch OFF.

9) Perform following checks with help of another person.

Brake pedal (1) should be depressed and then ignition

switch (2) turned ON by one person and wheel (3) should be

turned by another person’s hand. At this time, check that:

Operation sound of solenoid is heard and wheel turns only

about 0.5 sec (Brake force is depressurized).

Operation sound of pump motor is heard and pulsation is felt

at brake pedal.

10) If all 4-wheels cannot be checked during one ignition cycle

(OFF → ON), repeat Steps 8) and 9) till all 4 wheels are

checked.

If a faulty condition is found in Steps 9) and 10), replace

hydraulic unit.

11) Turn ignition switch OFF.

12) Remove service wire from monitor connector.

Page 347 of 687

Downloaded from www.Manualslib.com manuals search engine 5E-30 ANTILOCK BRAKE SYSTEM (ABS)

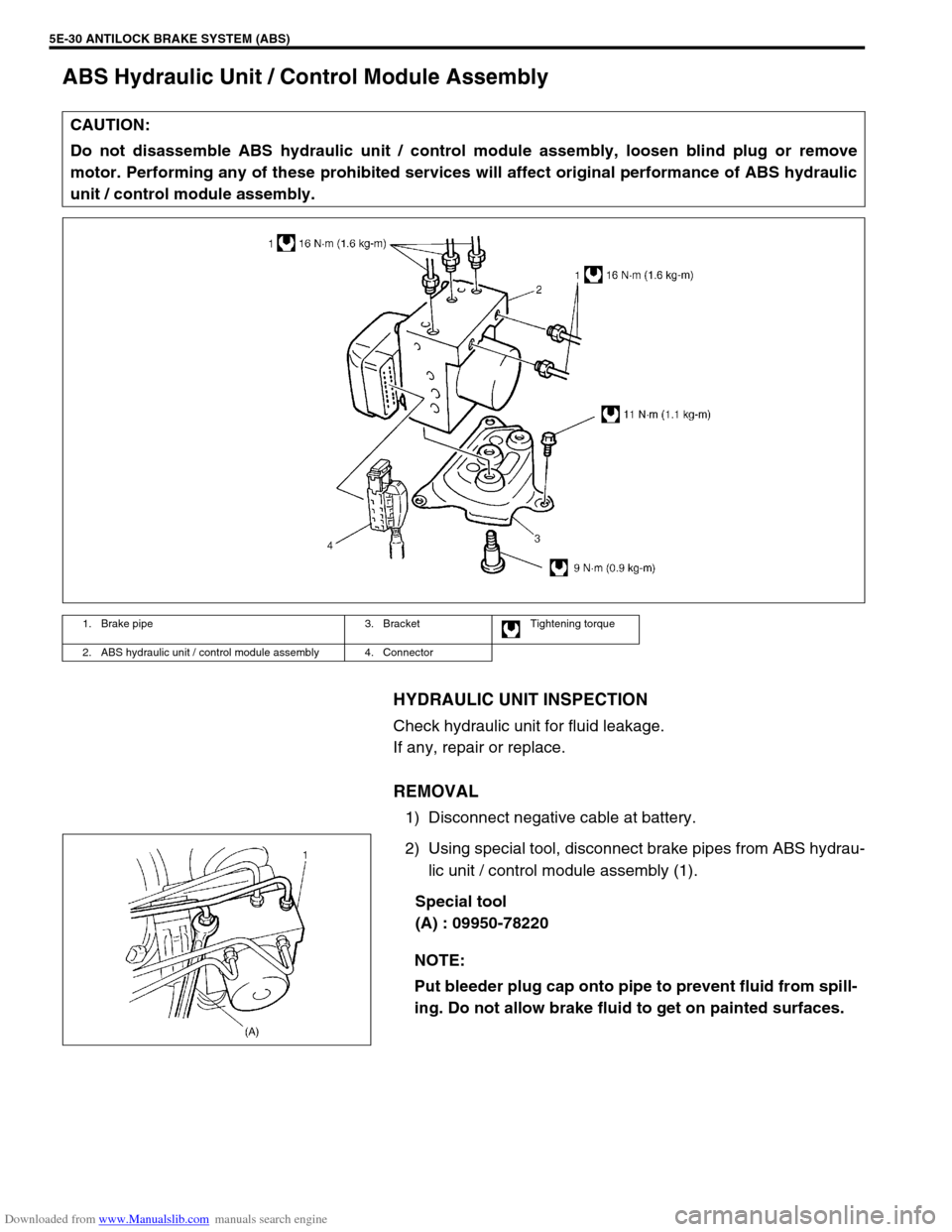

ABS Hydraulic Unit / Control Module Assembly

HYDRAULIC UNIT INSPECTION

Check hydraulic unit for fluid leakage.

If any, repair or replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Using special tool, disconnect brake pipes from ABS hydrau-

lic unit / control module assembly (1).

Special tool

(A) : 09950-78220 CAUTION:

Do not disassemble ABS hydraulic unit / control module assembly, loosen blind plug or remove

motor. Performing any of these prohibited services will affect original performance of ABS hydraulic

unit / control module assembly.

1. Brake pipe 3. Bracket Tightening torque

2. ABS hydraulic unit / control module assembly 4. Connector

NOTE:

Put bleeder plug cap onto pipe to prevent fluid from spill-

ing. Do not allow brake fluid to get on painted surfaces.

Page 350 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-33

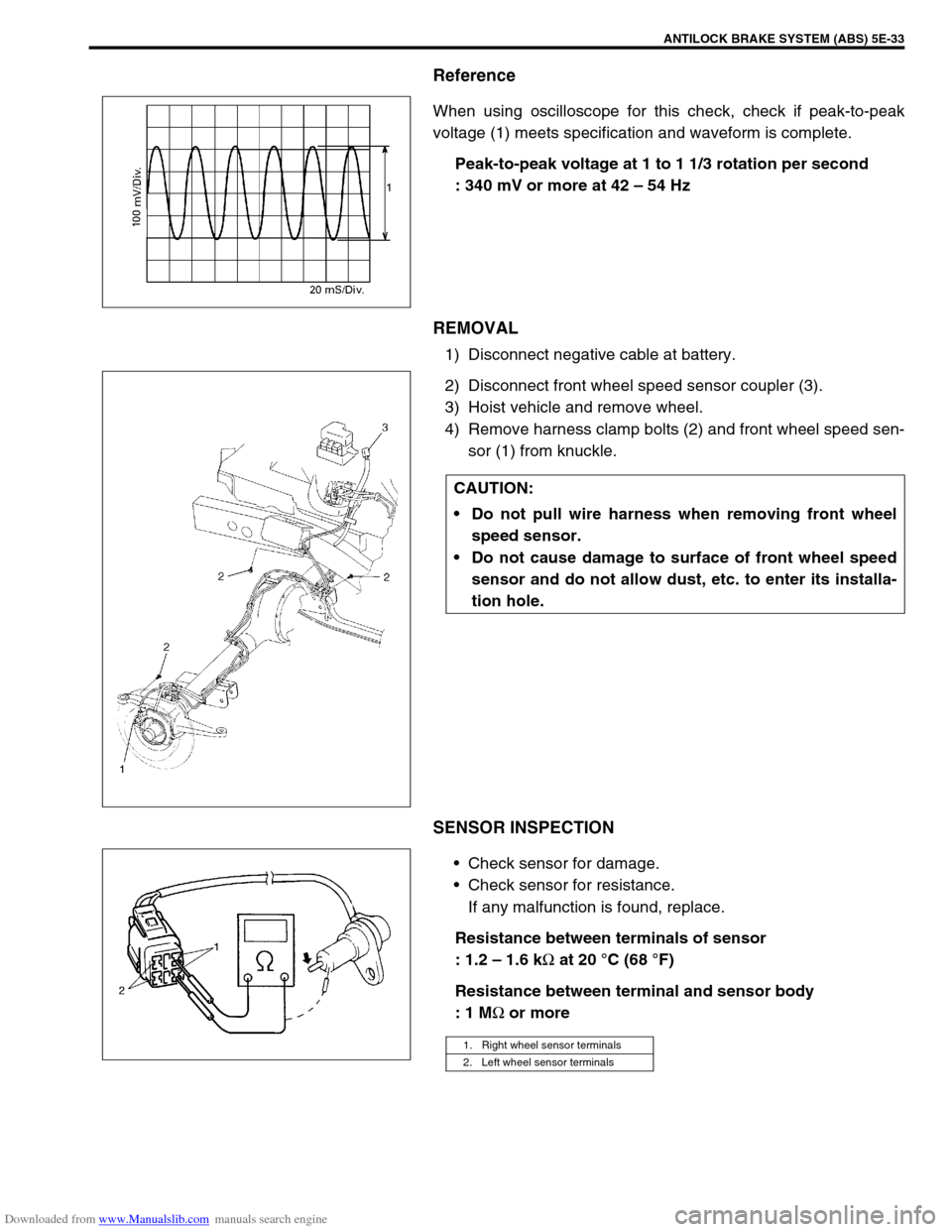

Reference

When using oscilloscope for this check, check if peak-to-peak

voltage (1) meets specification and waveform is complete.

Peak-to-peak voltage at 1 to 1 1/3 rotation per second

: 340 mV or more at 42 – 54 Hz

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect front wheel speed sensor coupler (3).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp bolts (2) and front wheel speed sen-

sor (1) from knuckle.

SENSOR INSPECTION

Check sensor for damage.

Check sensor for resistance.

If any malfunction is found, replace.

Resistance between terminals of sensor

: 1.2 – 1.6 k

Ω at 20 °C (68 °F)

Resistance between terminal and sensor body

: 1 M

Ω or more

CAUTION:

Do not pull wire harness when removing front wheel

speed sensor.

Do not cause damage to surface of front wheel speed

sensor and do not allow dust, etc. to enter its installa-

tion hole.

1. Right wheel sensor terminals

2. Left wheel sensor terminals

Page 353 of 687

Downloaded from www.Manualslib.com manuals search engine 5E-36 ANTILOCK BRAKE SYSTEM (ABS)

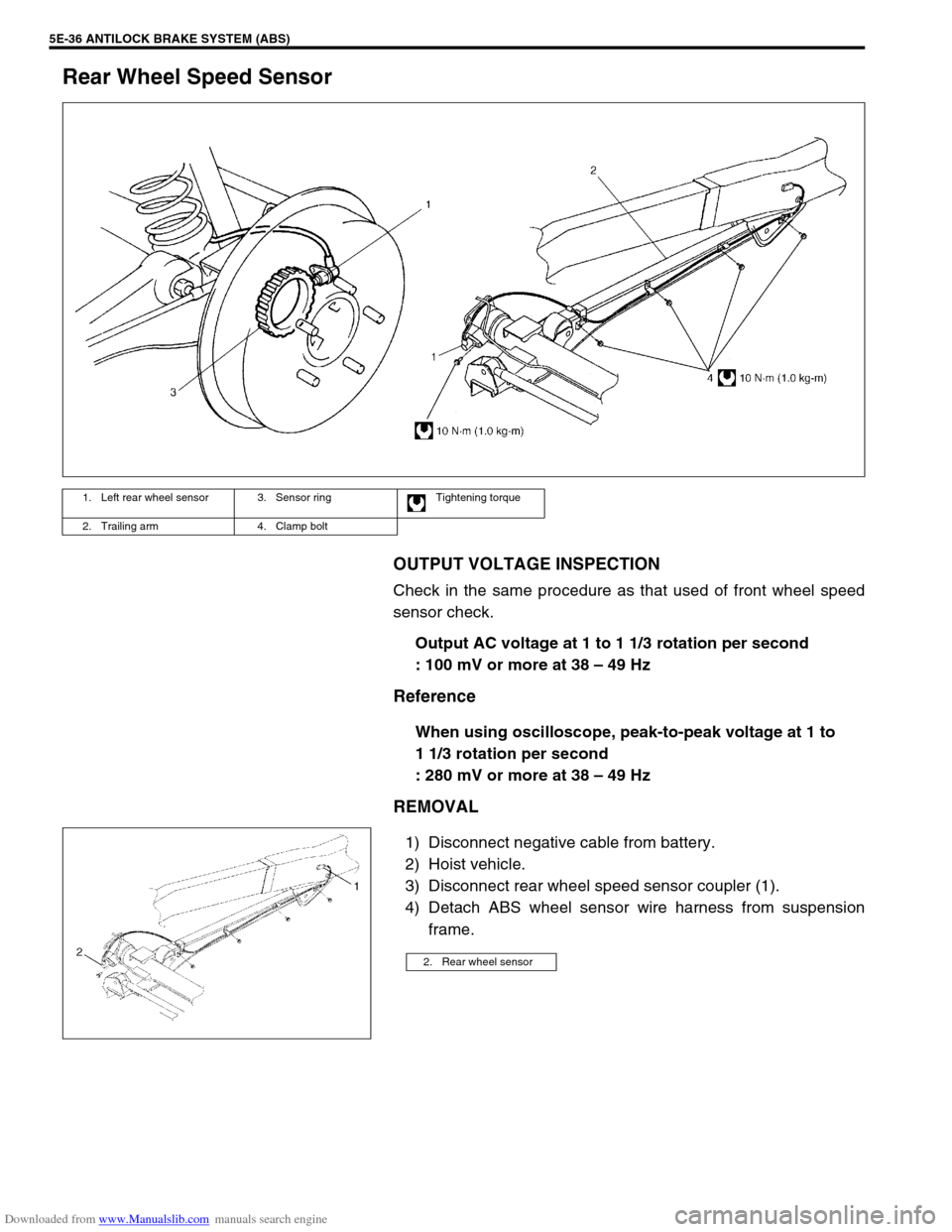

Rear Wheel Speed Sensor

OUTPUT VOLTAGE INSPECTION

Check in the same procedure as that used of front wheel speed

sensor check.

Output AC voltage at 1 to 1 1/3 rotation per second

: 100 mV or more at 38 – 49 Hz

Reference

When using oscilloscope, peak-to-peak voltage at 1 to

1 1/3 rotation per second

: 280 mV or more at 38 – 49 Hz

REMOVAL

1) Disconnect negative cable from battery.

2) Hoist vehicle.

3) Disconnect rear wheel speed sensor coupler (1).

4) Detach ABS wheel sensor wire harness from suspension

frame.

1. Left rear wheel sensor 3. Sensor ring Tightening torque

2. Trailing arm 4. Clamp bolt

2. Rear wheel sensor