PCV SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 27 of 687

Downloaded from www.Manualslib.com manuals search engine 0A-22 GENERAL INFORMATION

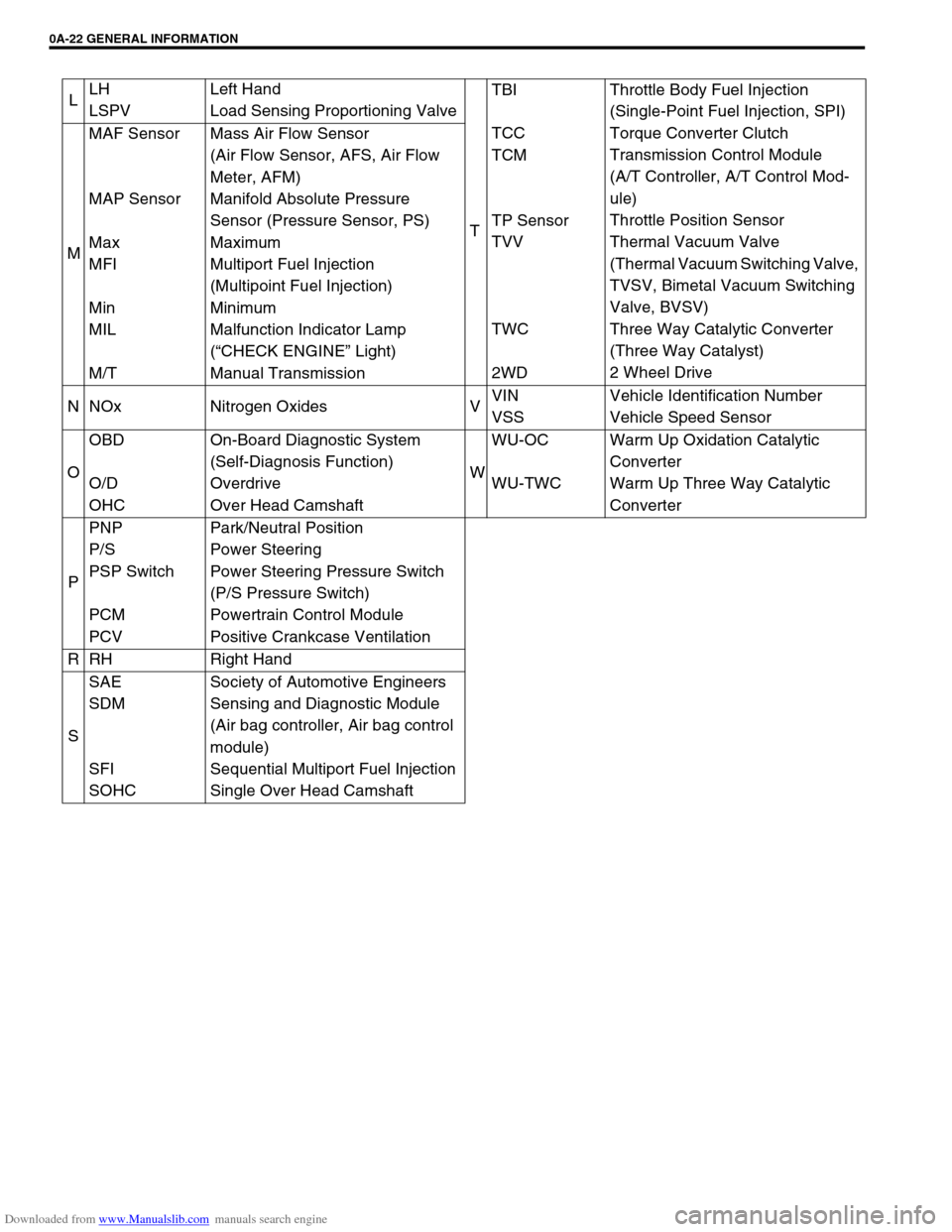

LLH

LSPVLeft Hand

Load Sensing Proportioning Valve

TTBI

TCC

TCM

TP Sensor

TVV

TWC

2WDThrottle Body Fuel Injection

(Single-Point Fuel Injection, SPI)

Torque Converter Clutch

Transmission Control Module

(A/T Controller, A/T Control Mod-

ule)

Throttle Position Sensor

Thermal Vacuum Valve

(Thermal Vacuum Switching Valve,

TVSV, Bimetal Vacuum Switching

Valve, BVSV)

Three Way Catalytic Converter

(Three Way Catalyst)

2 Wheel Drive MMAF Sensor

MAP Sensor

Max

MFI

Min

MIL

M/TMass Air Flow Sensor

(Air Flow Sensor, AFS, Air Flow

Meter, AFM)

Manifold Absolute Pressure

Sensor (Pressure Sensor, PS)

Maximum

Multiport Fuel Injection

(Multipoint Fuel Injection)

Minimum

Malfunction Indicator Lamp

(“CHECK ENGINE” Light)

Manual Transmission

N NOx Nitrogen Oxides VVIN

VSSVehicle Identification Number

Vehicle Speed Sensor

OOBD

O/D

OHCOn-Board Diagnostic System

(Self-Diagnosis Function)

Overdrive

Over Head CamshaftWWU-OC

WU-TWCWarm Up Oxidation Catalytic

Converter

Warm Up Three Way Catalytic

Converter

PPNP

P/S

PSP Switch

PCM

PCVPark/Neutral Position

Power Steering

Power Steering Pressure Switch

(P/S Pressure Switch)

Powertrain Control Module

Positive Crankcase Ventilation

R RH Right Hand

SSAE

SDM

SFI

SOHCSociety of Automotive Engineers

Sensing and Diagnostic Module

(Air bag controller, Air bag control

module)

Sequential Multiport Fuel Injection

Single Over Head Camshaft

Page 32 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-1

0A 6F1

0B

0B

6G

1A 6H

1B 6K

37A

3A 7A1

3B1 7B1

3C1 7C1

3D 7D

3E 7E

3F 7F

4A2 8A

4B 8B

8C

58D

5A 8E

5B

5C 9

5E

5E1 10

10A

610B

6-1

6A1

6A2

6A4

6B

6C

6E1

6E2

SECTION 0B

MAINTENANCE AND LUBRICATION

CONTENTS

Maintenance Schedule .................................. 0B-2

Maintenance Schedule Under Normal

Driving Conditions ........................................ 0B-2

Maintenance Recommended Under Severe

Driving Conditions ........................................ 0B-4

Maintenance Service...................................... 0B-5

Engine .......................................................... 0B-5

Drive Belt .................................................. 0B-5

Valve Lash................................................ 0B-6

Engine Oil and Filter ................................. 0B-6

Engine Coolant ......................................... 0B-8

Exhaust System ....................................... 0B-8

Ignition System ............................................. 0B-9

Spark Plugs .............................................. 0B-9

Fuel System ................................................. 0B-9

Air Cleaner Filter ...................................... 0B-9

Fuel Lines and Connections ................... 0B-10

Fuel Filter ............................................... 0B-10

Fuel Tank ............................................... 0B-10

Emission Control System ........................... 0B-10

Crankcase Ventilation Hoses and

Connections ........................................... 0B-10

PCV (Positive Crankcase Ventilation)

Valve ..................................................... 0B-11Fuel Evaporative Emission Control

System ................................................... 0B-11

Chassis and Body ...................................... 0B-11

Clutch ..................................................... 0B-11

Brake Discs and Pads ............................ 0B-11

Brake Drums and Shoes ........................ 0B-12

Brake Hoses and Pipes.......................... 0B-12

Brake Fluid ............................................. 0B-12

Parking Brake Lever and Cable ............. 0B-13

Tires/Wheels .......................................... 0B-13

Suspension System ............................... 0B-14

Propeller Shafts...................................... 0B-15

Manual Transmission Oil........................ 0B-16

Automatic Transmission Fluid ................ 0B-16

Transfer and Differential Oil ................... 0B-17

Steering System ..................................... 0B-18

Steering Knuckle Seal ............................ 0B-18

Power Steering (P/S) System

(if equipped) ........................................... 0B-19

All Hinges, Latches and Locks ............... 0B-19

Final Inspection............................................ 0B-20

Recommended Fluids and Lubricants ....... 0B-22

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 33 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-2 MAINTENANCE AND LUBRICATION

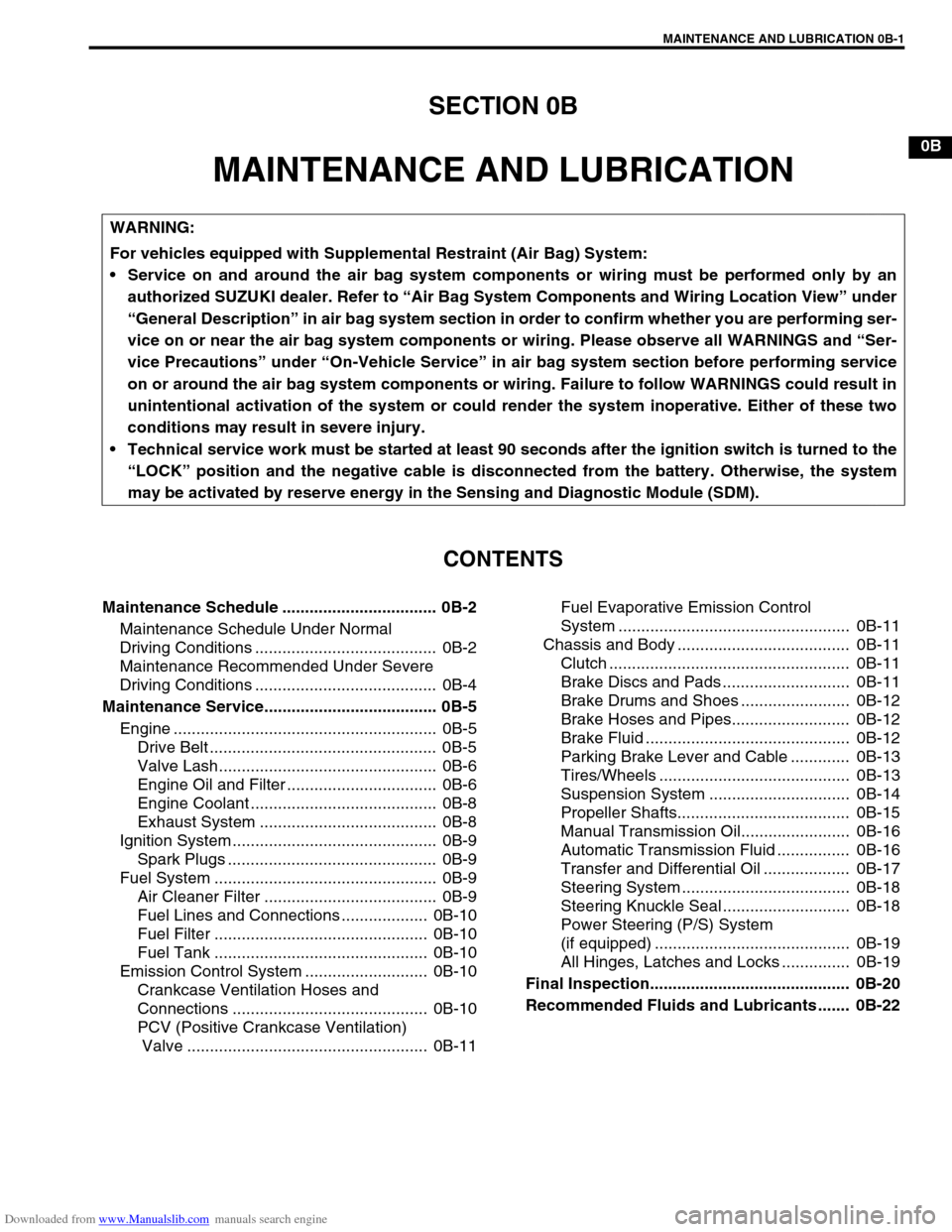

Maintenance Schedule

Maintenance Schedule Under Normal Driving Conditions

NOTE:

This interval should be judged by odometer reading or months, whichever comes first.

This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

IntervalKm (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 1827364554

Months 12 24 36 48 60 72

ENGINE

Drive belt V-belt I R I R I R

V-rib belt (Flat type)––I––R

Valve lash (clearance) –I–I–I

Engine oil and oil filter R R R R R R

Engine coolant––R––R

Exhaust system–I–I–I

IGNITION SYSTEM

✱Spark plugs When

unleaded

fuel is usedVehicle without

HO2SNickel spark

plug–R–R–R

Iridium spark

plug––R––R

Vehicle with

HO2SNickel spark

plug––R––R

Iridium spark

plug–––R––

When leaded fuel is used, refer to “Maintenance Recommended Under Severe Driving Condi-

tions” in this section.

FUEL SYSTEM

Air cleaner filter I I R I I R

Fuel lines and connections–I–I–I

Fuel filter Replace every 210,000 km (126,000 miles).

Fuel tank––I––I

EMISSION CONTROL SYSTEM

Crankcase ventilation hoses and connections

(Vehicle without HO2S)––I––I

✱PCV valve Vehicle without HO2S––I––I

Vehicle with HO2S–––––I

✱Fuel evaporative emission

control systemVehicle without HO2S–I–I–I

Vehicle with HO2S–––––I

NOTE:

“R”: Replace or change

“I”: Inspect and correct, replace or lubricate if necessary

For Sweden, items with

✱

✱✱ ✱ (asterisk) should be performed by odometer reading only.

For spark plugs, replace every 50,000 km if the local law requires.

Nickel spark plug: BKR6E-11 (NGK) or K20PR-U11 (DENSO)

Iridium spark plug: IFR5E11 (NGK) or SK16PR-A11 (DENSO)

Page 41 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-10 MAINTENANCE AND LUBRICATION

REPLACEMENT

Replace air cleaner filter with new one according to steps 1), 2)

and 5), 6) of inspection procedure.

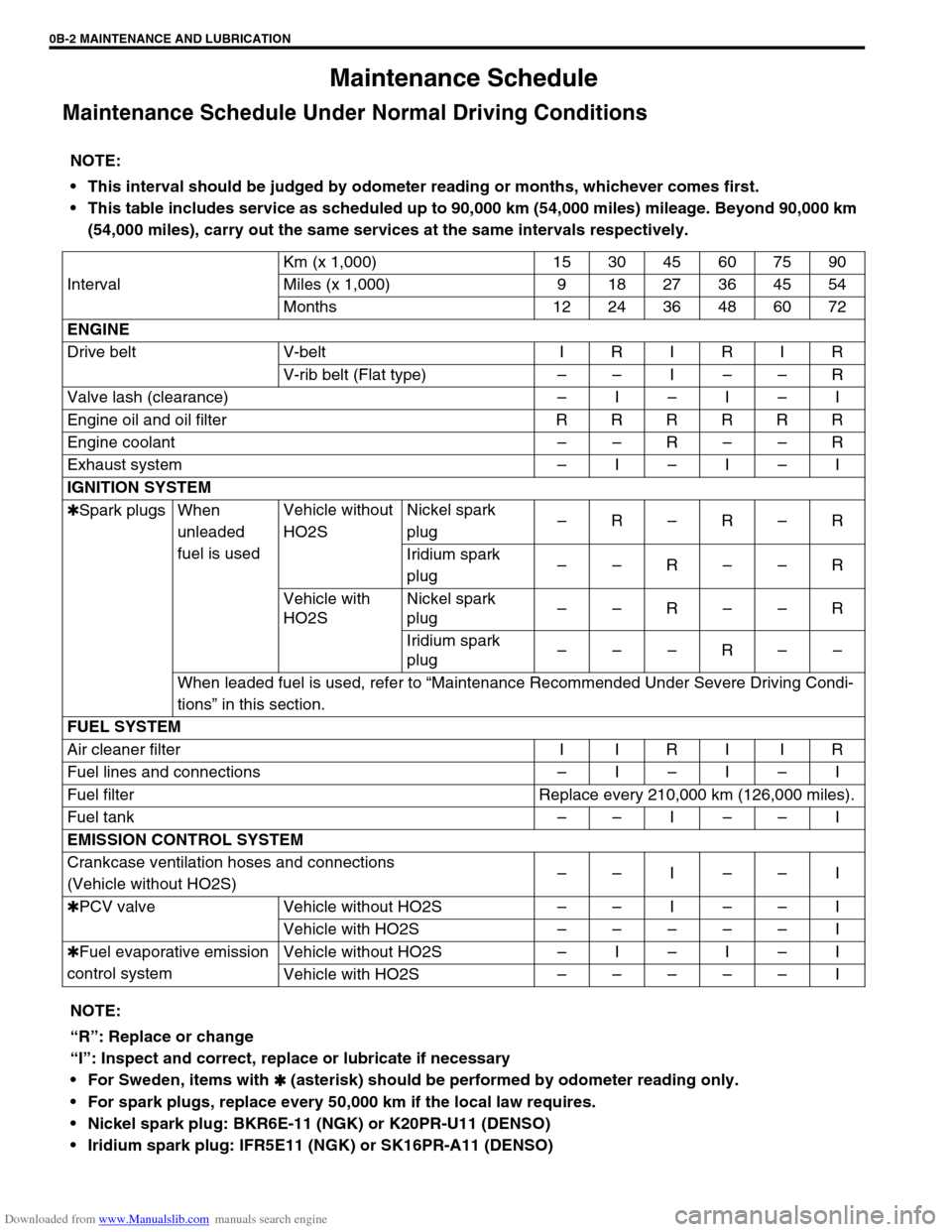

Fuel Lines and Connections

INSPECTION

1) Visually inspect fuel lines and connections for evidence of

fuel leakage, hose cracking and damage. Make sure all

clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

Fuel Filter

REPLACEMENT

Fuel filter (1) is a part of fuel pump assembly (2) which is installed

in fuel tank. Replace fuel filter with new one periodically, referring

to “Fuel Pump Assembly (with Fuel Filter, Fuel Level Gauge and

Fuel Cut Valve)” in Section 6C for proper procedure.

Fuel Tank

INSPECTION

Check fuel tank for damage, cracks, fuel leakage, corrosion and

tank bolts looseness.

If a problem is found, repair or replace.

Emission Control System

Crankcase Ventilation Hoses and Connections

INSPECTION

Refer to “PCV (Positive Crankcase Ventilation) Valve” in this sec-

tion.

WARNING:

This work must be performed in a well ventilated area

and away from any open flames (such as gas hot water

heaters).

Page 42 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-11

PCV (Positive Crankcase Ventilation) Valve

INSPECTION

Check crankcase ventilation hose and PCV hose for leaks, cracks

or clog, and PCV valve for stick or clog. Refer to “PCV System” of

Section 6E for PCV valve checking procedure.

Fuel Evaporative Emission Control System

INSPECTION

1) Visually inspect hoses for cracks, damage, or excessive

bends. Inspect all clamps for damage and proper position.

2) Check EVAP canister for operation and clog, referring to

“Evaporative Emission (EVAP) Control System” in Section

6E.

If a malfunction is found, repair or replace.

Chassis and Body

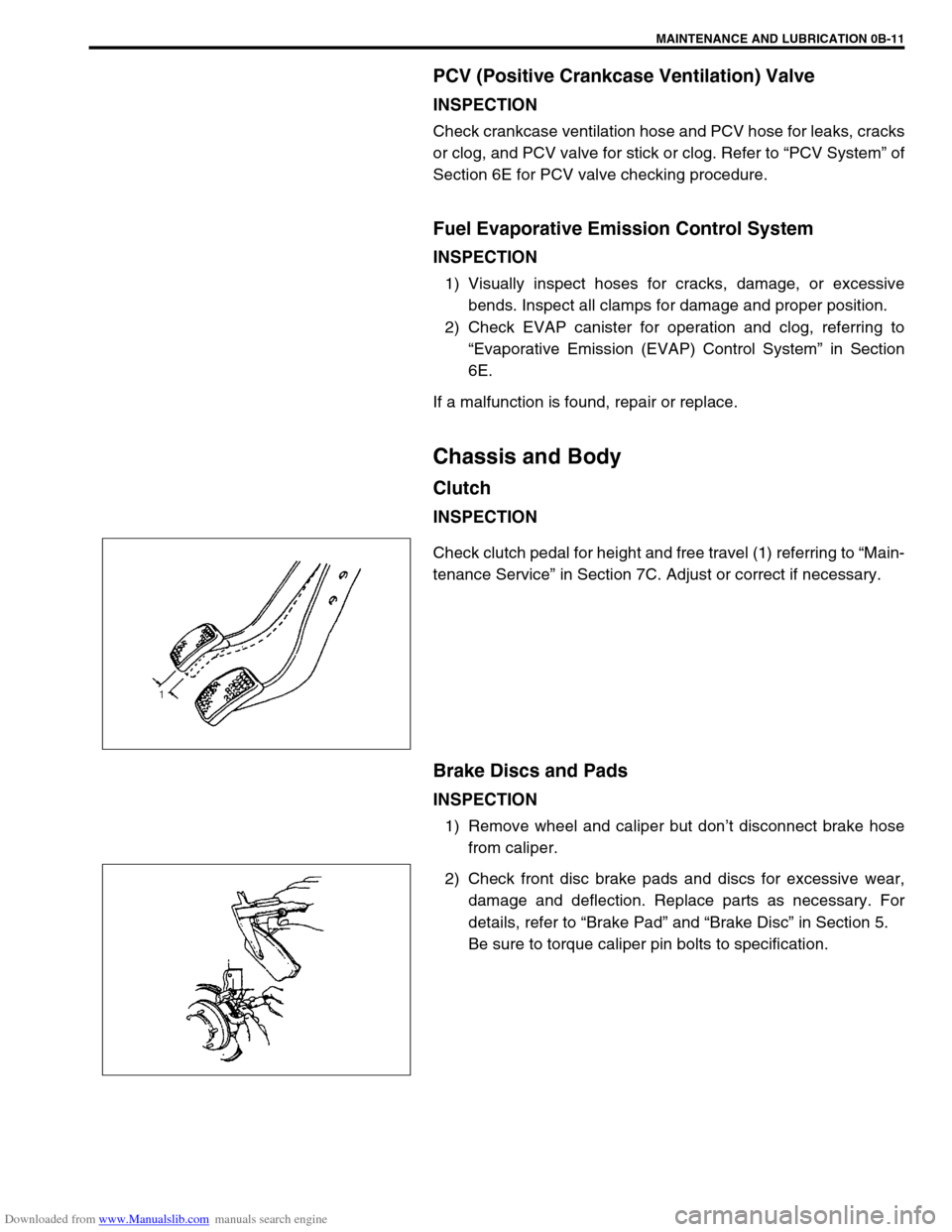

Clutch

INSPECTION

Check clutch pedal for height and free travel (1) referring to “Main-

tenance Service” in Section 7C. Adjust or correct if necessary.

Brake Discs and Pads

INSPECTION

1) Remove wheel and caliper but don’t disconnect brake hose

from caliper.

2) Check front disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary. For

details, refer to “Brake Pad” and “Brake Disc” in Section 5.

Be sure to torque caliper pin bolts to specification.

Page 380 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab](/img/20/7588/w960_7588-379.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis table

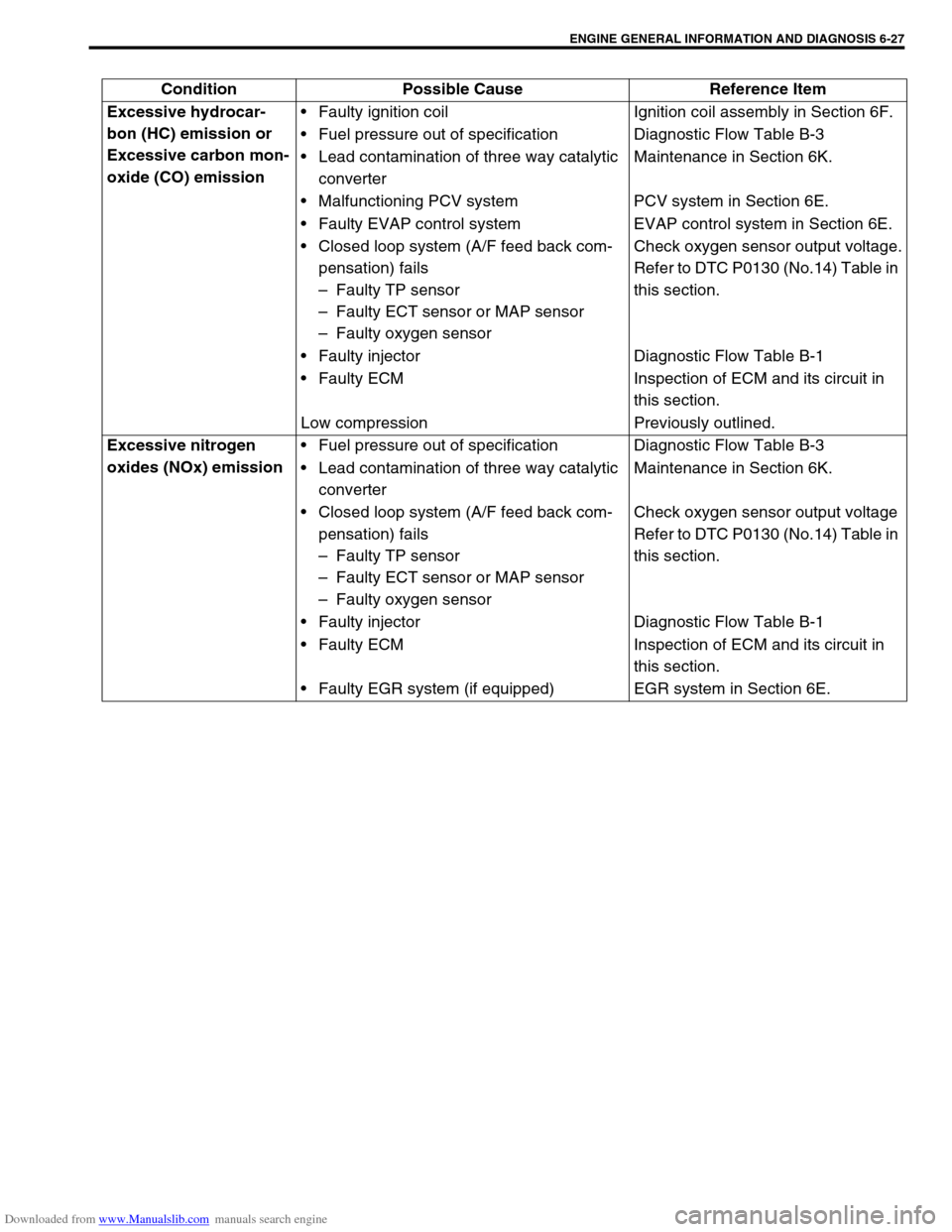

Perform troubleshooting referring to following table when ECM has no DTC and no abnormality found in visual

inspection and engine basic inspection previously.

Condition Possible Cause Reference Item

Hard Starting

(Engine cranks OK)Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty CMP sensing rotor or CKP sensing

rotorCMP sensing rotor or CKP sensing

rotor inspection in Section 6E.

Faulty idle air control system Diagnostic Flow Table B-4

Faulty ECT sensor, TP sensor, CKP sen-

sor, CMP sensor or MAP sensorECT sensor, TP sensor, CKP sensor,

CMP sensor or MAP sensor in Sec-

tion 6E.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty fuel injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning PCV system PCV system in Section 6E.

Low compression Compression check in Section 6A1.

Improper valve lash Valve lash in Section 6A1.

Improper valve timing Timing chain and chain tensioner in

Section 6A1.

Compression leak from valve seat Valves and cylinder head in Section

6A1.

Sticky valve stem Valves and cylinder head in Section

6A1.

Weak or damaged valve springs Valves and cylinder head in Section

6A1.

Compression leak at cylinder head gasket Valves and cylinder head in Section

6A1.

Sticking or damaged piston ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston, ring or cylinder Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Page 381 of 687

Downloaded from www.Manualslib.com manuals search engine 6-24 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Engine has no power

Engine overheating Refer to “Overheating” of this table.

Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Maladjusted accelerator cable play Accelerator cable adjustment in Sec-

tion 6E.

Low compression Previously outlined.

Dragging brakes Diagnosis table in Section 5.

Slipping clutch Diagnosis table in Section 7C.

Improper engine idling

or engine fails to idleFaulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty idle air control system Diagnostic Flow Table B-4

Faulty evaporative emission control sys-

temEVAP control system in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECT sensor, TP sensor or MAP

sensorECT sensor, TP sensor or MAP sen-

sor in Section 6E.

Malfunctioning PCV system PCV system in Section 6F.

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Engine hesitates

(Momentary lack of

response as the accel-

erator is depressed.

Can occur at all vehicle

speeds.

Usually most severe

when first trying to

make the vehicle move,

as from a stop sign.)Faulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Surges

(Engine power variation

under steady throttle or

cruise.

Feels like the vehicle

speeds up and down

with no change in the

accelerator pedal.)Faulty ignition coil or high-tension cord Ignition coil assembly or high-tension

cords in Section 6F.

Variable fuel pressure Diagnostic Flow Table B-3

Faulty MAP sensor MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E. Condition Possible Cause Reference Item

Page 384 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-27

Condition Possible Cause Reference Item

Excessive hydrocar-

bon (HC) emission or

Excessive carbon mon-

oxide (CO) emissionFaulty ignition coil Ignition coil assembly in Section 6F.

Fuel pressure out of specification Diagnostic Flow Table B-3

Lead contamination of three way catalytic

converterMaintenance in Section 6K.

Malfunctioning PCV system PCV system in Section 6E.

Faulty EVAP control system EVAP control system in Section 6E.

Closed loop system (A/F feed back com-

pensation) fails

–Faulty TP sensor

–Faulty ECT sensor or MAP sensor

–Faulty oxygen sensorCheck oxygen sensor output voltage.

Refer to DTC P0130 (No.14) Table in

this section.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Low compression Previously outlined.

Excessive nitrogen

oxides (NOx) emissionFuel pressure out of specification Diagnostic Flow Table B-3

Lead contamination of three way catalytic

converterMaintenance in Section 6K.

Closed loop system (A/F feed back com-

pensation) fails

–Faulty TP sensor

–Faulty ECT sensor or MAP sensor

–Faulty oxygen sensorCheck oxygen sensor output voltage

Refer to DTC P0130 (No.14) Table in

this section.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Page 425 of 687

![SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 Fuel System Too Lean

DTC P0172 Fuel System Too Rich

CIRCUIT DESCRIPTION

[a] : Signal to SUZUKI JIMNY 2005 3.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 Fuel System Too Lean

DTC P0172 Fuel System Too Rich

CIRCUIT DESCRIPTION

[a] : Signal to](/img/20/7588/w960_7588-424.png)

Downloaded from www.Manualslib.com manuals search engine 6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

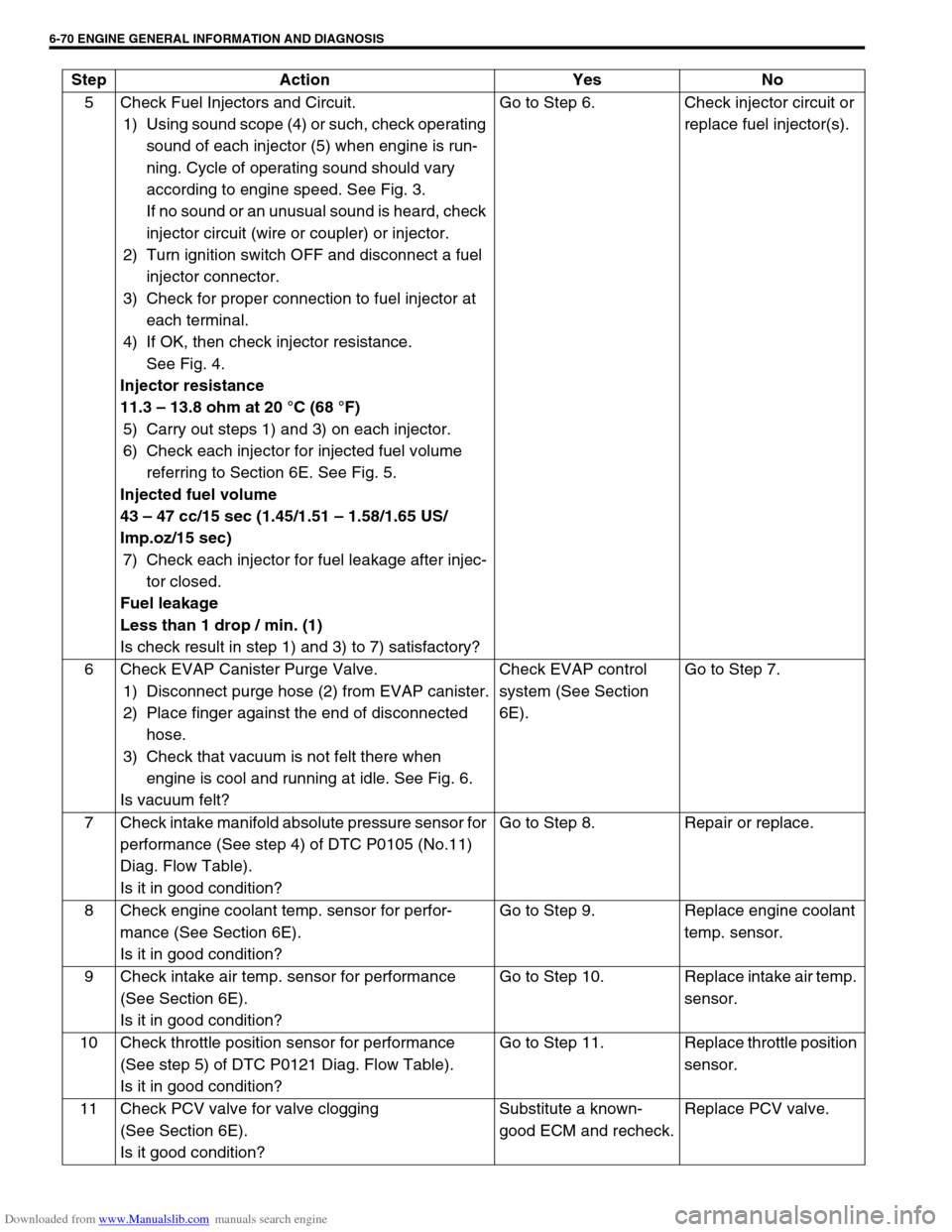

DTC P0171 Fuel System Too Lean

DTC P0172 Fuel System Too Rich

CIRCUIT DESCRIPTION

[a] : Signal to decrease amount of fuel injection [d] : A/F mixture becomes richer

(Oxygen concentration decreases)1. Injector

[b] : Signal to increase amount of fuel injection [e] : High voltage 2. Heated oxygen sensor-1 (HO2S-1)

[c] : A/F mixture becomes leaner

(Oxygen concentration increases)[f] : Low voltage

DTC DETECTING CONDITION POSSIBLE CAUSE

When following condition occurs while engine running

under closed loop condition.

–Air / fuel ratio too lean

(Total fuel trim (short and long terms added) is more

than 30%)

or

–Air / fuel ratio too rich

(Total fuel trim is less than –30%)

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.Vacuum leaks (air drawn in).

Exhaust gas leakage.

Heated oxygen sensor-1 circuit malfunction.

Fuel pressure out of specification.

Fuel injector malfunction (clogged or leakage).

MAP sensor poor performance.

ECT sensor poor performance.

IAT sensor poor performance.

TP sensor poor performance.

EVAP control system malfunction.

PCV valve malfunction.

Page 427 of 687

Downloaded from www.Manualslib.com manuals search engine 6-70 ENGINE GENERAL INFORMATION AND DIAGNOSIS

5 Check Fuel Injectors and Circuit.

1) Using sound scope (4) or such, check operating

sound of each injector (5) when engine is run-

ning. Cycle of operating sound should vary

according to engine speed. See Fig. 3.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Turn ignition switch OFF and disconnect a fuel

injector connector.

3) Check for proper connection to fuel injector at

each terminal.

4) If OK, then check injector resistance.

See Fig. 4.

Injector resistance

11.3 – 13.8 ohm at 20 °C (68 °F)

5) Carry out steps 1) and 3) on each injector.

6) Check each injector for injected fuel volume

referring to Section 6E. See Fig. 5.

Injected fuel volume

43 – 47 cc/15 sec (1.45/1.51 – 1.58/1.65 US/

Imp.oz/15 sec)

7) Check each injector for fuel leakage after injec-

tor closed.

Fuel leakage

Less than 1 drop / min. (1)

Is check result in step 1) and 3) to 7) satisfactory?Go to Step 6. Check injector circuit or

replace fuel injector(s).

6 Check EVAP Canister Purge Valve.

1) Disconnect purge hose (2) from EVAP canister.

2) Place finger against the end of disconnected

hose.

3) Check that vacuum is not felt there when

engine is cool and running at idle. See Fig. 6.

Is vacuum felt?Check EVAP control

system (See Section

6E).Go to Step 7.

7 Check intake manifold absolute pressure sensor for

performance (See step 4) of DTC P0105 (No.11)

Diag. Flow Table).

Is it in good condition?Go to Step 8. Repair or replace.

8 Check engine coolant temp. sensor for perfor-

mance (See Section 6E).

Is it in good condition?Go to Step 9. Replace engine coolant

temp. sensor.

9 Check intake air temp. sensor for performance

(See Section 6E).

Is it in good condition?Go to Step 10. Replace intake air temp.

sensor.

10 Check throttle position sensor for performance

(See step 5) of DTC P0121 Diag. Flow Table).

Is it in good condition?Go to Step 11. Replace throttle position

sensor.

11 Check PCV valve for valve clogging

(See Section 6E).

Is it good condition?Substitute a known-

good ECM and recheck.Replace PCV valve. Step Action Yes No