ABS SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 402 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-33

SCAN TOOL DATA DEFINITIONS :

FUEL SYSTEM (FUEL SYSTEM STATUS)

Air/fuel ratio feedback loop status displayed as either open or closed loop. Open indicates that ECM ignores

feedback from the exhaust oxygen sensor.

Closed indicates final injection duration is corrected for oxygen sensor feedback.

CALC LOAD (CALCULATED LOAD VALUE, %)

Engine load displayed as a percentage of maximum possible load. Value is calculated mathematically using the

formula : actual (current) intake air volume ÷ maximum possible intake air volume x 100%.

COOLANT TEMP. (ENGINE COOLANT TEMPERATURE, °C, °F)

It is detected by engine coolant temp. sensor

SHORT FT B1 (SHORT TERM FUEL TRIM, %)

Short term fuel trim value represents short term corrections to the air/fuel mixture computation. A value of 0 indi-

cates no correction, a value greater than 0 means an enrichment correction, and a value less than 0 implies an

enleanment correction.

LONG FT B1 (LONG TERM FUEL TRIM, %)

Long term fuel trim Value represents long term corrections to the air/fuel mixture computation. A value of 0 indi-

cates no correction, a value greater than 0 means an enrichment correction, and a value less than 0 implies an

enleanment correction.

MAP (INTAKE MANIFOLD ABSOLUTE PRESSURE, kPa, inHg)

It is detected by manifold absolute pressure sensor and used (among other things) to compute engine load.

ENGINE SPEED (rpm)

It is computed by reference pulses from crankshaft position sensor.

VEHICLE SPEED (km/h, MPH)

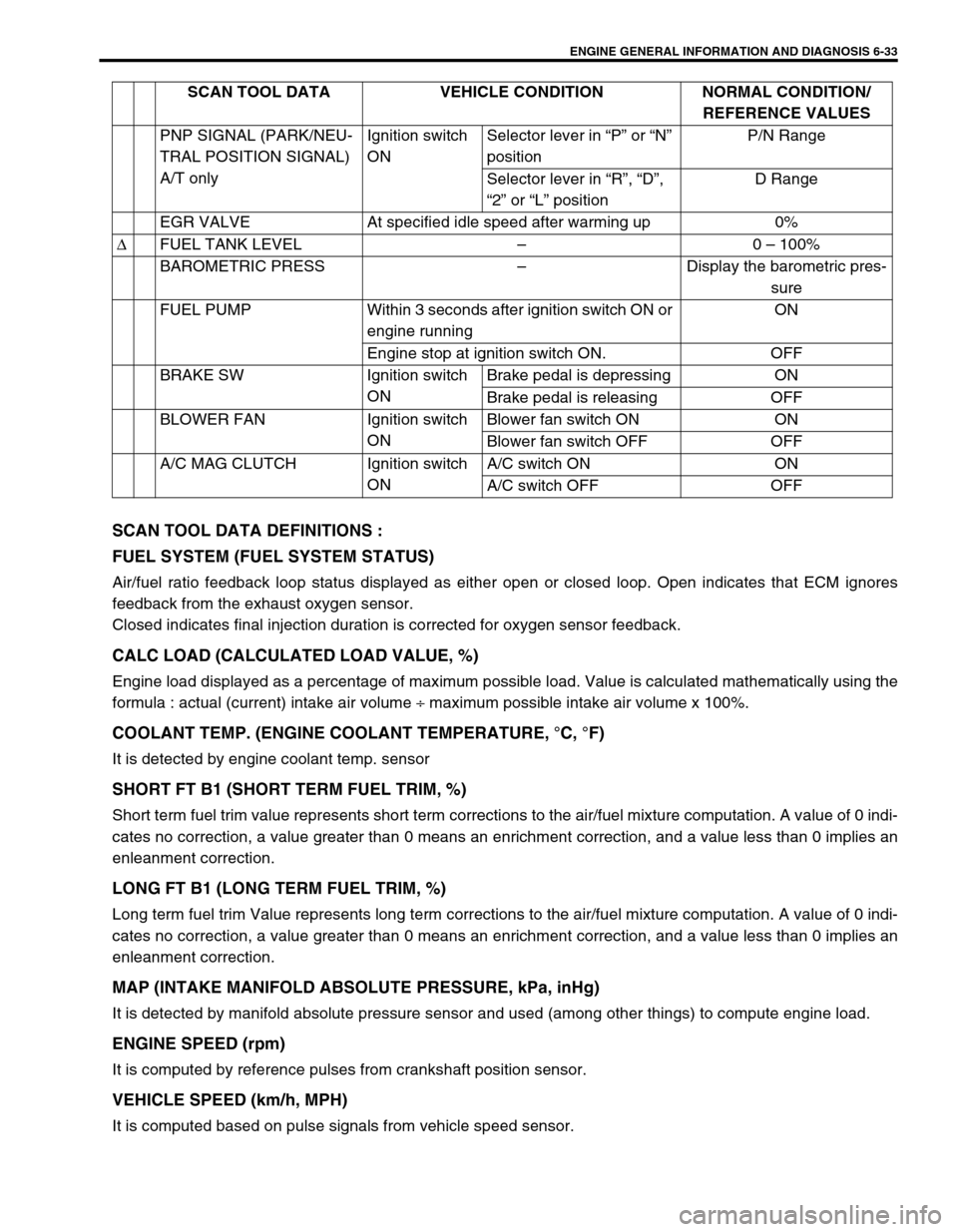

It is computed based on pulse signals from vehicle speed sensor.PNP SIGNAL (PARK/NEU-

TRAL POSITION SIGNAL)

A/T onlyIgnition switch

ONSelector lever in “P” or “N”

positionP/N Range

Selector lever in “R”, “D”,

“2” or “L” positionD Range

EGR VALVE At specified idle speed after warming up 0%

∆FUEL TANK LEVEL–0 – 100%

BAROMETRIC PRESS–Display the barometric pres-

sure

FUEL PUMP Within 3 seconds after ignition switch ON or

engine runningON

Engine stop at ignition switch ON. OFF

BRAKE SW Ignition switch

ONBrake pedal is depressing ON

Brake pedal is releasing OFF

BLOWER FAN Ignition switch

ONBlower fan switch ON ON

Blower fan switch OFF OFF

A/C MAG CLUTCH Ignition switch

ONA/C switch ON ON

A/C switch OFF OFF SCAN TOOL DATA VEHICLE CONDITION NORMAL CONDITION/

REFERENCE VALUES

Page 403 of 698

6-34 ENGINE GENERAL INFORMATION AND DIAGNOSIS

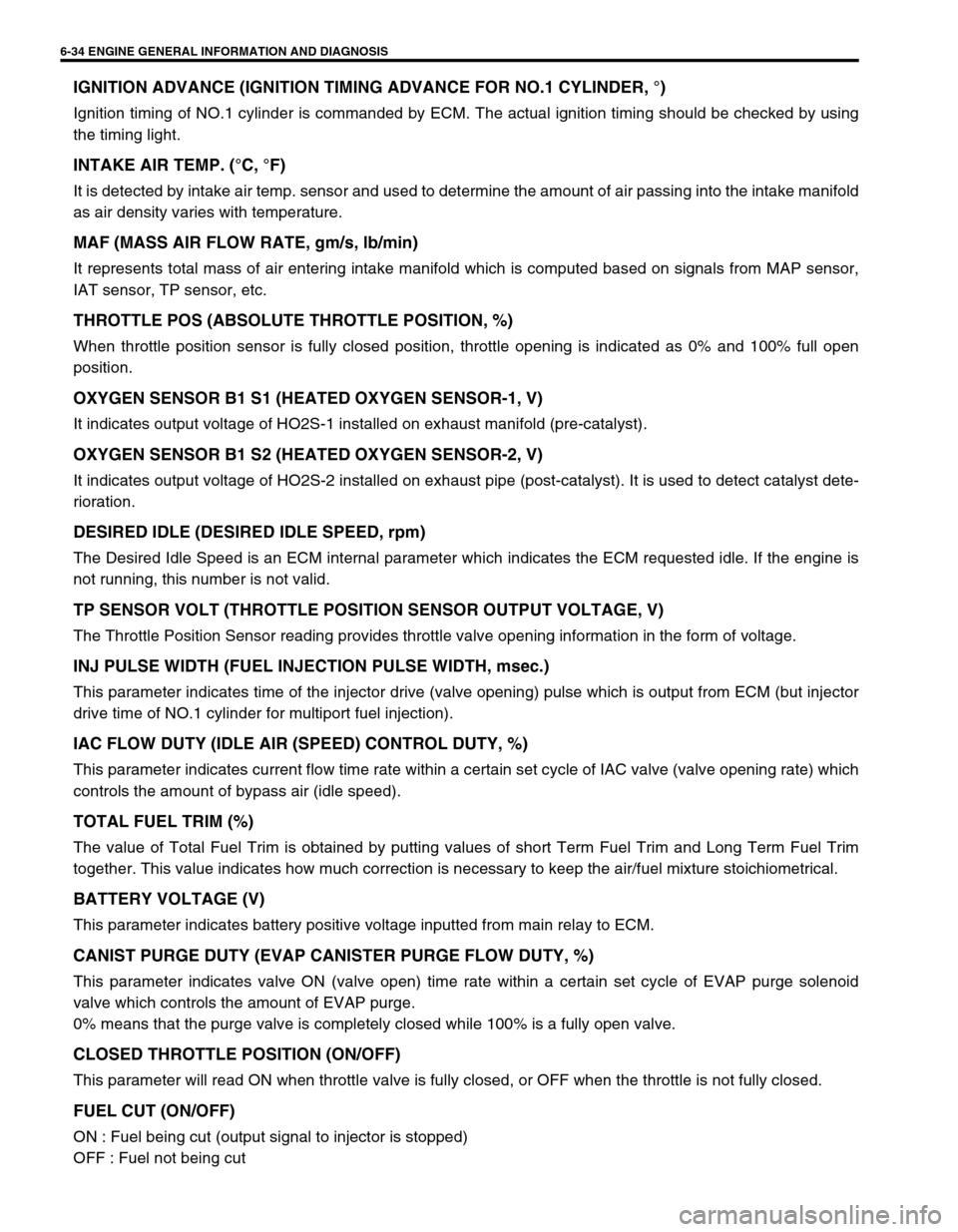

IGNITION ADVANCE (IGNITION TIMING ADVANCE FOR NO.1 CYLINDER, °)

Ignition timing of NO.1 cylinder is commanded by ECM. The actual ignition timing should be checked by using

the timing light.

INTAKE AIR TEMP. (°C, °F)

It is detected by intake air temp. sensor and used to determine the amount of air passing into the intake manifold

as air density varies with temperature.

MAF (MASS AIR FLOW RATE, gm/s, lb/min)

It represents total mass of air entering intake manifold which is computed based on signals from MAP sensor,

IAT sensor, TP sensor, etc.

THROTTLE POS (ABSOLUTE THROTTLE POSITION, %)

When throttle position sensor is fully closed position, throttle opening is indicated as 0% and 100% full open

position.

OXYGEN SENSOR B1 S1 (HEATED OXYGEN SENSOR-1, V)

It indicates output voltage of HO2S-1 installed on exhaust manifold (pre-catalyst).

OXYGEN SENSOR B1 S2 (HEATED OXYGEN SENSOR-2, V)

It indicates output voltage of HO2S-2 installed on exhaust pipe (post-catalyst). It is used to detect catalyst dete-

rioration.

DESIRED IDLE (DESIRED IDLE SPEED, rpm)

The Desired Idle Speed is an ECM internal parameter which indicates the ECM requested idle. If the engine is

not running, this number is not valid.

TP SENSOR VOLT (THROTTLE POSITION SENSOR OUTPUT VOLTAGE, V)

The Throttle Position Sensor reading provides throttle valve opening information in the form of voltage.

INJ PULSE WIDTH (FUEL INJECTION PULSE WIDTH, msec.)

This parameter indicates time of the injector drive (valve opening) pulse which is output from ECM (but injector

drive time of NO.1 cylinder for multiport fuel injection).

IAC FLOW DUTY (IDLE AIR (SPEED) CONTROL DUTY, %)

This parameter indicates current flow time rate within a certain set cycle of IAC valve (valve opening rate) which

controls the amount of bypass air (idle speed).

TOTAL FUEL TRIM (%)

The value of Total Fuel Trim is obtained by putting values of short Term Fuel Trim and Long Term Fuel Trim

together. This value indicates how much correction is necessary to keep the air/fuel mixture stoichiometrical.

BATTERY VOLTAGE (V)

This parameter indicates battery positive voltage inputted from main relay to ECM.

CANIST PURGE DUTY (EVAP CANISTER PURGE FLOW DUTY, %)

This parameter indicates valve ON (valve open) time rate within a certain set cycle of EVAP purge solenoid

valve which controls the amount of EVAP purge.

0% means that the purge valve is completely closed while 100% is a fully open valve.

CLOSED THROTTLE POSITION (ON/OFF)

This parameter will read ON when throttle valve is fully closed, or OFF when the throttle is not fully closed.

FUEL CUT (ON/OFF)

ON : Fuel being cut (output signal to injector is stopped)

OFF : Fuel not being cut

Page 406 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-37

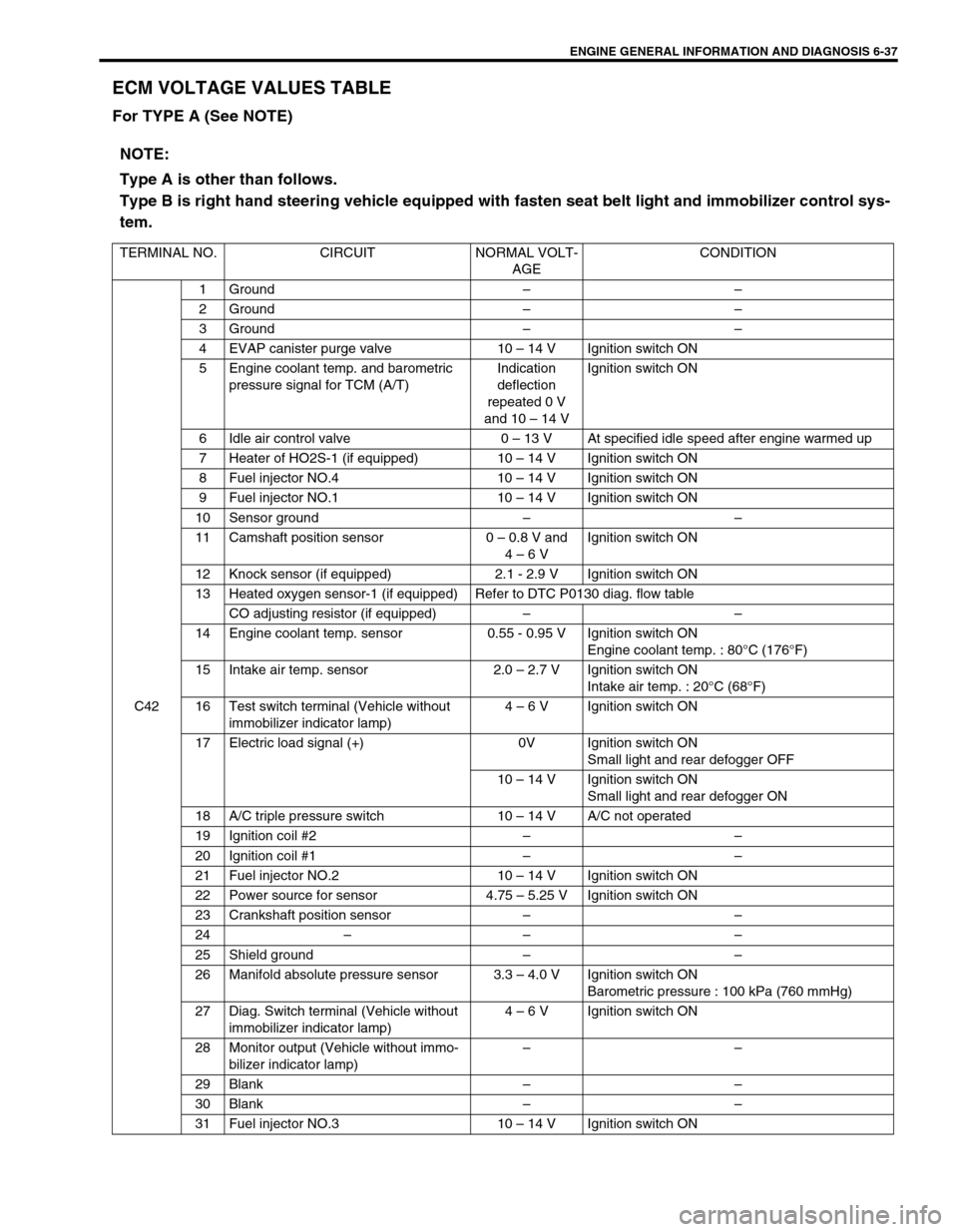

ECM VOLTAGE VALUES TABLE

For TYPE A (See NOTE)

NOTE:

Type A is other than follows.

Type B is right hand steering vehicle equipped with fasten seat belt light and immobilizer control sys-

tem.

TERMINAL NO. CIRCUIT NORMAL VOLT-

AGECONDITION

C421 Ground––

2 Ground––

3 Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5 Engine coolant temp. and barometric

pressure signal for TCM (A/T)Indication

deflection

repeated 0 V

and 10 – 14 VIgnition switch ON

6 Idle air control valve 0 – 13 V At specified idle speed after engine warmed up

7 Heater of HO2S-1 (if equipped) 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor 0 – 0.8 V and

4 – 6 VIgnition switch ON

12 Knock sensor (if equipped) 2.1 - 2.9 V Ignition switch ON

13 Heated oxygen sensor-1 (if equipped) Refer to DTC P0130 diag. flow table

CO adjusting resistor (if equipped)––

14 Engine coolant temp. sensor 0.55 - 0.95 V Ignition switch ON

Engine coolant temp. : 80°C (176°F)

15 Intake air temp. sensor 2.0 – 2.7 V Ignition switch ON

Intake air temp. : 20°C (68°F)

16 Test switch terminal (Vehicle without

immobilizer indicator lamp)4 – 6 V Ignition switch ON

17 Electric load signal (+) 0V Ignition switch ON

Small light and rear defogger OFF

10 – 14 V Ignition switch ON

Small light and rear defogger ON

18 A/C triple pressure switch 10 – 14 V A/C not operated

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensor 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor––

24–– –

25 Shield ground––

26 Manifold absolute pressure sensor 3.3 – 4.0 V Ignition switch ON

Barometric pressure : 100 kPa (760 mmHg)

27 Diag. Switch terminal (Vehicle without

immobilizer indicator lamp)4 – 6 V Ignition switch ON

28 Monitor output (Vehicle without immo-

bilizer indicator lamp)––

29 Blank––

30 Blank––

31 Fuel injector NO.3 10 – 14 V Ignition switch ON

Page 409 of 698

6-40 ENGINE GENERAL INFORMATION AND DIAGNOSIS

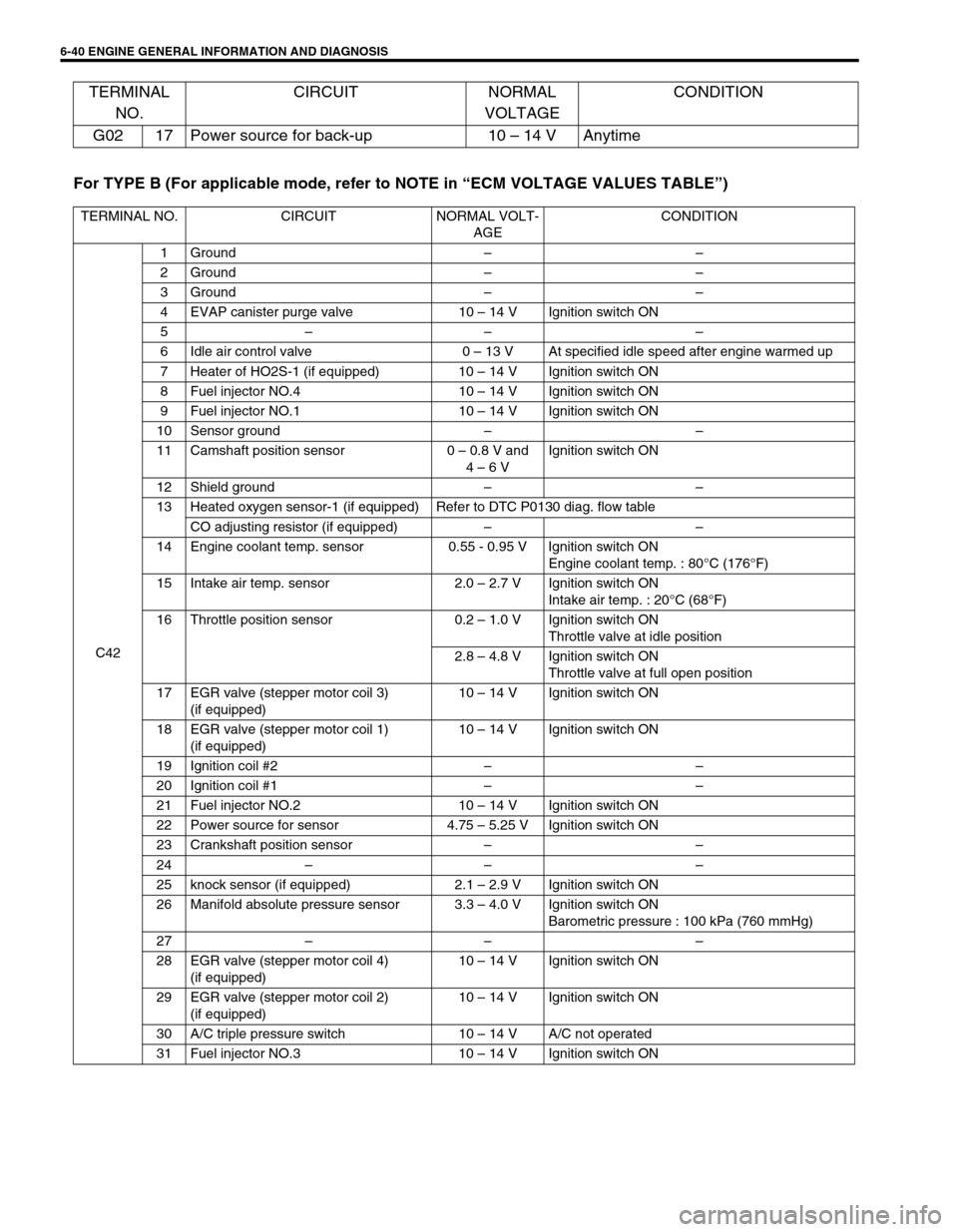

For TYPE B (For applicable mode, refer to NOTE in “ECM VOLTAGE VALUES TABLE”) G02 17 Power source for back-up 10 – 14 V Anytime

TERMINAL NO. CIRCUIT NORMAL VOLT-

AGECONDITION

C421Ground––

2Ground––

3Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5–– –

6 Idle air control valve 0 – 13 V At specified idle speed after engine warmed up

7 Heater of HO2S-1 (if equipped) 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor 0 – 0.8 V and

4 – 6 VIgnition switch ON

12 Shield ground––

13 Heated oxygen sensor-1 (if equipped) Refer to DTC P0130 diag. flow table

CO adjusting resistor (if equipped)––

14 Engine coolant temp. sensor 0.55 - 0.95 V Ignition switch ON

Engine coolant temp. : 80°C (176°F)

15 Intake air temp. sensor 2.0 – 2.7 V Ignition switch ON

Intake air temp. : 20°C (68°F)

16 Throttle position sensor 0.2 – 1.0 V Ignition switch ON

Throttle valve at idle position

2.8 – 4.8 V Ignition switch ON

Throttle valve at full open position

17 EGR valve (stepper motor coil 3)

(if equipped)10 – 14 V Ignition switch ON

18 EGR valve (stepper motor coil 1)

(if equipped)10 – 14 V Ignition switch ON

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensor 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor––

24–– –

25 knock sensor (if equipped) 2.1 – 2.9 V Ignition switch ON

26 Manifold absolute pressure sensor 3.3 – 4.0 V Ignition switch ON

Barometric pressure : 100 kPa (760 mmHg)

27–– –

28 EGR valve (stepper motor coil 4)

(if equipped)10 – 14 V Ignition switch ON

29 EGR valve (stepper motor coil 2)

(if equipped)10 – 14 V Ignition switch ON

30 A/C triple pressure switch 10 – 14 V A/C not operated

31 Fuel injector NO.3 10 – 14 V Ignition switch ON

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

Page 421 of 698

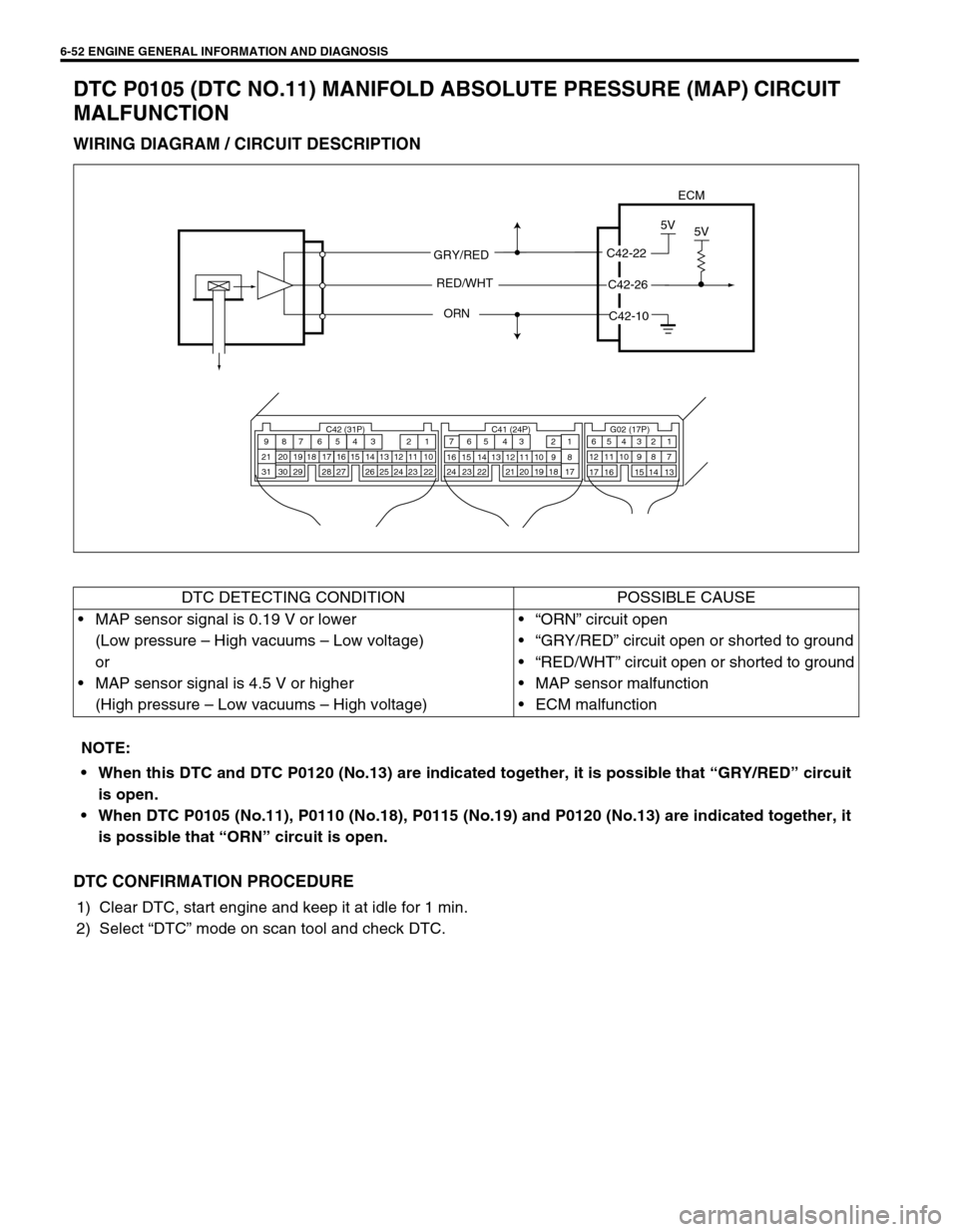

6-52 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0105 (DTC NO.11) MANIFOLD ABSOLUTE PRESSURE (MAP) CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

ECM

GRY/RED

ORN

C42-22

5V

AMPC42-26

5V

RED/WHT

C42-10

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

MAP sensor signal is 0.19 V or lower

(Low pressure – High vacuums – Low voltage)

or

MAP sensor signal is 4.5 V or higher

(High pressure – Low vacuums – High voltage)“ORN” circuit open

“GRY/RED” circuit open or shorted to ground

“RED/WHT” circuit open or shorted to ground

MAP sensor malfunction

ECM malfunction

NOTE:

When this DTC and DTC P0120 (No.13) are indicated together, it is possible that “GRY/RED” circuit

is open.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit is open.

Page 447 of 698

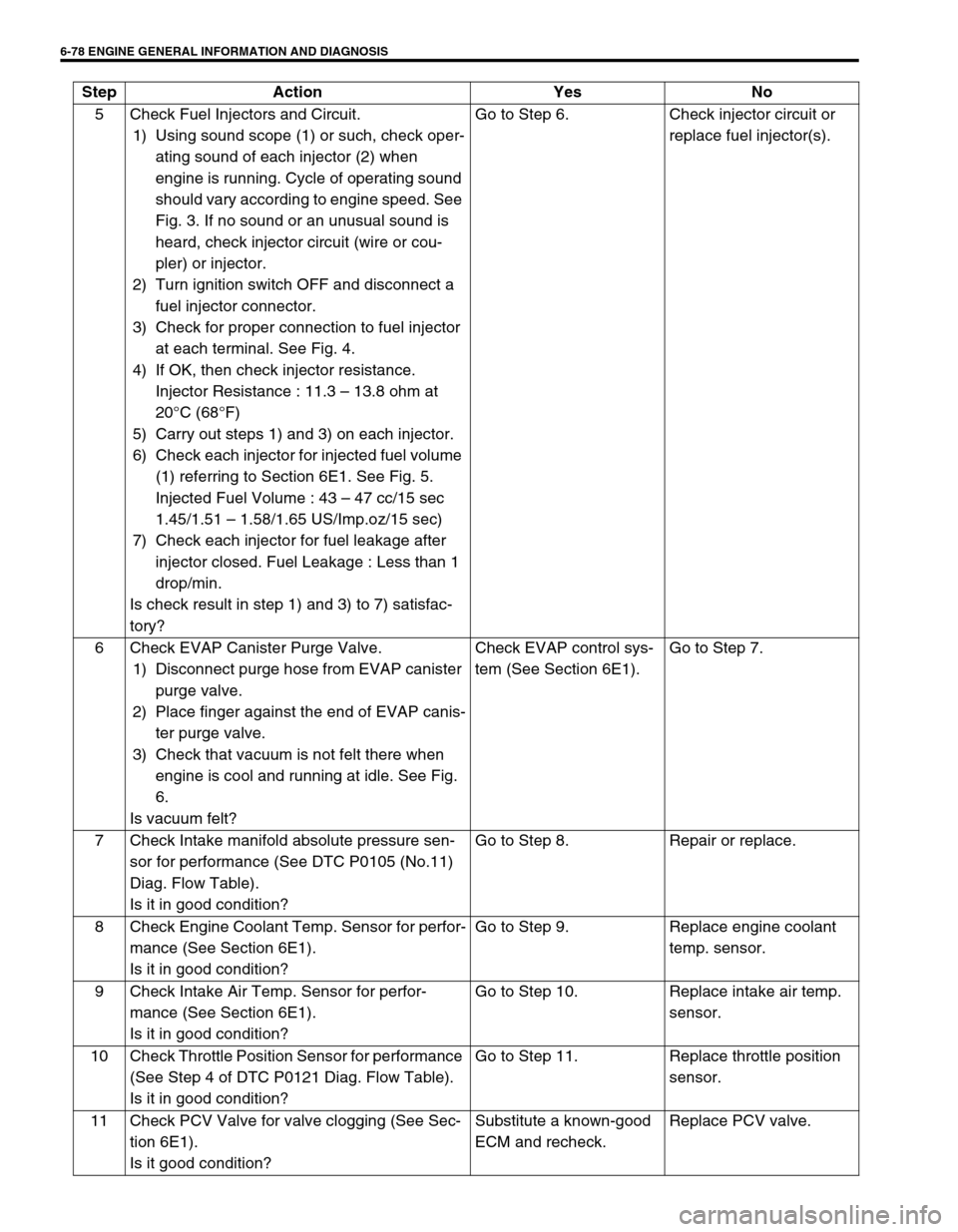

6-78 ENGINE GENERAL INFORMATION AND DIAGNOSIS

5 Check Fuel Injectors and Circuit.

1) Using sound scope (1) or such, check oper-

ating sound of each injector (2) when

engine is running. Cycle of operating sound

should vary according to engine speed. See

Fig. 3. If no sound or an unusual sound is

heard, check injector circuit (wire or cou-

pler) or injector.

2) Turn ignition switch OFF and disconnect a

fuel injector connector.

3) Check for proper connection to fuel injector

at each terminal. See Fig. 4.

4) If OK, then check injector resistance.

Injector Resistance : 11.3 – 13.8 ohm at

20°C (68°F)

5) Carry out steps 1) and 3) on each injector.

6) Check each injector for injected fuel volume

(1) referring to Section 6E1. See Fig. 5.

Injected Fuel Volume : 43 – 47 cc/15 sec

1.45/1.51 – 1.58/1.65 US/Imp.oz/15 sec)

7) Check each injector for fuel leakage after

injector closed. Fuel Leakage : Less than 1

drop/min.

Is check result in step 1) and 3) to 7) satisfac-

tory?Go to Step 6. Check injector circuit or

replace fuel injector(s).

6 Check EVAP Canister Purge Valve.

1) Disconnect purge hose from EVAP canister

purge valve.

2) Place finger against the end of EVAP canis-

ter purge valve.

3) Check that vacuum is not felt there when

engine is cool and running at idle. See Fig.

6.

Is vacuum felt?Check EVAP control sys-

tem (See Section 6E1).Go to Step 7.

7 Check Intake manifold absolute pressure sen-

sor for performance (See DTC P0105 (No.11)

Diag. Flow Table).

Is it in good condition?Go to Step 8. Repair or replace.

8 Check Engine Coolant Temp. Sensor for perfor-

mance (See Section 6E1).

Is it in good condition?Go to Step 9. Replace engine coolant

temp. sensor.

9 Check Intake Air Temp. Sensor for perfor-

mance (See Section 6E1).

Is it in good condition?Go to Step 10. Replace intake air temp.

sensor.

10 Check Throttle Position Sensor for performance

(See Step 4 of DTC P0121 Diag. Flow Table).

Is it in good condition?Go to Step 11. Replace throttle position

sensor.

11 Check PCV Valve for valve clogging (See Sec-

tion 6E1).

Is it good condition?Substitute a known-good

ECM and recheck.Replace PCV valve. Step Action Yes No

Page 451 of 698

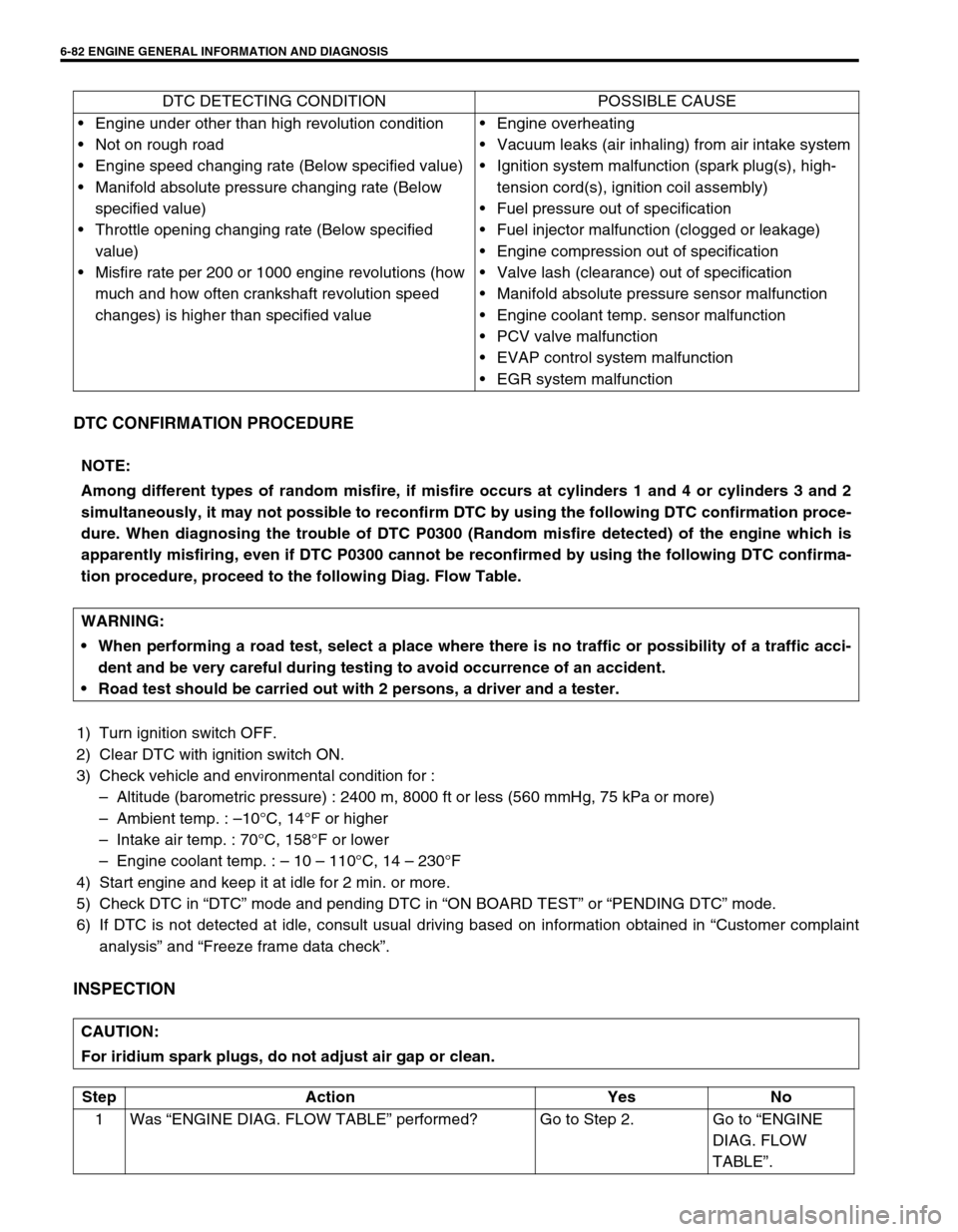

6-82 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 158°F or lower

–Engine coolant temp. : – 10 – 110°C, 14 – 230°F

4) Start engine and keep it at idle for 2 min. or more.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

6) If DTC is not detected at idle, consult usual driving based on information obtained in “Customer complaint

analysis” and “Freeze frame data check”.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine under other than high revolution condition

Not on rough road

Engine speed changing rate (Below specified value)

Manifold absolute pressure changing rate (Below

specified value)

Throttle opening changing rate (Below specified

value)

Misfire rate per 200 or 1000 engine revolutions (how

much and how often crankshaft revolution speed

changes) is higher than specified valueEngine overheating

Vacuum leaks (air inhaling) from air intake system

Ignition system malfunction (spark plug(s), high-

tension cord(s), ignition coil assembly)

Fuel pressure out of specification

Fuel injector malfunction (clogged or leakage)

Engine compression out of specification

Valve lash (clearance) out of specification

Manifold absolute pressure sensor malfunction

Engine coolant temp. sensor malfunction

PCV valve malfunction

EVAP control system malfunction

EGR system malfunction

NOTE:

Among different types of random misfire, if misfire occurs at cylinders 1 and 4 or cylinders 3 and 2

simultaneously, it may not possible to reconfirm DTC by using the following DTC confirmation proce-

dure. When diagnosing the trouble of DTC P0300 (Random misfire detected) of the engine which is

apparently misfiring, even if DTC P0300 cannot be reconfirmed by using the following DTC confirma-

tion procedure, proceed to the following Diag. Flow Table.

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

CAUTION:

For iridium spark plugs, do not adjust air gap or clean.

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE

DIAG. FLOW

TABLE”.

Page 463 of 698

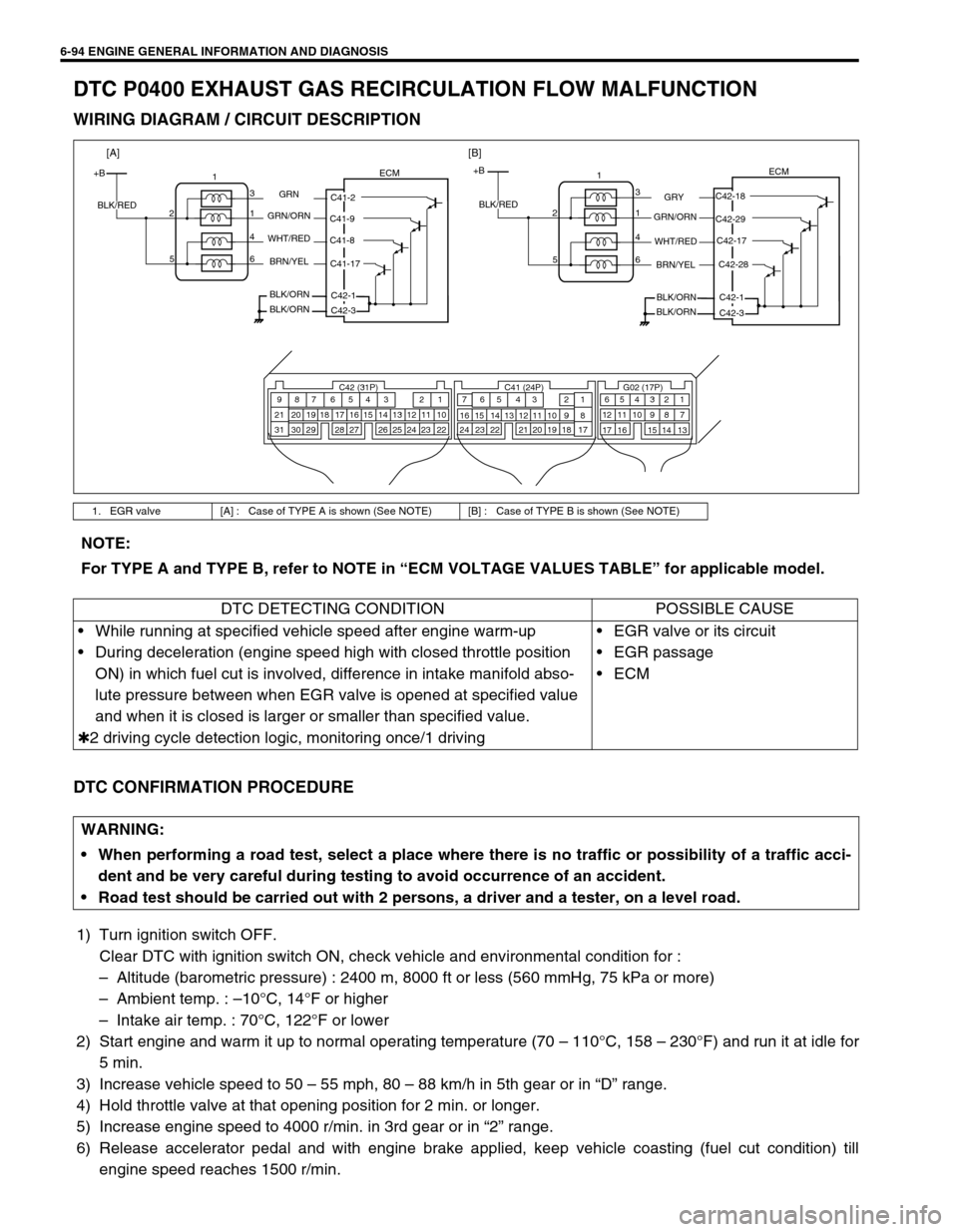

6-94 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0400 EXHAUST GAS RECIRCULATION FLOW MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 122°F or lower

2) Start engine and warm it up to normal operating temperature (70 – 110°C, 158 – 230°F) and run it at idle for

5 min.

3) Increase vehicle speed to 50 – 55 mph, 80 – 88 km/h in 5th gear or in “D” range.

4) Hold throttle valve at that opening position for 2 min. or longer.

5) Increase engine speed to 4000 r/min. in 3rd gear or in “2” range.

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (fuel cut condition) till

engine speed reaches 1500 r/min.

1. EGR valve [A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

+BECM

C42-18

C42-29

C42-28 C42-17

C42-1

GRY

GRN/ORN

WHT/RED

C42-3 BRN/YEL

BLK/ORN

BLK/ORN BLK/RED1

3

1 2

4

6 5

+BECM

C41-2

C41-9

C41-17 C41-8

C42-1

GRN

GRN/ORN

WHT/RED

C42-3 BRN/YEL

BLK/ORN

BLK/ORN BLK/RED1

3

1 2

4

6 5

[A][B]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

DTC DETECTING CONDITION POSSIBLE CAUSE

While running at specified vehicle speed after engine warm-up

During deceleration (engine speed high with closed throttle position

ON) in which fuel cut is involved, difference in intake manifold abso-

lute pressure between when EGR valve is opened at specified value

and when it is closed is larger or smaller than specified value.

✱2 driving cycle detection logic, monitoring once/1 drivingEGR valve or its circuit

EGR passage

ECM

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 477 of 698

6-108 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P1450 BAROMETRIC PRESSURE SENSOR LOW/HIGH INPUT

DTC P1451 BAROMETRIC PRESSURE SENSOR PERFORMANCE PROBLEM

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Barometric pressure sensor is installed in ECM.

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Turn ignition switch ON for 2 sec., crank engine for 2 sec. and run it at idle for 1 min.

4) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

INSPECTION

DTC P1450 :

Substitute a known-good ECM and recheck.

DTC P1451 :

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC P1450 :

Barometric pressure : Sensor voltage is 4.7 V or higher, or

1.6 V or lowerECM (barometric pressure sensor) malfunc-

tion

DTC P1451 :

Vehicle stopped

Engine cranking

Difference between barometric pressure and intake mani-

fold absolute pressure is 26 kPa, 200 mmHg or more

Difference between intake manifold absolute pressure at

engine start and the pressure after engine start is 1.3 kPa,

10 mmHg or less.

✱2 driving cycle detection logic, monitoring once/1 driving.Manifold absolute pressure sensor and its

circuit malfunction

ECM (barometric pressure sensor) malfunc-

tion

NOTE:

Note that atmospheric pressure varies depending on weather conditions as well as altitude.

Take that into consideration when performing these check.

Step Action Yes No

1 Check Barometric Pressure Valve.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON and select “DATA

LIST” mode on scan tool.

3) Check manifold absolute pressure. See Fig.

1.

Is it barometric pressure (approx. 100 kPa, 760

mmHg) at sea level?Substitute a known-good

ECM and recheck.Go to Step 2.

Page 478 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-109

Table 1

Fig. 1 for Step 1

Fig. 2 for Step 22 Check MAP Sensor.

1) Remove MAP sensor from intake manifold

and connect vacuum pump gauge to MAP

sensor. See Fig. 2.

2) Connect scan tool to DLC and turn ignition

switch ON.

3) Check intake manifold absolute pressure

displayed on scan tool for specified valve.

See Table 1.

Is check result satisfactory?Check air intake system

for air being drawn in and

engine compression.

If OK, then substitute a

known-good ECM and

recheck.Replace MAP sensor. Step Action Yes No

Applying Vacuum Displayed Value on Scan Tool

0 Barometric pressure

(Approx. 100 kPa, 760 mmHg)

27 kPa

200 mmHgBarometric pressure – 27 kPa

(Approx. 73 kPa, 560 mmHg)

67 kPa

500 mmHgBarometric pressure – 67 kPa

(Approx. 33 kPa, 260 mmHg)