leak SUZUKI JIMNY 2005 3.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 294 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-33

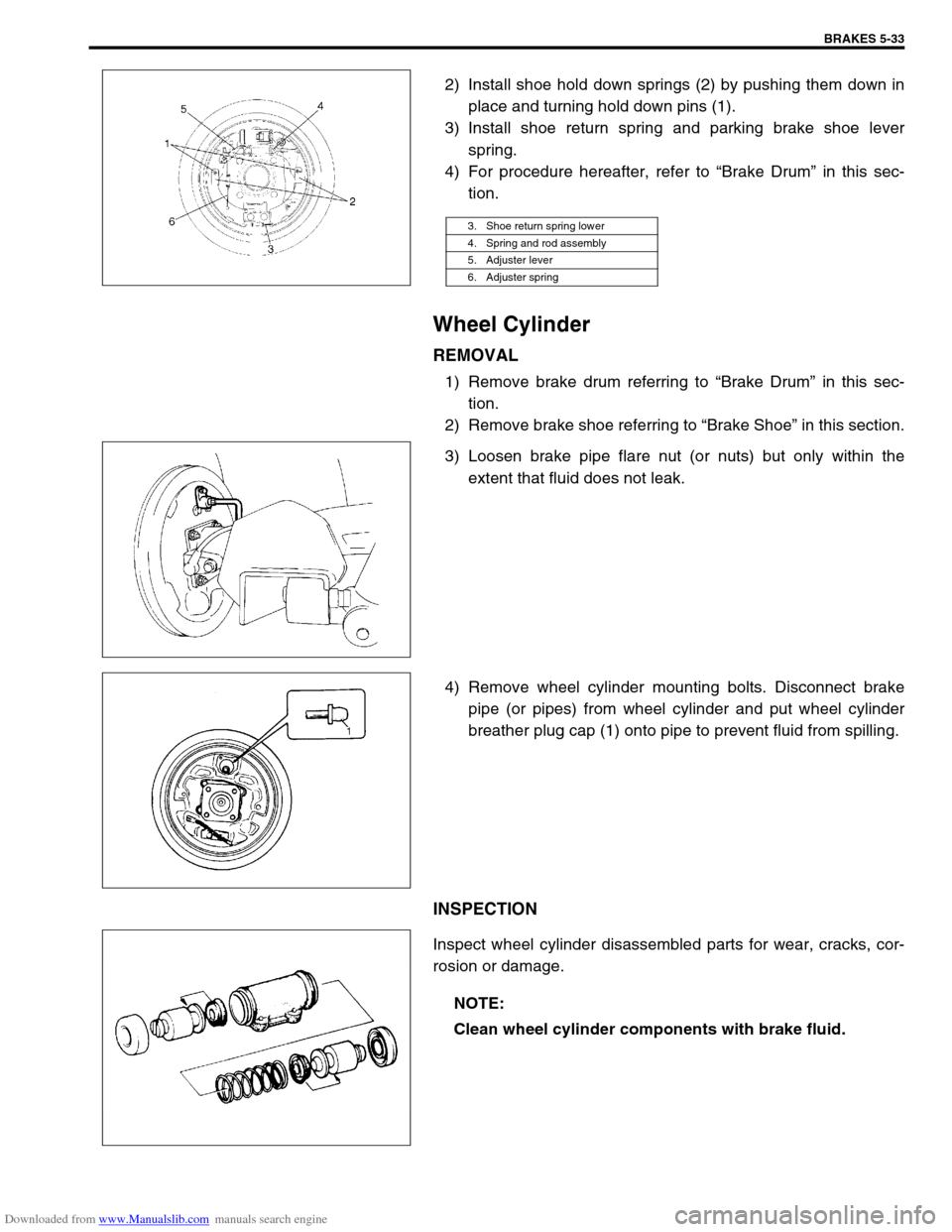

2) Install shoe hold down springs (2) by pushing them down in

place and turning hold down pins (1).

3) Install shoe return spring and parking brake shoe lever

spring.

4) For procedure hereafter, refer to “Brake Drum” in this sec-

tion.

Wheel Cylinder

REMOVAL

1) Remove brake drum referring to “Brake Drum” in this sec-

tion.

2) Remove brake shoe referring to “Brake Shoe” in this section.

3) Loosen brake pipe flare nut (or nuts) but only within the

extent that fluid does not leak.

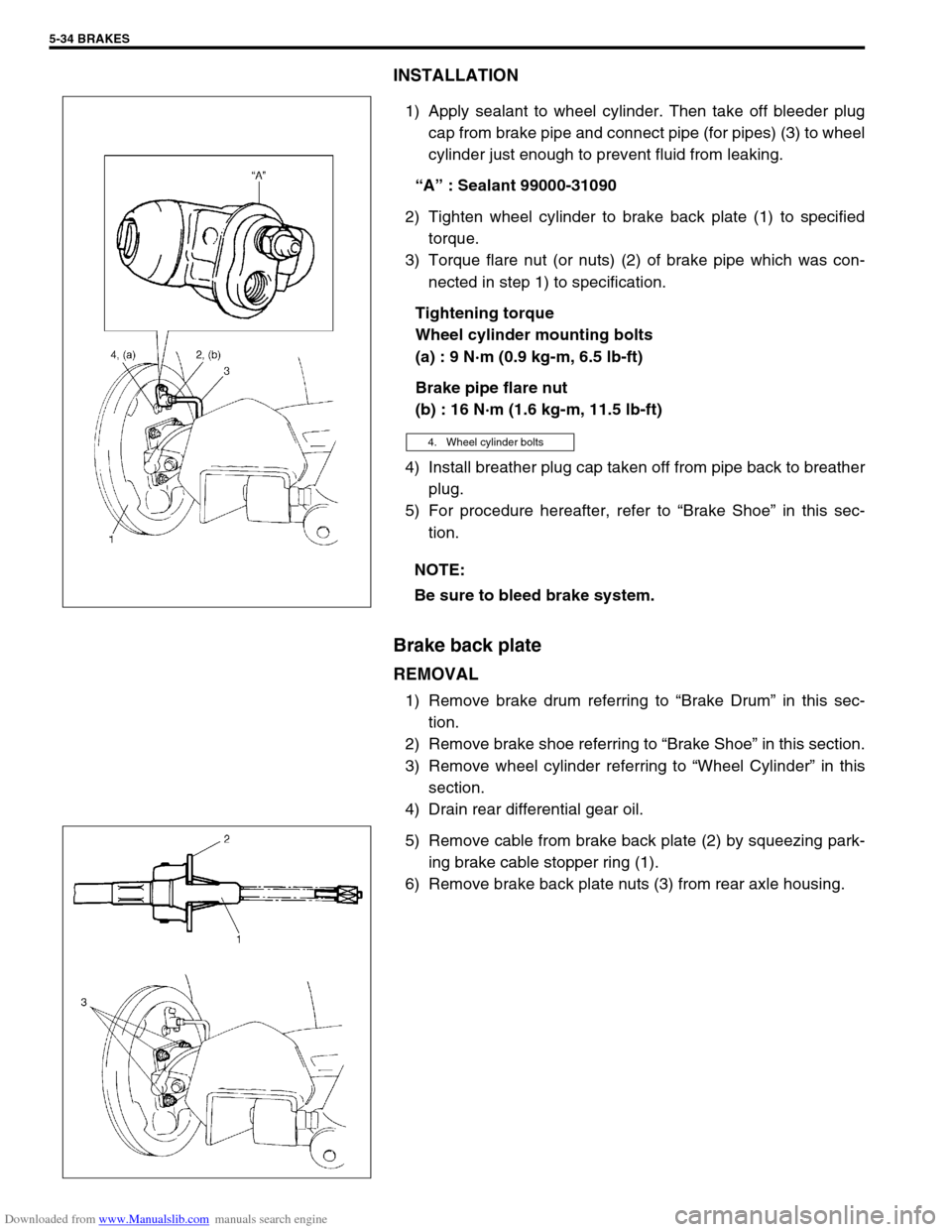

4) Remove wheel cylinder mounting bolts. Disconnect brake

pipe (or pipes) from wheel cylinder and put wheel cylinder

breather plug cap (1) onto pipe to prevent fluid from spilling.

INSPECTION

Inspect wheel cylinder disassembled parts for wear, cracks, cor-

rosion or damage.

3. Shoe return spring lower

4. Spring and rod assembly

5. Adjuster lever

6. Adjuster spring

NOTE:

Clean wheel cylinder components with brake fluid.

Page 295 of 687

Downloaded from www.Manualslib.com manuals search engine 5-34 BRAKES

INSTALLATION

1) Apply sealant to wheel cylinder. Then take off bleeder plug

cap from brake pipe and connect pipe (for pipes) (3) to wheel

cylinder just enough to prevent fluid from leaking.

“A” : Sealant 99000-31090

2) Tighten wheel cylinder to brake back plate (1) to specified

torque.

3) Torque flare nut (or nuts) (2) of brake pipe which was con-

nected in step 1) to specification.

Tightening torque

Wheel cylinder mounting bolts

(a) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

Brake pipe flare nut

(b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

4) Install breather plug cap taken off from pipe back to breather

plug.

5) For procedure hereafter, refer to “Brake Shoe” in this sec-

tion.

Brake back plate

REMOVAL

1) Remove brake drum referring to “Brake Drum” in this sec-

tion.

2) Remove brake shoe referring to “Brake Shoe” in this section.

3) Remove wheel cylinder referring to “Wheel Cylinder” in this

section.

4) Drain rear differential gear oil.

5) Remove cable from brake back plate (2) by squeezing park-

ing brake cable stopper ring (1).

6) Remove brake back plate nuts (3) from rear axle housing.

4. Wheel cylinder bolts

NOTE:

Be sure to bleed brake system.

Page 298 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-37

INSTALLATION

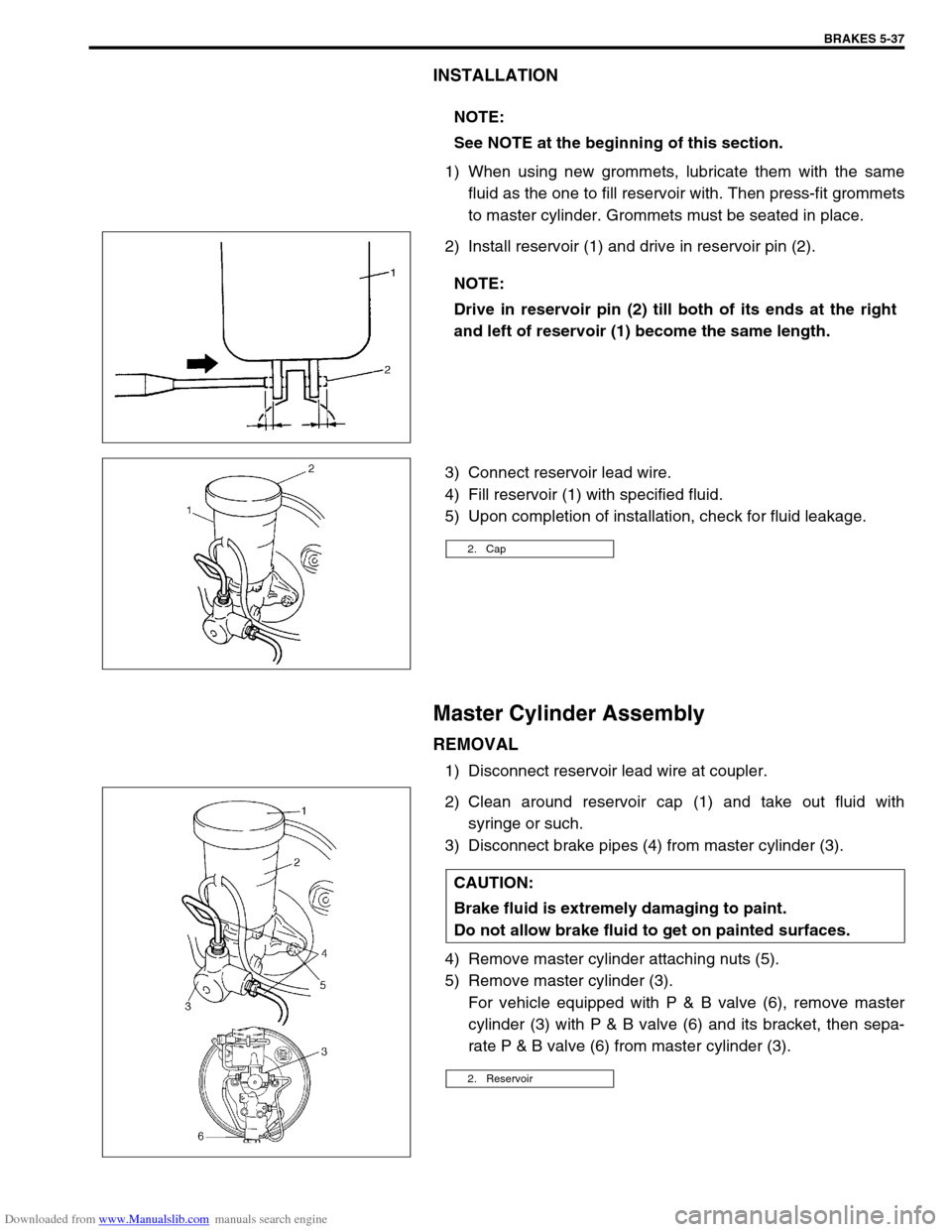

1) When using new grommets, lubricate them with the same

fluid as the one to fill reservoir with. Then press-fit grommets

to master cylinder. Grommets must be seated in place.

2) Install reservoir (1) and drive in reservoir pin (2).

3) Connect reservoir lead wire.

4) Fill reservoir (1) with specified fluid.

5) Upon completion of installation, check for fluid leakage.

Master Cylinder Assembly

REMOVAL

1) Disconnect reservoir lead wire at coupler.

2) Clean around reservoir cap (1) and take out fluid with

syringe or such.

3) Disconnect brake pipes (4) from master cylinder (3).

4) Remove master cylinder attaching nuts (5).

5) Remove master cylinder (3).

For vehicle equipped with P & B valve (6), remove master

cylinder (3) with P & B valve (6) and its bracket, then sepa-

rate P & B valve (6) from master cylinder (3). NOTE:

See NOTE at the beginning of this section.

NOTE:

Drive in reservoir pin (2) till both of its ends at the right

and left of reservoir (1) become the same length.

2. Cap

CAUTION:

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted surfaces.

2. Reservoir

Page 299 of 687

Downloaded from www.Manualslib.com manuals search engine 5-38 BRAKES

INSTALLATION

1) Install master cylinder as shown and torque attaching nuts to

specification.

Tightening torque

Master cylinder nuts

(a) : 13 N·m (1.3 kg-m, 9.5 Ib-ft)

2) Attach hydraulic lines and torque flare nuts to specification.

Tightening torque

Brake pipe flare nuts

(b) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

3) Connect reservoir lead wire.

4) Fill reservoir with specified brake fluid.

5) After installing, bleed air from system (refer to “Air Bleeding

of Brake System” in this section) and check brake pedal

height and play.

6) Perform brake test and check each installed part for fluid

leakage.

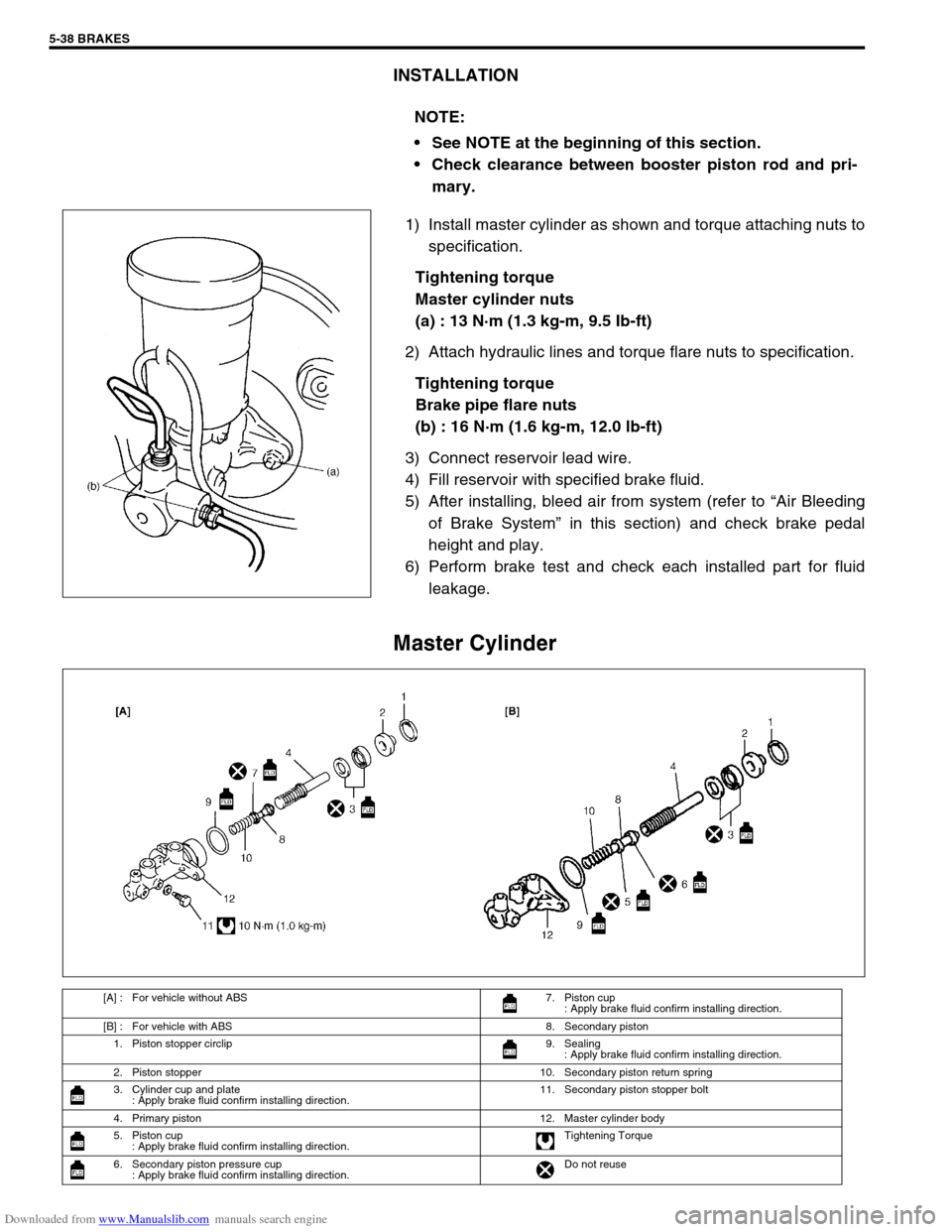

Master Cylinder

NOTE:

See NOTE at the beginning of this section.

Check clearance between booster piston rod and pri-

mary.

[A] : For vehicle without ABS 7. Piston cup

: Apply brake fluid confirm installing direction.

[B] : For vehicle with ABS 8. Secondary piston

1. Piston stopper circlip 9. Sealing

: Apply brake fluid confirm installing direction.

2. Piston stopper 10. Secondary piston return spring

3. Cylinder cup and plate

: Apply brake fluid confirm installing direction.11. Secondary piston stopper bolt

4. Primary piston 12. Master cylinder body

5. Piston cup

: Apply brake fluid confirm installing direction.Tightening Torque

6. Secondary piston pressure cup

: Apply brake fluid confirm installing direction.Do not reuse

Page 304 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-43

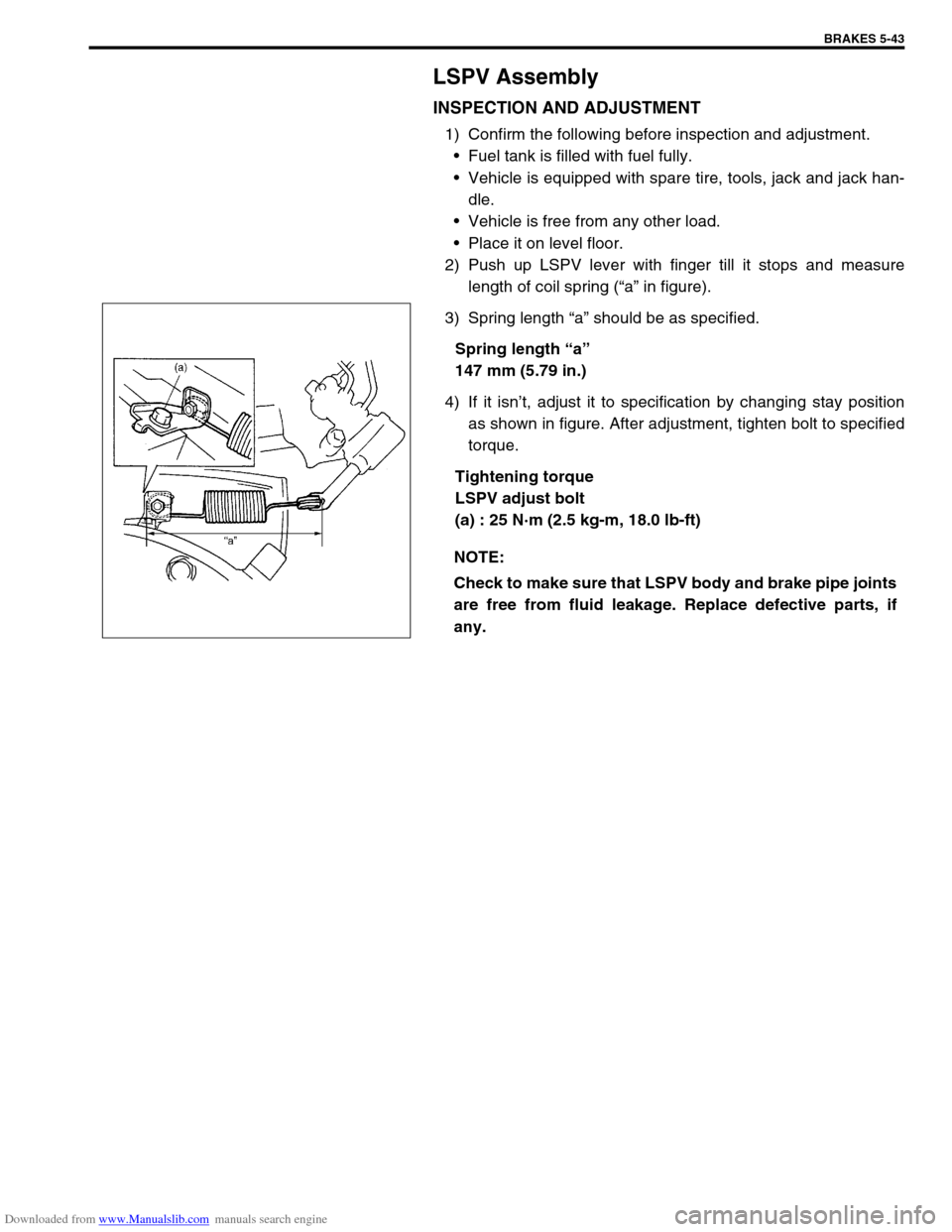

LSPV Assembly

INSPECTION AND ADJUSTMENT

1) Confirm the following before inspection and adjustment.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

Vehicle is free from any other load.

Place it on level floor.

2) Push up LSPV lever with finger till it stops and measure

length of coil spring (“a” in figure).

3) Spring length “a” should be as specified.

Spring length “a”

147 mm (5.79 in.)

4) If it isn’t, adjust it to specification by changing stay position

as shown in figure. After adjustment, tighten bolt to specified

torque.

Tightening torque

LSPV adjust bolt

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

NOTE:

Check to make sure that LSPV body and brake pipe joints

are free from fluid leakage. Replace defective parts, if

any.

Page 311 of 687

Downloaded from www.Manualslib.com manuals search engine 5-50 BRAKES

REMOVAL

1) Raise, suitably support vehicle. Remove wheel if necessary.

2) Clean dirt and foreign material from both hose end or pipe end fittings. Remove brake hose and pipe.

INSTALLATION

1) Install brake hose and pipe by reversing removal procedure, noting the following points.

For installation, make sure that steering wheel is in straightforward position and hose has no twist or kink.

Check to make sure that hose doesn’t contact any part of suspension, both in extreme right and extreme left

turn conditions. If it does at any point, remove and correct. Fill and maintain brake fluid level in reservoir.

Bleed brake system.

2) Perform brake test and check installed part for fluid leakage.

Page 312 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-51

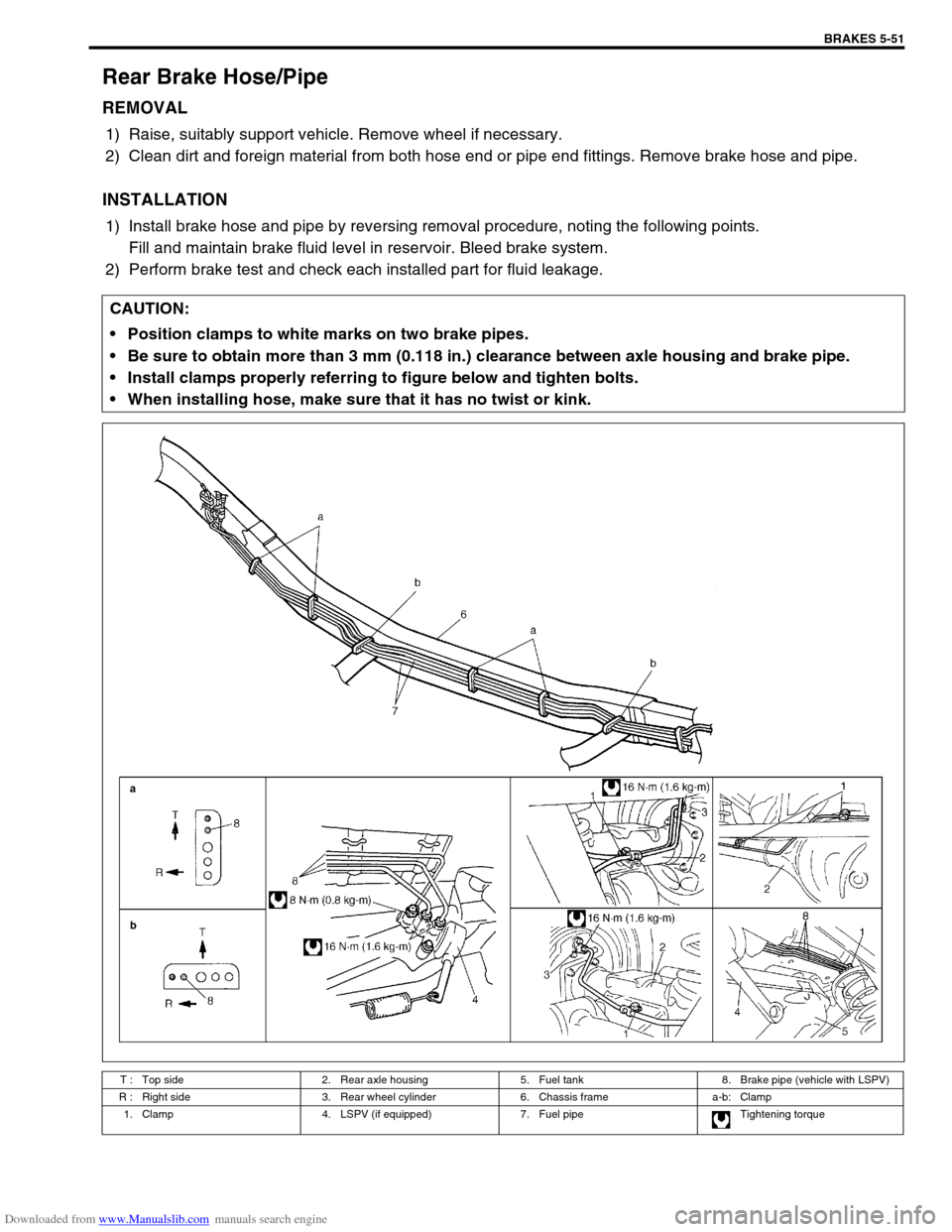

Rear Brake Hose/Pipe

REMOVAL

1) Raise, suitably support vehicle. Remove wheel if necessary.

2) Clean dirt and foreign material from both hose end or pipe end fittings. Remove brake hose and pipe.

INSTALLATION

1) Install brake hose and pipe by reversing removal procedure, noting the following points.

Fill and maintain brake fluid level in reservoir. Bleed brake system.

2) Perform brake test and check each installed part for fluid leakage.

CAUTION:

Position clamps to white marks on two brake pipes.

Be sure to obtain more than 3 mm (0.118 in.) clearance between axle housing and brake pipe.

Install clamps properly referring to figure below and tighten bolts.

When installing hose, make sure that it has no twist or kink.

T : Top side 2. Rear axle housing 5. Fuel tank 8. Brake pipe (vehicle with LSPV)

R : Right side 3. Rear wheel cylinder 6. Chassis frame a-b: Clamp

1. Clamp 4. LSPV (if equipped) 7. Fuel pipe Tightening torque

Page 347 of 687

Downloaded from www.Manualslib.com manuals search engine 5E-30 ANTILOCK BRAKE SYSTEM (ABS)

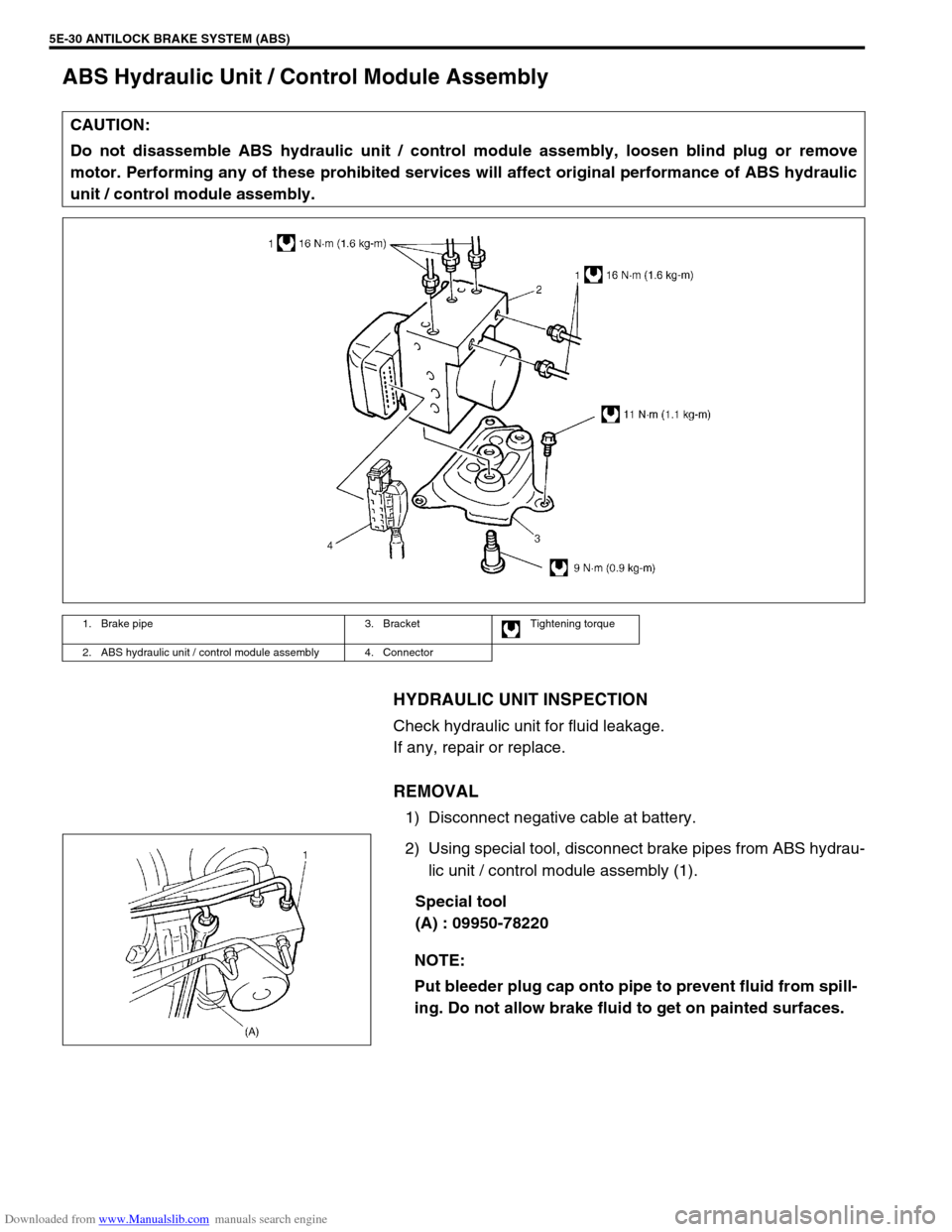

ABS Hydraulic Unit / Control Module Assembly

HYDRAULIC UNIT INSPECTION

Check hydraulic unit for fluid leakage.

If any, repair or replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Using special tool, disconnect brake pipes from ABS hydrau-

lic unit / control module assembly (1).

Special tool

(A) : 09950-78220 CAUTION:

Do not disassemble ABS hydraulic unit / control module assembly, loosen blind plug or remove

motor. Performing any of these prohibited services will affect original performance of ABS hydraulic

unit / control module assembly.

1. Brake pipe 3. Bracket Tightening torque

2. ABS hydraulic unit / control module assembly 4. Connector

NOTE:

Put bleeder plug cap onto pipe to prevent fluid from spill-

ing. Do not allow brake fluid to get on painted surfaces.

Page 348 of 687

Downloaded from www.Manualslib.com manuals search engine ANTILOCK BRAKE SYSTEM (ABS) 5E-31

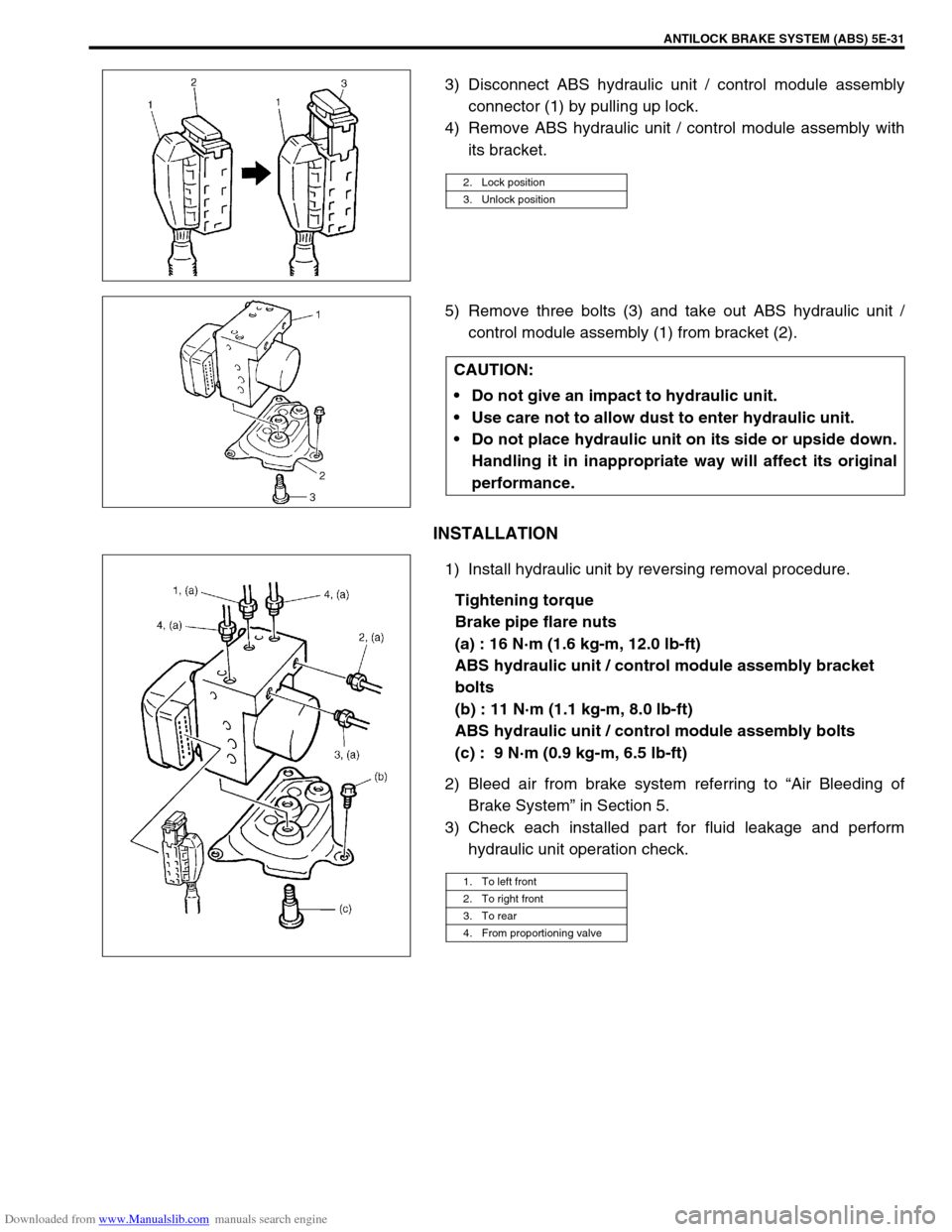

3) Disconnect ABS hydraulic unit / control module assembly

connector (1) by pulling up lock.

4) Remove ABS hydraulic unit / control module assembly with

its bracket.

5) Remove three bolts (3) and take out ABS hydraulic unit /

control module assembly (1) from bracket (2).

INSTALLATION

1) Install hydraulic unit by reversing removal procedure.

Tightening torque

Brake pipe flare nuts

(a) : 16 N·m (1.6 kg-m, 12.0 lb-ft)

ABS hydraulic unit / control module assembly bracket

bolts

(b) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

ABS hydraulic unit / control module assembly bolts

(c) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

2) Bleed air from brake system referring to “Air Bleeding of

Brake System” in Section 5.

3) Check each installed part for fluid leakage and perform

hydraulic unit operation check.

2. Lock position

3. Unlock position

CAUTION:

Do not give an impact to hydraulic unit.

Use care not to allow dust to enter hydraulic unit.

Do not place hydraulic unit on its side or upside down.

Handling it in inappropriate way will affect its original

performance.

1. To left front

2. To right front

3. To rear

4. From proportioning valve

Page 358 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8B

6

8D

8E

8B

9

10A

10B

SECTION 6

ENGINE GENERAL INFORMATION AND

DIAGNOSIS

GENERAL INFORMATION AND ENGINE DIAGNOSIS ..............................................................................

6-1

ENGINE MECHANICAL ...........................................................................................................................

6A1-1

ENGINE COOLING.....................................................................................................................................

6B-1

ENGINE FUEL ............................................................................................................................................

6C-1

ENGINE AND EMISSION CONTROL SYSTEM ........................................................................................

6E-1

IGNITION SYSTEM ....................................................................................................................................

6F-1

CRANKING SYSTEM .................................................................................................................................

6G-1

CHARGING SYSTEM .................................................................................................................................

6H-1

EXHAUST SYSTEM ...................................................................................................................................

6K-1

CONTENTS

General Information .......................................... 6-3

Statement on Cleanliness and Care ............... 6-3

General Information on Engine Service .......... 6-3

Precaution on fuel system service............... 6-4

Fuel pressure relief procedure .................... 6-5

Fuel leakage check procedure .................... 6-5

Engine Diagnosis .............................................. 6-6

General Description ........................................ 6-6

On-Board Diagnostic System (Vehicle with

Immobilizer Indicator Lamp) ............................ 6-6On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)............................ 6-9

Precaution in Diagnosing Trouble ................. 6-10

Engine Diagnostic Flow Table ...................... 6-11

Customer problem inspection form

(example) .................................................. 6-13

Malfunction indicator lamp (MIL) check..... 6-14

Diagnostic trouble code (DTC) check ....... 6-14

Diagnostic trouble code (DTC)

clearance................................................... 6-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether the following systems (parts) are used in the particular vehicle or not depends on vehicle

specifications. Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor(s) or CO adjusting resistor

Three-way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)