full SUZUKI JIMNY 2022 Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2022, Model line: JIMNY, Model: SUZUKI JIMNY 2022Pages: 421, PDF Size: 6.35 MB

Page 351 of 421

NOTE: SUZUKI highly recommends the use of ECSTAR brend brake fluid. ECSTAR has been specially formulated for your SUZUKI product and contributes to the desired vehicle performance and ideal driving experience.

A WARNING

Failure to follow the guidelines below can result in personal injury or serious damage to the brake system. . If the brake fluid in the reservoir drops below a certain level, the brake warning light on the instrument cluster will come on (the engine must be running with the parking brake fully dise~gaged). Should the light come on, 1mmed1-ately ask a SUZUKI dealer to inspect the brake system. A rapid fluid loss indicates leakage in the brake system which should be inspected by a SUZUKI dealer immediately. Do not use any fluid other than DOT3 or SAE J1703 brake fluid. Do not use reclaimed fluid or fluid that has been stored in old or open containers. It is essential that foreign particles and other liquids are kept out of the brake fluid reservoir.

A CAUTION

Brake fluid can harm your eyes and damage painted surfaces. Be careful when refilling the reservoir.

A WARNING

Brake fluid is harmful or fatal if swallowed, and harmful if it comes in contact with skin or eyes. If swallowed, do not induce vomiting. Immediately contact a poison control center or a physician. If brake fluid gets in eye~, flush eyes with water and seek medical attention. Wash thoroughly after handling. Solution can be poisonous to animals. Keep out of reach of children and animals.

NOTE: • The fluid /eve/ can be expected to gredually fall as the brake pad and/or shoe wear. Brake fluid absorbs water over time and brake fluid with high water content may cause vapor lock or breke system malfunction. Replace your breke fluid in accordance with the maintenance schedule m your Owner's Manual.

INSPECTION AND MAINTENANCE

Brake pedal

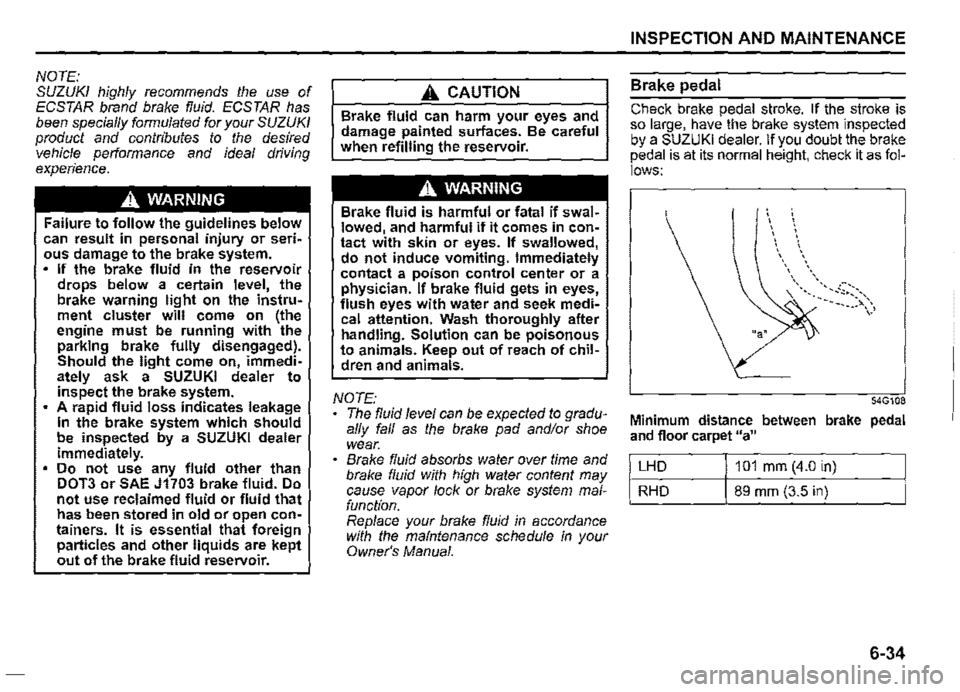

Check brake pedal stroke. If the stroke is so large, have the brake system inspected by a SUZUKI dealer. If you doubt th_e brake pedal is at its normal height, check 1t as follows:

54G108

Minimum distance between brake pedal and floor carpet "a"

LHD 101 mm (4.0 in)

RHD 89 mm (3.5 in)

6-34

Page 352 of 421

INSPECTION AND MAINTENANCE

With the engine running, measure the distance between the brake pedal and floor carpet when the pedal is depressed with approximately 30 kg (66 lbs) of force. The minimum distance required is as specified. Since your vehicle's brake system is selfadjusting, there is no need for pedal adjustment. If the pedal to floor carpet distance as measured above is less than the minimum distance required, have your vehicle inspected by a SUZUKI dealer.

NOTE: • When measuring the distance between the brake pedal and floor wall, be sure not to include the floor mat or rubber on the floor carpet in your measurement. Measure the distance at the brake pedal's side facing toward the passenger's door.

6-35

52RM70500

A WARNING

If you experience any of the following problems with your vehicle's brake system, have the vehicle inspected immediately by a SUZUKI dealer. Poor braking performance Uneven braking (brakes not working uniformly on all wheels.) Excessive pedal travel Brake dragging Excessive noise

Parking brake

~

54G109

Ratchet tooth specification 11b": 4th-9th Lever pull force (1 ): 200 N (20 kg, 45 lbs)

Check the parking brake for proper adjustment by counting the number of clicks made by the ratchet teeth as you slowly pull up on the parking brake lever to the point of full engagement. The parking brake lever should stop between the specified ratchet teeth and the rear wheels should be securely locked. If the parking brake is not properly adjusted or the brakes drag is suspected even after the lever has been fully released, have the parking brake inspected and/or adjusted by a SUZUKI dealer.

Page 356 of 421

INS.PECTION AND MAINTENANCE

4-tyre rotation

65D459

To avoid uneven wear of your tyres and to prolong their life, rotate the tyres as illustrated. Tyres should be rotated every 10000 km (6000 miles). After rotation, adjust front and rear tyre pressures to the specification listed on your vehicle's Tyre Information Label.

6-39

Changing Wheels

78RB07014

To change a wheel, use the following procedure:

1) Remove the jack, tools and spare wheel from the vehicle.

NOTE: How to remove the spare wheel:

78RB07052

1. Remove the center nut (1 ), then remove the spare wheel half cover (2) (if equipped). 2. Remove the wheel nuts of the spare wheel, then remove the spare wheel with both hands.

2) Loosen, but do not remove the wheel nuts. 3) Jack up the vehicle (follow the jacking instructions in the "EMERGENCY SERVICE" section in this manual) 4) Remove the wheel nuts and wheel. 5) Before installing the new wheel, clean any mud or dirt off from the surface of the wheel and hub with a clean cloth. Clean the hub carefully; it may be hot from driving.

Page 357 of 421

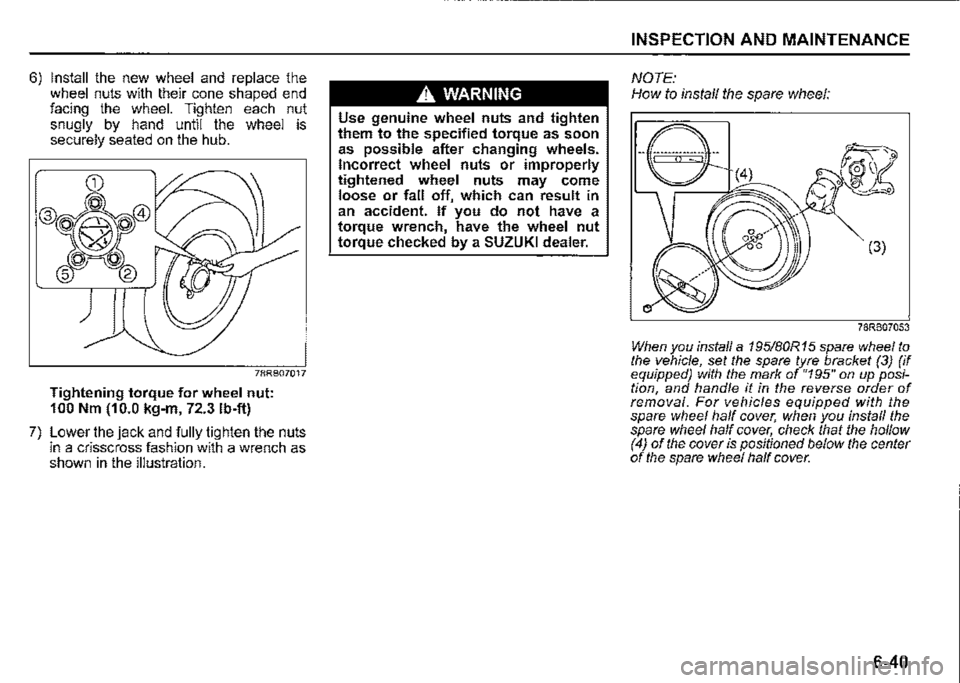

6) Install the new wheel and replace the wheel nuts with their cone shaped end facing the wheel. Tighten each nut snugly by hand until the wheel is securely seated on the hub.

78RB07017

Tightening torque for wheel nut: 100 Nm (10.0 kg-m, 72.3 lb-ft)

7) Lower the jack and fully tighten the nuts in a crisscross fashion with a wrench as shown in the illustration.

A WARNING

Use genuine wheel nuts and tighten them to the specified torque as soon as possible after changing wheels. Incorrect wheel nuts or improperly tightened wheel nuts may come loose or fall off, which can result in an accident. If you do not have a torque wrench, have the wheel nut torque checked by a SUZUKI dealer.

INSPECTION AND MAINTENANCE

NOTE: How to install the spare wheel:

(3)

78RB07053

When you install a 195/B0R 15 spare wheel to the vehicle, set the spare tyre bracket (3) (if equipped) with the mark of "195" on up position, and handle it in the reverse order of removal. For vehicles equipped with the spare wheel half cover; when you install the spare wheel half cover, check that the hollow (4) of the cover is positioned below the center of the spare wheel half cover.

6-40

Page 364 of 421

INSPECTION AND MAINTENANCE

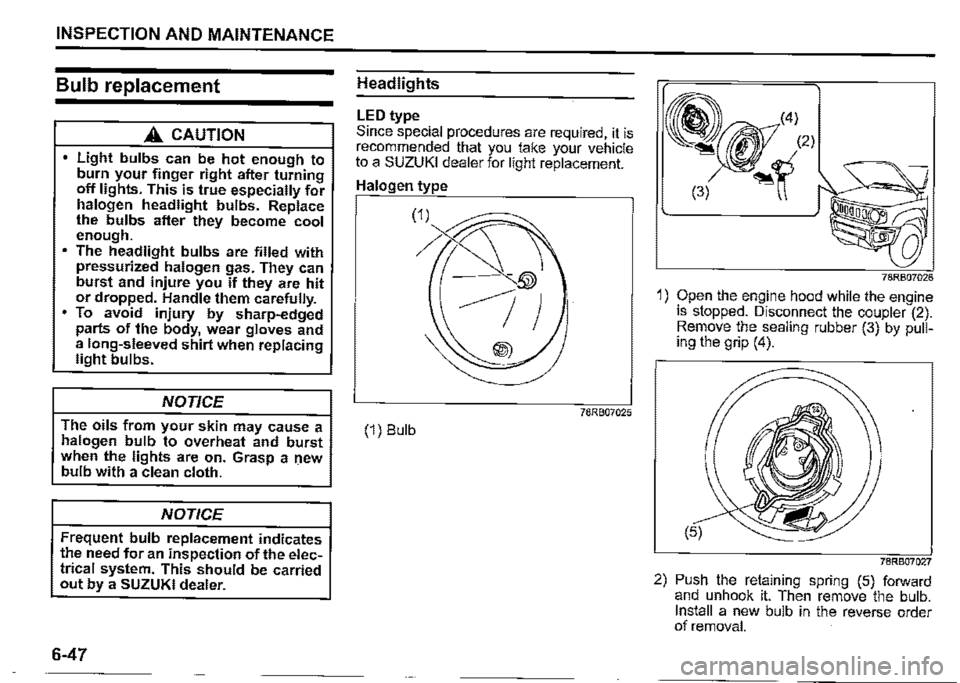

Bulb replacement

_A CAUTION

Light bulbs can be hot enough to burn your finger right after turning off lights. This is true especially for halogen headlight bulbs. Replace the bulbs after they become cool enough.

The headlight bulbs are filled with pressurized halogen gas. They can burst and injure you if they are hit or dropped. Handle them carefully. To avoid injury by sharp-edged parts of the body, wear gloves and a long-sleeved shirt when replacing light bulbs.

NOTICE

The oils from your skin may cause a halogen bulb to overheat and burst when the lights are on. Grasp a new bulb with a clean cloth.

NOTICE

Frequent bulb replacement indicates the need for an inspection of the electrical system. This should be carried out by a SUZUKI dealer.

6-47

Headlights

LED type

Since special procedures are required, it is recommended that you take your vehicle to a SUZUKI dealer for light replacement.

Halogen type

78RB07025

(1) Bulb

8~'",,,

""

'\:~

(3) ~f I r-,.t:: l'1

Jlilt10or\01 ~o

"-" [l!l ,Q

78RB07026

1) Open the engine hood while the engine is stopped. Disconnect the coupler (2). Remove the sealing rubber (3) by pulling the grip (4).

78RB07027

2) Push the retaining spring (5) forward and unhook it. Then remove the bulb. Install a new bulb in the reverse order of removal.

Page 379 of 421

Front wheel/Rear wheel

54G277

(1) Boss

6) Position the jack vertically and raise the jack by turning the jack handle clockwise until the jack head hole fits into the boss (1) of the body as the illustration. 7) Continue to raise the jack slowly and smoothly until the tyre clears the ground. Do not raise the vehicle more than necessary.

A WARNING

• Use the jack only to change wheels on level, hard ground. • Never jack up the vehicle on an inclined surface. • Never raise the vehicle with the jack in a location other than between the frame bosses near the wheel to be changed. • Make sure that the jack is raised at least 51 mm (2 inches) before it contacts the boss. Use of the jack when it is within 51 mm (2 inches) of being fully collapsed may result in failure of the jack. No person should place any portion of their body under a vehicle that is supported by a jack. • Never run the engine when the vehicle is supported by the jack and never allow passengers to remain in the vehicle.

EMERGENCY SERVICE

7-2

Page 381 of 421

NOTICE

Never apply a garage jack to the exhaust pipe, front fender splash guard, side sill splash, rear fender splash guard, front differential or rear differential.

NOTE: For more details, contact a SUZUKI dealer.

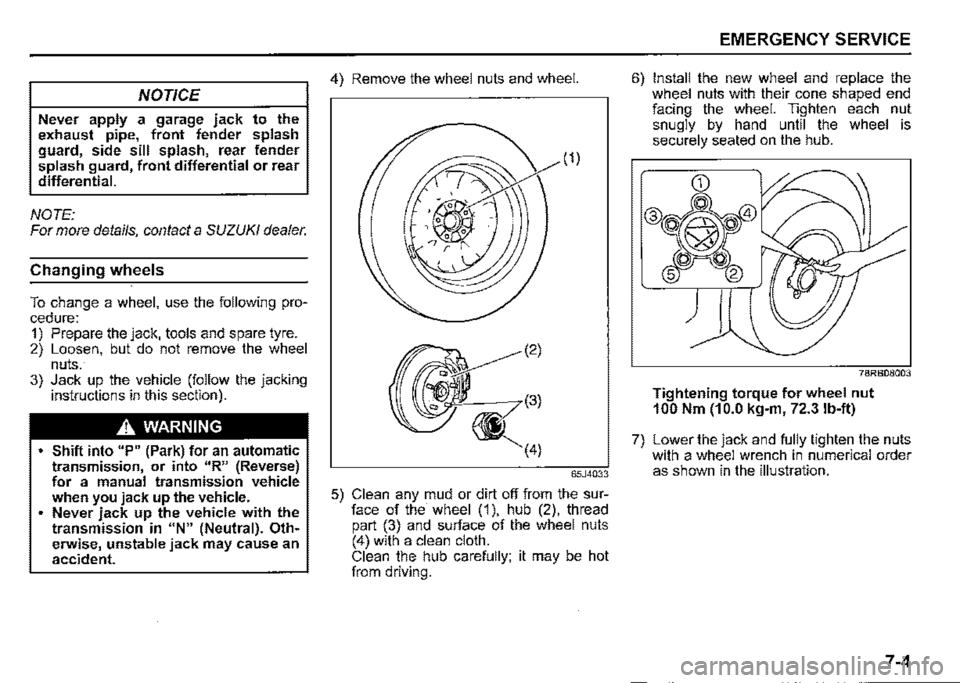

Changing wheels

To change a wheel, use the following pro

cedure: 1) Prepare the jack, tools and spare tyre. 2) Loosen, but do not remove the wheel nuts. 3) Jack up the vehicle (follow the jacking instructions in this section).

A WARNING

Shift into "P" (Park) for an automatic transmission, or into 11R" (Reverse) for a manual transmission vehicle when you jack up the vehicle. Never jack up the vehicle with the transmission in "N" (Neutral). OthR erwise, unstable jack may cause an accident.

4) Remove the wheel nuts and wheel.

65J4033

5) Clean any mud or dirt off from the surface of the wheel (1 ), hub (2), thread part (3) and surface of the wheel nuts (4) with a clean cloth. Clean the hub carefully; it may be hot from driving.

EMERGENCY SERVICE

6) Install the new wheel and replace the wheel nuts with their cone shaped end facing the wheel. Tighten each nut snugly by hand until the wheel is securely seated on the hub.

78RB08003

Tightening torque for wheel nut 100 Nm (10.0 kg-m, 72.3 lb-ft)

7) Lower the jack and fully tighten the nuts with a wheel wrench in numerical order as shown in the illustration.

7-4

Page 382 of 421

EMERGENCY SERVICE

A. WARNING

Use genuine wheel nuts and tighten them to the specified torque as soon as possible after changing wheels. Incorrect wheel nuts or improperly tightened wheel nuts may come loose or fall off, which can result in an accident. If you do not have a torque wrench, have the wheel nut torque checked by a SUZUKI dealer.

7-5

Jump-starting instructions

A. WARNING

Never attempt to jump-start your vehicle if the lead-acid battery appears to be frozen. Batteries in this condition may explode. When making jump lead connections, check that your hands and the jump leads remain clear from pulleys, belts or fans. Lead-acid batteries produce flammable hydrogen gas. Keep flames and sparks away from the battery or an explosion may occur. Never smoke when working near the battery. If the booster battery you use for jump-starting is installed in another vehicle, check that the two vehicles are not touching each other. If your lead-acid battery discharges repeatedly, for no apparent reason, have your vehicle inspected by a SUZUKI dealer. • To avoid harm to yourself or damage to your vehicle or battery, follow the jump-starting instructions below. If you are in doubt, call for qualified road service.

NOTICE

Your vehicle should not be started by pushing or towing. This starting method could result in permanent damage to the catalytic converter. Use jump leads to start a vehicle with a weak or flat battery.

1) Use only a 12-volt lead-acid battery to jump-start your vehicle. Position the good 12-volt lead-acid battery close to your vehicle so that the jump leads will reach both batteries. When using a battery installed on another vehicle, check that two vehicles do not touch each other. Set the parking brakes fully on both vehicles. 2) Turn off all vehicle accessories, except those necessary for safety reasons (for example, headlights or hazard lights).

Page 388 of 421

EMERGENCY SERVICE

If the high engine coolant temperature warning light does not go off or the temperature indication does not come down to within the normal, acceptable range:

1) Turn off the engine and check that the water pump belt and pulleys are not damaged or slipping. If any abnormality is found, correct it. 2) Check the coolant level in the reservoir. If it is found to be lower than "LOW" line, check radiator, water pump, radiator hoses and heater hoses for leakage. If leakage that may cause overheating is found, do not run the engine until these problems have been corrected. 3) If leakage is not found, carefully add coolant to the reservoir and then the radiator, if necessary. (Refer to "Engine coolant" in "INSPECTION AND MAINTENANCE" section.)

NOTE: If engine overheats and you are not sure what to do, contact a SUZUKI dealer.

7-11

650614

A WARNING

• It is hazardous to remove the radiator cap when the water temperature is high, because scalding fluid and steam may be blown out under pressure. The cap should only be taken off when the coolant temperature has lowered. To help prevent personal injury, keep hands, tools and clothing away from the engine cooling fan and air-conditioner fan. These electric fans can automatically turn on without warning.

Page 390 of 421

APPEARANCE CARE

Corrosion prevention

It is_ important to take good care of your vehicle to protect it from corrosion. Listed below are instructions for how to maintain your vehicle to prevent corrosion. Please read and follow these instructions carefully.

Important information about corro

sion

Common causes of corrosion 1) Accumulation of road salt, dirt moisture or chemicals in hard-to-reach areas of the vehicle underbody or frame. 2) Chipping, scratches and any damage to treated or painted metal surfaces resulting from minor accidents or abrasion by stones and gravel.

Environmental conditions which accelerate corrosion 1) Road salt, dust control chemicals, sea breeze or industrial pollution will all accelerate the corrosion of metal. 2) High humidity will increase the rate of corrosion particularly when the temperature range is just above the freezing point. 3) Moisture in certain areas of a vehicle for an extended period of lime may promote corrosion even though other body sections may be completely dry.

8-1

4) High temperatures will cause an accelerated rate of corrosion to parts of the vehicle which are not well-ventilated to permit quick drying.

This information illustrates the necessity of keeping your vehicle (particularly the ~nderbody) as clean and dry as possible. It Is equally important to repair any damage to the paint or protective coatings as soon as possible.

How to help prevent corrosion

Wash your vehicle frequently The_ best way to preserve the finish on your vehicle and to help avoid corrosion is to keep it clean with frequent washing. Wash your vehicle at least once during the winter and once immediately after the winter. K<:ep your vehicle, particularly the underside, as clean and dry as possible. If you frequently drive on salted roads your vehicle should be washed at least once a month during the winter. If you live near the ocean, your vehicle should be washed at least once a month throughout the year.

For washing instructions, refer to "Vehicle cleaning" section.

Remove foreign material deposits Foreign materials such as salts chemicals road oil or tar, tree sap, bird droppings and industnal fall-out may damage the finish of your vehicle if it is left on painted surfaces. Remove these types of deposits as quickly as possible. If these deposits are difficult to wash off, an additional cleaner may be required. Check that any cleaner you use is not harmful to painted surfaces and is specifically intended for your purposes. Follow the manufacturer's directions when using these special cleaners.

Repair finish damage Carefully examine your vehicle for damage to the painted surfaces. Should you find any chip~ or scratches in the paint, touch them up 1mmed1ately to prevent corrosion from starting. If the chips or scratches have gone through to the bare metal have a qualified body shop make the rep~ir.

Keep passenger and luggage compartments clean Moisture, dirt or mud can accumulate under the floor mats and may cause corrosion. Occasionally, check under these mats to ensure that this area is clean and dry. More fr~quent checks are necessary if the vehicle Is used for off-road driving or in wet weather. Certain cargos such as chemicals, fertilizers, cleaners, salts, etc. are extremely corrosive by nature. These products should be transported in sealed containers. If they